Backlight module, display device and assembling method of display device

A technology for backlight modules and backlight components, which is applied in the direction of light guides, optics, optical components, etc., can solve the problems of high risk of appearance defects, low product production efficiency, cumbersome manufacturing process, etc., and achieve easy repair in time, less flipping times, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

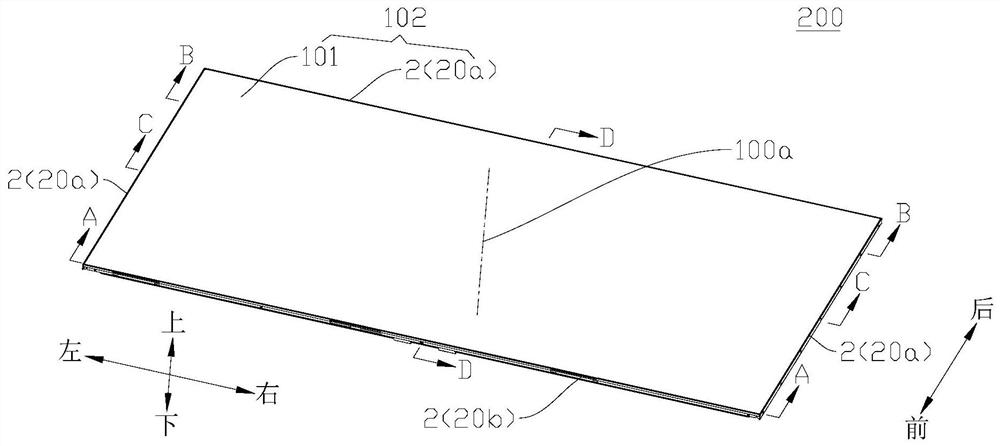

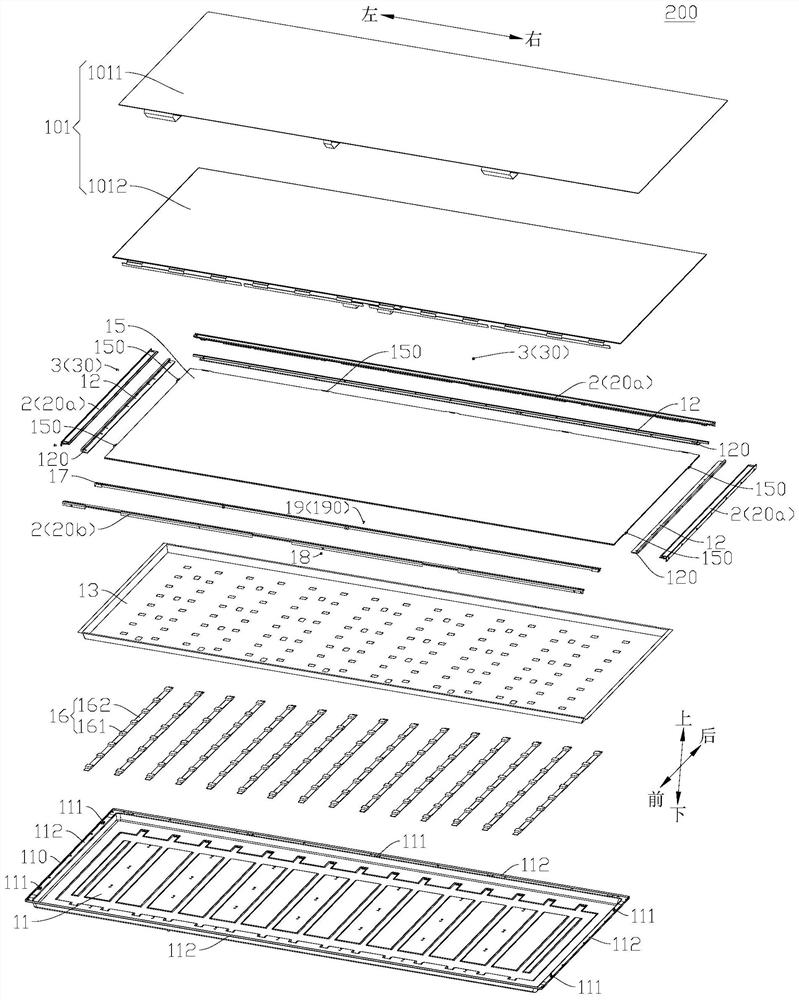

[0130]In this embodiment, asFigure 1-Figure 15withFigure 18 As shown, the display device 200 includes a display screen 101 and a backlight module 100. The backlight module 100 includes a backlight assembly 1 and an outer frame 2. The outer frame 2 is provided on the front side of the backlight assembly 1 and the outer frame 2 is fixedly connected to the backlight assembly 1. , The display screen 101 is installed on the outer frame 2, and the display screen 101 is pasted to the outer frame 2. Among them, the display screen 101 is a capacitive touch screen such as a fully laminated electronically controlled touch screen. The display screen 101 includes touch glass 1011 and liquid crystal glass 1012. The liquid crystal glass 1012 is pasted on the back side of the touch glass 1011. The glass 1011 is pasted on the outer frame 2; the plane where the display screen 101 is located may be perpendicular to the thickness direction of the backlight module 100.

[0131]The backlight module 100 furt...

Embodiment 2

[0145]Such asFigure 16 As shown, the structure of this embodiment is approximately the same as that of the first embodiment, wherein the same components are given the same reference numerals, and the difference is that the backlight module 100 further includes a second back lock 5 and a second back lock 5 The second side frame 122 and the first surface frame 21 are locked from the back of the backlight module 100.

[0146]The assembling method of the display device 200 further includes: after the outer frame 2 and the first transfer frame 12 are locked by the first side lock 3, the backlight assembly 1 and the display screen 102 are turned over, and the second back lock 5 is used to remove the backlight module The back of the group 100 is secured to the first transfer frame 12 and the outer frame 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com