Two-layer conveyor for tea leaf spreading machine

A double-layer conveying and spreading machine technology, applied in the direction of conveyor, transportation and packaging, tea treatment before extraction, etc., can solve the problems of slowing down the running speed of the belt, limiting the amount of tea processing, reducing the utilization rate of equipment, etc., to increase the Permeability, time saved, effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

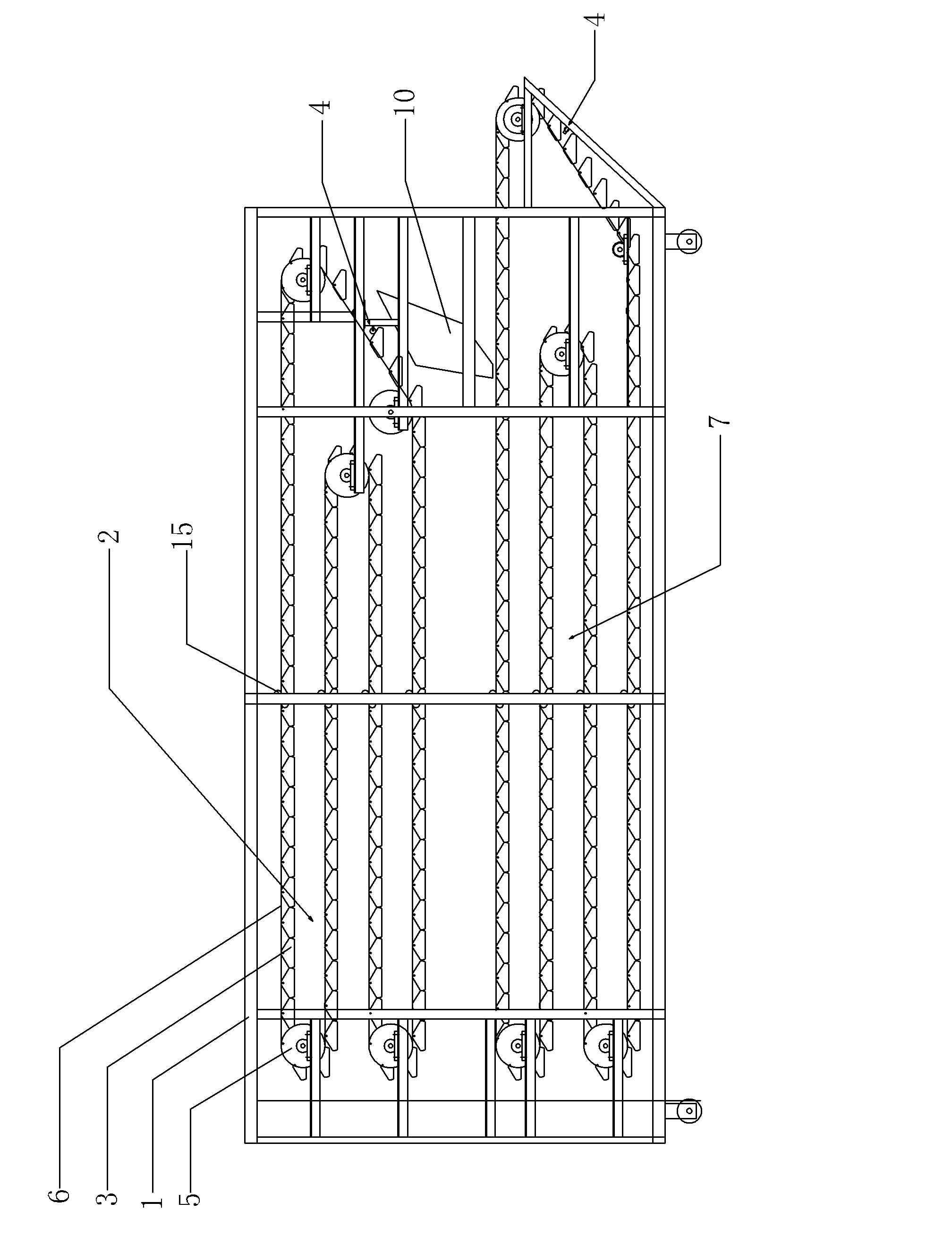

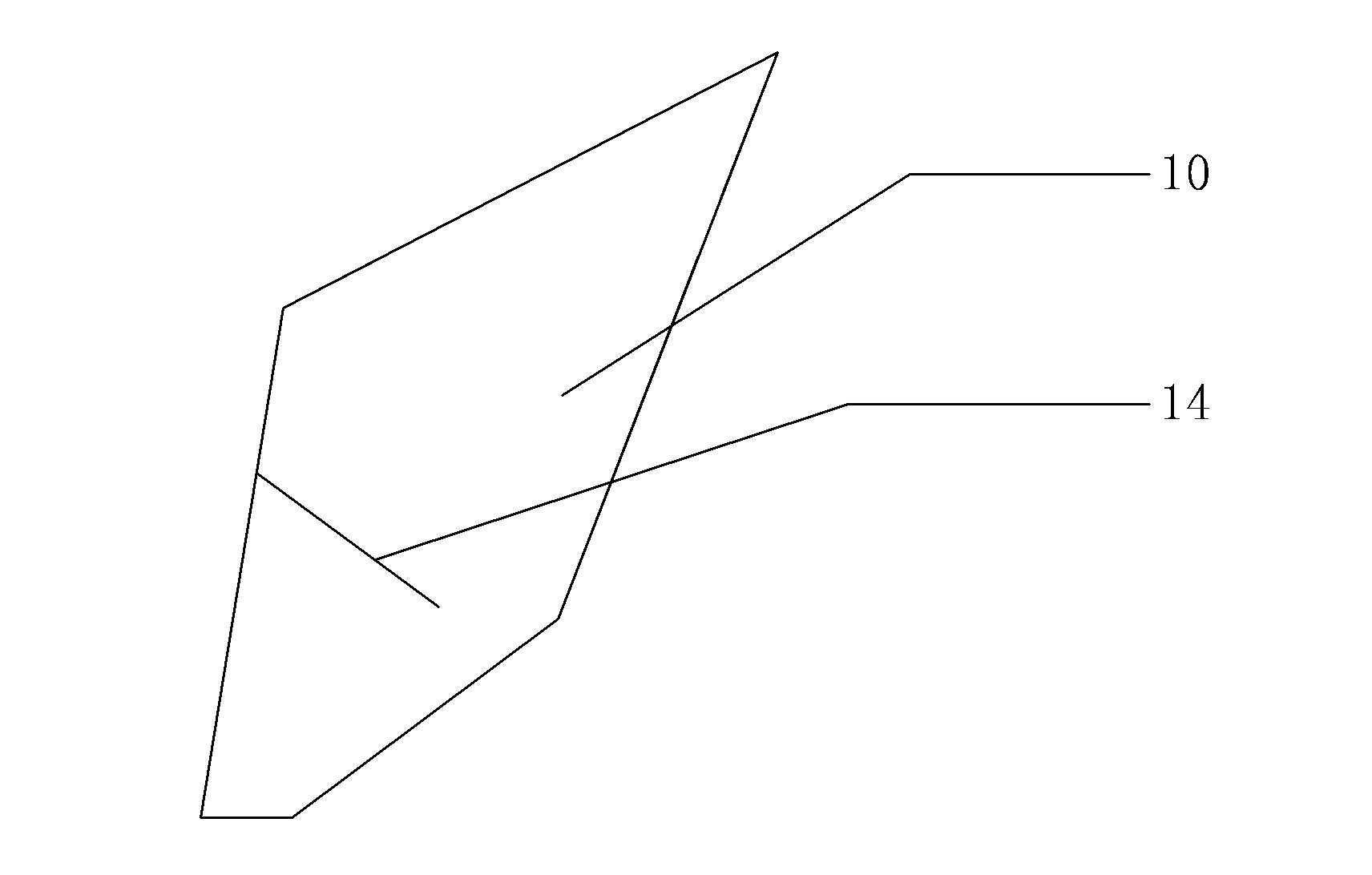

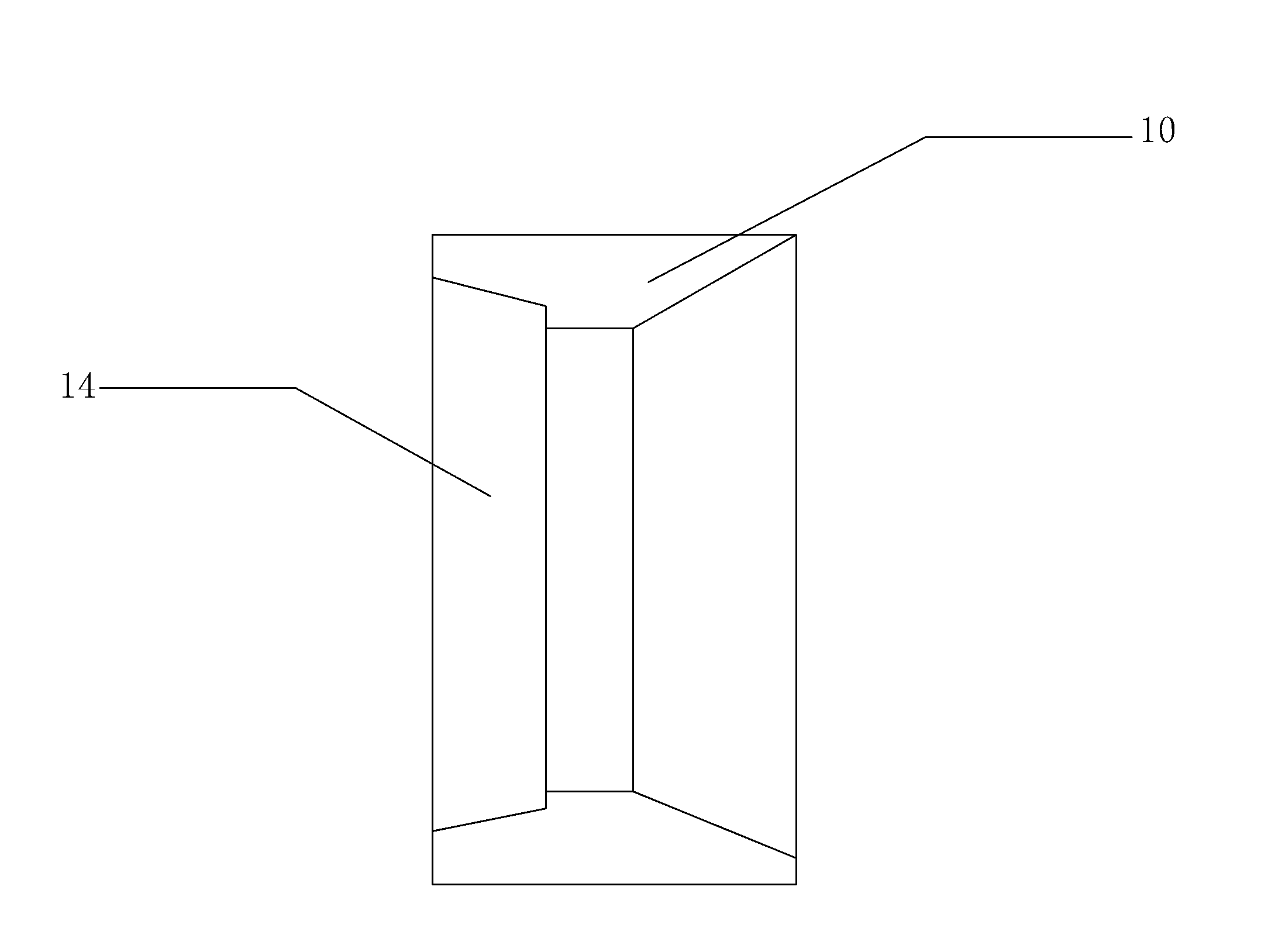

[0020] Such as figure 1 The shown double-layer conveying device of a tea stand green machine is composed of a support 1, and the support 1 is provided with an upper transmission mechanism 2 and a lower transmission mechanism 7 that are distributed up and down and overlapped in the vertical projection. Mechanism 2 and lower transmission mechanism 7 all comprise the multiple guide wheel shafts 8 that are arranged vertically and horizontally on both sides of the frame, and each guide wheel shaft 8 is provided with two symmetrically arranged capstans 5 (such as Figure 4 As shown), a closed chain 6 is wound around all the capstans 5 on the same side in sequence, thereby forming two closed chains 6, and a plurality of tea buckets 3 that are movably connected with the closed chains 6 are arranged between the two closed cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com