Patents

Literature

64results about How to "Reduce welding errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

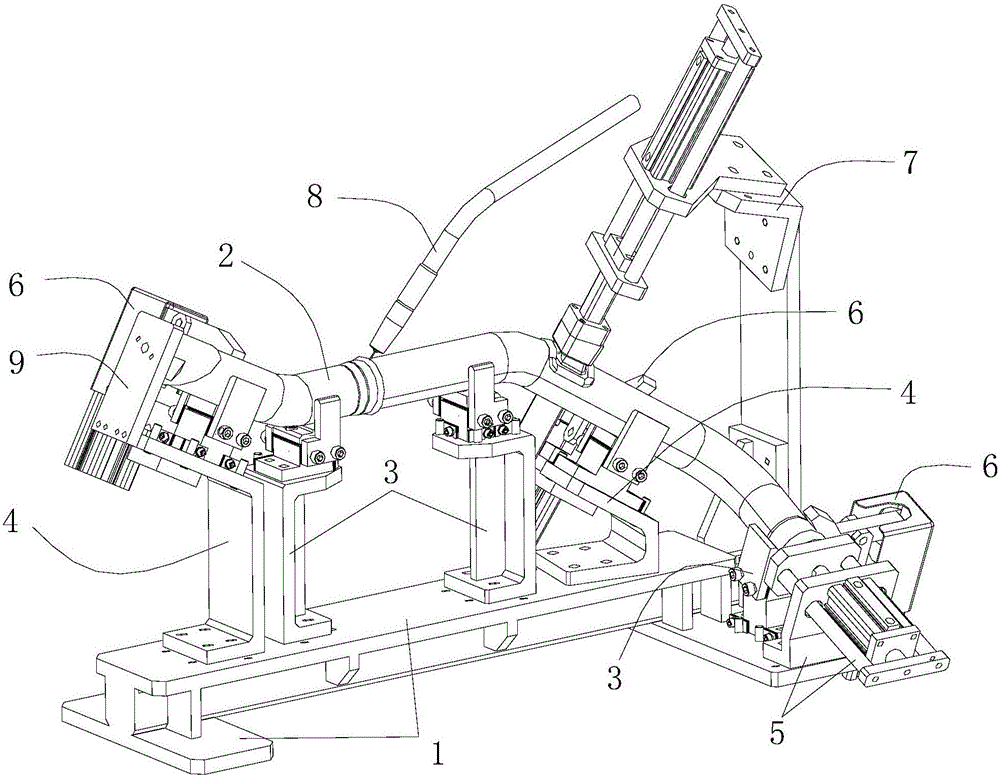

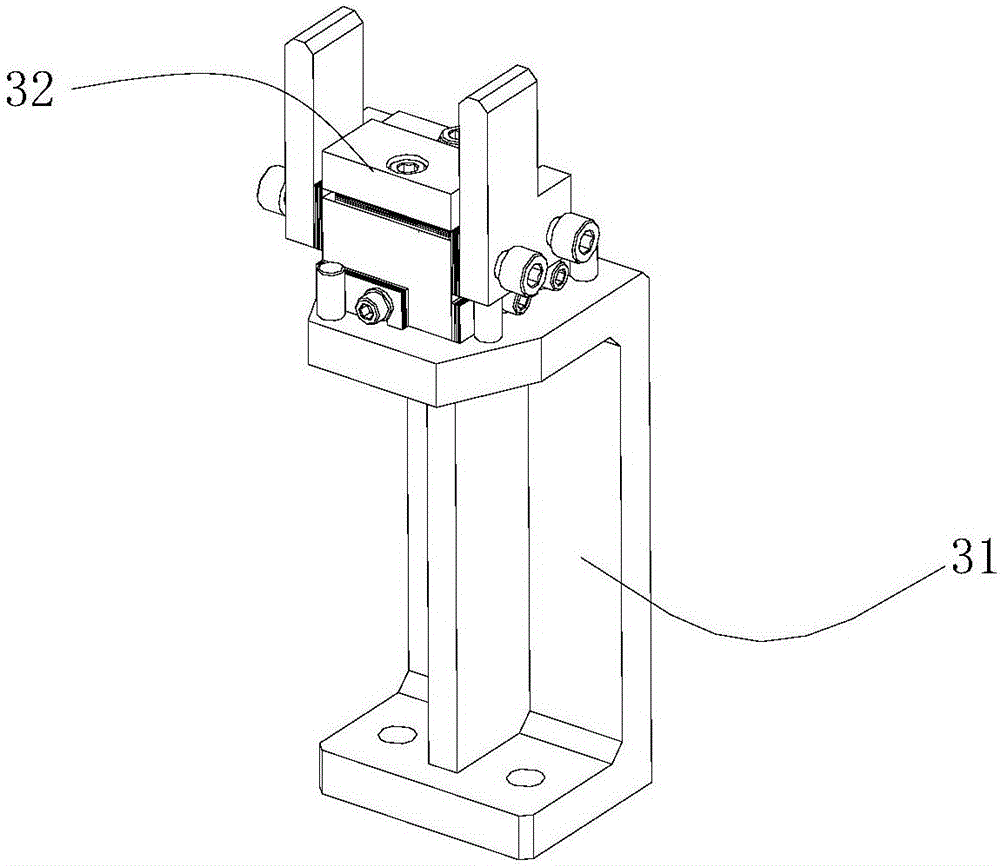

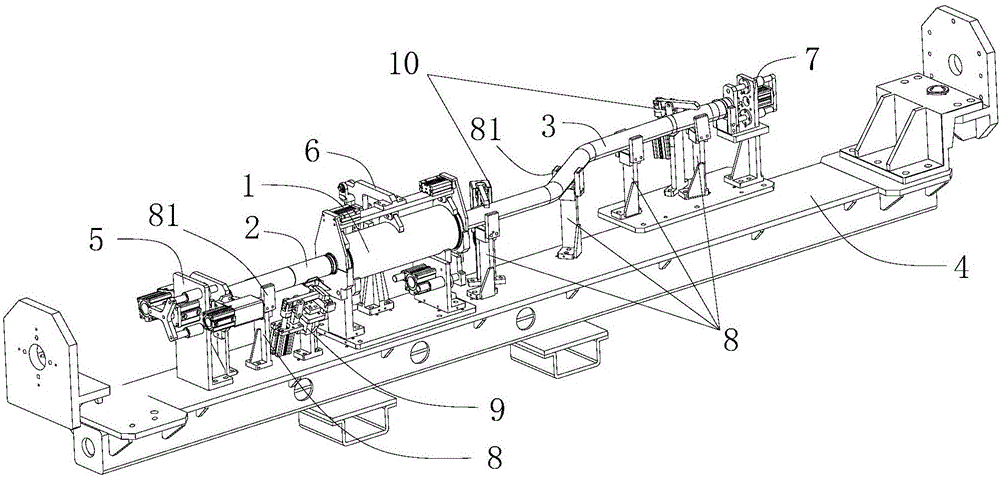

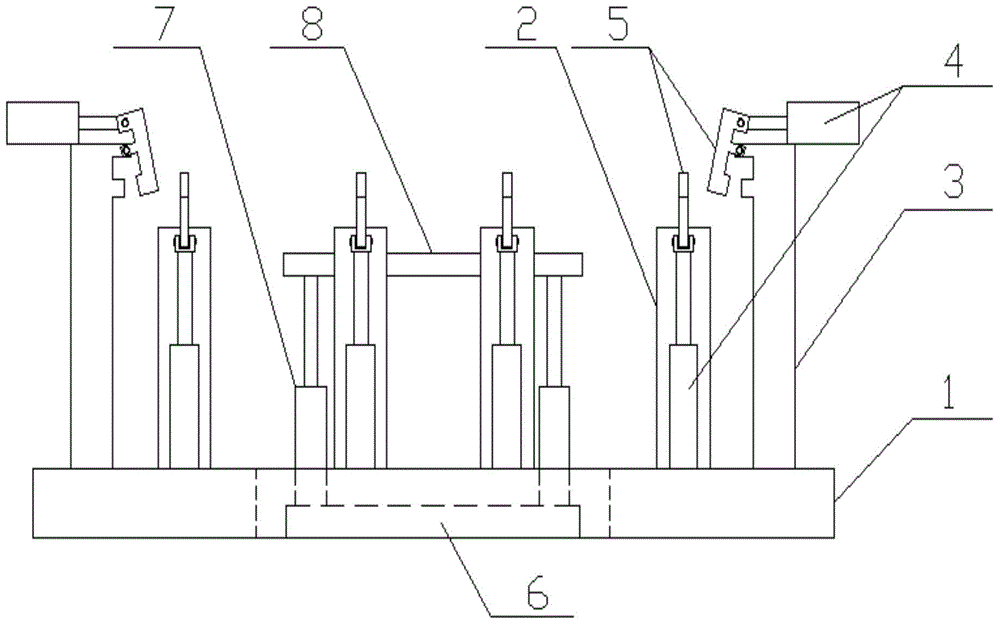

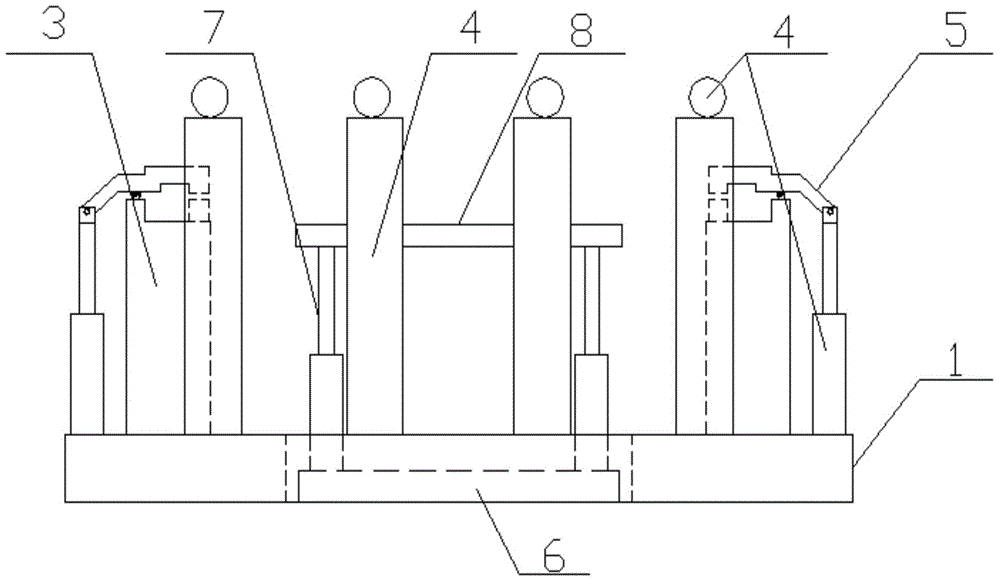

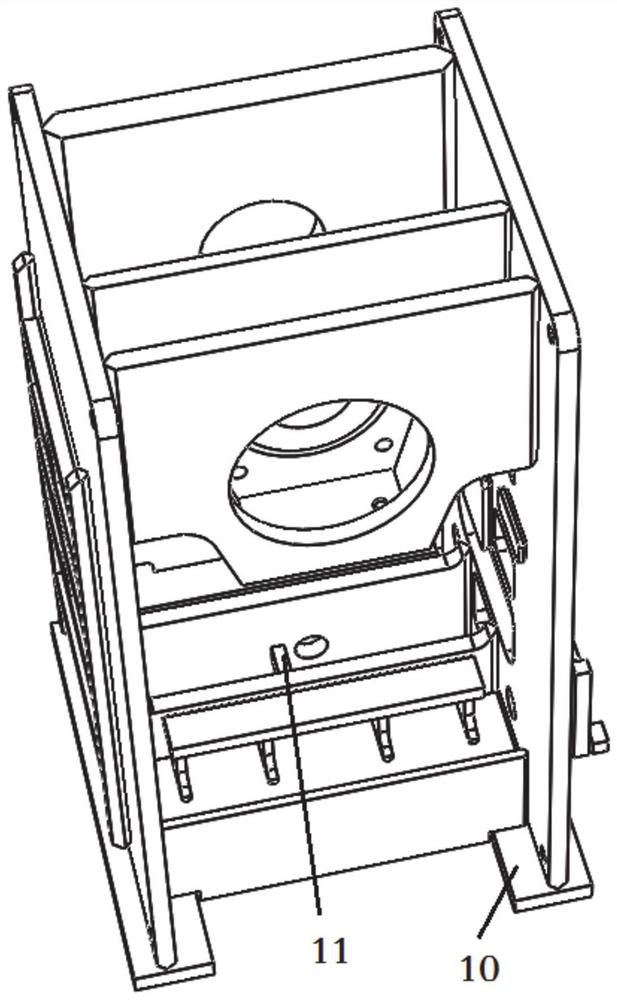

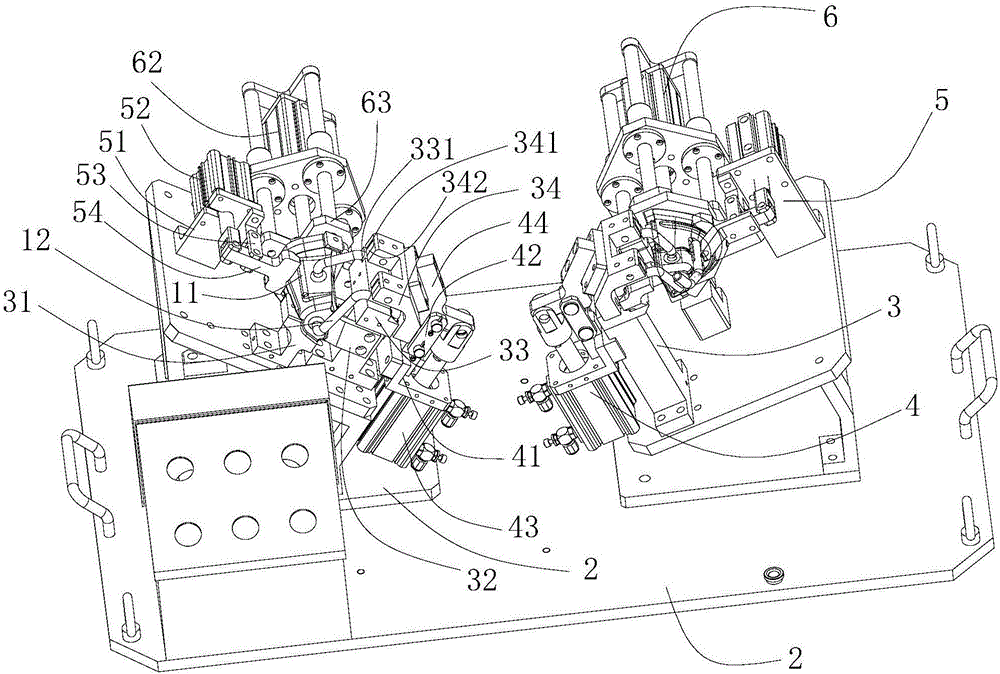

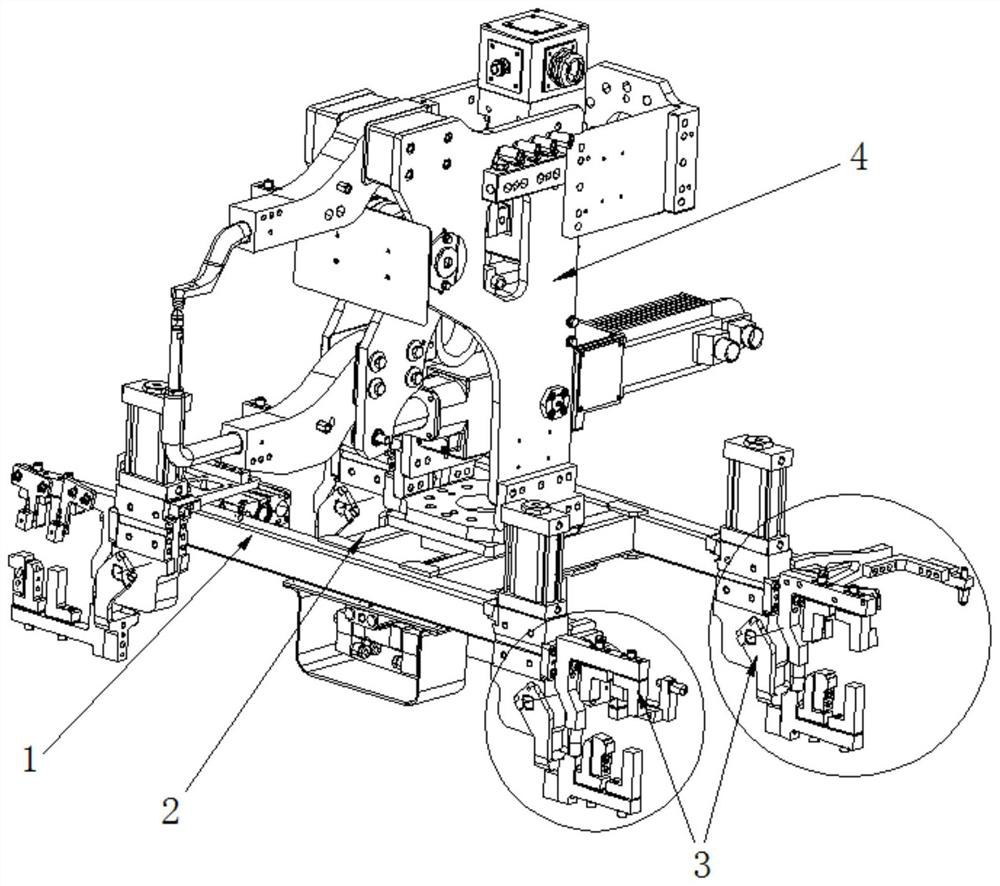

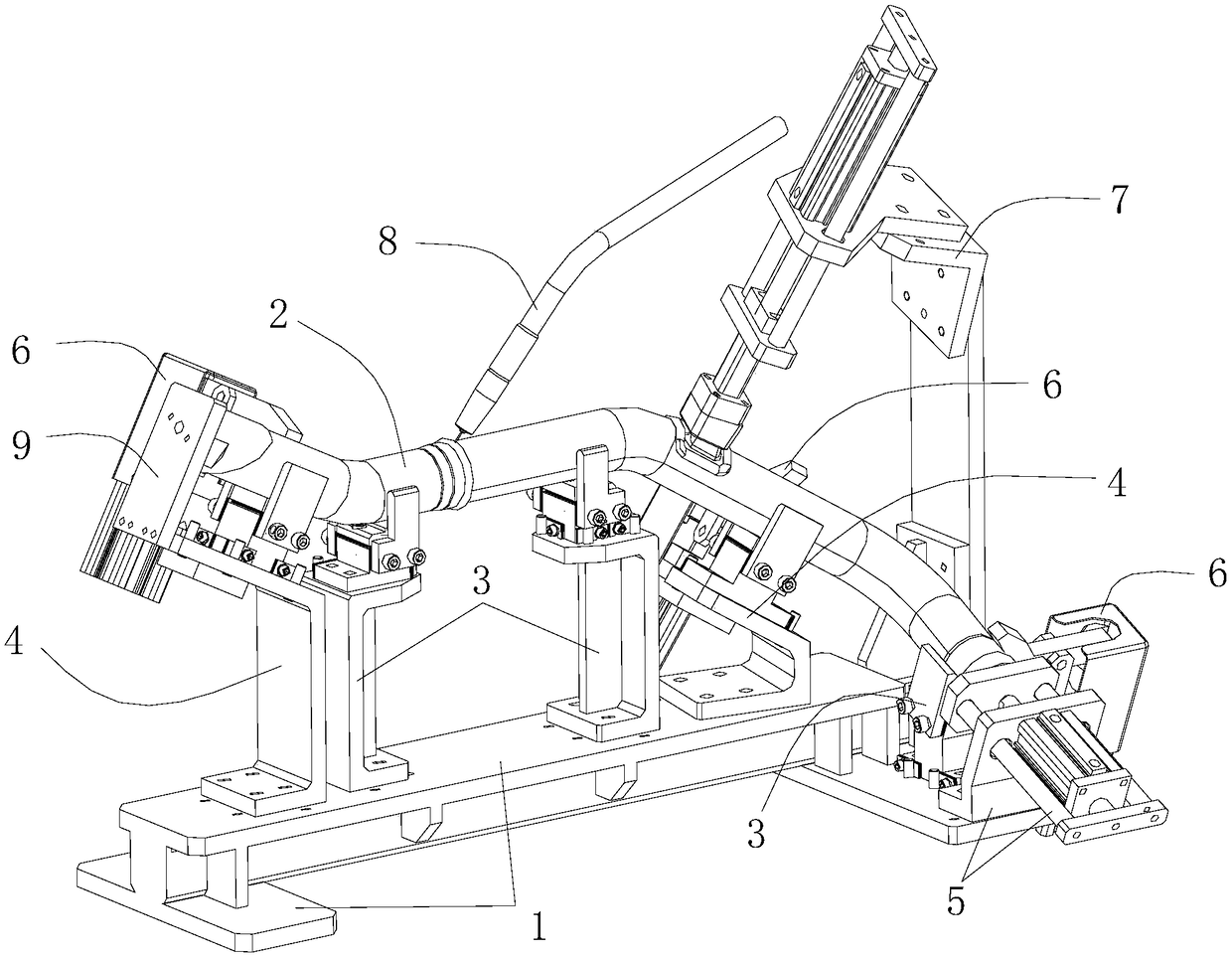

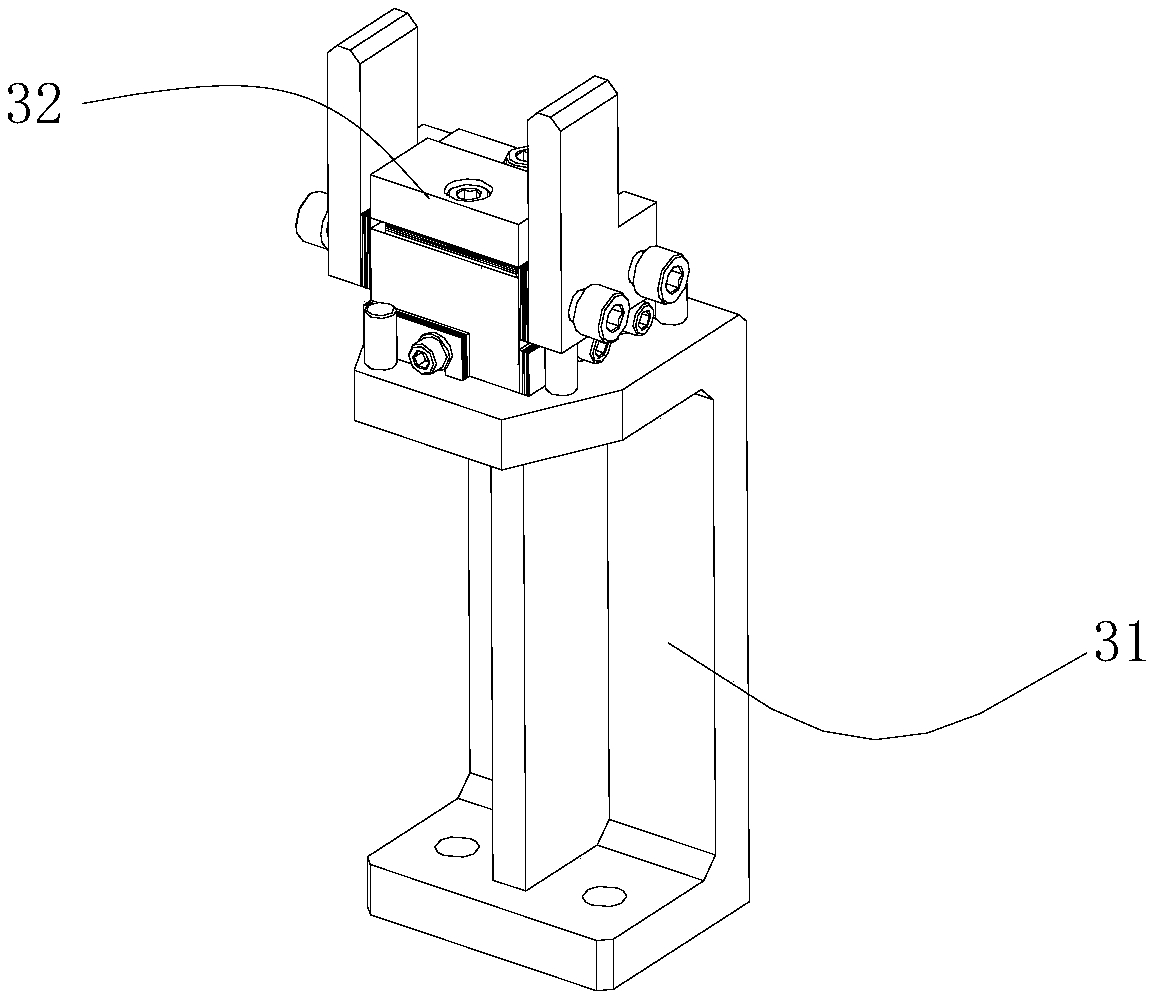

Welding device for special-shaped bent pipe

ActiveCN106514106APrecise positioningNot easy to moveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding device for a special-shaped bent pipe. The special-shaped bent pipe is installed on a working platform. The special-shaped bent pipe comprises a plurality of horizontal sections and a plurality of oblique sections. The horizontal sections are parallel to the working platform. An included angle is formed between each oblique section and the working platform. The welding device for the special-shaped bent pipe comprises at least one first supporting mechanism used for supporting the horizontal sections, at least one second supporting mechanism for supporting the oblique sections, a limiting mechanism used for limiting the movable end of the special-shaped bent pipe, at least one first clamping mechanism for clamping the special-shaped bent pipe, and a second clamping mechanism for clamping the middle portion of the special-shaped bent pipe. The welding device is simple in structure, the special-shaped bent pipe is clamped and positioned, looseness and displacement are not likely to happen, the welding precision of the special-shaped bent pipe is effectively guaranteed, welding application of a welding machine is facilitated, the welding and assembling efficiency is improved, welding errors are reduced, and the welding quality of products is improved.

Owner:景和智能制造(广东)有限公司

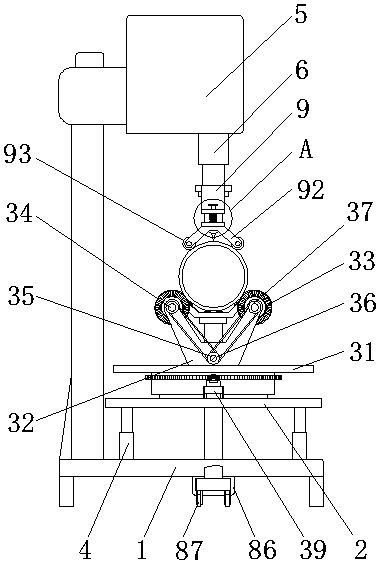

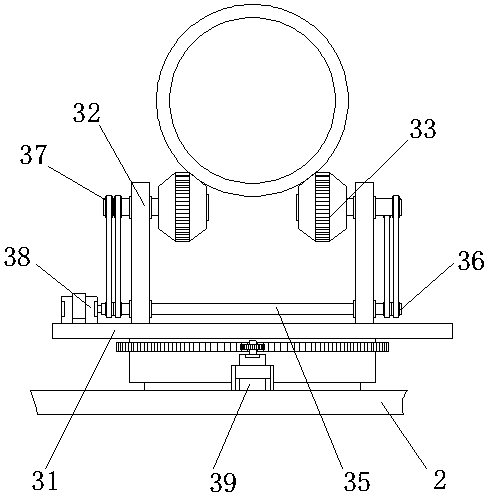

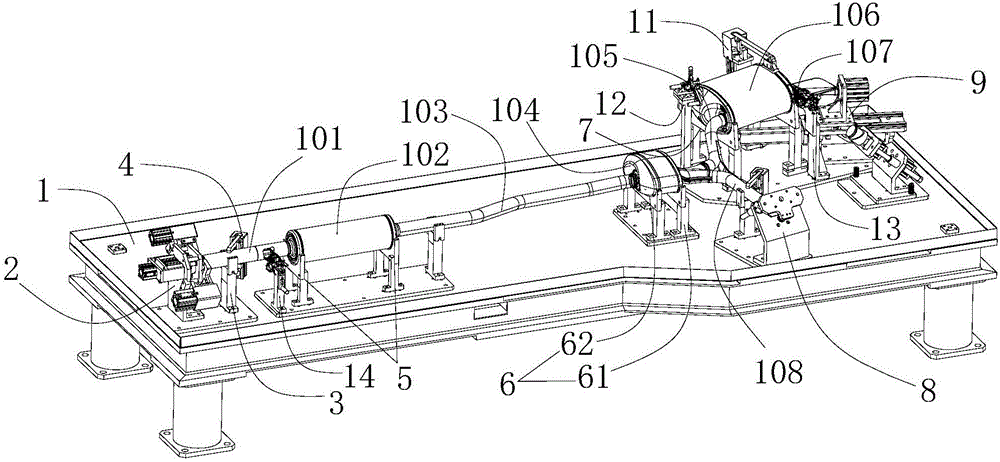

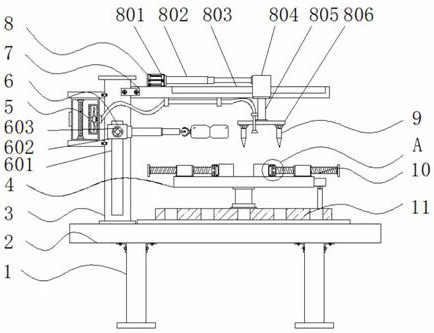

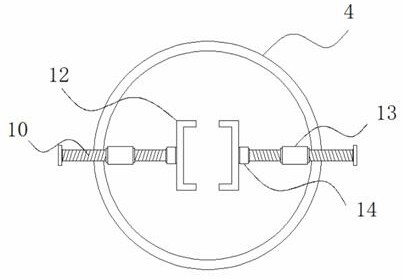

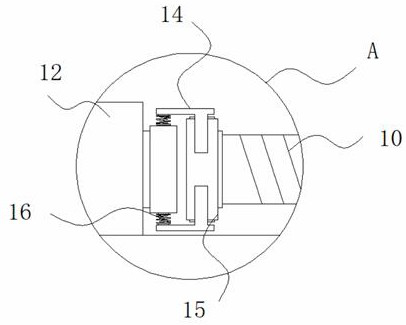

Automatic welding device for nanometer thin-wall pipe fitting

ActiveCN111375941AEnable mobilityAchieve rotation controlWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderPipe fitting

The invention discloses an automatic welding device for a nanometer thin-wall pipe fitting. The automatic welding device comprises a base, wherein a lifting plate is arranged at the top of the base, supporting conveying mechanisms are arranged at the two ends of the top of the lifting plate correspondingly, a first hydraulic cylinder is fixedly installed between the lifting plate and the base, a welding machine is arranged at the top of the base, a second hydraulic cylinder is fixedly installed at the bottom of the welding machine, a welding gun is fixedly connected to the bottom end of the second hydraulic cylinder, each supporting conveying mechanism comprises a supporting base, the supporting bases are rotationally connected to the top of the lifting plate, and gear teeth are arranged on the circumferential side of the bottom end of each supporting base. By means of rotation of the supporting bases, two sets of supporting idler wheels can change states continuously, moving and rotating control over a to-be-welded pipe is achieved, and then the processes of automatic feeding, aligning, seam aligning, automatic welding and automatic discharging of the to-be-welded pipe are achieved, so that the practicability and convenience of using the device are improved.

Owner:聊城市瀚格智能科技有限公司

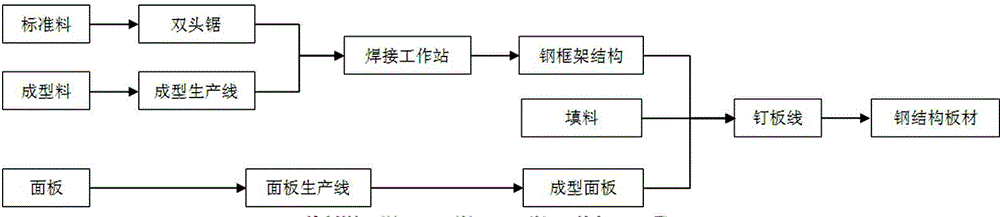

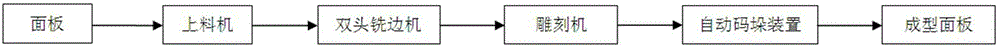

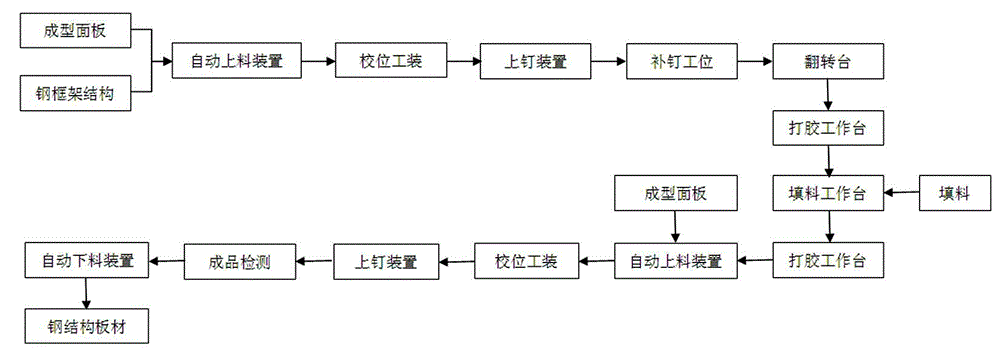

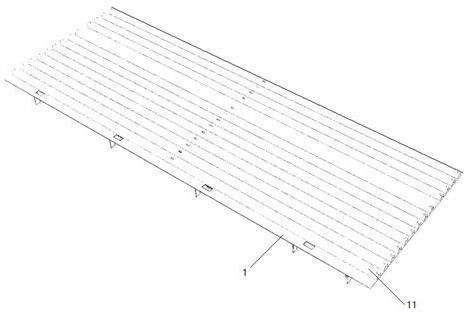

Production line and production method for steel structure plates

ActiveCN104405073AImprove stabilityReduce welding errorsConstruction materialOther manufacturing equipments/toolsProduction lineMetallurgy

The invention discloses a production line and production method for steel structure plates. The production line comprises a panel production line for processing panels, a double-end saw used for cutting standard materials, a steel structure forming production line used for steel structure processing, a welding operation station used for welding steel frame structures, and a plate nailing production line used for combining the steel structure plates. The production line for steel structure plates, provided by the invention, has the characteristics of high automation degree, and stable quality of produced steel structure plate products.

Owner:广东耀达房屋科技股份有限公司

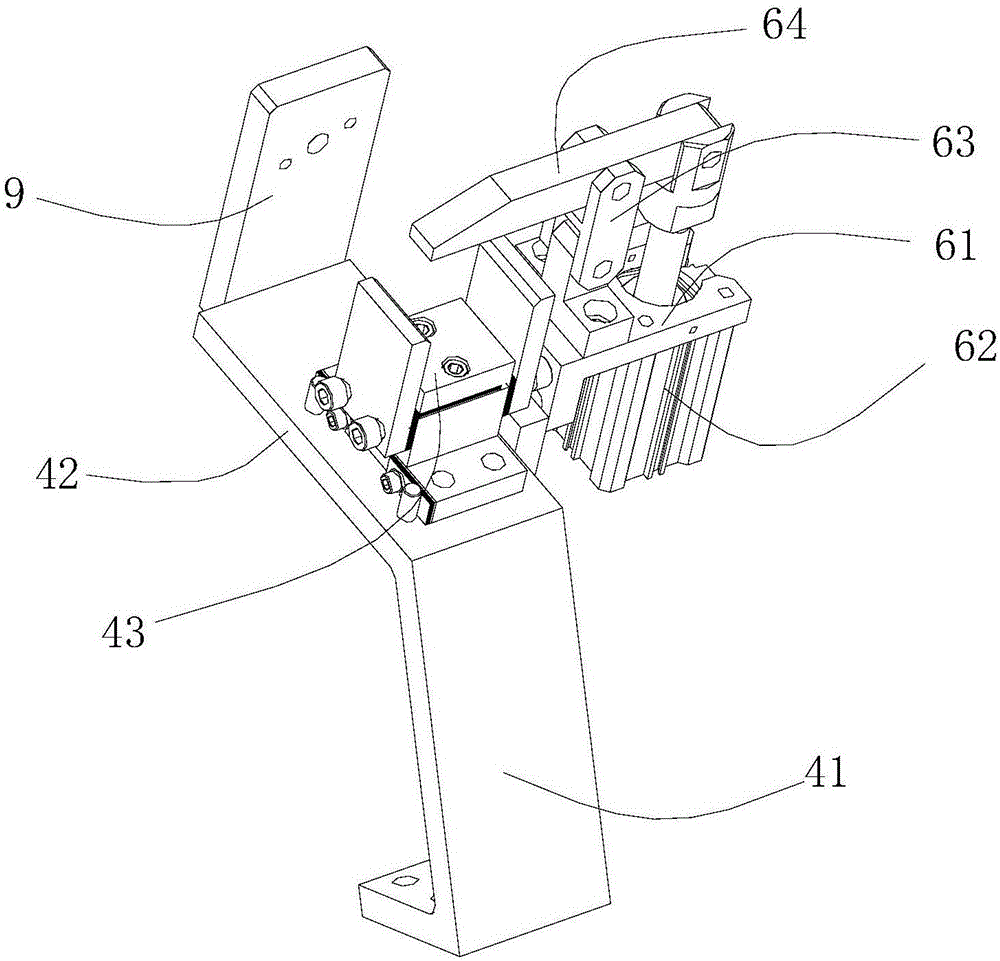

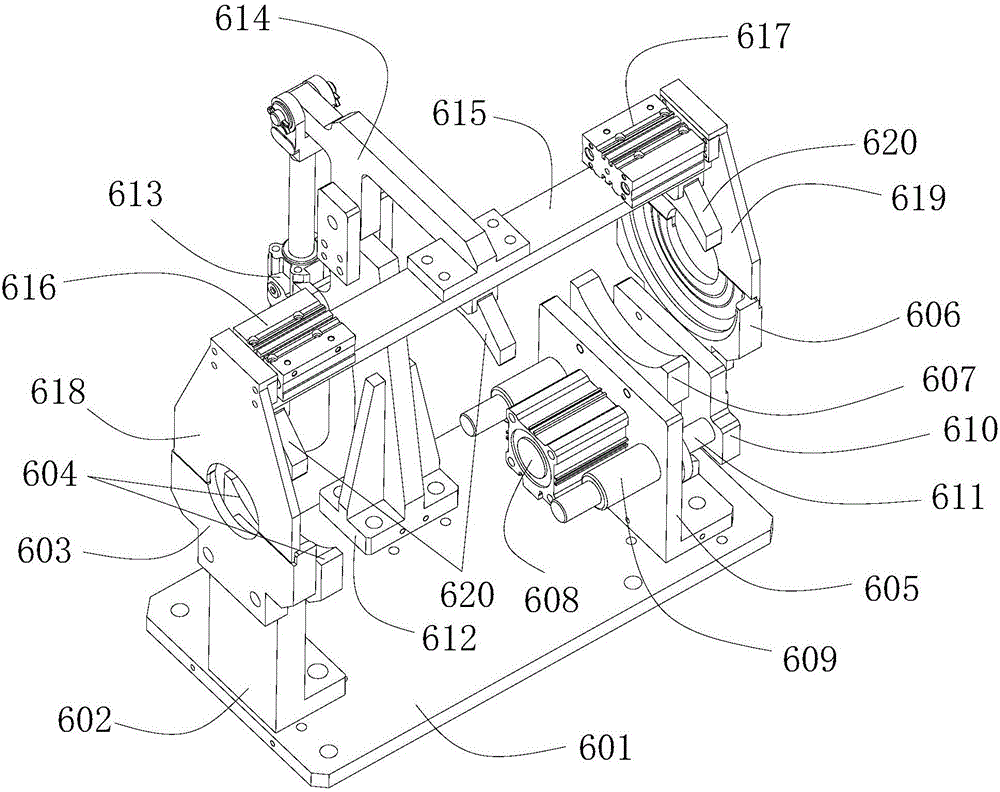

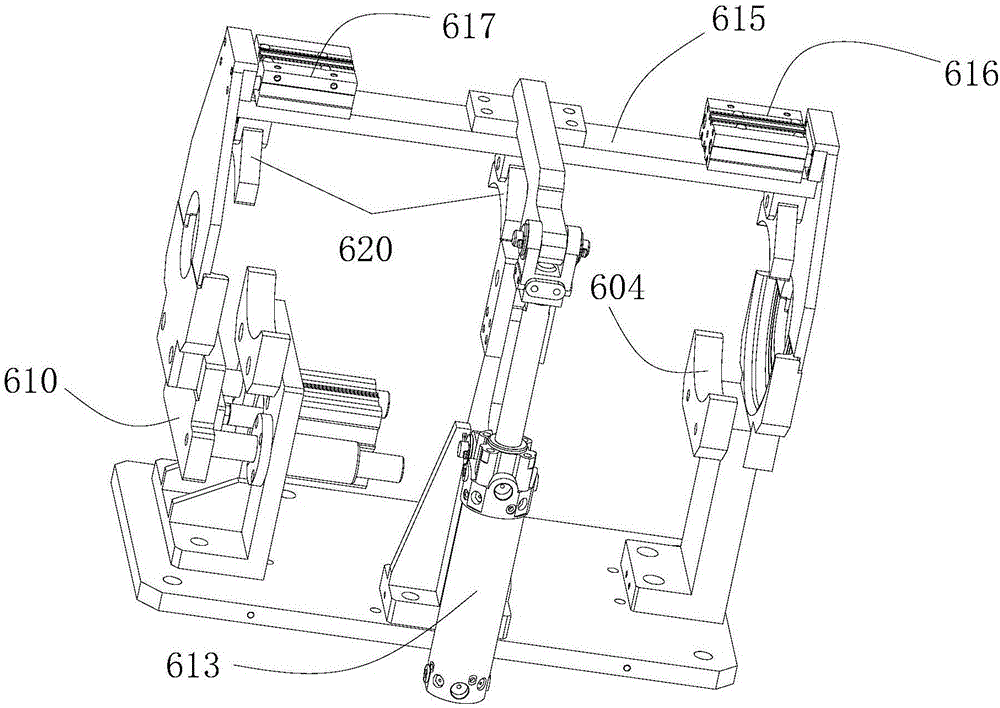

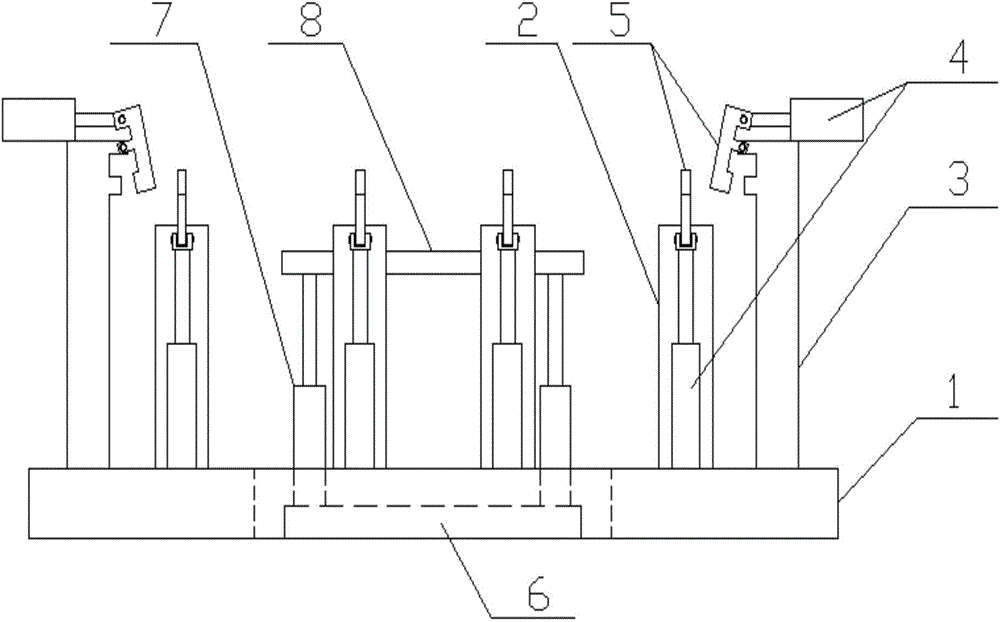

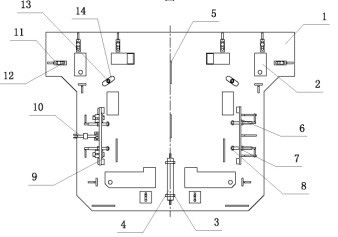

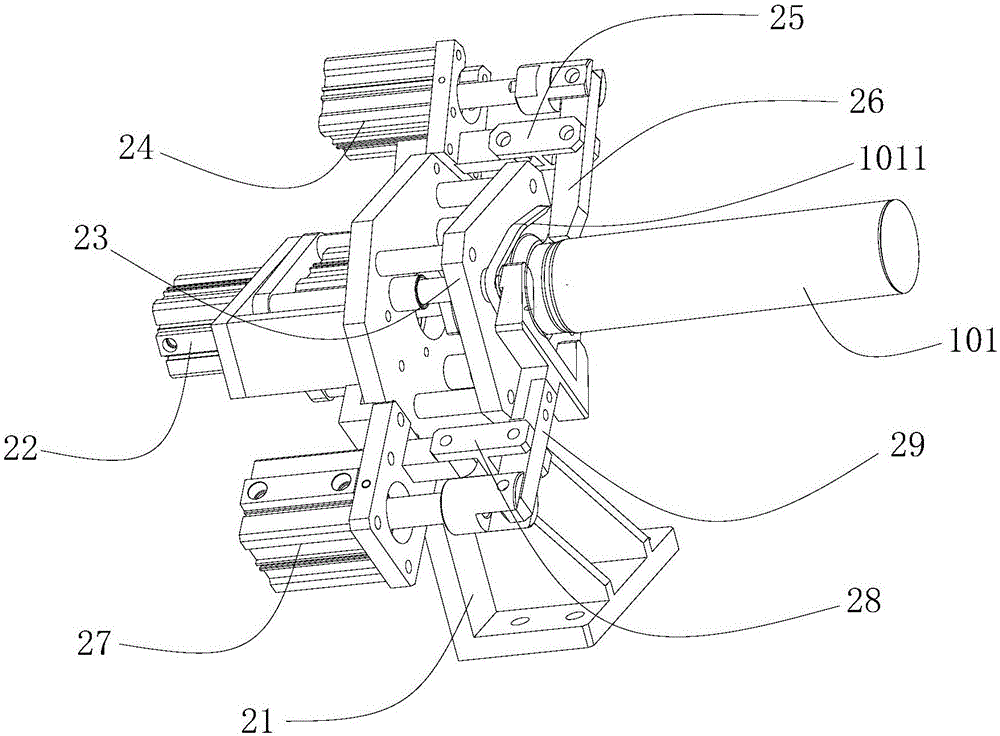

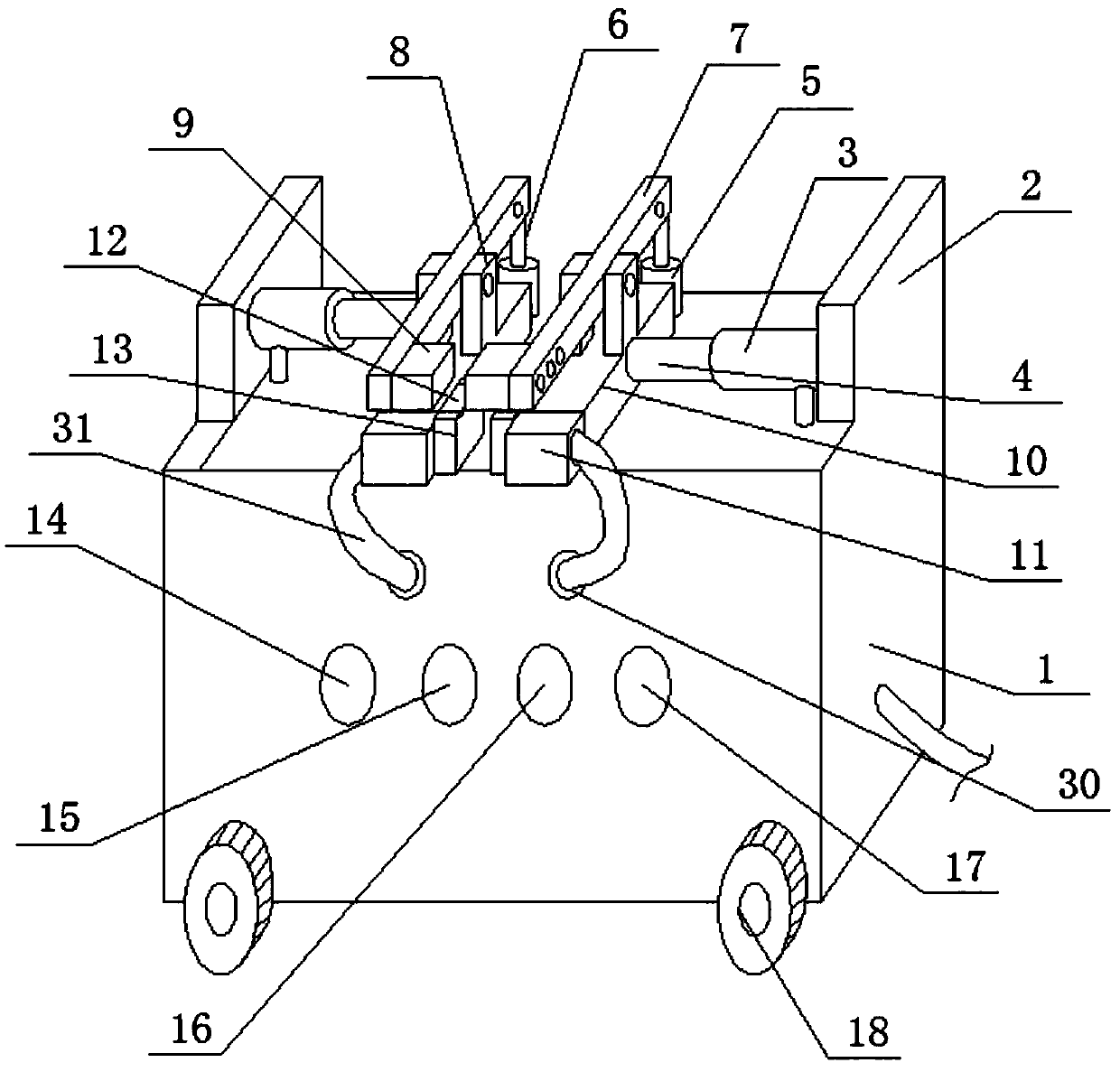

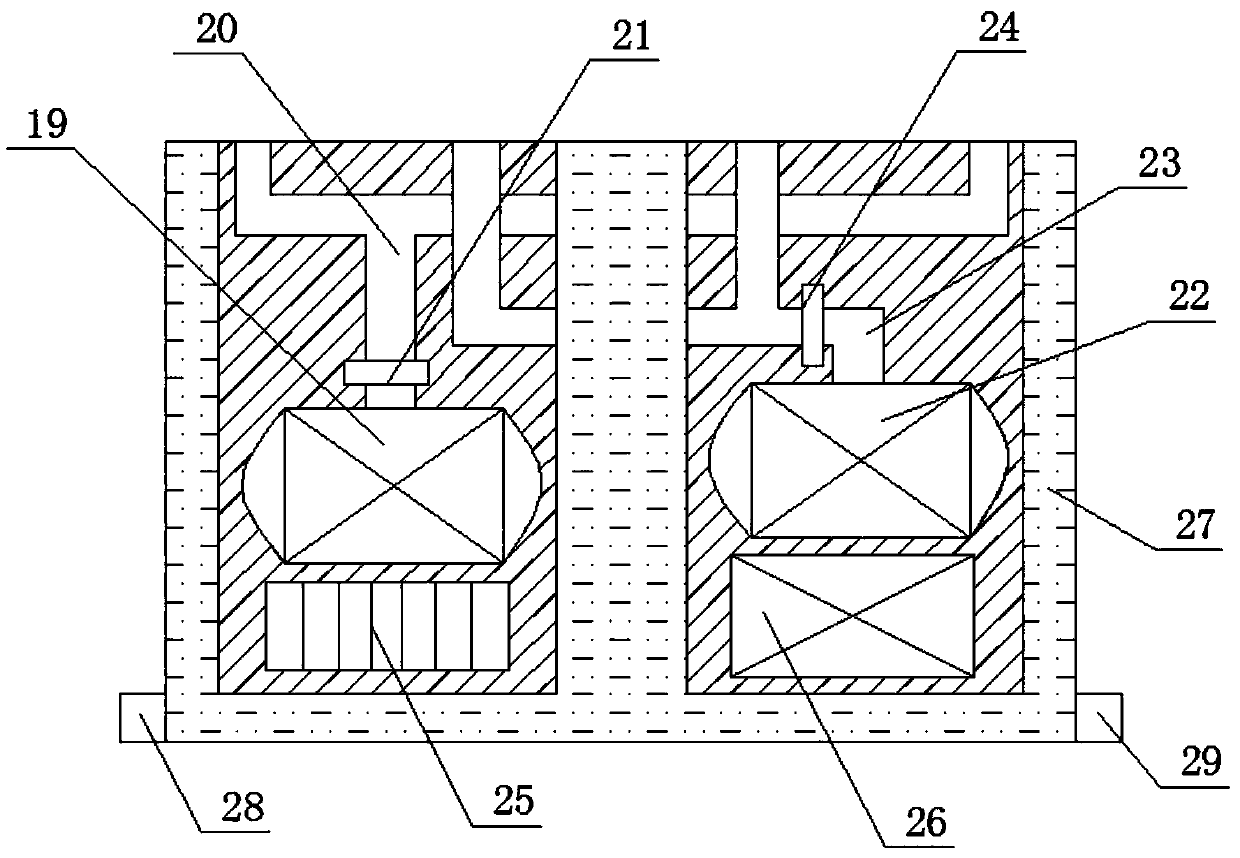

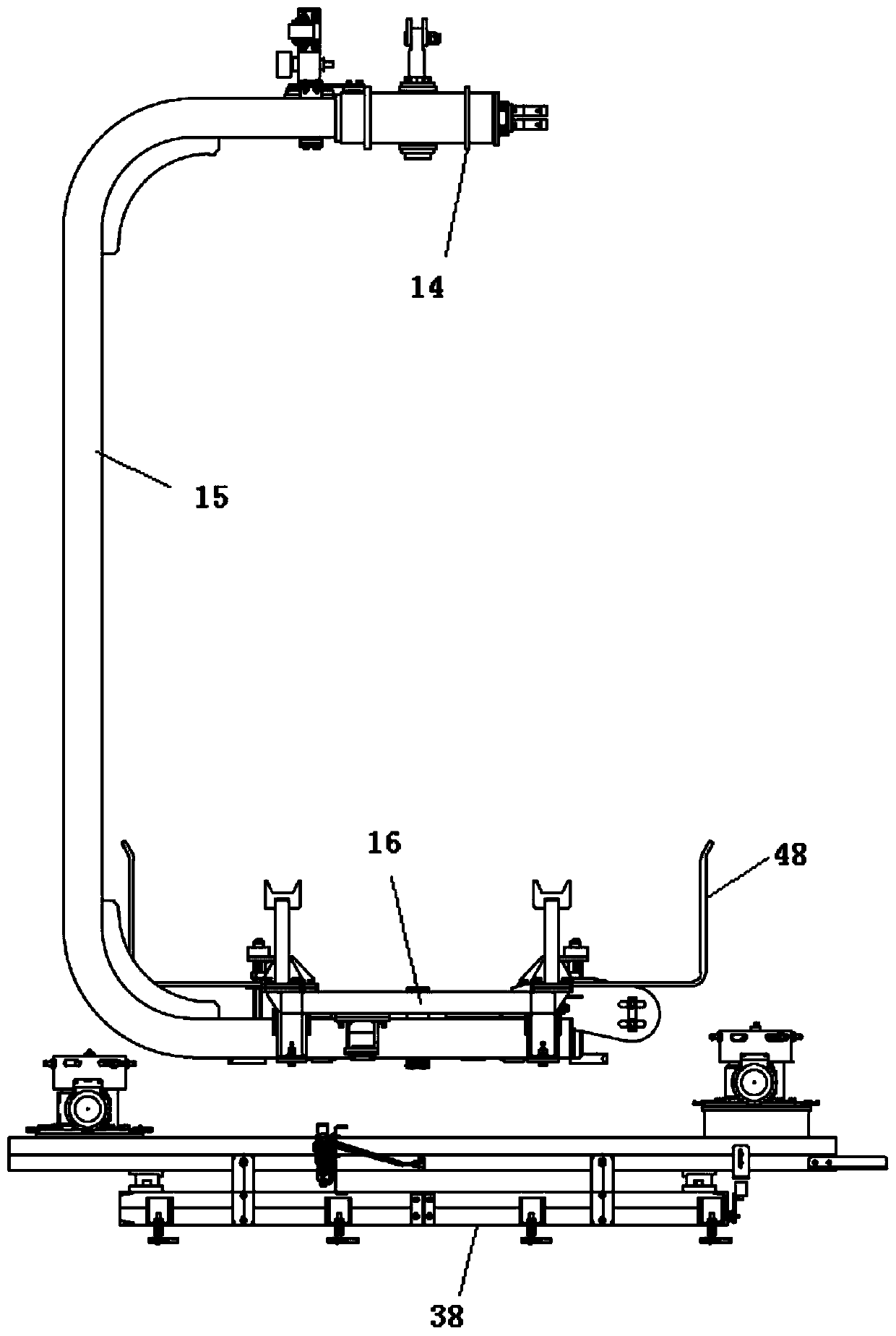

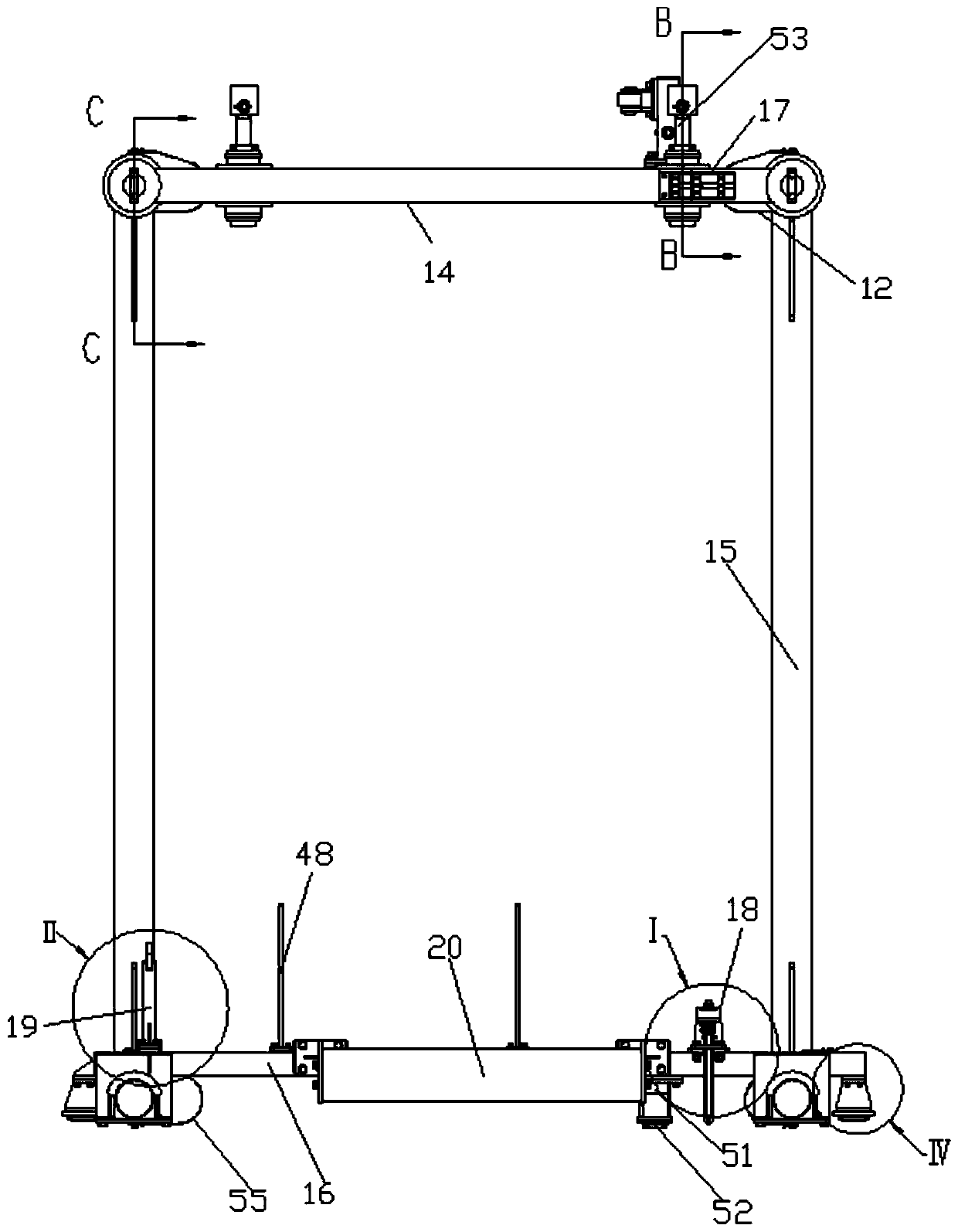

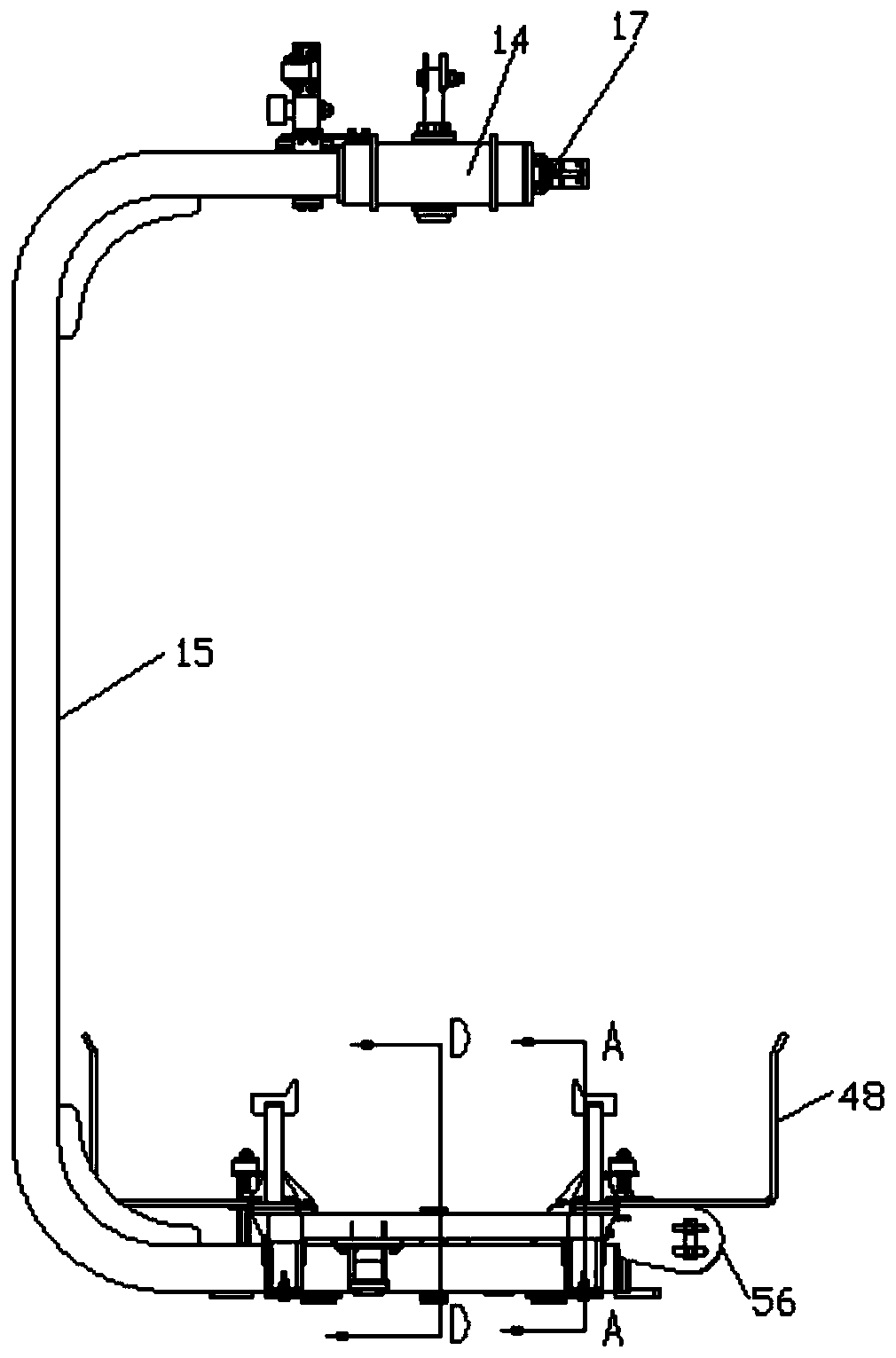

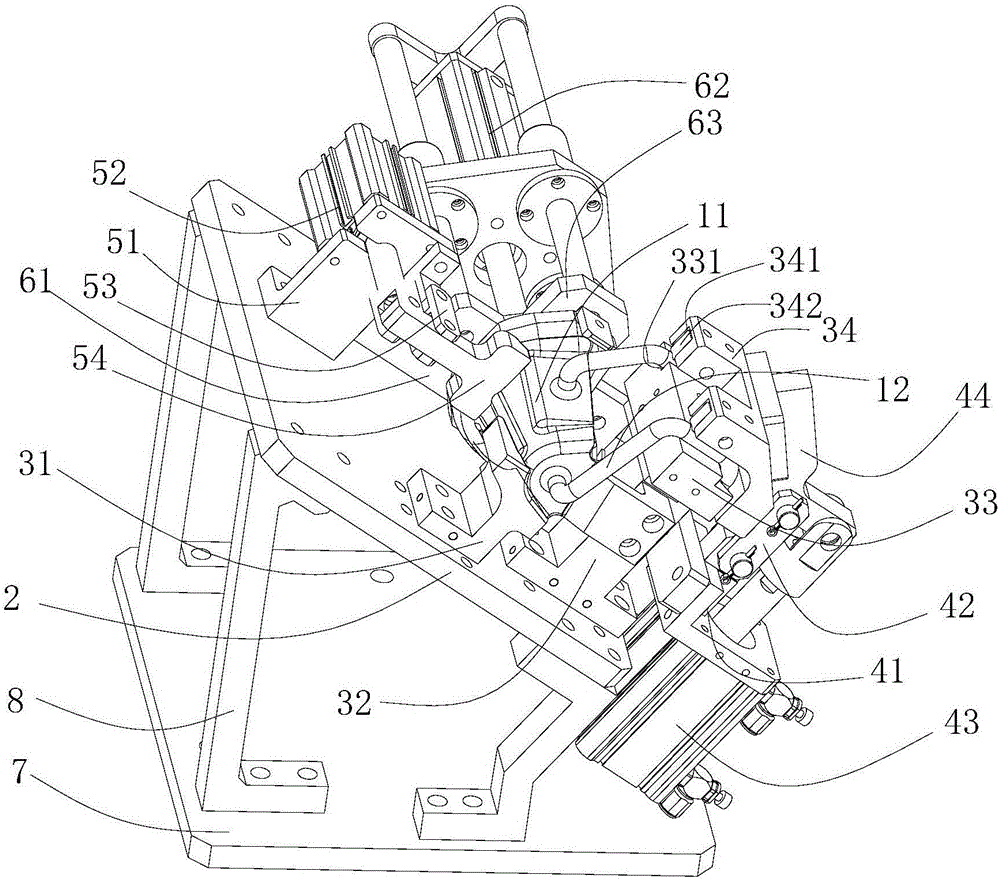

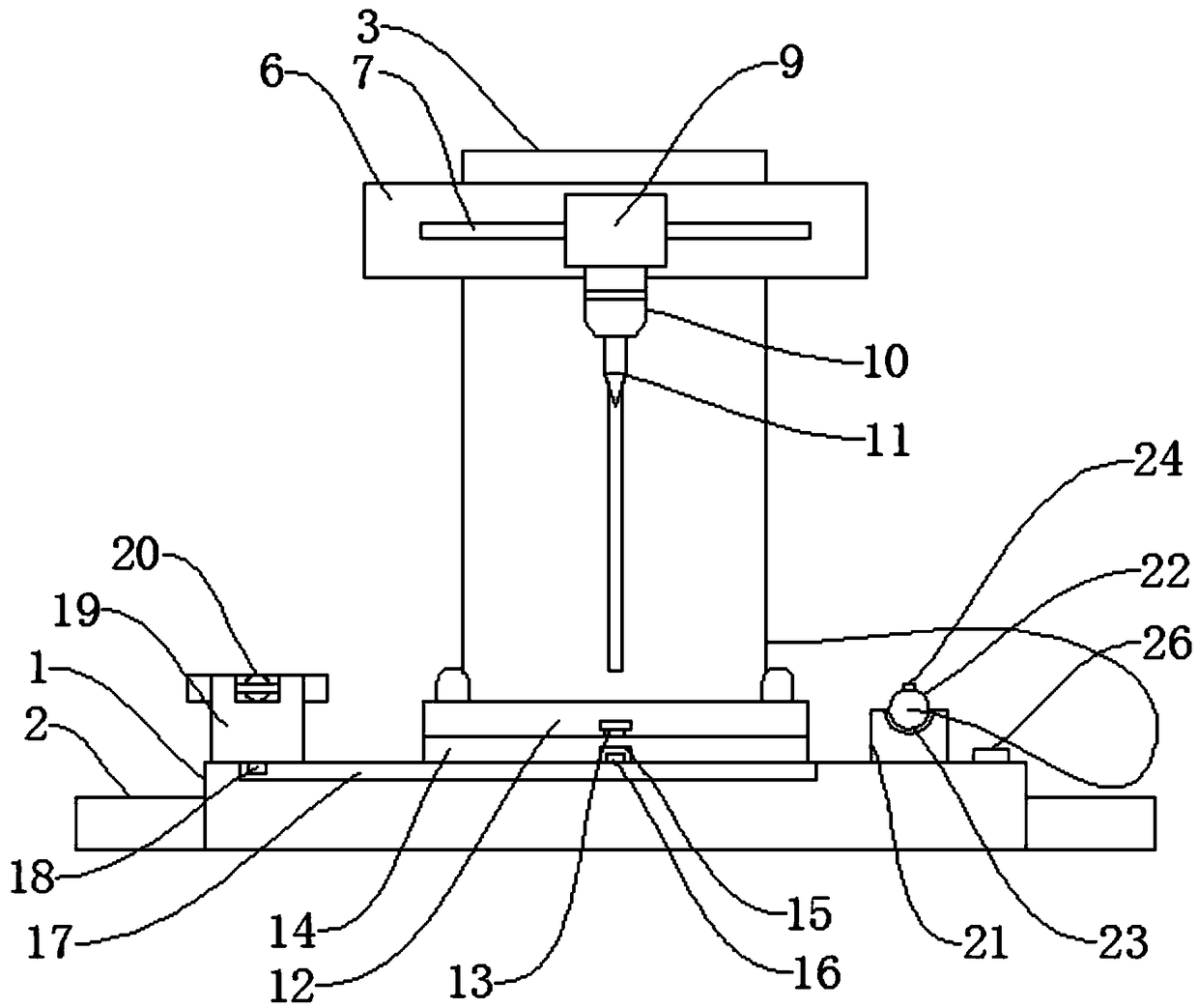

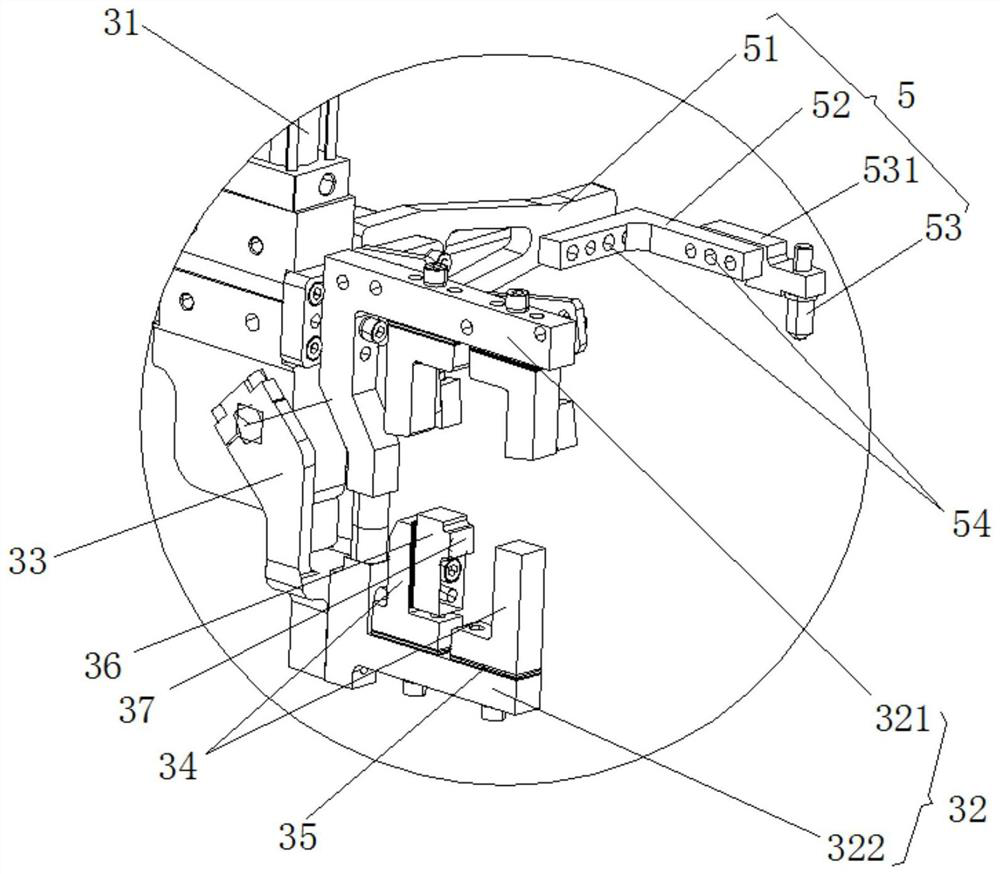

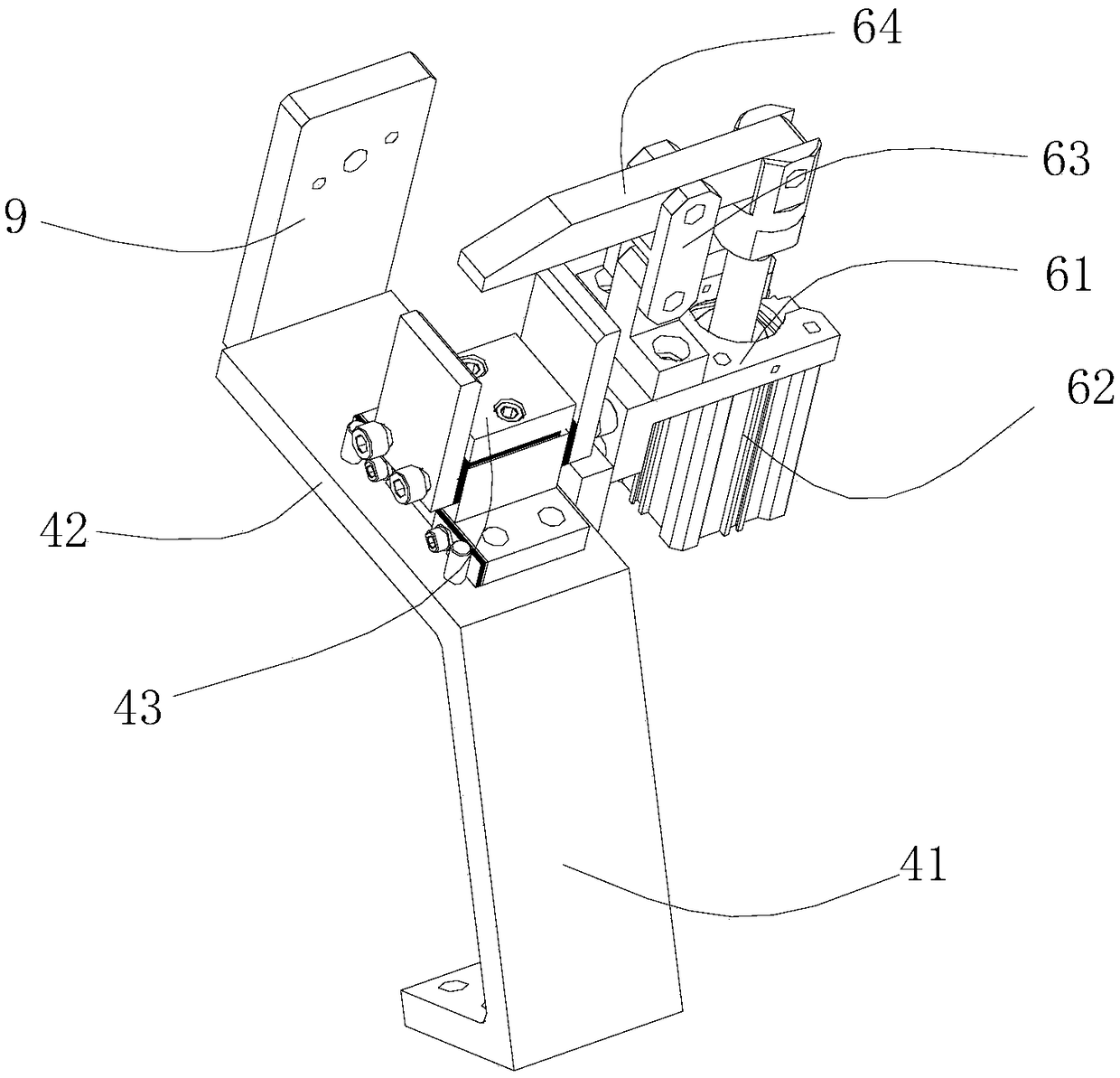

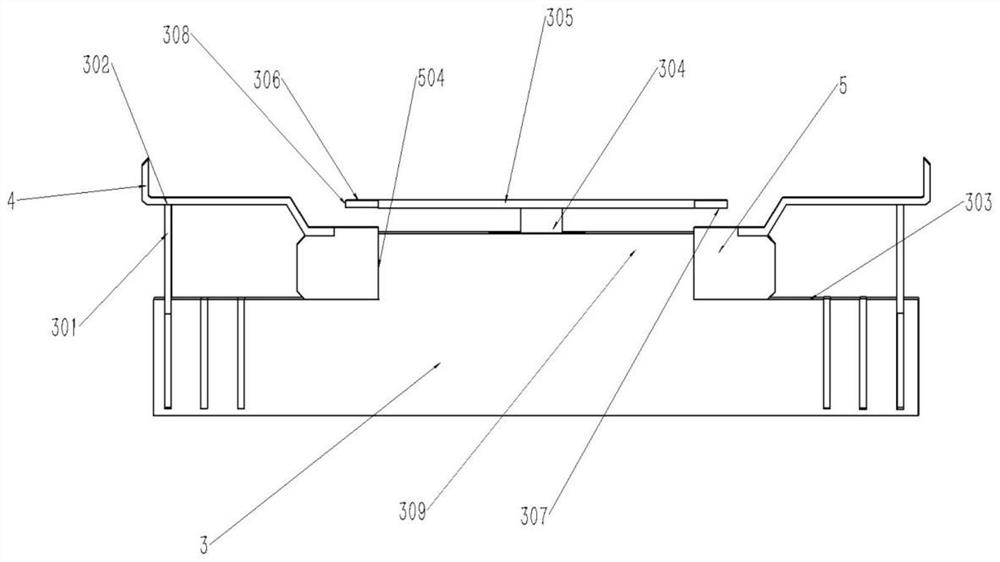

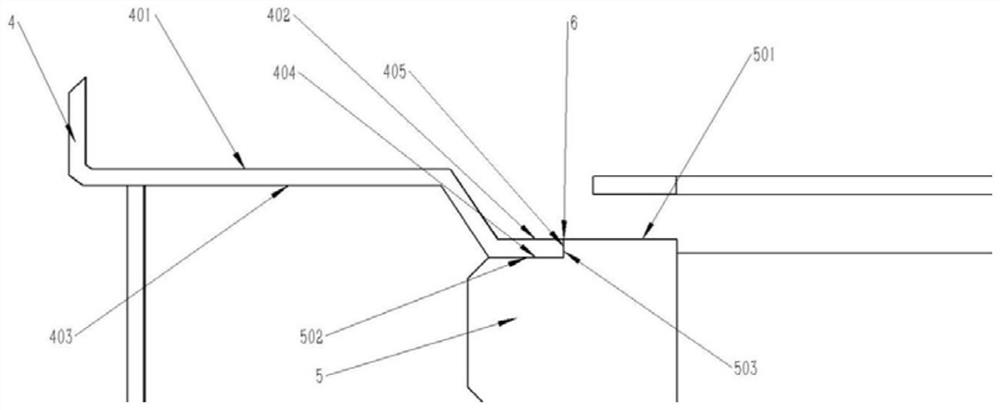

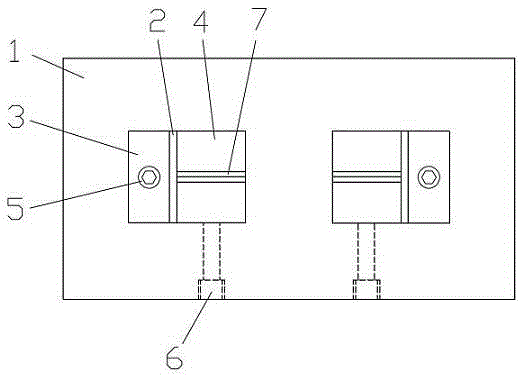

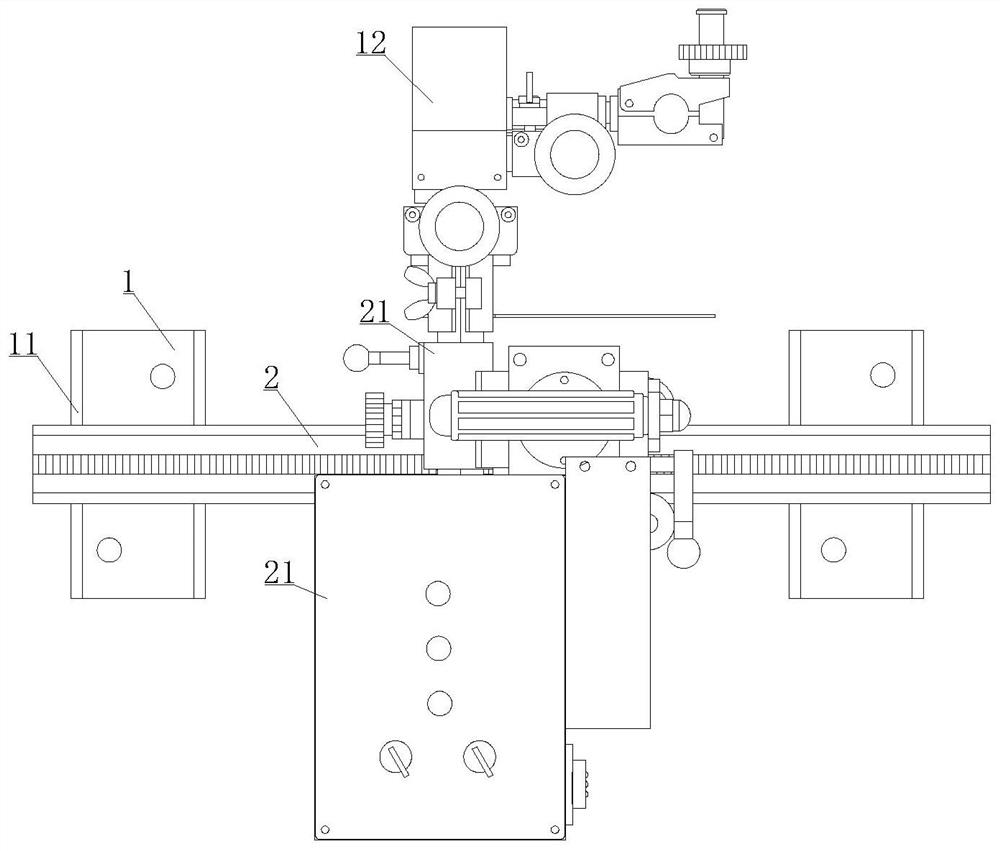

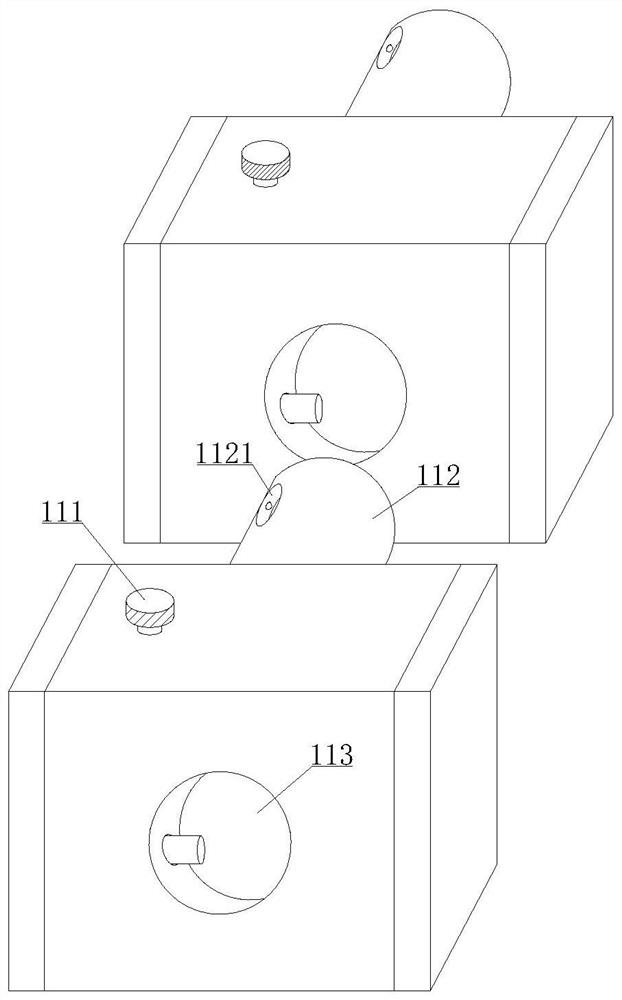

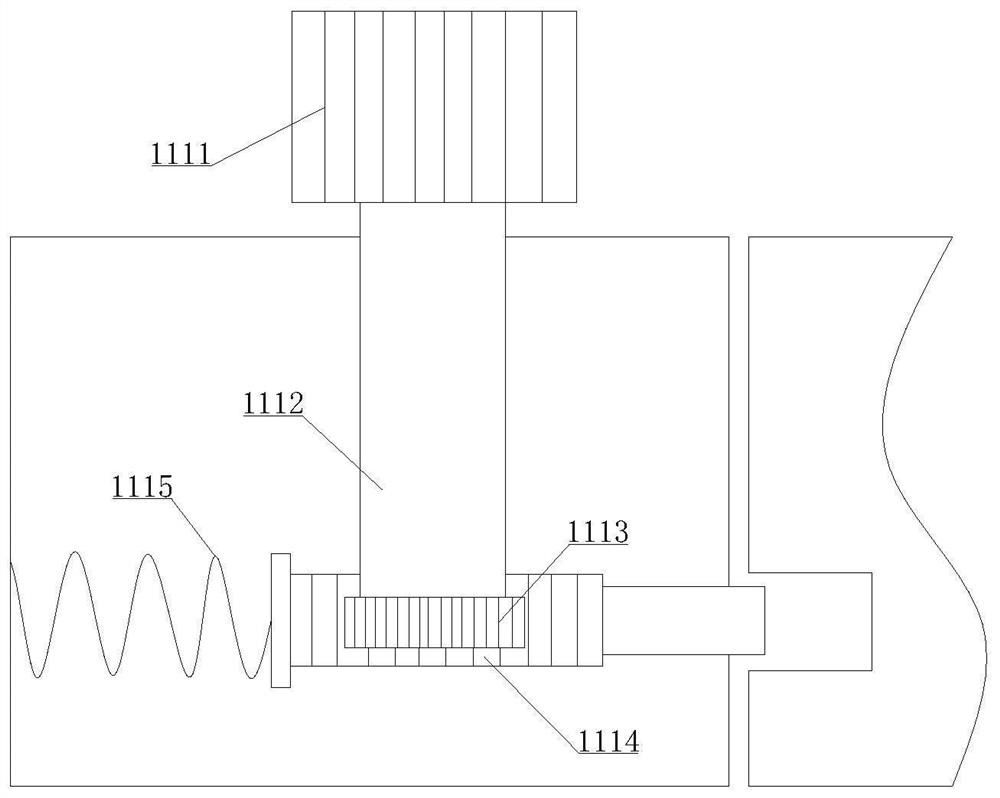

Clamping device for special-shaped pipe welding

ActiveCN106475721ASimple structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringExhaust pipe

The invention discloses a clamping device for special-shaped pipe welding. The clamping device comprises a work platform. The work platform is provided with a first clamping mechanism used for clamping the free end of a first exhaust pipe, a second clamping mechanism used for clamping and fixing a silencer body, a third clamping mechanism used for clamping the free end of a second exhaust pipe, a plurality of clamping grooves, a fourth clamping mechanism used for clamping the fixed end of the first exhaust pipe, and a limiting mechanism. At least one clamping groove is formed between the first clamping mechanism and the second clamping mechanism. At least one clamping groove is formed between the first clamping mechanism and the second clamping mechanism. At least one limiting mechanism is arranged and located between the second clamping mechanism and the third clamping mechanism. The device is simple in structure, an automobile silencer welding and clamping tool can be convenient to operate, and the welding assembling efficiency is improved; and in the welding process, all components, especially a special-shaped pipe, of an automobile silencer can be fixed, the welding error is reduced, and the product welding quality is improved.

Owner:景和智能制造(广东)有限公司

Front passenger car wall assembly welding clamp and technique using the same to weld front wall assembly

ActiveCN104526224AIncrease the level of detailGood lookingWelding/cutting auxillary devicesArc welding apparatusEngineeringSpare part

The invention relates to a front passenger car wall assembly welding clamp and a technique using the same to weld a front wall assembly. The front passenger car wall assembly welding clamp comprises a pedestal, a short support, a long support, a cylinder and a clamp wall, a plurality of first supports are fixed at the front and rear sides of the pedestal, a plurality of second supports are fixed at the left and right sides of the pedestal, and a jacking device is fixed at the middle position. The technique using the clamp to weld the front wall assembly includes steps that firstly, using the clamp to clamp, fix and weld spare parts of a front wall framework into a single body, using the jacking device to jack up, and using a cantilever crane to hoist out the front wall framework; secondly, using the clamp to clamp, fix and weld spare parts of a front wall skin into a single body, and using the jacking device to jack up; finally, hoisting the front wall framework into the front wall skin, resetting the jacking device, compressing the front wall framework and front wall skin, and welding to form the front wall assembly. The technique enables the precision quality and appearance effect of the front wall assembly to be guaranteed.

Owner:BAODING CHANGAN BUS MFG

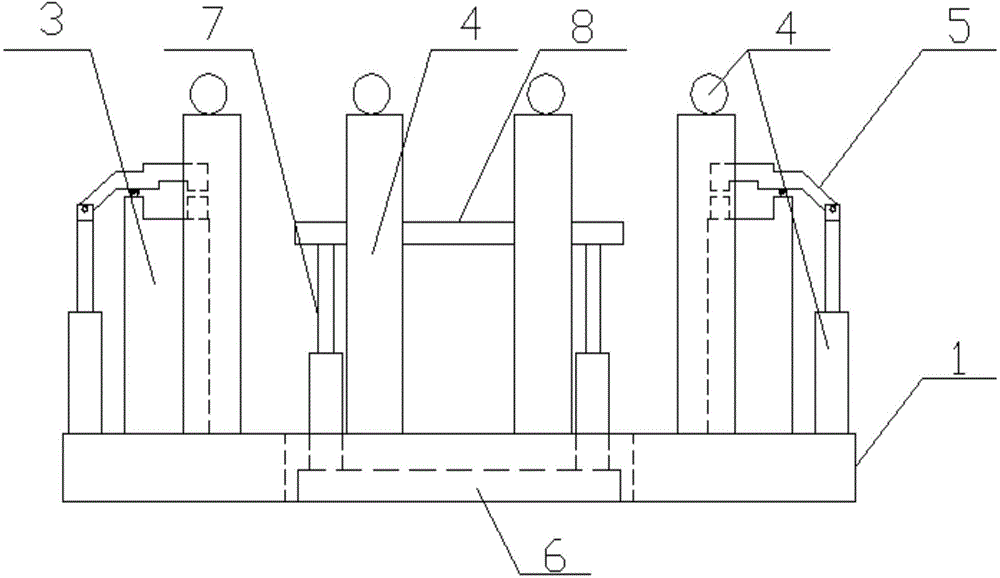

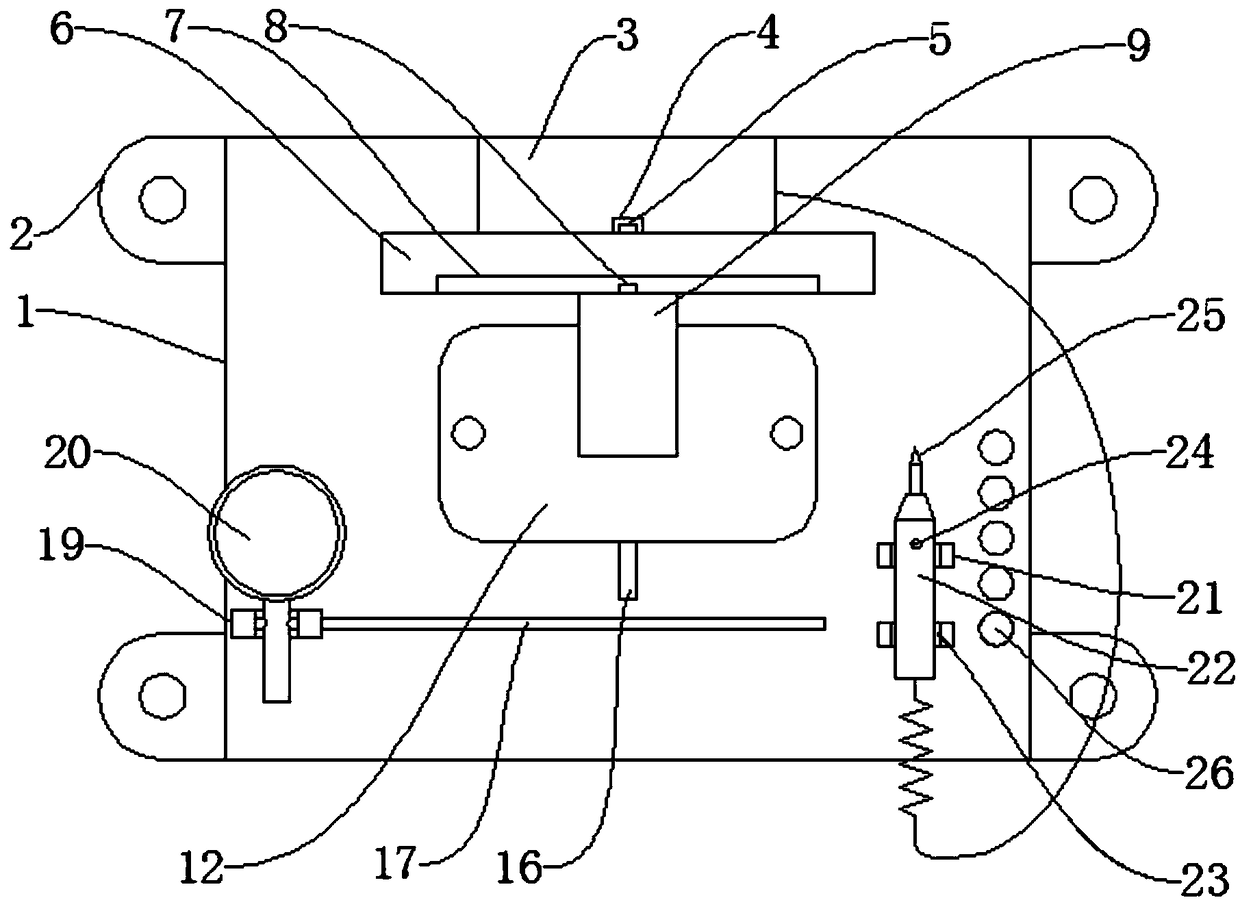

Ring beam rivet weld device for mining dumper

InactiveCN101987405AReduce welding errorsGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesBlock matchSteel casting

The invention discloses a ring beam rivet weld device for a mining dumper, which is characterized by comprising an installation platform matched with a ring beam structure, wherein a centralized positioning structure is arranged on a central line of the installation platform, corresponding to a middle lower steel casting of a ring beam; a central measuring basis structure is arranged on the middle part of the installation platform on the central line; a fixed positioning structure is arranged on the right side of the central measuring basis structure; a movable positioning structure is arranged on the left side of the central measuring basis structure; the fixed positioning structure and the movable positioning structure are arranged symmetrically; the installation platform is provided with an observing block matched with steel castings of the ring beam; a movable positioning plate structure is arranged on the outer side of the observing block; and the installation platform is provided with a compaction structure matched with the ring beam. The ring beam rivet weld device can position ring beam assemblies conveniently, reduce the welding errors of the ring beam effectively, ensurethe welding quality of the ring beam and improve the efficiency.

Owner:SANY MINING MACHINERY

Rear passenger car wall assembly welding clamp and technique using the same to weld rear wall assembly

ActiveCN104526123AIncrease the level of detailGood lookingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpare part

The invention relates to a rear passenger car wall assembly welding clamp and a technique using the same to weld a rear wall assembly. The rear passenger car wall assembly welding clamp comprises a pedestal, a short support, a long support, a cylinder and a clamp wall, a plurality of first supports are fixed at the front and rear sides of the pedestal, a plurality of second supports are fixed at the left and right sides of the pedestal, and a jacking device is fixed at the middle position. The technique using the clamp to weld the rear wall assembly includes steps that firstly, using the clamp to clamp, fix and weld spare parts of a rear wall framework into a single body, using the jacking device to jack up, and using a cantilever crane to hoist out the rear wall framework; secondly, using the clamp to clamp, fix and weld spare parts of a rear wall skin into a single body, and using the jacking device to jack up; finally, hoisting the rear wall framework into the rear wall skin, resetting the jacking device, compressing the rear wall framework and rear wall skin, and welding to form the rear wall assembly. The technique enables the precision quality and appearance effect of the rear wall assembly to be guaranteed.

Owner:BAODING CHANGAN BUS MFG

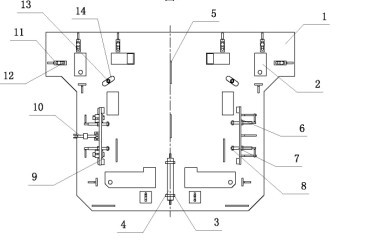

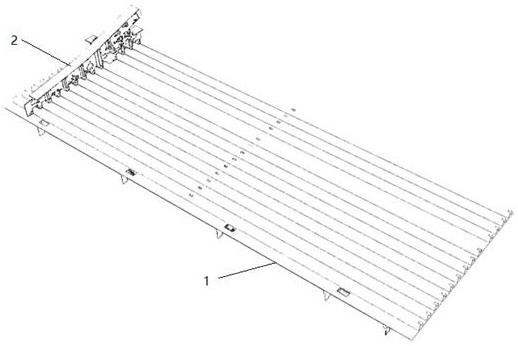

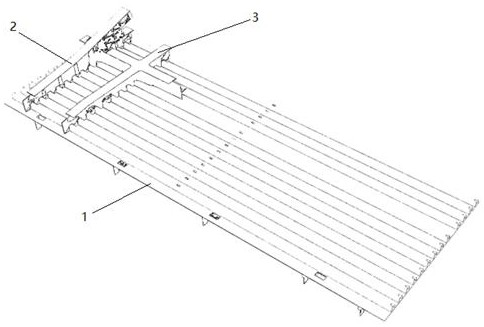

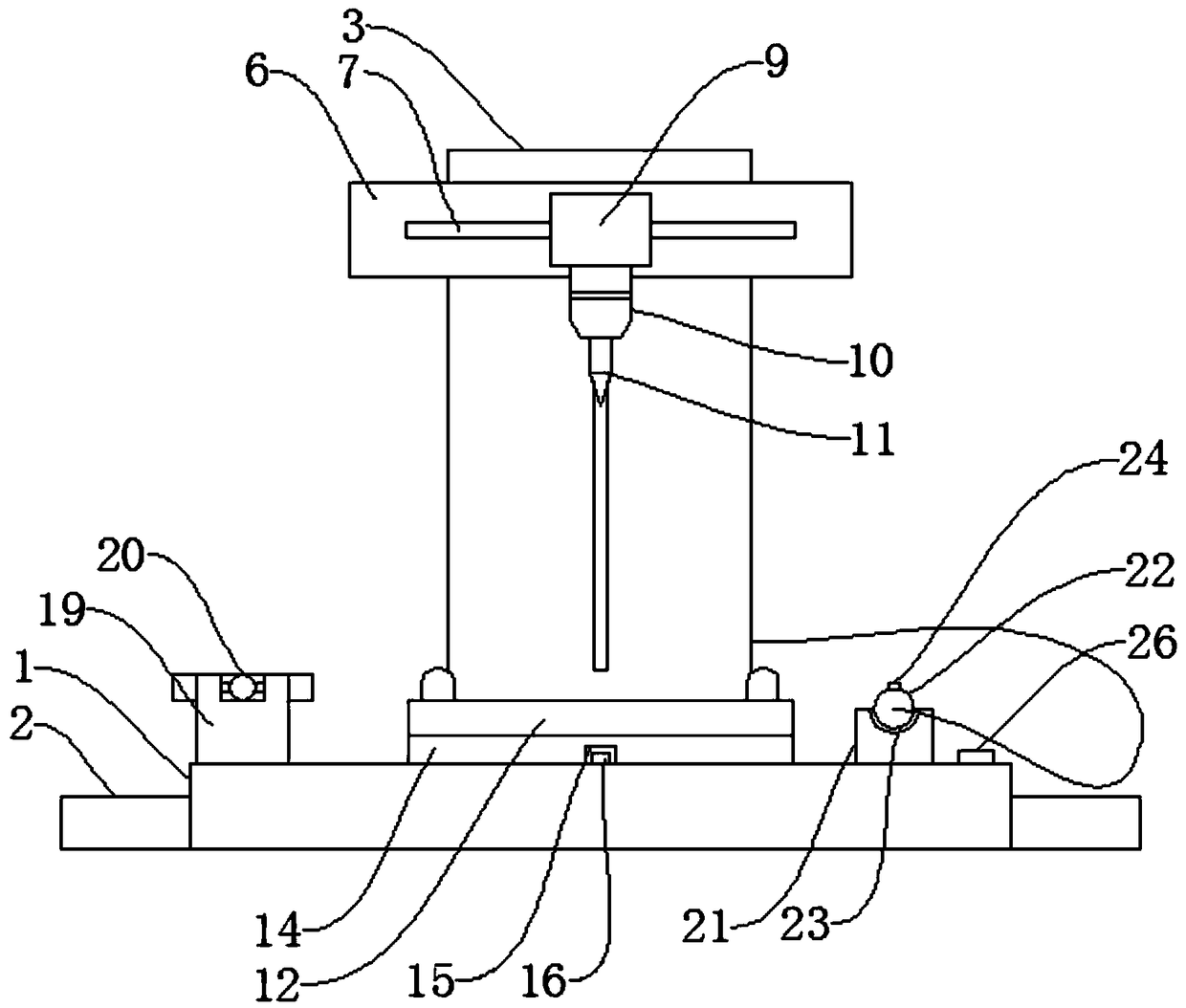

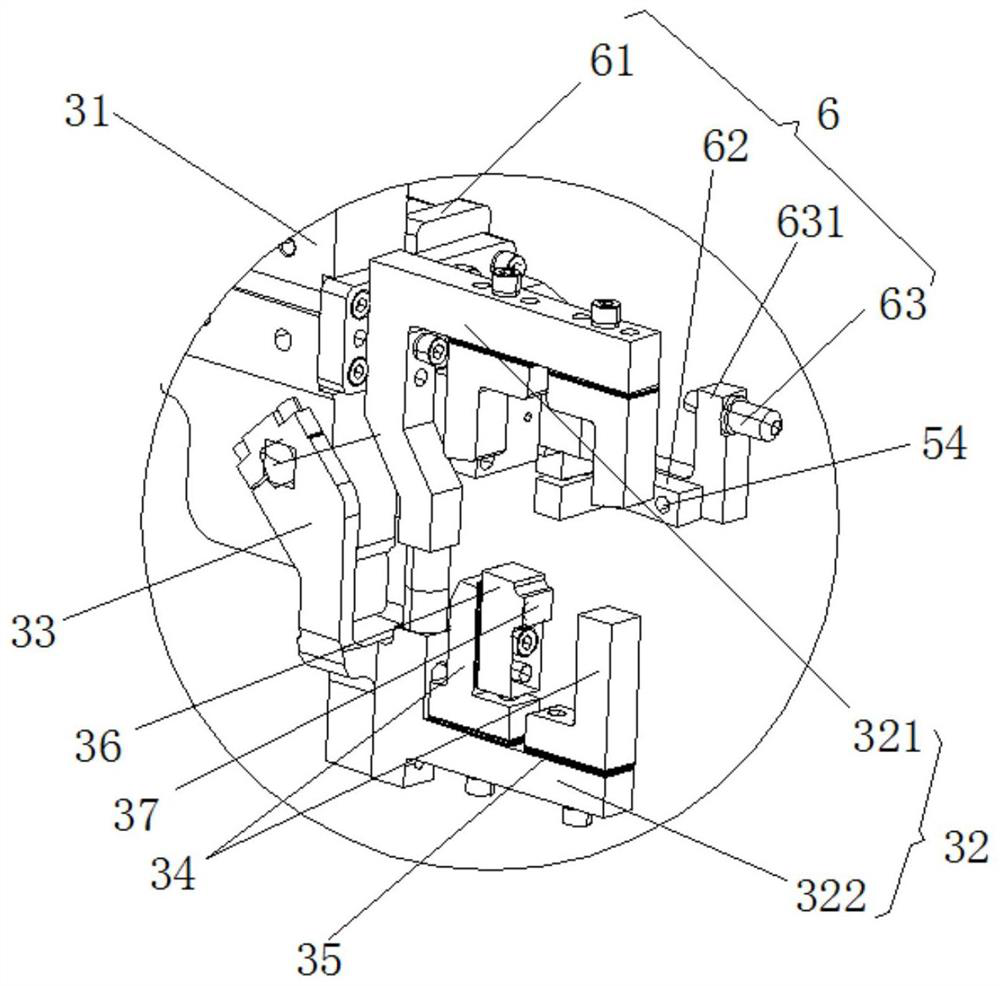

Clamping device for automobile muffler

ActiveCN106736153AGuaranteed accuracyEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMuffler

The invention discloses a clamping device for an automobile muffler. The clamping device comprises a workbench, and a first clamping mechanism, a first supporting mechanism used for supporting air pipes, a second clamping mechanism used for clamping the air pipes, a second supporting mechanism used for supporting a three-way catalytic converter, a third supporting mechanism used for supporting a front silencer, a fourth supporting mechanism used for supporting a main silencer, a third clamping mechanism used for clamping a side connecting air pipe and a fourth clamping mechanism used for clamping an air pipe at the back end of the main silencer, which are installed on the workbench; the main silencer is provided with a fifth clamping mechanism used for compressing the top of the main silencer, a sixth clamping mechanism and a seventh clamping mechanism; and the sixth clamping mechanism and the seventh clamping mechanism are used for clamping the front side and the back side of the main silencer respectively. The clamping device has a simple structure, does not easily have the phenomena of loosening and displacement when clamping and positioning the automobile muffler, effectively guarantees the welding accuracy of each component of the automobile muffler, enables welding of a welding machine to be convenient, improves the welding assembly efficiency, reduces the welding error and improves the welding quality of a product.

Owner:景和智能制造(广东)有限公司

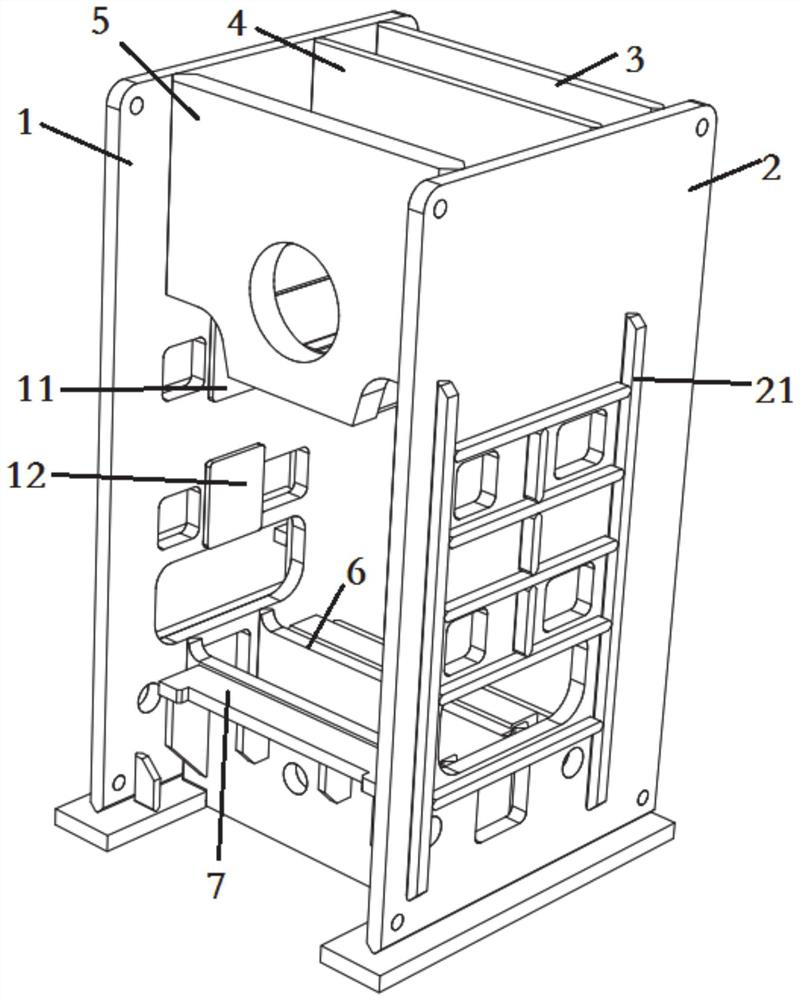

Welding method and manufacturing process of press machine body

ActiveCN112059457AReduce welding errorsReduce distortionWelding apparatusPressesEngineeringWelding deformation

The invention provides a welding method and a manufacturing process of a press machine body, and belongs to the field of large-scale load bearing chassis. The method comprises the following steps that1, two vertical side plates in the press machine body and a middle supporting plate and a bottom plate supporting plate which are arranged in longitudinal side plates are pre-assembled, wherein the middle supporting plate comprises a first middle plate, a second middle plate and a third middle plate which are parallel to one another and the bottom plate supporting plate comprises a first bottom supporting plate and a second bottom supporting plate; 2, the two longitudinal side plates are vertically placed, the first middle plate and the first bottom supporting plate are welded to the same side in the width direction, then the two vertical side plates are turned over by 90 degrees to be placed, the second middle plate and the third middle plate are welded to the upper portion of the firstmiddle plate in sequence, the second bottom supporting plate is welded to the upper portion of the bottom supporting plate in the first step; and thirdly, a base supporting plate is welded to the bottoms of the two longitudinal side plates. By means of the welding method, welding deformation is effectively controlled, and the production efficiency is improved.

Owner:中船发动机有限公司

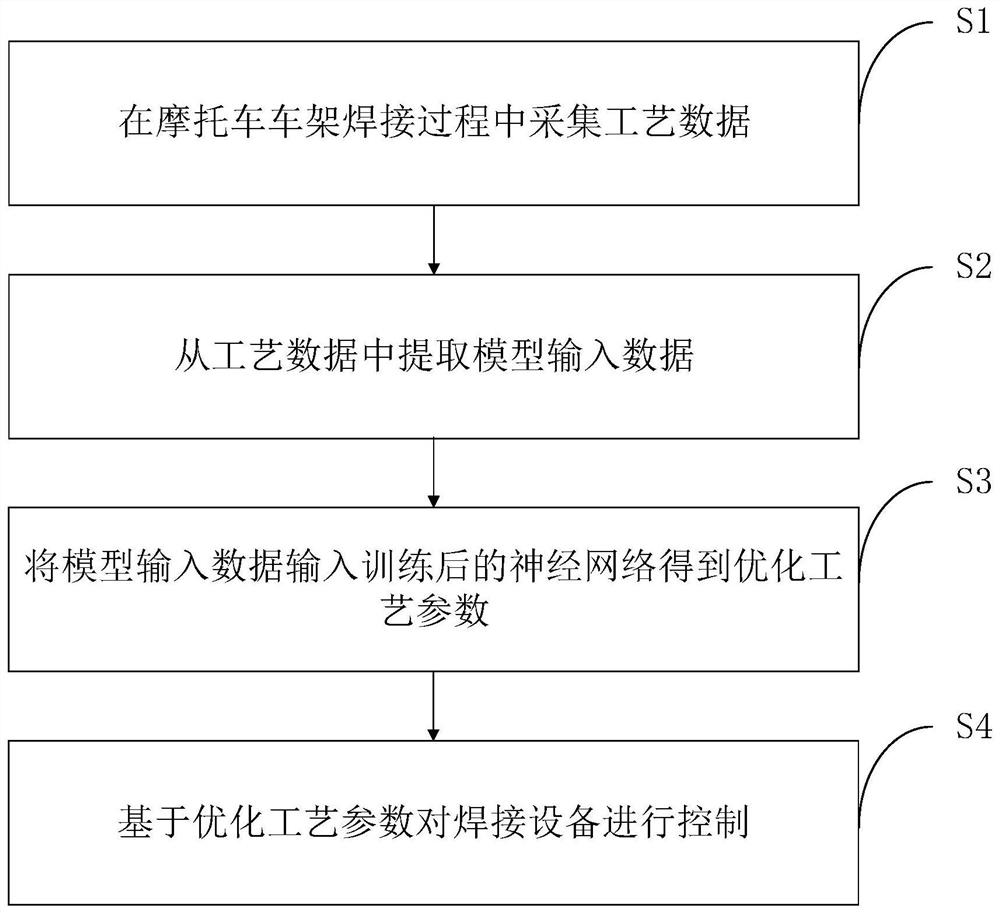

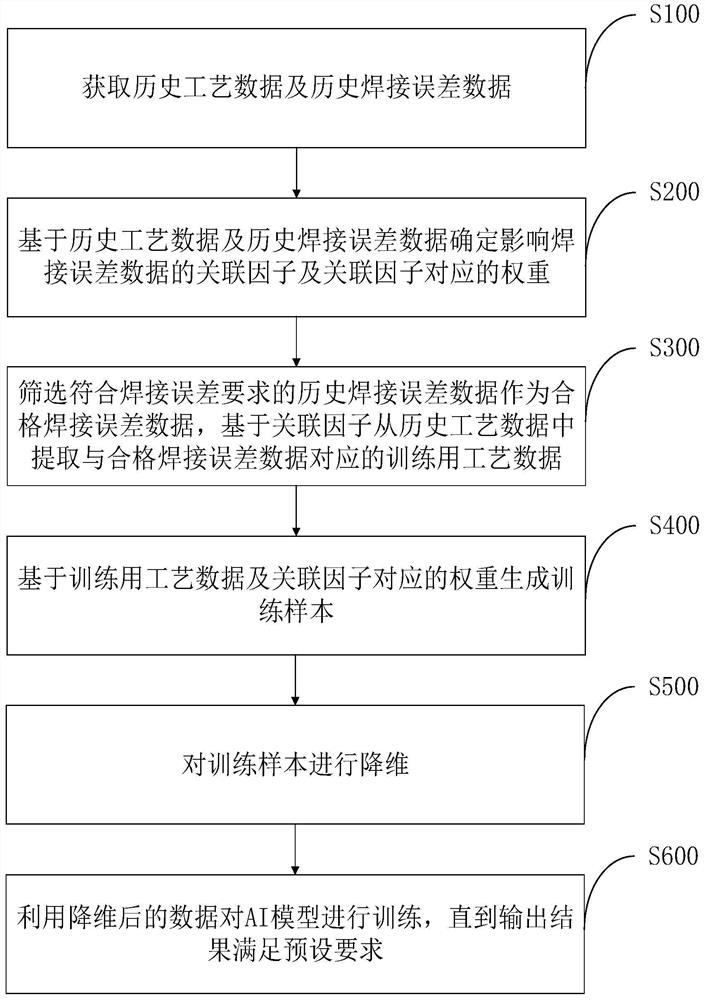

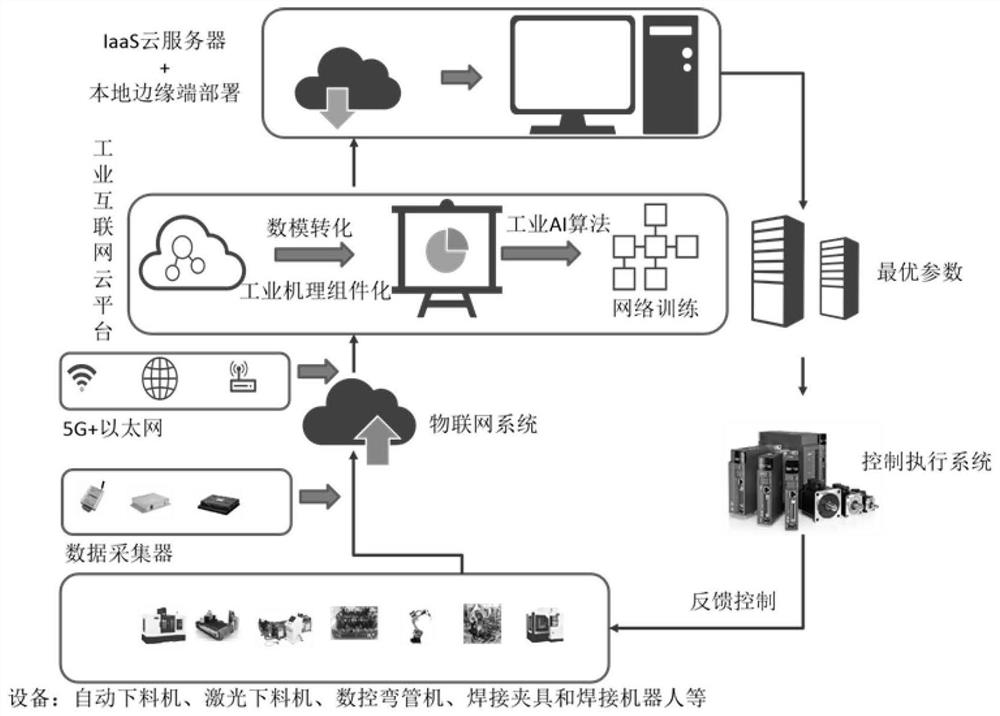

Welding structural part process optimization method and system based on industrial AI technology

InactiveCN112651080ASimple production processReduce welding errorsGeometric CADDesign optimisation/simulationVehicle frameProcess engineering

The invention discloses a welding structural part process optimization method and system based on an industrial AI technology. The method comprises the steps of extracting associated feature data from process data in the motorcycle frame welding process; inputting the associated feature data into the trained AI model to obtain optimized process parameters; and controlling the welding equipment based on the optimized process parameters. According to the invention, the welding process data in the motorcycle frame welding process can be collected and processed, then correlation analysis is conducted on the welding process data and the measured welding error of the welded motorcycle frame, the correlation of the data is found through a model algorithm, and the production process control method for reducing the welding error is found; process data are analyzed through the AI model, feedback control is conducted by optimizing process parameters, the welding quality of the motorcycle frame can be controlled in the manufacturing process, and compared with the prior art, the one-time offline qualification rate of the welded motorcycle frame is increased, the manual correction cost is reduced, the product quality stability is kept, and the product consistency is improved.

Owner:重庆忽米网络科技有限公司

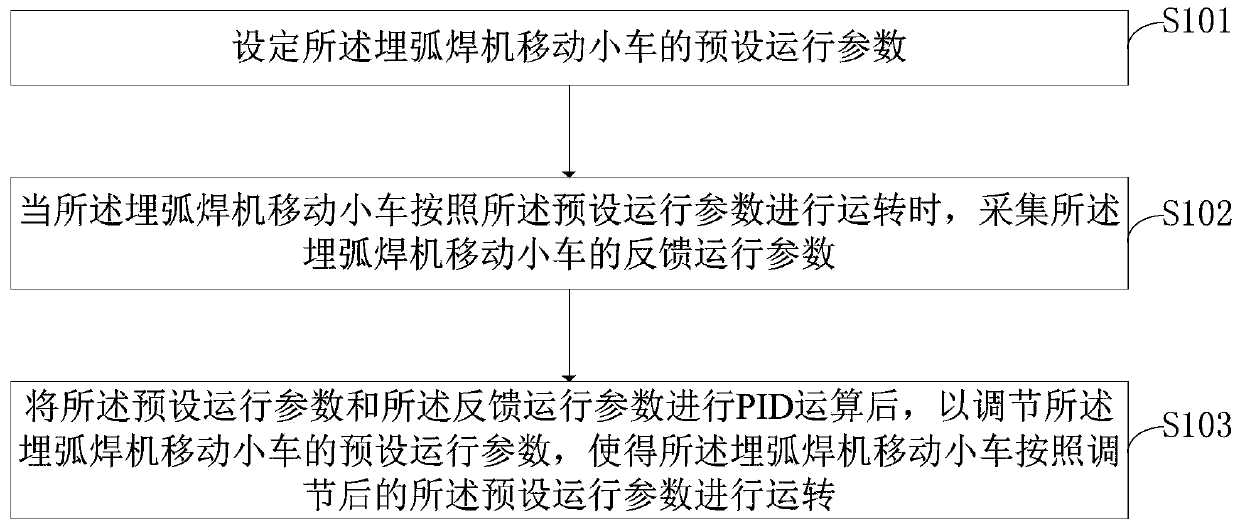

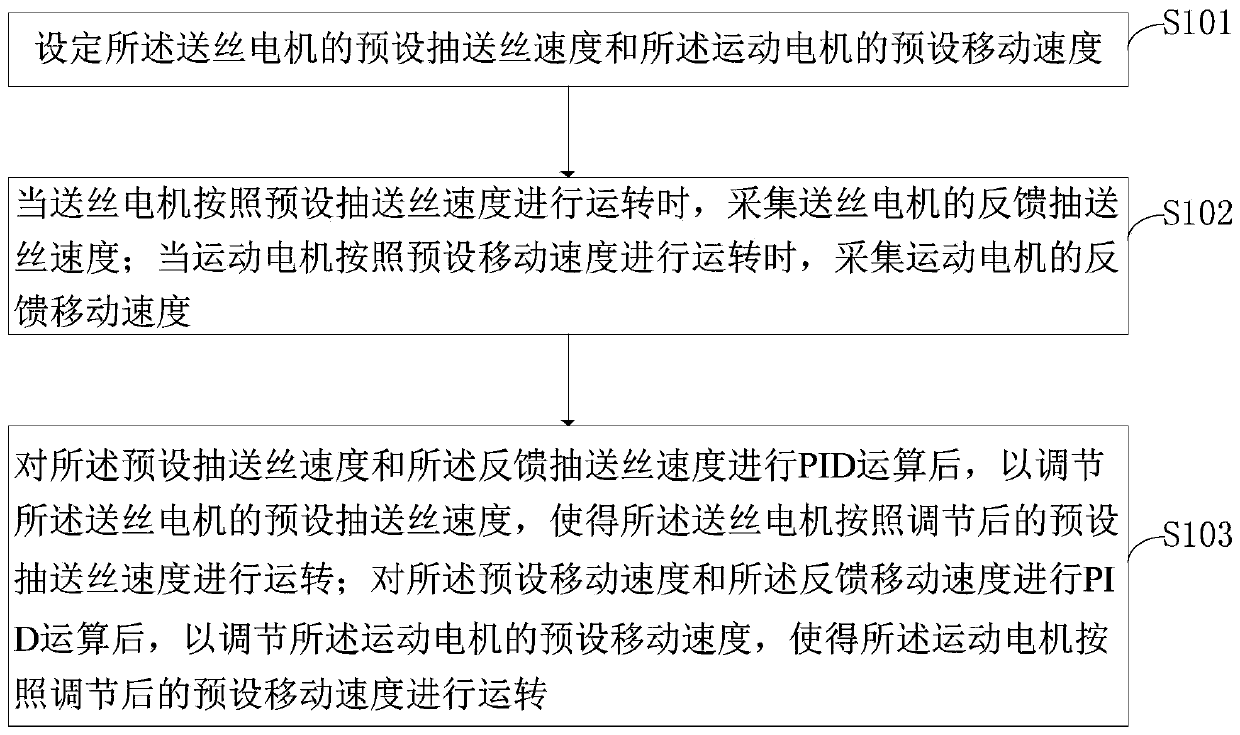

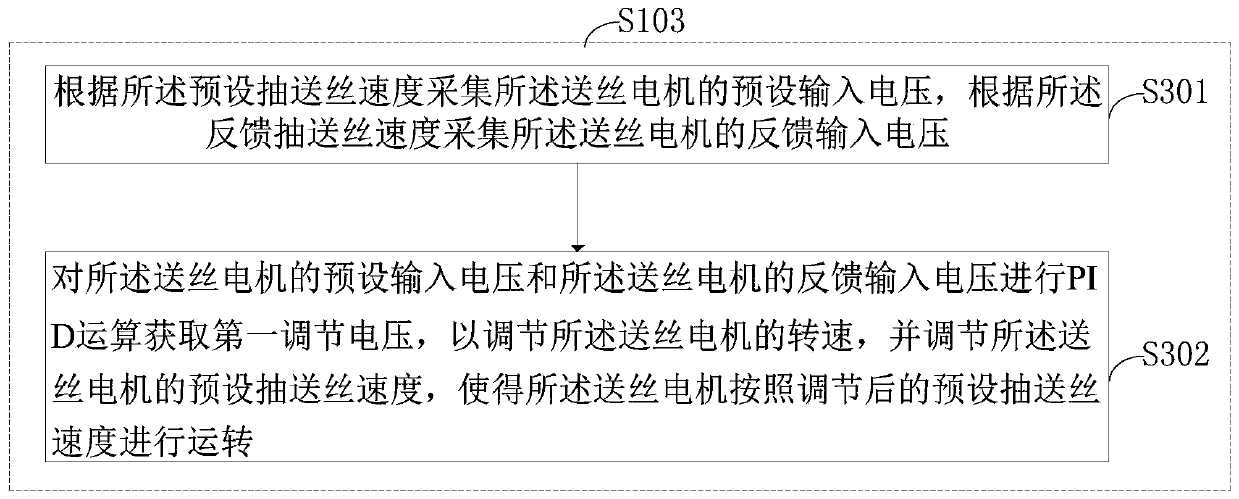

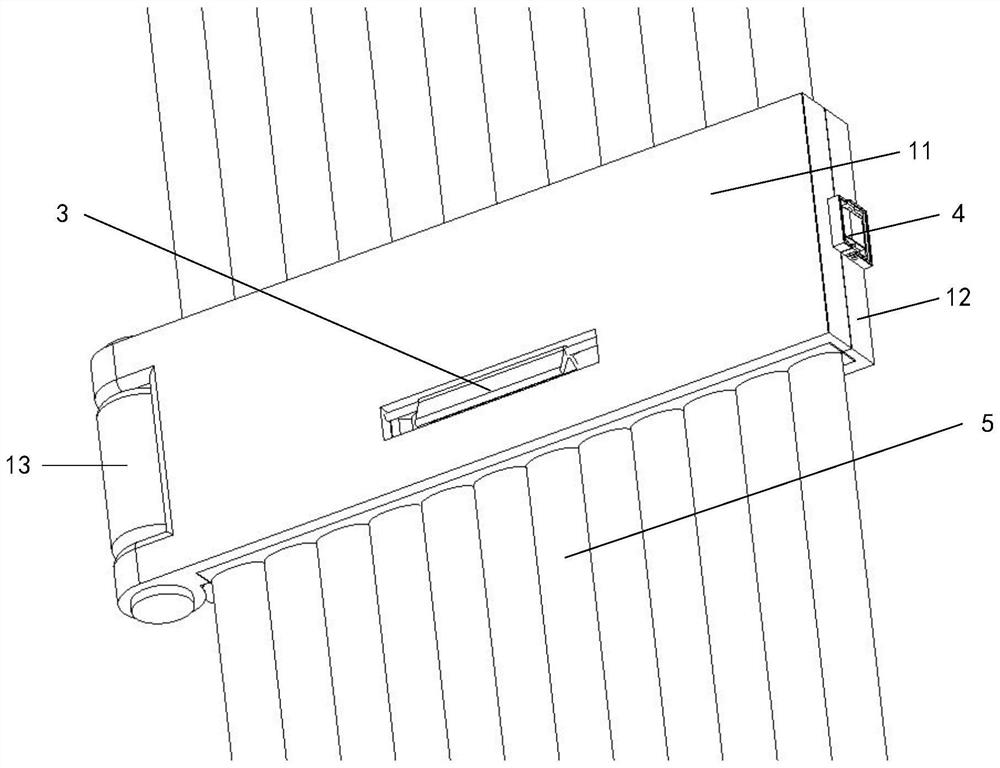

Moving trolley of submerged-arc welding machine and control method and control device of moving trolley

ActiveCN110125517AGuaranteed welding accuracyGuaranteed accuracyWelding accessoriesAutomatic controlTechnician

The invention relates to a control method of a moving trolley of a submerged-arc welding machine, a control device of the moving trolley and the submerged-arc welding machine. The control method comprises the following steps of setting preset operating parameters of a moving trolley of the submerged-arc welding machine, when the moving trolley of the submerged-arc welding machine operates according to the preset operating parameters, collecting feedback operation parameters of the moving trolley of the submerged-arc welding machine, performing PID operation on the preset operation parameters and the feedback operation parameters to adjust the preset operation parameters of the movable trolley of the submerged arc welding machine, so that the moving trolley of the submerged-arc welding machine is operated according to the adjusted preset operating parameters. According to the control method disclosed by the embodiment of the method, automatic PID adjustment can be carried out on the running state of the moving trolley of the submerged-arc welding machine, so that the running state of the submerged arc welding machine moving trolley is matched with the welding speed, the welding precision and the welding quality are improved, the operation state of the submerged-arc welding machine moving trolley has high-precision and automatic control functions, and great convenience is broughtto the operation process of technicians.

Owner:SHENZHEN JASIC TECH

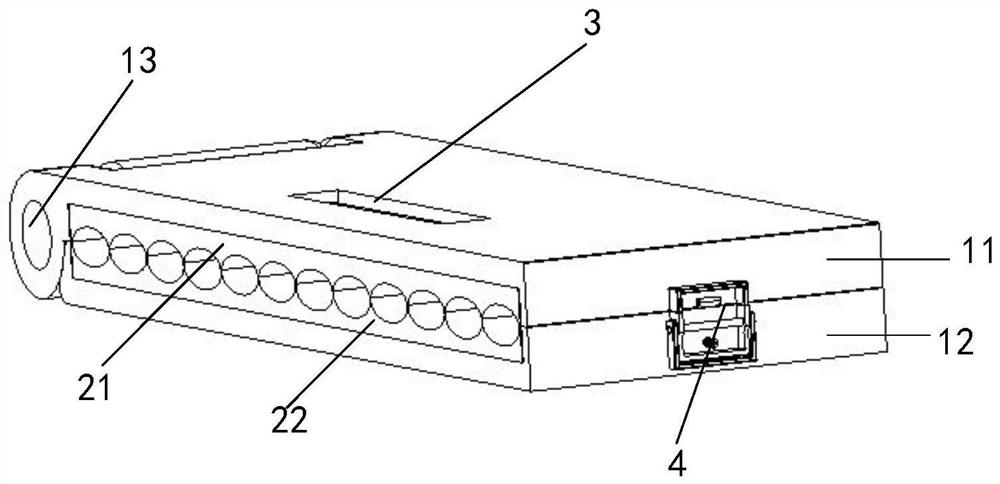

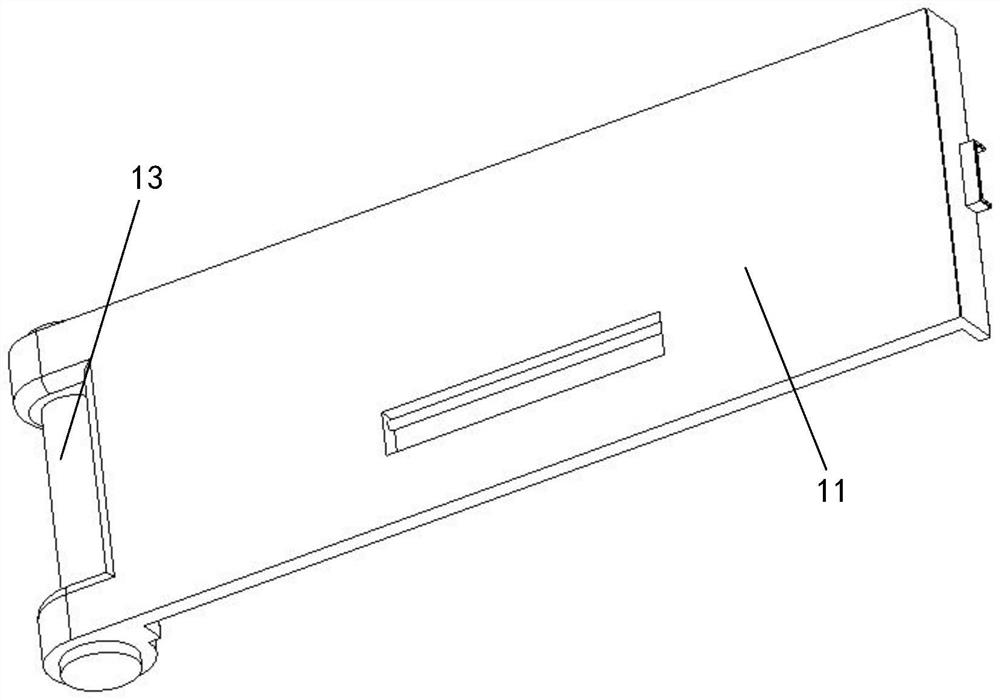

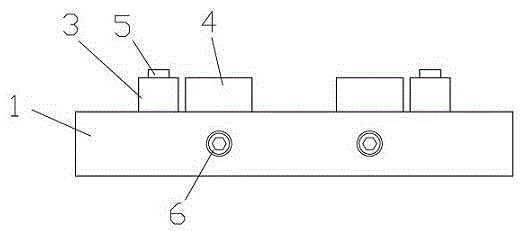

Cable management frame device and cable welding equipment

ActiveCN112202026ASave man hoursImprove work efficiencyLine/current collector detailsIndustrial equipmentCable management

The invention provides a cable management frame device and cable welding equipment, belongs to the technical field of industrial equipment, and solves the technical problem of relatively low efficiency when server cables are welded in the prior art. The device comprises a cable management plate and a locking plate. The locking plate comprises an upper locking plate and a lower locking plate, one sides of the upper locking plate and the lower locking plate are connected through a rotating shaft, and the other sides of the upper locking plate and the lower locking plate are fixed through a locking device; the cable arrangement plate comprises an upper cable arrangement plate and a lower cable arrangement plate, the upper cable arrangement plate and the lower cable arrangement plate are respectively provided with a plurality of grooves, and the grooves of the upper cable arrangement plate and the lower cable arrangement plate are oppositely combined to form a cable groove for accommodating a cable; the cable arranging plate is arranged between the upper locking plate and the lower locking plate, and the upper cable arranging plate and the lower cable arranging plate are respectively fixed with the upper locking plate and the lower locking plate through fixing structures.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

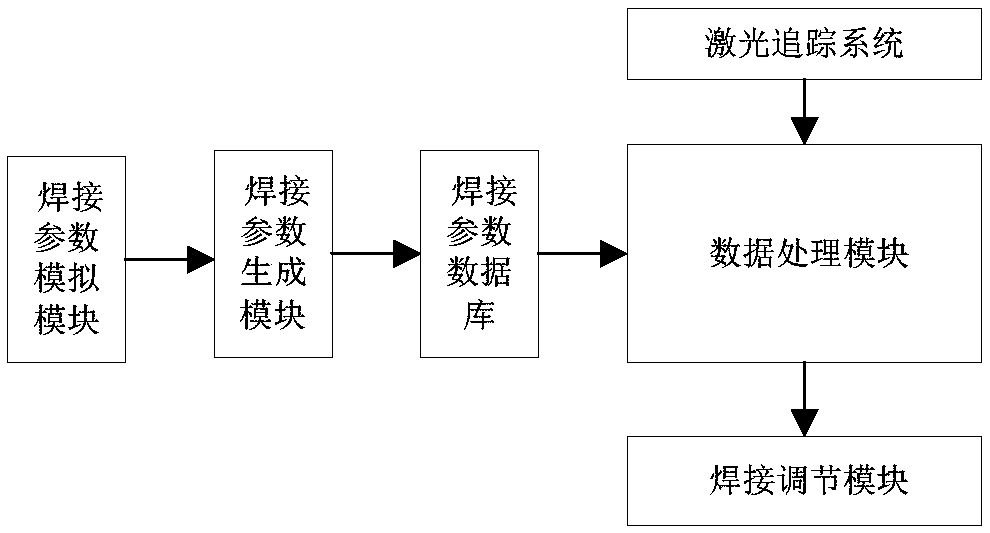

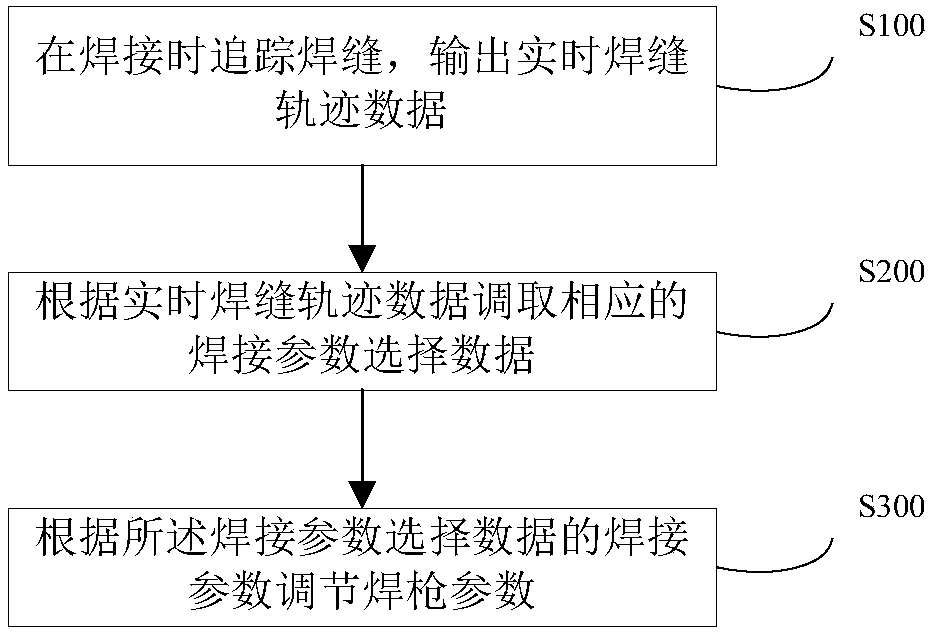

Laser tracking type angle welding system and method for large curved plate

PendingCN108080827AReduce welding errorsLabor savingWelding/cutting auxillary devicesArc welding apparatusData libraryLaser

The invention relates to a laser tracking type angle welding system and method for a large curved plate. The system comprises a laser tracking system, a welding parameter database, a data processing module and a welding adjusting module, wherein the laser tracking system is used for outputting real-time weld joint track data, the welding parameter database is used for storing welding parameter selecting data, the data processing module is used for retrieving corresponding welding parameter selecting data according to the real-time weld joint track data and outputting the corresponding weldingparameter selecting data to the welding adjusting module, and the welding adjusting module is used for adjusting a welding gun according to the welding parameters. The method comprises the steps thata weld joint is tracked in the welding process, and the real-time weld joint track data is output; the corresponding welding parameter selecting data is retrieved according to the real-time weld jointtrack data and is output to the welding adjustment module; the welding gun is adjusted according to the welding parameters of the welding parameter selecting data; and each piece of the welding parameter selecting data comprises a welding parameter part and weld joint track information corresponding to the welding parameter part. The system and method have the beneficial effects that the weldingparameters can be adjusted according to real-time weld joint data in the welding process, and therefore the welding errors can be conveniently reduced.

Owner:WISE WELDING TECH & ENG

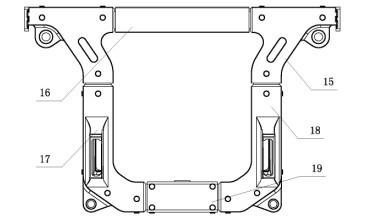

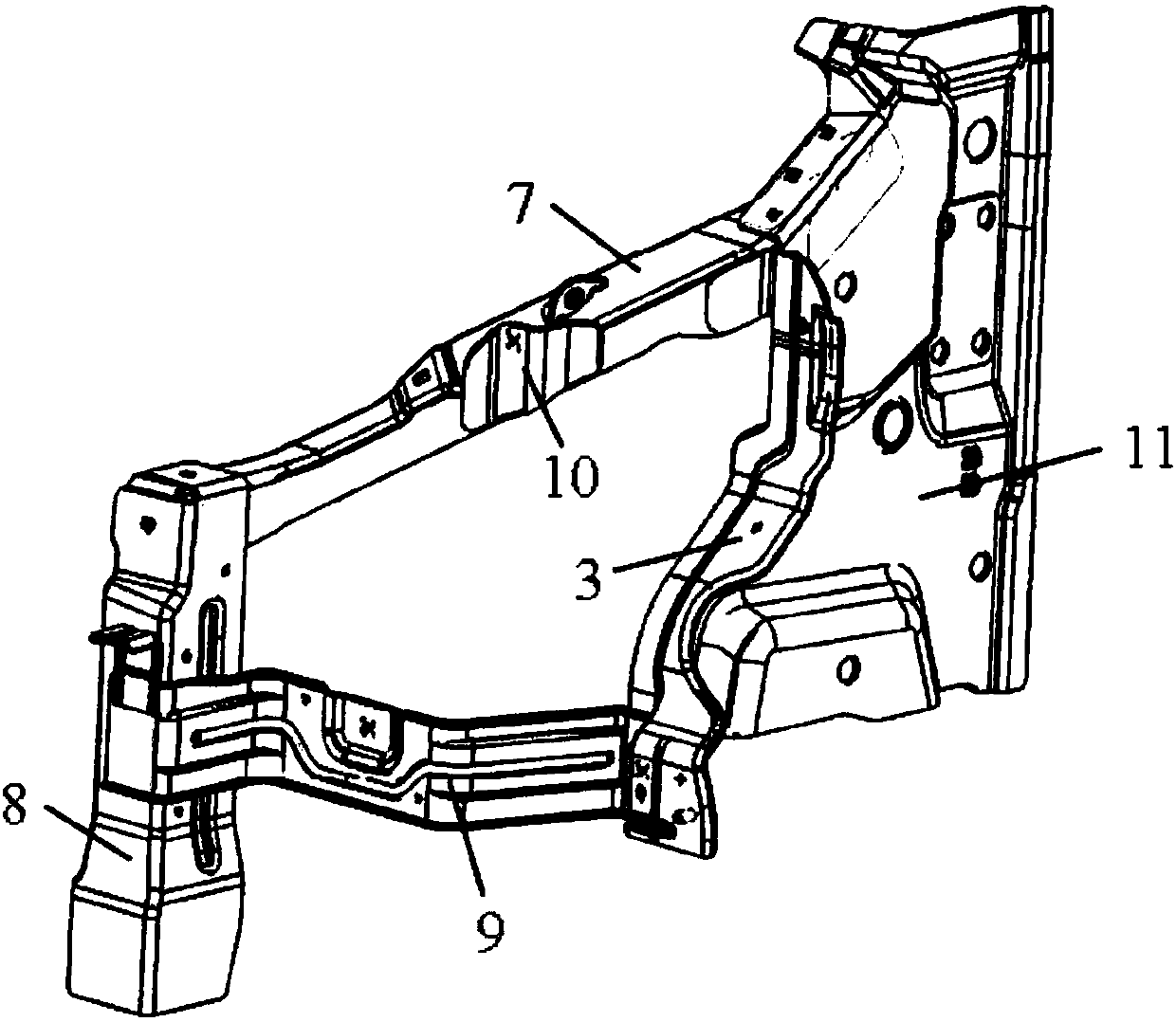

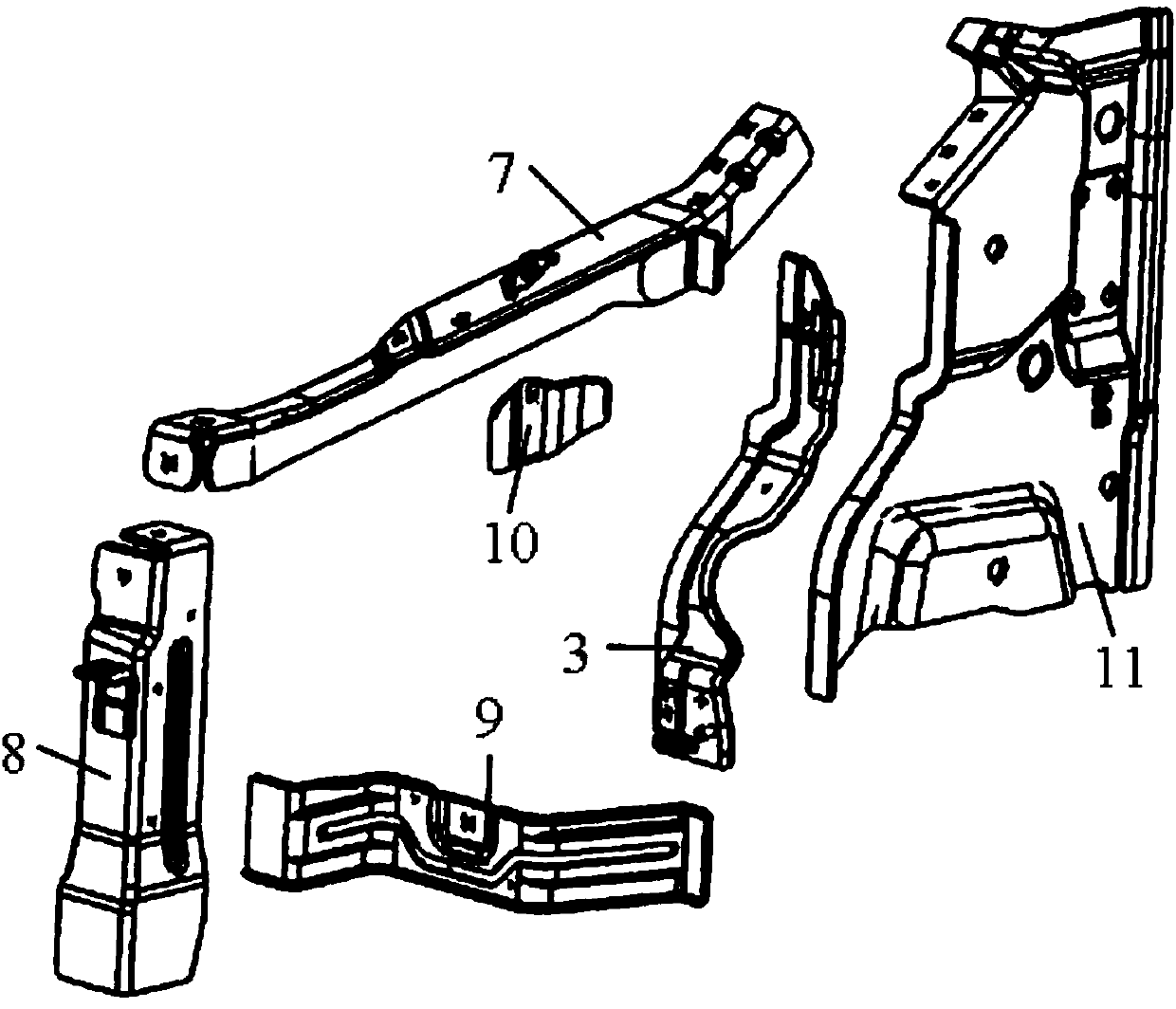

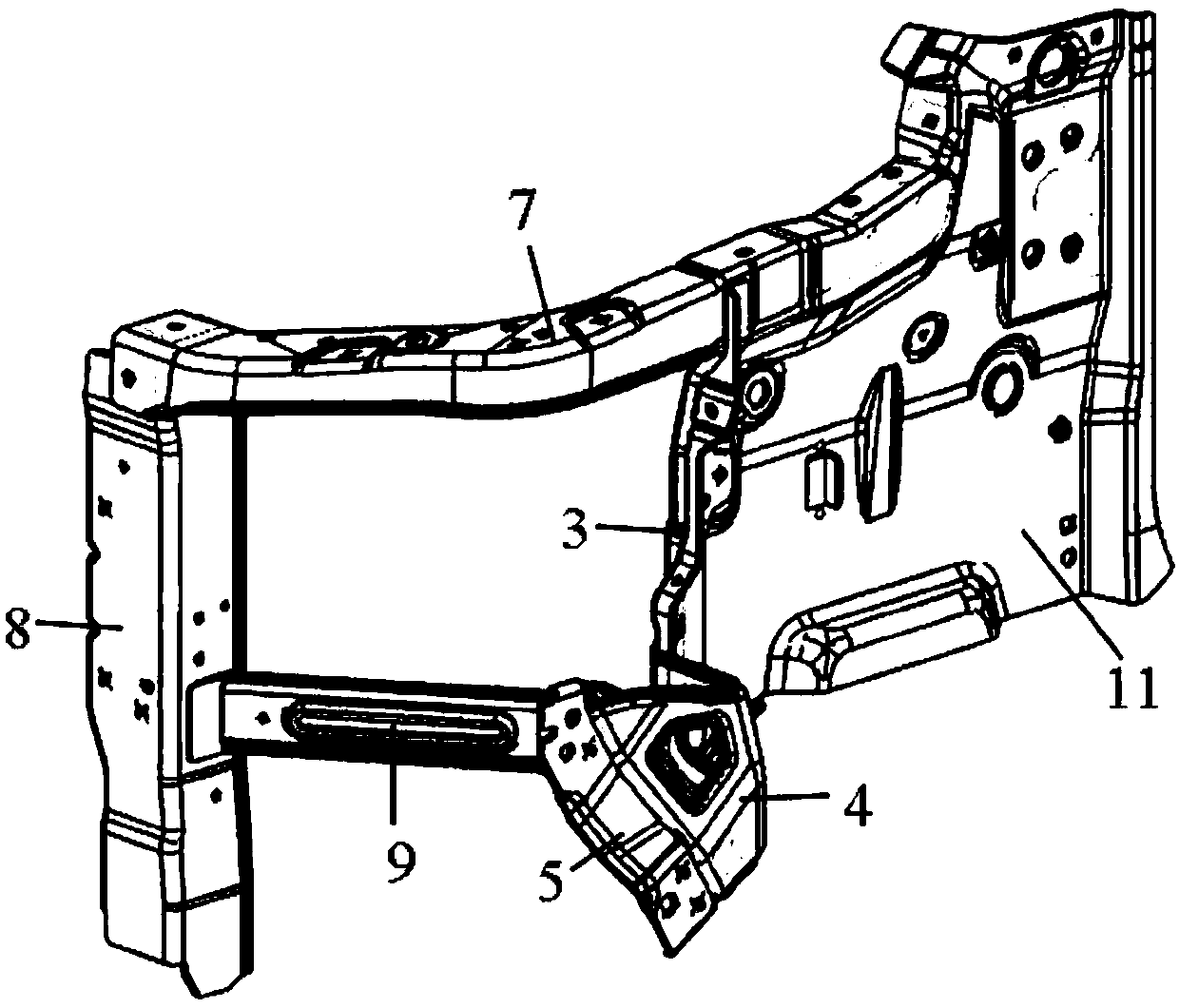

Mounting assembly of headlamp and fender

PendingCN110341581AReduce welding errorsThe installation structure is stableSuperstructure subunitsOptical signallingEngineering management

The invention discloses a mounting assembly of a headlamp and a fender. The mounting assembly comprises a front connecting plate, a headlamp mounting beam assembly, a fender mounting reinforcing plateand a fender mounting bracket; the front connecting plate is fixedly arranged on a front plate, the headlamp mounting beam assembly is fixedly connected with the front connecting plate, the fender mounting reinforcing plate is fixedly connected with the lower portion of the front connecting plate, the fender mounting bracket fixed on the fender mounting reinforcing plate in a position adjustablemode, a headlamp is respectively fixedly connected with the headlamp mounting beam assembly, the front connecting plate and the fender mounting bracket, and a fender body is fixedly connected with theheadlamp mounting beam assembly and the fender mounting bracket respectively. According to the mounting assembly of the front headlamp and the fender in the invention, the segment gap clearance between the fender body and the headlamp can be effectively controlled and quickly adjusted.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

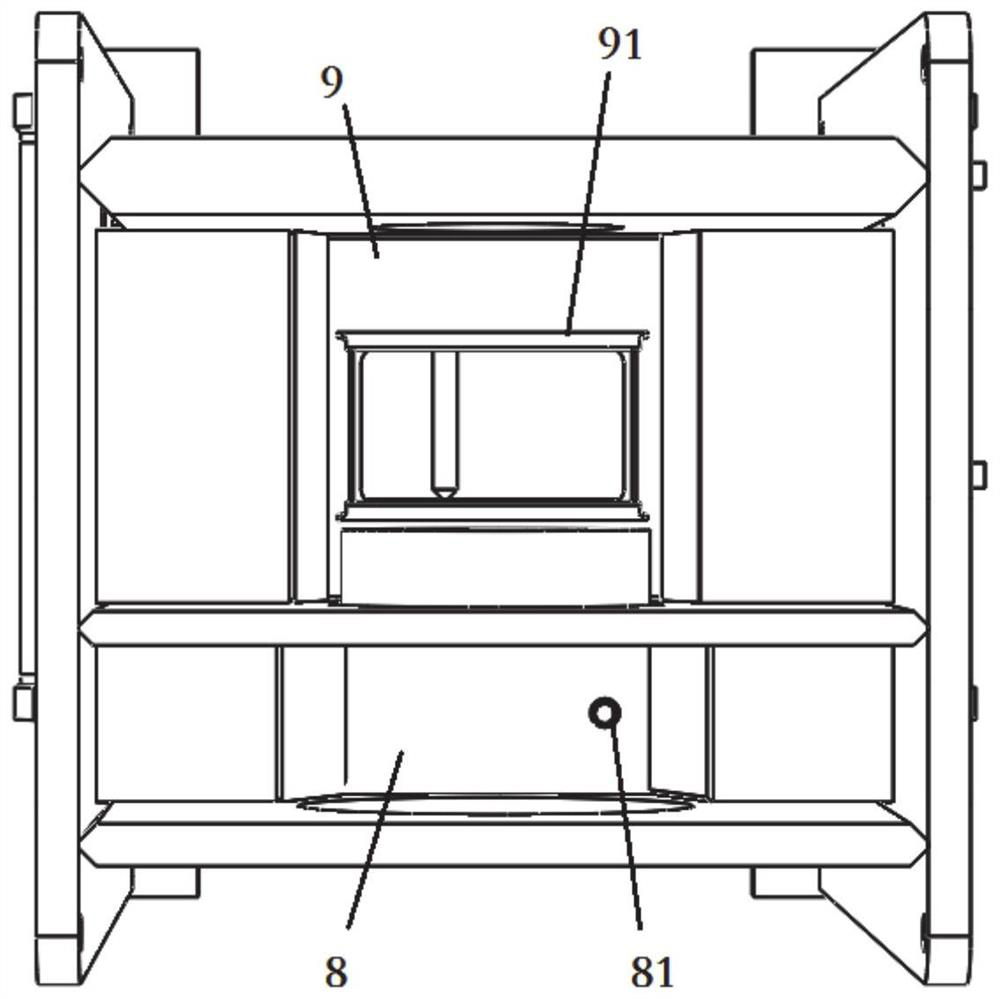

Short pipe flange welding device

InactiveCN110977253AGuaranteed uniformitySave high input costWelding/cutting auxillary devicesAuxillary welding devicesWeld seamSkelp

The invention relates to the welding device technology field, and discloses a short pipe flange welding device. The device comprises a fixing mechanism and a welding mechanism. A flange to be welded is fixed to a rotary disc through the fixing mechanism, the rotary disc drives the flange on the rotary disc to rotate, the welding mechanism welds the rotated flange, and uniformity of flange weld seams is guaranteed. A position of a welding head is changed by adjusting the positions of a Z-direction sliding frame and an X-direction sliding frame so that the positions of flange welding seams can be optimally matched, welding errors are reduced, and welding quality is guaranteed. By using the short pipe flange welding device, simple automatic welding is achieved through an existing semi-automatic welding auxiliary device, high investment cost of intelligent and automatic welding equipment is saved, investments of low-technology welding tasks on manpower and financial resources are reduced,construction cost can be reduced, and economic practicability is high.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Manufacturing process of cantilever type steel box girder

ActiveCN112496590AReduce internal stressReduce welding errorsInternal combustion piston enginesWelding/cutting auxillary devicesButt jointCantilever

The invention relates to a manufacturing process of a cantilever type steel box girder. In the manufacturing process, cantilevers and cross ribs which are alternately arranged are spliced firstly, during welding, the joint positions of the cross ribs and the cantilevers are welded firstly, and errors generated by alternate welding are reduced while the strength is guaranteed; and in addition, perpendicularity of the cross ribs is guaranteed by welding the butt joint positions of the cross ribs and a bottom plate, finally, the structures of the cantilevers and the bottom plate are welded, and therefore the internal stress of the cantilevers can be reduced, and the welding errors of cantilever welding are reduced.

Owner:JIANGSU JINGHU HEAVY IND +1

Butt welding machine for steel structure engineering

InactiveCN110449713APrecision weldingQuality improvementResistance electrode holdersWelding/cutting auxillary devicesButt weldingFixed frame

The invention discloses a butt welding machine for steel structure engineering. The butt welding machine comprises a butt welding machine body, wherein the butt welding machine body comprises a butt welding box, fixing plates are arranged at the top of the butt welding box, an extrusion outer rod is arranged on one side of each fixing plate, an extrusion cavity is formed in each extrusion outer rod, and an extrusion inner rod is arranged in each extrusion cavity; a sliding table is arranged on one side of each extrusion inner rod, a fixing frame is arranged at the top of each sliding table, alifting frame is arranged on each fixing frame, and a pressing block and a rotating shaft are arranged on each lifting frame; and lifting outer rods are arranged on the top of the butt welding box, alifting cavity is formed in each lifting outer rod, a lifting inner rod is arranged in each lifting cavity, each lifting inner rod is connected to the corresponding lifting frame through the corresponding rotating shaft, and a conductive table is arranged on each sliding table. The butt welding machine for steel structure engineering has the advantages of being reasonable in design, high in practicability, convenient to use and suitable for popularization.

Owner:邹雅莉

Rapid forming precision mold manufacturing welding device

PendingCN112719581ARealize the collectionEasy to replaceLaser beam welding apparatusCircular discMachining

The invention discloses a rapid forming precision mold manufacturing welding device, and particularly relates to the technical field of mold machining. The rapid forming precision mold manufacturing welding device comprises supporting legs and a base, and the four sets of supporting legs are fixedly connected to the four corners of the bottom end of the base. By arranging a disc, grooves, a limiting block and a limiting rod, a mold needs to be welded in multiple directions in the mold welding process, it is troublesome to directly move the die, the disc fixed to the top end of the base, a rotating shaft at the top end of the disc and a workbench are fixedly connected, and the clamped mold does not need to be rotated; the limiting rod hinged to the bottom end of the limiting block is taken out of one groove of the disc, then the workbench is rotated to enable the mold to rotate to a proper position, and then the limiting rod is placed into the corresponding groove in the disc so that the workbench can be limited, and welding machining is prevented from being affected by rotation of the workbench; and in this way, welding machining can be conducted on the mold in multiple directions without moving the mold, and the machining efficiency is improved.

Owner:林海生

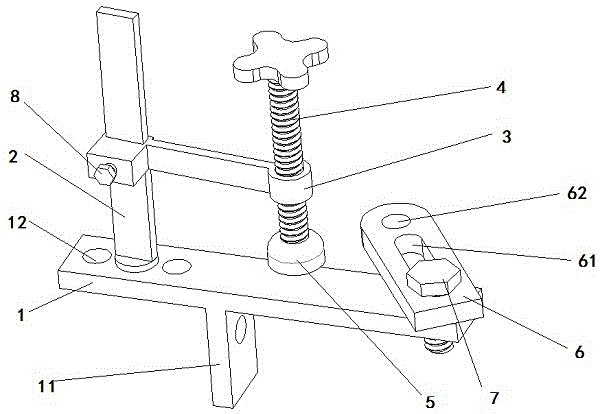

Welding clamp for heavy truck bumper assembly

InactiveCN105033552ASimple structureReduce welding errorsWelding/cutting auxillary devicesAuxillary welding devicesTruckEngineering

The invention relates to a welding clamp for a heavy truck bumper assembly. The welding clamp comprises a base, a supporting frame, a sliding rod, an adjustment threaded rod, a threaded disc, a rotating plate, a bolt and an adjusting screw. The base is fixed to the upper portion of a welding working table. A boss is connected below the base and fixed to the lateral side of the welding working table. A plurality of positioning holes are formed in the upper portion of the base. The supporting frame is arranged in the positioning hole in the left side of the base. The sliding rod capable of vertically sliding is arranged on the supporting frame, and the specific position of the sliding rod is adjusted through the adjusting screw. The adjusting threaded rod vertically penetrating the sliding rod is arranged at the other end of the sliding rod. The threaded disc is connected to the lower portion of the adjusting threaded rod. The rotating plate is arranged in the positioning hole in the right side of the base. A sliding groove is formed in the rotating plate. The bolt penetrates the sliding groove and the positioning hole below the sliding groove. The bottom end of the bolt is fixed into a threaded hole in the welding working table. A fixing hole is formed in the other end of the rotating plate. The welding clamp is simple in structure, and welding errors are reduced; and the welding clamp is suitable for welding various heavy truck bumper assemblies, light in weight and convenient to use, and has the high universality; and the production efficiency is greatly improved.

Owner:HEFEI CHANGQING MACHINERY

C-shaped lifting appliance with locking function

ActiveCN110436334ABig spaceReduce the amount of weldingLoad-engaging elementsElectricityWear resistant

The invention provides a C-shaped lifting appliance with a locking function. The C-shaped lifting appliance is characterized by comprising an upper frame, a lower frame, suspension arms and a lockingdevice; and the upper frame is connected to the suspension arms through bolts, the upper frame is connected to a trolley unit through a hanging shaft, and the middle of the upper frame is ensured to be insulated through a polytetrafluoroethylene spacer bush. The upper frame is provided with an electrifying device, and electricity is conducted through conductive copper plates on the outer side of aelectrophoresis station. The suspension arms are formed by welding tubes and plates, the suspension arms are formed by hot bending once by adopting steel tubes, are connected to the upper frame and the lower frame through bolts up and down, and the welding error is reduced while the welding amount is reduced. Special tool clamps are used for manufacturing the suspension arms, and the machining error of the suspension arms is within 2 mm. The lower frame is connected to the suspension arms through bolts, and the middle of the lower frame is ensured to be wear-resistant and corrosion-resistantthrough a polytetrafluoroethylene spacer bush. The locking device is arranged below the lifting appliance, and the locking device is used for automatically clamping parts which are hoisted and moved by the lifting appliance, so that the purpose of automatic production is achieved, and the purpose of improving the production efficiency is achieved.

Owner:江苏长虹机械设计院有限公司 +1

Device for welding pothook

ActiveCN106514108AGuaranteed accuracyImprove assembly efficiencyWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention discloses a device for welding a pothook. The pothook comprises a pothook cover and a hanging ring arranged on the pothook cover; the device for welding the pothook comprises a fixed plate; the pothook cover is arranged laterally; a central axis of the pothook cover in the direction from the top part to the bottom face is parallel to the fixed plate; and a first supporting mechanism for supporting the pothook, a first clamping mechanism for clamping the hanging ring, a second clamping mechanism for clamping the side face of the pothook cover, and a second supporting mechanism for pressing against the bottom face of the pothook cover are arranged on the fixed plate. The device for welding the pothook provided by the invention has the advantages that the structure of the device is simple; the device can be used for clamping and positioning the pothook, so that the phenomena of loosening and moving cannot occur easily; the device is convenient to operate; the accuracy in welding is effectively ensured; the welding assembly efficiency is improved; the welding error is reduced; and the welding quality of products is improved.

Owner:景和智能制造(广东)有限公司

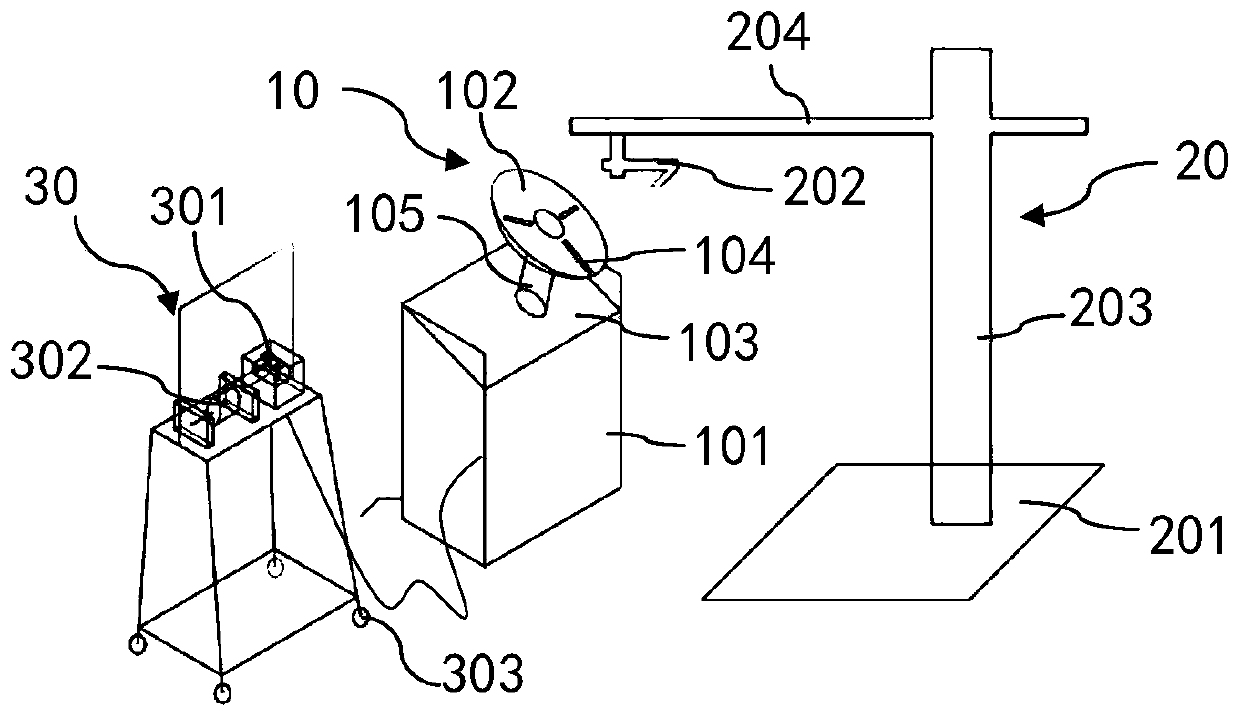

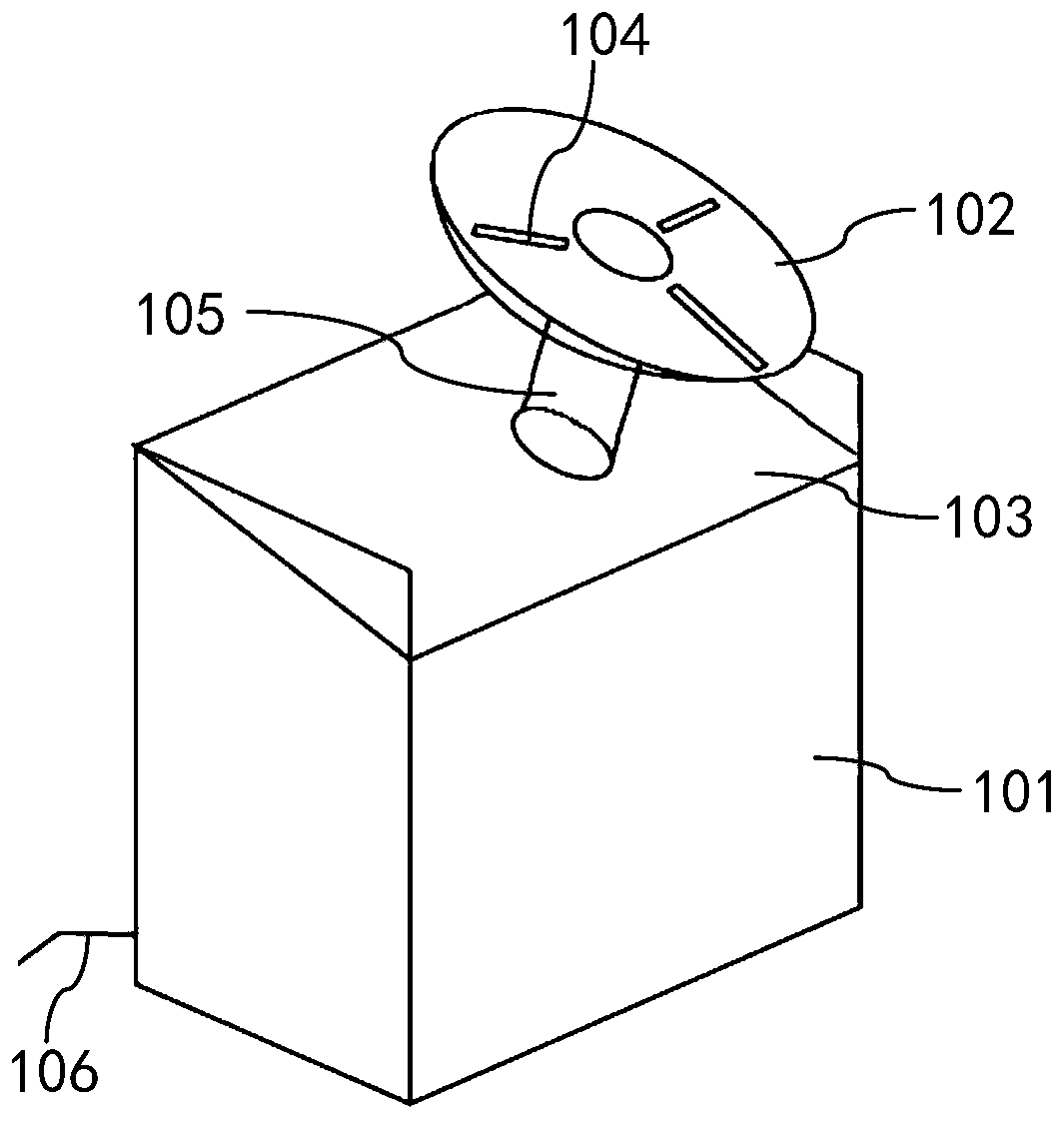

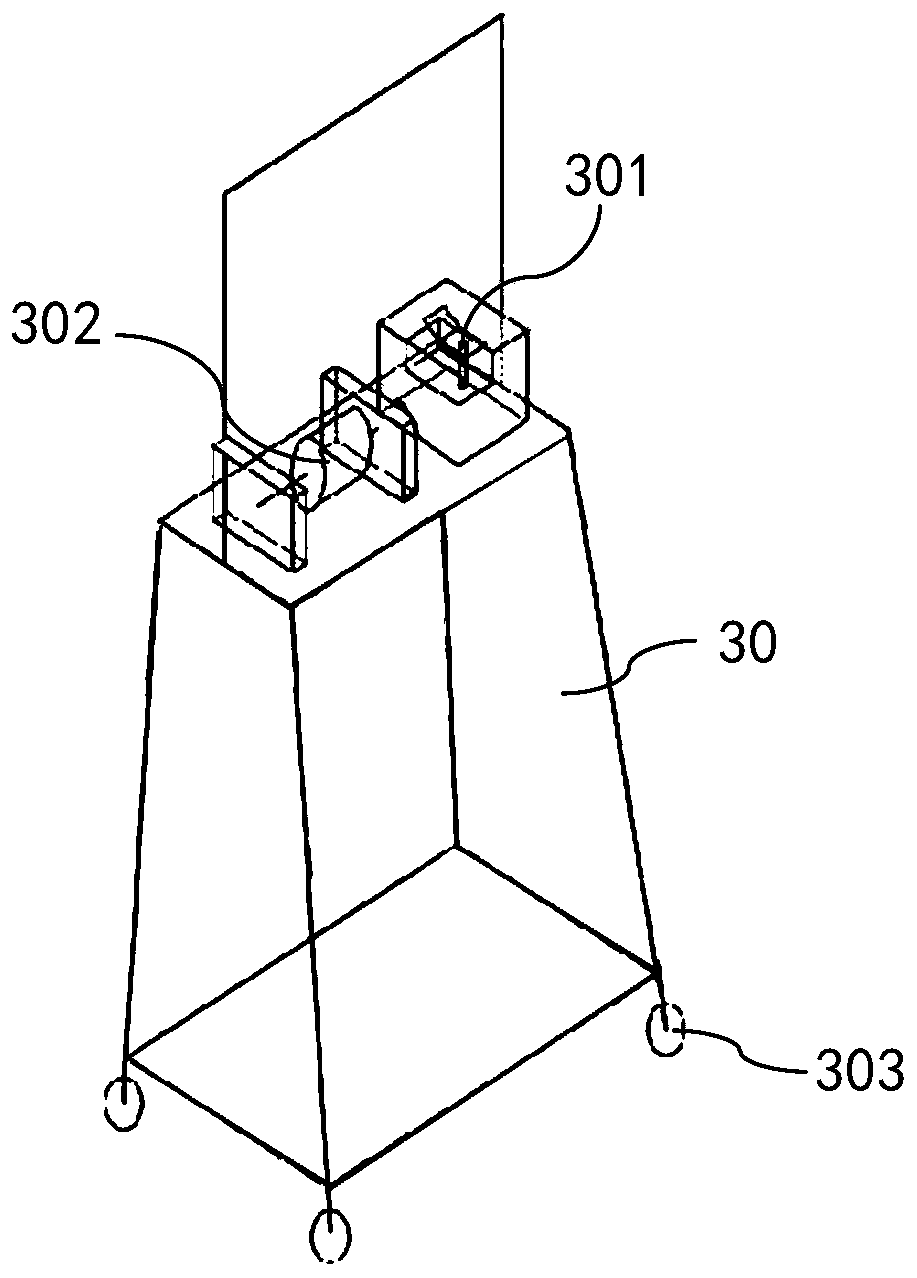

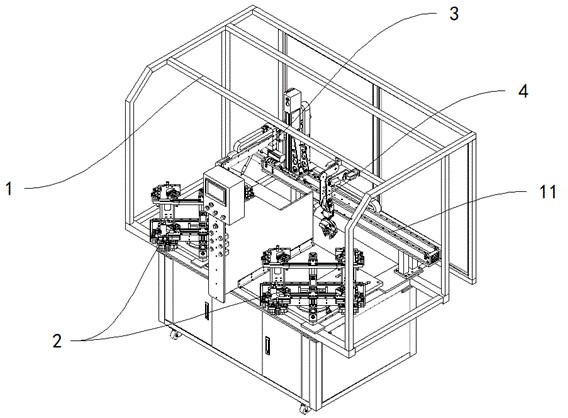

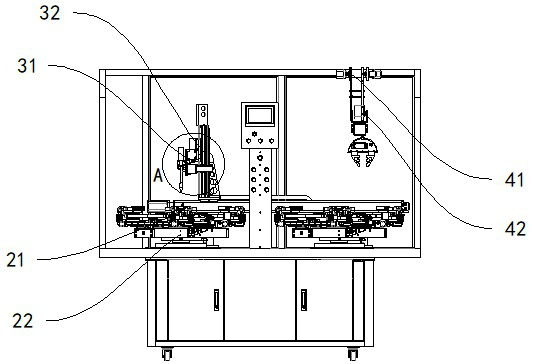

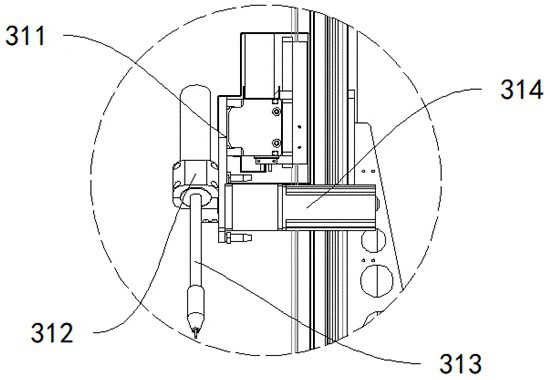

Welding equipment

ActiveCN113369782AAchieve rotationEasy to installWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention relates to the technical field of machining, in particular to welding equipment. The welding equipment comprises a workbench, a clamping mechanism, a welding mechanism and a moving mechanism. A first guide rail is arranged on the workbench; the clamping mechanism comprises a mounting seat and a clamping device mounted on the mounting seat; the mounting seat is mounted on the workbench, the clamping device can rotate relative to the mounting seat, and the clamping device is used for clamping a profile; the welding mechanism comprises a connecting assembly, and a welding assembly slidably connected with the connecting assembly; the connecting assembly is installed on the first guide rail and can slide relative to the first guide rail; the welding assembly is located above the clamping device and used for welding the profile; and the moving mechanism is located above the clamping mechanism and used for conveying the profile to the clamping mechanism. The problem that traditional welding equipment is low in welding efficiency is solved, and the welding equipment has the advantages of being capable of rapidly fixing profiles and high in automation degree.

Owner:佛山市腾翱科技有限公司

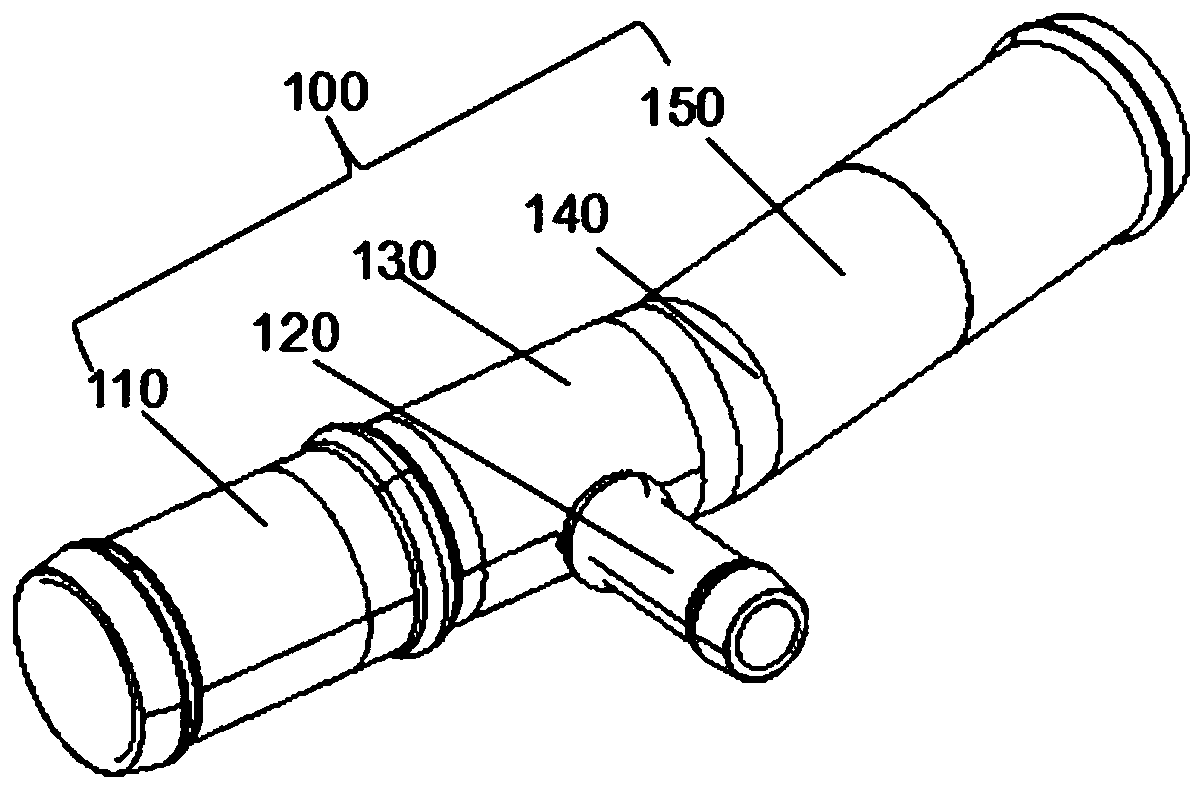

Welding device for water temperature sensor production

InactiveCN109226999AEasy to useEasy to observeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWater temperature

The invention discloses a welding device for water temperature sensor production. The welding device comprises a base plate, installing lugs, a vertical plate and a transverse plate; the installing lugs are arranged at the two sides of the base, the base and the installing lugs are welded, the vertical plate is arranged above the base plate, the vertical plate and the base plate are welded, a vertical sliding groove is formed in the vertical plate, a first electric sliding block is arranged inside the vertical sliding groove, a transverse plate is arranged at the front portion of the verticalplate, a horizontal sliding groove is formed in the transverse plate, and a second electric sliding block is arranged inside the horizontal sliding groove. The welding device is stable in structure and convenient to use, a movable base can drive a magnifying lens for moving transversely, the angle of the magnifying lens is adjustable, observation of operators in the welding process is facilitated,the welding error is lowered, the welding quality is improved, and by arranging a sliding workbench and a movable workbench, the operator can use the device more conveniently.

Owner:WUHU UNION AUTOMATION EQUIP CO LTD

Welding and carrying integrated welding gun device

PendingCN111660041AThe solution is not easy to fixFixed state stableWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding process

The invention discloses a welding and carrying integrated welding gun device. The welding and carrying integrated welding gun device comprises double transverse frames, grabbing parts, a welding gun,a first positioning assembly and a second positioning assembly; the double transverse frames are fixedly connected through a reinforcer, and the grabbing parts are arranged at the tail ends of the double transverse frames and comprise corner air cylinders and clamping parts; the corner air cylinders are fixedly mounted at the tail ends of the double transverse frames and used for driving the clamping parts to be occluded or separated; the welding gun is fixedly mounted above the double transverse frames or the reinforce; and the first positioning assembly and the second positioning assembly are used for determining positions of parts in advance. Through the positioning and fixing modes of stillness and motion of the left side and the right side in two different directions and the combination of clamping positioning of the two clamping parts of the grabbing parts for the parts, four points on each part are positioned and fixed, thus the fixed state of the parts is very stable, executionof a later welding process is facilitated, the welding error is reduced, and the welding quality of the part welding process is improved.

Owner:HUNAN YUANCHUANG MACHINERY

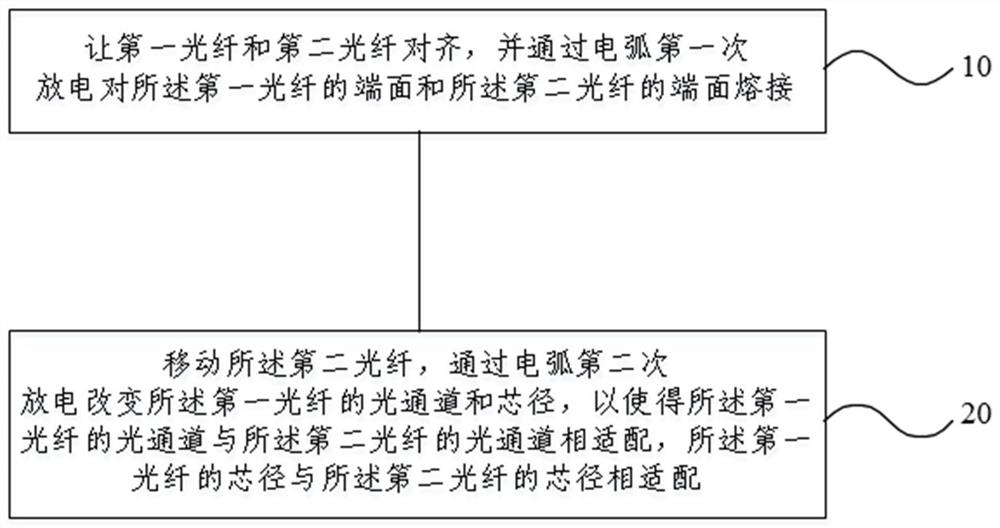

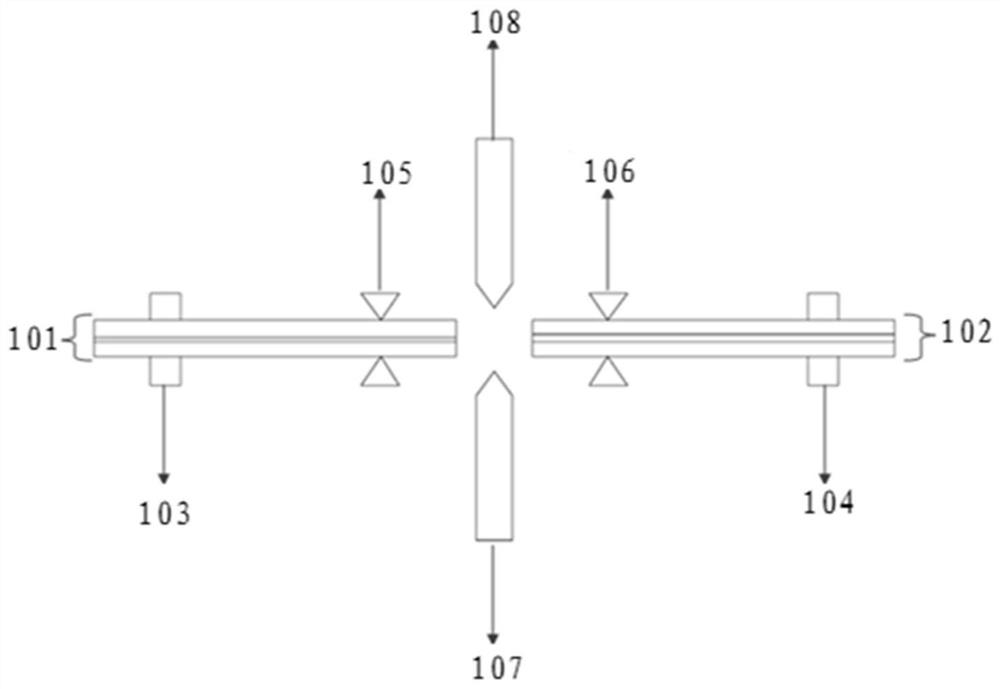

Optical fiber welding method

PendingCN112612081AReduce the temperatureLower temperature riseCoupling light guidesFusion splicingMaterials science

The invention provides an optical fiber welding method, which comprises the following steps of: aligning a first optical fiber and a second optical fiber, and welding the end surface of the first optical fiber and the end surface of the second optical fiber through arc first discharge; and moving the second optical fiber, and changing the optical channel and the core diameter of the first optical fiber through electric arc secondary discharging, so that the optical channel of the first optical fiber is matched with the optical channel of the second optical fiber, and the core diameter of the first optical fiber is matched with the core diameter of the second optical fiber. According to the optical fiber fusion splicing method provided by the invention, accompanying discharge is added, that is, after fusion splicing is completed, a section of optical fiber of the fiber core with a small size is discharged again through the optical fiber fusion splicing system, the core diameter of the fiber core is properly enlarged, and the optical channel of pump light is widened, so that the fiber core can be better matched with the fiber core with a large fusion splicing size; and therefore, the effect of reducing the welding error is achieved, and the problem of high light temperature of the missing cladding caused by welding deviation is reduced.

Owner:无锡锐科光纤激光技术有限责任公司

Welding device for special-shaped elbow

ActiveCN106514106BGuaranteed accuracyEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Owner:景和智能制造(广东)有限公司

Anti-sputtering device for electron beam welding

InactiveCN114871555AImprove work efficiencyLow costWelding/cutting auxillary devicesAuxillary welding devicesRotational axisGear wheel

The invention relates to the field of electron beam welding, in particular to an electron beam welding anti-sputtering device. An electron beam welding anti-sputtering device comprises an anti-sputtering baffle, an expansion piece, a supporting table, a clutch hub, a sun gear and a combination part. The sun gear is a sun gear of a planetary gear mechanism, a joint surface of a clutch hub and a joint surface of the sun gear form a joint part, and the sun gear forms a welding part of electron beam EB work welding, and is formed into a circular ring shape surrounding a rotating shaft X at a predetermined interval when viewed from the direction of the rotating shaft X. The anti-splashing device solves the problems that splashing generated during welding cannot be completely prevented, deviation is still generated during welding of a clutch hub and a sun gear, and meanwhile splashing still exists.

Owner:哈尔滨冠东工业设计有限责任公司

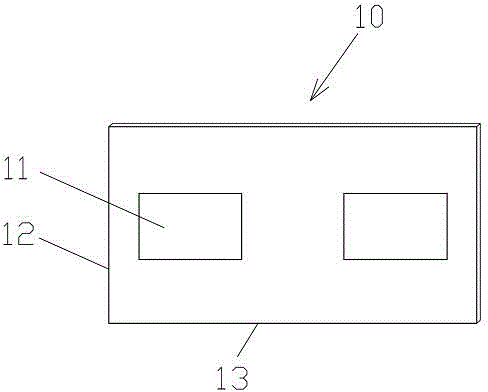

Welding fixture for reinforcing ribs of knee guard bar

InactiveCN103252604BReduce welding errorsLow costWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringGuar

The invention discloses a welding fixture for reinforcing ribs of a knee guard bar. The welding fixture comprises a base. Two grooves are formed in the upper surface of the base, wherein the two grooves correspond to through holes of the reinforcing ribs of the knee guar bar respectively. A first direction positioning block and second direction positioning blocks are arranged inside each groove, the first direction positioning blocks which are arranged in the two grooves respectively are locked through locking bolts and are used for positioning the reinforcing ribs of the knee guard bar in the first direction, at least two second direction positioning blocks are arranged in each groove, and the second direction positioning blocks which are arranged in the two grooves respectively are locked through locking bolts and are used for positioning the reinforcing ribs of the knee guard bar in the second direction. The welding fixture for the reinforcing ribs of the knee guard bar has the advantages that welding error is small when through holes are used for positioning, further, the locating reference can be adjusted so that the reference can be adjusted effectively after the reference is worn, and cost is reduced.

Owner:奇昊汽车系统(苏州)有限公司

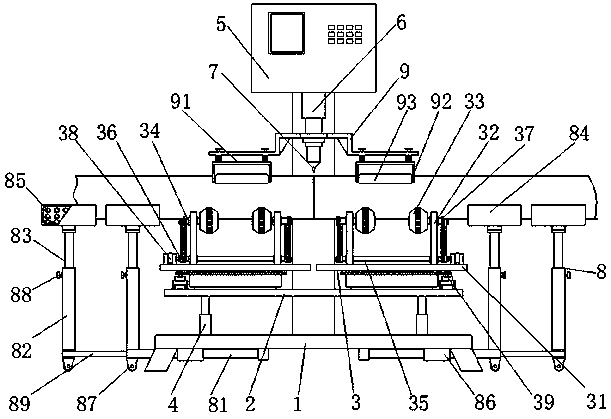

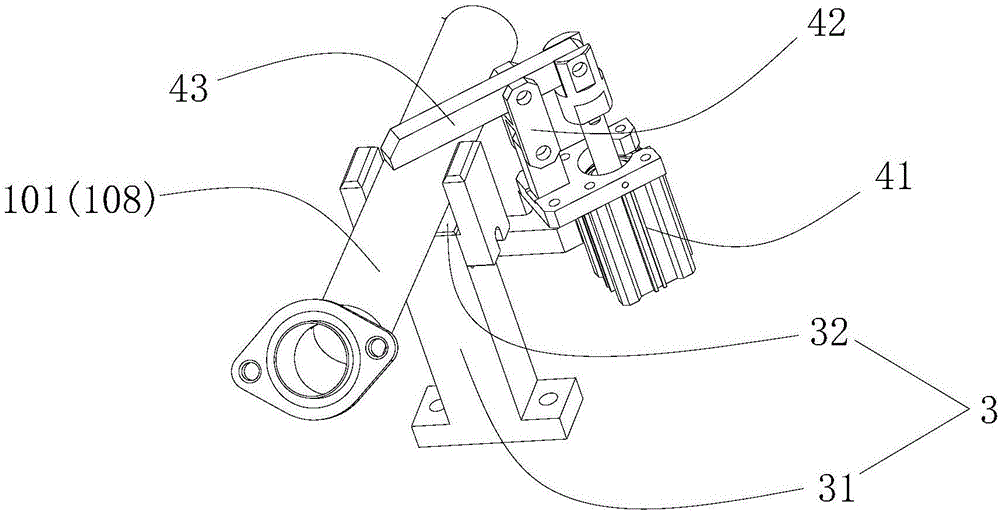

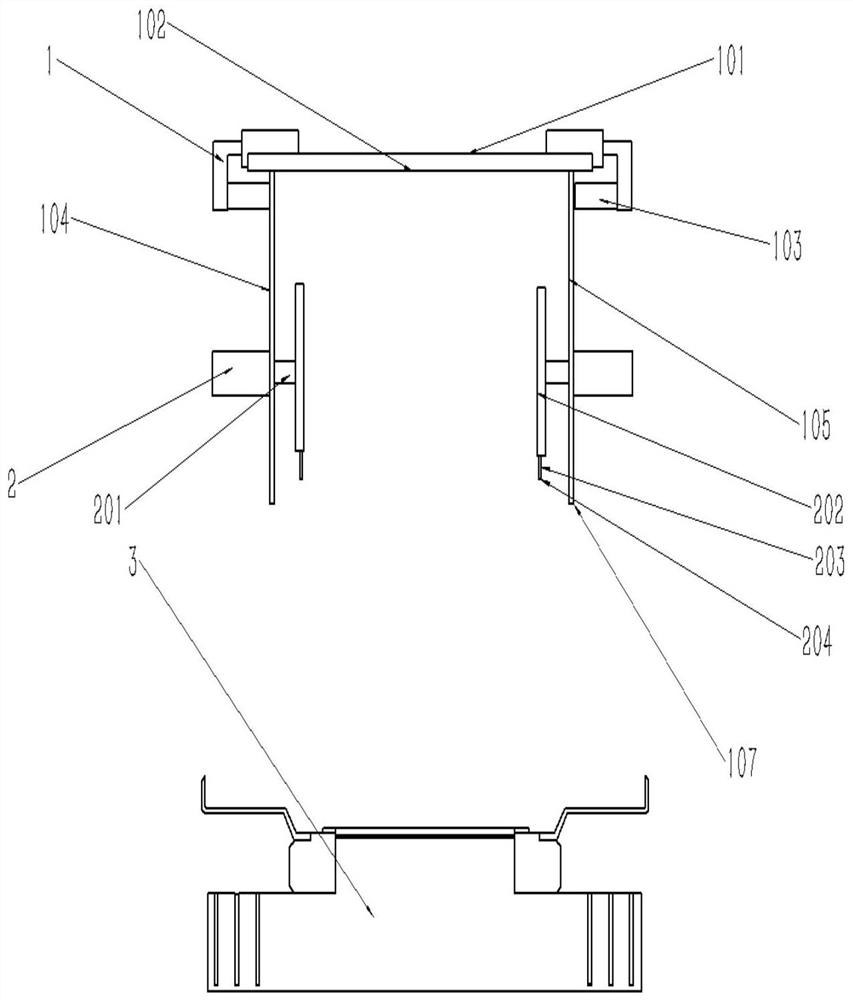

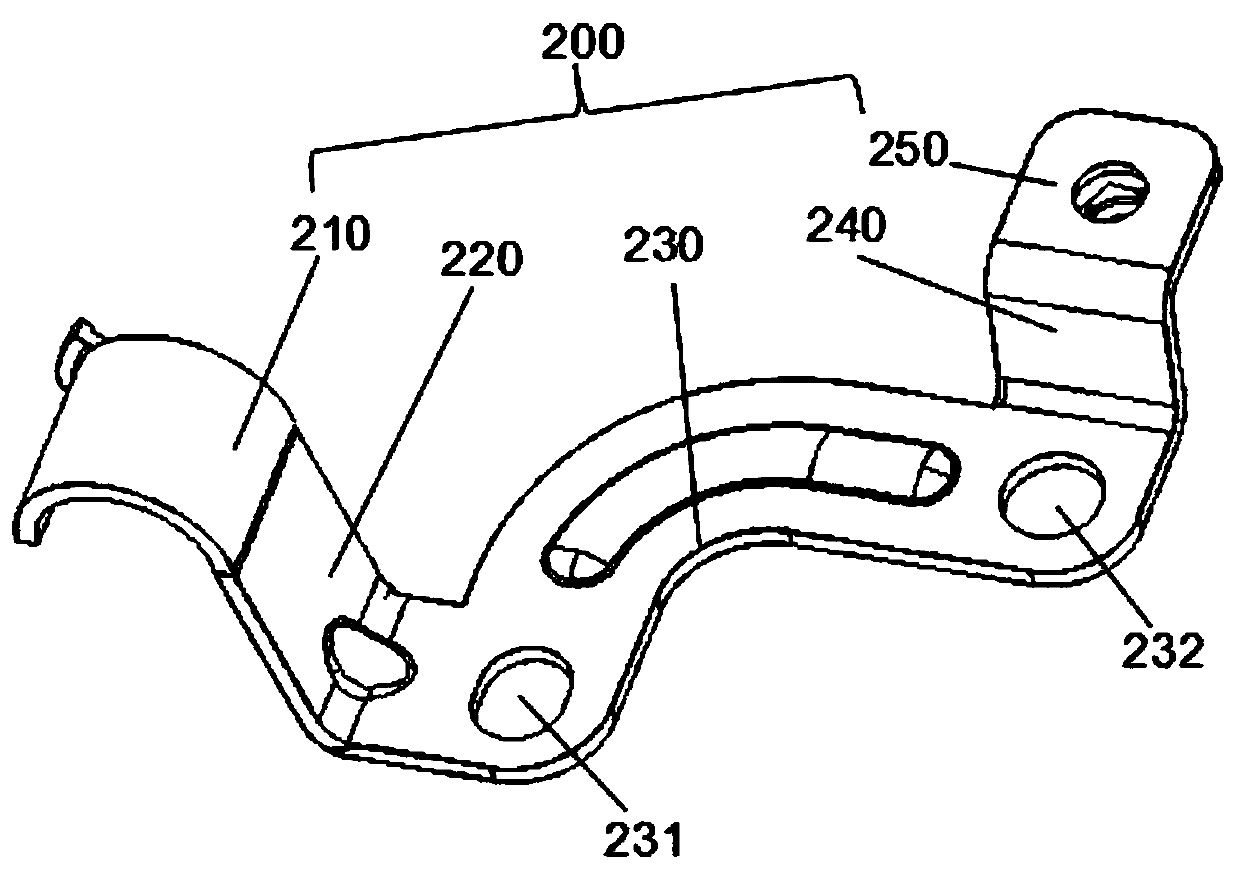

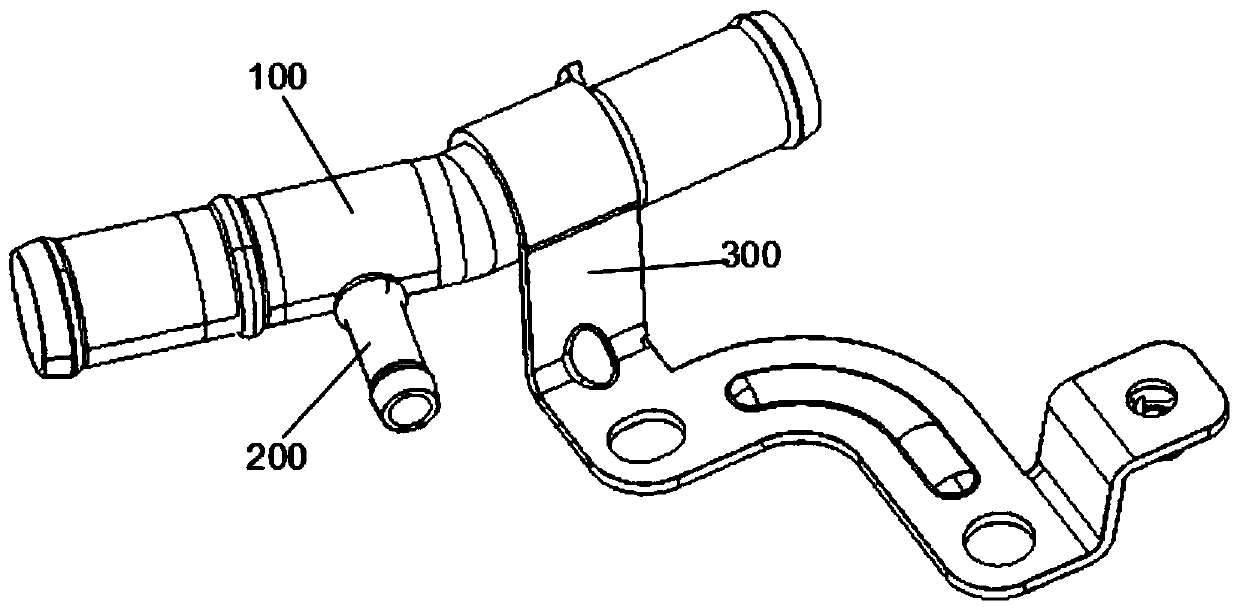

A combined welding positioning and clamping device for automobile special water inlet pipe workpiece and bracket

ActiveCN108788601BAvoid deflectionPrevent rollingWelding/cutting auxillary devicesAuxillary welding devicesCompression deviceEngineering

The invention provides a special car water inlet pipe workpiece and support combined welding positioning clamping device. The special car water inlet pipe workpiece and support combined welding positioning clamping device comprises a base plate, a welding positioning base installed at the middle portion of the base plate, a right pipe end positioning base installed on the right side of the weldingpositioning base, a left pipe end positioning base installed on the left side of the welding positioning base, a pipe end compression device installed on the left side of the left pipe end positioning base, a branch pipe limiting device installed on the front side of the left pipe end positioning base, a support positioning plate installed on the right side of the branch pipe limiting device, a first quick clamp installed on the side of the support positioning plate and a second quick clamp installed on the back side of the welding positioning base. By means of the special car water inlet pipe workpiece and support combined welding positioning clamping device, quick positioning and clamping of a water inlet pipe and a water inlet pipe support can be achieved, the poor welding quality caused by movement of the water inlet pipe or the water inlet pipe support in the welding process is reduced, and the welding efficiency and quality are improved.

Owner:GUANGDONG JUNCHI TECH HLDG

Automatic welding trolley for hatch cover guide rail and sealed flat steel of bulk cargo ship

PendingCN112404872AImprove abilitiesRealize splicingWelding/cutting auxillary devicesAuxillary welding devicesBulk cargoSynchronous motor

The invention discloses an automatic welding trolley for a hatch cover guide rail and a sealed flat steel of a bulk cargo ship. The automatic welding trolley comprises a welding device and a welding trolley body, and the welding device is installed at the exterior of the welding trolley body; a toothed plate linkage rod is driven by an adjusting and fixing mechanism to extrude a spring, and splicing and fixing of two adjustable magnets are achieved; The problem that rail hatch cover accessories are higher is solved by splicing the adjustable magnets, and secondary fixing of splicing of the twoadjustable magnets is achieved through hemispherical contact blocks and fastening springs of limiting blocks; welding errors due to loosening of the adjustable magnets are avoided, and the welding errors of welding work are reduced; and a clamping assembly is fine adjusted through control over a synchronous motor, and the welding errors of welding work of a trolley main body is reduced overall.

Owner:DALIAN COSCO KHI SHIP ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com