Laser tracking type angle welding system and method for large curved plate

A laser tracking, large-scale technology, applied in the direction of welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of rigid movement trajectory of automatic welding robots, weld seam error cannot be adjusted in real time, and welding effect is not good, etc., to achieve simplified calculations Power consumption, labor saving, and the effect of reducing welding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

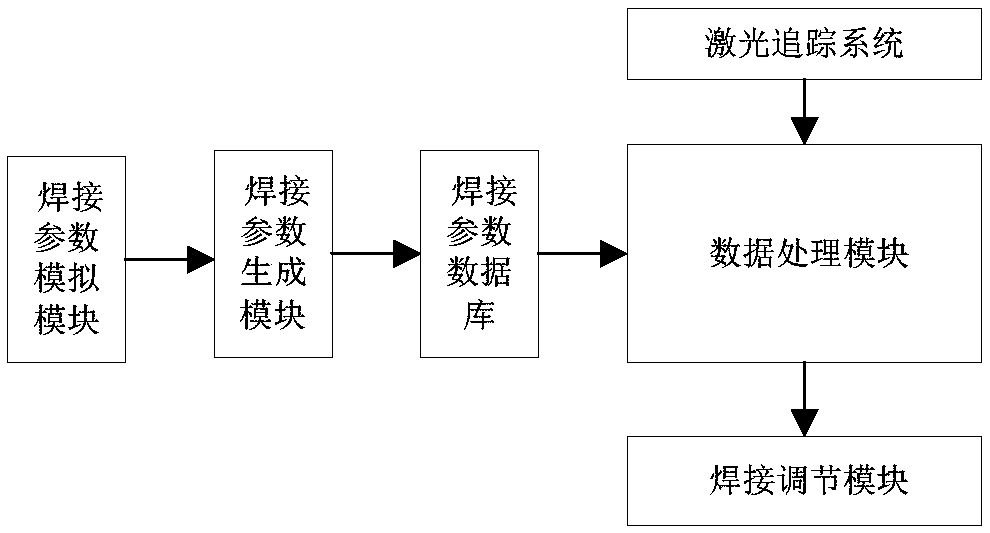

[0035] Such as figure 1 As shown, the present invention provides a laser tracking system for fillet welding of large curved panels, including:

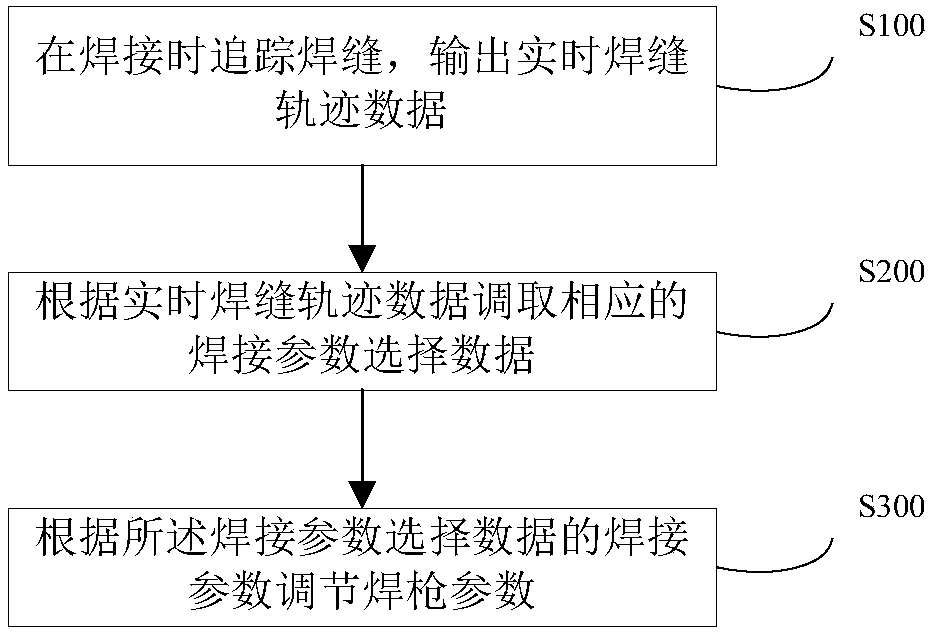

[0036] The laser tracking system is used to track the weld seam during welding and output real-time weld seam trajectory data;

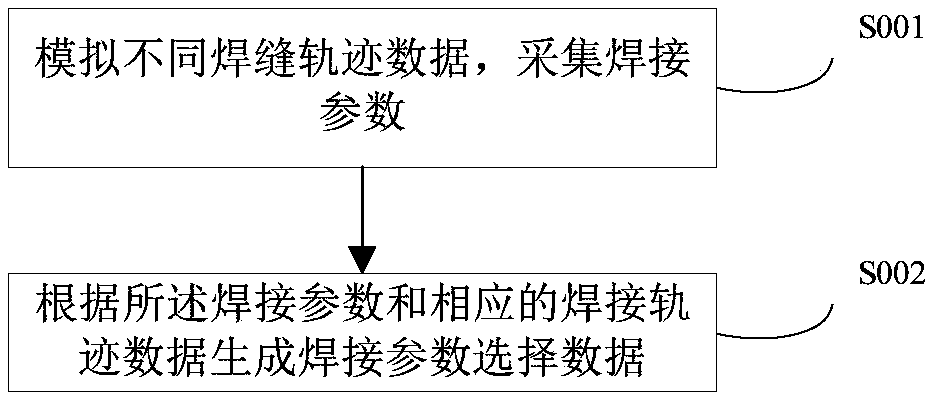

[0037] The welding parameter database is used to store welding parameter selection data; each piece of welding parameter selection data includes a welding parameter part and weld track information corresponding to the welding parameter part;

[0038] A data processing module, configured to retrieve corresponding welding parameter selection data according to the real-time weld track data and output it to the welding adjustment module;

[0039] The welding adjustment module is used to adjust the welding torch according to the welding parameters; in this embodiment, the welding param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com