Deformation controlling method for machining double-side multi-rib structural part

A part processing and deformation control technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as cracks, affecting product quality of parts, uneven stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A deformation control method in the processing of double-sided multi-rib structural parts, comprising the following steps:

[0018] 1) Use tooling to clamp the part blank;

[0019] 2) Milling single-sided datum can see the inner layer of new metal;

[0020] 3) Turn the part over, and clamp the part with vacuum adsorption and external tooling;

[0021] 4) Process the web and sides on the front side, leave a small margin or directly process them in place, and do not process the height of the ribs;

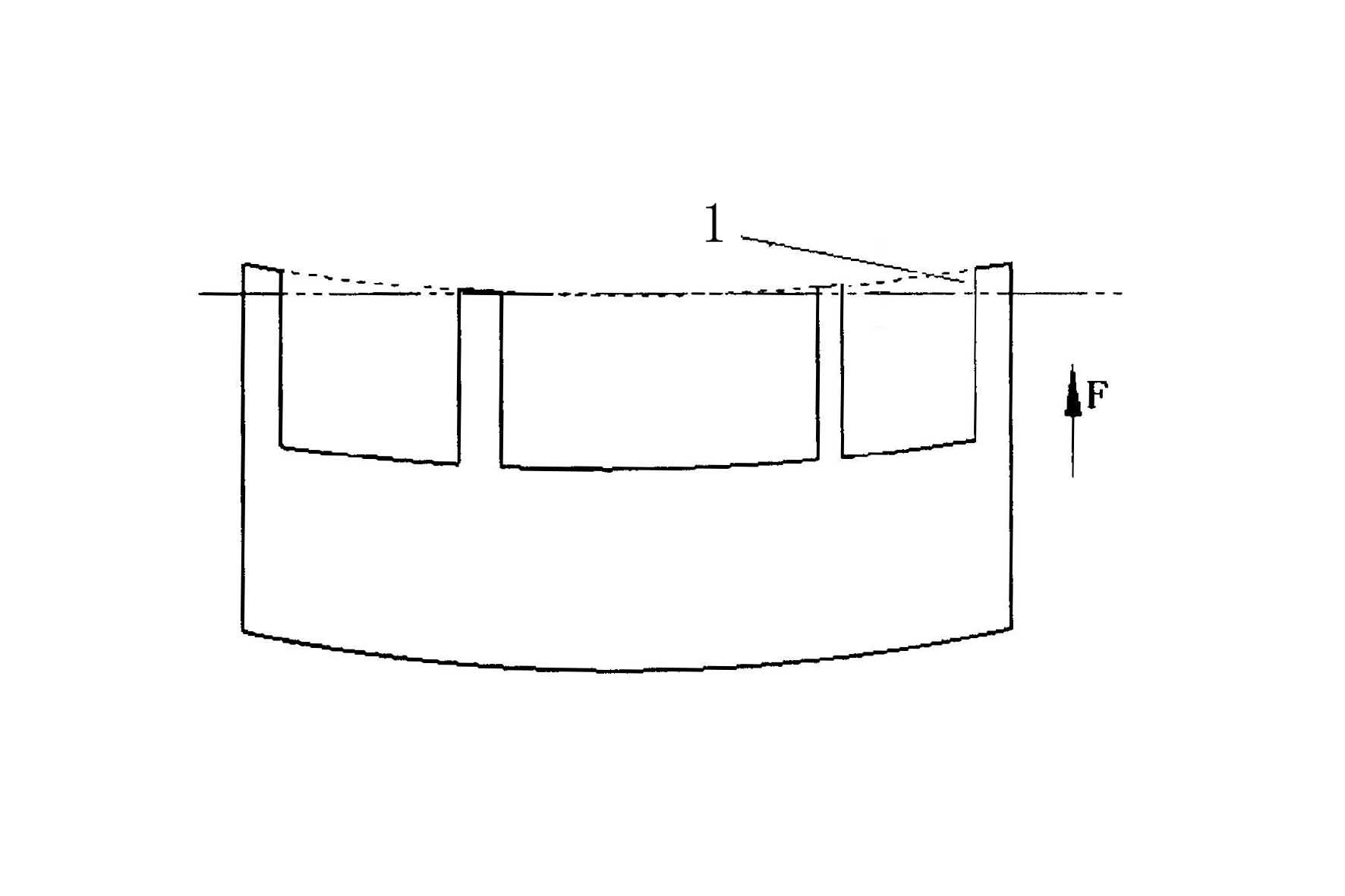

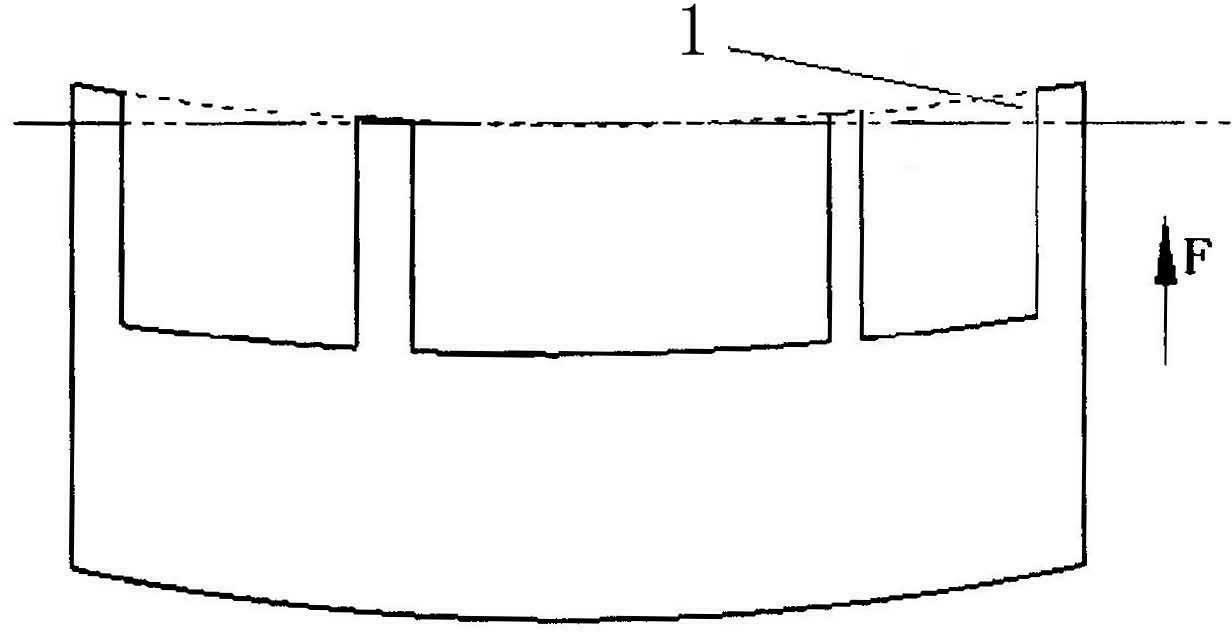

[0022] 5) Remove vacuum adsorption and external tooling, such as figure 1 As shown, the deformation of the upper surface part is removed in the natural state 1;

[0023] 6) After turning over, use vacuum adsorption and external tooling to clamp the part again, and carry out rough machining and finishing machining on the reverse side until it reaches the size of the part;

[0024] 7) Turn over again, use vacuum adsorption and external tooling to clamp the part, mill the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com