Patents

Literature

74results about How to "Reduce the number of flips" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

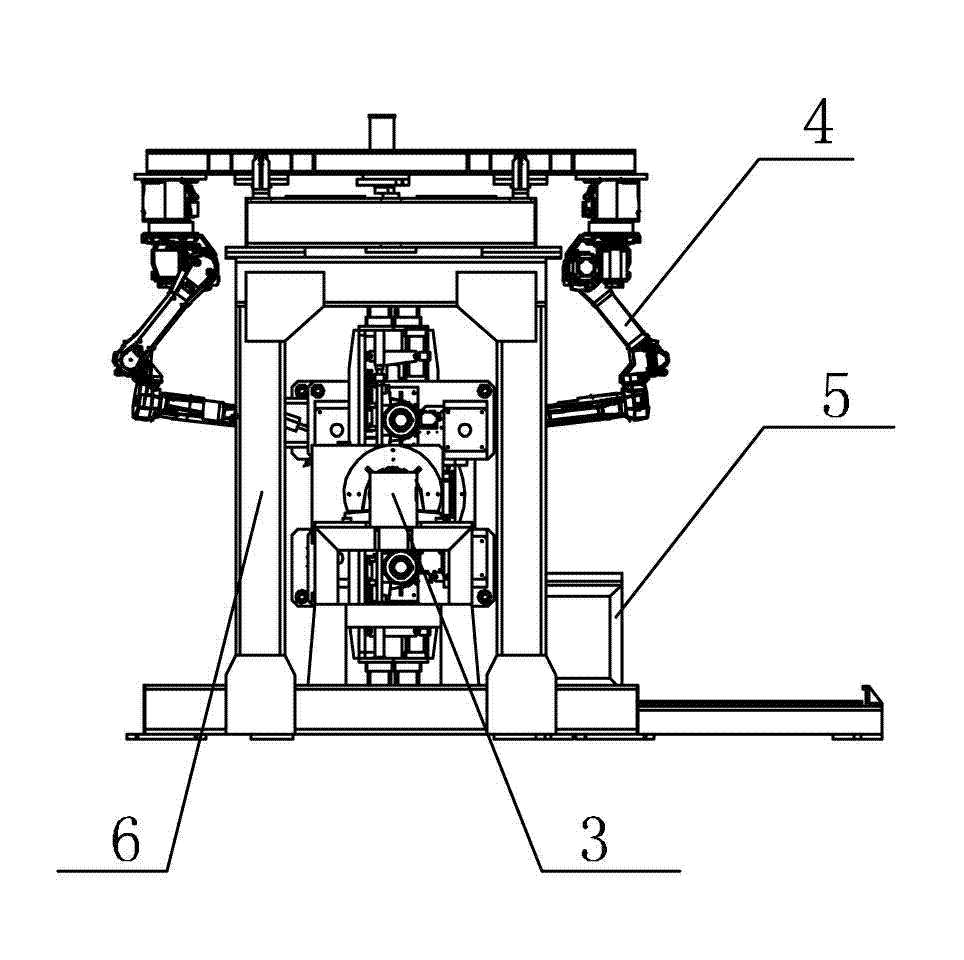

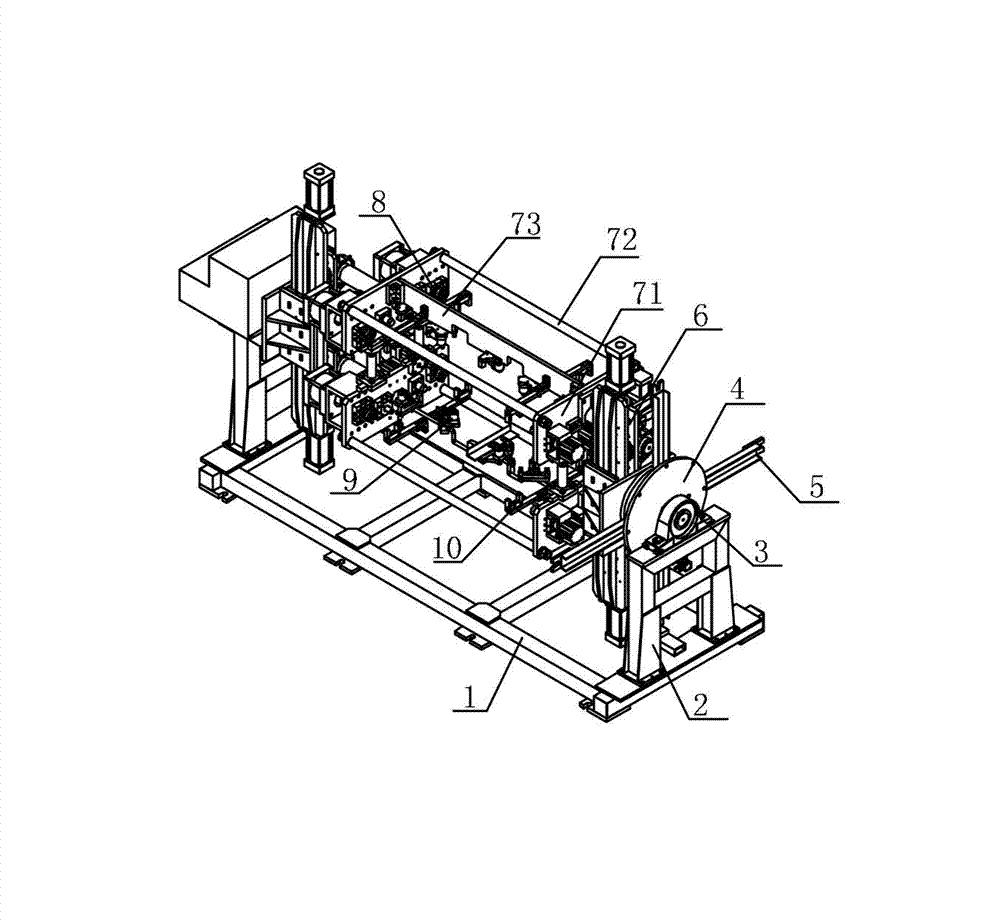

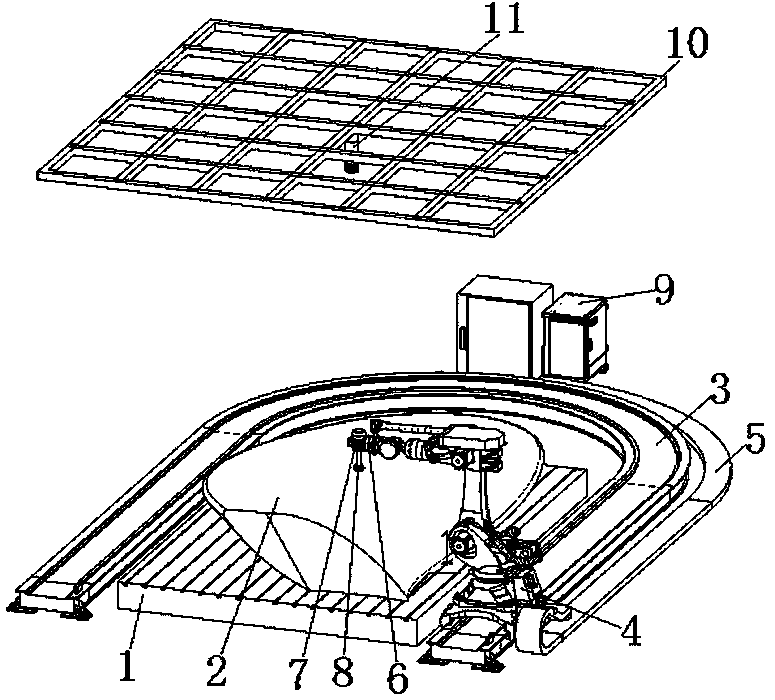

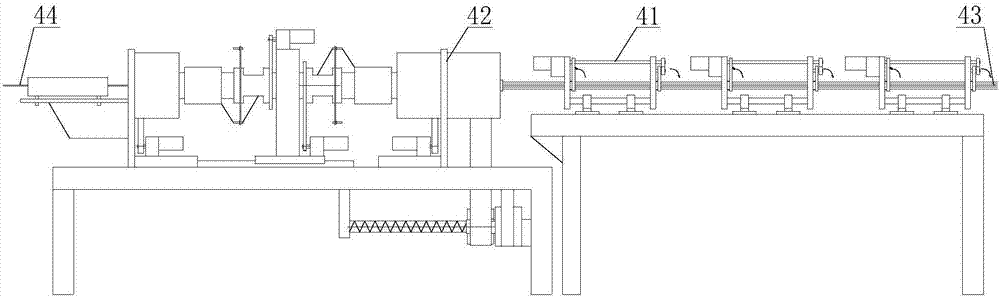

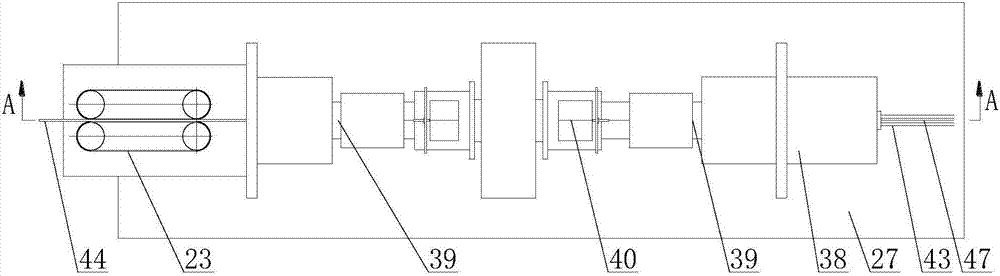

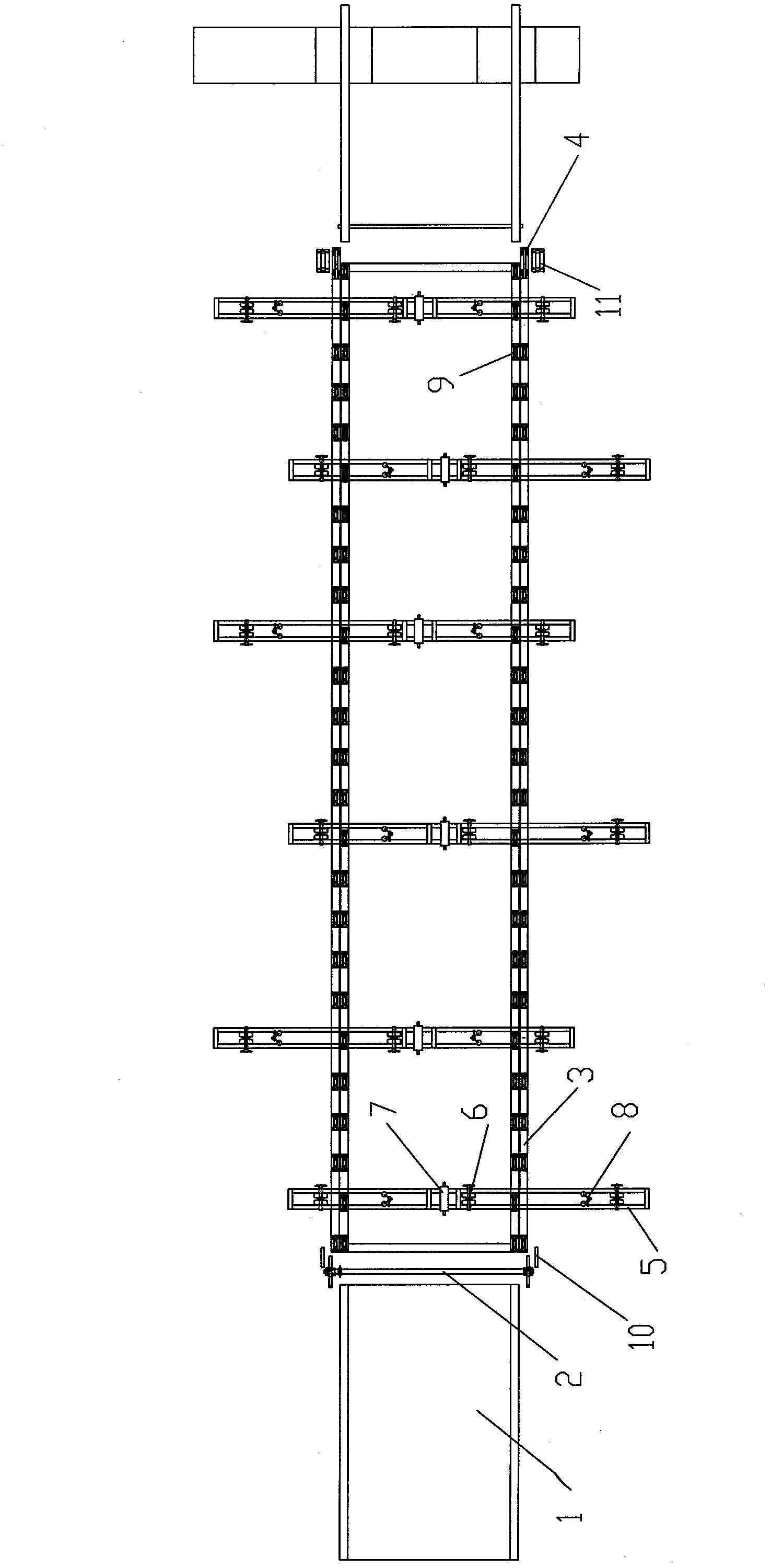

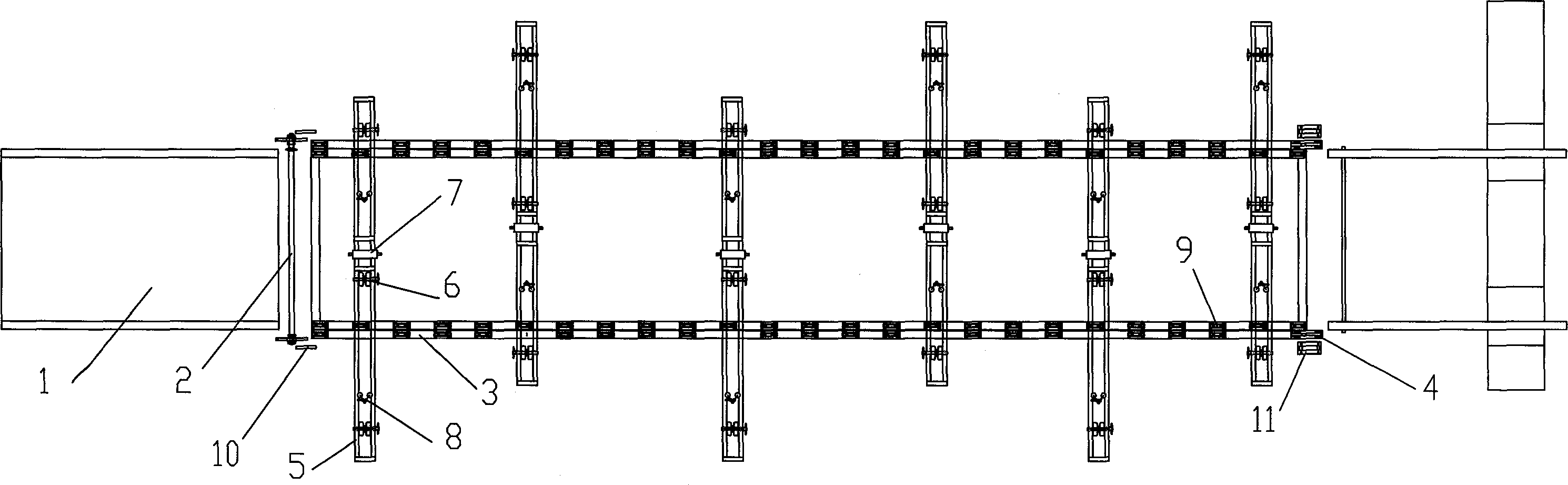

Integrated equipment of automatic robot welding system of standard knots

ActiveCN102896445AGuaranteed synchronicityImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesManipulatorRobot welding

The invention discloses integrated equipment of an automatic robot welding system of standard knots. The integrated equipment comprises a feeding sliding table tooling, a transporting manipulator, a standard knot deflection tooling, a welding manipulator and a discharging mechanism, wherein a three-dimensional coordinate detection device of the standard knot tooling is arranged on the standard knot deflection tooling; an electromagnetic clamp is arranged on the transporting manipulator; a welding gun guide track is arranged on the arm of the transporting manipulator; a welding gun sliding mechanism is connected with two sides of the welding gun guide track; a welding gun is fixed on the welding gun sliding mechanism; the rotary disc of the standard knot deflection tooling is integrally connected with a standard knot positioning bracket; the rotary disc is driven by a speed change motor; the welding manipulator is hung on a truss; and the standard knot deflection tooling is arranged below the truss. Compared with the traditional manual welding method, the consistency in welding quality, the welding efficiency and the safety reliability can all meet the requirements on the quality and the number in manufacturing modern high-tech products.

Owner:重庆立诚重工科技集团有限公司

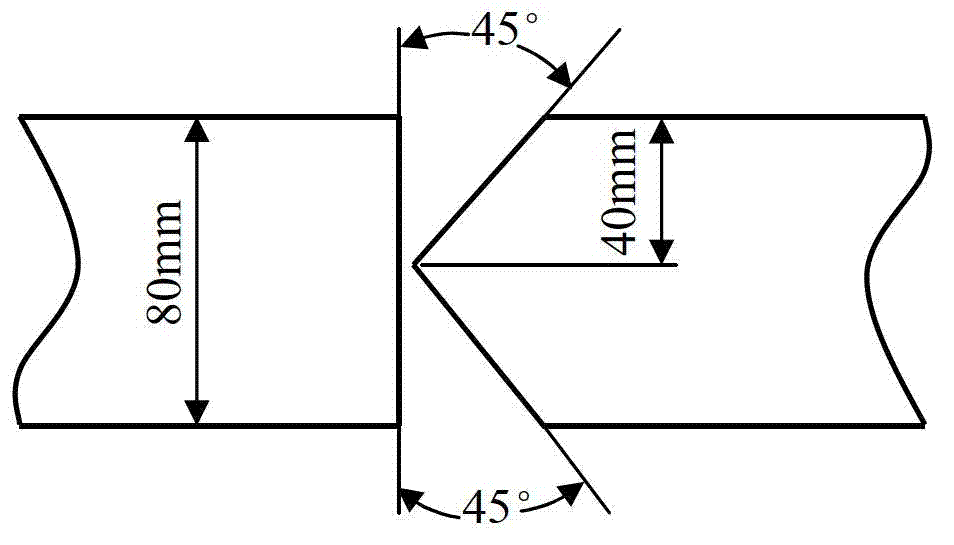

Submerged arc welding method for K-shaped groove of 80mm extra-thick steel plate with excellent plate shape after welding

InactiveCN102922103AReduce peak residual stressOffset deformationArc welding apparatusWorkpiece edge portionsResidual deformationMixed gas

Owner:NANJING IRON & STEEL CO LTD

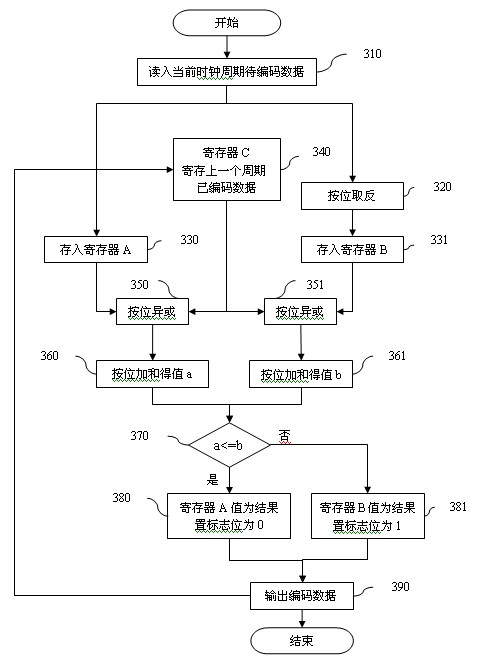

Bit flipping based LDPC code local searching and decoding method

InactiveCN104218955AReduce the number of flipsShorten the timeError correction/detection using multiple parity bitsCommunications systemRound complexity

The invention discloses a bit flipping based LDPC code local searching and decoding method and mainly aims at solving the problem that an existing bit flipping type algorithm is poor in error correction performance and sum-product algorithm hardware implementation is complicated. The technical scheme is that a linear programming decoding mode and odd-even check are combined to form a new decoding model to implement the method, and the method comprises the steps of 1 initializing decoding parameters; 2 sequentially flipping multiple variable nodes simultaneously, and receiving a nearest code words by decreasing a target function value searching distance; 3 judging whether decoding is completed or not according to syndrome vectors; 4 sequentially flipping a value of one variable node and searching effective code words by decreasing non-zero elements in the syndrome vectors; 5 constructing multiple initial solution vectors to execute bit flipping code search in a looping mode; 6 using solution vector outputs as translated code words if the syndrome vectors are zero vectors. The bit flipping based LDPC code local searching and decoding method is good in error correction performance, high in convergence rate and low in hardware implementation complication level, can remarkably improve the efficiency of a decoding module of a communication system with a binary symmetric channel and can be used in the technical field of communication.

Owner:HENAN UNIV OF SCI & TECH

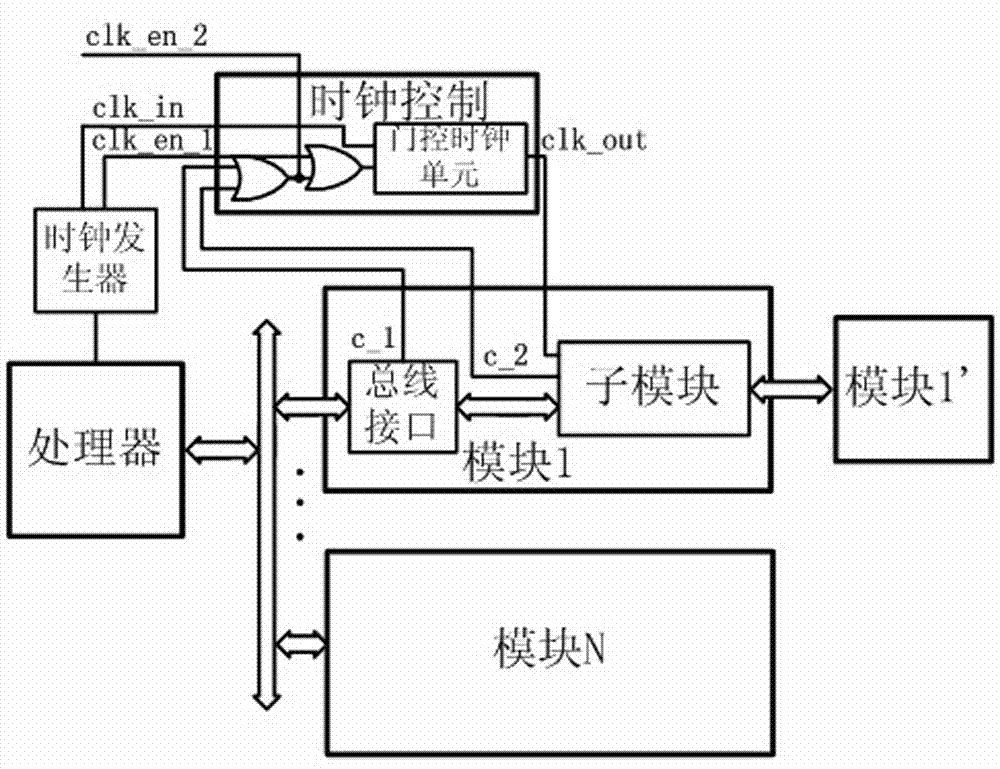

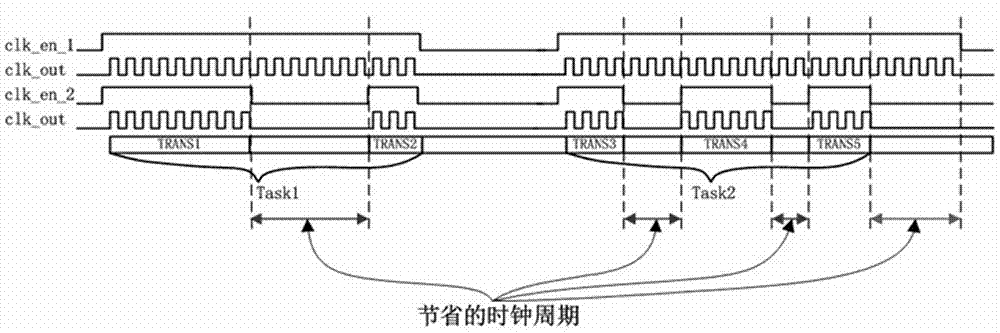

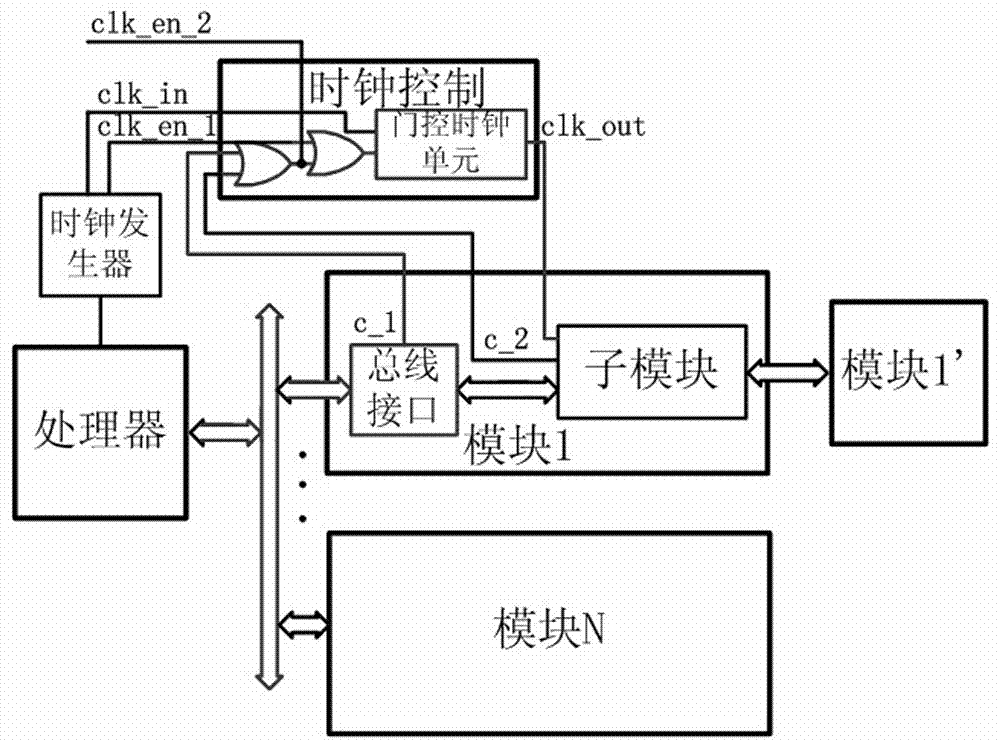

System on a chip (SoC) system clock control method and SoC

ActiveCN103116384AReduce dry runReduce the number of flipsPower supply for data processingGenerating/distributing signalsControl signalComputer module

The invention discloses a system on a chip (SoC) system clock control method and a SoC. According to the SoC system clock control method and the SoC, when an executive module or a function module is carried out an internal arithmetic or is interacted with the other modules, a processor does not participate in a clock control any more, the executive module is used for controlling, and a smaller unit is used for controlling, that is a plurality of transmission (Trans) operations under an operation are used for driving. An idle phase among the operations corresponds to a dry running of an original method, and the executive module does not operate any more, so that a control signal can be generated through the executive module according to an actual working condition, a clock signal required by the executive module is generated precisely, dry running states of the executive module are reduced to reduce times of circuit flip, and power dissipation of the SoC is effectively reduced.

Owner:SHANDONG SINOCHIP SEMICON

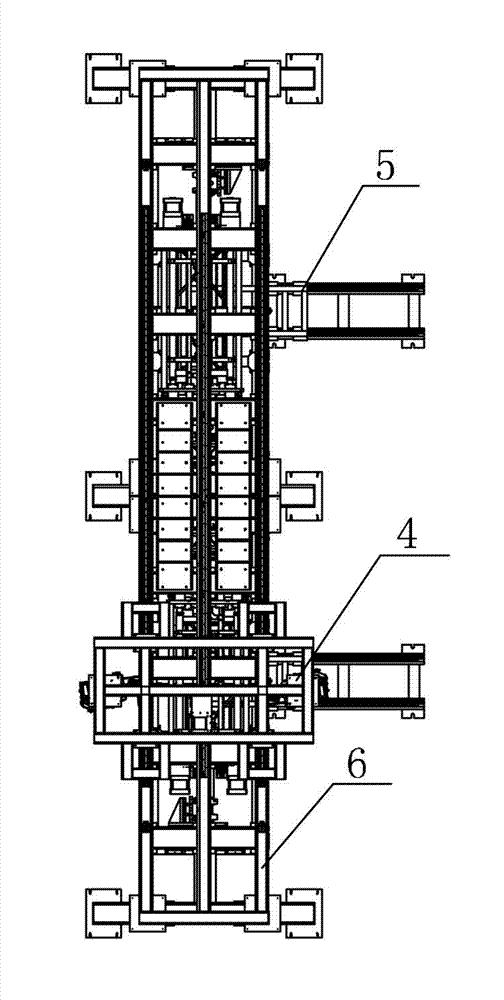

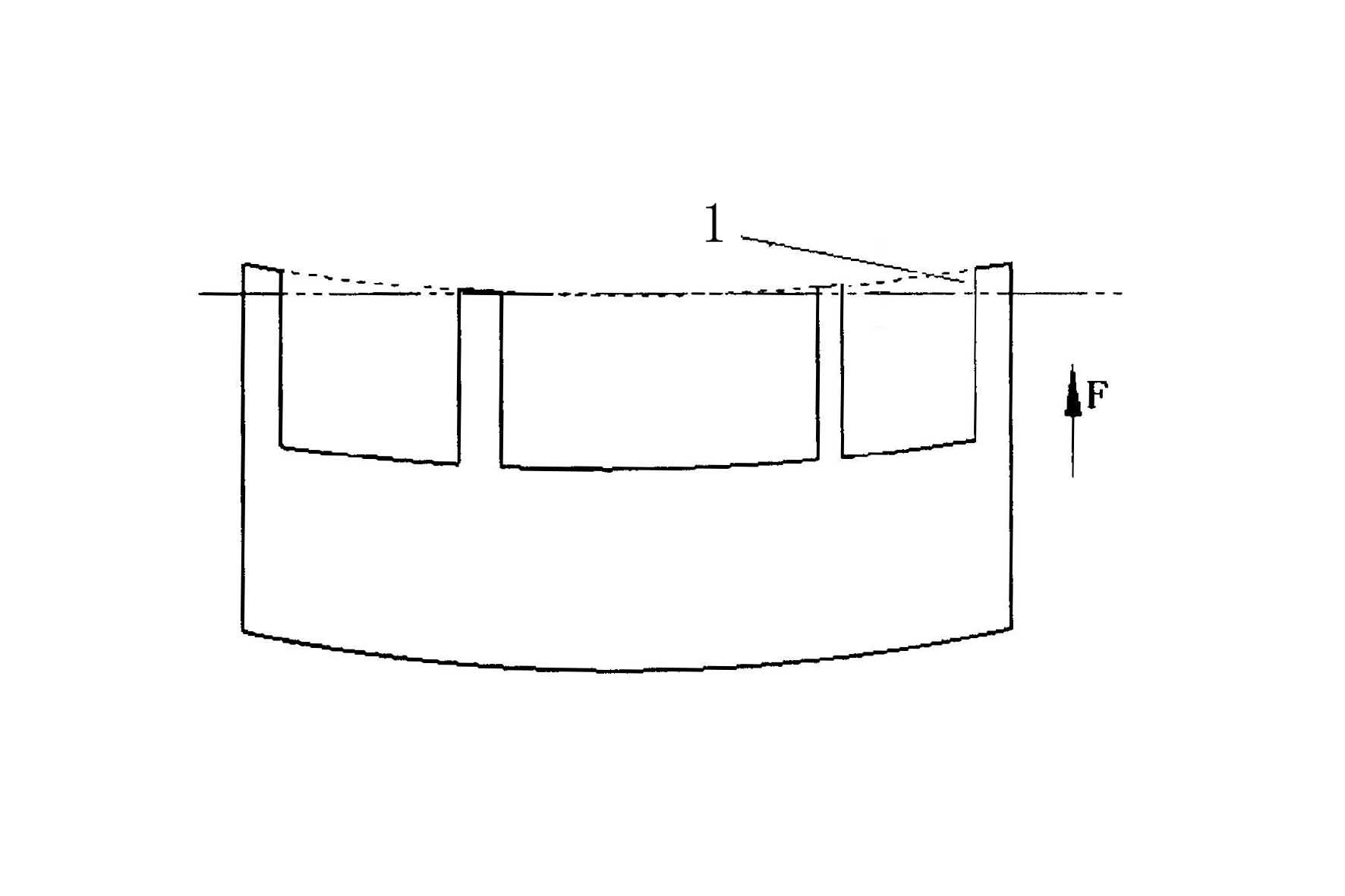

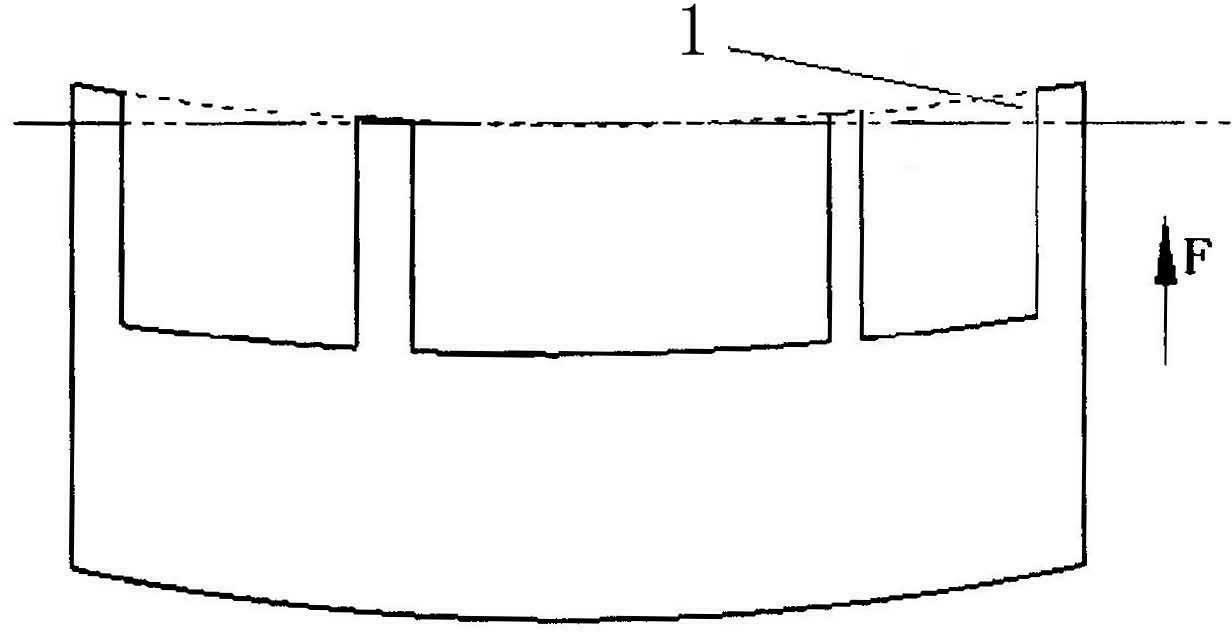

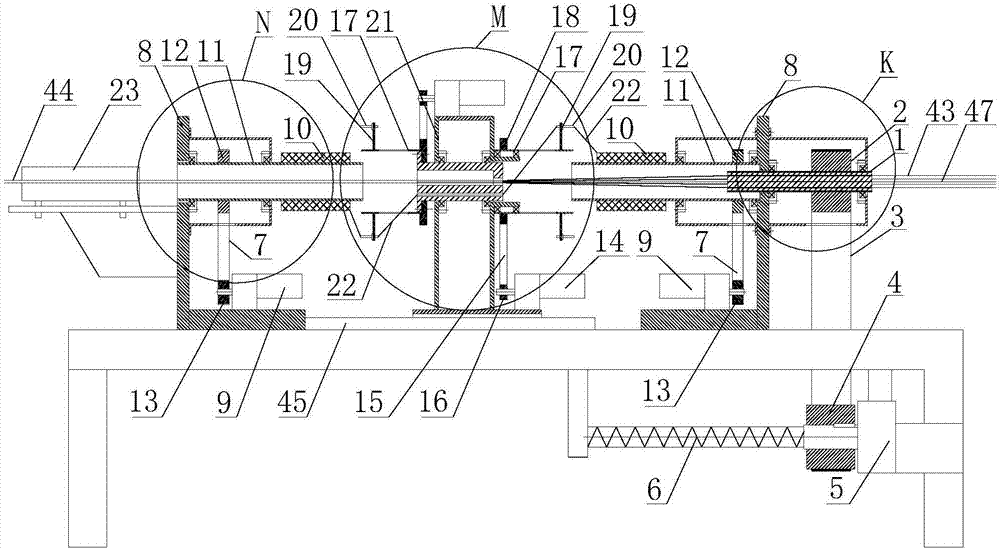

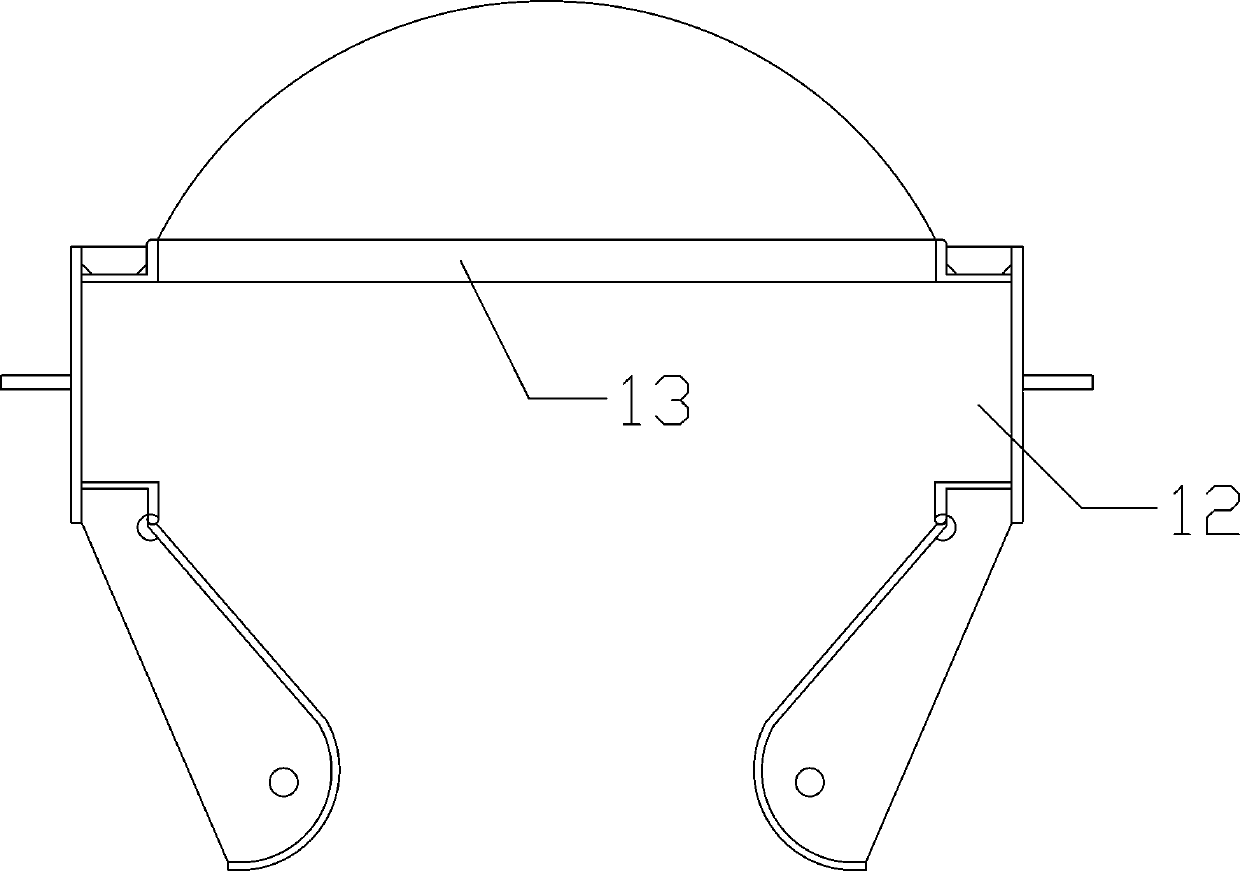

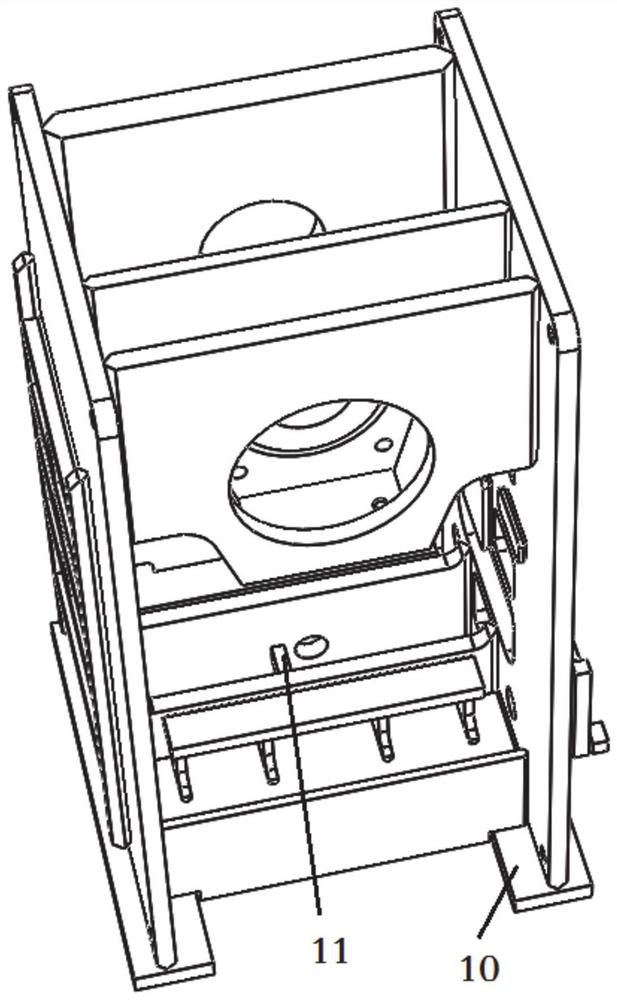

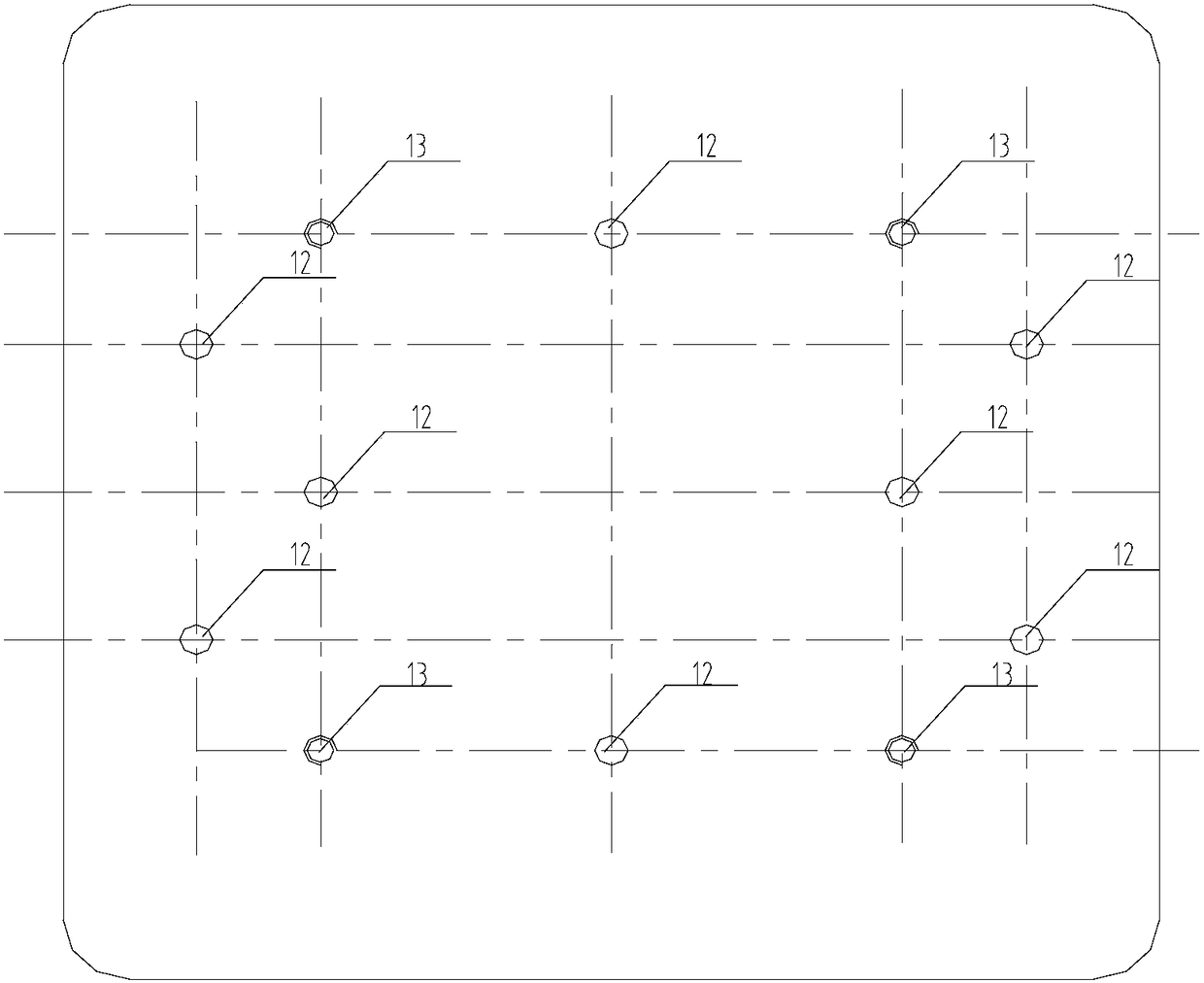

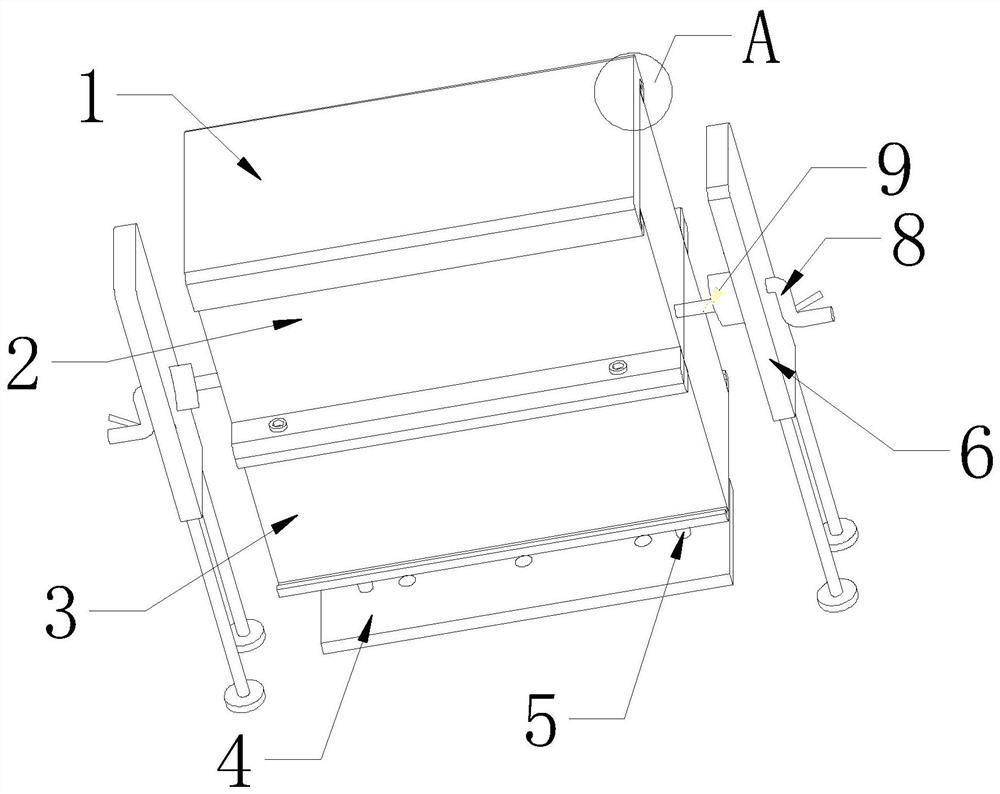

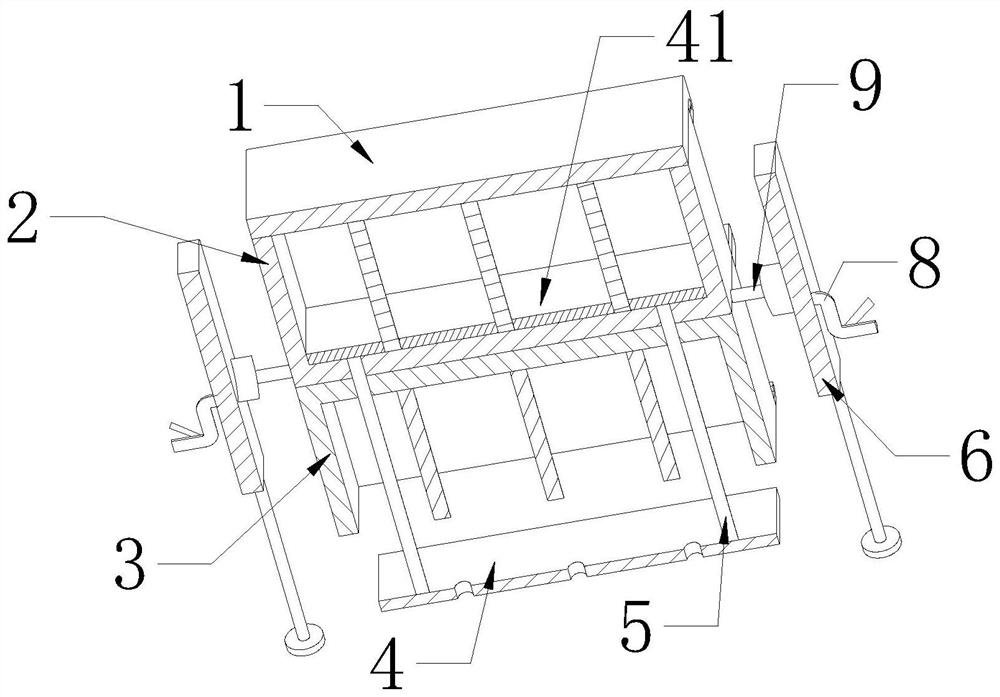

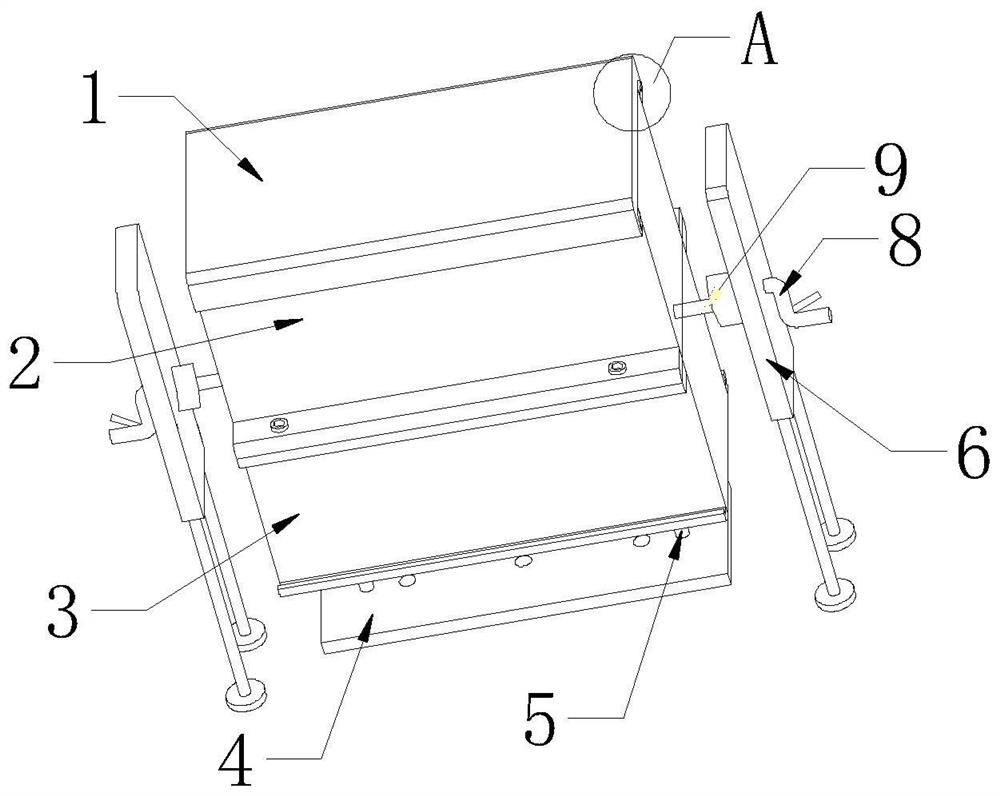

Full-automatic standard section overturning tooling

InactiveCN102896454AGuaranteed synchronicityAvoid the problem of prone to flip out of syncWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDrive motor

The invention discloses a full-automatic standard section overturning tooling. The full-automatic standard section overturning tooling comprises a base, two ends of the base are connected with left and right supporting seats, upper ends of the left and right supporting seats are connected with left and right bearing seats, the left and right bearing seats are connected with left and right rotary disks respectively, the left or right rotary disk is connected with a drive motor, the left and right rotary disks are directly connected with a standard section tooling support, the standard section tooling support comprises an ejecting air cylinder rack body and a rack, a main string tube air cylinder lifting pin, a standard section gear rack air cylinder lifting pin, an electric control fixture and a positioning structure are arranged on the rack, an ejecting air cylinder is installed in the ejecting air cylinder rack body, and the ejecting air cylinder is connected with the main string tube air cylinder lifting pin and the standard section gear rack air cylinder lifting pin. By means of the full-automatic standard section overturning tooling, the integral rotating and welding can be performed, the standard section overturning and welding speed is increased, the probability of errors is reduced, and the quality of standard section finished product is improved.

Owner:CHONGQING YINGFENGSHENG MACHINERY EQUIP

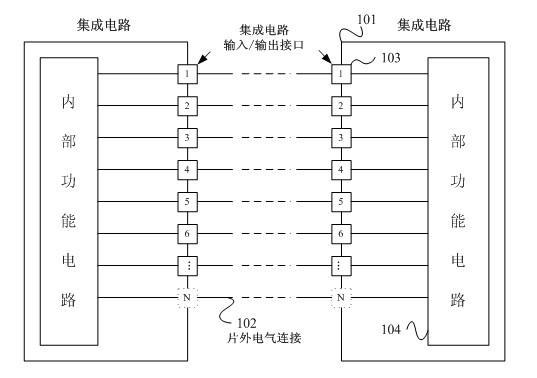

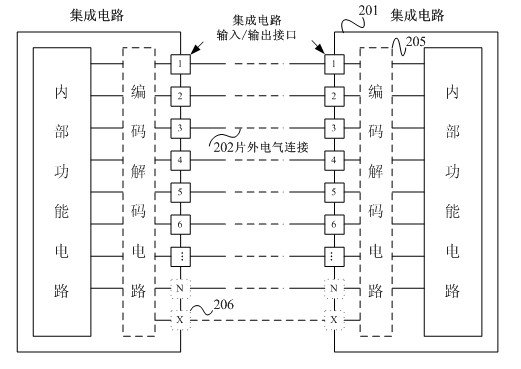

Method for reducing power consumption of integrated circuit system of Ethernet passive optical network physical layer

InactiveCN102611951AReduce peak power consumptionImprove efficiencyMultiplex system selection arrangementsData switching networksEmbedded systemIntegrated circuit

The invention relates to a method for reducing power consumption of an integrated circuit system of an Ethernet passive optical network physical layer and designs a device for reducing power consumption of I / O (input / output) unit of an integrated circuit. The device is used as a module capable of being integrated into a physical layer integrated circuit. The method includes: encoding data before parallel binary data are transmitted to an I / O interface, computing the number of binary bits changed in two group data in adjacent clock period, turning and setting a zone bit as 1 if the number of changed bits is large; judging whether the data are turned or not according to the zone bits and turning and decoding according to the bits; dividing binary data into multiple sections for parallel I / O with wider bit width, and encoding and decoding the multiple sections; caching n data with bit width of m, grouping the n data and arranging n zone bits into data with bit width of m, and utilizing m-n binary bits without zone bits for checking, wherein the data are used a key frame.

Owner:SOUTHEAST UNIV

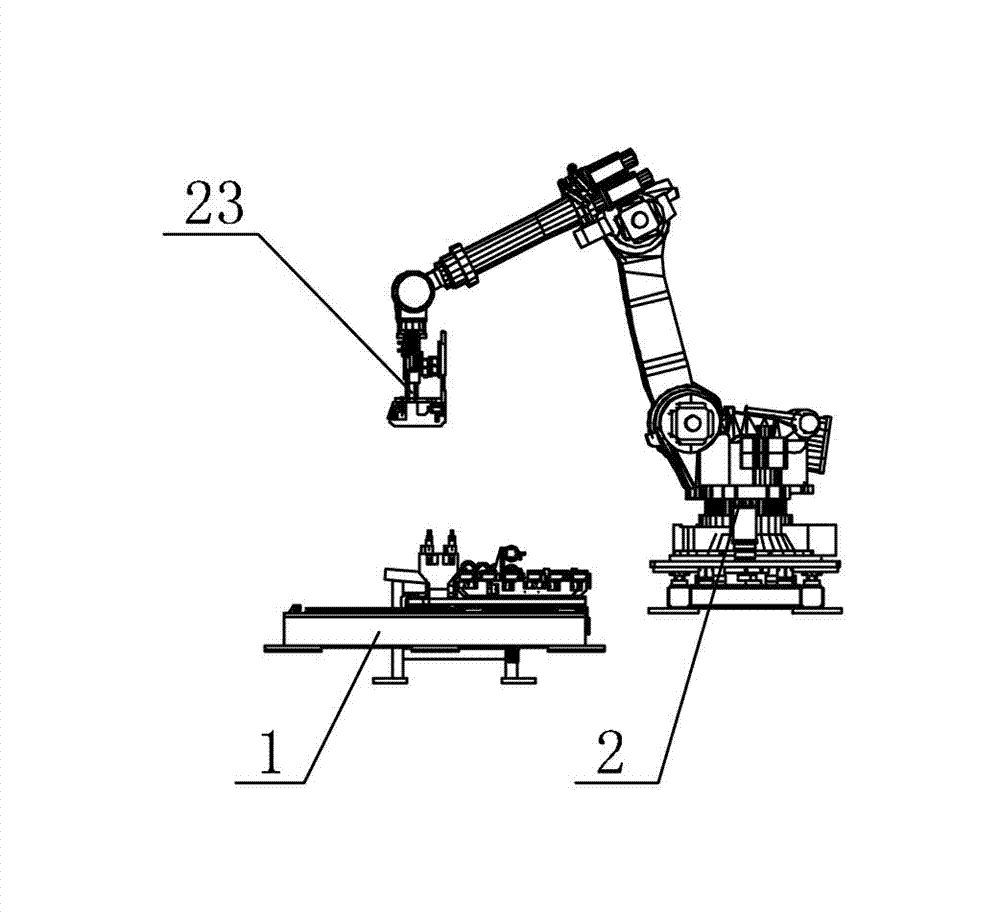

Automatic polishing system for water turbine blades

InactiveCN107866717AEffective sandingImprove sanding qualityAutomatic grinding controlGrinding machinesWater turbineControl system

The invention discloses an automatic polishing system for water turbine blades. The automatic polishing system for the water turbine blades comprises a clamping platform, an industrial robot, a polishing control system and a visual image system, and wherein the clamping platform is used for positioning and clamping the water turbine blade to be polished; the industrial robot is provided with a polishing mechanism, and the industrial robot is controlled by a polishing control system and is used for polishing the blade clamped on the clamping platform; and the polishing control system directs atthe current polishing surface of the blade to be polished and is used for planning a corresponding polishing path, then the planned polishing path is converted into a polishing action control programof the industrial robot and is conveyed to the industrial robot, and the visual image system is used for detecting the polishing quality and feeding back the polishing quality to the polishing control system. According to the automatic polishing system for the water turbine blades, the surface of the impact-type water turbine blade formed by precision casting can be provided with an automatic, intelligent and unified polishing treatment; and thus the polishing quality of the surface of the blade can be improved accurately and reliably.

Owner:SICHUAN ENG TECHN COLLEGE

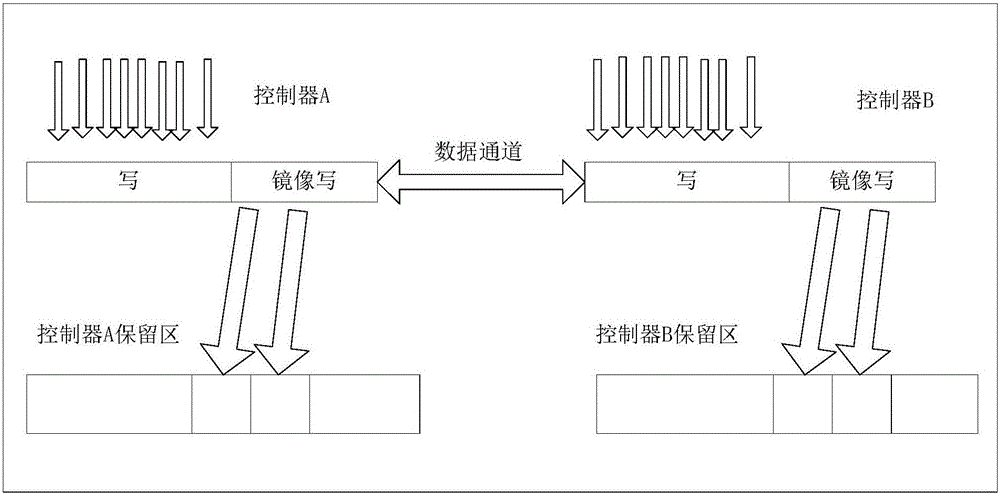

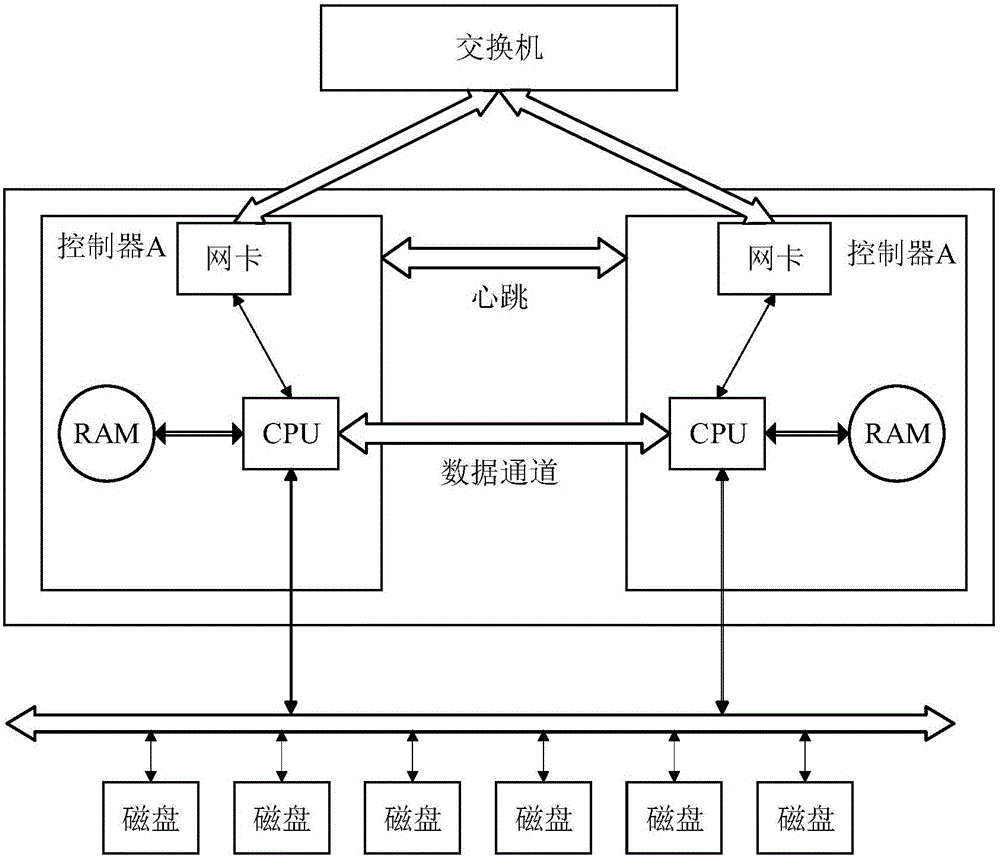

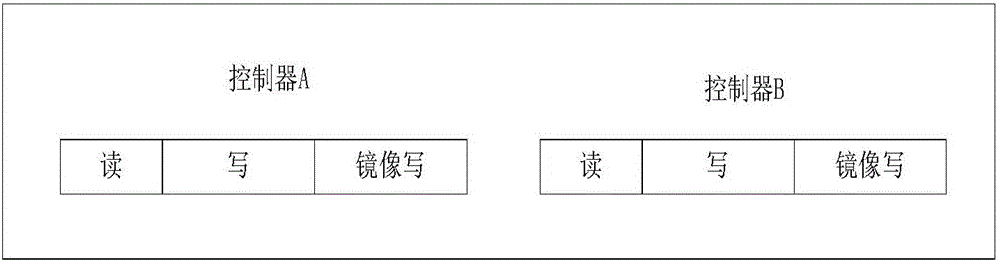

Method for RAID dual-controller to write cache mirror with disk

ActiveCN105955841AIncrease profitReduce data duplicationInput/output to record carriersRedundant operation error correctionRAIDDirty data

The invention discloses a method for an RAID (redundant array of independent disks) dual-controller to write cache mirror with a disk. The method consists of: allocating a reserve area for the controller in a disk; backing up dirty data in a mirror write area of the controller to the reserve area; when the controller receives a read request, reading data from the cache; when the controller receives a notice of writing to the disk, if the data is in Cache, transferring the data block to clean; and if the data block is in the reserve area, releasing the data block in the reserve area; when the controller Cache space is not enough and space needs to be acquired, performing inverting the disk according to the sequence of the clean area, the write area and the mirror write area; when the controller receives the notice of writing the dirty data back into the disk, if data is in the Cache, transferring the data to clean; if the data is in the reserve area, releasing the space in the reserve area; and when the mirror write area of the controller breaks down, performing data recovery through the Cache of the controller and data in the reserve area. The method can reduce Cache data repetition rate of the controller, and has the effect of improving the hit rate.

Owner:HUAZHONG UNIV OF SCI & TECH

Deformation controlling method for machining double-side multi-rib structural part

InactiveCN102581359AReduce the number of flipsShorten the processing cycleMilling equipment detailsPositioning apparatusEngineeringMachining process

The invention relates to a deformation controlling method for machining a double-side multi-rib structural part. The method comprises the following steps of: 1) clamping a part blank by adopting a tool; 2) milling a single side reference till a new metal inner layer appears; 3) turning over the part, and clamping the part by using vacuum adsorption and an external tool; 4) machining a web plate and a lateral surface on the front side, and reserving low allowance or directly machining in place, wherein ribs are not machined in height; 5) removing the vacuum adsorption and the external tool, and removing the deformation of the upper surface part in a natural state; 6) turning over and then clamping the part by using the vacuum adsorption and the external tool again, and performing rough machining and finish machining on the reverse side sequentially till the size of the part is achieved; and 7) turning over again, clamping the part by using the vacuum adsorption and the external tool, milling the ribs on the front side until the height is appropriate, and performing finish machining till the size of the part is achieved. According to the method, the deformation of the part is controlled by adopting an internal stress counteraction method in the part machining process, so that the machining period is shortened, and the quality of the part is improved.

Owner:SHENYANG AIRCRAFT CORP

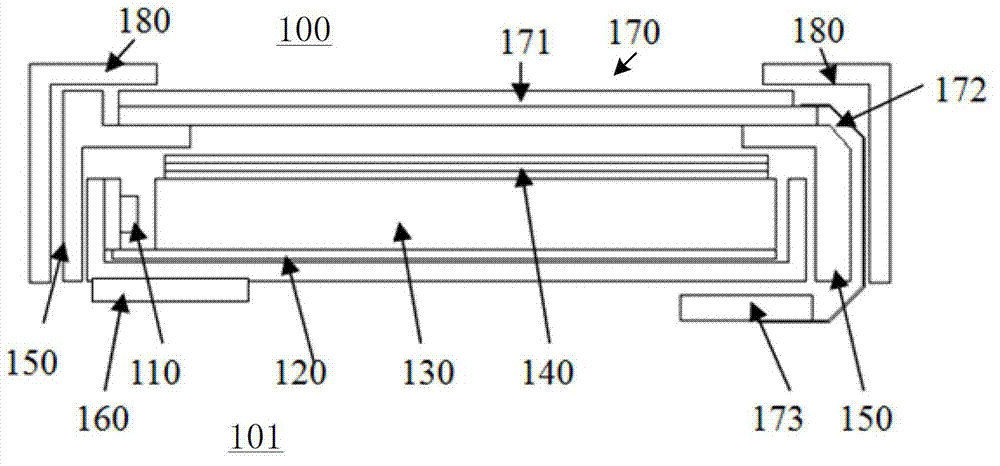

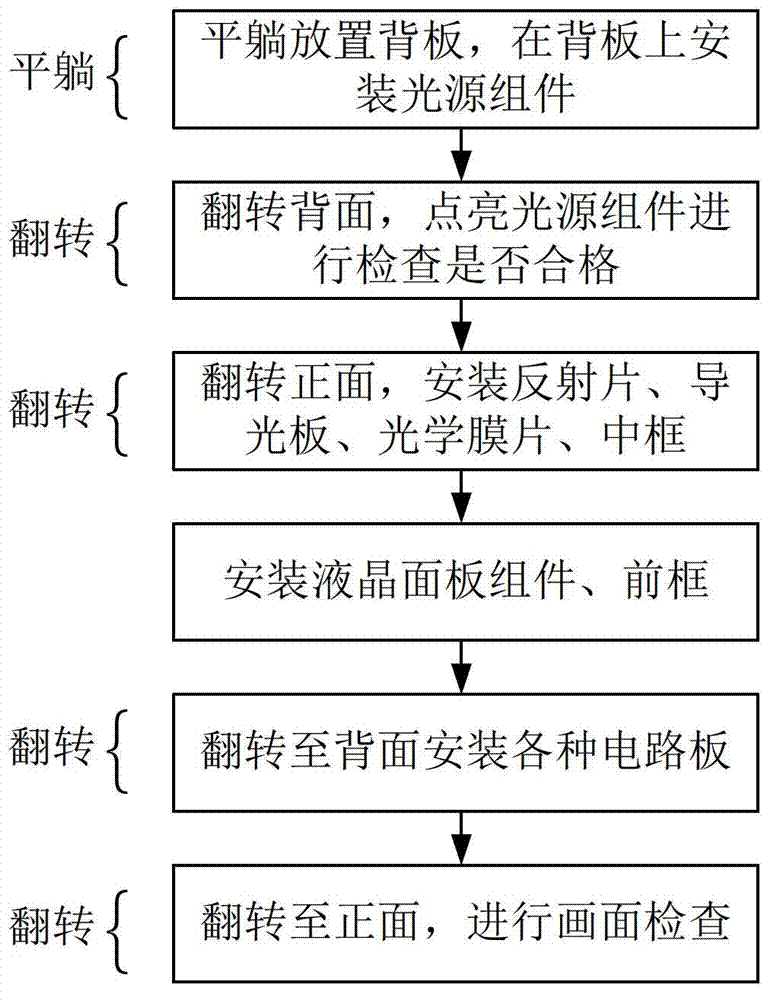

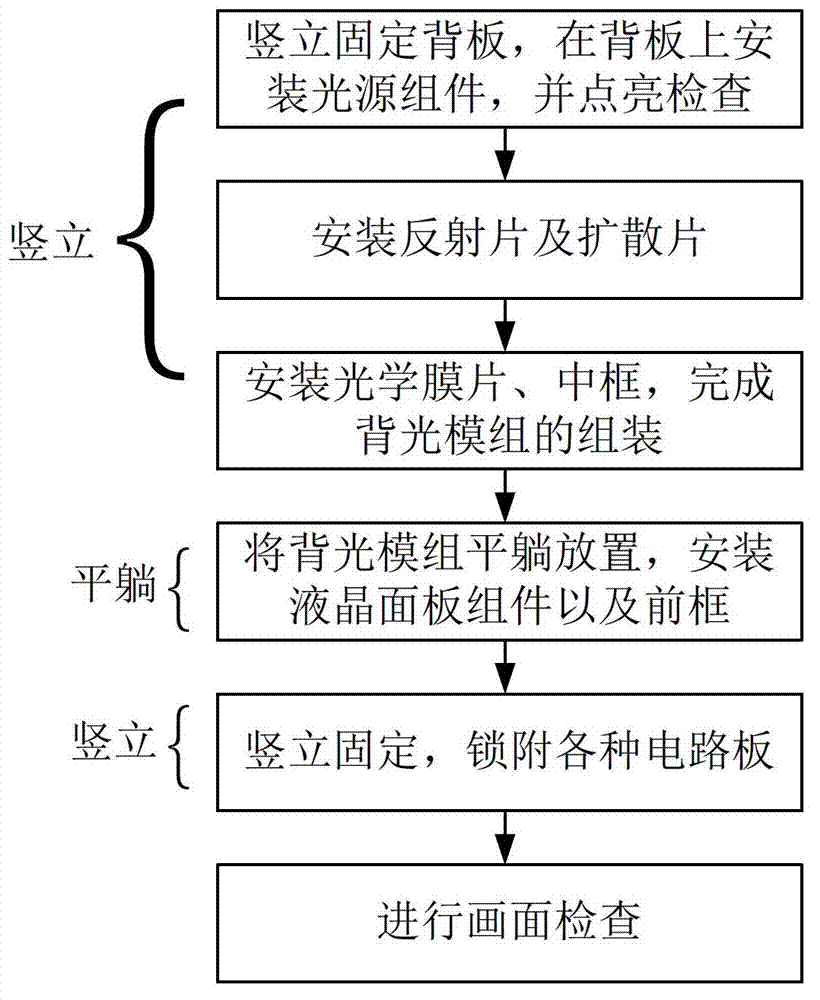

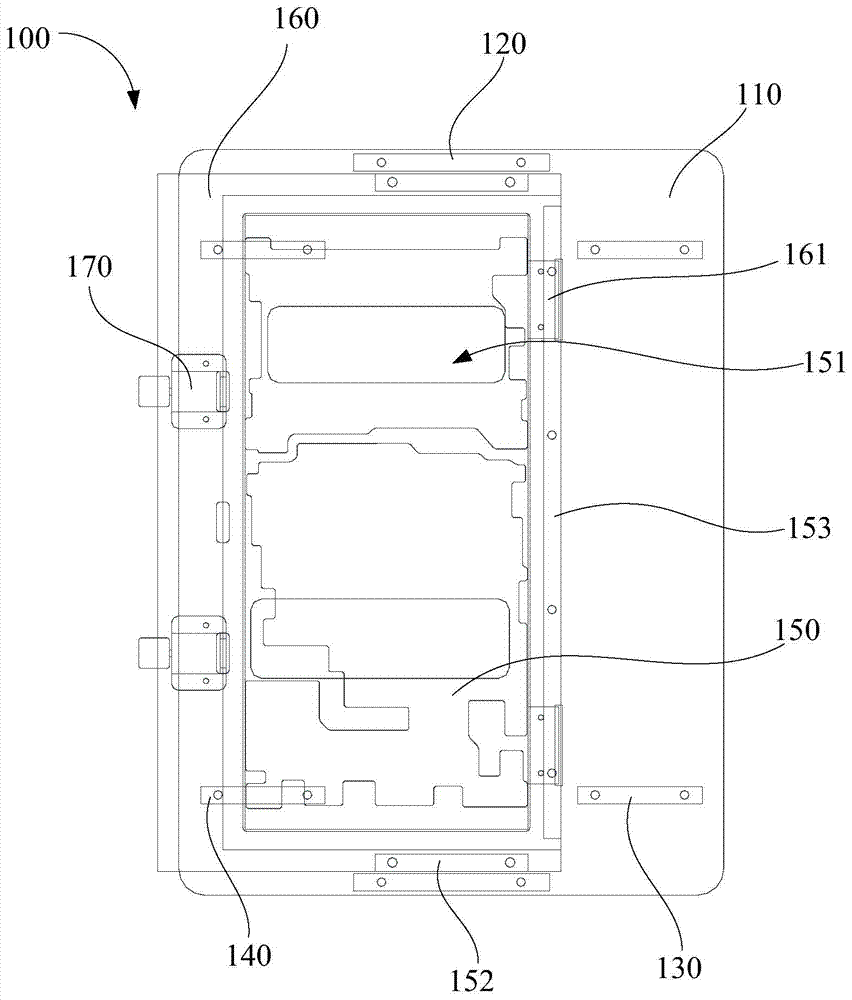

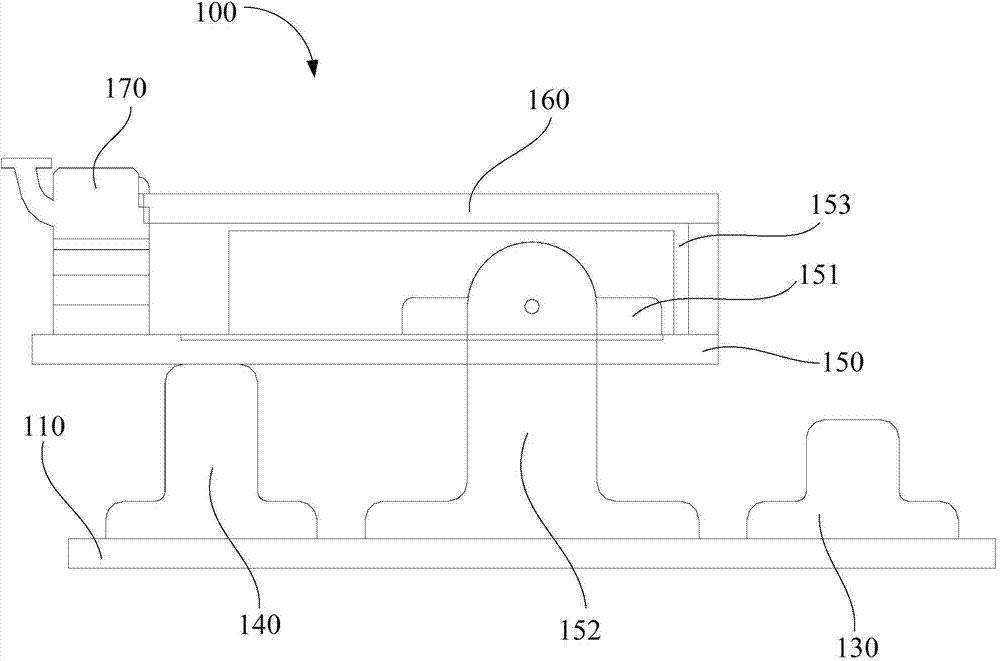

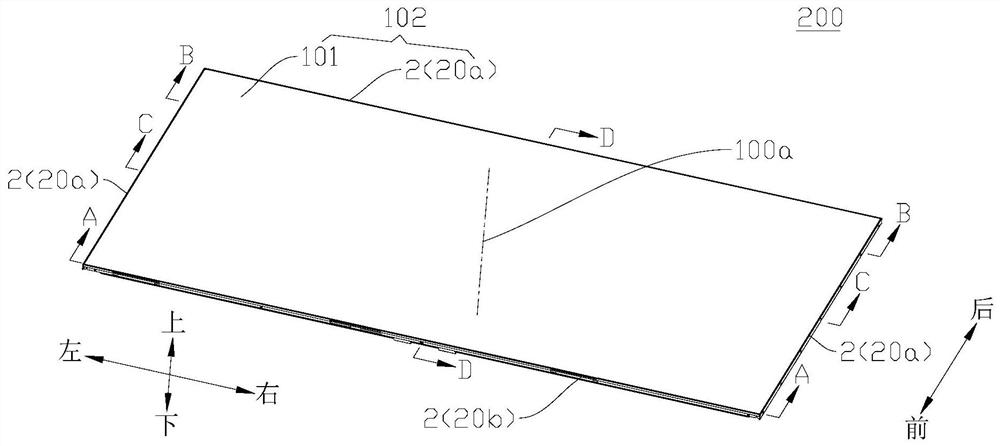

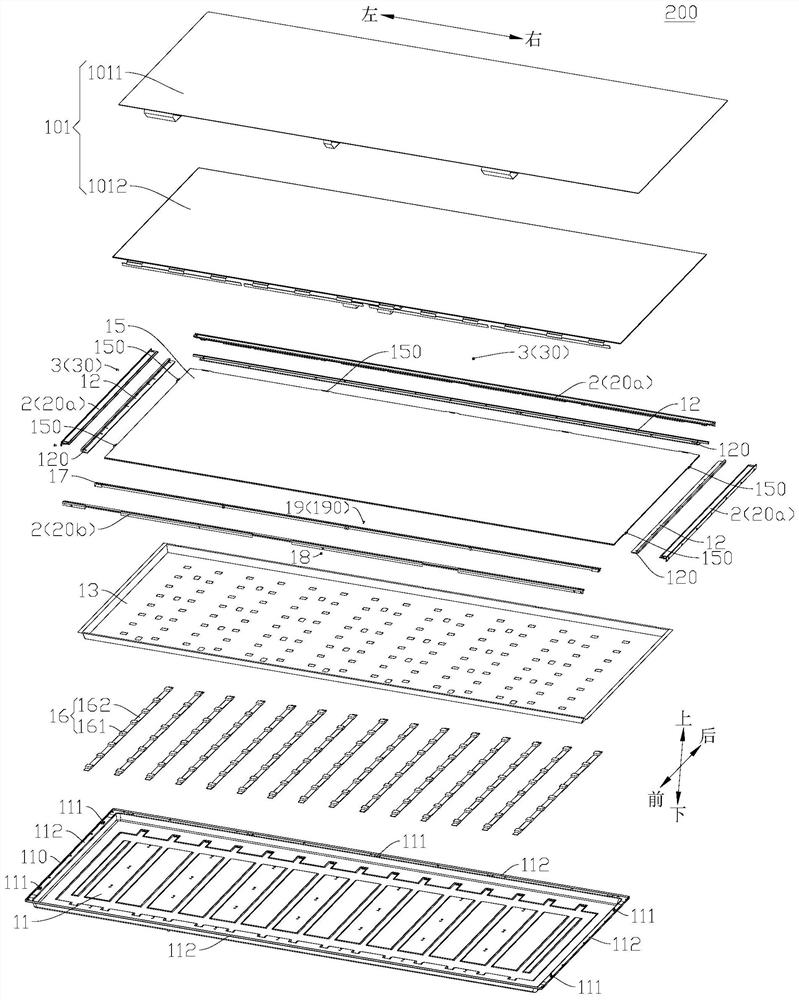

Liquid crystal display module and packaging method

ActiveCN103048812AAvoid damageReduce the number of flipsNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a liquid crystal display module and a packaging method. The liquid crystal display module comprises a back plate, wherein the back plate is provided with a fixing beam used for fixing the back plate erectly. As the back plate of the liquid crystal display module is provided with the fixing beam used for providing support to fix the back plate erectly, the back plate can be erected during the mounting process per se for the installation of a backlight module and a liquid crystal display component. Therefore, in the assembling process of the liquid crystal display module, a two-overturning process, that means, a process of mounting the liquid crystal display component horizontally and remounting a circuit board erectly, is only necessary when the liquid crystal display component is assembled, and the reduction of the overturning time decreases damage probability of the liquid crystal display component in installation during the assembling process; and as the erect mounting way is adopted for assembling the backlight module, a worker can operate in a standing manner, a wider reachable distance of the operation is can be obtained, and the operating distance can be enabled to adapt to an ergonomic and comfortable distance so as to improve the production efficiency.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Auxiliary welding device for components of PCBA

InactiveCN104759730ADeskewImprove welding qualityPrinted circuit assemblingMetal working apparatusEngineeringUltimate tensile strength

The invention discloses an auxiliary welding device for components of a PCBA. The auxiliary welding device for the components of the PCBA is used for positioning the components of the PCBA on a PCB and comprises a base, a supporting base installed on the base, a welding positioning block, an insertion positioning block, a PCB positioning plate and an upper fixing cover plate. The welding positioning block and the insertion positioning block are installed on the supporting base and are oppositely arranged in a spaced mode, and the supporting base is arranged between the welding positioning block and the insertion positioning block. The PCB positioning plate is connected with the supporting base in a rotary mode through a rotary shaft, and a hollowed-out part used for exposing the welding portion of the PCB is arranged on the PCB. The upper fixing cover plate is movably connected with the PCB positioning plate. A positioning structure used for positioning the components of the PCBA is arranged on the surface, opposite to the PCB positioning plate, of the upper fixing cover plate. The upper fixing cover plate rotates around the rotary shaft along with the PCB positioning plate and can be selectively overturned onto one of the welding positioning block and the insertion positioning block. The auxiliary welding device for the components of the PCBA has the advantages that the welding quality of the components of the PCBA can be improved, welding efficiency is high, the welding cost can be lowered and labor intensity can be relieved.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

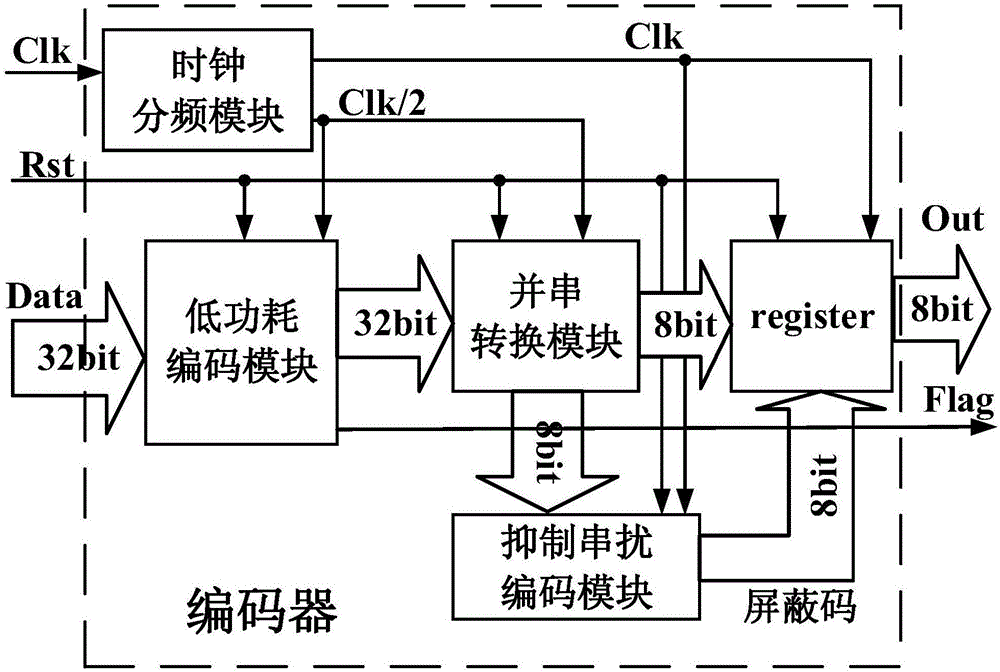

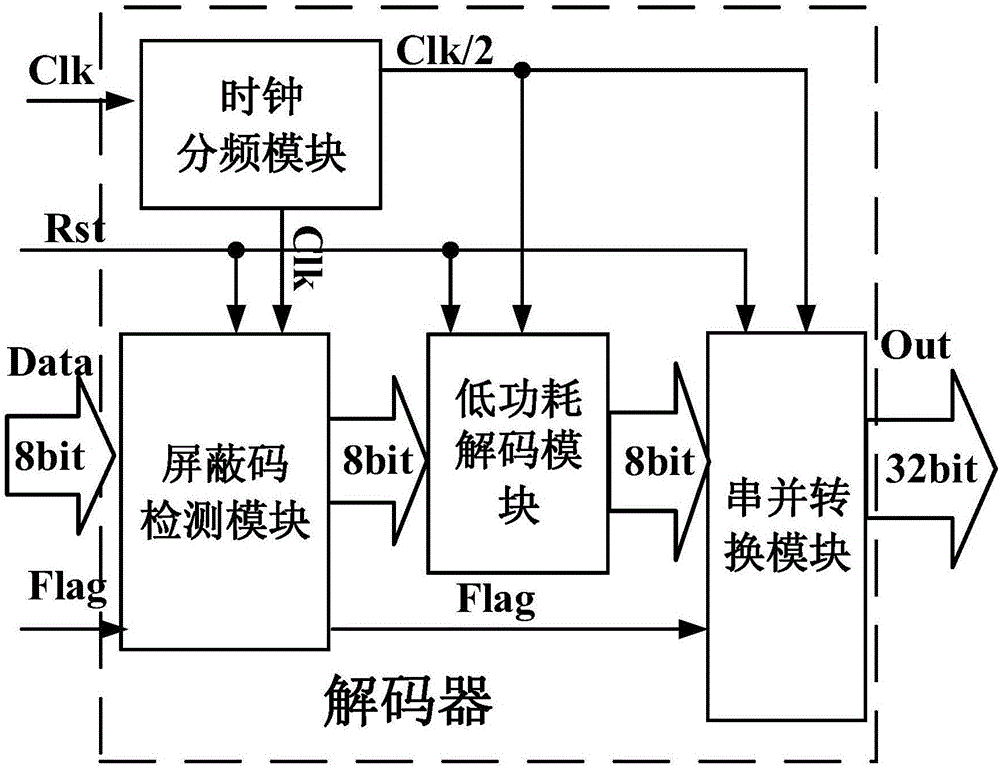

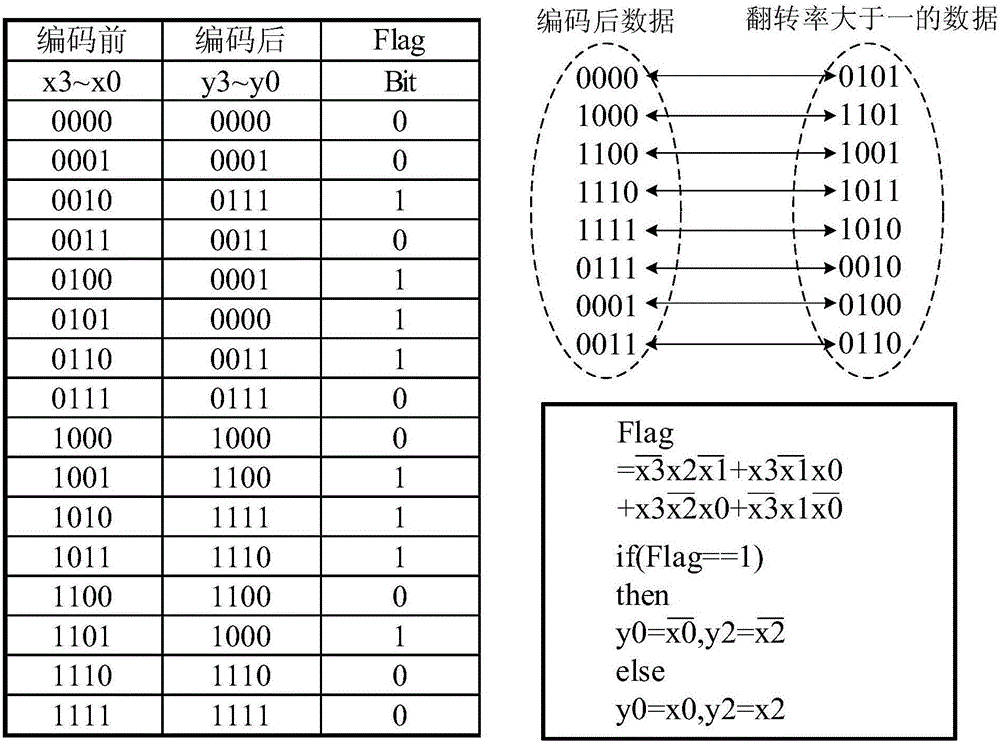

Low power consumption and crosstalk resistant coding and decoding method and coding and decoding device for network on chip

ActiveCN106849954AReduce the number of flipsReduce dynamic power consumptionIndividual digits conversionEnergy efficient computingDecoding methodsOriginal data

The invention provides a crosstalk resistant and low power consumption coding and decoding method and a codec thereof, which can effectively reduce the dynamic power consumption of data transmission and improve the quality of the data transmission. The coding and decoding method of the invention changes the encoding mode of data by considering the reduction of the number of turns between data; compared with original data, the number of turns can be reduced by 37.56%, so that the dynamic power consumption in the data transmission is effectively reduced; and by inserting a mask code in the worst crosstalk condition, the crosstalk between data can be effectively reduced on the premise of minimizing the additional power consumption. For a random data source, the crosstalk resistant and low power consumption coding and decoding method and the codec thereof provided by the invention reduce the transmission power consumption by 37.51% while avoiding the worst crosstalk.

Owner:XIDIAN UNIV

Slow-release fertilizer for watermelons in dry sandy field

InactiveCN102674984AReduce the frequency of fertilizationReduce labor intensityAgriculture gas emission reductionFertilizer mixturesChemistrySoil science

The invention discloses a slow-release fertilizer for watermelons in dry sandy field. The slow-release fertilizer comprises the following compositions in percentage by weight: 20 percent of urea, 60 percent of calcium superphosphate, 19.4 percent of potassium sulfate, and 0.6 percent of sustained release drug; the sustained release drug is prepared by mixing nitrogen inhibitor and phosphorous activating agent according to weight ratio of 3:1; and the nitrogen inhibitor is prepared by mixing nitrification inhibitor and urease inhibitor according to a weight ratio of 1:0.3. The slow-release fertilizer for watermelons in dry sandy field has the advantages of being simple to apply, capable of conducting application at one time, low in production cost, and high in fertilizer utilization rate, and increasing the yield of watermelons.

Owner:甘肃省农业科学院蔬菜研究所

High-speed optical cable SZ stranding binding machine with low turnover number

ActiveCN107219601ARealize continuous automaticLighten the steering loadFibre mechanical structuresMotor driveTurnover number

The invention discloses a high-speed optical cable SZ stranding binding machine with a low turnover number, which comprises a stranding binding part. The stranding binding part comprises a first rack, and a stranding device, a winding and binding device and a passive anti-back twisting belt are sequentially arranged on the first rack along an optical fiber sleeve conveying direction; the stranding device comprises a stranding pipe and a positive and negative rotation motor, the stranding pipe is arranged horizontally along the stranding axis of the optical cable, the stranding pipe is connected with the positive and negative rotation motor, the output shaft of the positive and negative rotation motor is also connected with one end of an elastic energy storage device, the other end of the elastic energy storage device is connected with the first rack, and the positive and negative rotation motor drives the stranding pipe to rotate in a positive and negative alternative mode through a stranding synchronous belt. Continuous and automatic SZ stranding and binding for the optical fiber sleeve can be realized, the rotation speed is improved and the SZ stranding turnover number in a unit time is reduced, the stranding quality is improved, the cabling speed is improved, energy is saved, consumption is reduced, and the operation noise is reduced.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

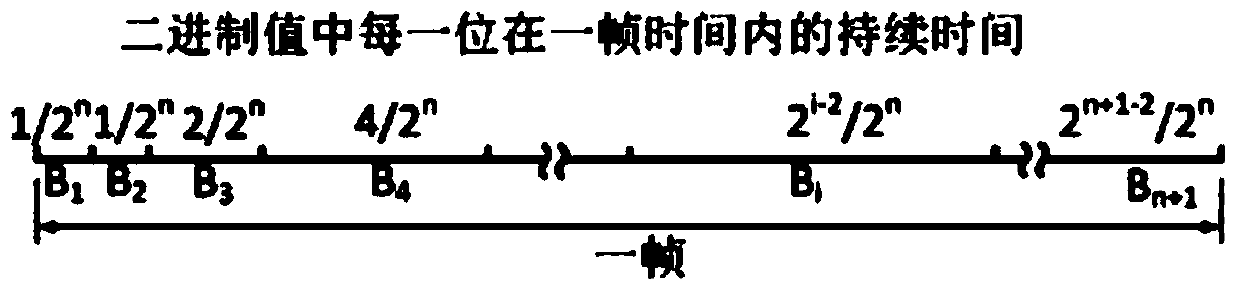

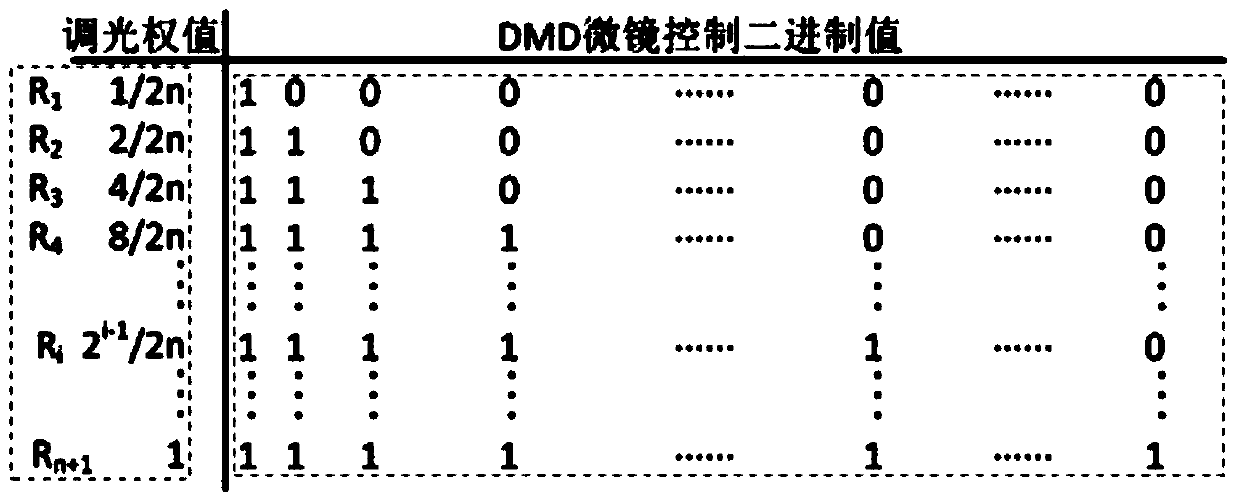

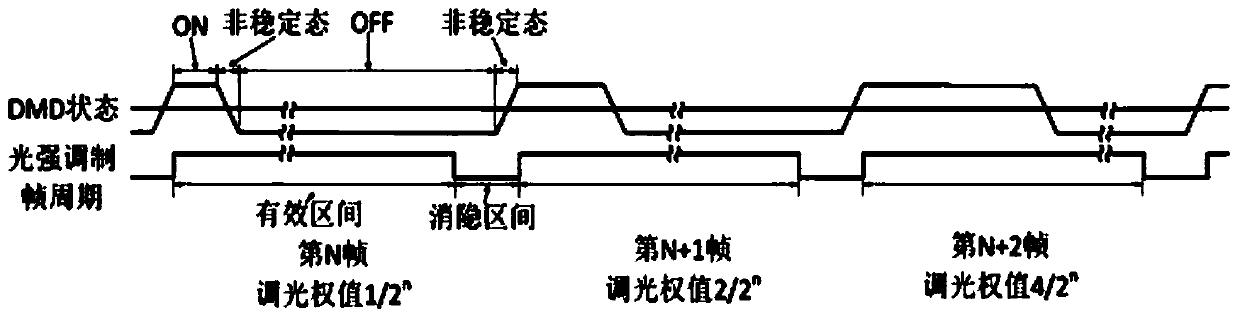

DMD control method in high dynamic range imaging

InactiveCN104184955AReduce light pollutionHigh precisionTelevision system detailsColor television detailsRadiation fieldNuclear medicine

The invention relates to a DMD control method in high dynamic range imaging, relates to DMD light intensity modulation and control manners in the imaging detection field of high-dynamic-range radiation scenes, and aims at solving the problem that a present DMD light intensity modulation technology tends to cause multiple times of micromirror overturn in one frame of light intensity modulation. The DMD control method comprises the steps of limiting a light intensity modulation weight, and limiting the continuous time of each bit of a binary value of the light intensity modulation weight within one frame. The DMD control method can reduce the overturn times of the DMD in the imaging detection of high-dynamic-range radiation scenes, and improves the DMD light modulation precision.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Floating type bollard guide groove assembling device and assembling method

ActiveCN110284482AReduce manufacturing difficultyReduce installation difficultyDry-docksInversion methodsQuality Control Problem

The invention relates to a floating type bollard guide groove assembling device and an assembling method. The floating type bollard guide groove assembling device comprises a plurality of steel tire templates, the multiple steel tire templates are arranged on a supporting platform at equal intervals, and the steel tire templates are vertically arranged and are supported and foxed by diagonal braces. The bollard guide groove assembling method is used for assembling bollard guide grooves in a segmented inversion method. By adopting the above structure, through an on-site installation manner, the problem about manufacturing quality control in a floating type bollard guide groove embedded piece factory is solved, the production cycle is shortened, and the floating type bollard guide groove installation efficiency is improved.

Owner:CHINA GEZHOUBA GROUP MACHINERY & SHIP

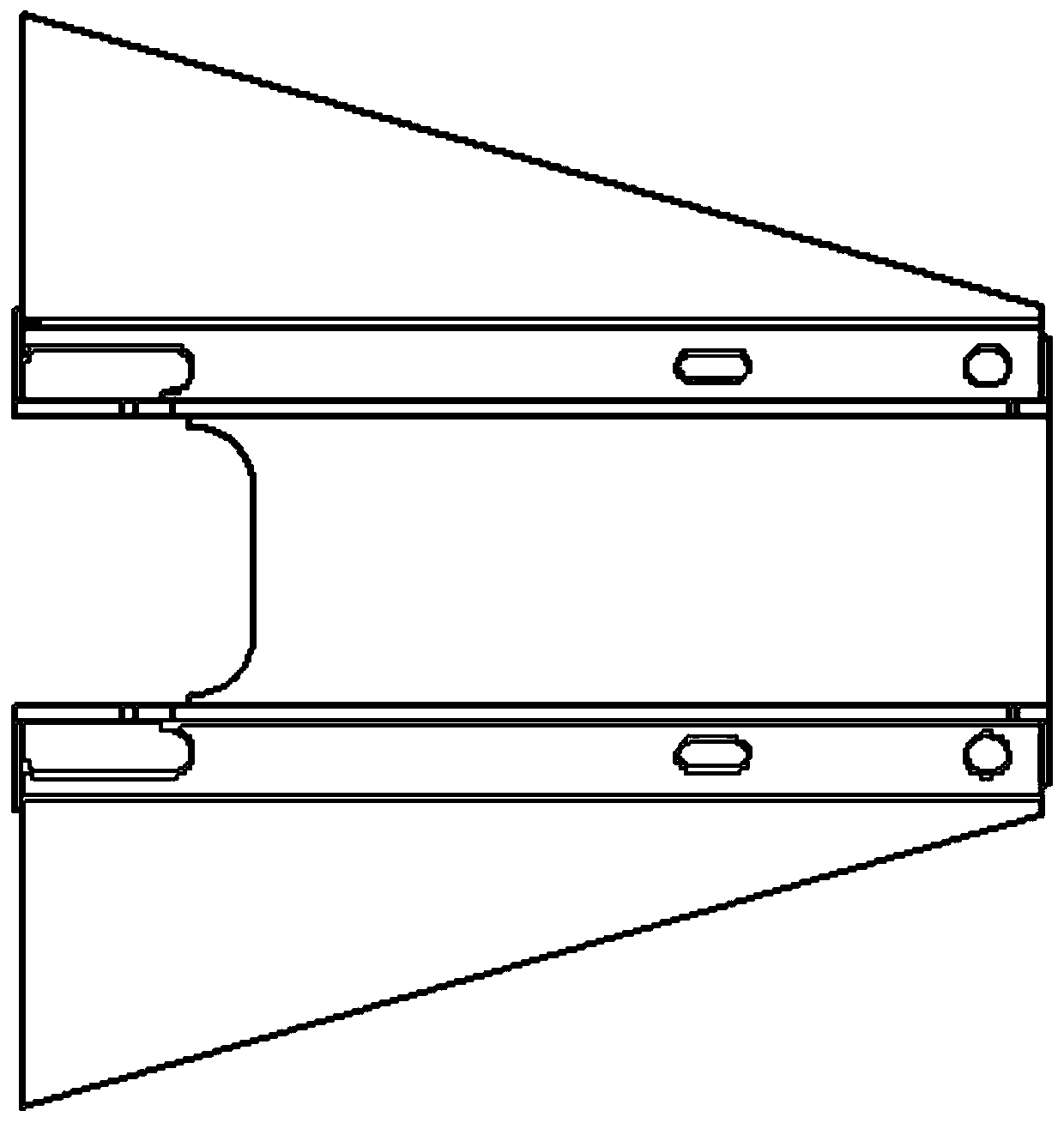

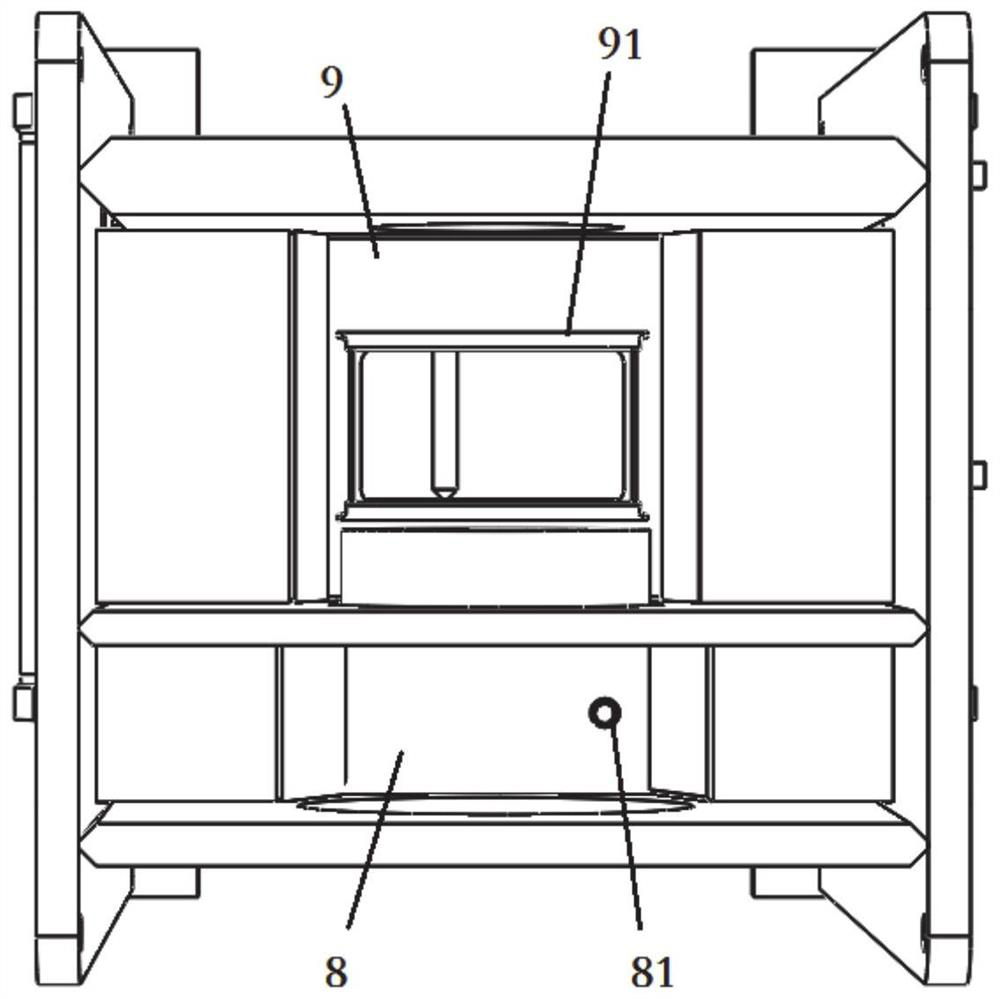

Marine low-speed diesel engine rack monolithic welding method

InactiveCN111168315AReduce weightReduce complexityWelding/cutting auxillary devicesAuxillary welding devicesDieselingWeld seam

The invention aims to provide a novel marine low-speed diesel engine rack monolithic welding method. The assembling and welding sequence is optimized according to marine low-speed diesel engine rack monolithic welding parts, weld joint layout and quality requirements. According to the method, the mode of assembling and welding a web plate, guide rail plates and then wing plates in the existing marine low-speed diesel engine rack monolithic welding sequence is changed; and the guide rail plates and the wing plates are assembled and welded firstly, and then the two sets of guide rail plates andwing plates are assembled and welded together through the web plate. Due to the fact that the overall welding mode is adjusted to separate welding and then assembly welding, the weight of a single setof welding bodies is reduced, the complexity is reduced, ground level operation can be achieved, climbing is not needed, the safety production risk is effectively reduced, a special welding supporting tool does not need to be manufactured, and the production cost is saved. Rack monolithic welding is carried out according to the assembling and welding sequence, the risk of falling from high altitude can be avoided, the production efficiency is improved, the production cost is reduced, and the welding quality is guaranteed.

Owner:中国船舶重工集团柴油机有限公司

Anti-collision circuit of RFID (Radio Frequency Identification Device)tag and realizing method thereof

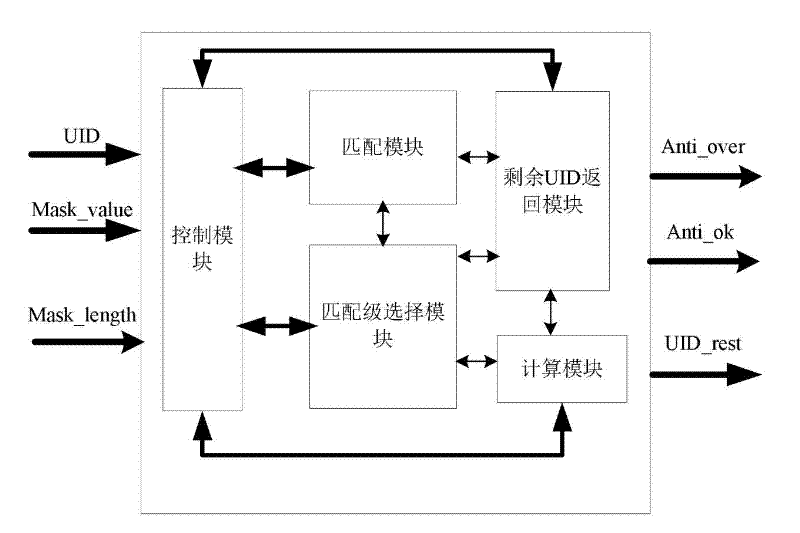

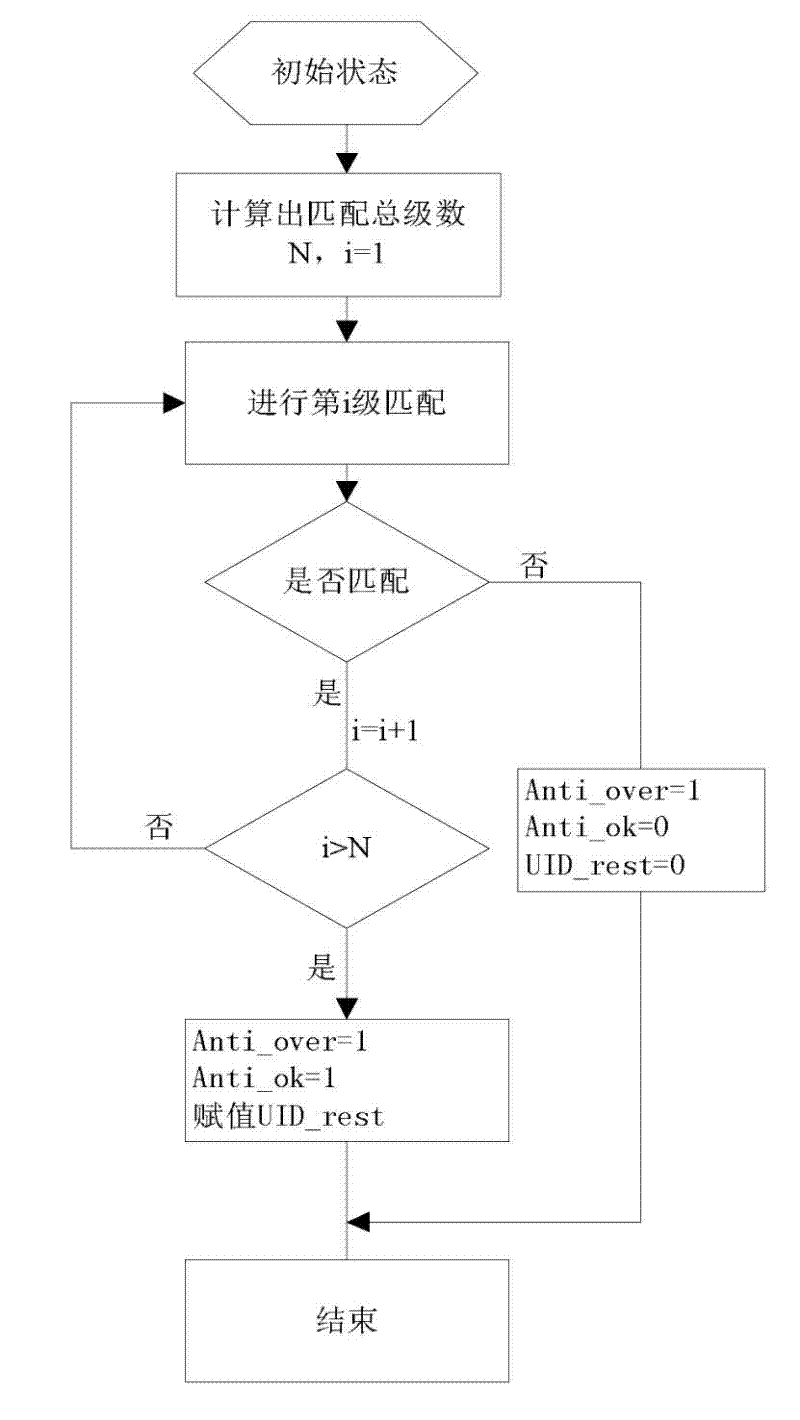

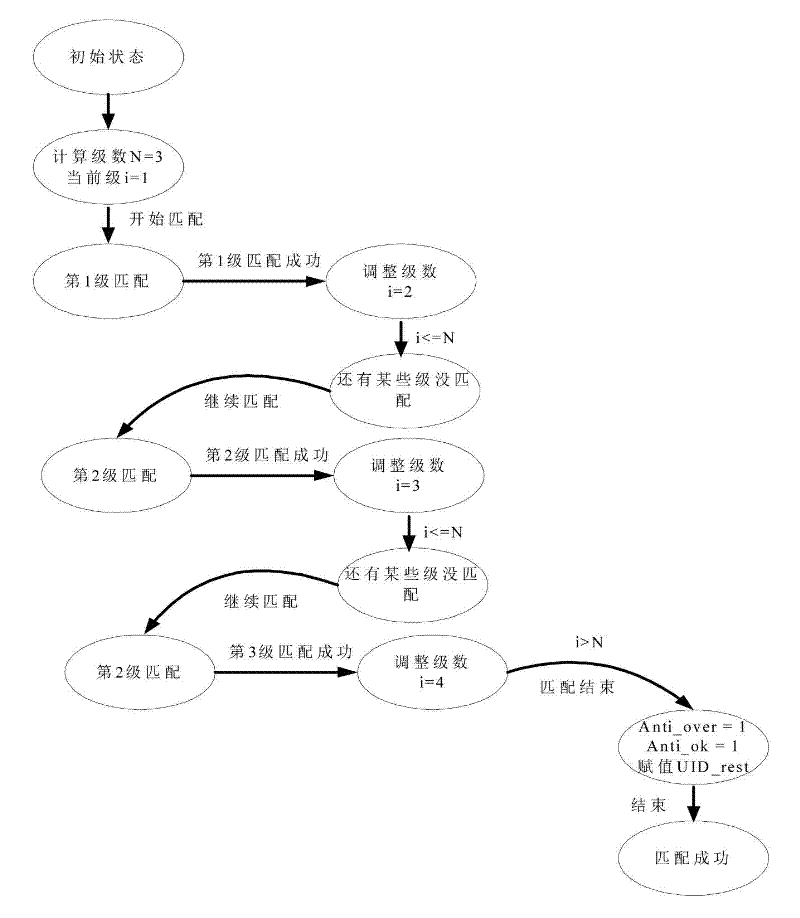

InactiveCN102411721AReduce the numberReduce the number of flipsRecord carriers used with machinesProcessor registerComputer science

The invention discloses an anti-collision circuit of RFID (Radio Frequency Identification Device)tags and a realizing method thereof. The anti-collision circuit comprises three signal input terminals of UID (User Interface Design) values, mask values and mask length values, three signal input terminals of matching ending signal values, matching result values and residue UID values, and a control module, a matching module, a matching level selecting module, a residue UID return module and a calculating module. The realizing method comprises: according to the mask length values and a preset matching level number, calculating the total level number that the UID values match with the mask values; regarding the matching level number as a basic unit number, selecting a value of a basic unit number from both the UID values and the mask values successively for carrying out multi-level matching comparison. By adopting a method of multi-level matching to the UID values, the circuit in the invention reduces the numbers of registers used in the anti-collision circuit of the RFID tag, so that not only the area of a chip circuit is saved but also the number of registers which are turned over simultaneously is reduced, thereby reducing energy consumption of the chip circuit of the RFID tag greatly. The circuit in the invention is applicable in RFID system field.

Owner:GUANGZHOU SYSUR MICROELECTRONICS

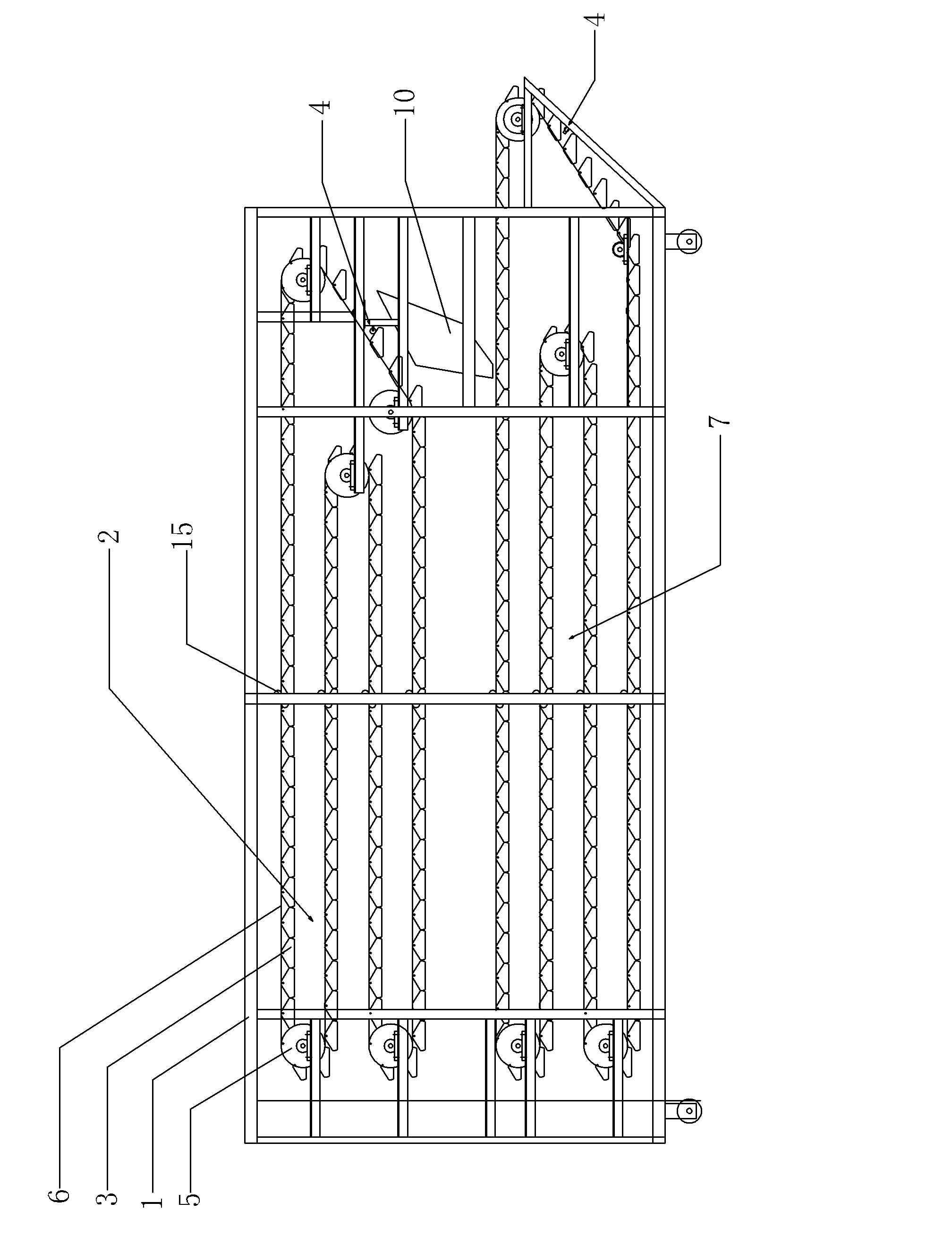

Two-layer conveyor for tea leaf spreading machine

InactiveCN102556581AReduce the number of flipsAffect the quality of fryingConveyorsPre-extraction tea treatmentVertical projectionTime transfer

The invention relates to a two-layer conveyor for a tea leaf spreading machine. In the prior art, defects of high turning frequency, low equipment utilization rate and low yield by a method of matching multiple pulleys. The two-layer conveyor comprises a support, wherein the support is provided with an upper transmission mechanism and a lower transmission mechanism which are distributed up and down and of which the vertical projection parts are overlapped; the upper transmission mechanism and the lower transmission mechanism respectively comprise a plurality of horizontal guide wheel shaft in the longitudinal direction on two sides of the frame; each guide wheel shaft is provided with two symmetrically arranged main guide wheels; a closed chain is wound on main guide wheels on the same side, so two closed chains are formed; a plurality of tea leaf hoppers movably connected with the closed chains are arranged between the two closed chains; the frame is provided with two turning mechanisms matched with the tea leaf hoppers; and tea leaves pass through the turning mechanisms and are subjected to one-time transfer between the transmission mechanisms, so that the aims of turning and completely drying the tea leaves are fulfilled and the frequency of transferring, dropping and turning the tea leaves is reduced to the greatest extent.

Owner:ZHEJIANG HENGFENG TECH DEV

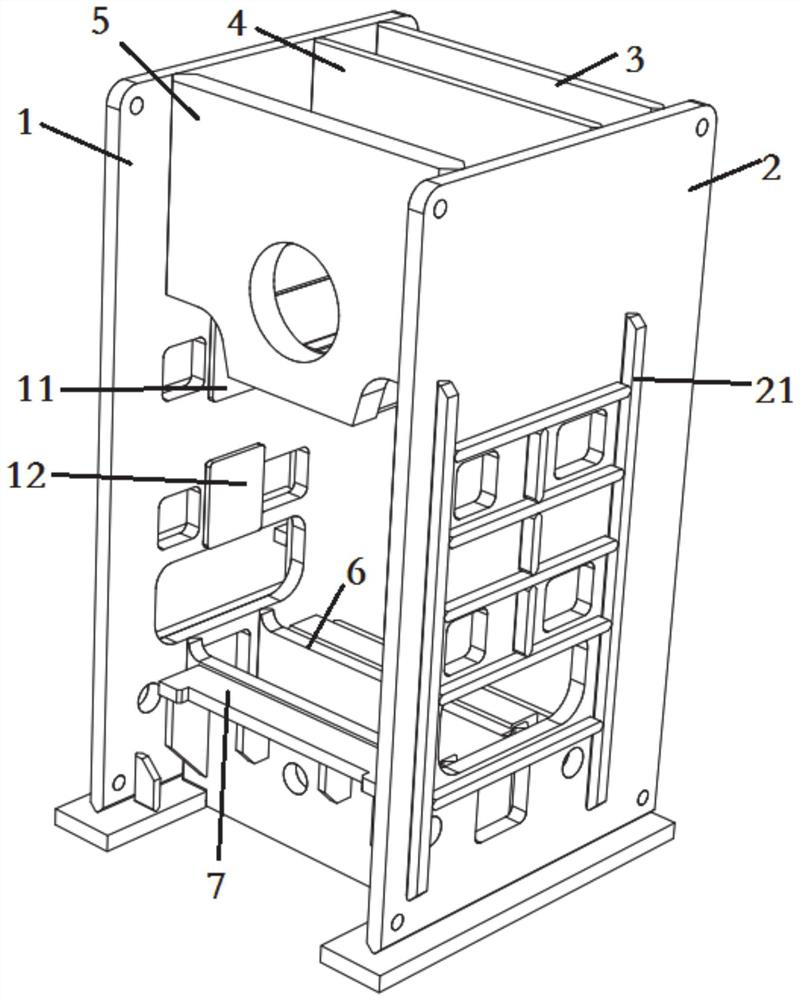

Welding method and manufacturing process of press machine body

ActiveCN112059457AReduce welding errorsReduce distortionWelding apparatusPressesEngineeringWelding deformation

The invention provides a welding method and a manufacturing process of a press machine body, and belongs to the field of large-scale load bearing chassis. The method comprises the following steps that1, two vertical side plates in the press machine body and a middle supporting plate and a bottom plate supporting plate which are arranged in longitudinal side plates are pre-assembled, wherein the middle supporting plate comprises a first middle plate, a second middle plate and a third middle plate which are parallel to one another and the bottom plate supporting plate comprises a first bottom supporting plate and a second bottom supporting plate; 2, the two longitudinal side plates are vertically placed, the first middle plate and the first bottom supporting plate are welded to the same side in the width direction, then the two vertical side plates are turned over by 90 degrees to be placed, the second middle plate and the third middle plate are welded to the upper portion of the firstmiddle plate in sequence, the second bottom supporting plate is welded to the upper portion of the bottom supporting plate in the first step; and thirdly, a base supporting plate is welded to the bottoms of the two longitudinal side plates. By means of the welding method, welding deformation is effectively controlled, and the production efficiency is improved.

Owner:中船发动机有限公司

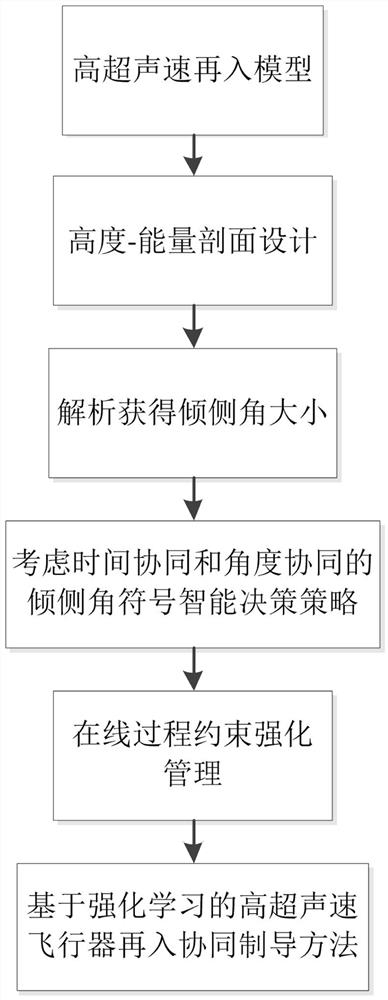

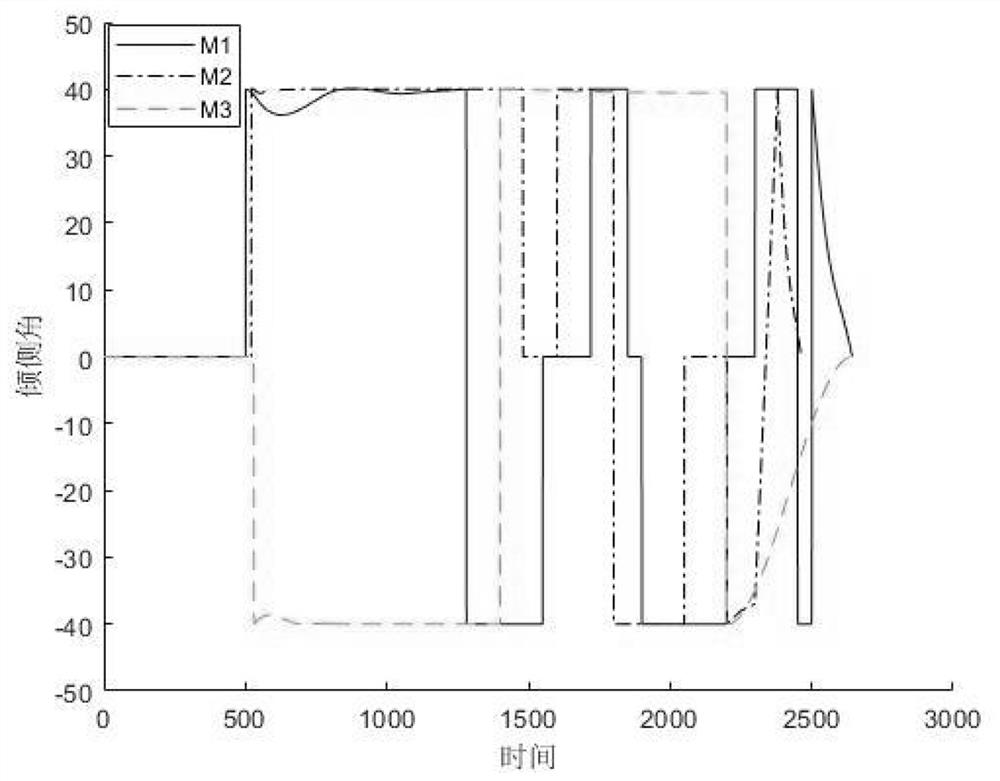

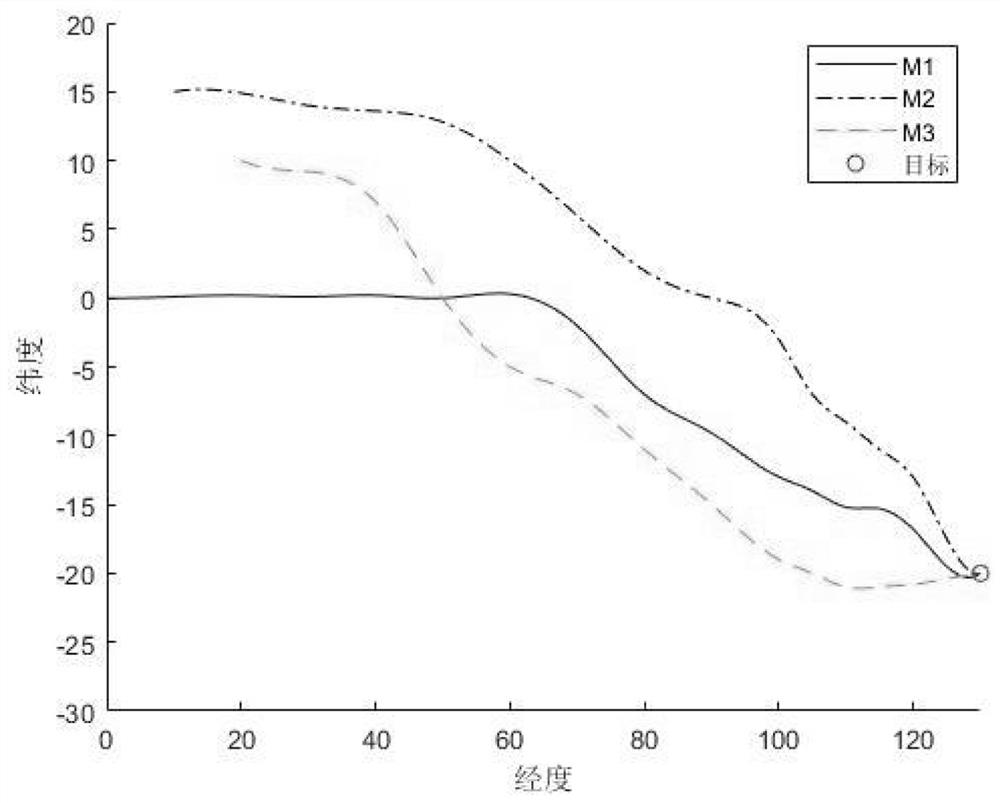

Hypersonic aircraft reentry cooperative guidance method based on reinforcement learning

ActiveCN114675545AQuick calculationSatisfy the terminal constraintsSustainable transportationMachine learningFlight vehicleControl theory

The invention discloses a hypersonic flight vehicle reentry cooperative guidance method based on reinforcement learning, and particularly relates to a hypersonic flight vehicle reentry cooperative guidance method based on reinforcement learning. Establishing a hypersonic velocity reentry kinetic model and a multi-constraint reentry model; designing an attack angle profile and a height energy profile, and obtaining analytic solutions of the attack angle and the heeling angle; intelligent decision making is carried out on heeling angle symbols according to a DQN algorithm, the action space of the heeling angle symbols is expanded, and a step-shaped mixed reward function is designed by considering time collaboration and falling angle collaboration; the hypersonic aircraft reentry cooperative guidance method based on intelligent reinforcement learning is obtained by training a heeling angle intelligent decision-making model offline and giving cooperative time and a cooperative fall angle to obtain a guidance instruction online, the defect that in an aircraft guidance strategy, heeling angle symbols are turned frequently is effectively overcome, time cooperation and fall angle cooperation are met, and the guidance efficiency is improved. A simulation experiment verifies that the method can well consider time and fall angle cooperation to carry out multi-hypersonic-velocity aircraft guidance.

Owner:中国人民解放军火箭军工程大学

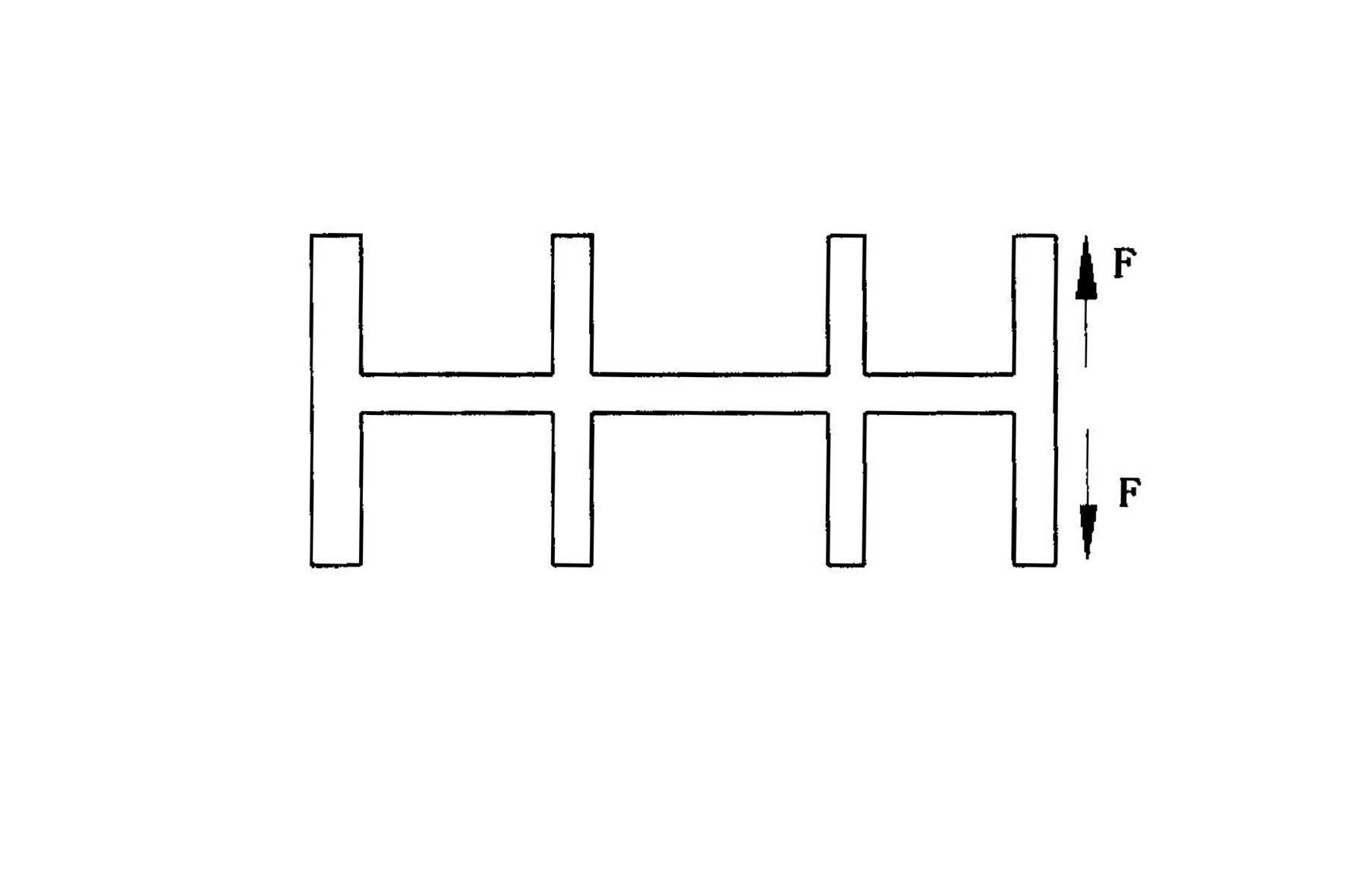

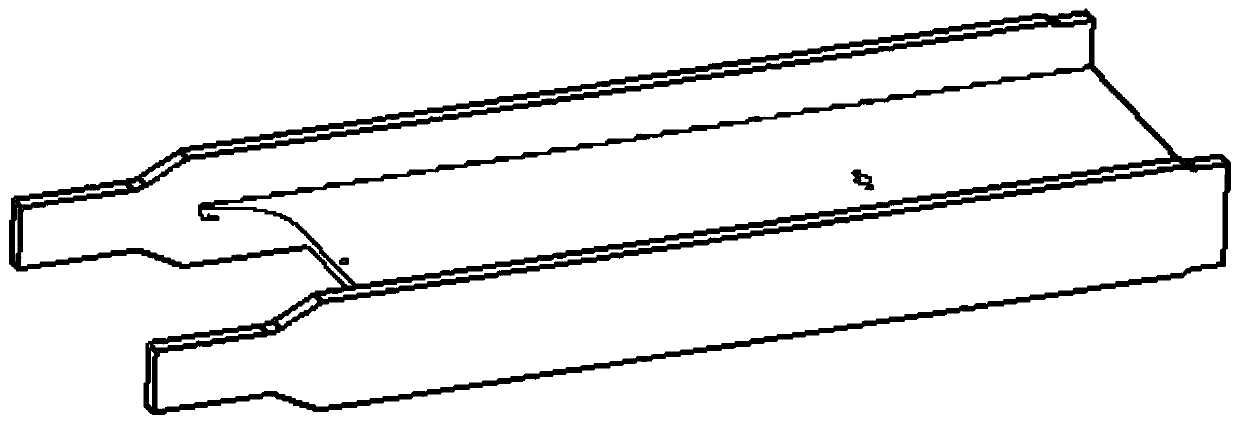

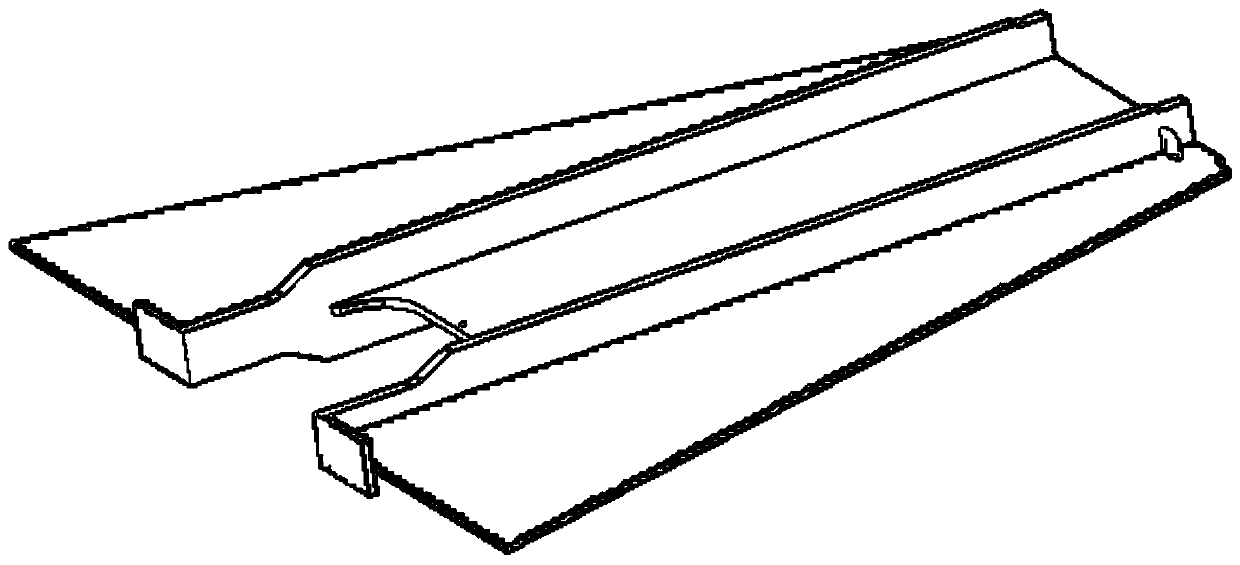

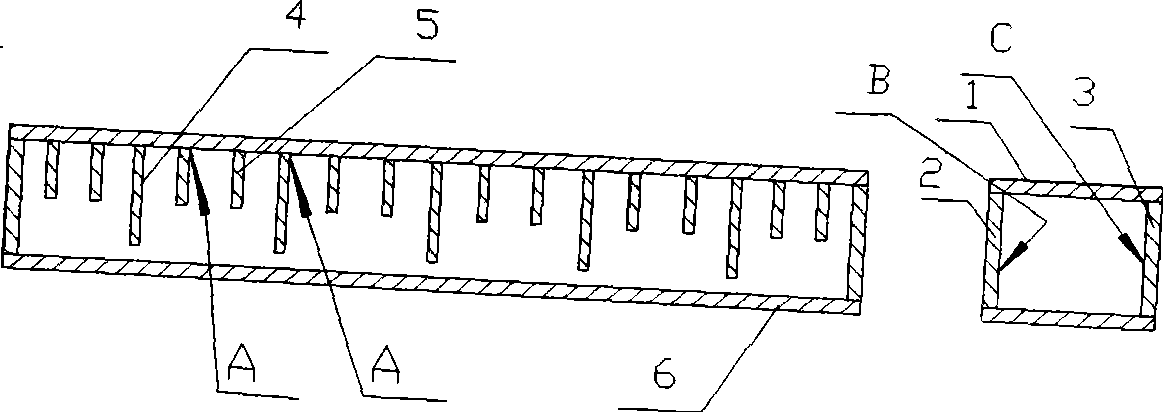

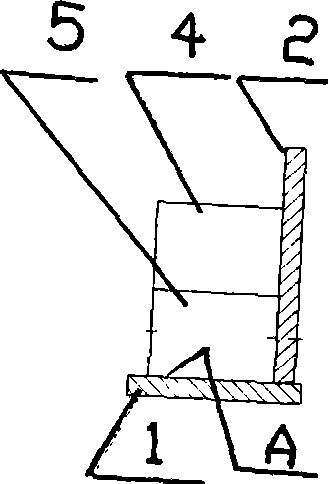

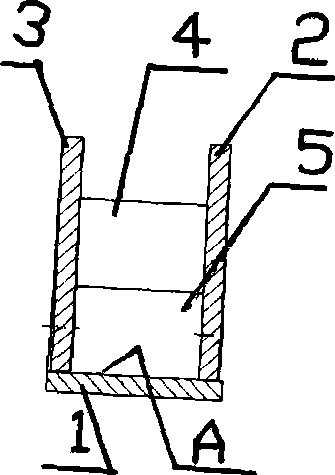

Assembling and welding technique for box shape steel structure girder

InactiveCN101469565AMeet technical requirementsLarge welding errorGirdersJoistsWeld lineWelding process

The invention provides a welding process for box type steel structure beam, including assembling a upper wing board 1 and a long and a short reinforcing plate 4, 5, welding a welding line A, assembling ventral boards 2, 3, laying members and welding a welding line C, turning over, welding a welding line B, assembling and welding a lower wing board 6, enclosing the box type beam. The process is in accordance with technical requirement of steel structure beam, without downwarping generated after welding, but with slightly upwarping.

Owner:JIANGXI COPPER CORP

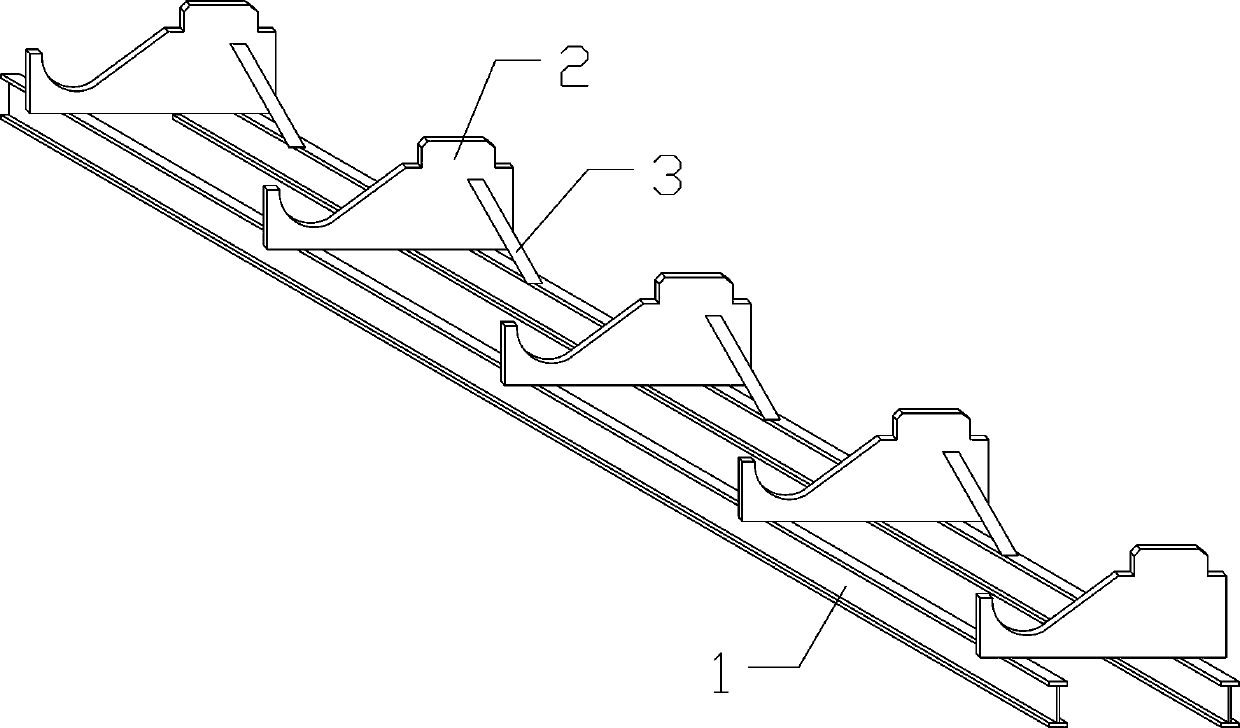

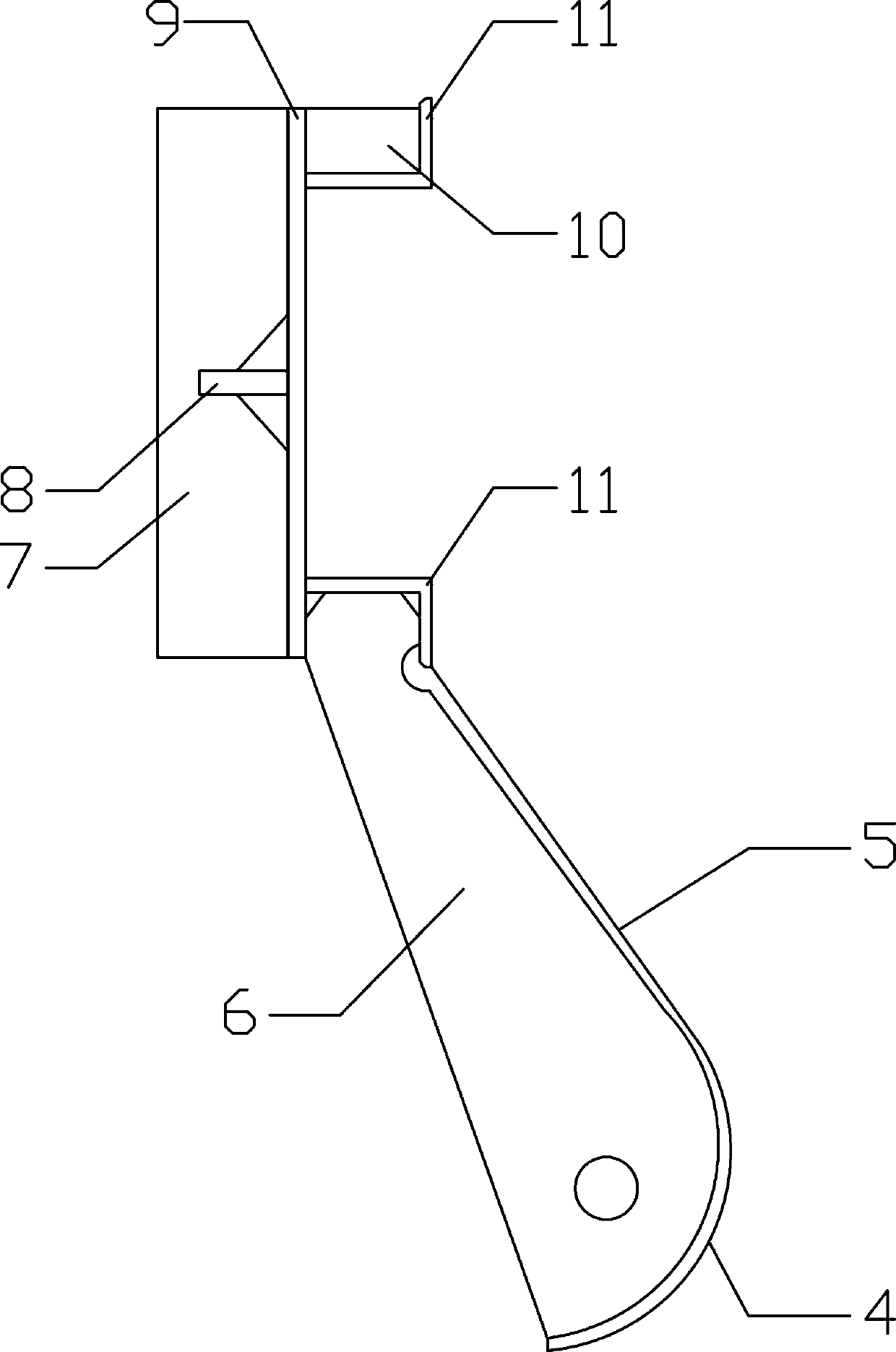

Automatic logistic conveying device for machining end face of lift guide rail

InactiveCN102689223AReduce labor intensityHigh degree of automationMetal working apparatusProduction lineEngineering

The invention relates to an automatic logistic conveying device for machining an end face of a lift guide rail. The automatic logistic conveying device comprises a feeding rack, and is characterized in that a feeding turnover mechanism is arranged at the output end of the feeding rack; and a step fixing rack is arranged at the output end of the feeding turnover mechanism. Meanwhile, a discharging turnover assembly is arranged at the output end of the step fixing rack; and lathe feeding and discharging racks are distributed on the step fixing rack. Thus, the labor intensity of workers can be reduced, and the production enthusiasm can be improved. Meanwhile, the transporting and turning-over frequency of products in a process can be reduced, so that the product collision defect is reduced, and the product quality is improved. Furthermore, the labor participation in a product manufacturing process is further reduced, and the influence on the product quality due to factors, such as human mood, can be reduced. More importantly, the automation of an assembly line is improved, and the risk and the hidden danger of influencing the production by staff variation can be reduced. Moreover, the layout is more compact, the production beat is stable and consistent, and the entire production image is improved.

Owner:长江润发(张家港)机械有限公司

Read operating circuit, semiconductor memory, and read operating method

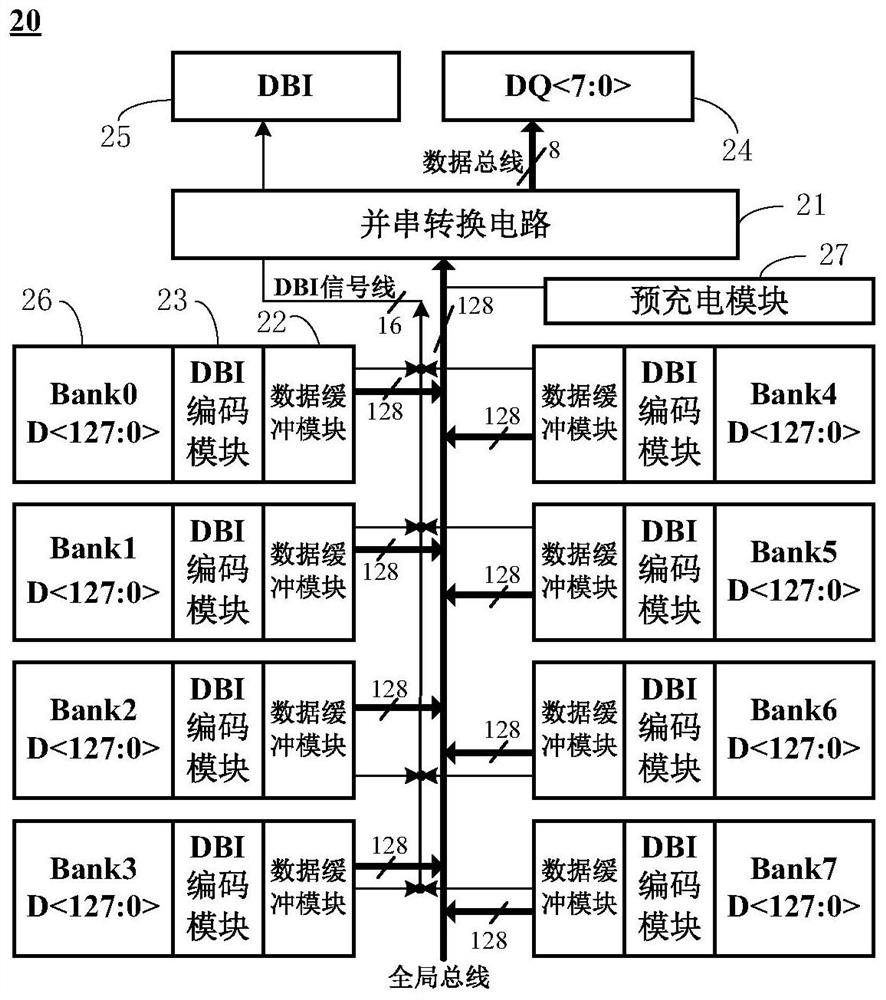

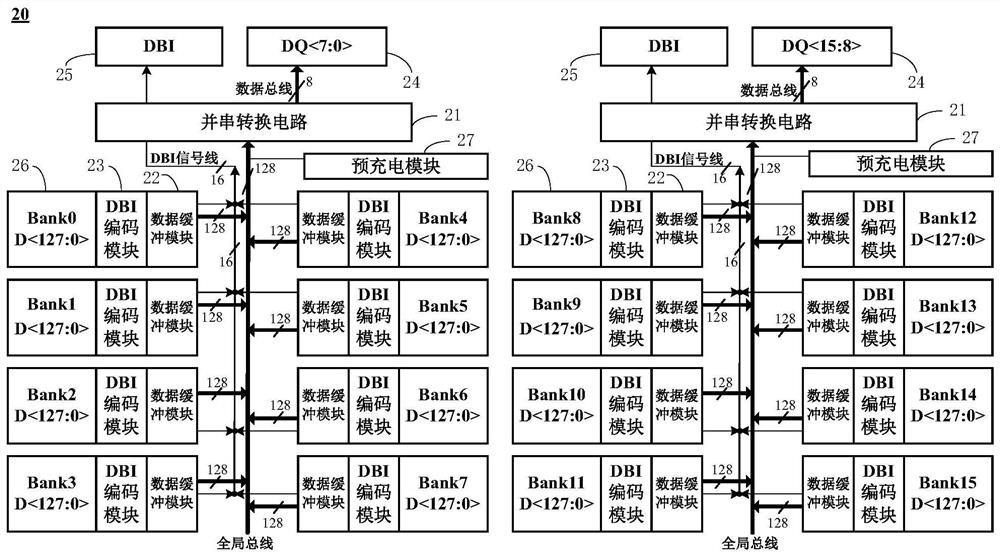

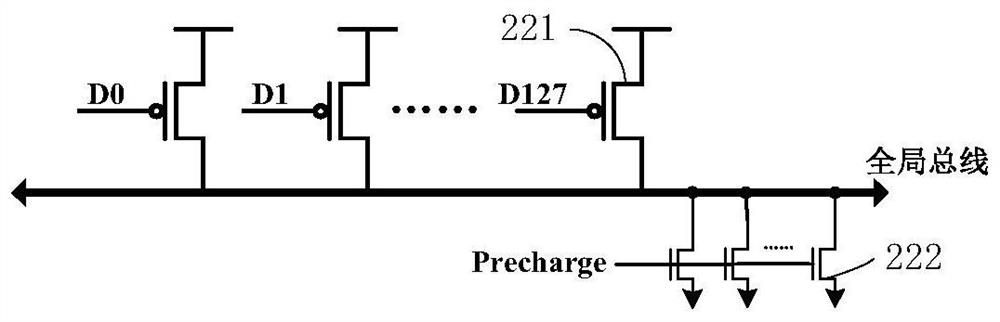

The embodiment of the invention at least provides a read operation circuit. Theread operation circuit comprises: a DBI encoding module which is used for reading read data from a storage block and determining whether to overturn the read data according to the digit of the data which is high in the read data so as to output global bus data transmitted by a global bus and DBI data transmitted by a DBI signal line, and a DBI port used for receiving the DBI data; a parallel-serial conversion circuit which is used for carrying out parallel-serial conversion on the global bus data so as to generate output data of the DQ port; a data buffer module which is connected to the storage block through a global bus; and a pre-charging module which is connected to the pre-charging signal line and is used for setting the initial state of the global bus to be low. According to the technical scheme of the embodiment of the invention, more '0' data can be transmitted on the global bus of the Precharge pull-down architecture, so that the turnover frequency of the internal global bus can be reduced, the current is greatly compressed, and the power consumption is reduced.

Owner:CHANGXIN MEMORY TECH (SHANGHAI) INC

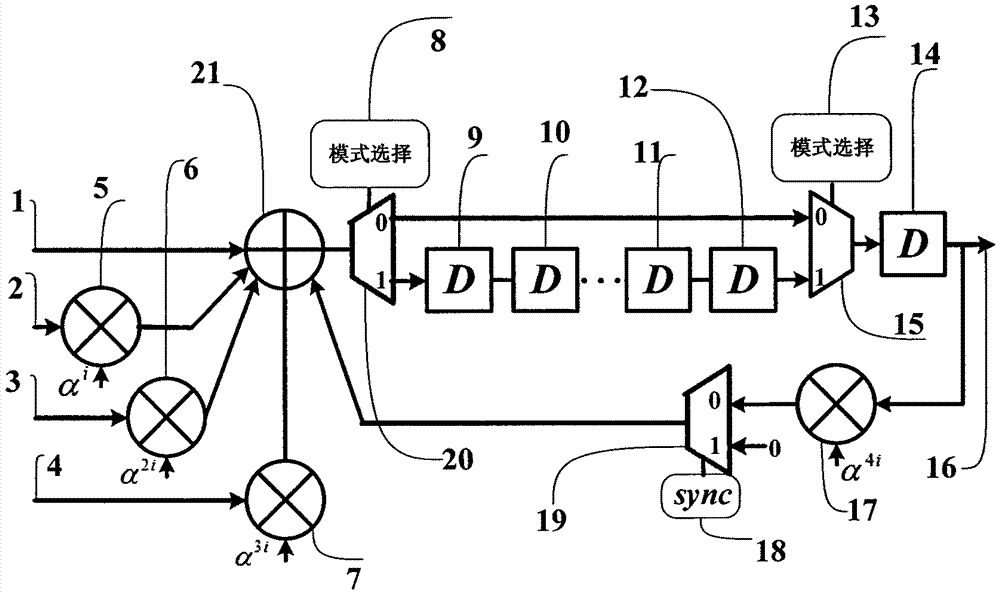

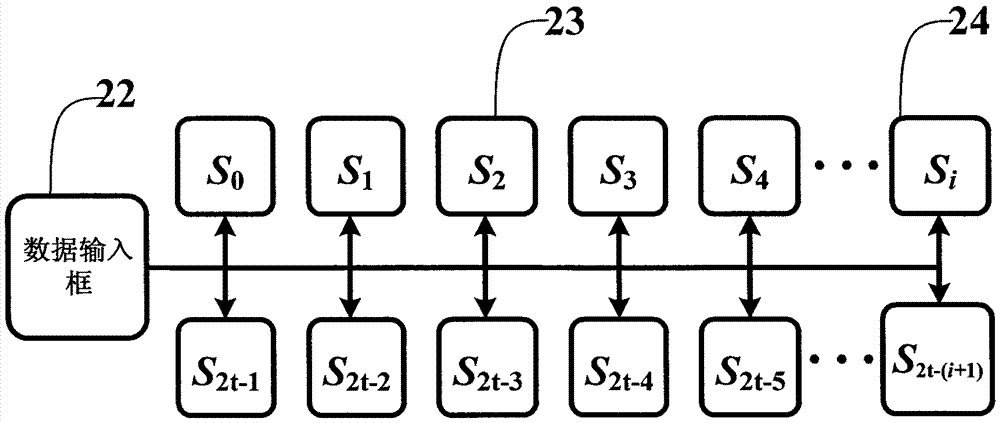

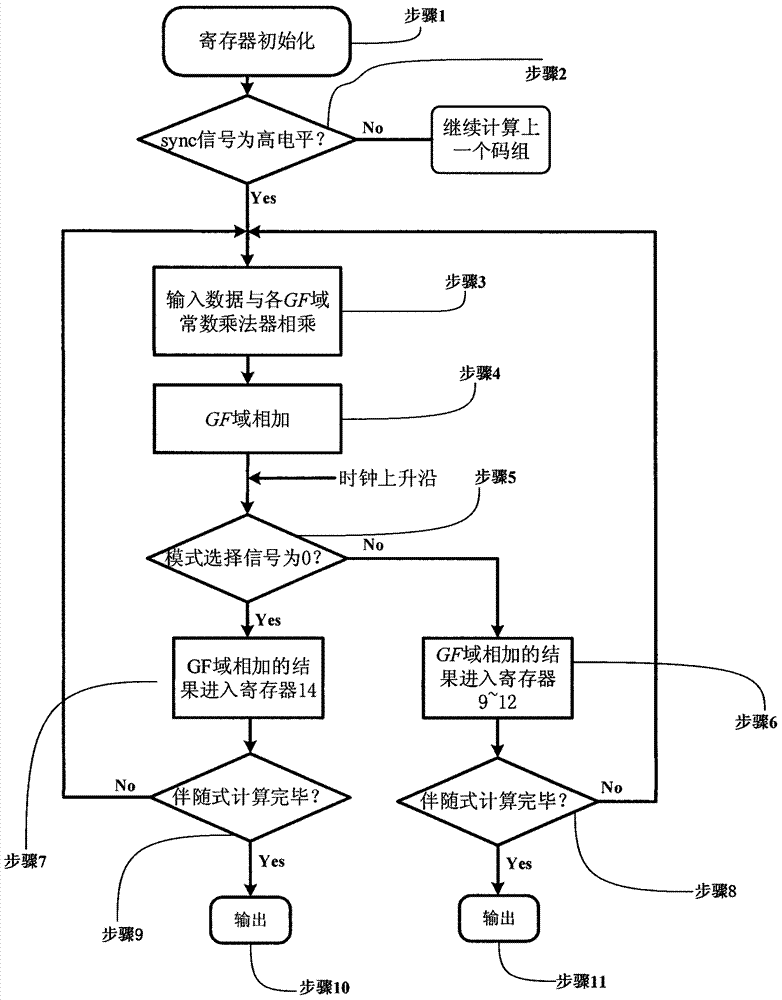

Device for calculating adjoint polynomial in RS encoder

InactiveCN103929208AImprove data throughputReduce the number of clock cyclesError preventionCyclic codesMultiplexerProcessor register

The invention discloses a device for calculating an adjoint polynomial in an RS encoder. The device has the smaller adjoint calculation delay and the higher encoding rate, and meanwhile the device does not need to be provided with a front-arrangement de-interleave device. In order to achieve the aim, the invention discloses a method for enabling an adjoint calculation device to support the multichannel parallel input through the adjoint calculation formula conversion. The adjoint calculation device comprises a multichannel parallel data input interface and 2t basic units. Each basic unit comprises a plurality of Galois field constant multipliers connected with the multichannel parallel input, a Galois field summator, a Galois field constant multiplier, a plurality of registers, a plurality of multiplexers and a plurality of demultiplexers, wherein the Galois field constant multiplier is connected with the registers.

Owner:PEKING UNIV

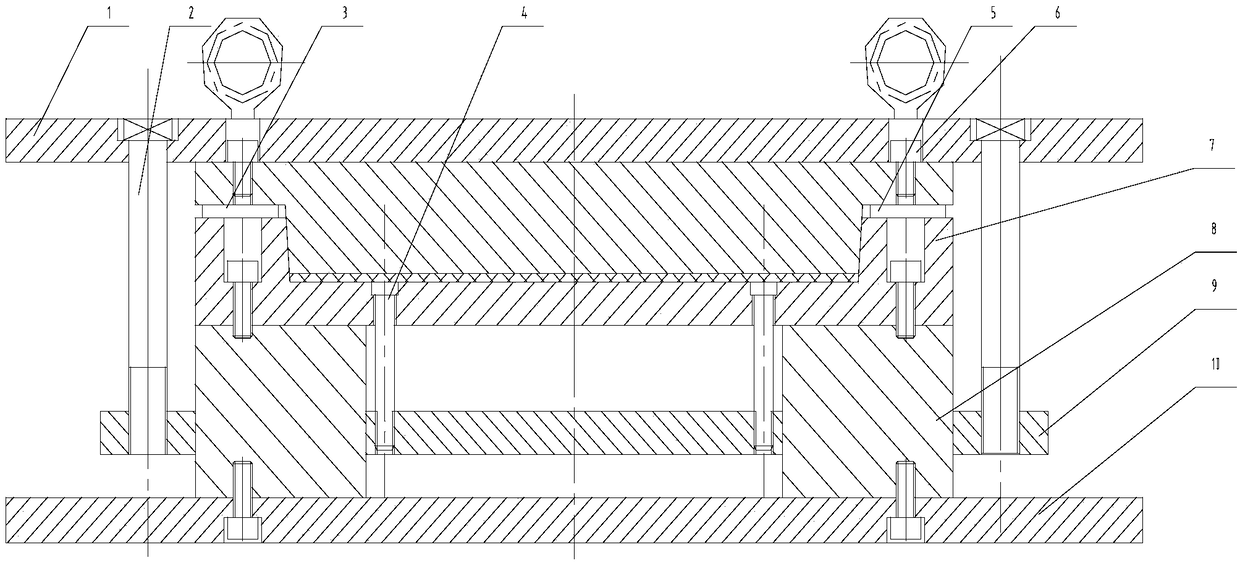

Universal compression moulding mould for forming flat plate type composite material components with large sizes and different thicknesses

PendingCN108068358AReduce the number of flipsIncrease productivityFlat articlesLarge sizeContinuous operation

The invention aims to provide a universal compression moulding mould for forming flat plate type composite material components with large sizes and different thicknesses. The universal compression moulding mould comprises a top plate, demoulding screws, a male mould, ejection rods, a pressing block, a female mould, supporting columns, a supporting plate, a bottom plate, inner hexagonal screws, hoisting rings, connecting positioning holes, hoisting threaded holes and threaded connecting holes. According to the universal compression moulding mould for forming the flat plate type composite material components with the large sizes and the different thicknesses, an upper-lower bipartition structure is adopted so that continuous operation of packing, mould pressing and demoulding of a pluralityof products can be realized; and for solving the problem that production efficiency is low in the forming process and the demoulding process of large-size products, a connecting rod type automatic demoulding structure is adopted, so that the hoisting operation process and circulation operation on different equipment are omitted, production efficiency is improved by 30%, safety is improved, and product size precision is improved.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

Backlight module, display device and assembling method of display device

PendingCN112305810AImprove structural stabilitySimplify machining toolingPlanar/plate-like light guidesElectric digital data processingLight guideDisplay device

The invention discloses a backlight module, a display device and an assembling method of the display device. The backlight module comprises a backlight assembly, an outer frame and a first side locking piece, the backlight assembly comprises a back plate and a first switching frame, the back plate is fixedly connected with a first switching frame, and a light guide plate is arranged on the back plate; the light guide plate and the first switching frame are located on the two opposite sides of the back plate respectively, the outer frame and the light guide plate are arranged on the same side of the back plate, and the outer frame is fixedly connected with the first switching frame so that the outer frame can be fixedly connected with the back plate through the first switching frame. According to the backlight module, the assembly is reliable, the structure is stable, the assembly process is convenient to simplify, and the production efficiency is improved.

Owner:BOE TECH GRP CO LTD +1

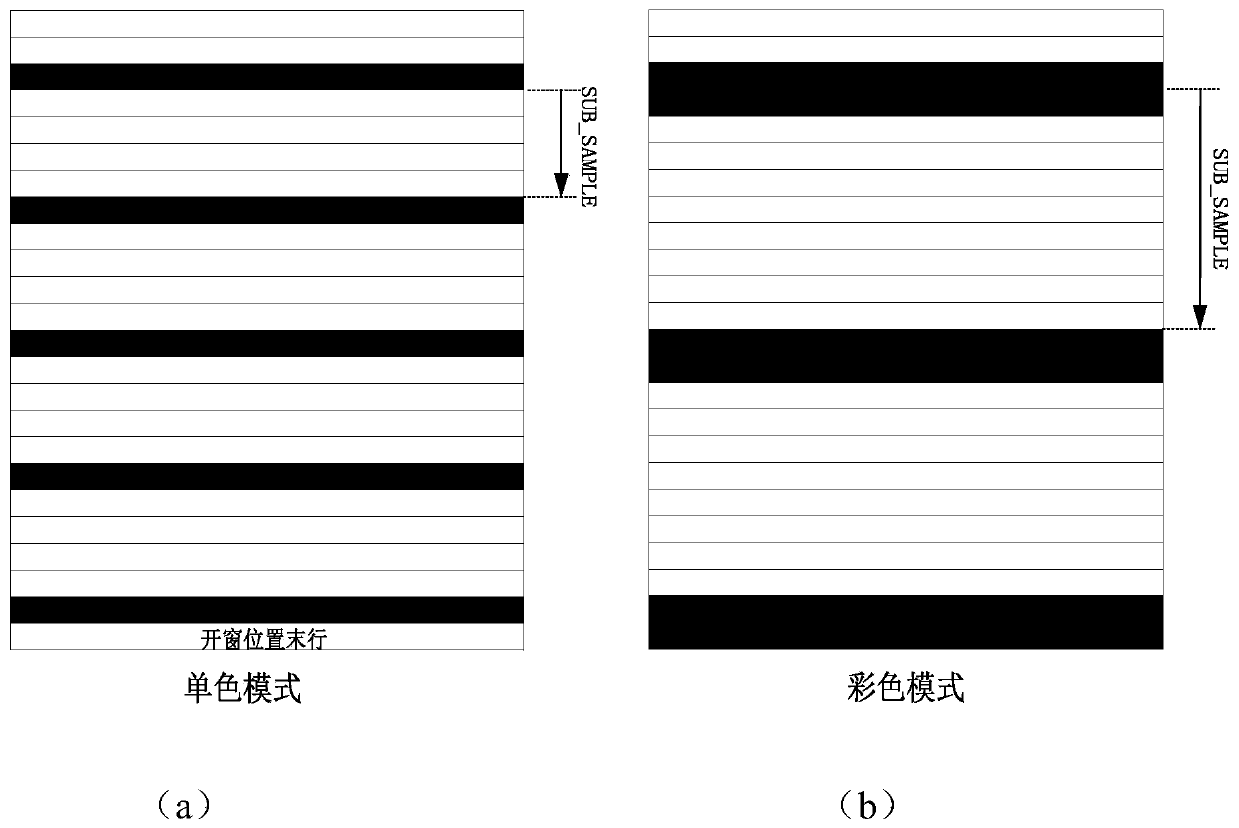

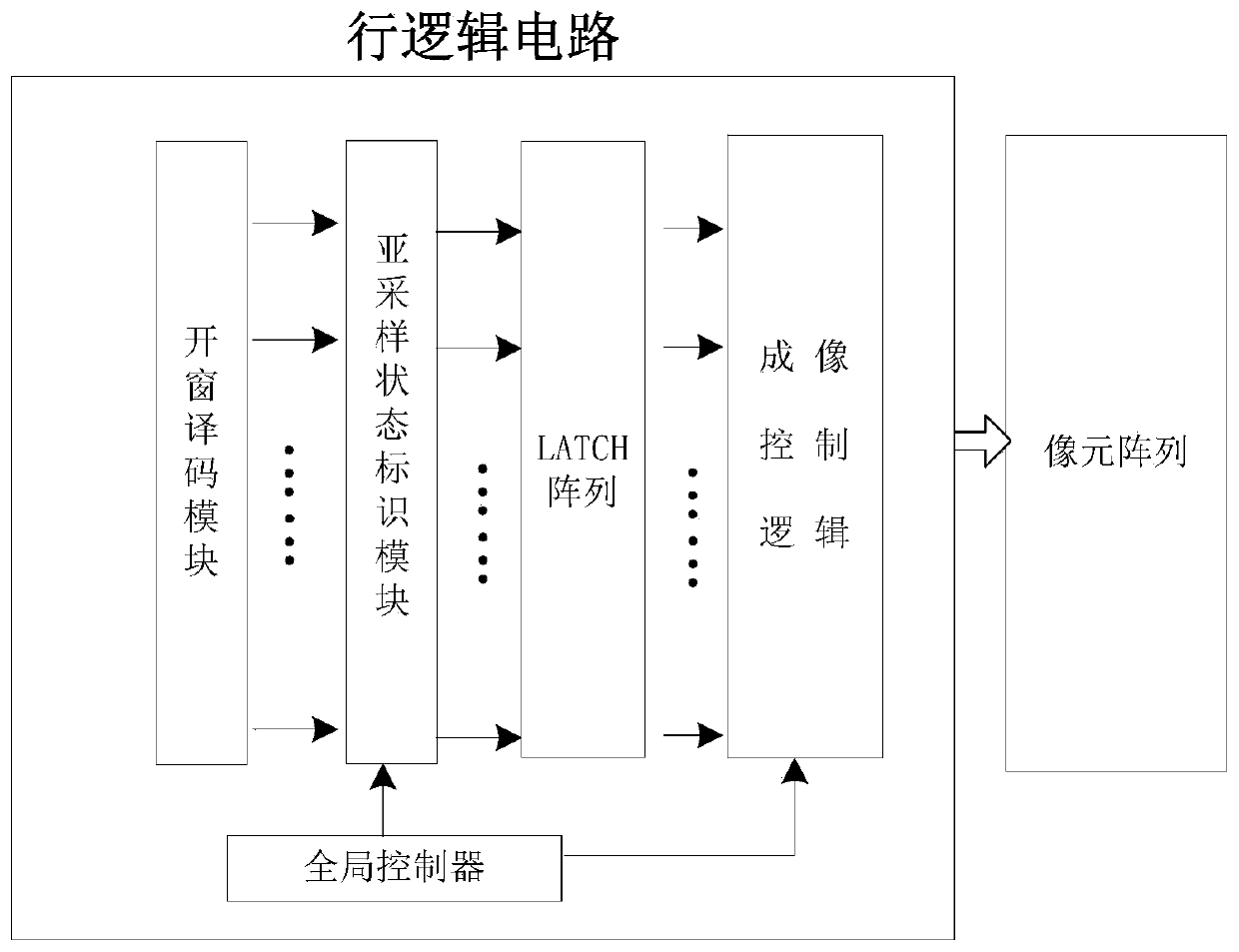

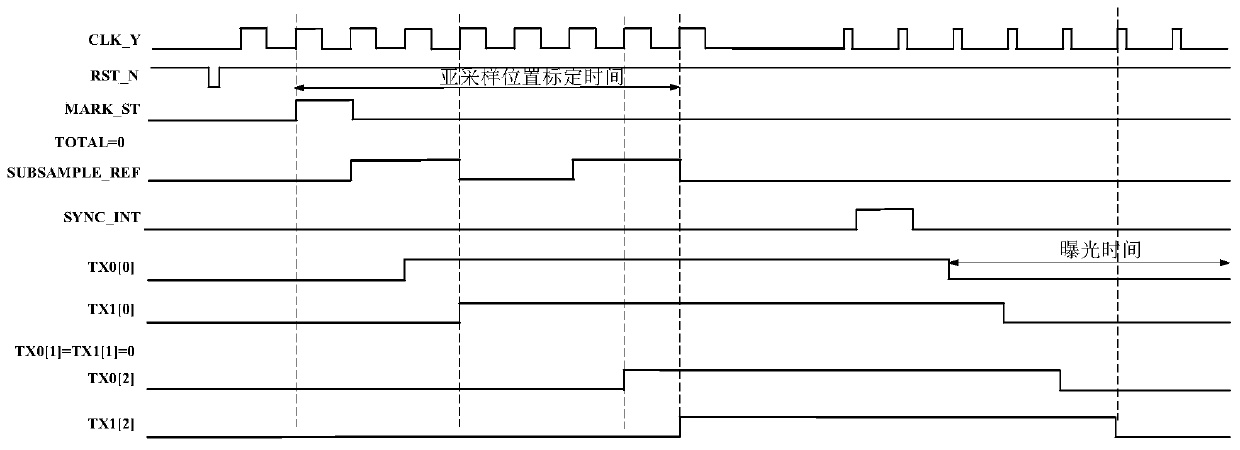

Free sub-sampling type row logic circuit for image sensor and working method thereof

ActiveCN111294530AFix timing issuesQuick lockTelevision system detailsColor television detailsExposureEmbedded system

The invention belongs to the technical field of image sensors, and discloses a free sub-sampling type row logic circuit for an image sensor and a working method thereof. According to the invention, through a windowing decoding module, a sub-sampling state identification module, a LATCH array, a global controller and an imaging control logic module, control of pixel rows of the image sensor is completed; a plurality of exposure modes are supported; full-array free sub-sampling of the super-large-scale pixel array is realized through sub-sampling identification of the pixel array; through the design of an address identifier and a sub-sampling pointer chain, a small-area sub-sampling mark in a windowing range is supported; subsampling one-key turn-off is supported; through clock gating design, the sub-sampling identification and the pixel imaging work frequency are different, and sub-sampling rapid calibration is realized. The free sub-sampling type row logic circuit is simple in design structure, flexible in configuration, wide in application range and capable of supporting multiplexing and splicing and can be applied to different types of image sensor chip circuits.

Owner:XIAN MICROELECTRONICS TECH INST

Mold for concrete prefabricated part production

ActiveCN111716500AOmit the step of bringing upEasy to operateMouldsStructural engineeringMechanical engineering

Owner:HOHAI UNIV

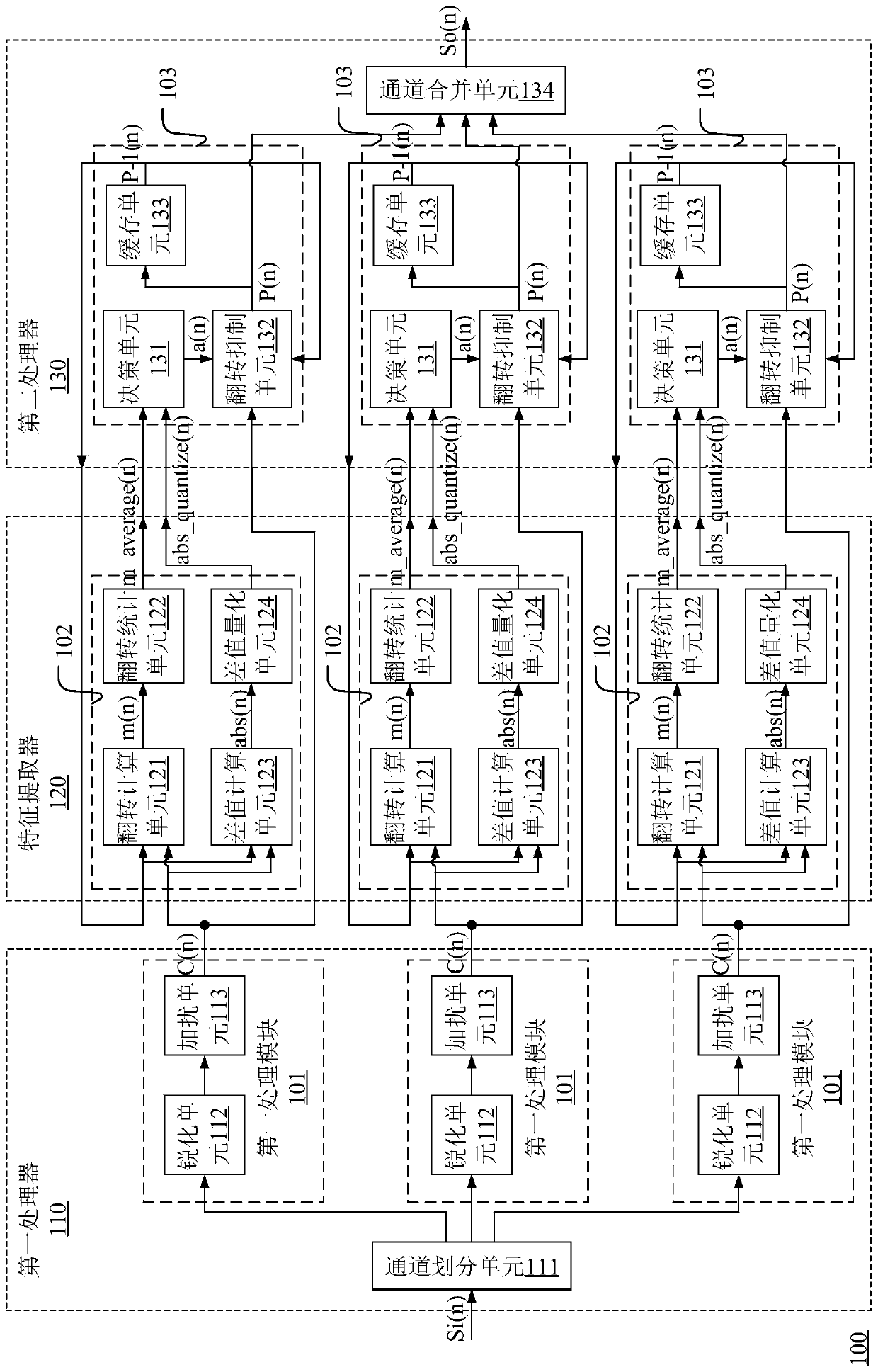

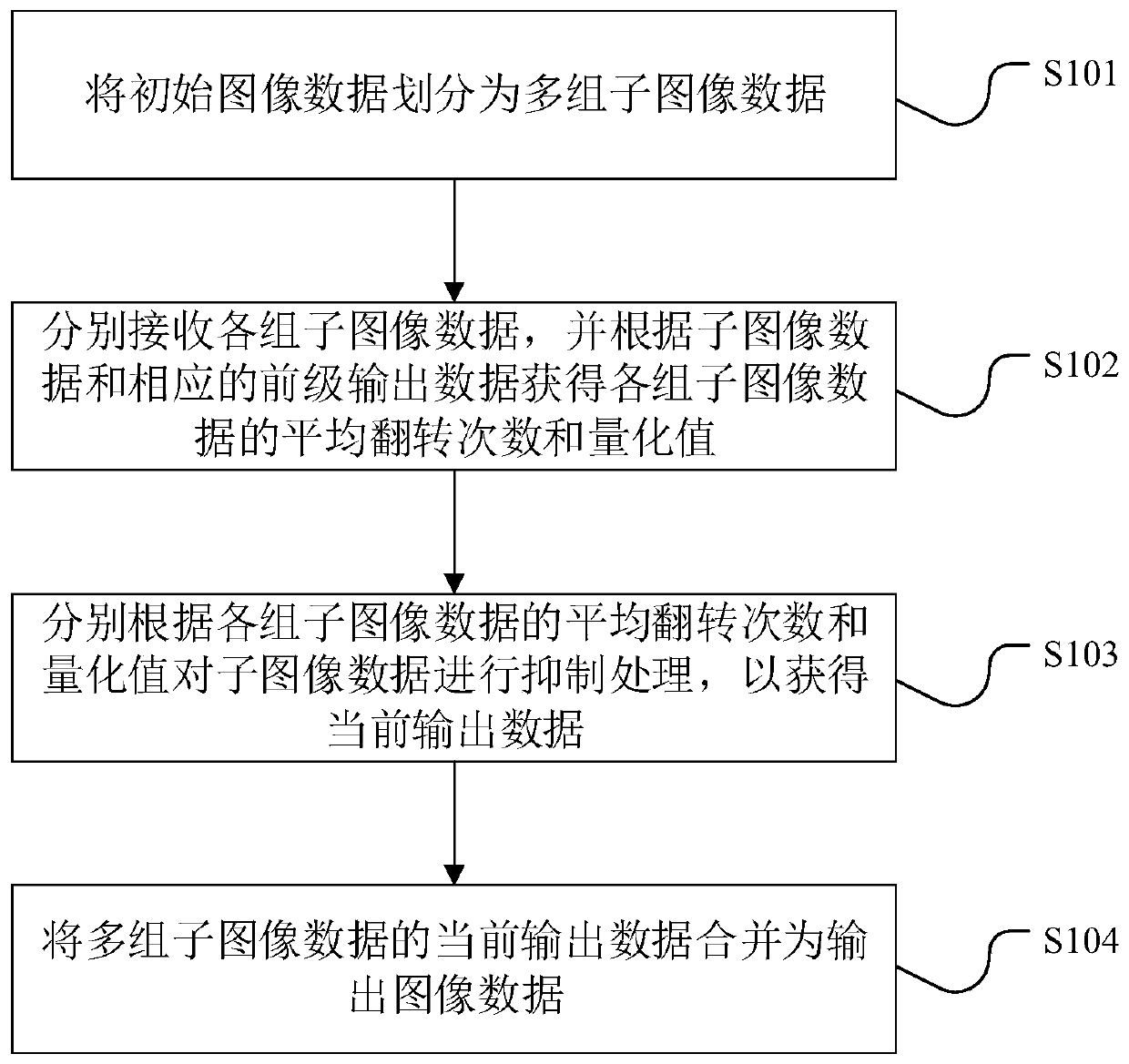

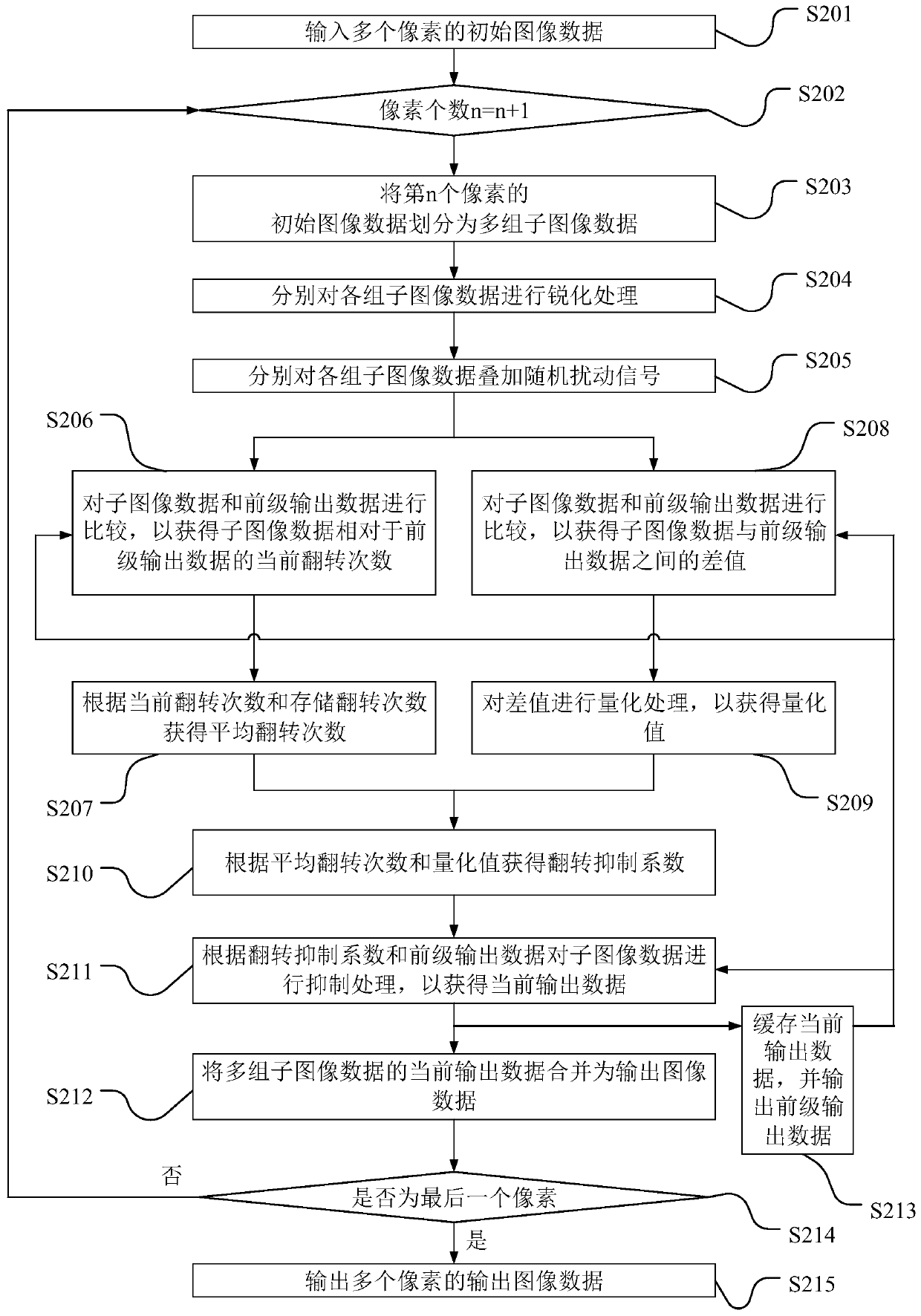

Image processing device and method, and display device

PendingCN111161164AReduce power consumptionPreserve qualityImage enhancementStatic indicating devicesNuclear medicineDisplay device

The invention discloses an image processing device and a method, and a display device. The image processing apparatus includes: a first processor that divides initial image data into a plurality of groups of sub-image data; a feature extractor which is provided with a plurality of feature extraction modules which are used for receiving one group of the multiple groups of sub-image data respectively and obtaining the average turnover frequency and the quantized value of the sub-image data according to the sub-image data and the preceding-stage output data; a second processor which has multipleprocessing module, and each group of sub-image data is suppressed according to the average turnover frequency and the quantized value so as to obtain current output data, the second processor combinesthe multiple current output data output by the multiple processing modules into output image data, and the turnover frequency of the output image data is not greater than the turnover frequency of the initial image data. The image processing device suppresses the number of flipping times of output image data and reduces the overall power consumption of a post-stage system.

Owner:GIGADISPLAY SEMICON CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com