Full-automatic standard section overturning tooling

A technology for flipping tooling and standard sections, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of coordinate offset of standard section weldments, damage to positioning stops, and long time-consuming, etc., to avoid out-of-synchronization of flipping , to ensure synchronization and reduce the number of flips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

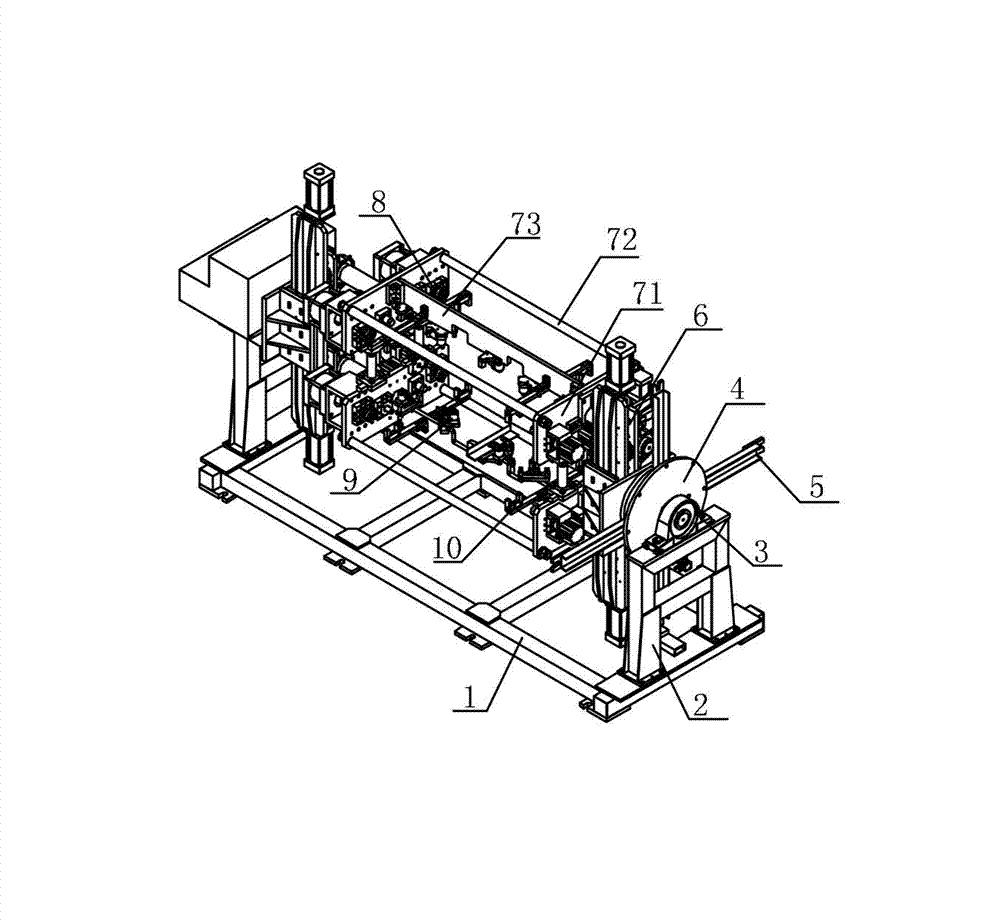

[0011] Such as figure 1 Shown: a fully automatic standard section turning tool, including a base 1, the left support base and the right support base 2 are connected to the two ends of the base 1, and the upper ends of the left support base and the right support base 2 are respectively connected with a left bearing seat and a right bearing base 3. The left bearing seat and the right bearing seat 3 are respectively connected to the left rotary table and the right rotary table 4, and the left rotary table or the right rotary table 4 is connected to the standard section tooling support, and the left rotary table or the right rotary table 4 is driven by a geared motor Rotate; the left rotary disc and the right rotary disc 4 are connected with a cross-shaped limit plate 5, the end of the limit plate 5 is U-shaped, and the base 1 is equipped with a limit pin controlled by a cylinder; the above limit After the spacer pin is ejected from the base 1 by the cylinder control, it can be cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com