A combined welding positioning and clamping device for automobile special water inlet pipe workpiece and bracket

A clamping device and welding positioning technology, which is applied to welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency, easy deflection, rolling, and cumbersome alignment steps, etc., to improve welding quality and fast The effect of positioning clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

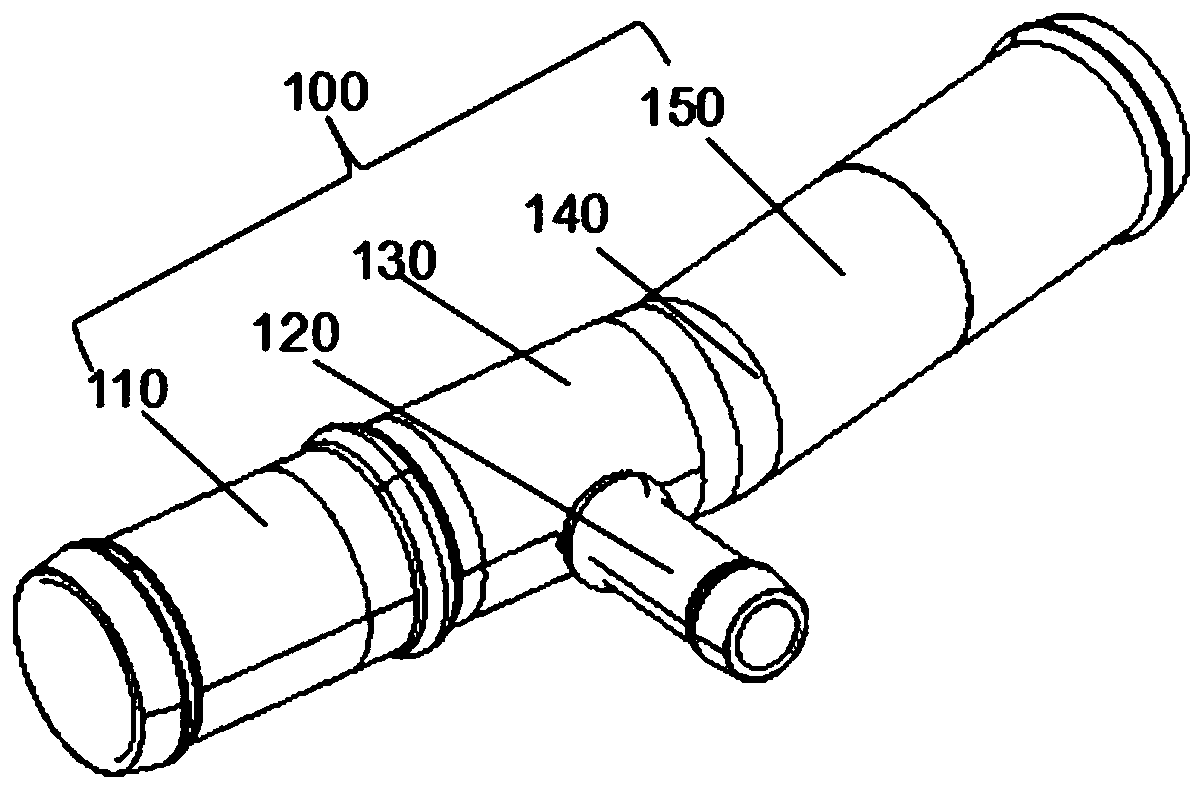

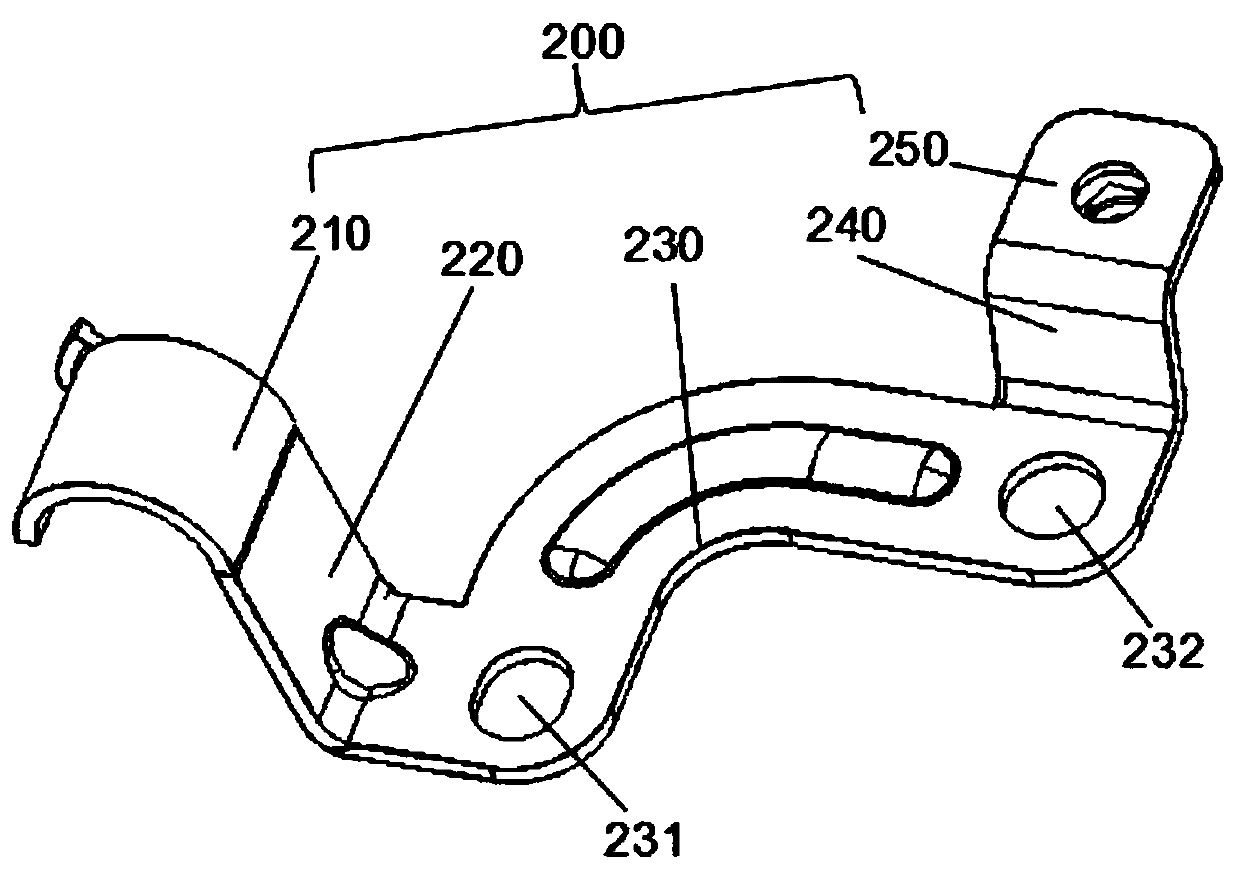

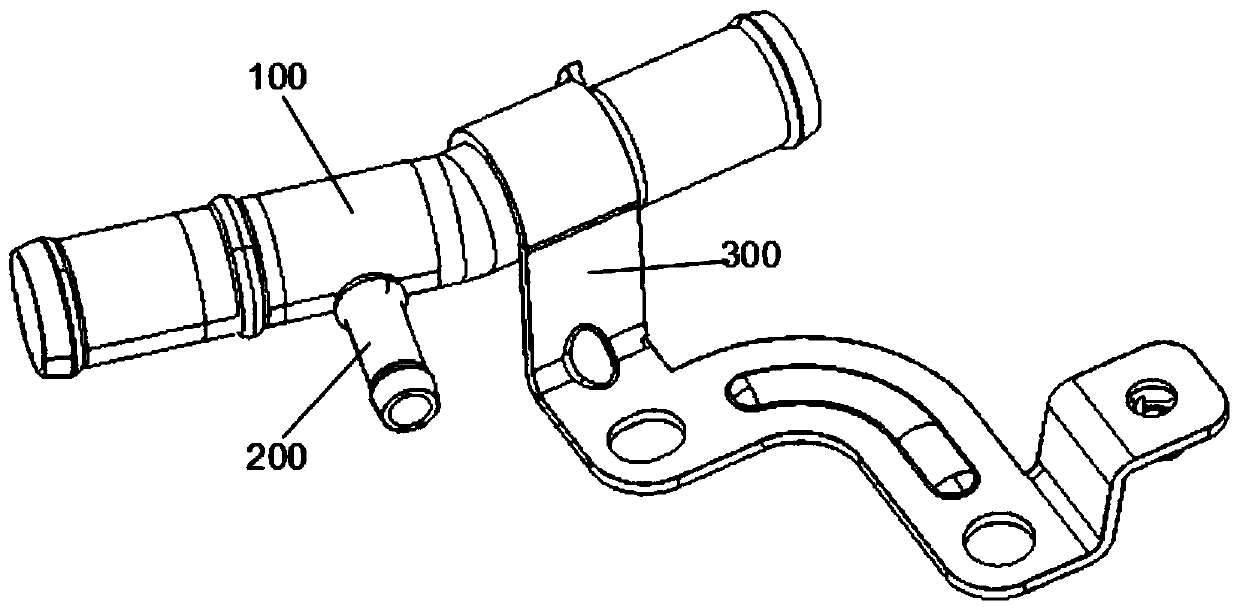

[0026] Embodiment: A joint welding positioning and clamping device for a special water inlet pipe workpiece and a bracket for an automobile.

[0027] refer to Figure 1 to Figure 10 As shown in the figure, a joint welding positioning and clamping device for a special water inlet pipe workpiece and a bracket for an automobile includes:

[0028] Bottom plate 1; the welding positioning seat 10 fixed on the middle part of the bottom plate 1 by screws, the welding positioning seat 10 is a square with the top flush, during specific welding, the right end pipe 150 of the water inlet pipe 100 is placed on the welding positioning seat 10, and at the same time The arc welding part 210 of the water pipe bracket 200 is overlapped on the right end pipe 150, and the welding positioning seat 10 is used to form a support for the joint of the water inlet pipe 100 and the water inlet pipe bracket 200 (refer to Figure 4 shown);

[0029] The right pipe end positioning seat 7 installed on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com