Floating type bollard guide groove assembling device and assembling method

A technology for assembling devices and bollards, which is applied in the direction of ship lifting devices, ship locks, buildings, etc., can solve the problems of production quality control, etc., and achieve the effects of saving labor, reducing the difficulty of production and installation, and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

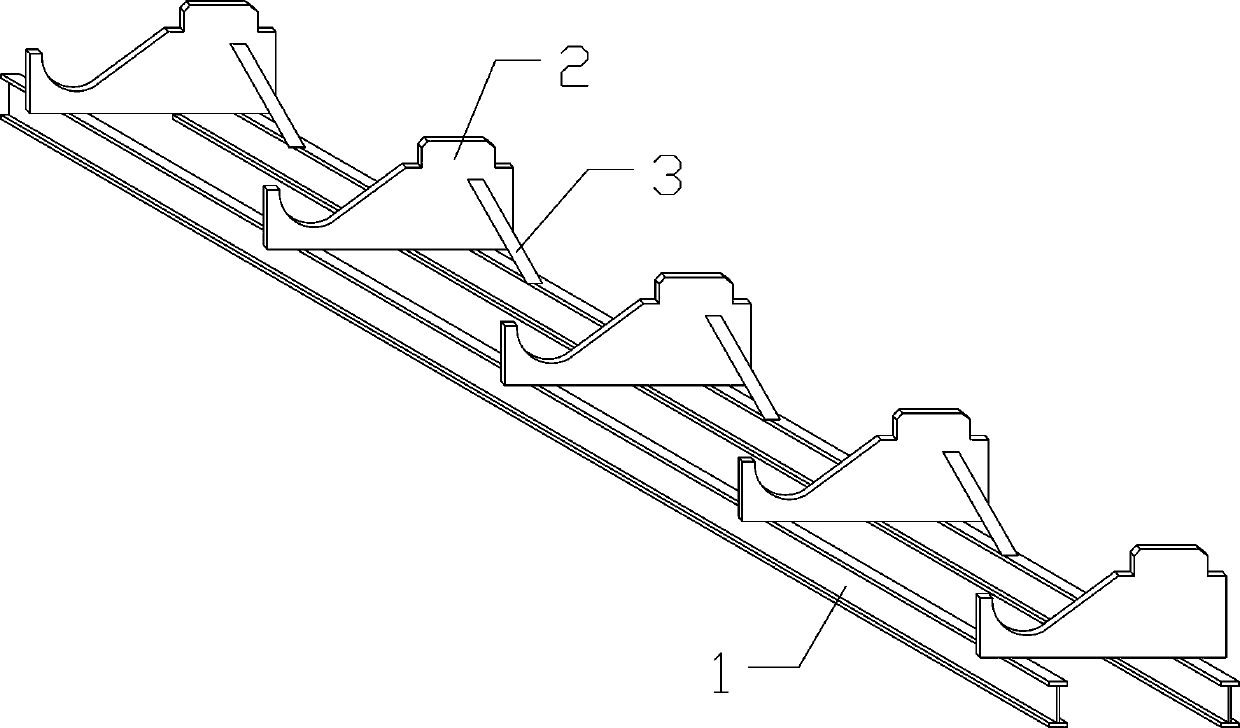

[0031] Such as figure 1 Among them, an assembly device for floating bollard guide grooves, including a steel tire formwork 2, said steel tire formwork 2 is a plurality, and a plurality of steel tire formworks 2 are equidistantly arranged on the support platform 1, and the steel tire formwork The template 2 is vertically arranged and supported and fixed by the diagonal brace 3 .

[0032] In a preferred solution, the support platform 1 is made of two 600-700mm high section steels.

[0033] In a preferred solution, the distance between two adjacent steel tire templates 2 is 1200mm-1500mm.

Embodiment 2

[0035] Based on the bollard guide channel assembly method of the above-mentioned floating bollard guide channel assembly device, the assembly of the bollard guide channel is carried out by segmental inversion method, which specifically includes the following steps:

[0036] 1) Pre-install the supporting platform 1 on both sides of the lock chamber of the ship lock;

[0037] 2) The installation of the first section of the bollard guide groove is carried out between the two steel tire templates 2 at the lowermost end of the support platform 1;

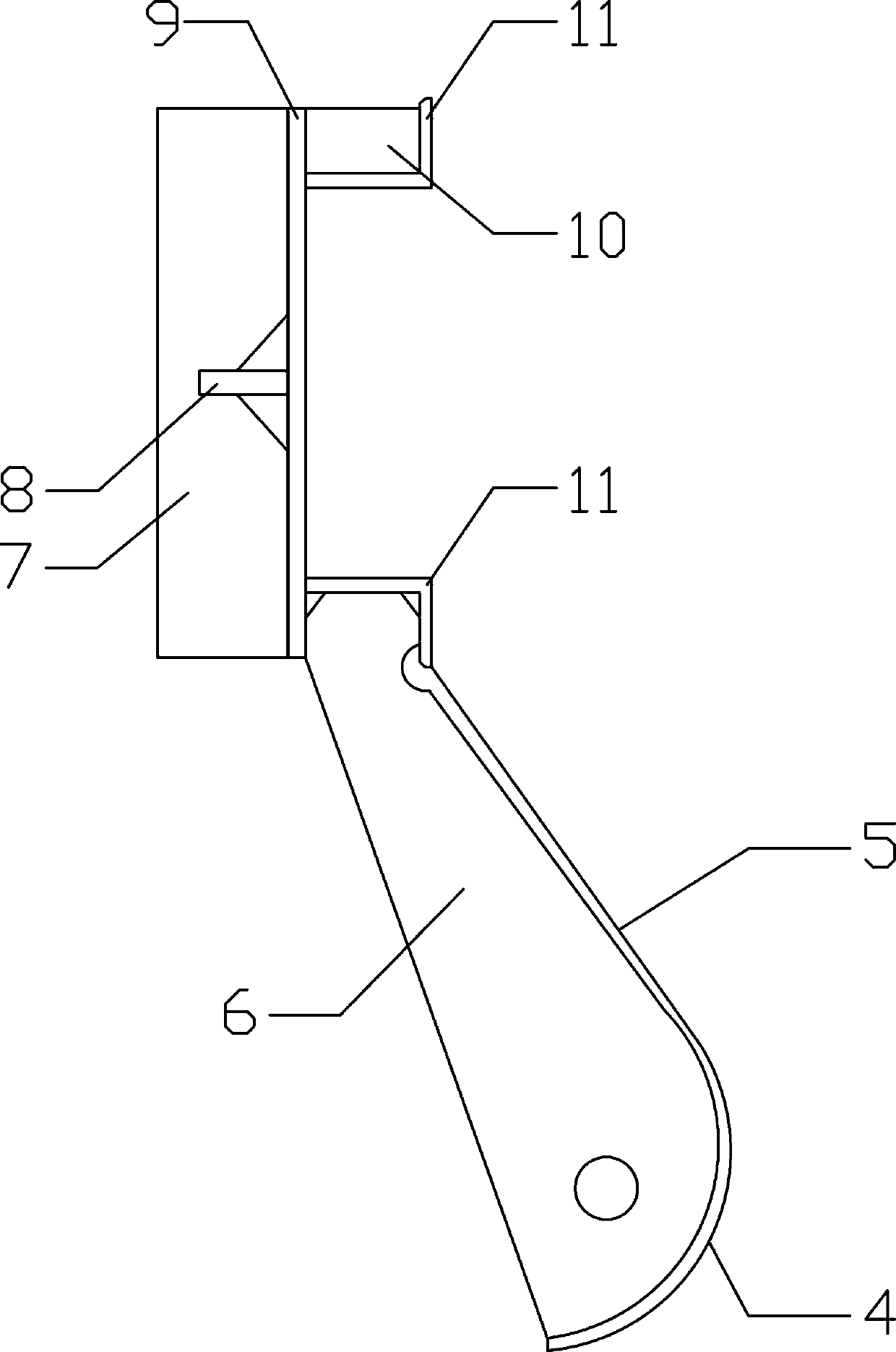

[0038] 1) Align the centerline of the second guard plate 9 with the centerline of the steel tire template 2;

[0039] 2) Weld the angle steel 11 on the same side direction at both ends of the second guard plate 9;

[0040] 3) Install the curved rib 6 on the angle steel 11 at one end;

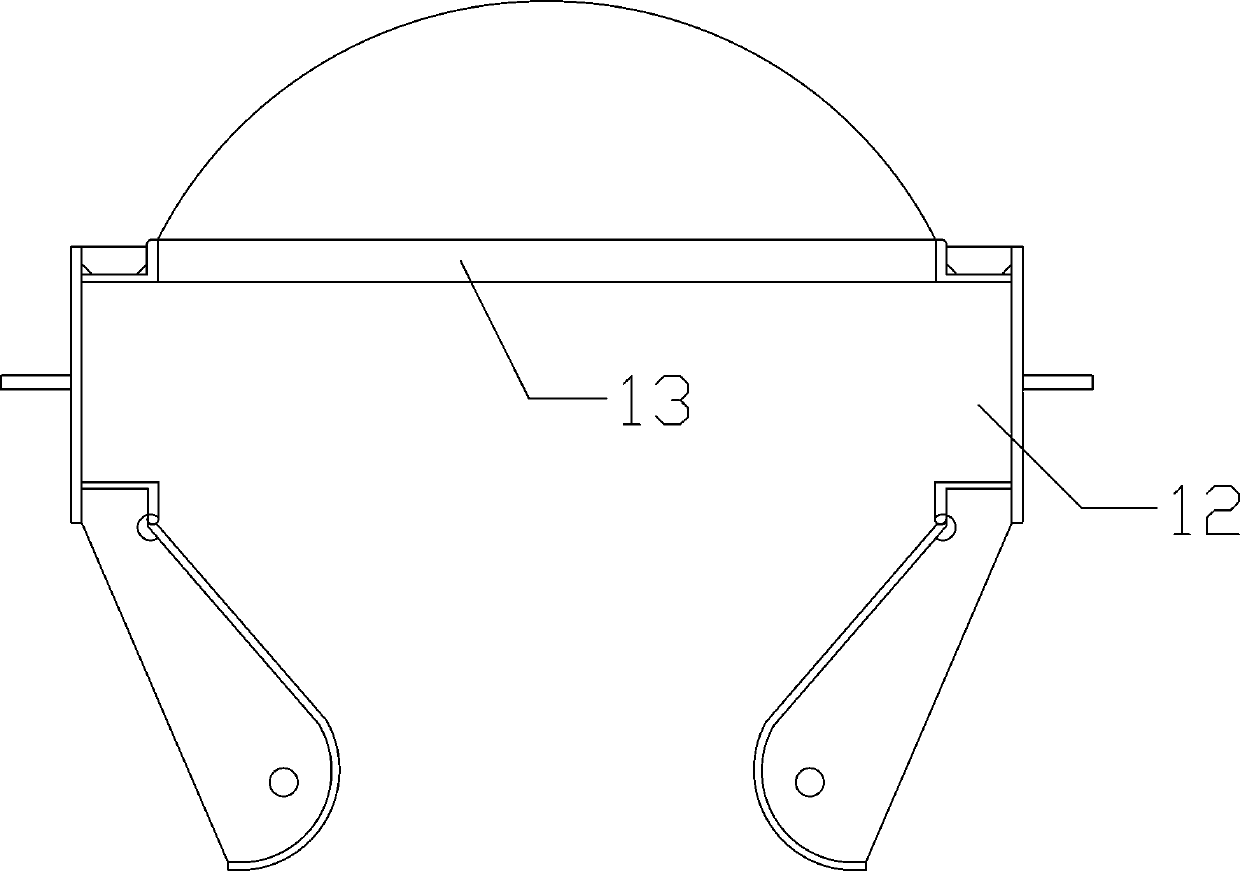

[0041] 4) Flip over the bollard guide groove of the first section, and weld and fix the angle steel 11 with the rib plate 10 and the bottom sill 13;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com