Cable management frame device and cable welding equipment

A wire management device and cable technology, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve problems such as low efficiency, reduce welding errors, improve work efficiency, and save man-hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

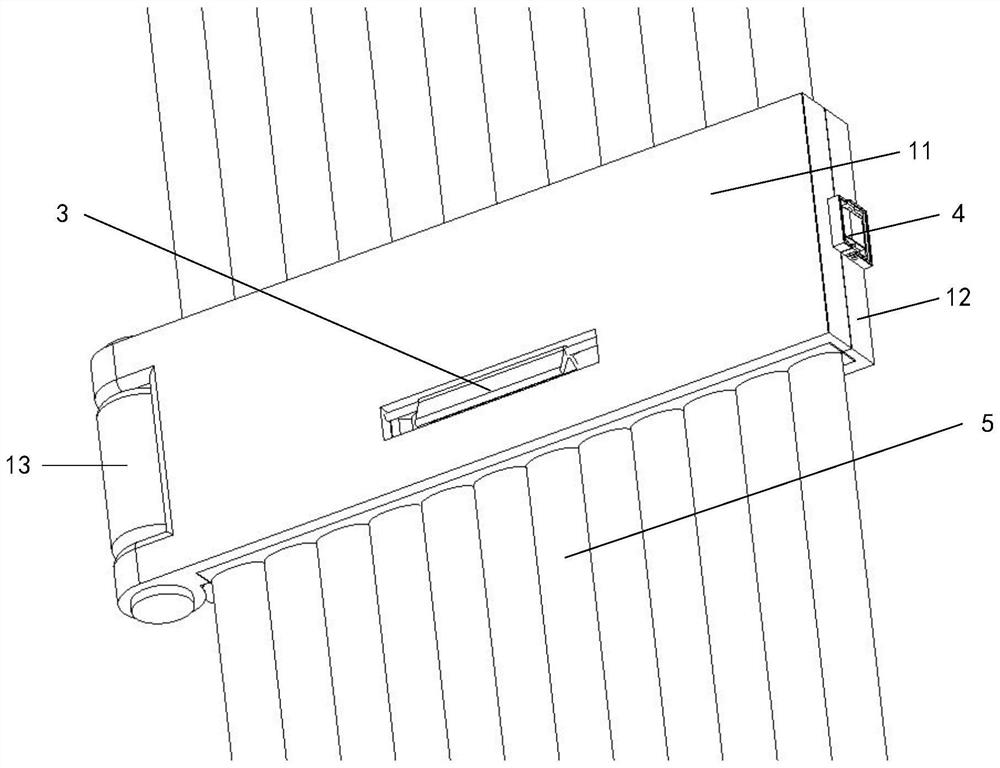

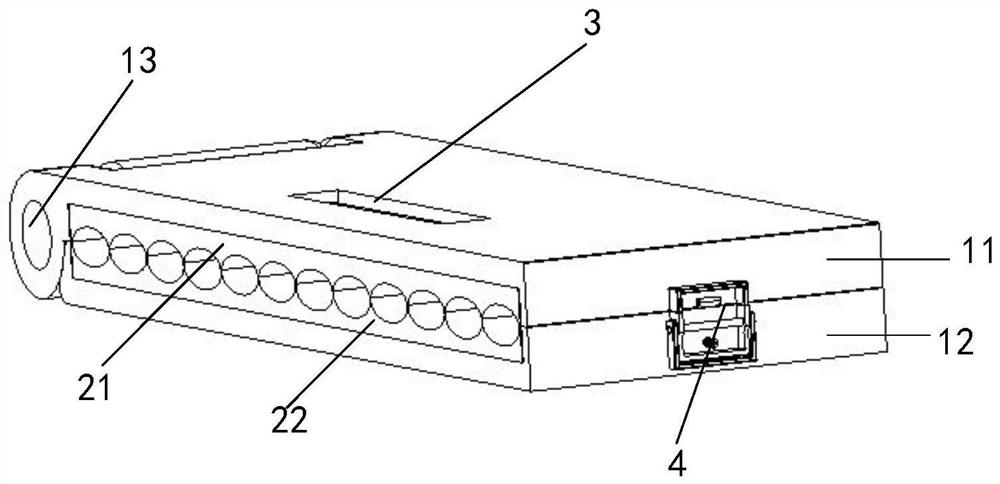

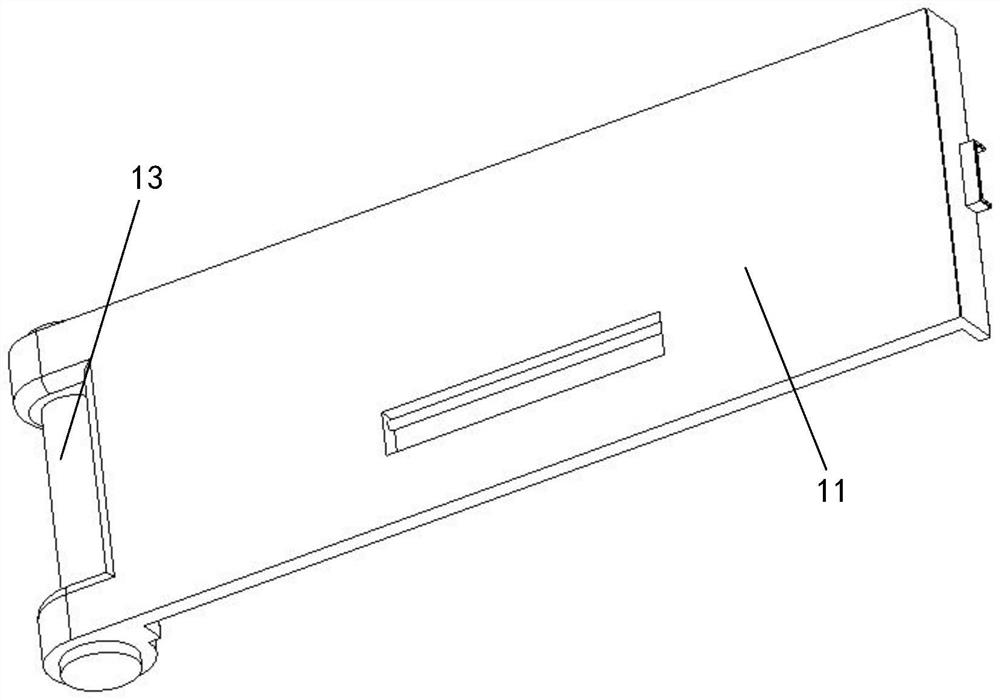

[0047] Such as figure 1 , figure 2 As shown, the embodiment of the present invention provides a cable management device, including a cable management board and a locking board. The locking plate includes an upper locking plate 11 and a lower locking plate 12 , one side of the upper locking plate 11 and the lower locking plate 12 are connected by a rotating shaft 13 , and the other side is fixed by a locking device 4 . The locking plates can be opened and closed through the rotating shaft 13, and the locking device 4 can fix the upper and lower locking plates. The wire management board comprises an upper wire management board 21 and a lower wire management board 22, and the upper wire management board 21 and the lower wire management board 22 are all provided with a plurality of grooves, and the grooves of the upper wire management board 21 and the lower wire management board 22 are opposite to each other. Combined to form a wire groove for accommodating the cables 5, the ca...

Embodiment 2

[0058] An embodiment of the present invention also provides a cable welding device, including the cable management device provided in the above-mentioned embodiment 1. The cable welding equipment using the cable management device will have more efficient operation efficiency, and will improve the user experience of the cable welding equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com