Automatic polishing system for water turbine blades

A technology for water turbines and blades, which is used in grinding automatic control devices, grinding machines, grinding workpiece supports, etc., can solve the problem that the manual grinding quality of the blade surface cannot be unified, the grinding quality of the blade surface is unstable, and the grinding quality is difficult to achieve consistent. To solve the problems such as chemical, to achieve the effect of outstanding economic benefits, reduced position interference, and reliable grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

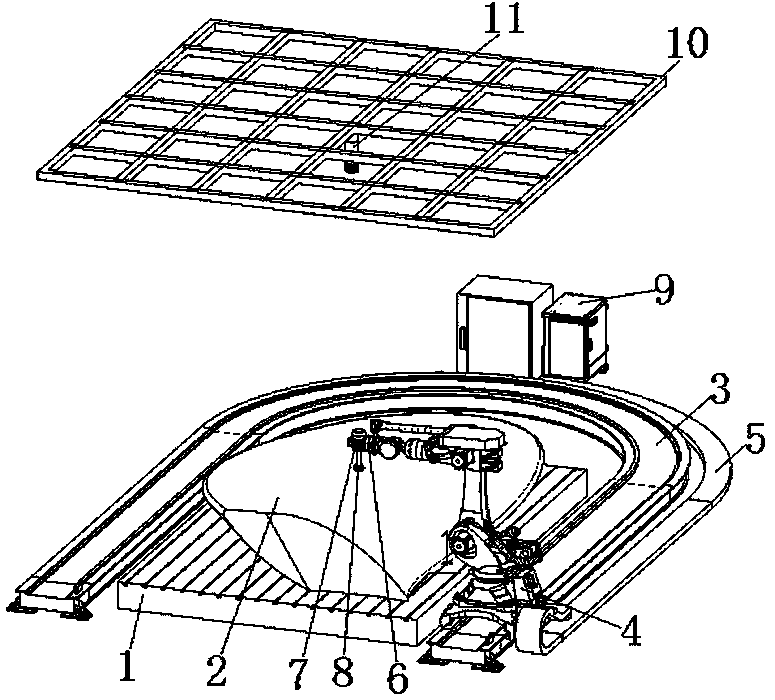

[0023] The invention relates to an automatic grinding technology, in particular to an automatic grinding system for a water turbine blade, which is used for grinding the surface of a counterattack water turbine blade formed by precision casting. Below in conjunction with the accompanying drawings of the description - that is figure 1 The technical content of the present invention is described in detail and clearly.

[0024] see figure 1 As shown, the present invention includes a clamping platform 1, an industrial robot 4, a grinding control system, a visual image system and a grinding mechanism.

[0025] Wherein, the clamping platform 1 is used for positioning and clamping the blade 2 to be polished, and the blade 2 is stably clamped and fixed on the clamping platform 1 by the positioning member and the clamping member. The outer periphery of the clamping platform 1 is provided with a U-shaped guide rail 3 in the circumferential direction of the semi-package clamping platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com