Liquid crystal display module and packaging method

A technology for a liquid crystal display module and an assembly method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of reducing production efficiency and increasing the risk of liquid crystal group rupture, and achieves the effects of improving production efficiency and wide reachable distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, the present invention is described by taking a super large liquid crystal display module (above 60 inches) of the direct-lit type as an example.

[0044] Such as Figure 4 As shown, the assembly of a super large liquid crystal display module needs to assemble the backplane first, and the backplane 310 is processed into a whole backplane 310 by riveting, welding, screwing and other processes for multiple block parts, so as to provide the liquid crystal display module. enough strength. The backplane 310 in this embodiment is formed by splicing a plurality of splicing blocks of rectangular structure, and the figure shows only one kind of spliced backplane structure, but this patent should not be limited to this exemplary structure.

[0045] Such as Figure 5 As shown, two parallel fixed beams 311 are also arranged on the back side of the back plate 310. The two parallel fixed beams 311 can improve the strength of the spliced back plate, and at the...

Embodiment 2

[0061] The liquid crystal display module in this embodiment adopts side-incoming light, and the difference from the first embodiment is that the light source assembly is fixed on the side wall of the back plate, and the light guide plate is used to convert the side-incoming light into a surface light source, while the first embodiment One of the light source components is arranged on the surface of the backplane.

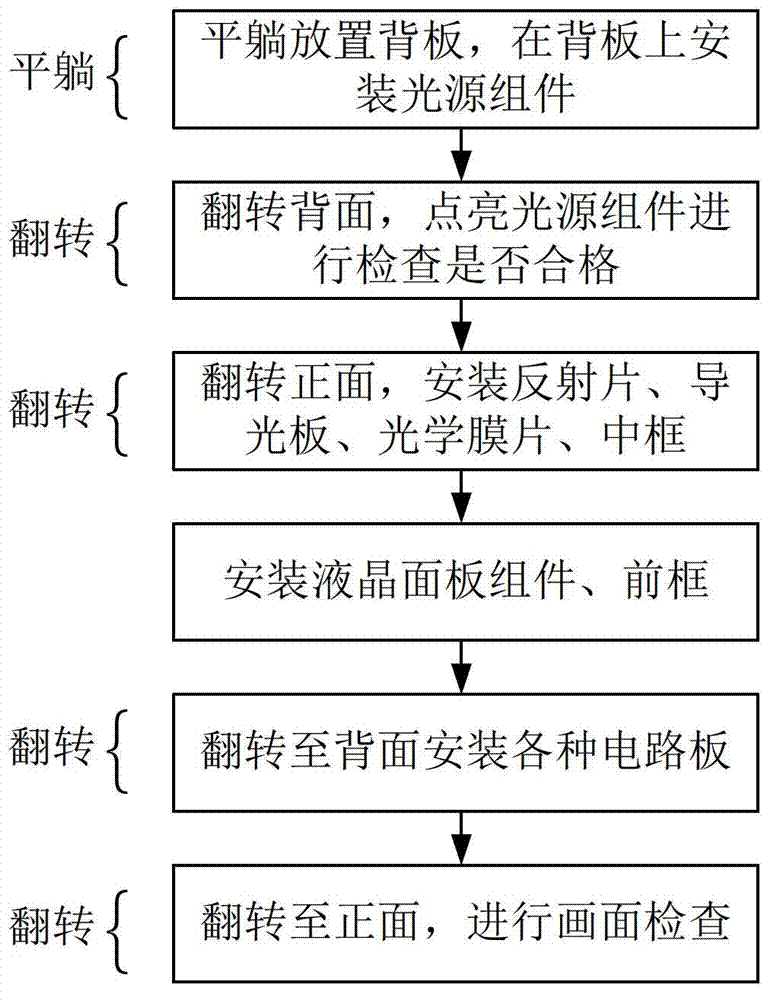

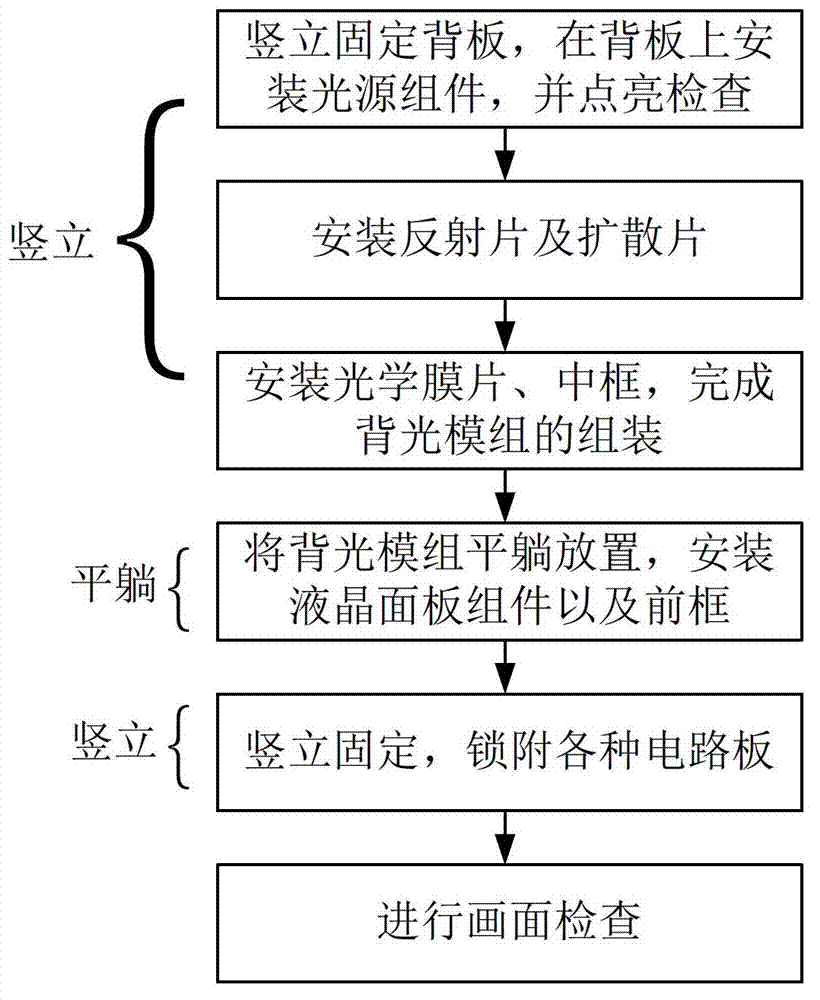

[0062] Such as image 3 Shown, assembly process of the present invention can be summarized as following steps:

[0063] a1. Erect and fix the backboard, install the light source components on the backboard, and light it up for inspection;

[0064] a2. Install reflector and diffuser;

[0065] a3. Install optical diaphragm and middle frame;

[0066] a4. Lay the backlight module flat, install the LCD panel assembly and the front frame;

[0067] a5, erect and fixed, and lock various circuit boards;

[0068] a6. Check the screen.

[0069] Among them, in steps a1-a3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com