Production line and production method for steel structure plates

A production method and steel structure technology, applied in building materials, building components, building structures, etc., can solve the problems of low production efficiency, affecting the process of industrial assembly of integrated houses, and insufficient automation, so as to improve efficiency and reduce labor costs. Cost and labor intensity, and the effect of improving the welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The present invention will be described in further detail below in combination with specific embodiments.

[0052] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

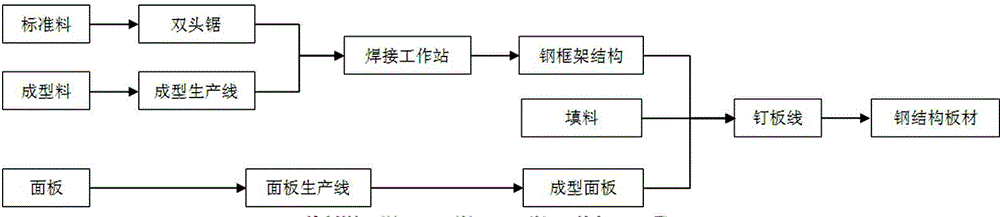

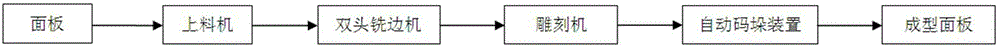

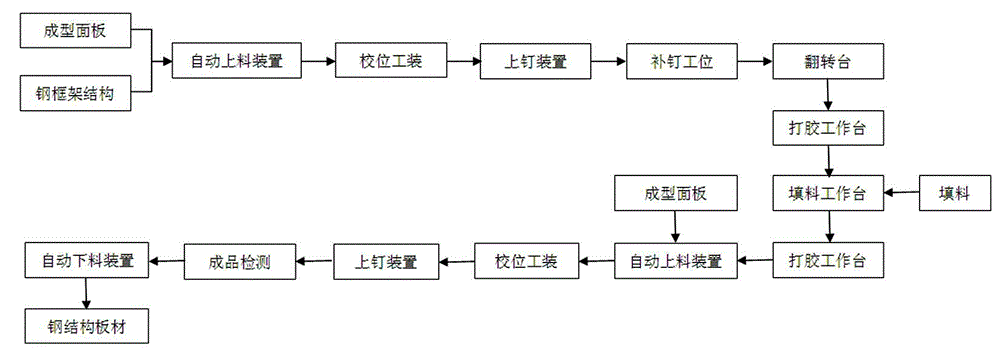

[0053] Such as figure 1 Shown is the process flow diagram of the present invention, the standard material is a hollow cuboid steel, and the molding material is a coiled rectangular steel, and the specific process steps are as follows:

[0054] (1) The standard material is the standard material cut into specified specifications by double-head sawing;

[0055] (2) The molding material is processed by the molding production line into unwinding, feeding, punching, forming with multiple sets of die wheels, and cutting in the middle of the hole to obtain a cross-sectional shape of large C shape, small C shape, and Z shape;

[0056] (3) Assemble the obtained formed steel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com