Welding device for special-shaped bent pipe

A welding device and pipe bending technology, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problems such as unsatisfactory positioning effect of special-shaped elbows, affecting the accuracy of welding positions, and affecting the welding quality of products, so as to improve welding quality. Assembly efficiency, improved welding quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

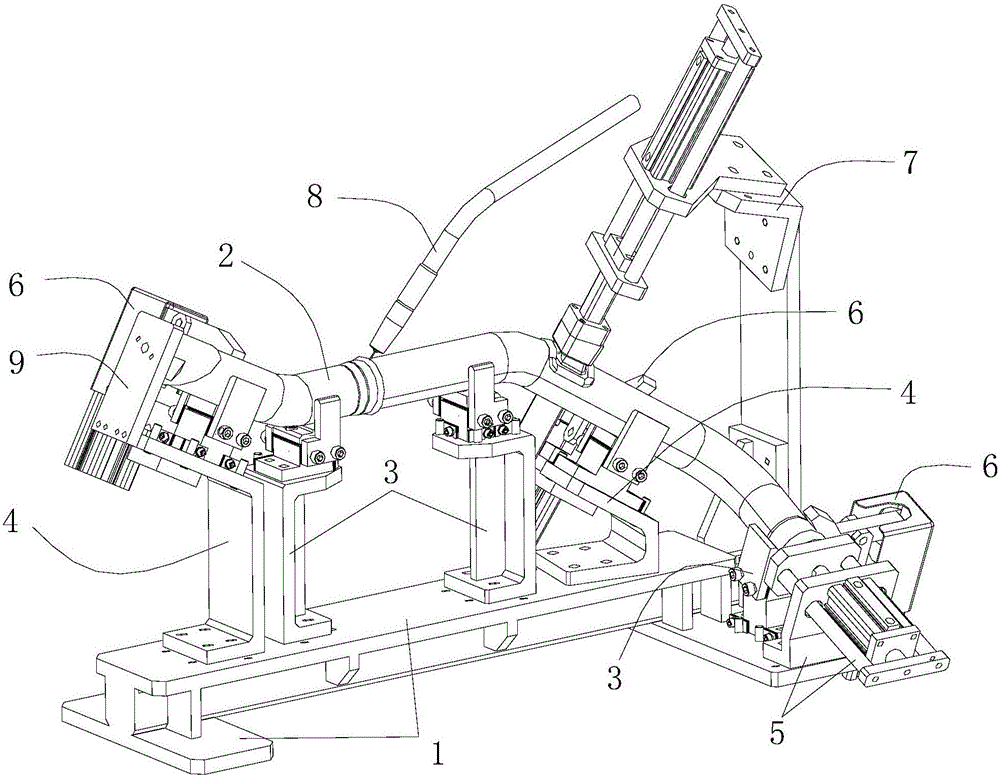

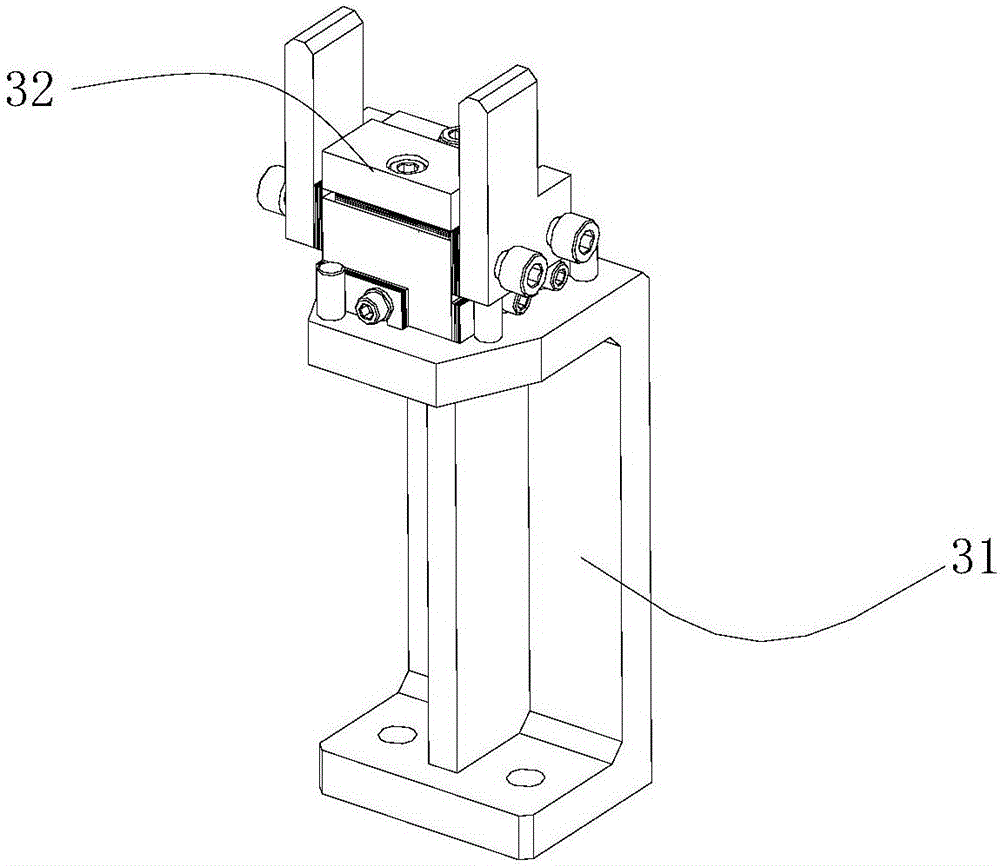

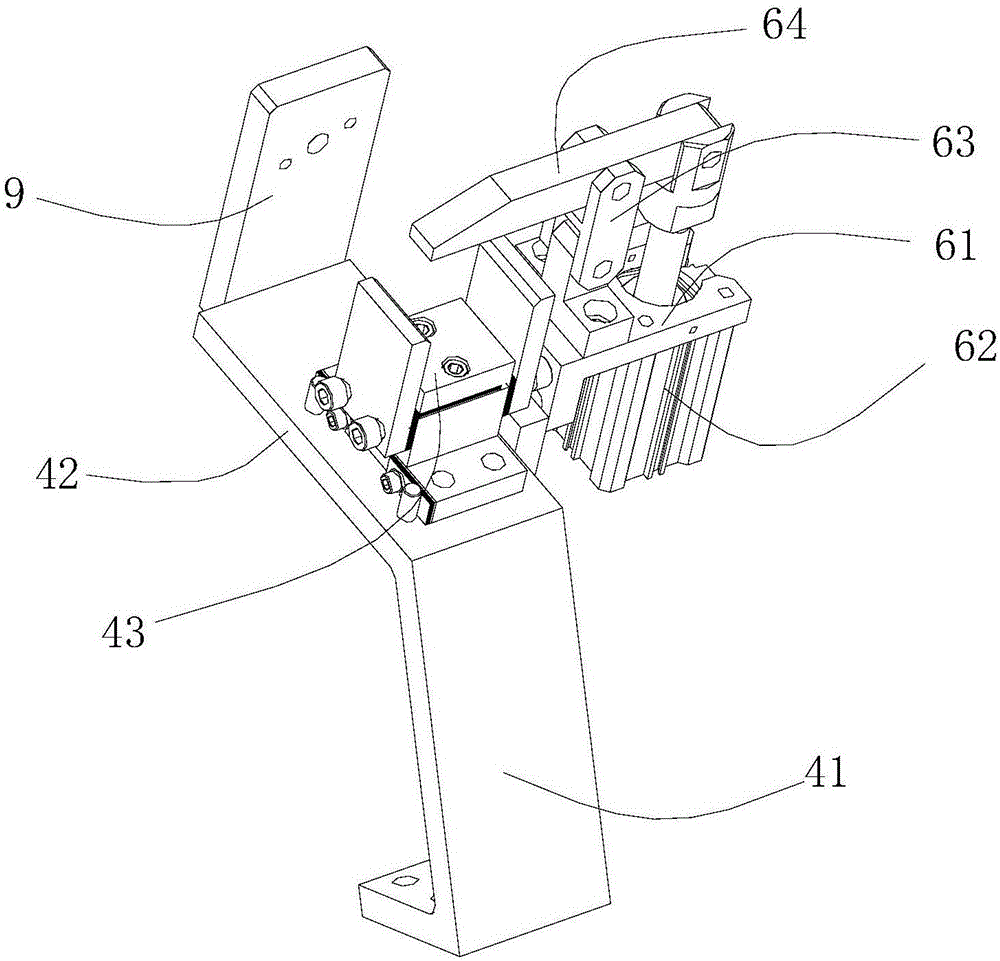

[0020] refer to Figure 1 to Figure 5 , is a kind of special-shaped bending pipe welding device, installed on the working platform 1, the special-shaped bending pipe 2 includes several horizontal sections and several inclined sections, the horizontal section is parallel to the working platform 1, and the inclined section has an included angle with the working platform 1, The special-shaped elbow welding device includes at least one first support mechanism 3 for supporting the horizontal section, at least one second support mechanism 4 for supporting the inclined section, a limit mechanism 5 for limiting the movable end of the special-shaped elbow 2, at least one A first clamping mechanism 6 for clamping the special-shaped elbow 2 and a second clamping mechanism 7 for clamping the middle part of the special-shaped elbow 2 .

[0021] The first support mechanism 3 and the second support mechanism 4 respectively support the horizontal section and the inclined section of the specia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com