Patents

Literature

102results about How to "Lower elastic modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

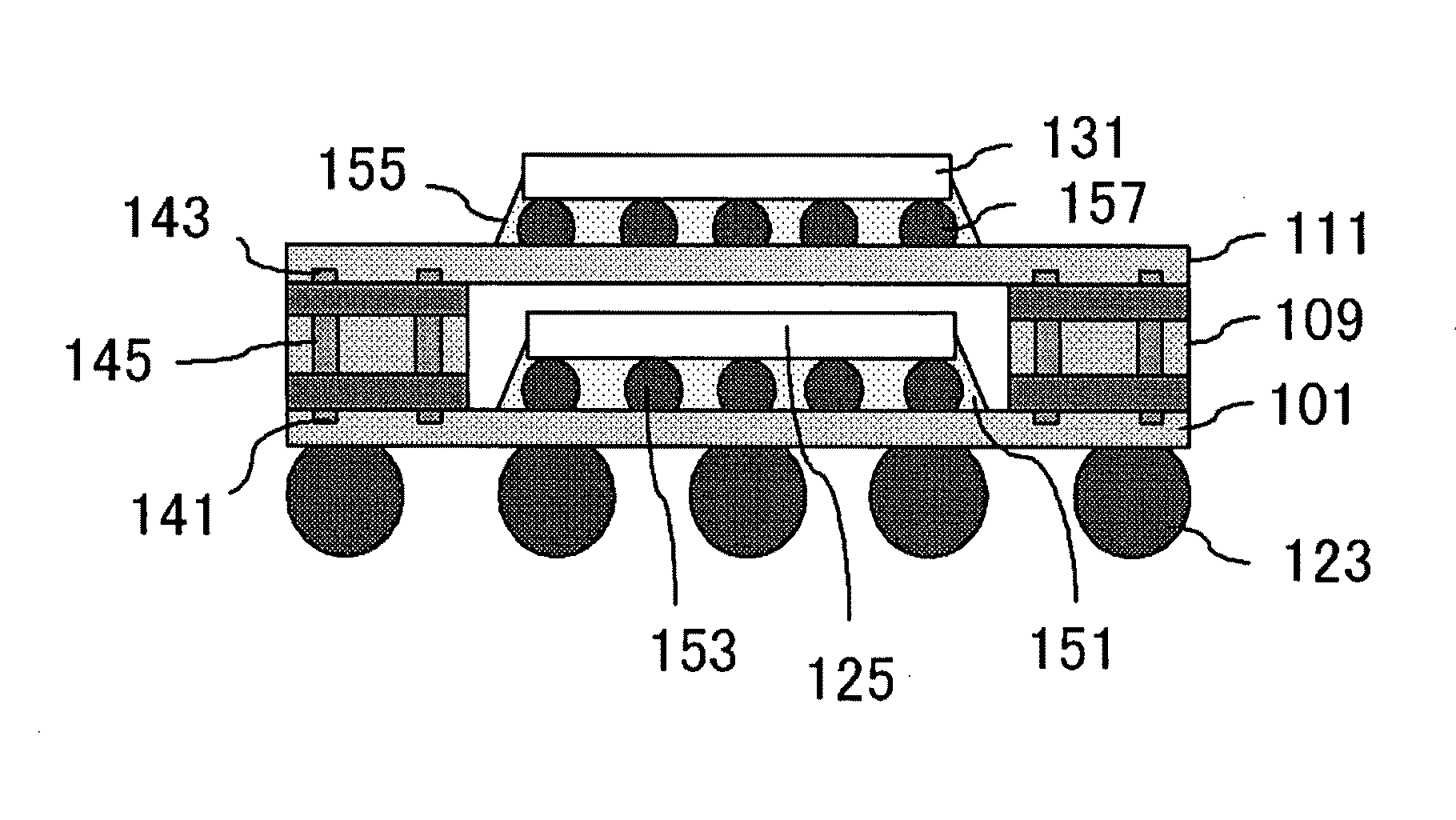

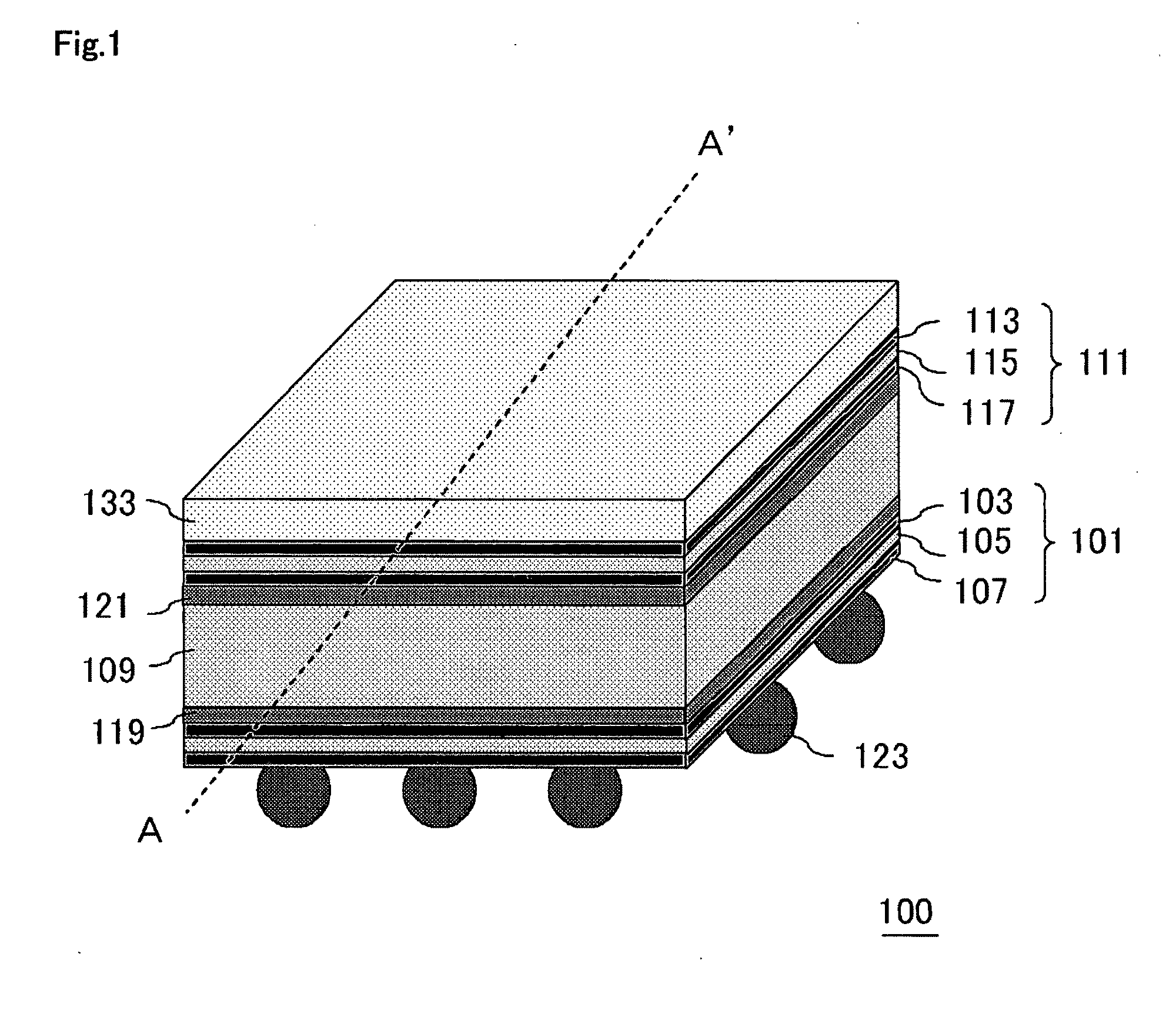

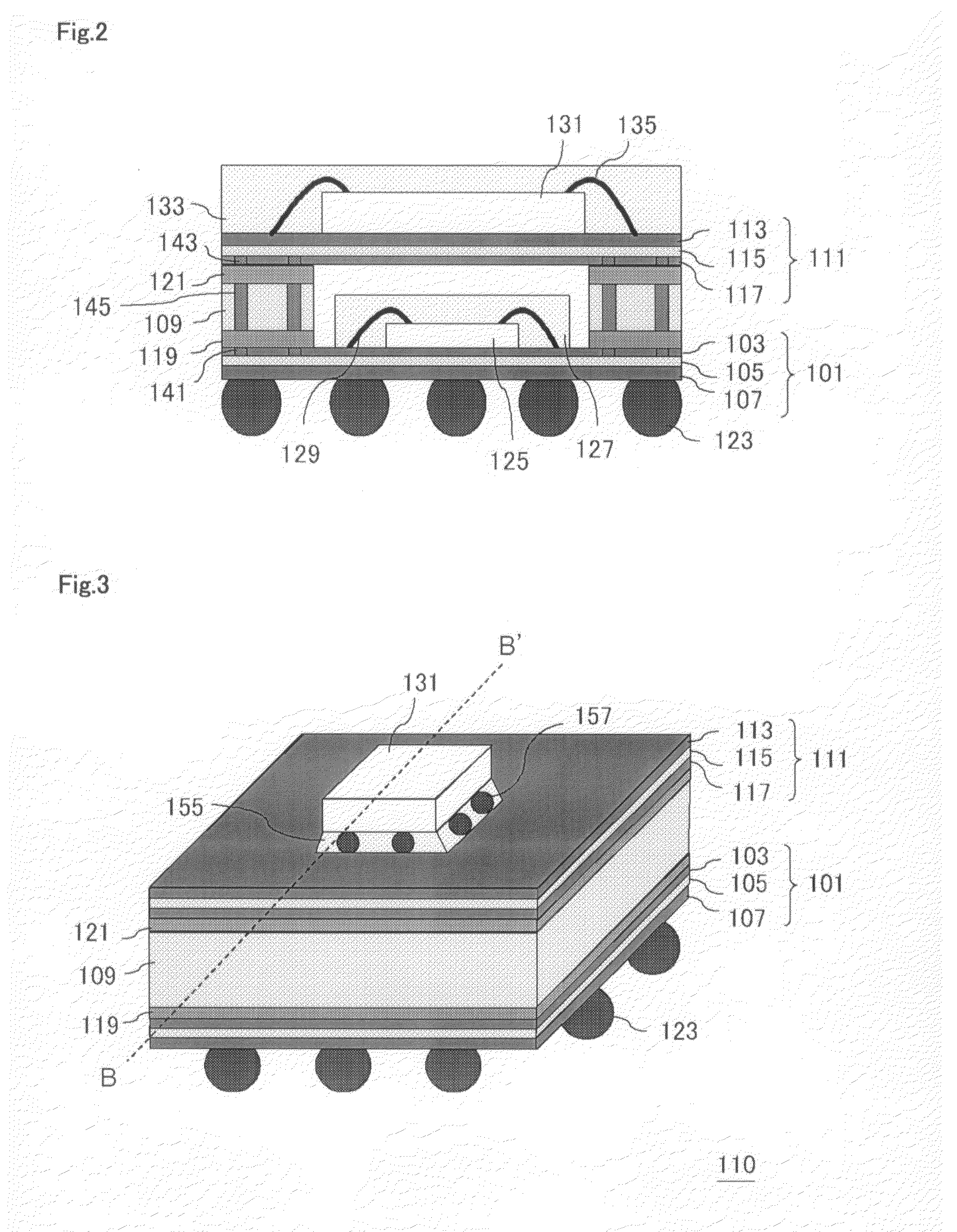

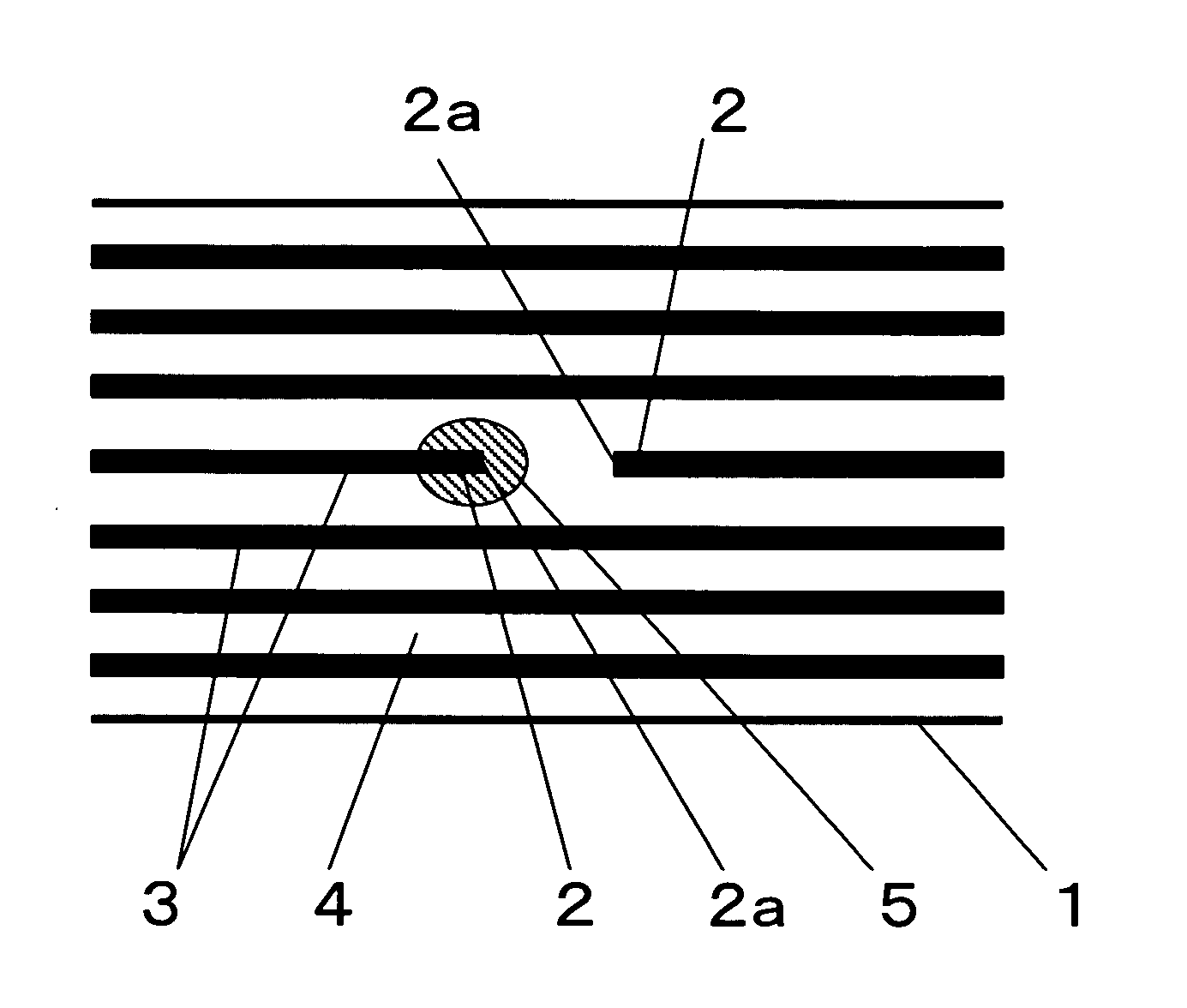

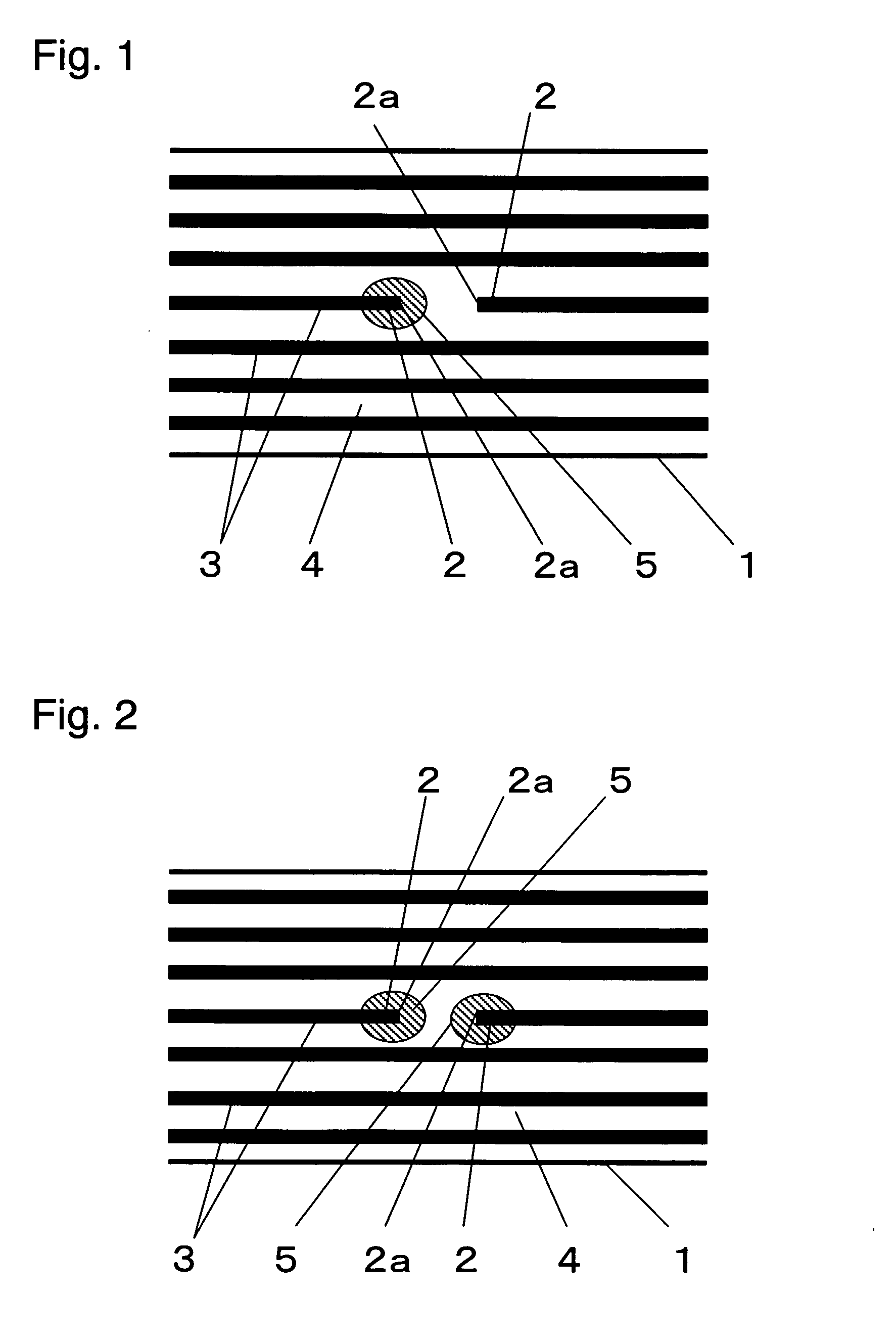

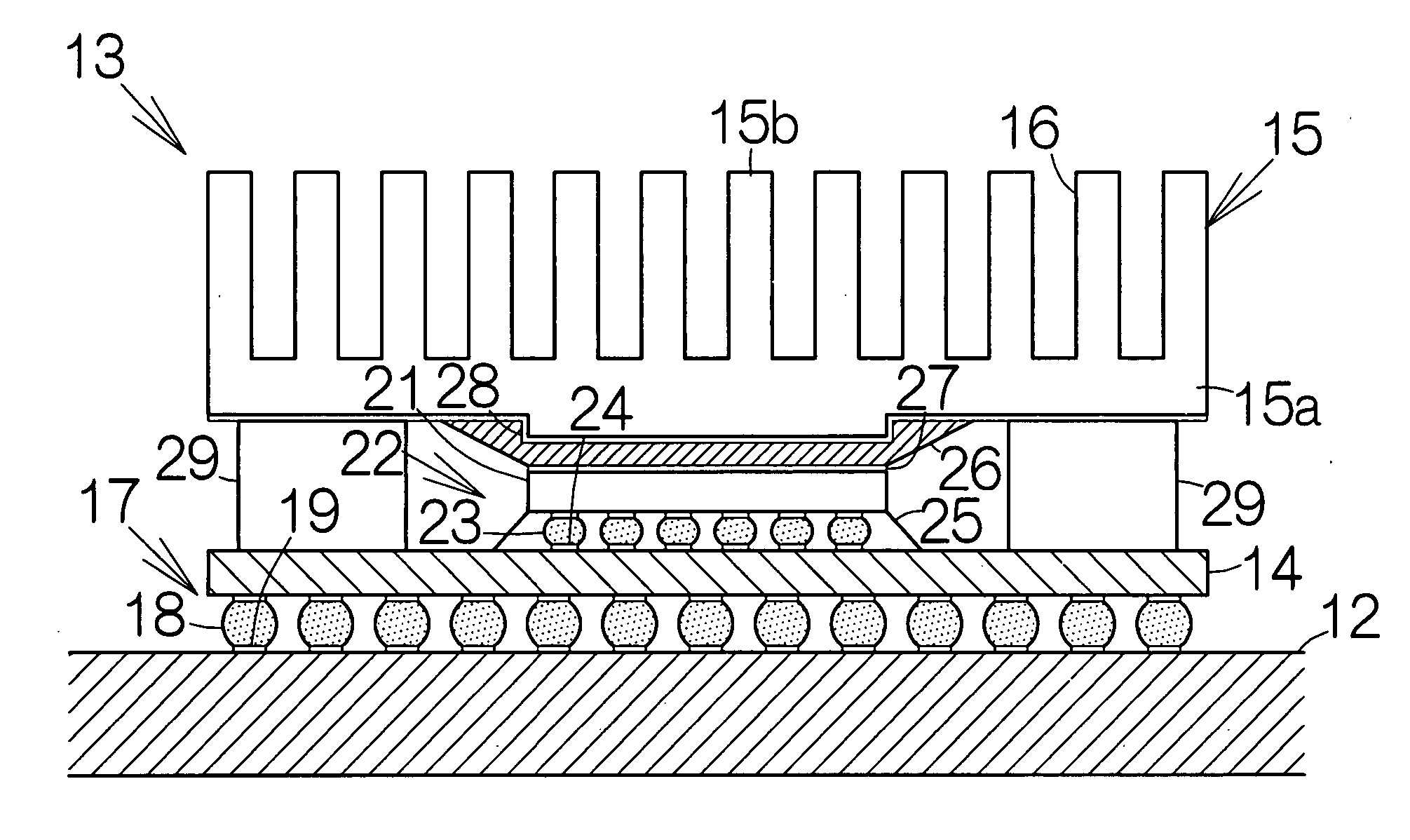

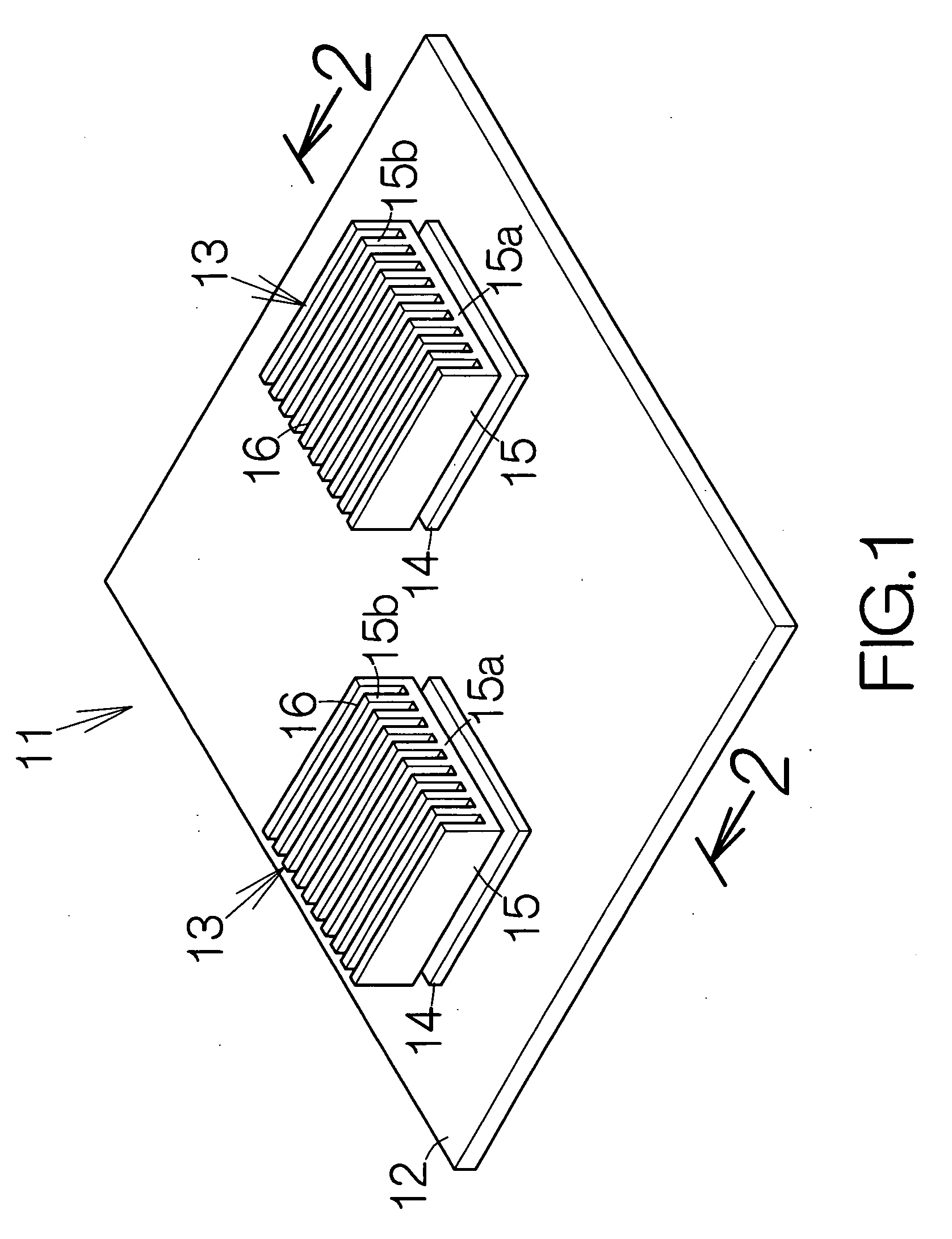

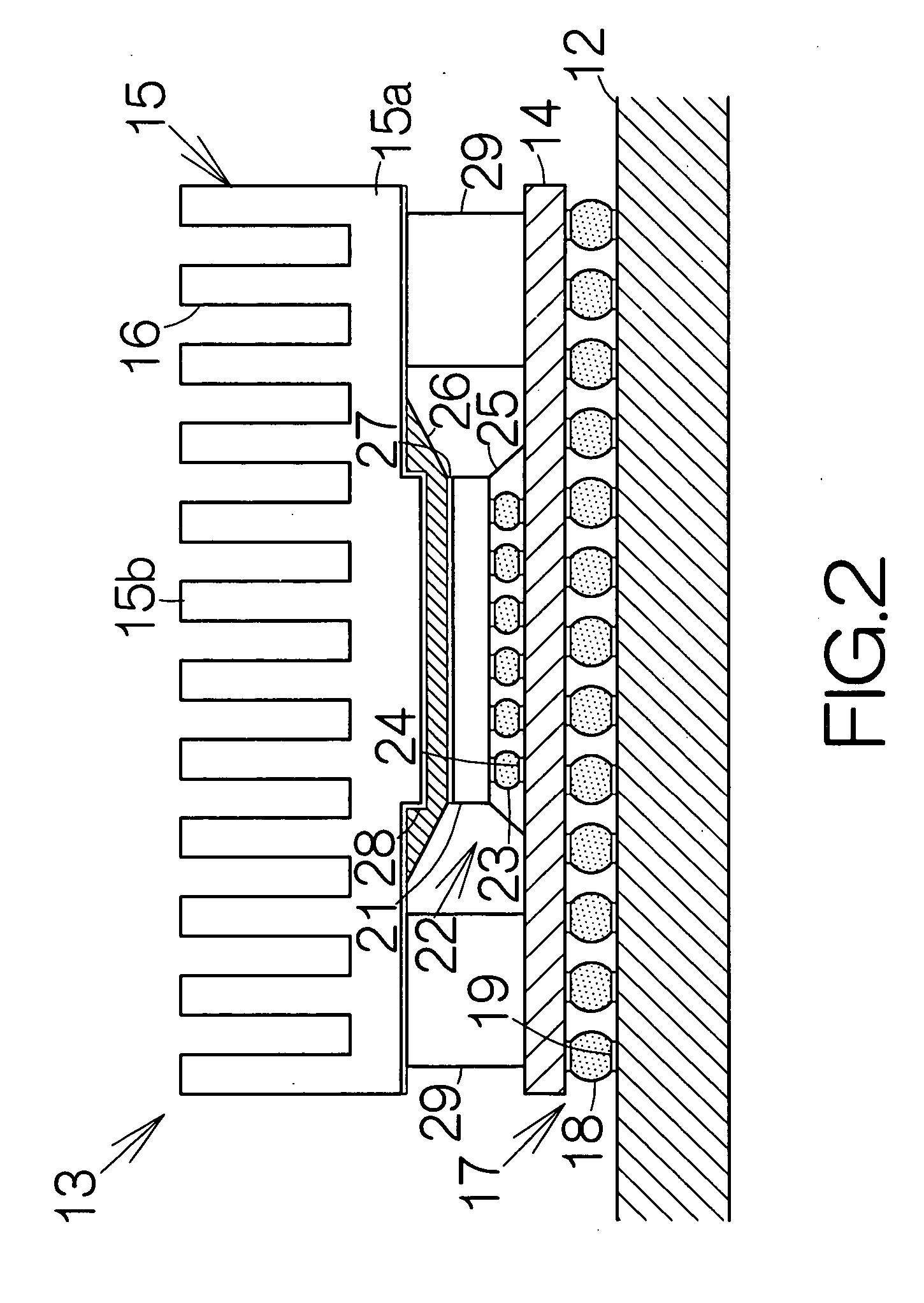

Semiconductor Device and Method for Manufacturing Semiconductor Device

InactiveUS20090243065A1Improve joint reliabilityLower elastic modulusSemiconductor/solid-state device detailsSolid-state devicesSurface mountingSemiconductor chip

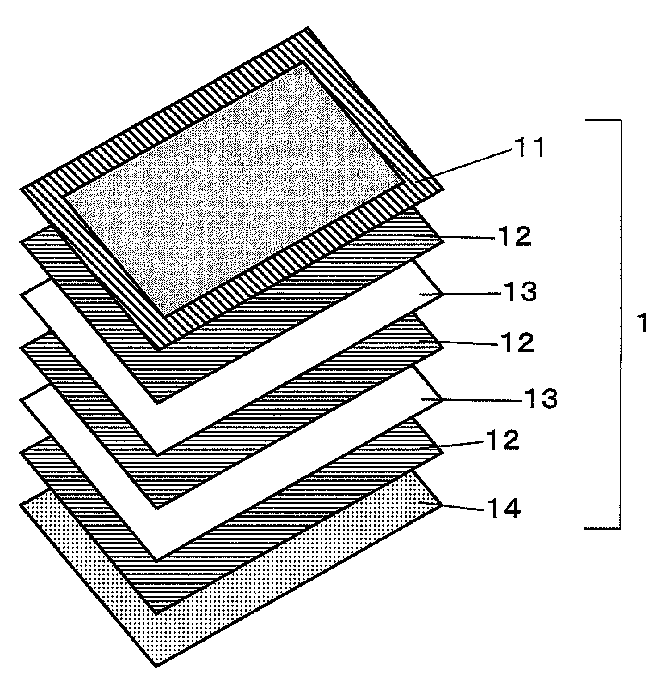

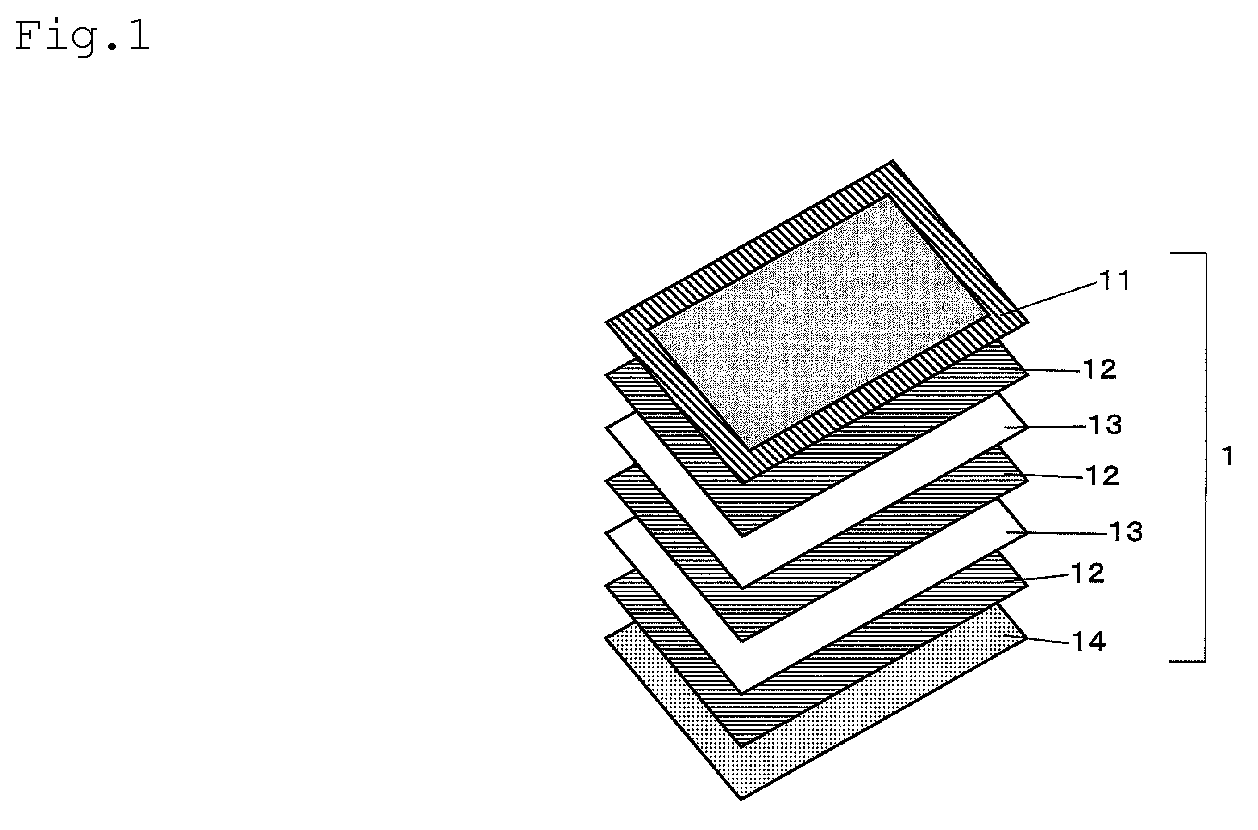

A semiconductor device (100) comprises a first resin substrate (101) on which a first semiconductor chip (125) is mounted a surface thereof; a second resin substrate (111) on which a second semiconductor chip (131) is mounted on a surface thereof; and a resin base material (109), joined to a front surface of the first resin substrate (101) and to a back surface of the second resin substrate (111), so that these surfaces are electrically connected. The resin base material (109) is disposed in a circumference of the first resin substrate (101) in the surface of the first resin substrate (101). Further, the first semiconductor chip (125) is disposed in a space section provided among the first resin substrate (101), the second resin substrate (111) and the resin base material (109) in the surface of the first resin substrate (101).

Owner:SUMITOMO BAKELITE CO LTD

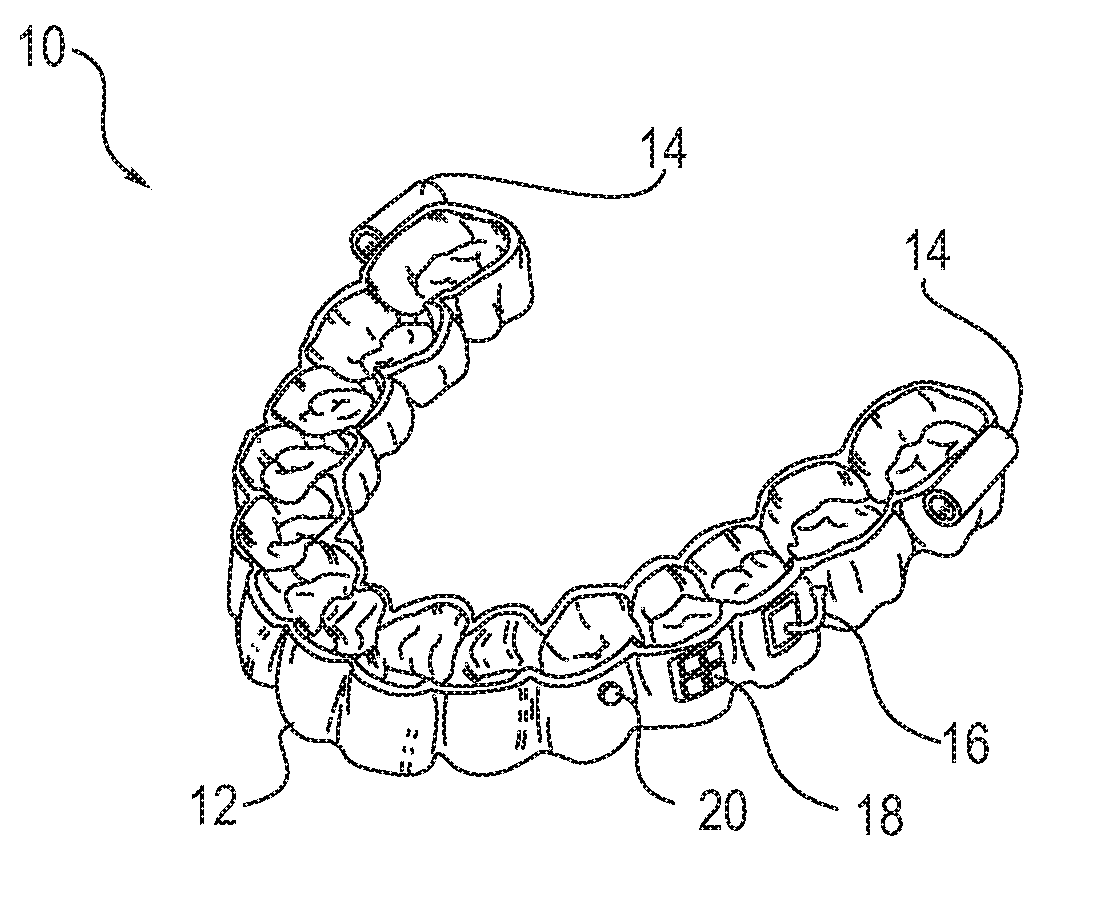

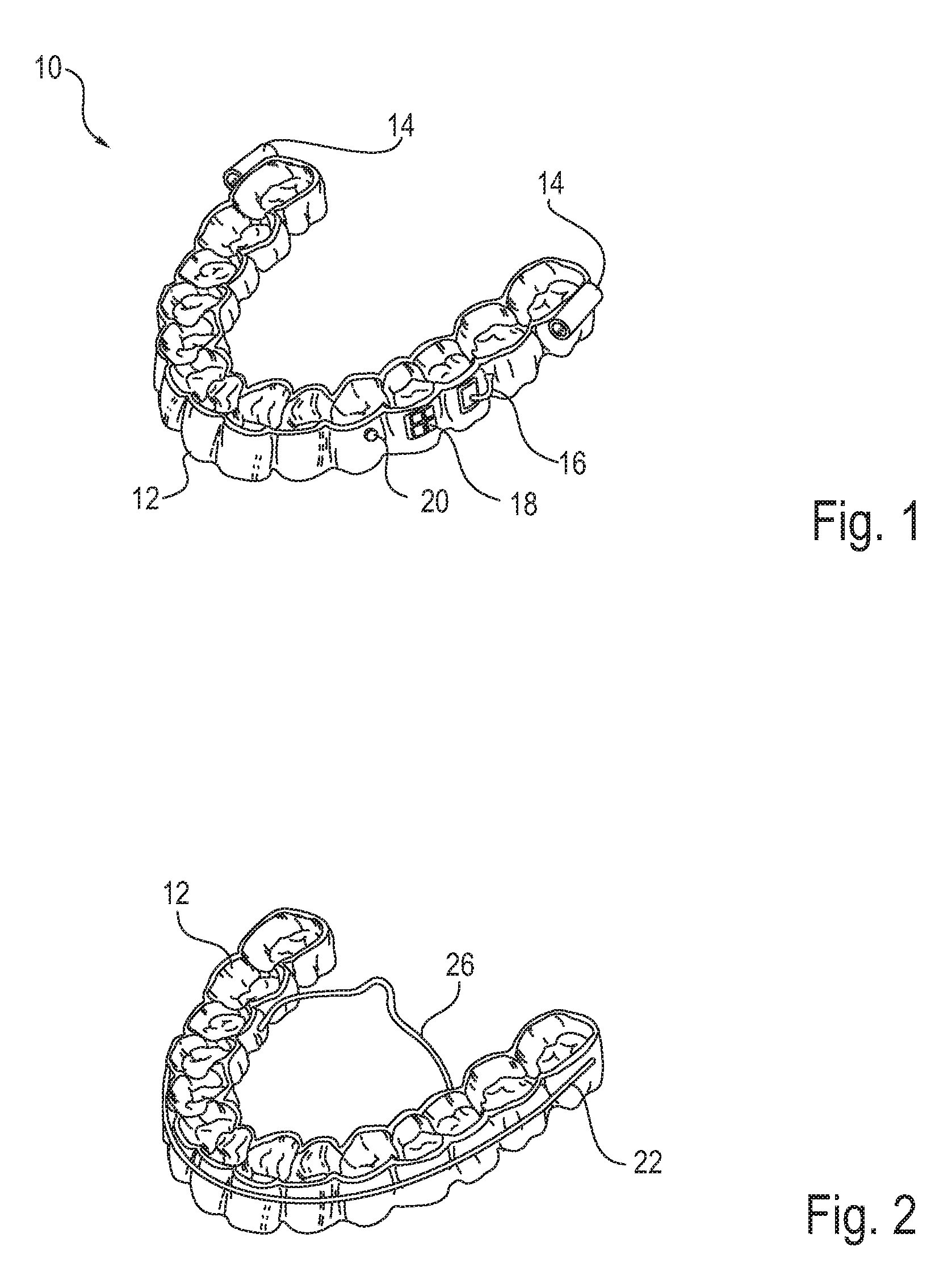

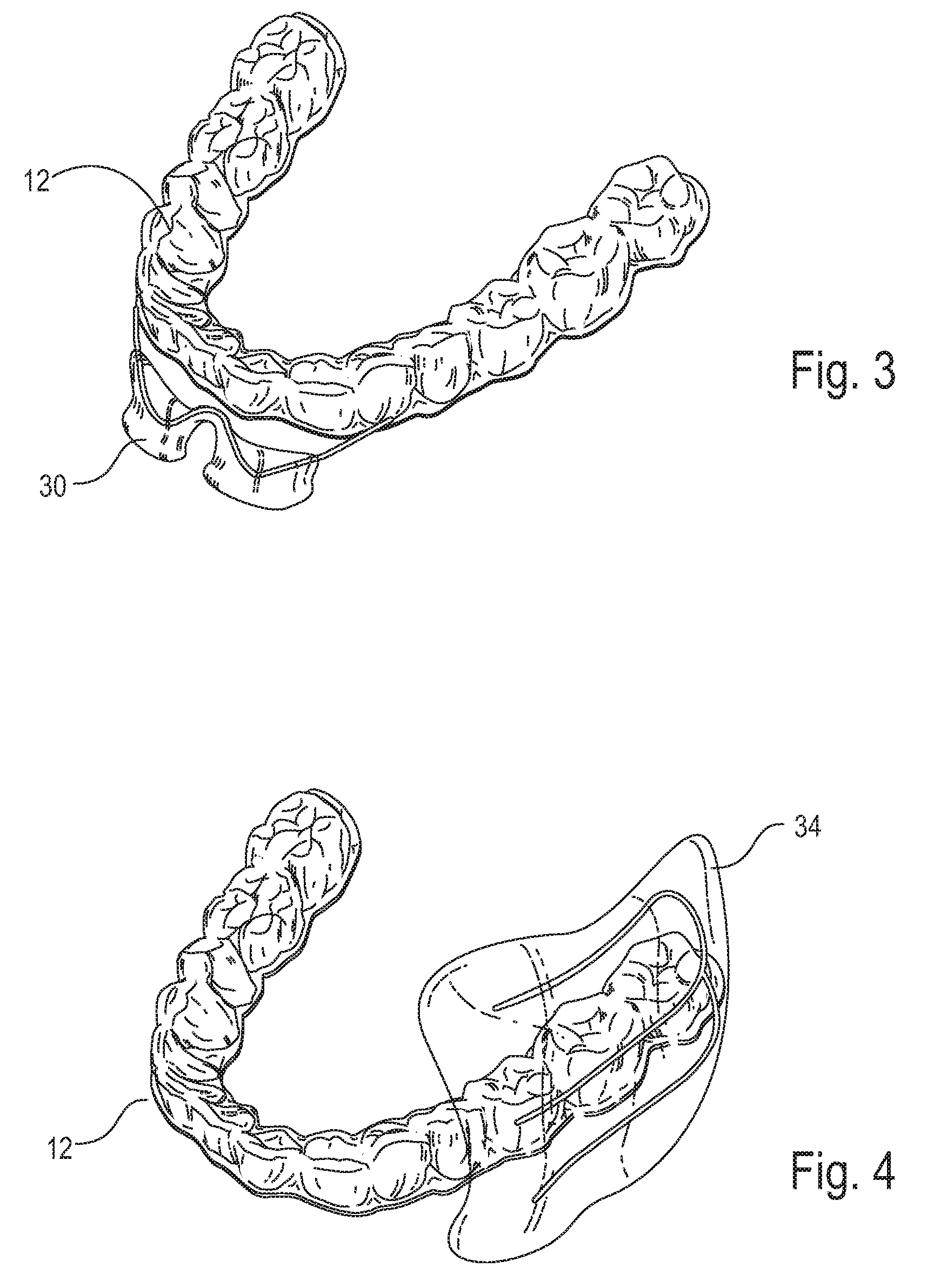

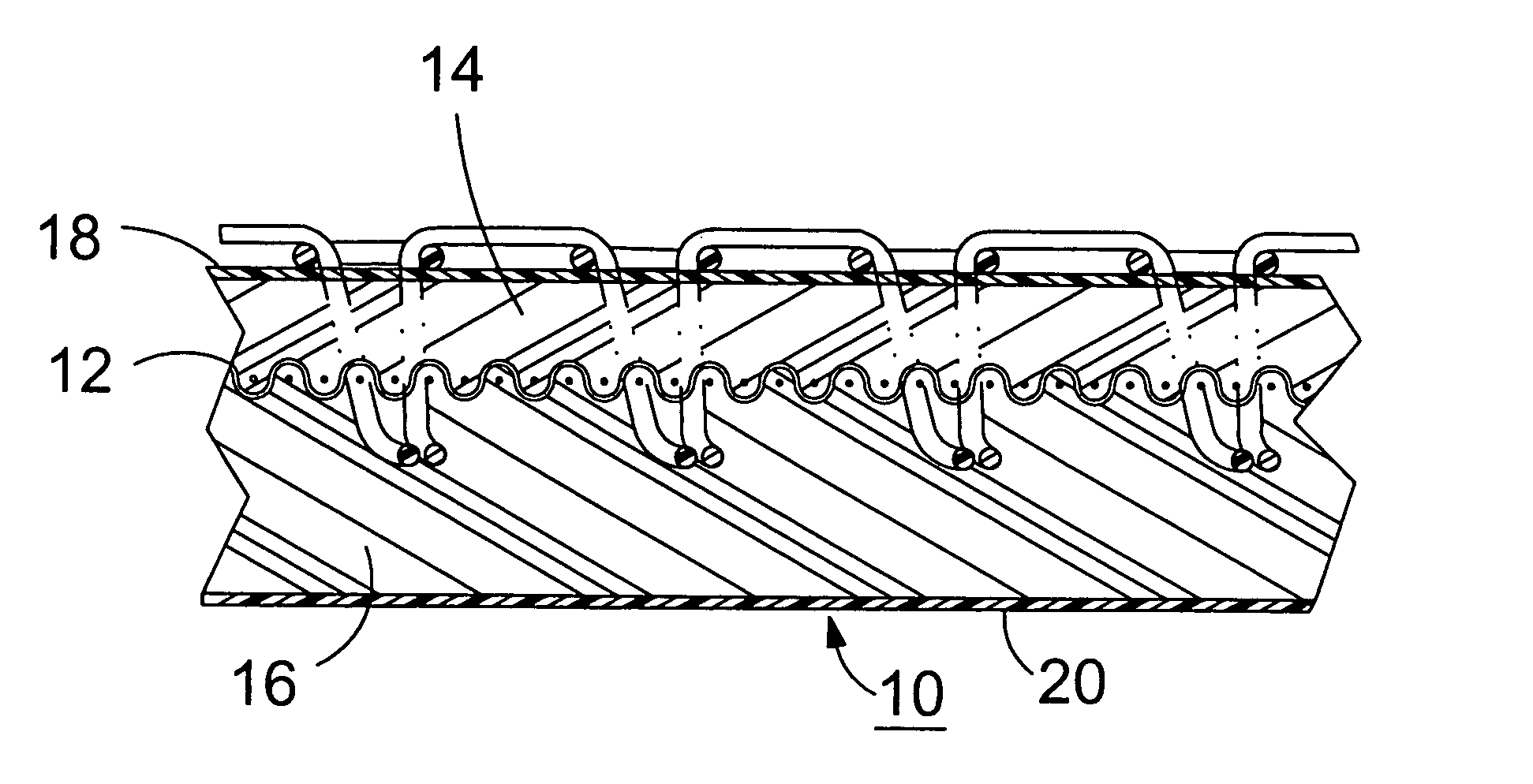

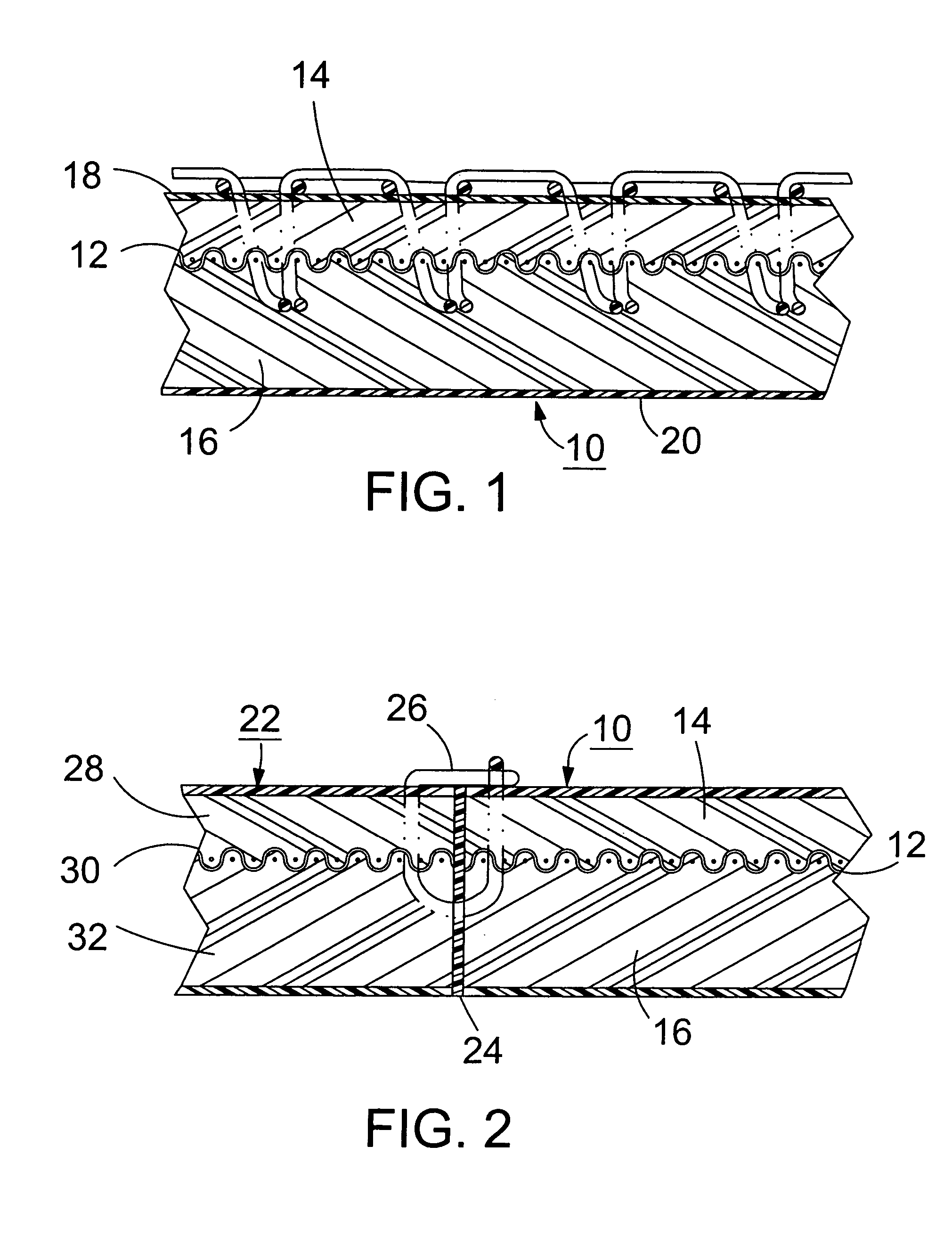

Embedded features and methods of a dental appliance

InactiveUS20080020337A1Improve treatmentGood lookingOthrodonticsDental toolsOrthodonticsDental appliances

Traditional orthodontic treatment often involves the use of basic repositioning devices, such as braces, and the use of supplementary devices, components or accessories to achieve desired end results. Such components may be mounted on fixed, non-removable devices or they may be part of a removable appliance typically worn prior to the application of the fixed devices. As with traditional treatment, it may be desired to utilize similar components when repositioning teeth with removable elastic repositioning appliances. Due to the nature of elastic appliances, such components may take a variety of forms ranging from readily available traditional accessories to specially created devices. Thus, traditional components may be mounted on or embedded in an elastic appliance, or the appliance may be formed to provide similar components. Likewise, the appliance may be modified to provide additional features for specific orthodontic treatments.

Owner:ALIGN TECH

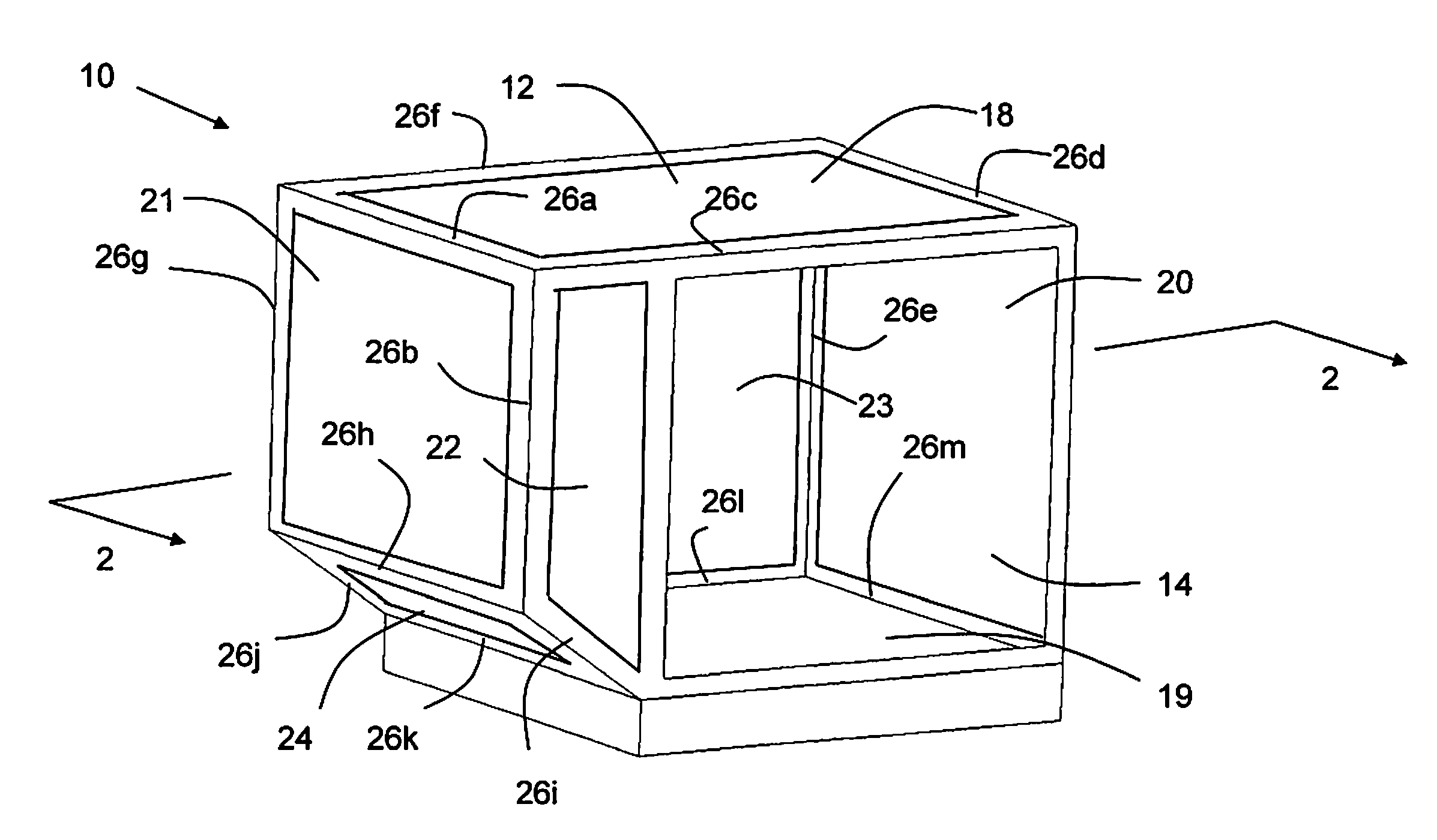

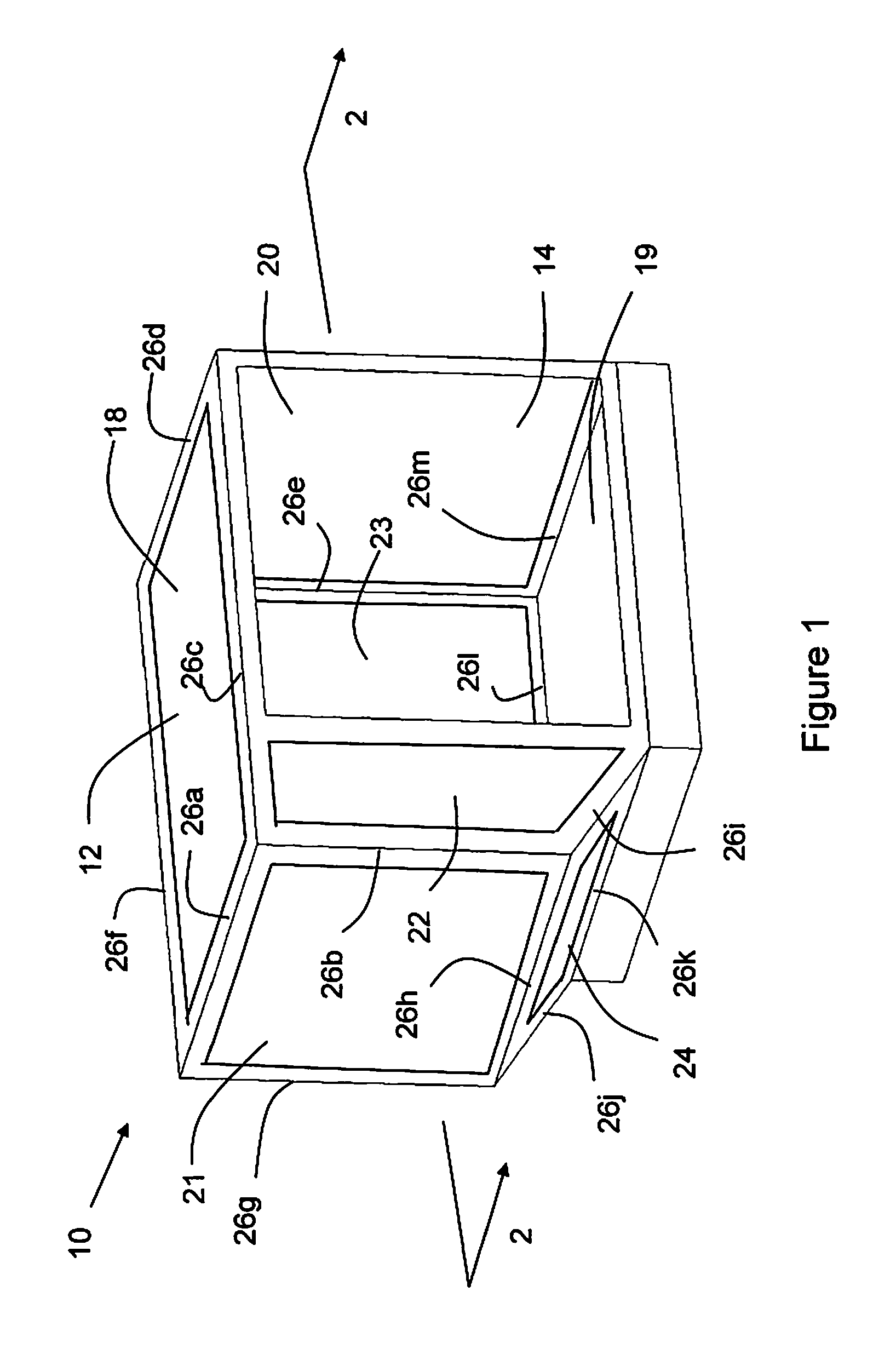

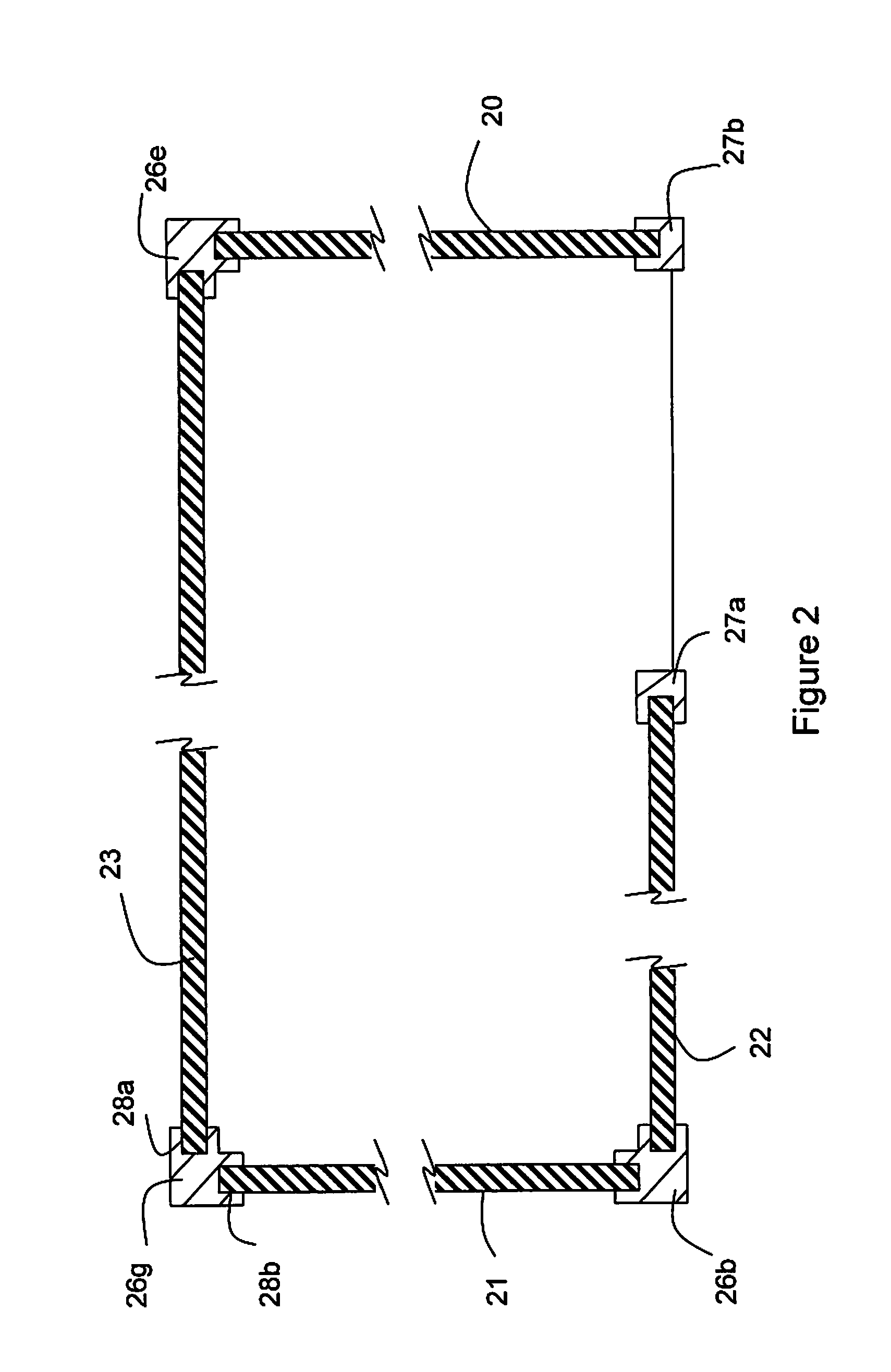

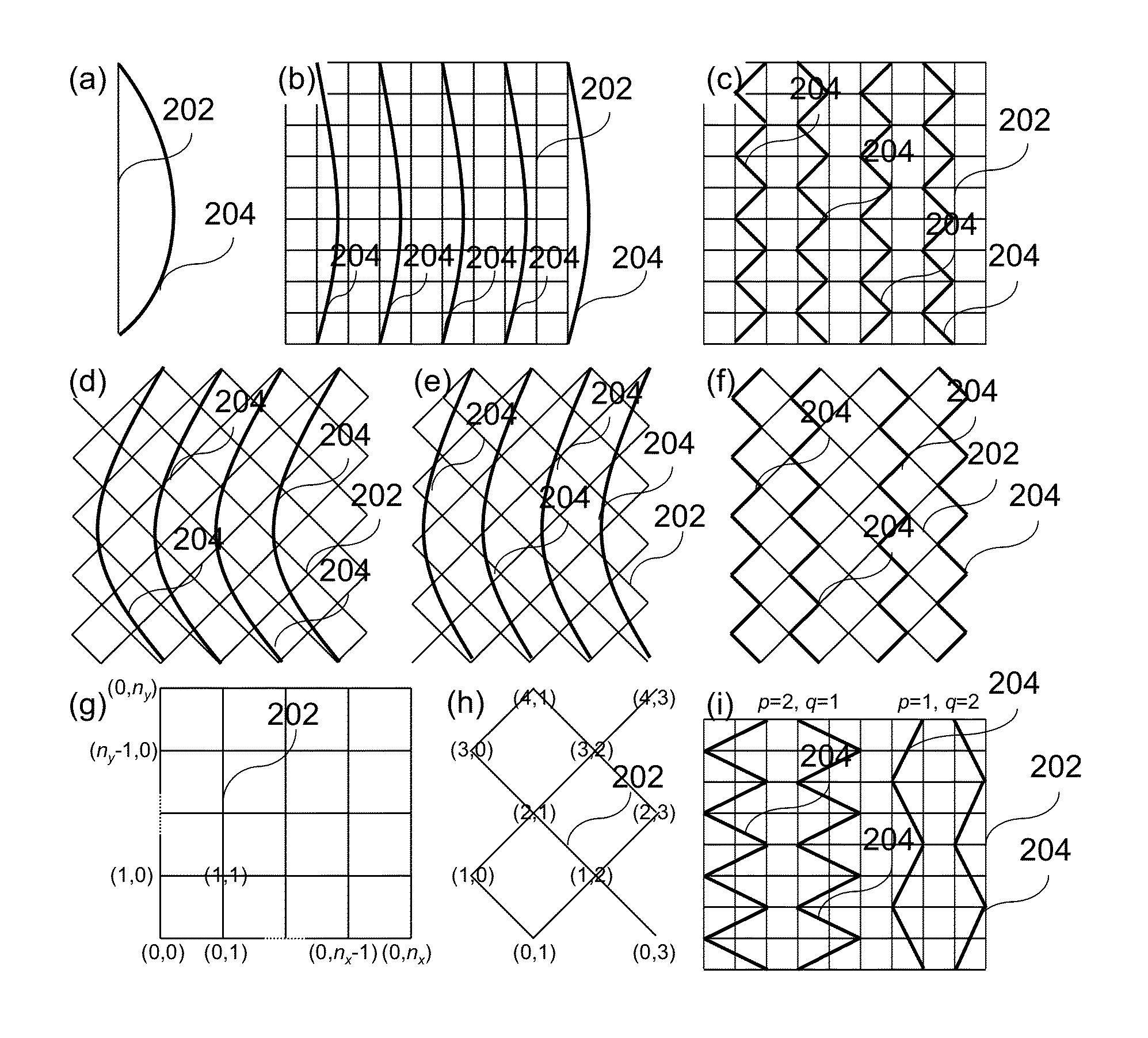

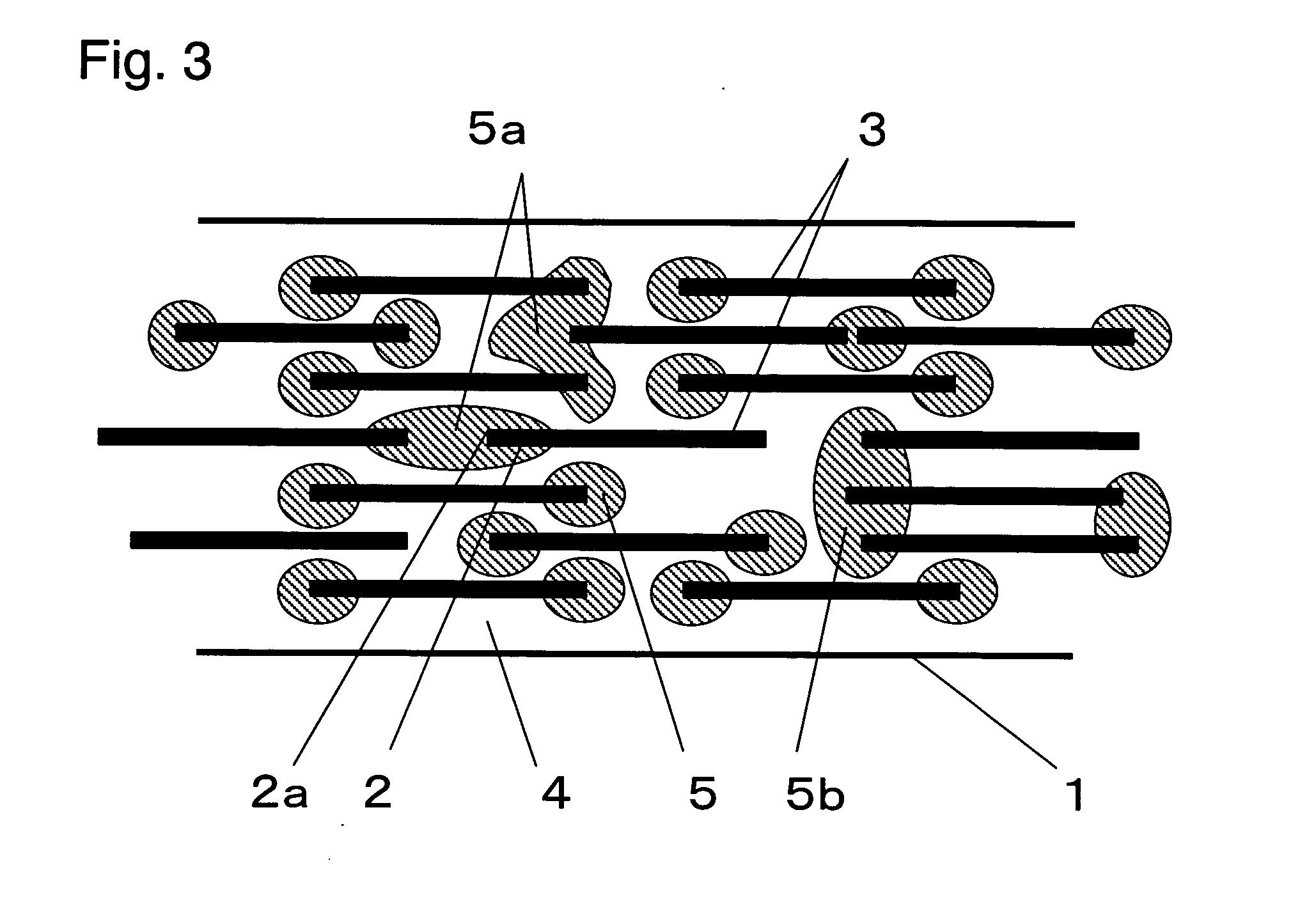

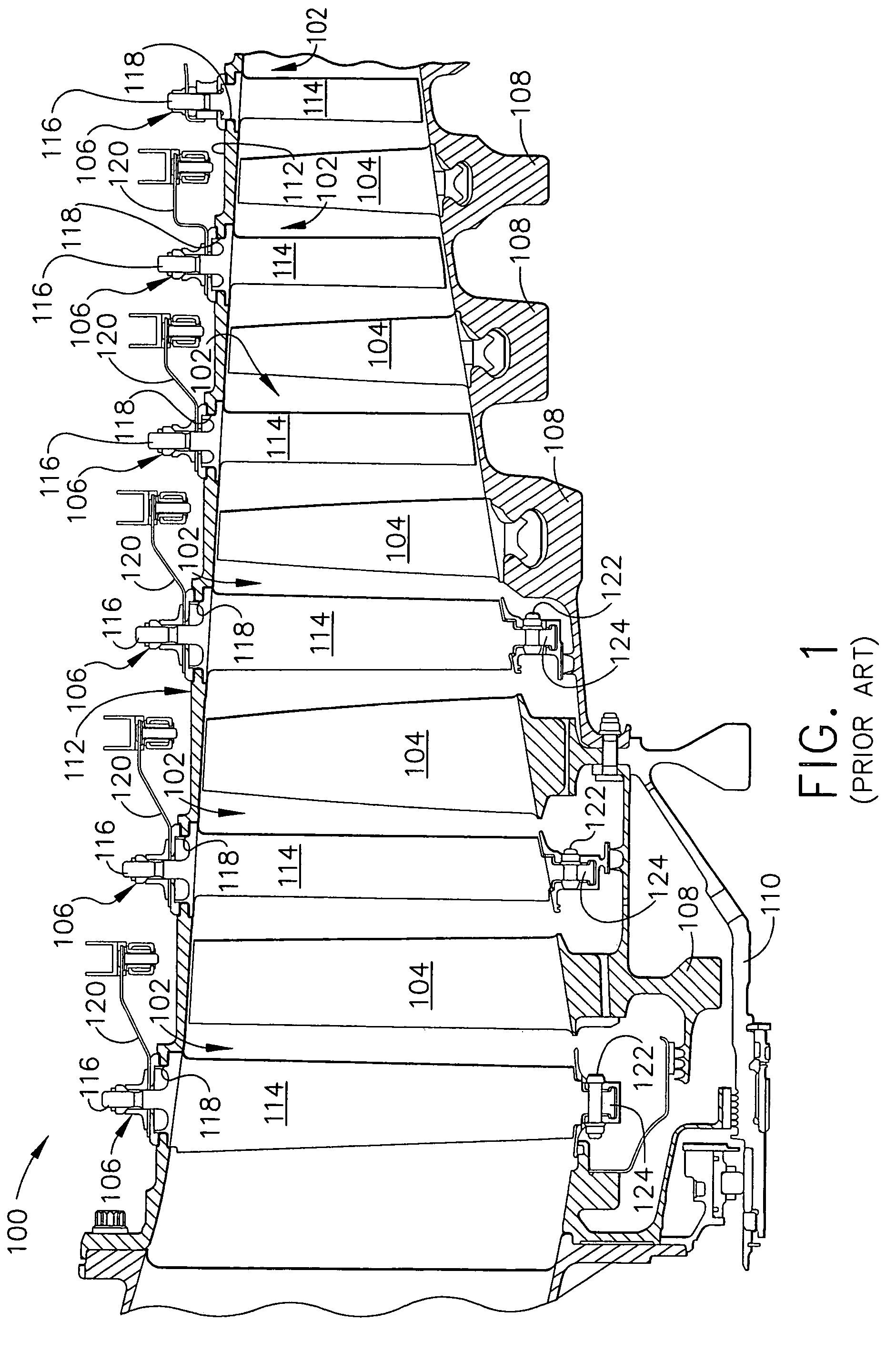

Lightweight unit load device

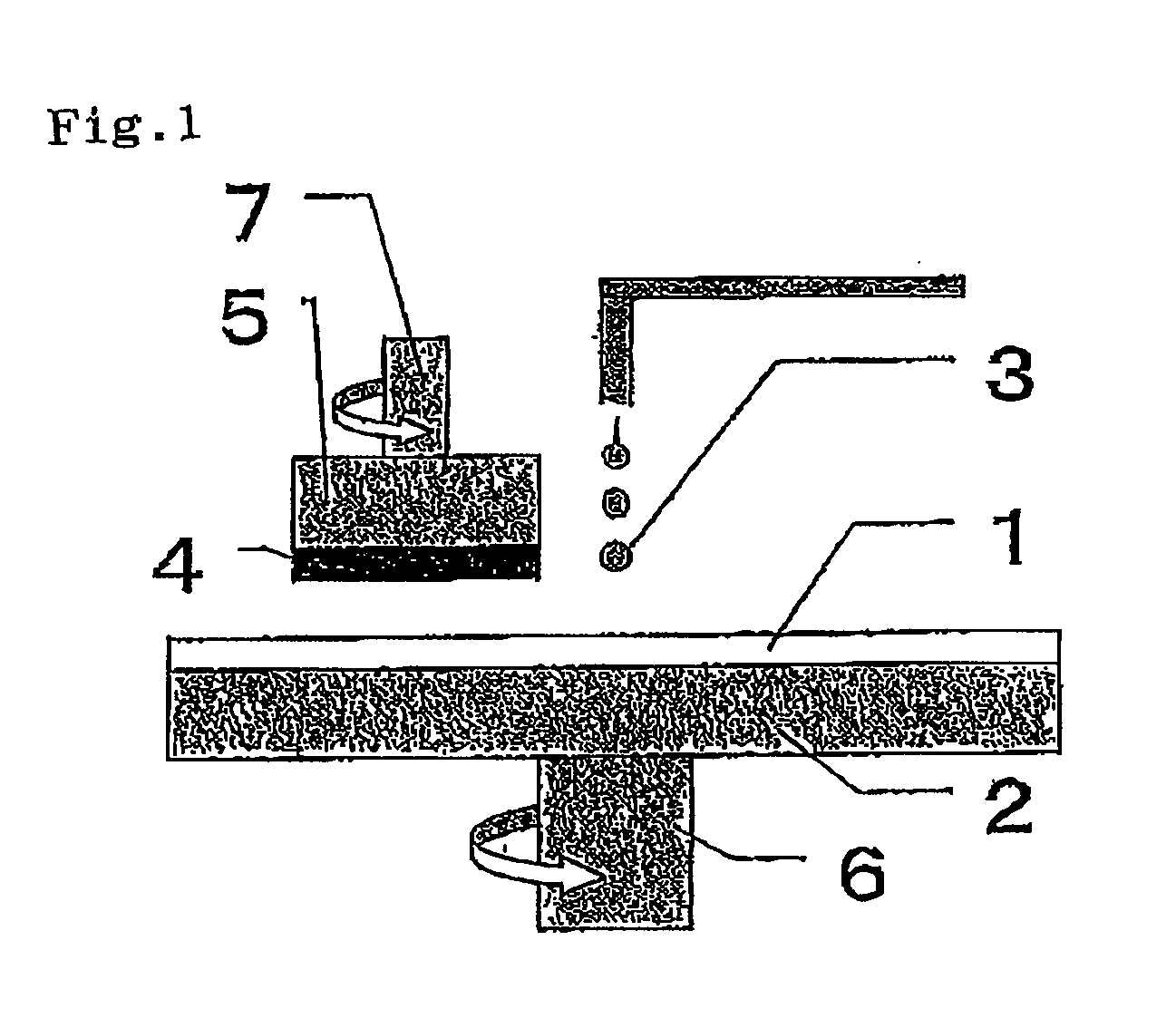

InactiveUS20110247958A1Reduce weightRaise the ratioSynthetic resin layered productsLarge containersUnit load deviceUnit device

A unit load device constructed from fiber reinforced polymer matrix composite materials is described. Individual panels of the unit load device may be customized with composite materials and patterns. The joints are adapted to receive the ends of the panels of the unit load device and may further be customized with fiber reinforced composite materials to strengthen the joint. Some embodiments provide for construction of a unit load device from a variety of fiber reinforcing materials utilizing a matrix of thermoplastic polymers with similar softening temperatures. Each component part within the container was designed and / or created to address the specific needs of the particular part. The unit load devices described herein provide for all composite containers with a significant weight savings from conventional unit load devices.

Owner:COMPOSITE TRANSPORT TECH

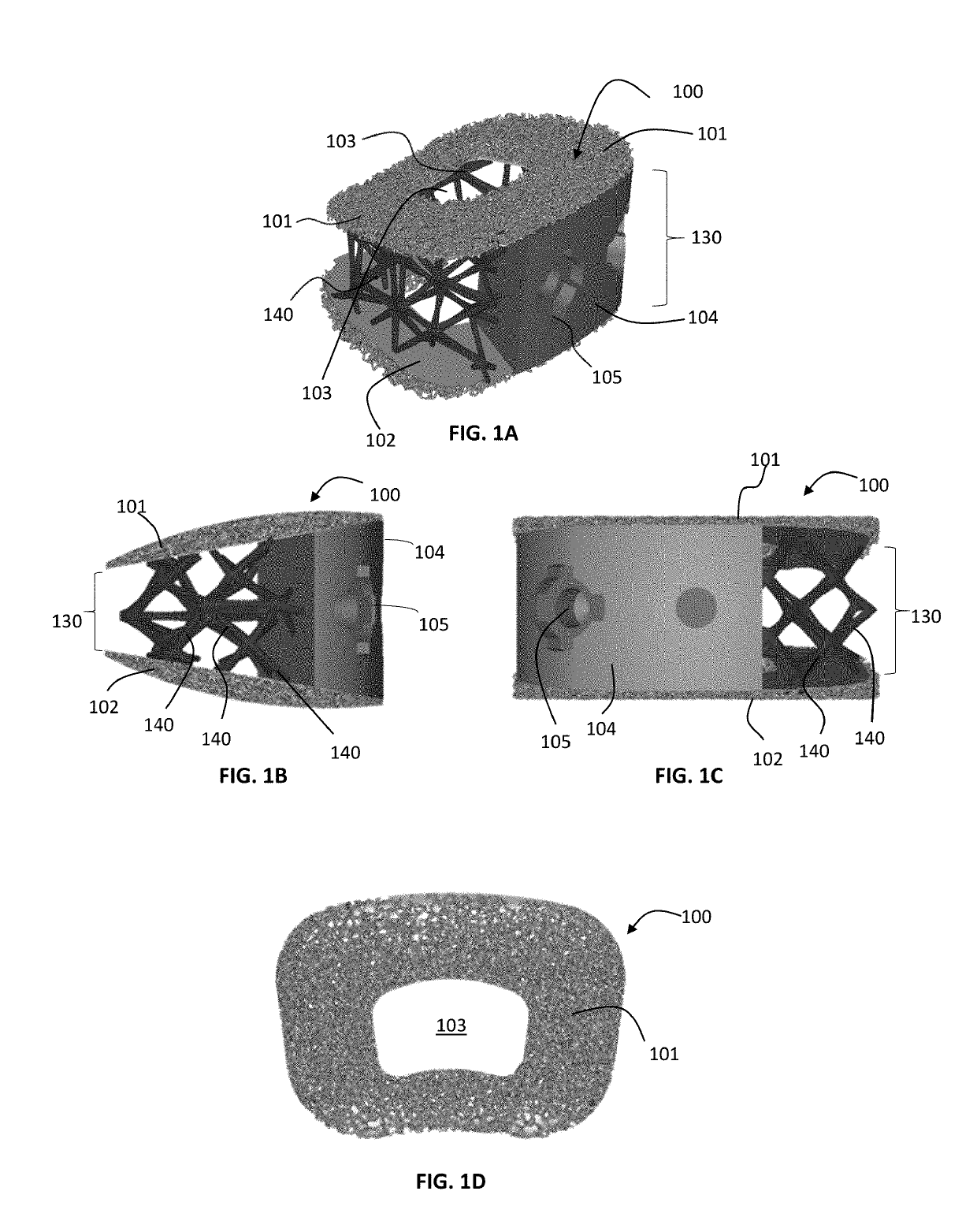

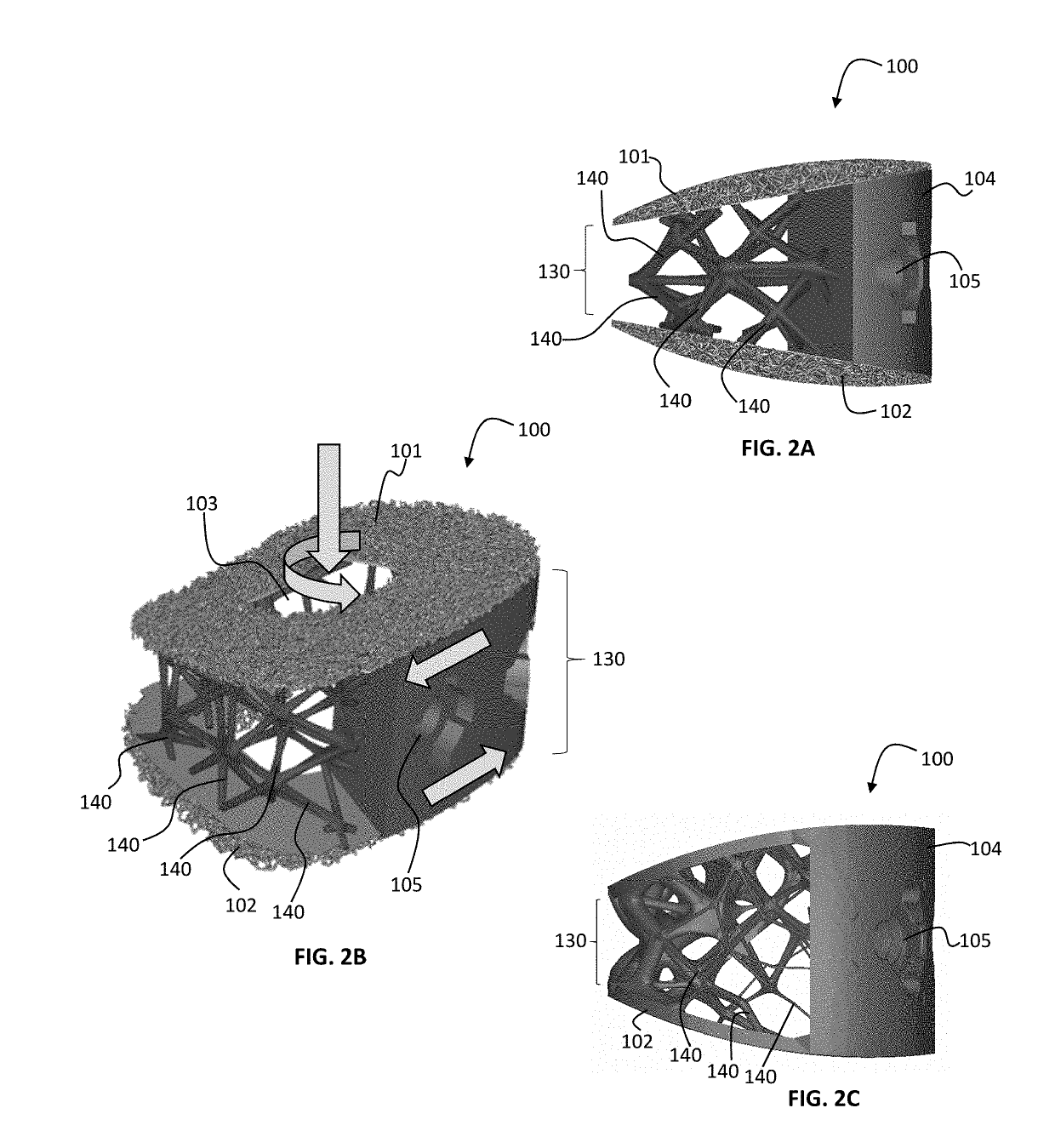

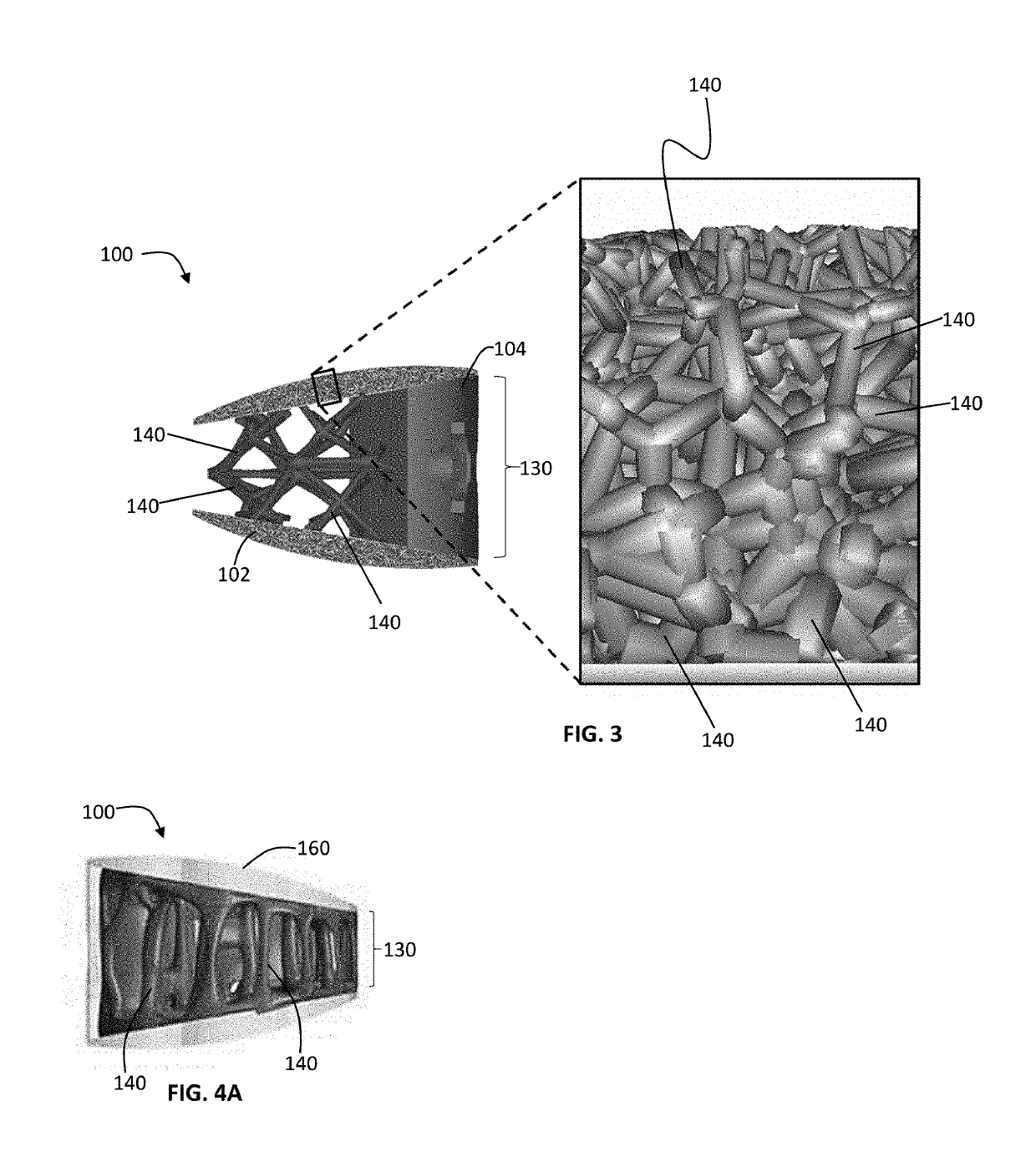

Porous Spinal Fusion Implant

ActiveUS20190133783A1Lower elastic modulusJoint implantsSpinal implantsBiomedical engineeringSpinal fusion

The present disclosure in one aspect provides a surgical implant comprising an upper bone contacting surface comprising a plurality of irregularly shaped pores having an average pore size, where the pores are formed by a plurality of struts, a lower bone contacting surface comprising a plurality of irregularly shaped pores having an average pore size, wherein the pores are formed by a plurality of struts; and a central body comprising a plurality of irregularly shaped pores having an average pore size, wherein the pores are formed by a plurality of struts, wherein the average pore size on the upper and lower bone contacting surfaces is different than the average pore size on the central body.

Owner:NUVASIVE

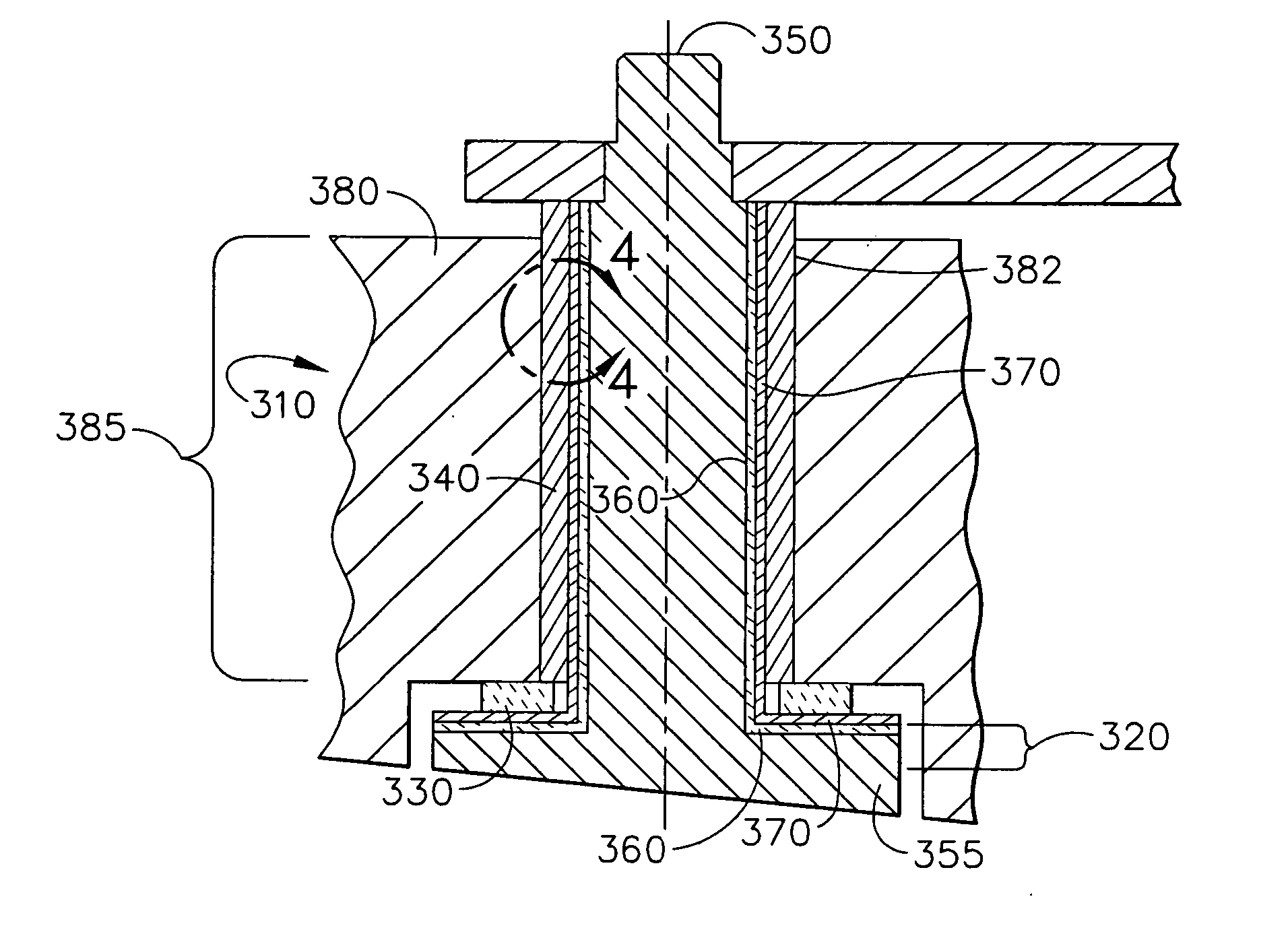

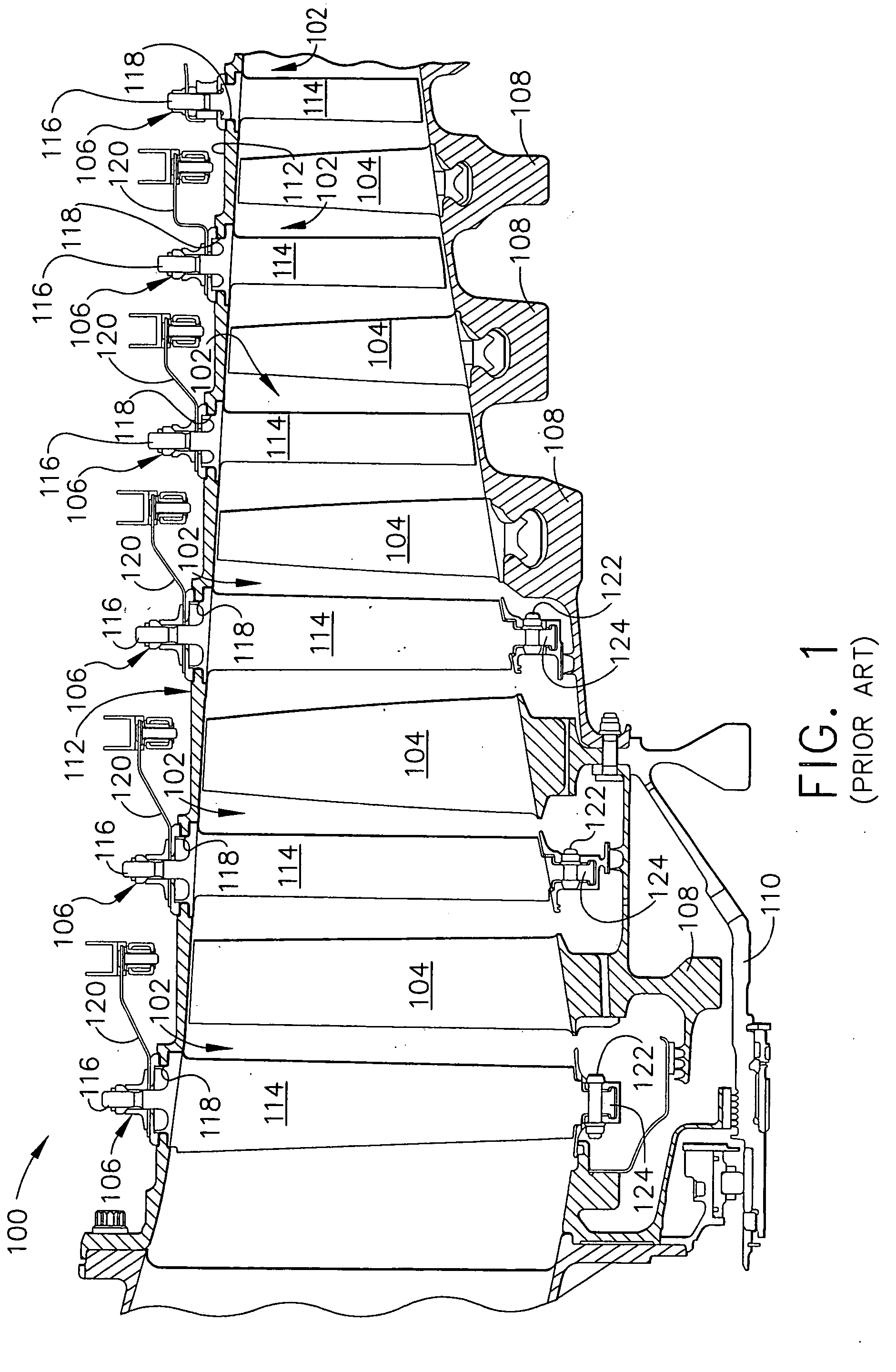

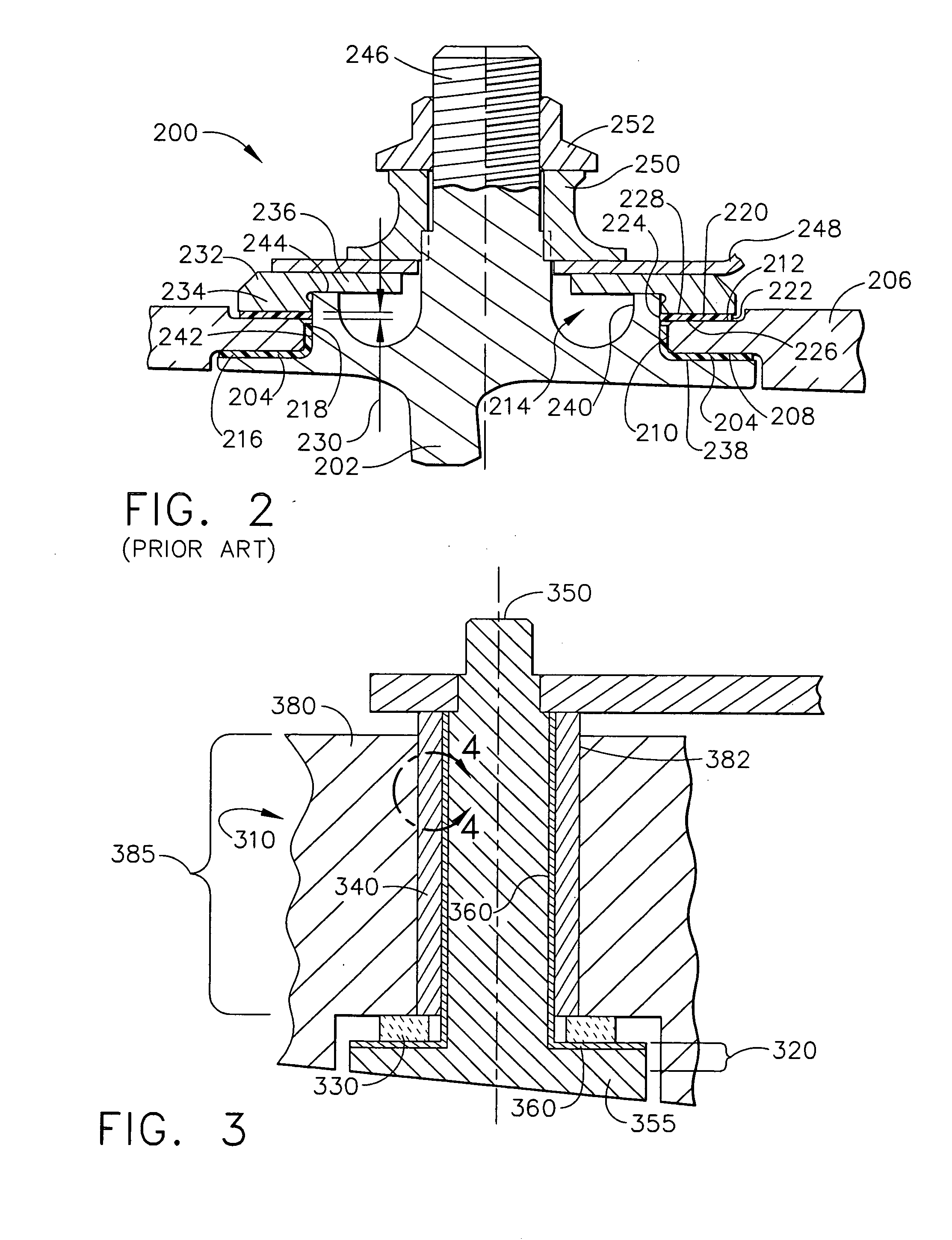

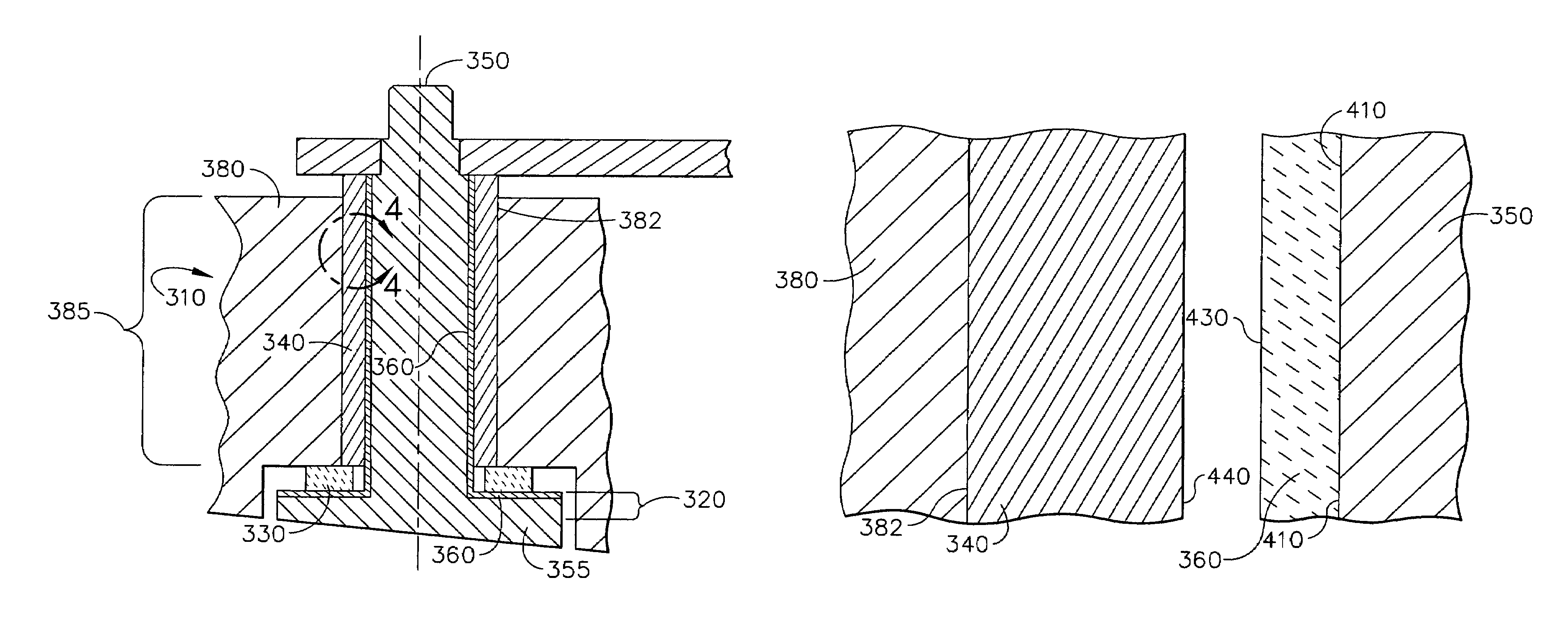

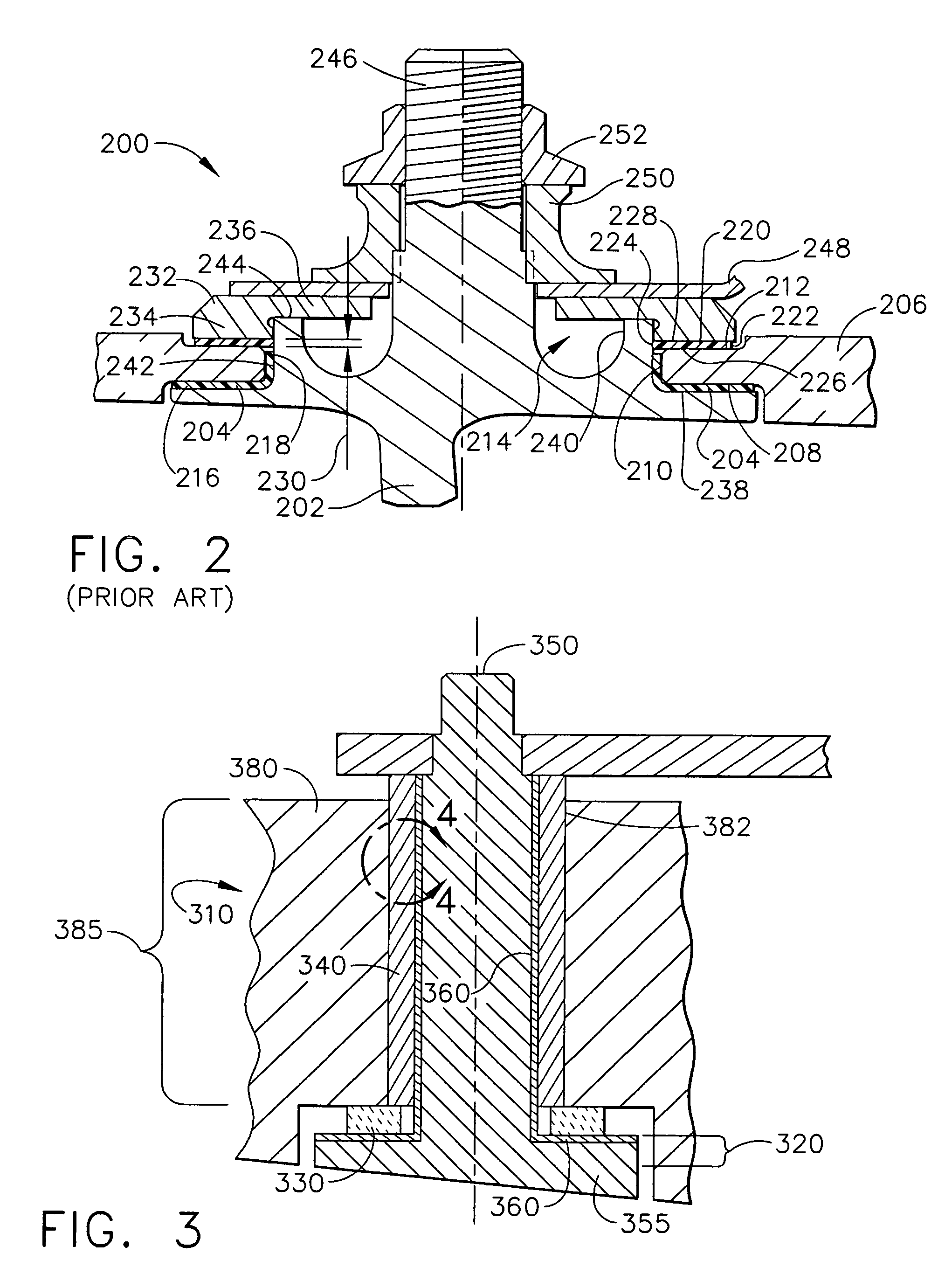

Variable stator vane bushings and washers

InactiveUS20060110246A1Reduce overhaul costsImprove efficiencyPump componentsWind motor controlTitanium nitrideTurbine

A variable stator vane assembly for use in a compressor section of a turbine engine having a plurality of movable metallic stator vanes and a method for making a variable stator vane assembly. The variable stator vane assembly includes a metallic stator casing supporting the vanes and a bushing system positioned between the stator vanes and the stator casings. The bushing system includes a bushing fabricated from a material selected from the group consisting of metal, ceramic or combinations thereof. The variable stator vane further including a titanium nitride wear coating disposed on a surface of the vanes in contact with the bushing system.

Owner:GENERAL ELECTRIC CO

Biomimetic multiple strand fiber mesh and sutures

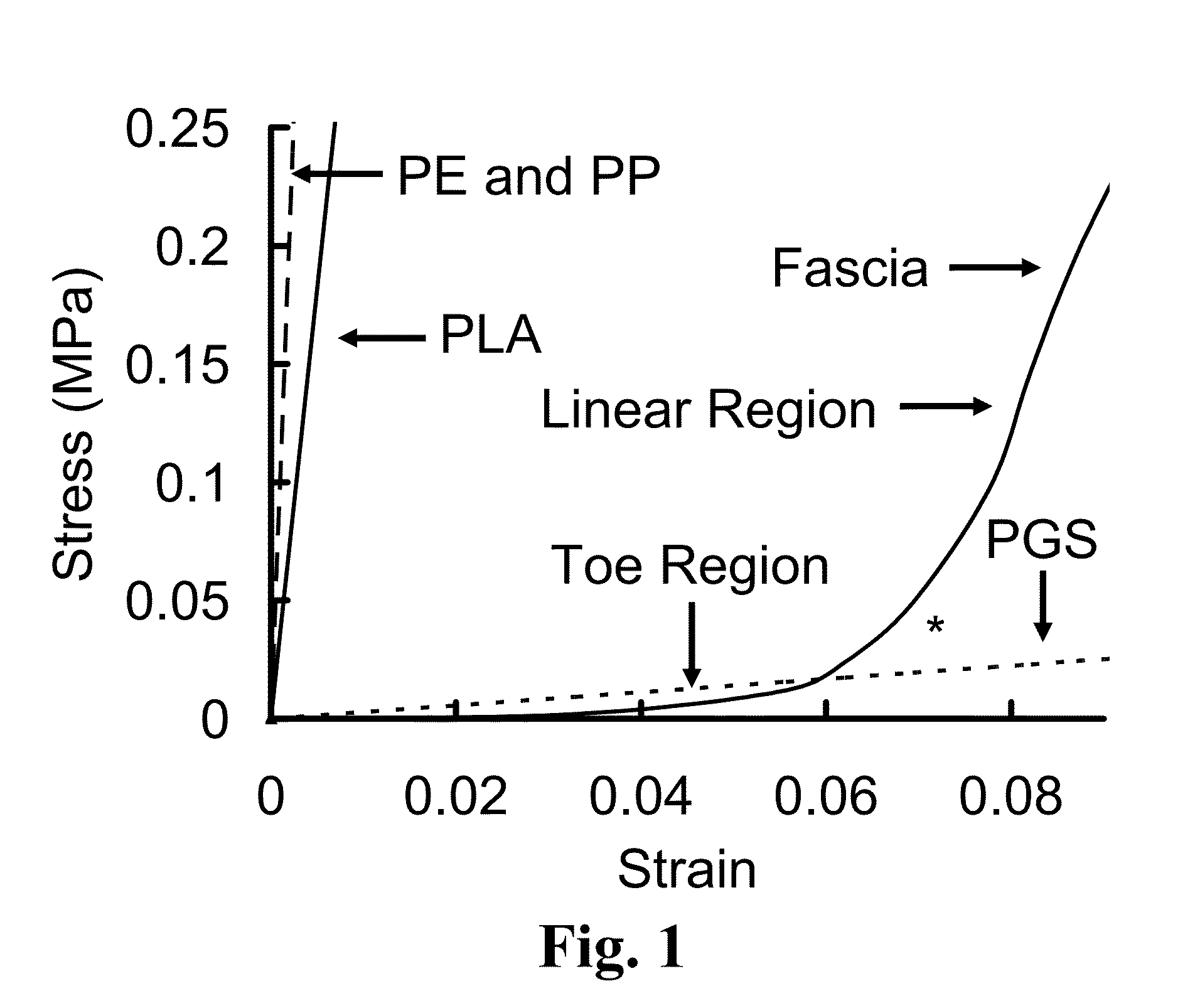

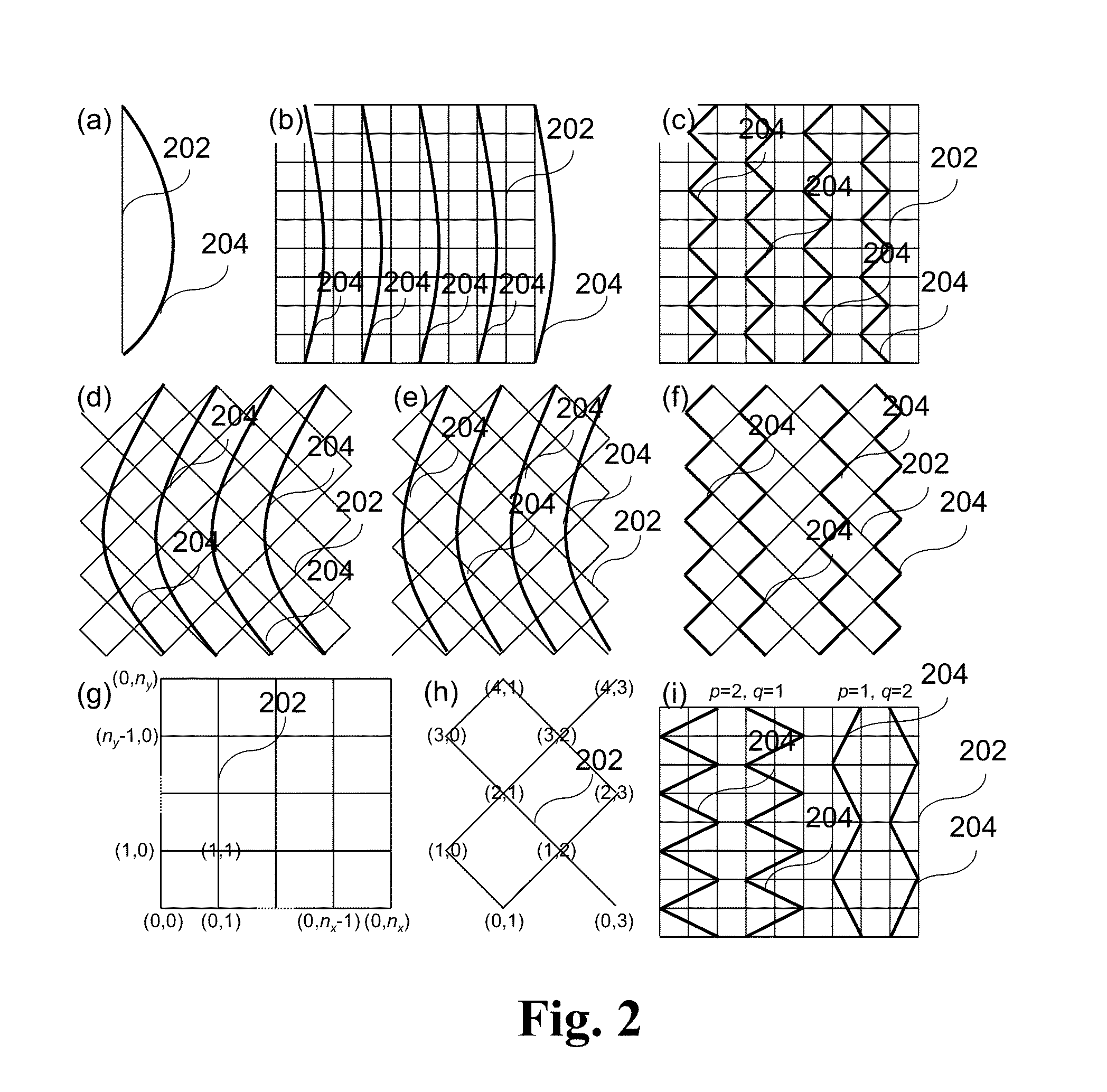

InactiveUS20130103079A1Lower elastic modulusHigh elastic modulusSuture equipmentsFiberMaterials science

A material comprising two or more fibers, wherein each of the fibers has a mechanical modulus, and the mechanical modulus of at least one fiber is higher than the mechanical modulus of another fiber. The higher modulus fiber has a longer length than the lower modulus fiber. In various embodiments, the higher modulus fiber is collagen mimetic and the lower modulus fiber is elastin mimetic. A suture is also described, comprising two or more fibers. At least one of the fibers is elastin-like and has a lower elastic modulus than another fiber that is collagen-like and has a higher elastic modulus. The higher modulus collagen-like fiber is longer than the lower modulus elastin-like fiber.

Owner:NOVO IP LLC

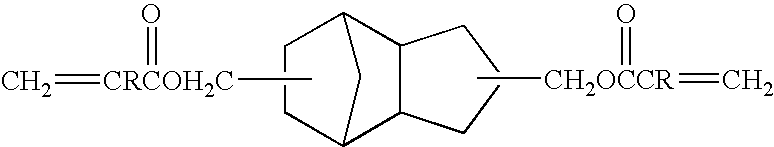

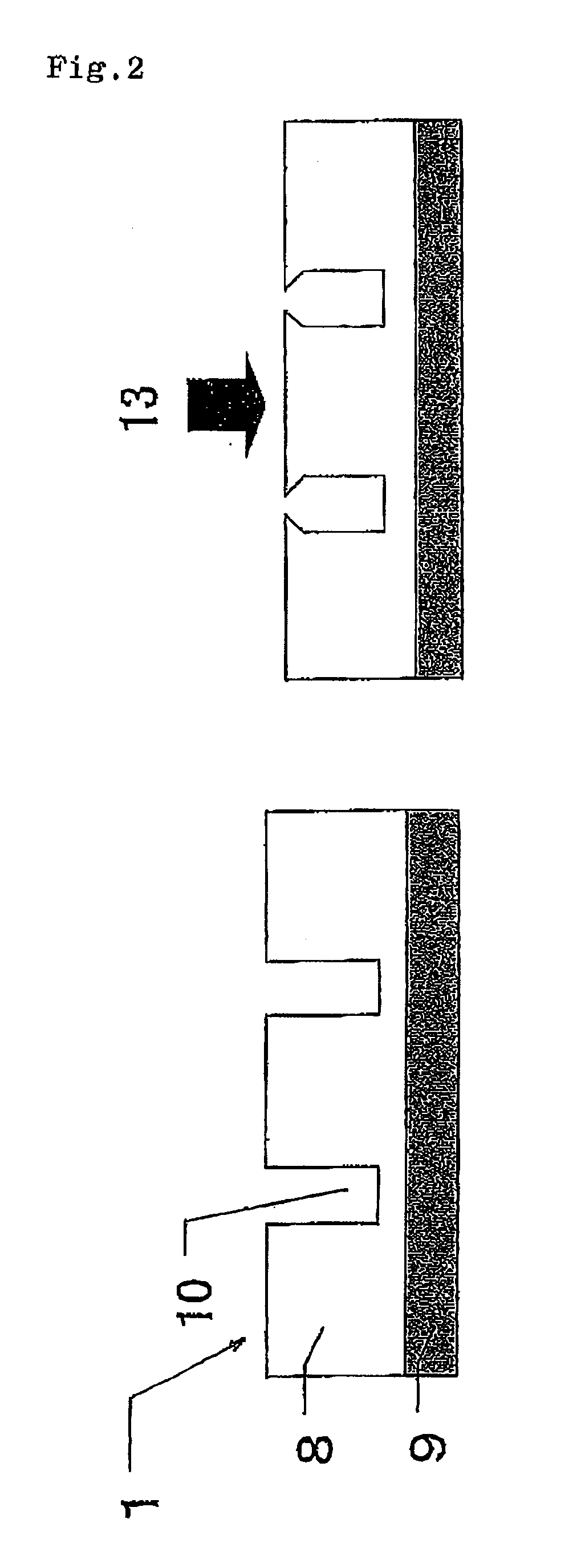

Fiber-reinforced composite material and method for production thereof

InactiveUS20050053787A1Lower elastic modulusWood working apparatusDomestic articlesElastic modulusFiber-reinforced composite

A fiber-reinforced composite material comprised of reinforcing fibers and a matrix resin, wherein at least some of the reinforcing fibers have their ends in the matrix resin, characterizes in that a second resin having an elastic modulus less than that of the matrix resin is present in contact with fiber ends of at least some of reinforcing fibers having above-mentioned ends and only in the neighborhood thereof.

Owner:TORAY IND INC

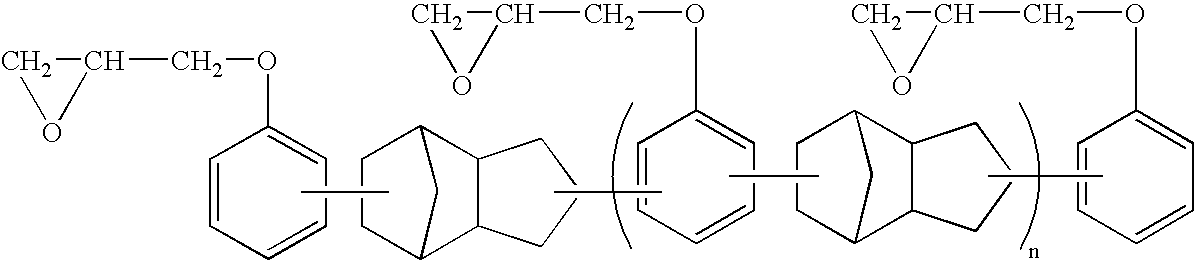

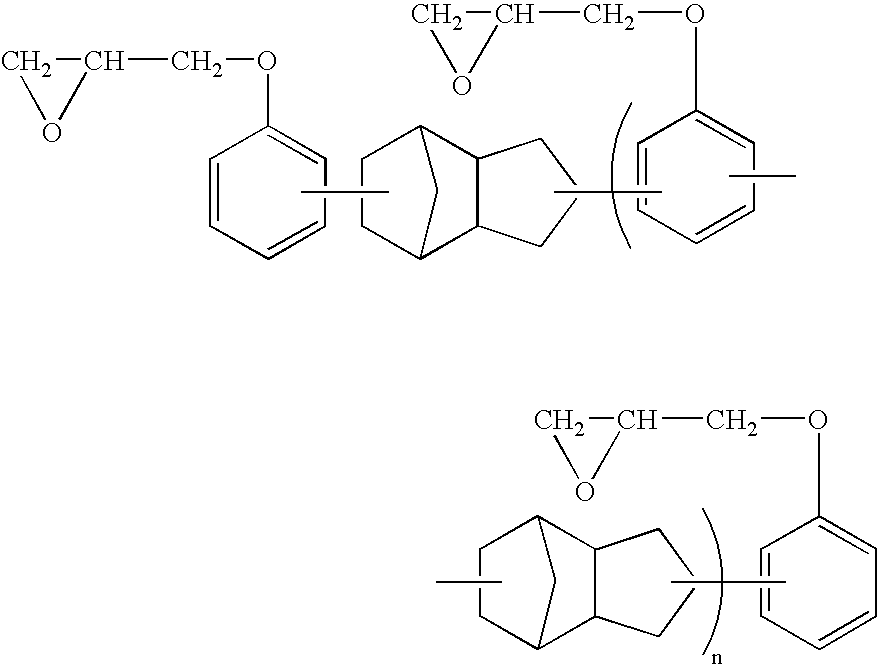

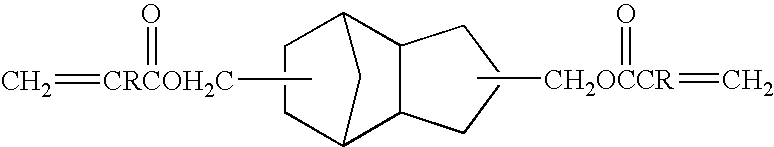

Adhesive tape

InactiveUS20040232563A1Improve abilitiesAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesEpoxyElastic modulus

An adhesive tape comprising a base and, superimposed thereon, an adhesive layer, this adhesive layer comprising an adherent component (A), an epoxy resin (B), a thermally active latent epoxy resin curing agent (C), an energy radiation polymerizable compound (D) and a photopolymerization initiator (E), wherein either or both of the epoxy resin (B) and energy radiation polymerizable compound (D) have a dicyclopentadiene skeleton in its molecule or molecules thereof. The resultant adhesive tape has an adhesive layer which provides reduced water absorption of an adhesive curing product and which enables a lowering of the elastic modulus thereof during thermocompression bonding.

Owner:LINTEC CORP

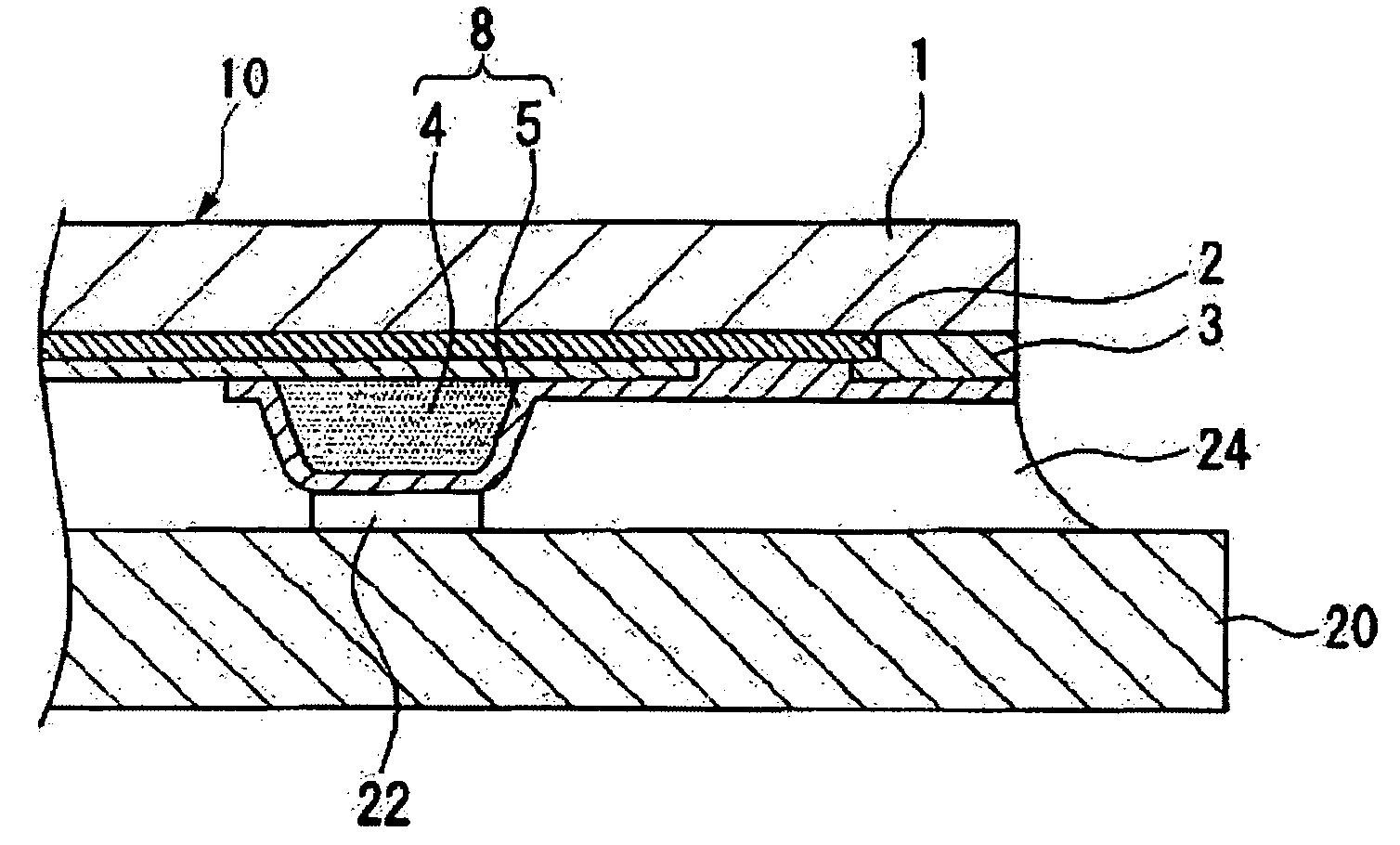

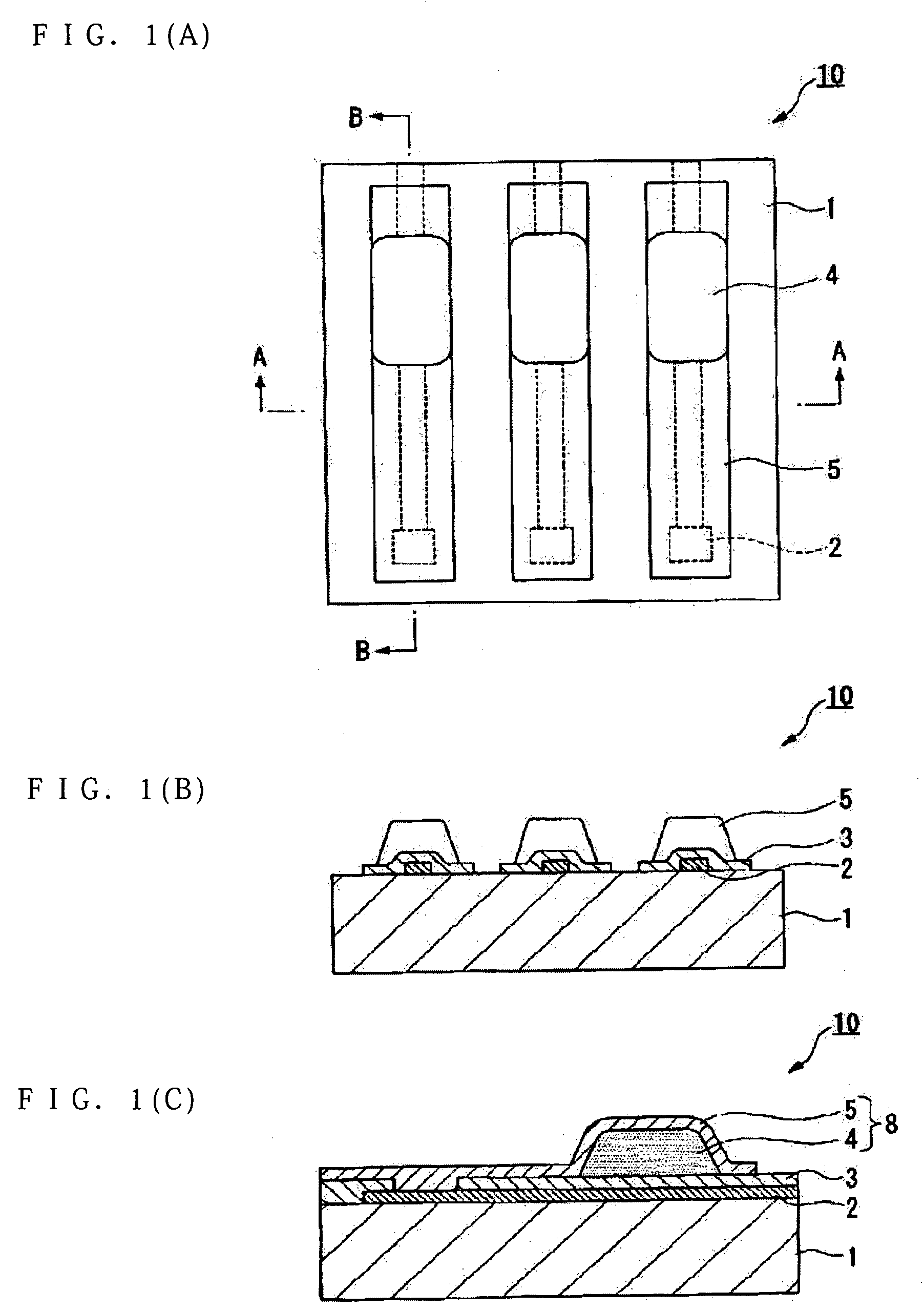

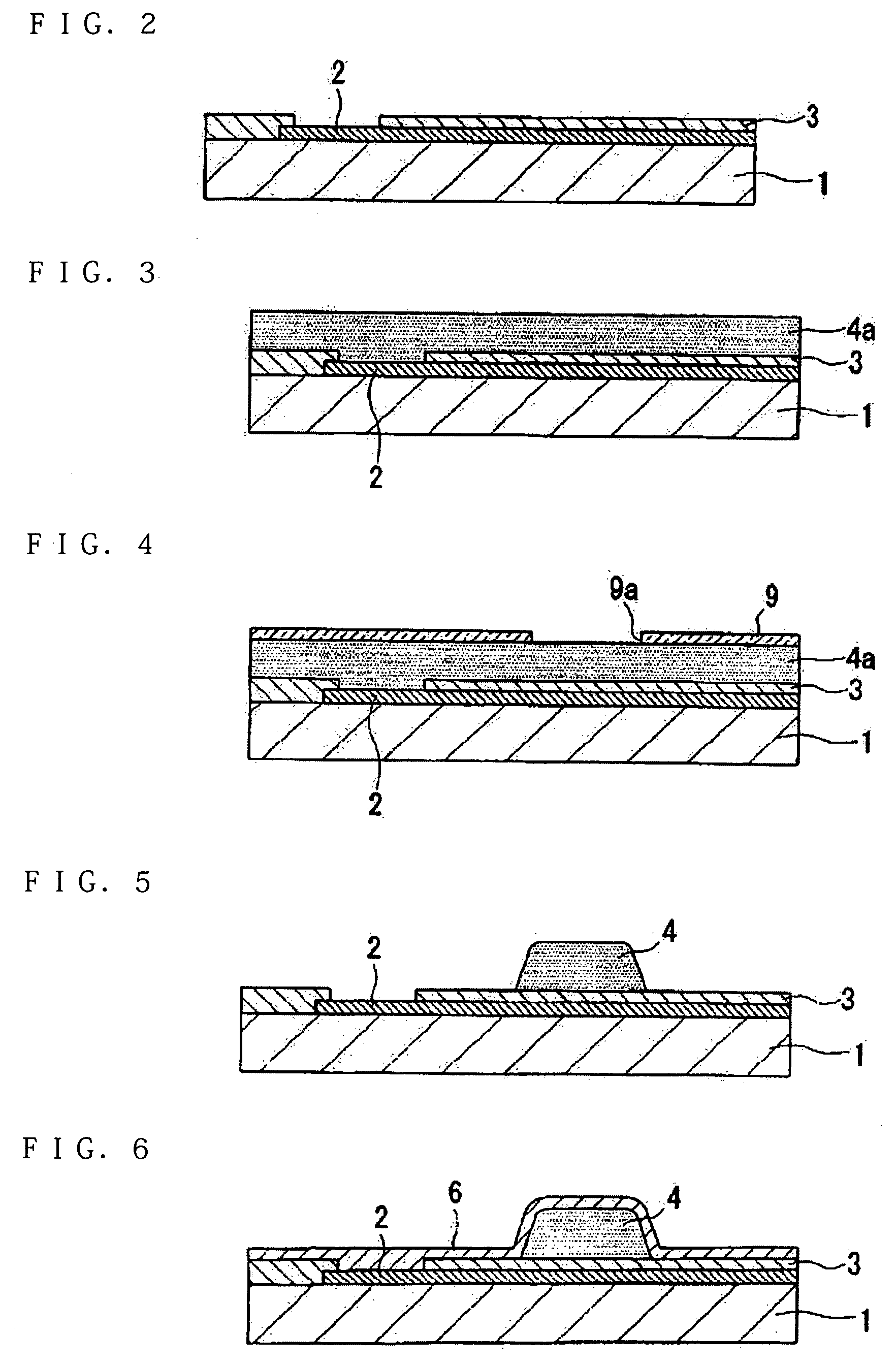

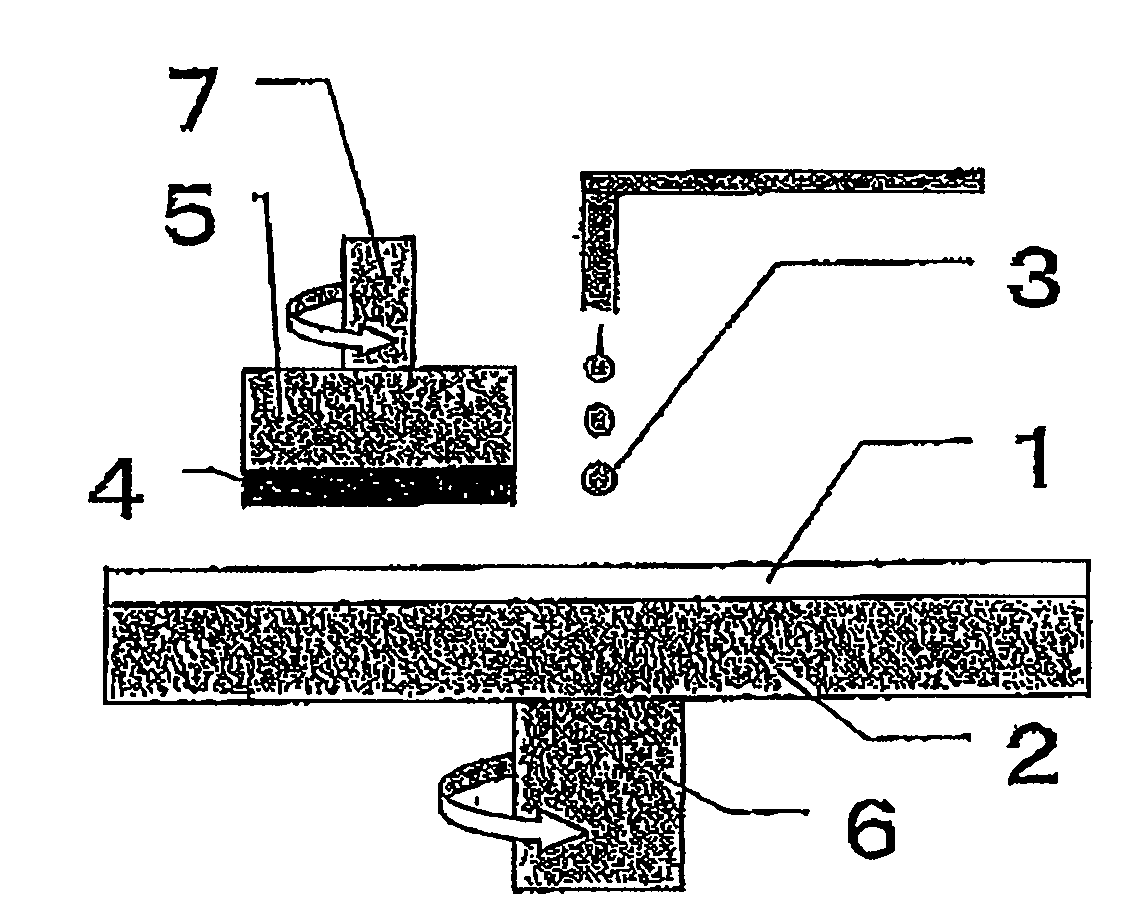

Method for mounting semiconductor device, as well as circuit board, electrooptic device, and electronic device

InactiveUS20050236104A1Improve reliabilityHigh elastic modulusSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectro-optics

A method of forming a bonded structure comprises the steps of: mounting a semiconductor device having an electrode; a convexity protruding higher than the electrode and formed of a resin; and a conductive unit electrically coupled to the electrode and extending over the surface of the convexity, onto a specific substrate with an intermediary of a bonding material; and mounting the semiconductor device by hot pressing within a temperature range including the glass transition temperature of the resin.

Owner:SEIKO EPSON CORP

Method for Production of a Laminate Polishing Pad

ActiveUS20080305720A1Reduce in quantityImprove productivityAbrasion apparatusSemiconductor/solid-state device manufacturingProduction rateSlurry

Disclosed is a method for production of a laminate polishing pad which comprises a reduced number of steps and is excellent in productivity rate, and which causes no detachment between a polishing layer and a cushion layer and can prevent the groove clogging caused by a slurry or the like. Also disclosed is a laminate polishing pad produced by the method. A method for production of a laminate polishing pad, comprising the steps of: preparing a cell-dispersed urethane composition by a mechanical frothing process; ejecting the cell-dispersed urethane composition onto a cushion layer continuously while feeding the cushion layer; curing the cell-dispersed urethane composition while controlling the thickness of the composition evenly to form a polishing layer made of a polyurethane foam, thereby producing a long laminate sheet; and cutting the long laminate sheet.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

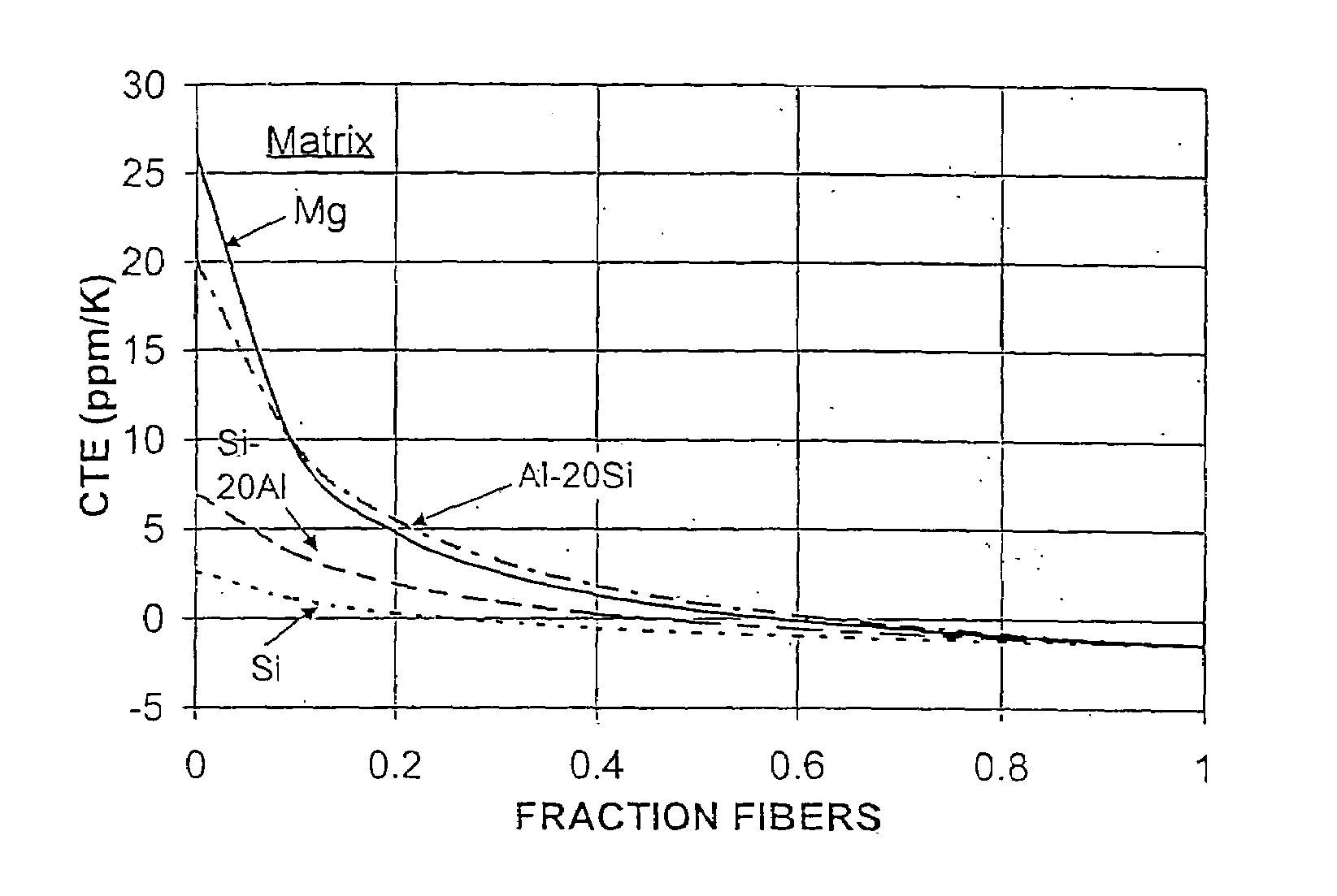

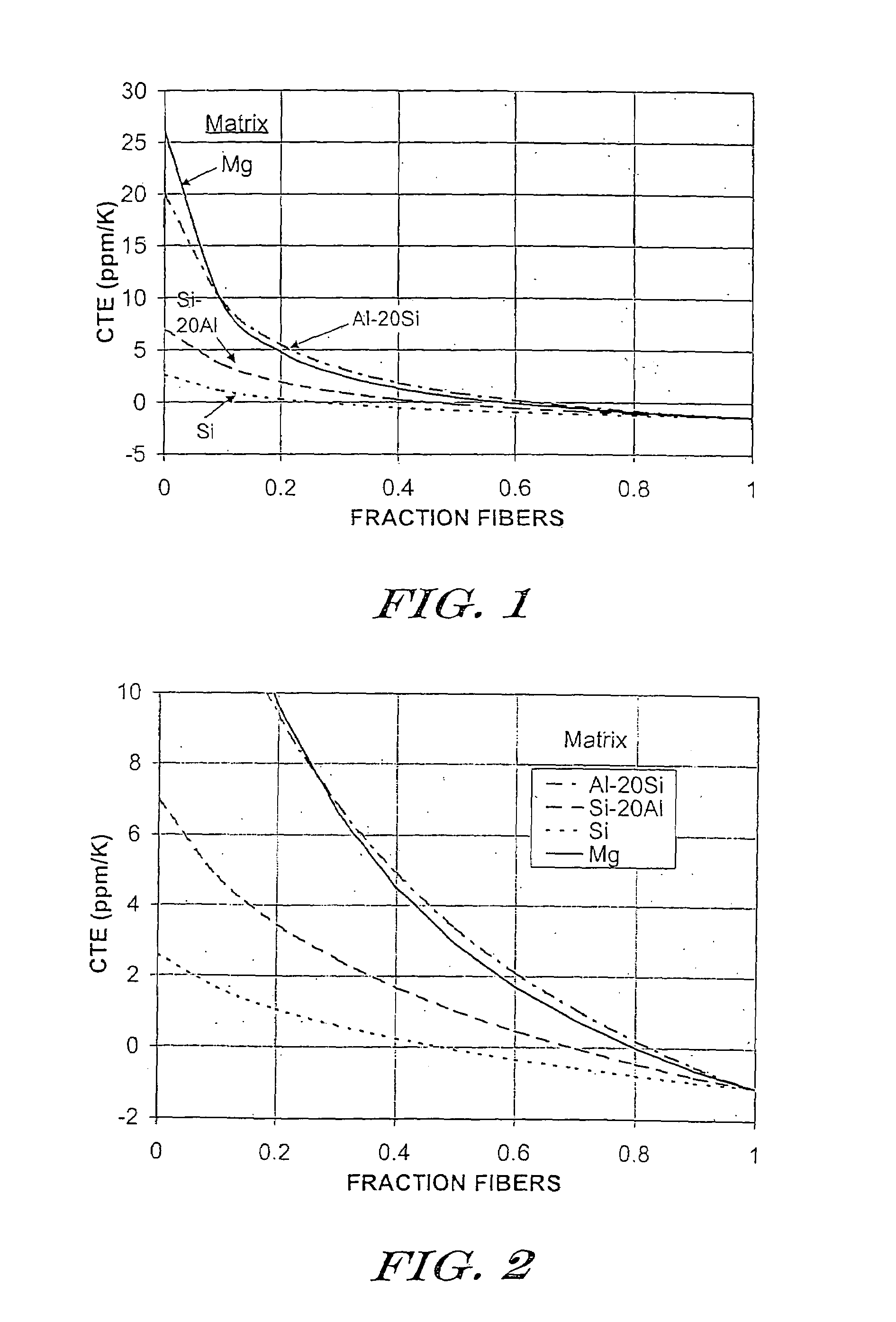

Low expansion metal-ceramic composite bodies, and methods for making same

InactiveUS7169465B1Reduce bloatMore impactMaterial nanotechnologyNatural cellulose pulp/paperFiberCeramic composite

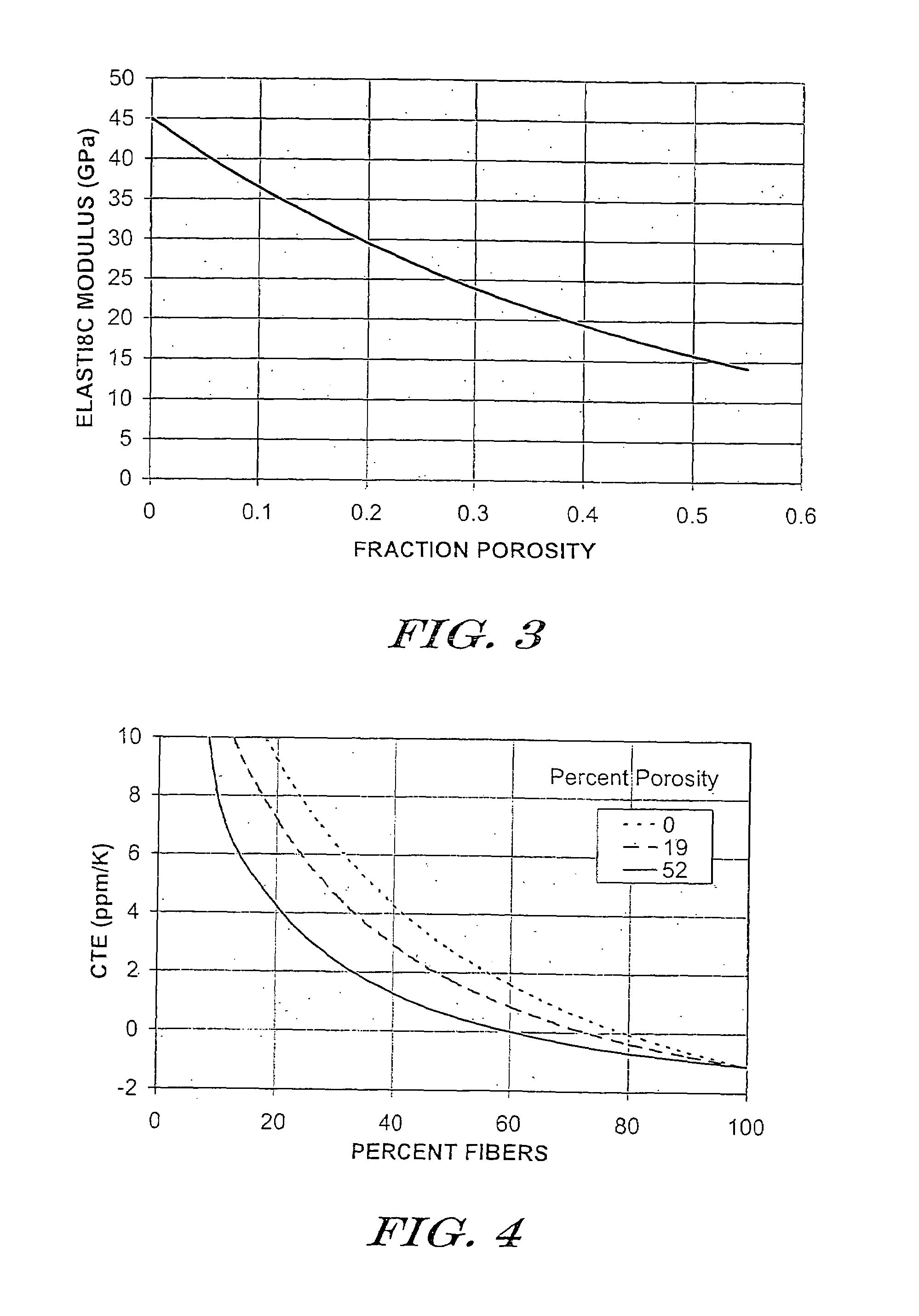

A low CTE metal-ceramic composite material featuring carbon fibers reinforcing a matrix featuring silicon metal or silicon alloy. The fibers have a low coefficient of thermal expansion (CTE) in the axial direction, and preferably negative. The principles of making Si / SiC composites can be adapted to produce the instant Si matrix composites. The CTE of the composite body depends not only upon the relative CTE's of the fibers and matrix, and their relative amounts (e.g., loadings), but also upon the relative elastic moduli of the fibers and matrix. Thus, Si / SiC matrices produced by a reaction-bonding process inherently possess low CTE, but the instant inventors prefer to make such composites having relatively large fractions of unreacted silicon, thereby driving composite CTE lower still. Here, the carbon fibers are protected from reaction with the silicon infiltrant with one or more materials disposed between the fibers and the infiltrant. Providing at least a degree of toughness or impact resistance can also be realized in these composites. Laminates produce Isotropic or quasi-isotropic properties in the composite body can be realized by, for example, providing the fibers in the form of cross-plied laminates featuring the fibers in parallel or woven arrays.

Owner:II VI DELAWARE INC

Variable stator vane bushings and washers

InactiveUS7163369B2Equal and good wear resistanceReduce material costsWind motor controlPump componentsTitanium nitrideEngineering

Owner:GENERAL ELECTRIC CO

Pressure-sensitive adhesive sheet for surface protection

ActiveUS20120202058A1High resistanceIncrease suppressionSynthetic resin layered productsThin material handlingRise ratePressure sensitive

A surface-protecting pressure-sensitive adhesive sheet includes: a substrate; and a pressure-sensitive adhesive layer that is provided on at least one side of the substrate and made from a polyester-based pressure-sensitive adhesive composition containing a crosslinking agent and a polyester including at least a lactic acid unit, a dibasic acid unit, and a glycol unit. The dibasic acid unit includes a dimer acid, the polyester has a weight average molecular weight of 20,000 to 200,000 and a glass transition temperature of −70 to −20° C. as measured using a differential scanning calorimeter at a temperature rise rate of 20° C. / minute, the polyester-based pressure-sensitive adhesive composition has a hydroxyl value of 20 to 60 mgKOH / g, and the pressure-sensitive adhesive layer has a gel fraction of 85 to 99% by weight.

Owner:NITTO DENKO CORP

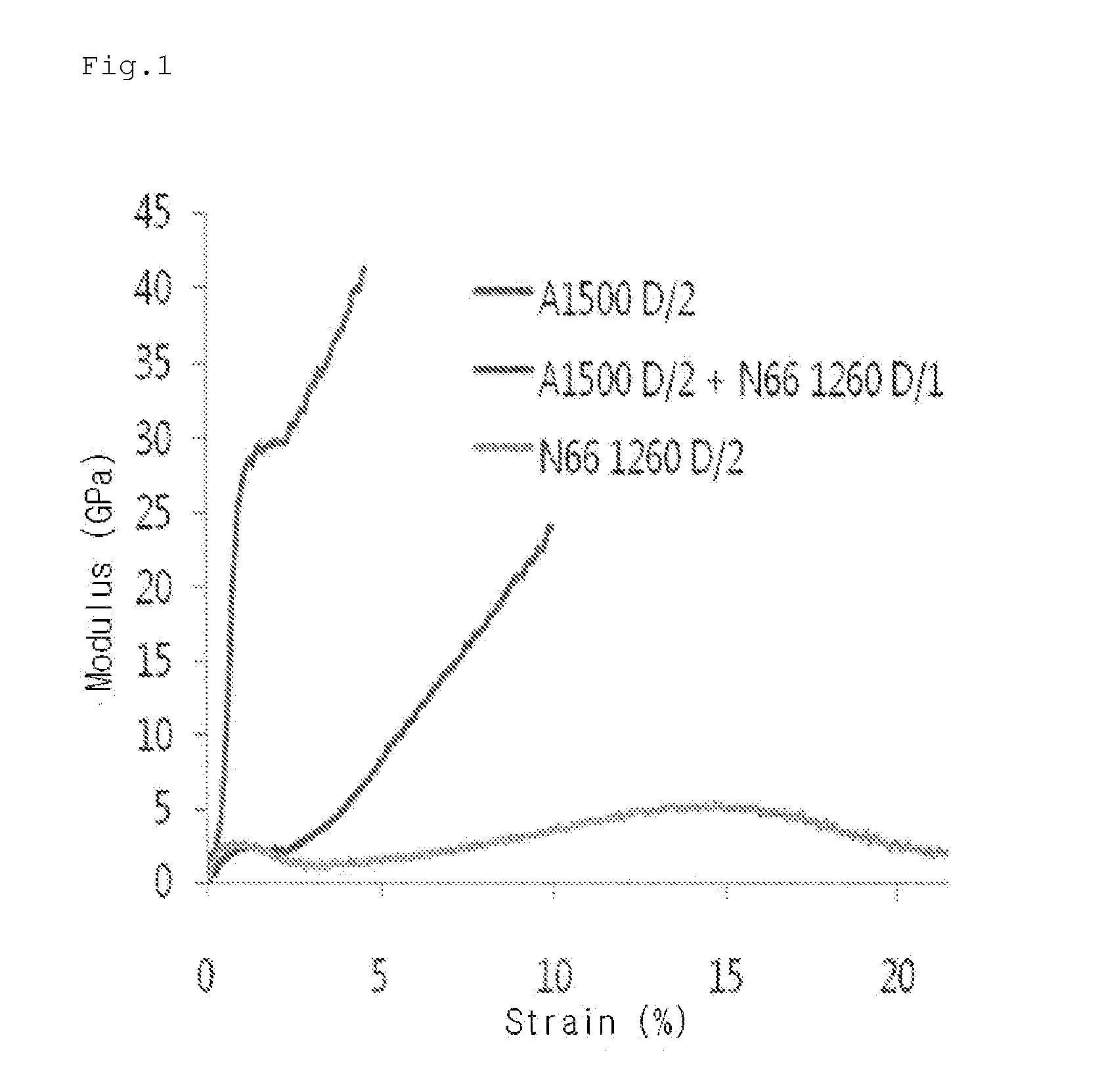

Hybrid cord composed of aramid cord and nylon 66 cord, and pneumatic tire using the same as reinforcing cord

InactiveUS20130025758A1High speed durabilityImprove steering stabilityPneumatic tyre reinforcementsYarnNylon 66Engineering

Provided is a high-performance pneumatic radial tire for passenger cars which uses a hybrid cord composed of an aramid cord and a Nylon 66 cord having different twist counts for the first twist and different twist counts for the second twist, as a reinforcing belt, and thereby has improved high speed durability and steering stability.

Owner:HANKOOK TIRE WORLDWIDE

Polyolefin resin composition, film, and multilayer structure

InactiveUS20040096682A1Few transferLower elastic modulusSynthetic resin layered productsThin material handlingButenePolymer science

A polyolefin base resin composition (A) comprising [I] a 1-butene base polymer in an amount of 1 to 99% by weight, [II] a propylene base resin in an amount of 99 to 1% by weight and a nucleus-forming agent in an amount of 10 ppm or more, wherein [I] the 1-butene base polymer satisfies the requirements of a melting point, a stereospecific index, a molecular weight distribution and a weight average molecular weight. The polyolefin base resin composition (A) provides a film which is excellent in a flexibility and an impact resistance and which rises in a crystal stabilizing rate, and the multilayer laminate in which at least one of outermost layers is constituted from a polyolefin resin composition (B) provides a multilayer film which is improved in a low temperature heat sealing property and a hot tacking property making the best use of an excellent characteristic of crystalline polyolefin.

Owner:IDEMITSU KOSAN CO LTD

Film base material for adhesive skin patch and adhesive skin patch

InactiveUS20050169975A1Change physical propertiesFailure in characteristicAdhesive dressingsAbsorbent padsFilm basePolypropylene glycol

To have acceptable moisture permeability and enable prevention of deformation due to swelling, the film base material for an adhesive skin patch includes an ether-based urethane resin obtained from at least one member selected from the group consisting of polyoxytetramethylene glycol, butanediol, polyethylene glycol, and polypropylene glycol as a diol component, and methylene diphenyl-diisocyanate as an isocyanate component. The film base material for an adhesive skin patch has a moisture permeability of preferably 800 to 4,000 g / m2·24 hrs. The adhesive skin patch can be produced by forming a pressure-sensitive adhesive layer on one side of the film base material for an adhesive skin patch.

Owner:NITTO DENKO CORP

Adhesive tape

InactiveUS7135224B2Low water absorptionImprove abilitiesSynthetic resin layered productsSolid-state devicesEpoxyElastic modulus

Owner:LINTEC CORP

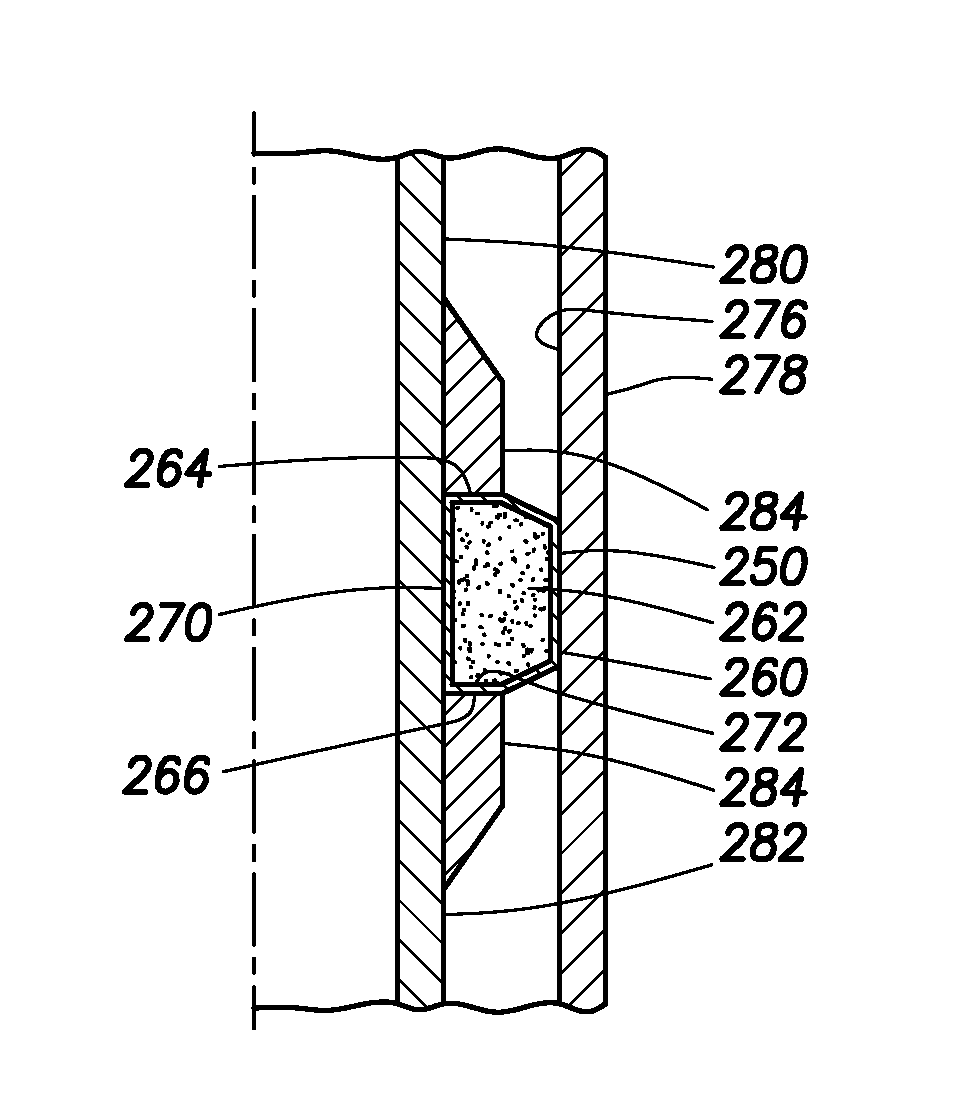

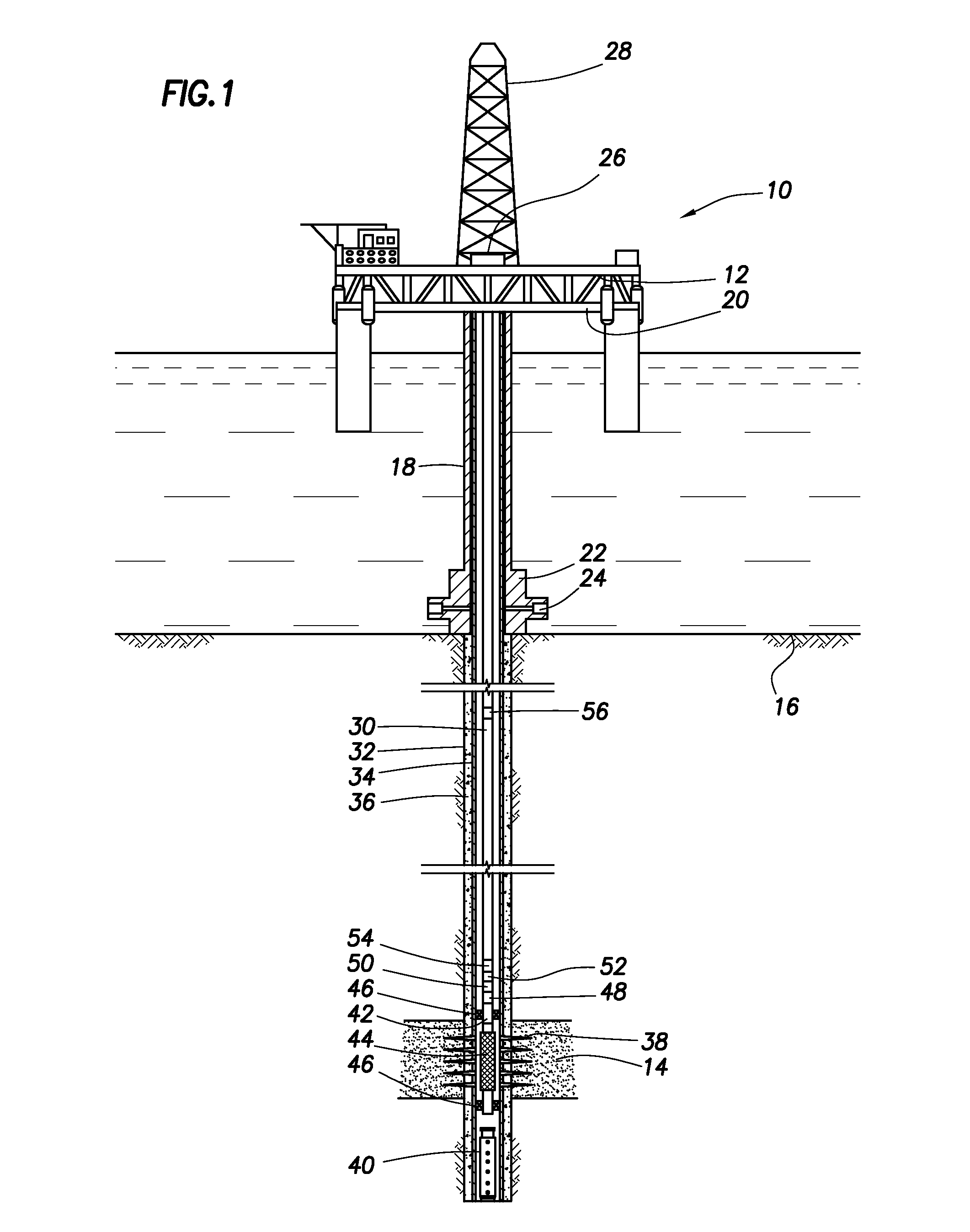

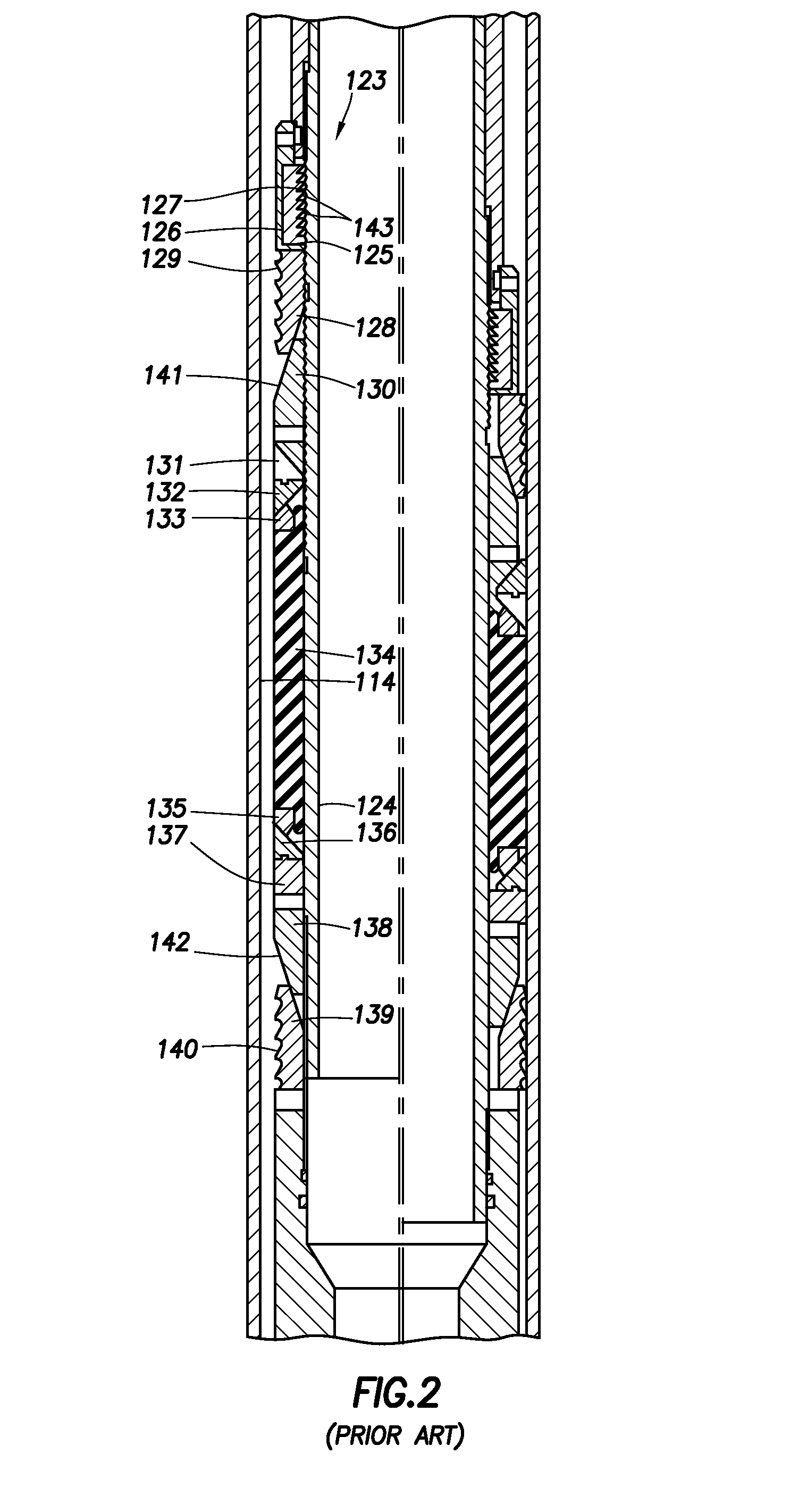

Multi-layered temperature responsive pressure isolation device

ActiveUS20150218903A1High melting pointLow melting pointEngine sealsDrilling rodsPolymerMaterials science

A sealing element comprises two distinct materials of different melting points. An outer shell material has a higher melting point than an inner core material. The core material can be a relatively low melting point metal, plastic or polymer. The seal is positioned in the wellbore and, in response to heating to a selected temperature, such as a bottom hole static temperature, the core material melts or softens. Upon melting or softening of the inner material, the outer shell's elastic modulus decreases, allowing longitudinal compression and radial expansion of the sealing element. The inner material can also thermally expand and thereby assist or cause radial expansion of the outer shell. The sealing element can provide a metal-to-metal seal with a casing or tubing. The cross-sectional shape of the outer shell can take various shapes to promote controlled compression, expansion and sealing.

Owner:HALLIBURTON ENERGY SERVICES INC

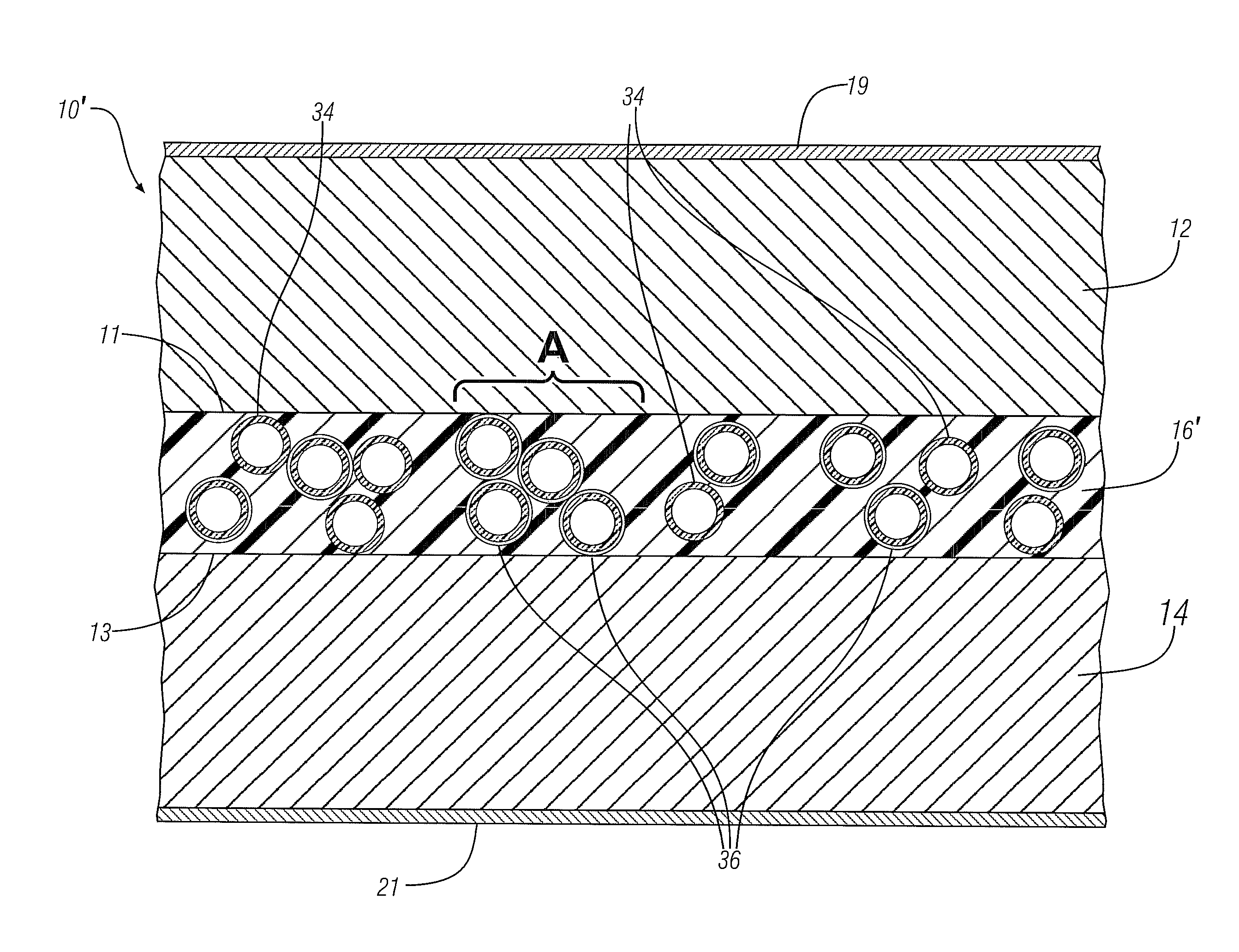

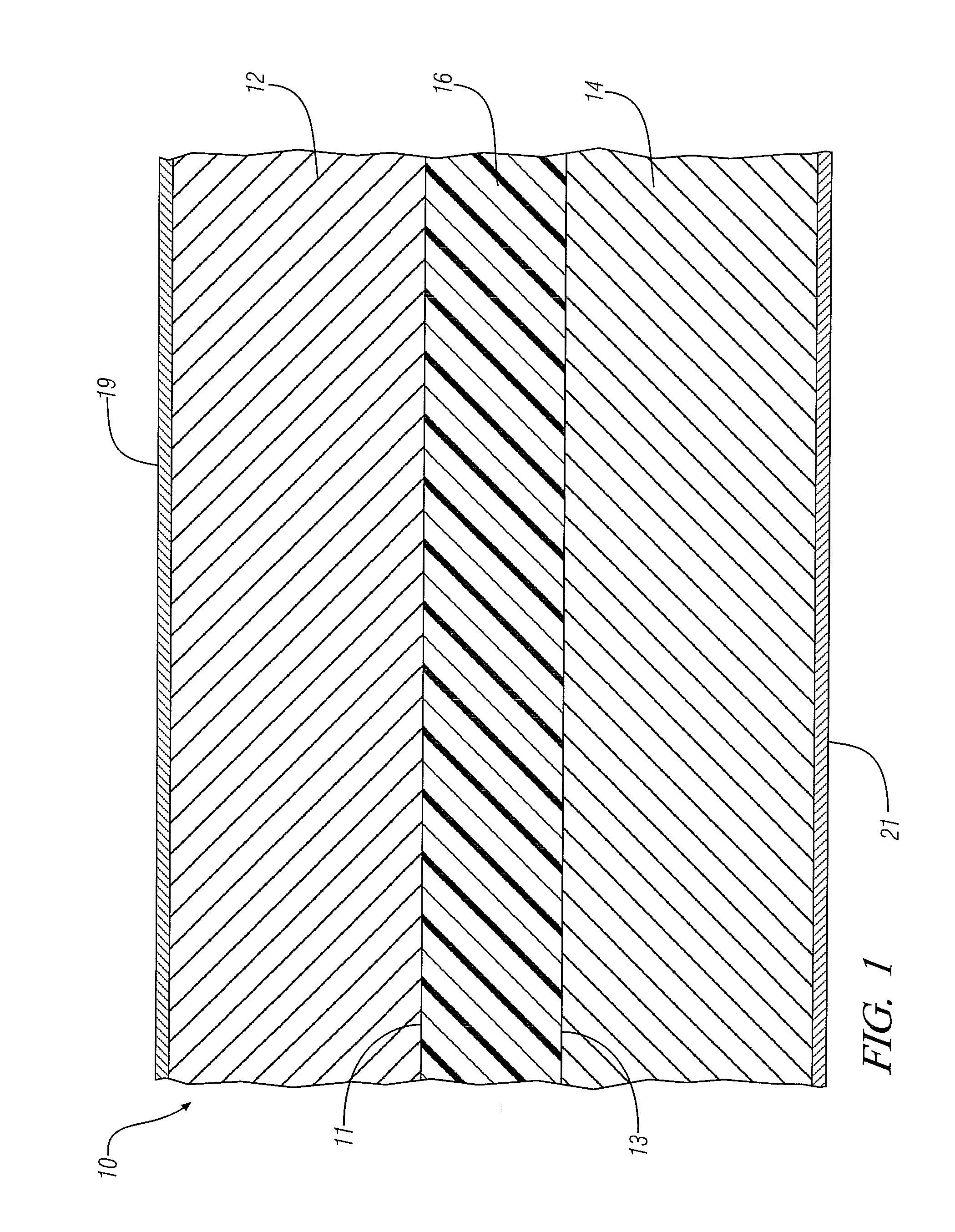

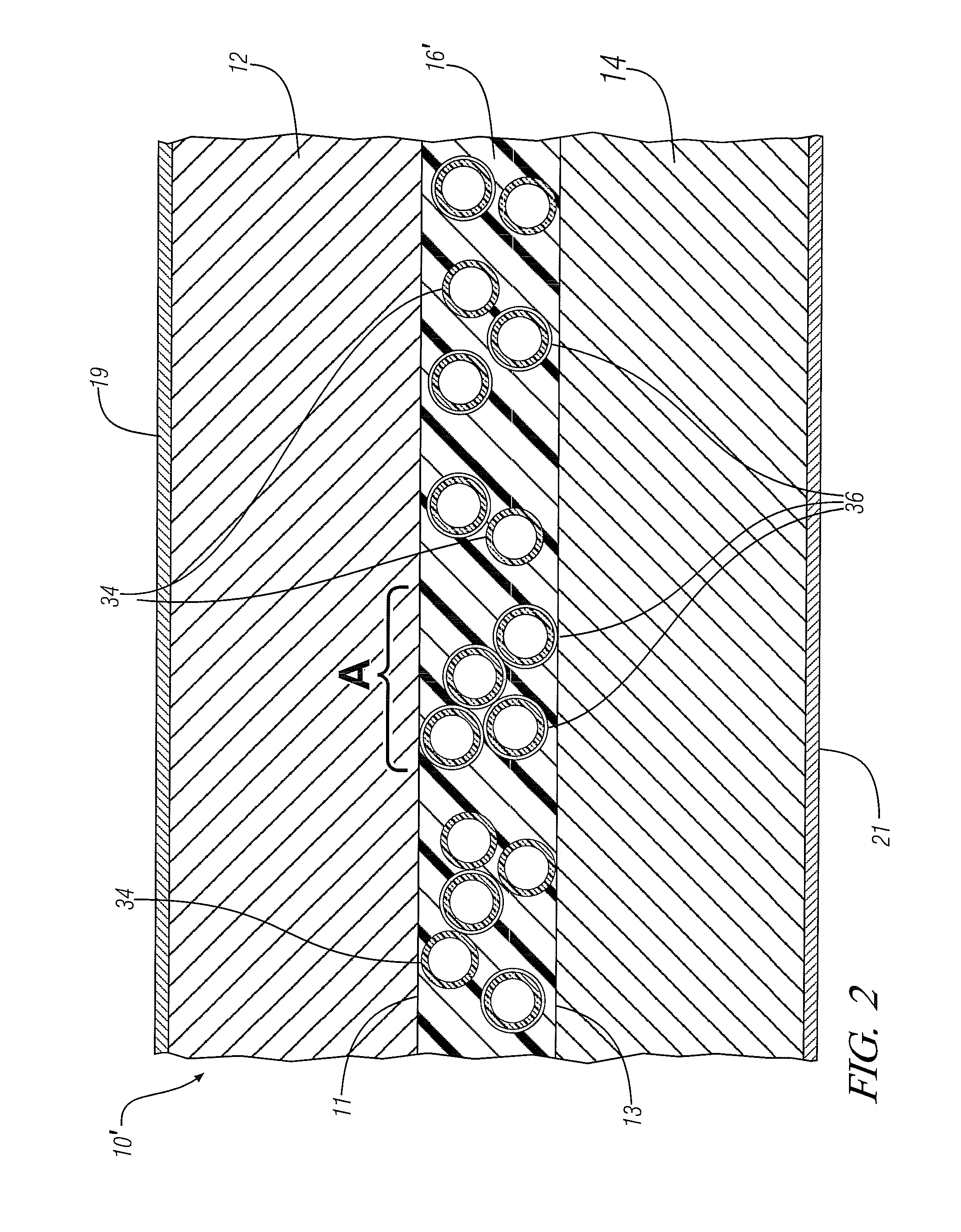

Laminated steel with compliant viscoelastic core

InactiveUS8328971B2Reduce impactImprove thermal stressSynthetic resin layered productsLaminationElectrical resistance and conductanceMetallurgy

Laminated metallic sheets which comprise an interior layer of a viscoelastic polymeric compound sandwiched between outer layers of metallic sheet may exhibit enhanced properties through modification of the viscoelastic phase. In a first embodiment the elastic modulus of the viscoelastic polymeric compound may be reduced by incorporating voids, bubbles or pores within the compound. These voids which may be introduced by introduction of polymeric microspheres are effective in reducing the internal stresses induced in the laminate by temperature changes. In a second embodiment, coating the microspheres with an electrically-conductive layer may be effective in enabling resistance spot welding of such laminated materials.

Owner:GM GLOBAL TECH OPERATIONS LLC

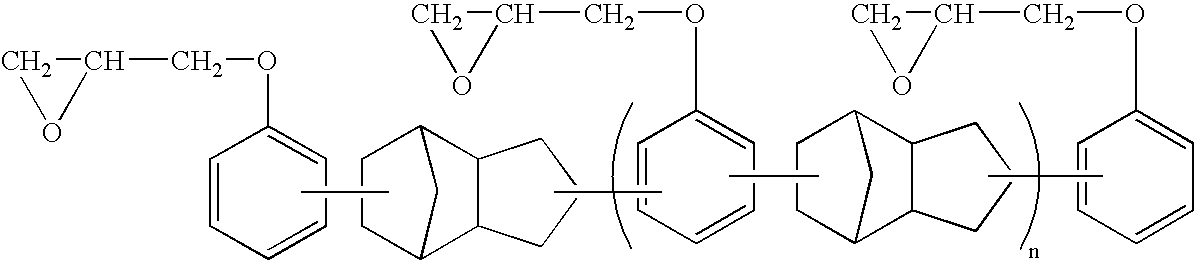

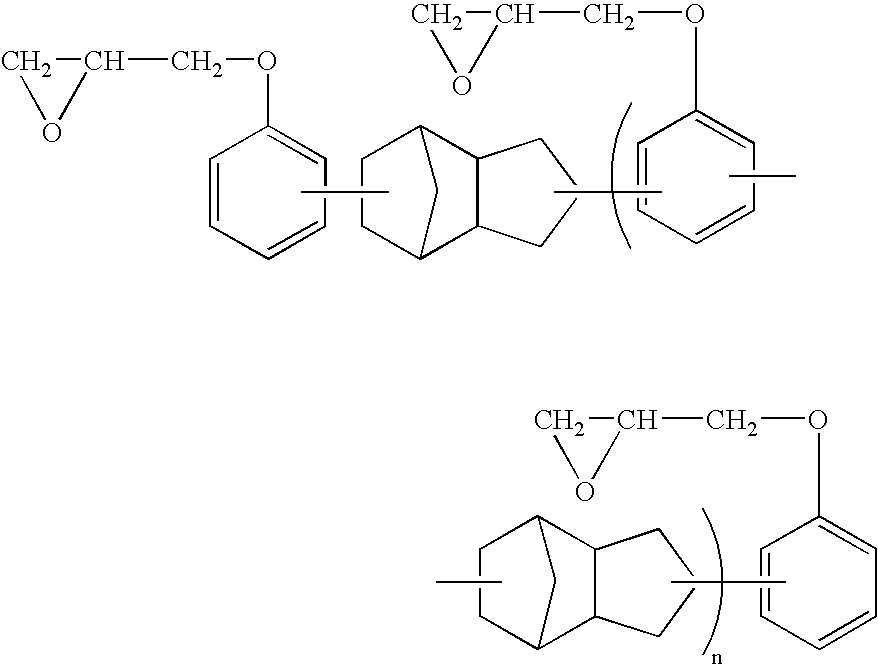

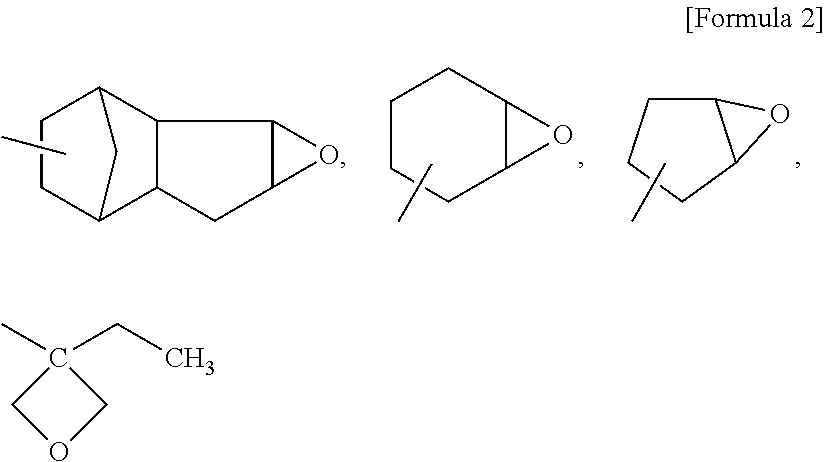

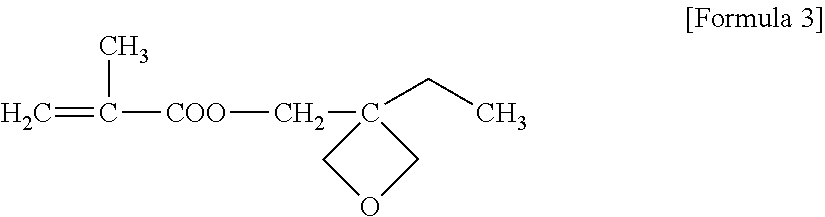

Inorganic filler and organic filler-containing curable resin composition, resist film coated printed wiring board, and method for producing the same

InactiveUS20090087775A1Lower elastic modulusEasy curingPhotosensitive materialsPrinted circuit aspectsPolymer sciencePolymer chemistry

A curable resin composition comprises: (I) 100 parts by-weight of a curable resin; (II) 10 to 1200 parts by weight of an inorganic filler; and (III) 1 to 100 parts by weight of an organic filler having an elastic modulus of 1 to 2000 (MPa) and an average particle diameter of 0.01 to 10 μm, wherein a content weight ratio of the components (II) and (III) is 1 to 41.

Owner:SANEI KAGAKU KK

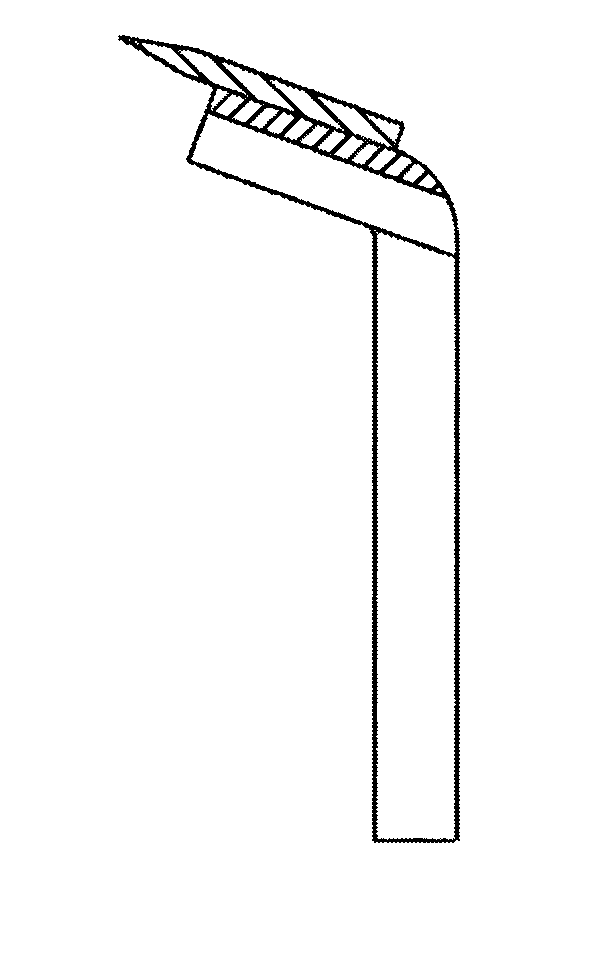

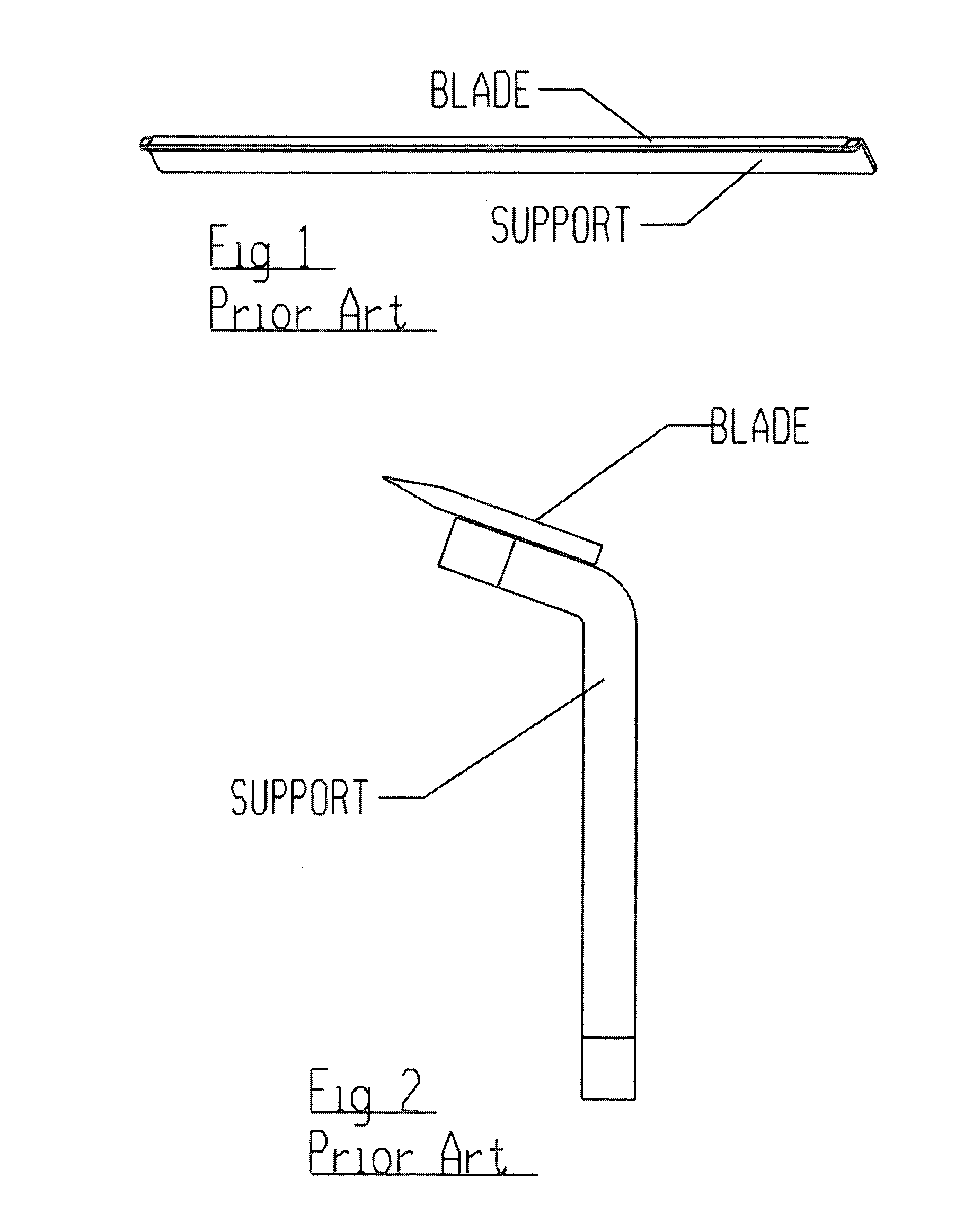

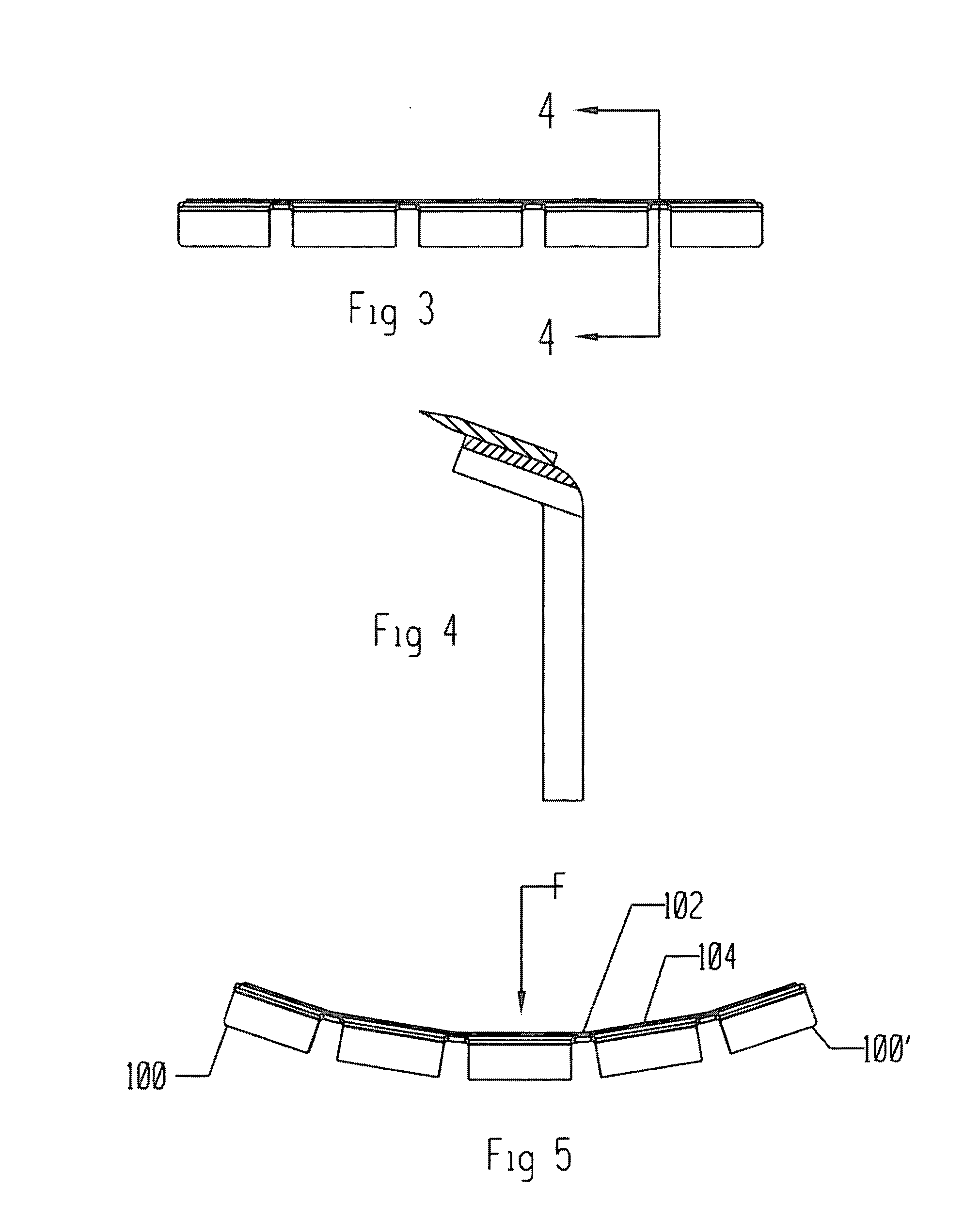

Razor blade and support assembly

ActiveUS20060248726A1Lower elastic modulusControl deflectionMetal working apparatusEngineeringKnife blades

A razor blade and support assembly is provided which flexes in response to shaving forces near slots in the blade support. A razor cartridge includes one or more of the aforementioned razor blade and support assemblies positioned in a housing. The razor cartridge may be permanently or removably coupled to a handle to provide a shaving razor.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

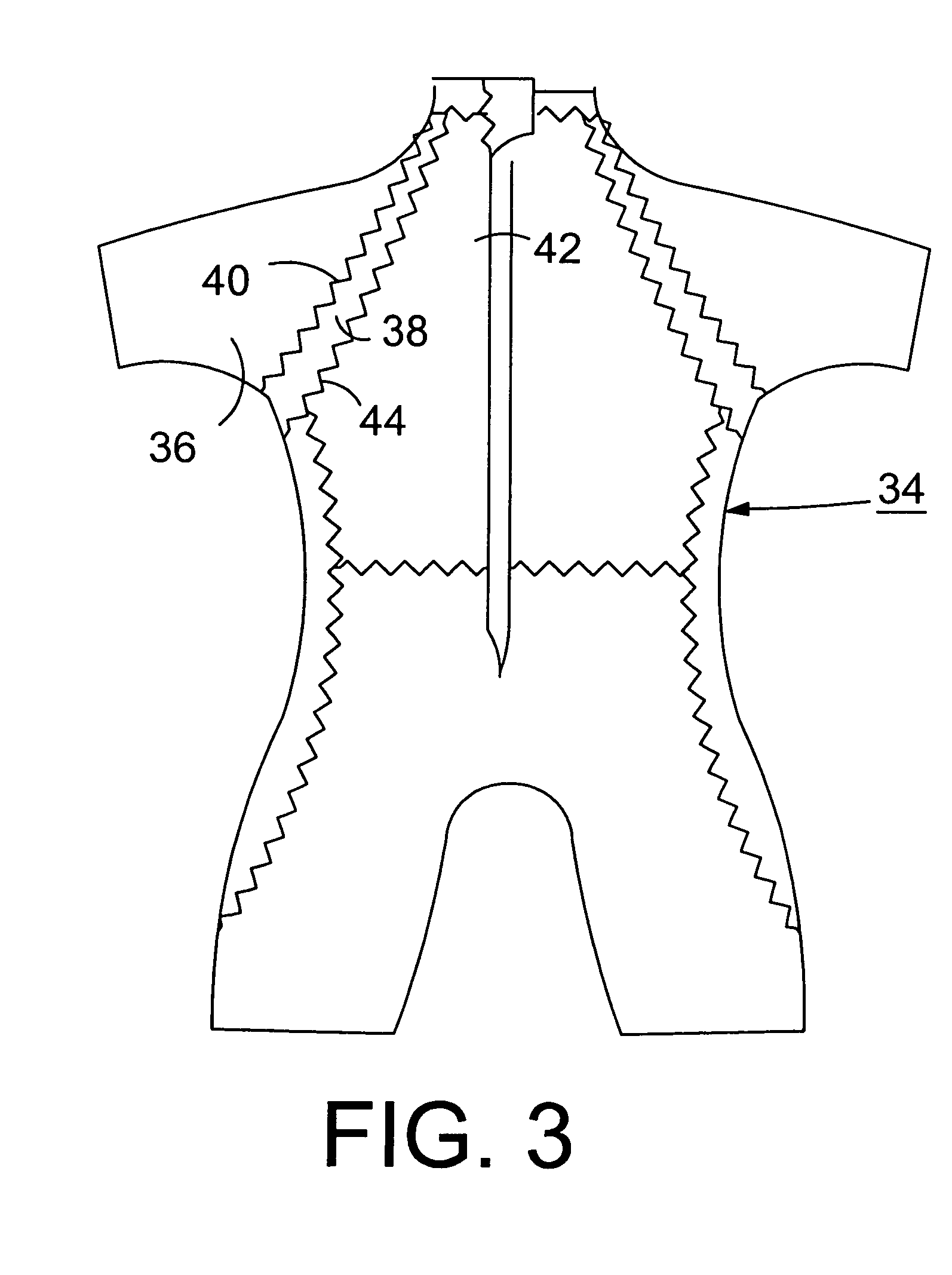

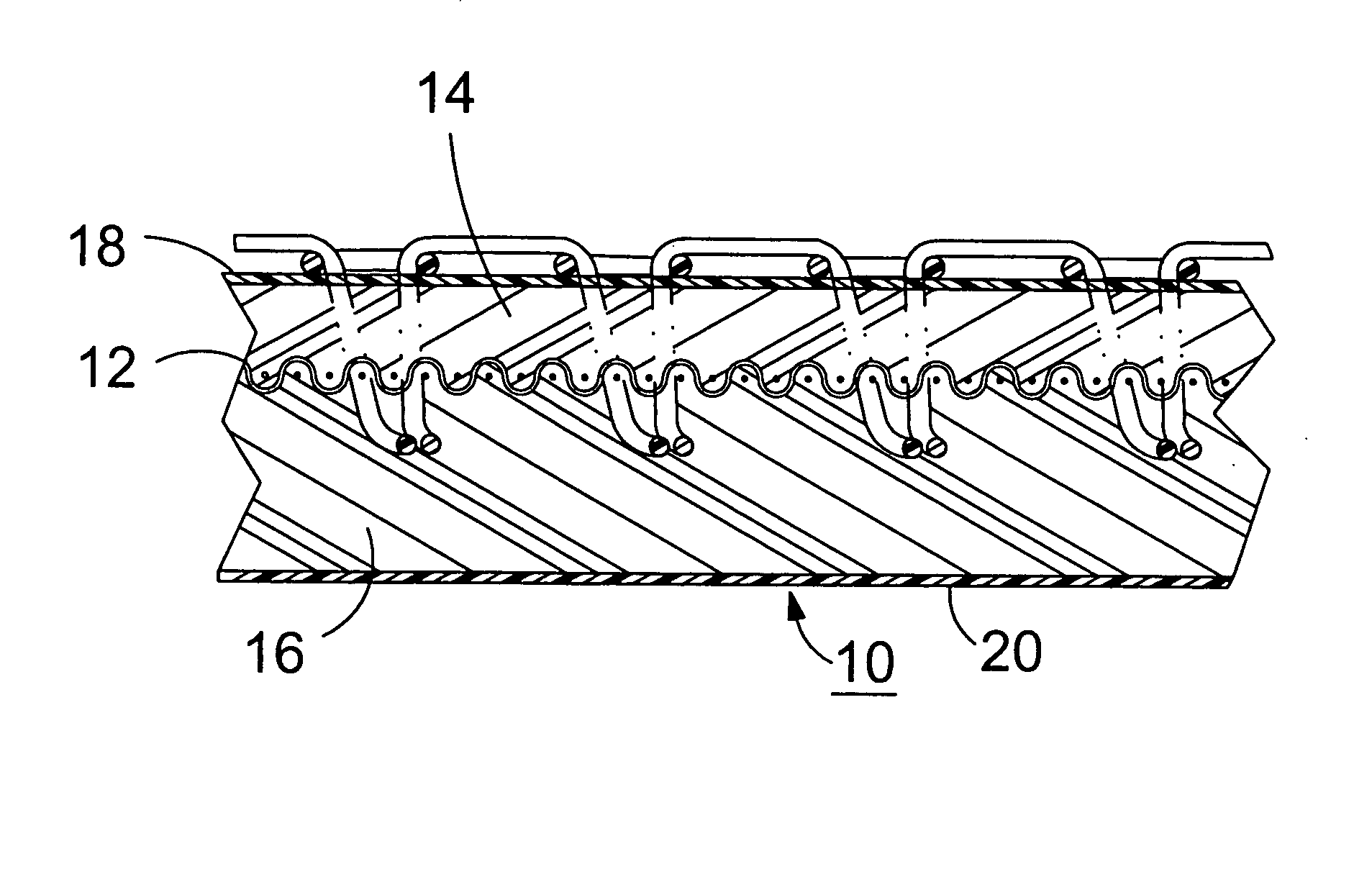

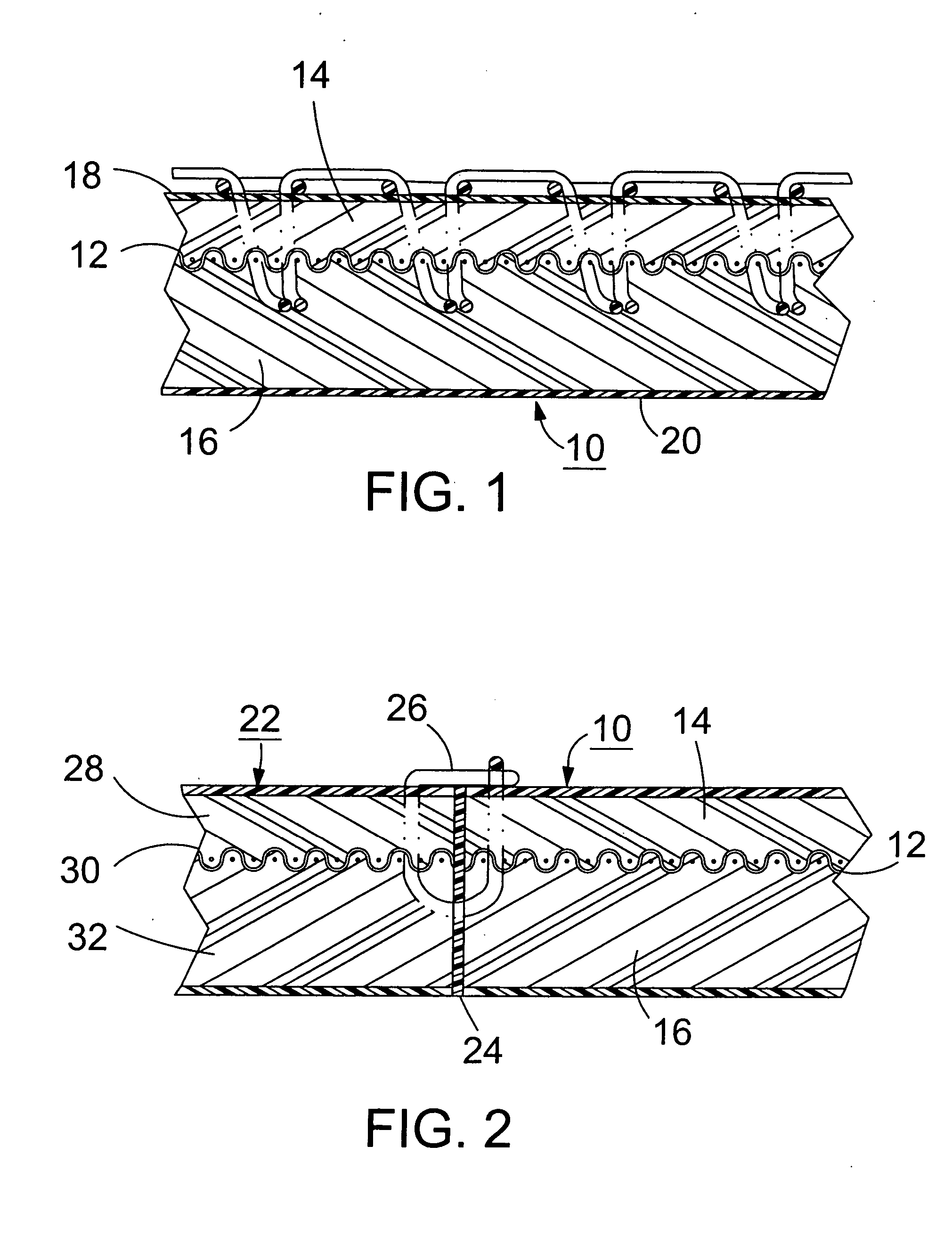

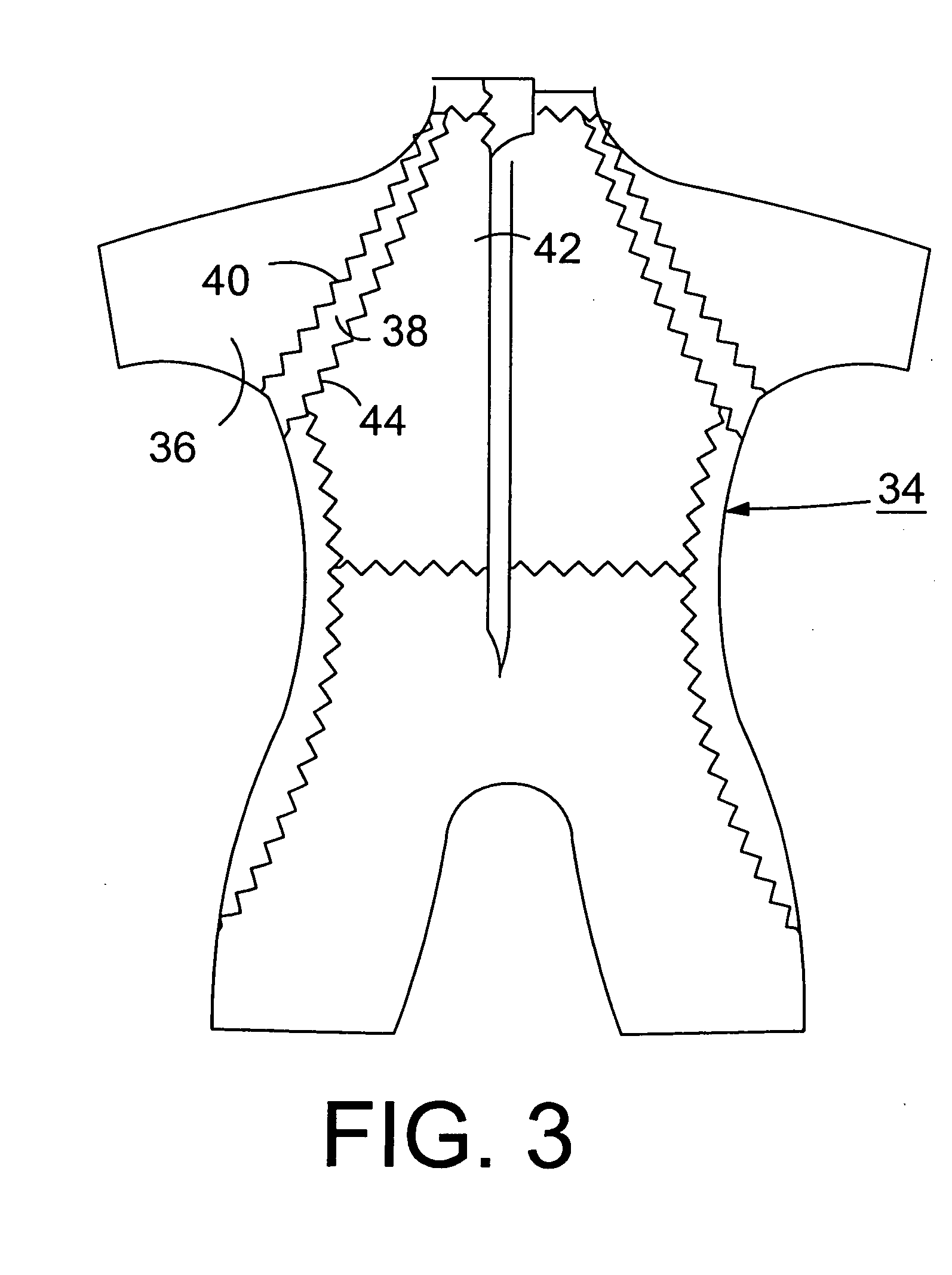

Wetsuit and wetsuit material

InactiveUS7051375B2Resist damageFast dryingProtective equipmentRubber layered productsAdhesiveEngineering

A wetsuit is composed multiple panels sewn together in edge-to-edge relationship, each panel comprising a highly stretchable base fabric sandwiched between an outer and inner layer of synthetic rubber, the outer synthetic rubber layer is dense and tough, providing protection against damage by abrasion, while the inner synthetic rubber layer is thicker and less dense, providing the material with a good insulating ability. The outer layer is thinner than the inner layer to compensate for the higher elastic modulus of the denser outer layer, so that the layers stretch uniformly. A thin, colored, chloroprene adhesive coating is provided on the outside of the outer layer, and the outer layer is embossed with a mesh pattern. The seams are blind-stitched through the base fabric from the outside. Because the stretchable fabric is on the inside of the wetsuit material, the wetsuit dries rapidly.

Owner:HENDERSON AQUATICS

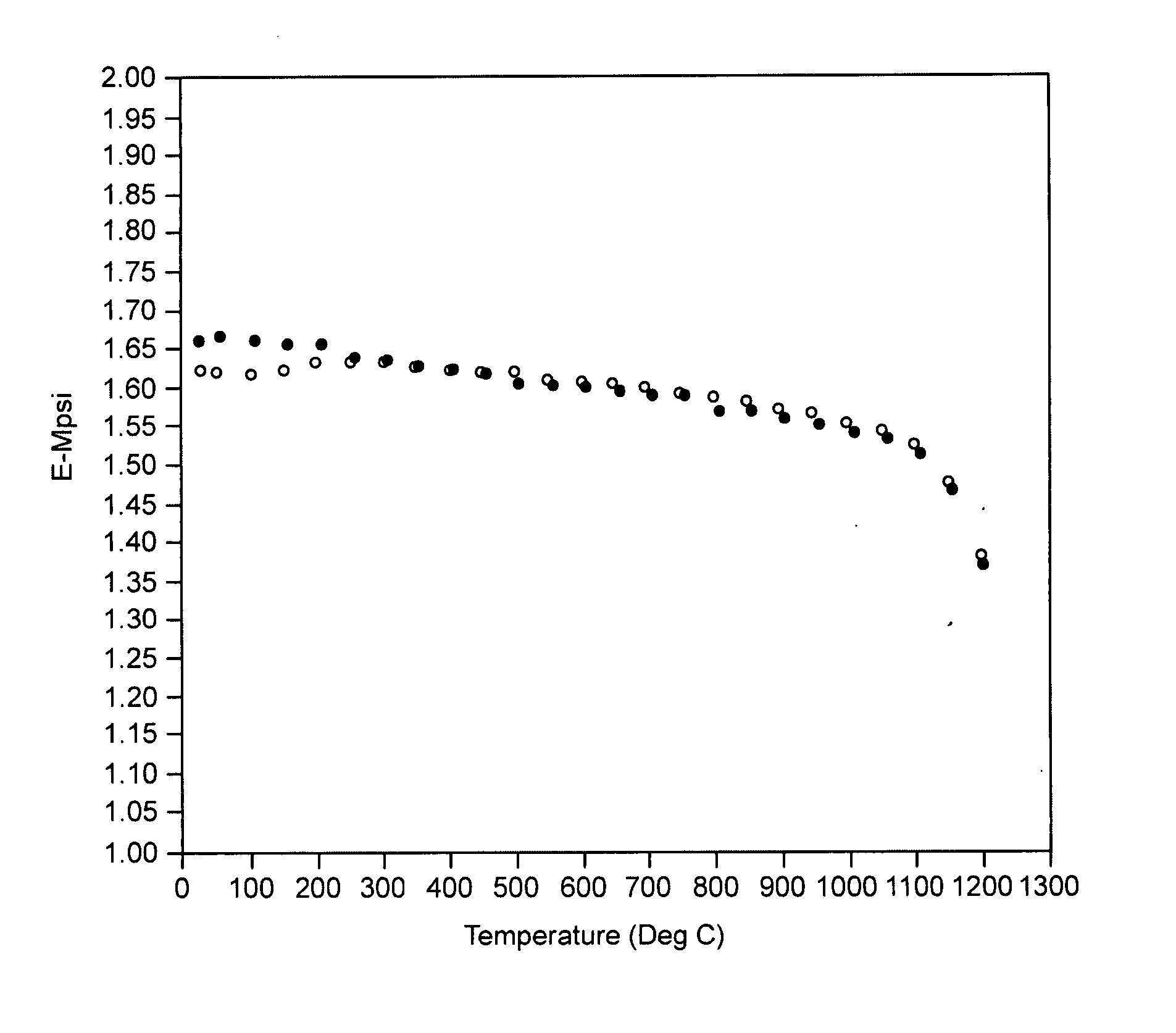

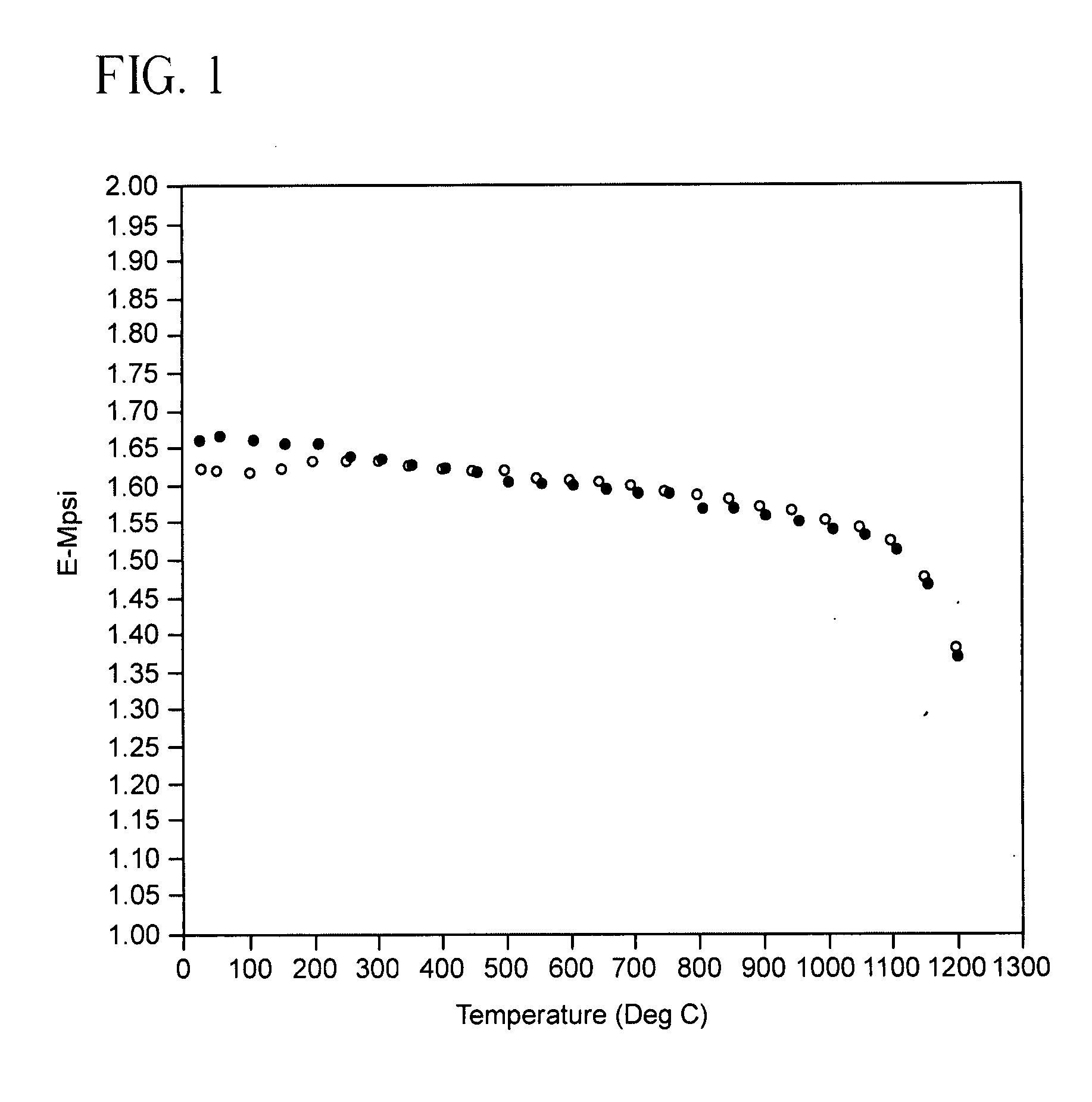

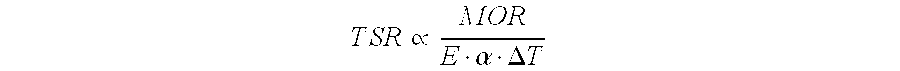

High porosity thermally shock resistant ceramic structures

ActiveUS20080063833A1High modulusImprove thermal shock resistanceCombination devicesLayered productsComposite ceramicHoneycomb structure

A thermally shock resistant ceramic body, such as a porous ceramic honeycomb structure for a wall flow diesel engine exhaust filter or a flow-through ceramic catalyst support, is formed of a composite ceramic material comprising a major first ceramic phase exhibiting good thermal shock resistance and a minor second phase material that substantially reduces the elastic modulus of the composite ceramic material at elevated temperatures.

Owner:CORNING INC

Wetsuit and wetsuit material

InactiveUS20050071905A1Resist damageFast dryingProtective equipmentRubber layered productsAdhesiveEngineering

A wetsuit is composed multiple panels sewn together in edge-to-edge relationship, each panel comprising a highly stretchable base fabric sandwiched between an outer and inner layer of synthetic rubber, the outer synthetic rubber layer is dense and tough, providing protection against damage by abrasion, while the inner synthetic rubber layer is thicker and less dense, providing the material with a good insulating ability. The outer layer is thinner than the inner layer to compensate for the higher elastic modulus of the denser outer layer, so that the layers stretch uniformly. A thin, colored, chloroprene adhesive coating is provided on the outside of the outer layer, and the outer layer is embossed with a mesh pattern The seams are blind-stitched through the base fabric from the outside. Because the stretchable fabric is on the inside of the wetsuit material, the wetsuit dries rapidly.

Owner:HENDERSON AQUATICS

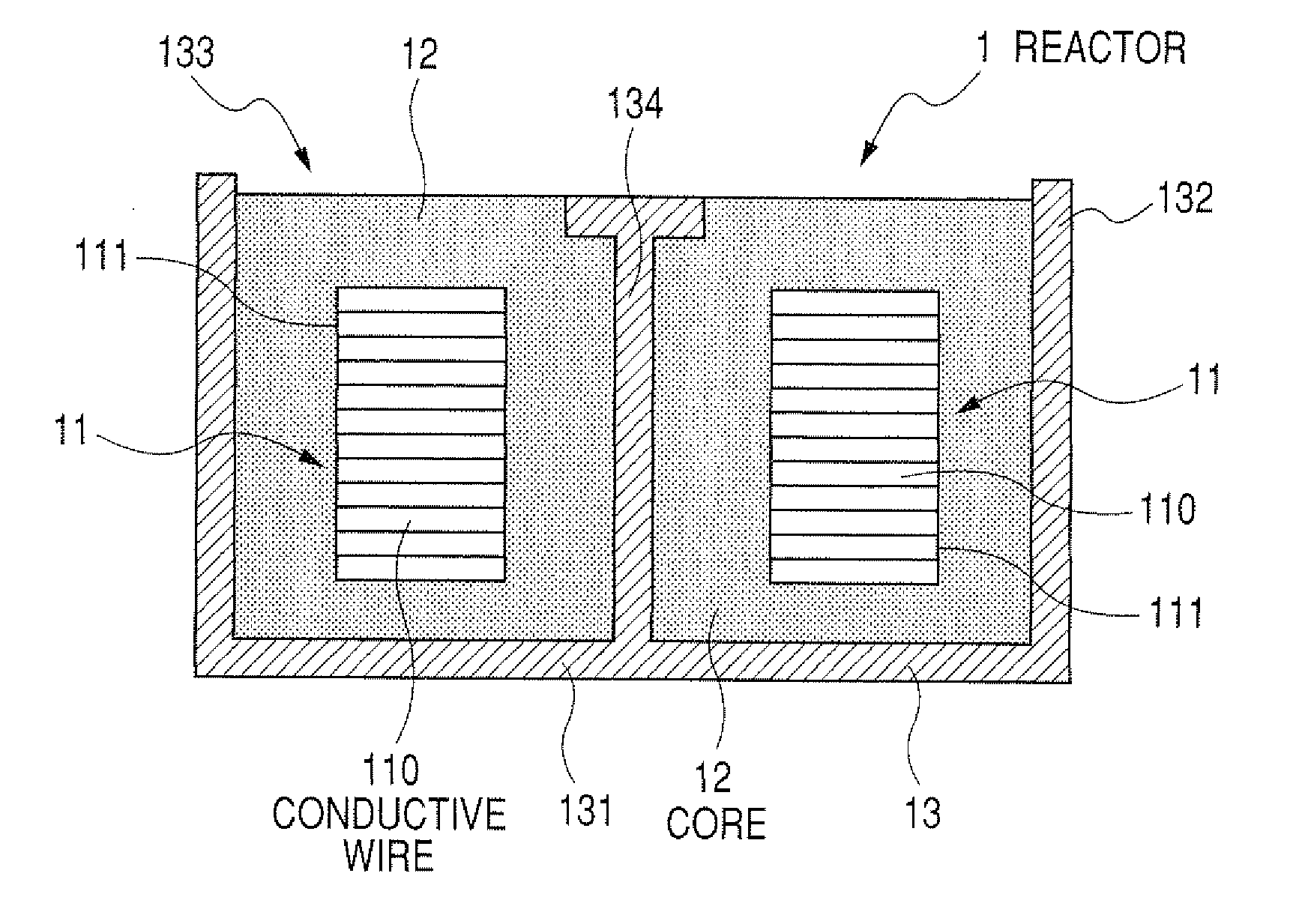

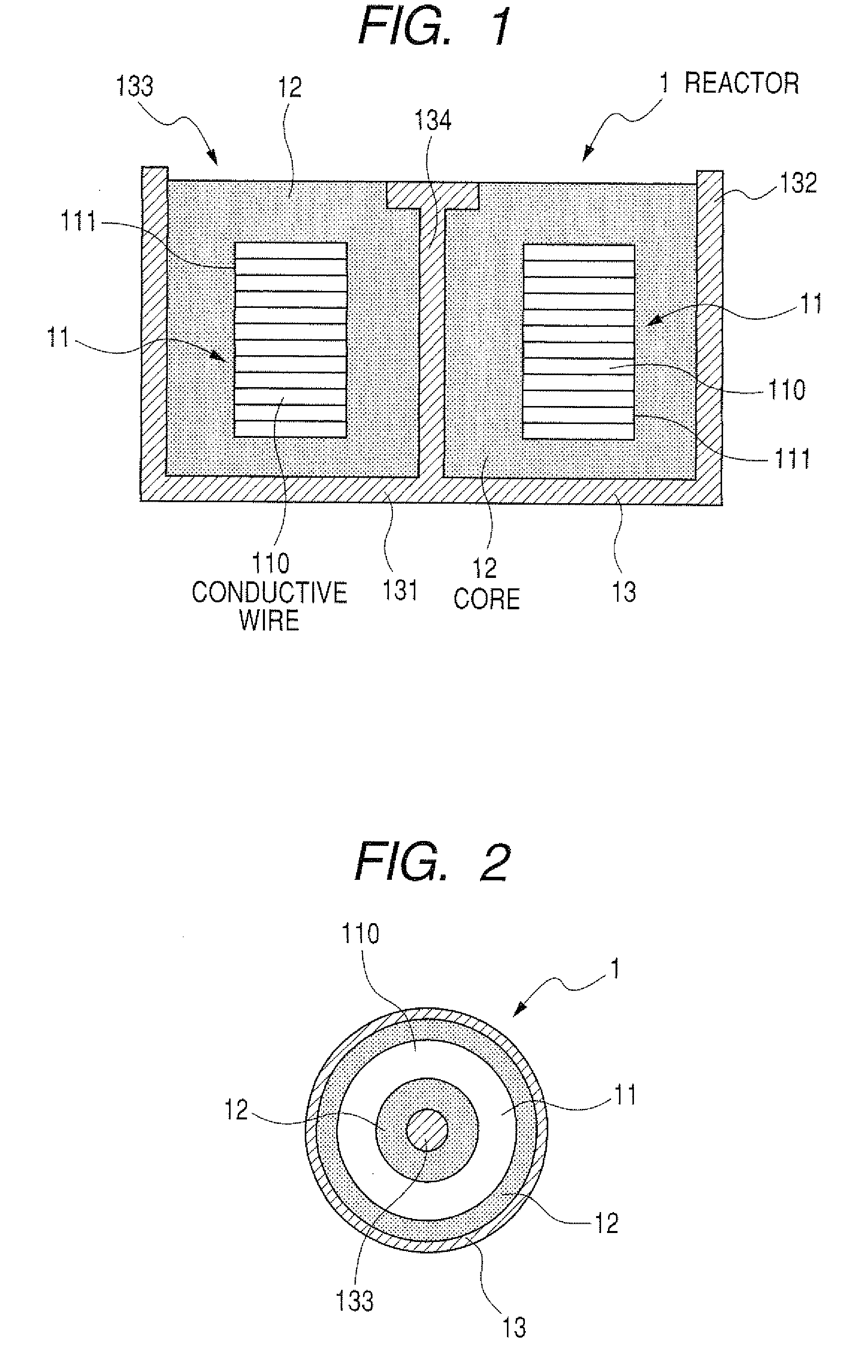

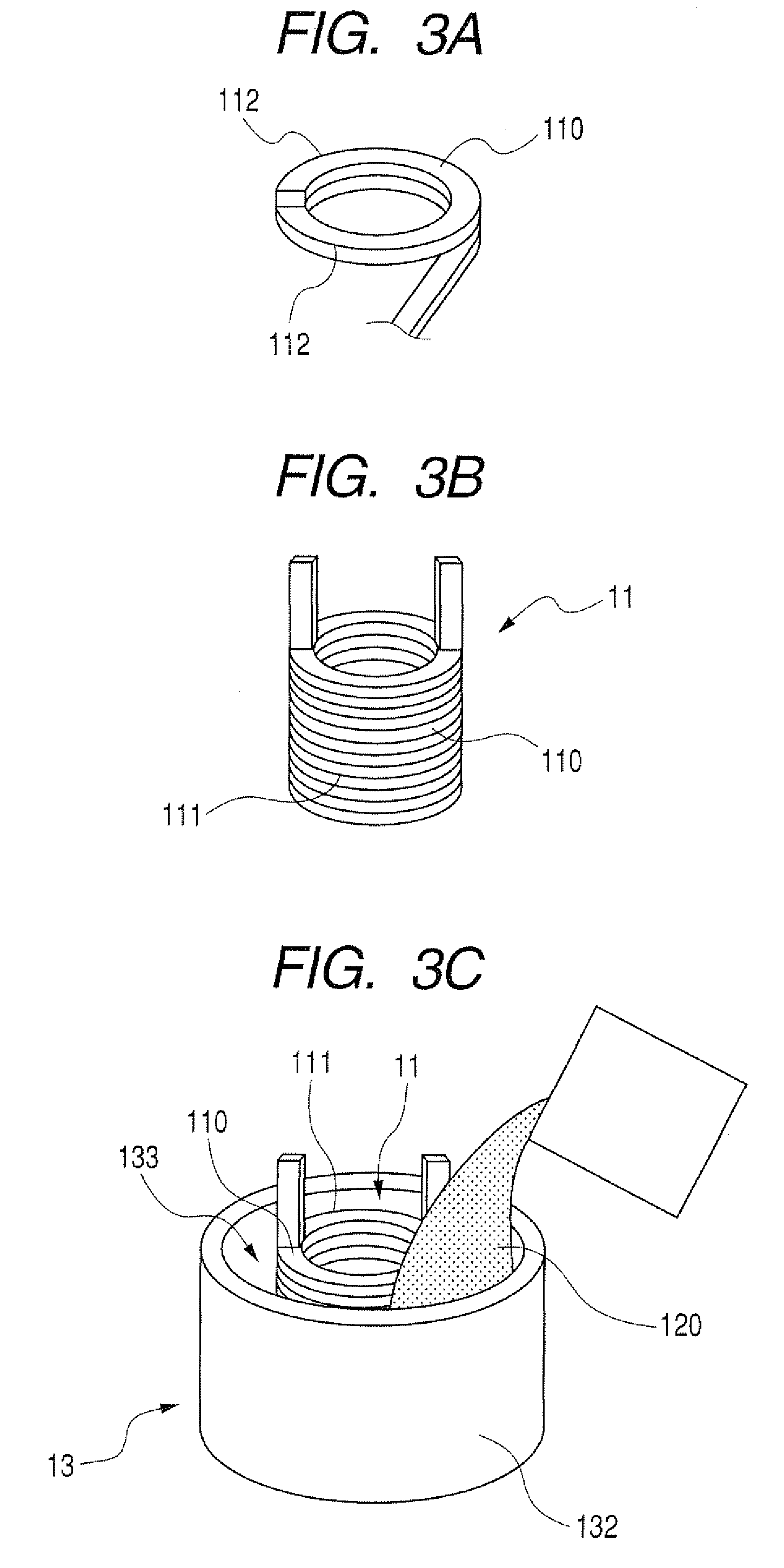

Method of fabricating reactor

ActiveUS20100031497A1Decrease in elastic modulusDecrease in yield strengthTransformers/inductances casingsTransformers/inductances coils/windings/connectionsMagnetic coreMagnetic powder

A method of fabricating a reactor composed of a coil, a core, and a container, capable of suppressing the core to break when a current flows in the coil to generate magnetic flux. In the method, the coil is formed by spirally winding a conductive wire. The coil is immersed in an insulating film in liquid with electrical insulation. The coil is placed in a furnace. Annealing for the coil and thermosetting for the insulating film are performed at a temperature within 250 to 320° C. for a period of time within 30 minutes to one hour before forming the core in the container. The coil is then disposed in the container. Inside and outside areas of the coil in the container is filled with a resin mixture composed of magnetic powder and resin. The resin mixture in the container is hardened to form the core.

Owner:DENSO CORP +1

Inorganic filler and organic filler-containing curable resin composition, resist film coated printed wiring board, and method for producing the same

ActiveUS20130164679A1Lower elastic modulusEasy curingCosmetic preparationsLiquid surface applicatorsPolyresinOrganic chemistry

A curable resin composition comprises: (I) 100 parts by weight of a curable resin; (II) 10 to 1200 parts by weight of an inorganic filler; and (III) 1 to 100 parts by weight of an organic filler having an elastic modulus of 1 to 2000 (MPa) and an average particle diameter of 0.01 to 10 v, wherein a content weight ratio of the components (II) and (III) is 1 to 41.

Owner:SANEI KAGAKU KK

Electronic component package including joint material having higher heat conductivity

InactiveUS20070012477A1Reliably contributing to effective heat transferReduce heat resistance requirementsSemiconductor/solid-state device detailsPrinted electric component incorporationElectronic componentThermal transmittance

An electronic component is mounted on the surface of a printed wiring board. A heat conductive member is received on the surface of the electronic component. A joint material is interposed between the electronic component and the heat conductive member. The joint material is made of material containing Ag in a range exceeding 3 wt % and In. The inventors have demonstrated that voids decrease at the boundary between the joint material and the electronic component as well as at the boundary between the joint material and the heat conductive member as the content of Ag increases in the overall weight of the joint material. The joint material is allowed to enjoy a higher heat conductivity as compared with a conventional solder material. The joint material allows the heat conductive member to efficiently receive heat from the electronic component.

Owner:FUJITSU LTD

Surface protecting adhesive film for semiconductor wafer and processing method for semiconductor wafer using said adhesive film

InactiveUS6879026B2Straighten and avoid warpageEasy to peelFilm/foil adhesivesSemiconductor/solid-state device detailsSize changeEngineering

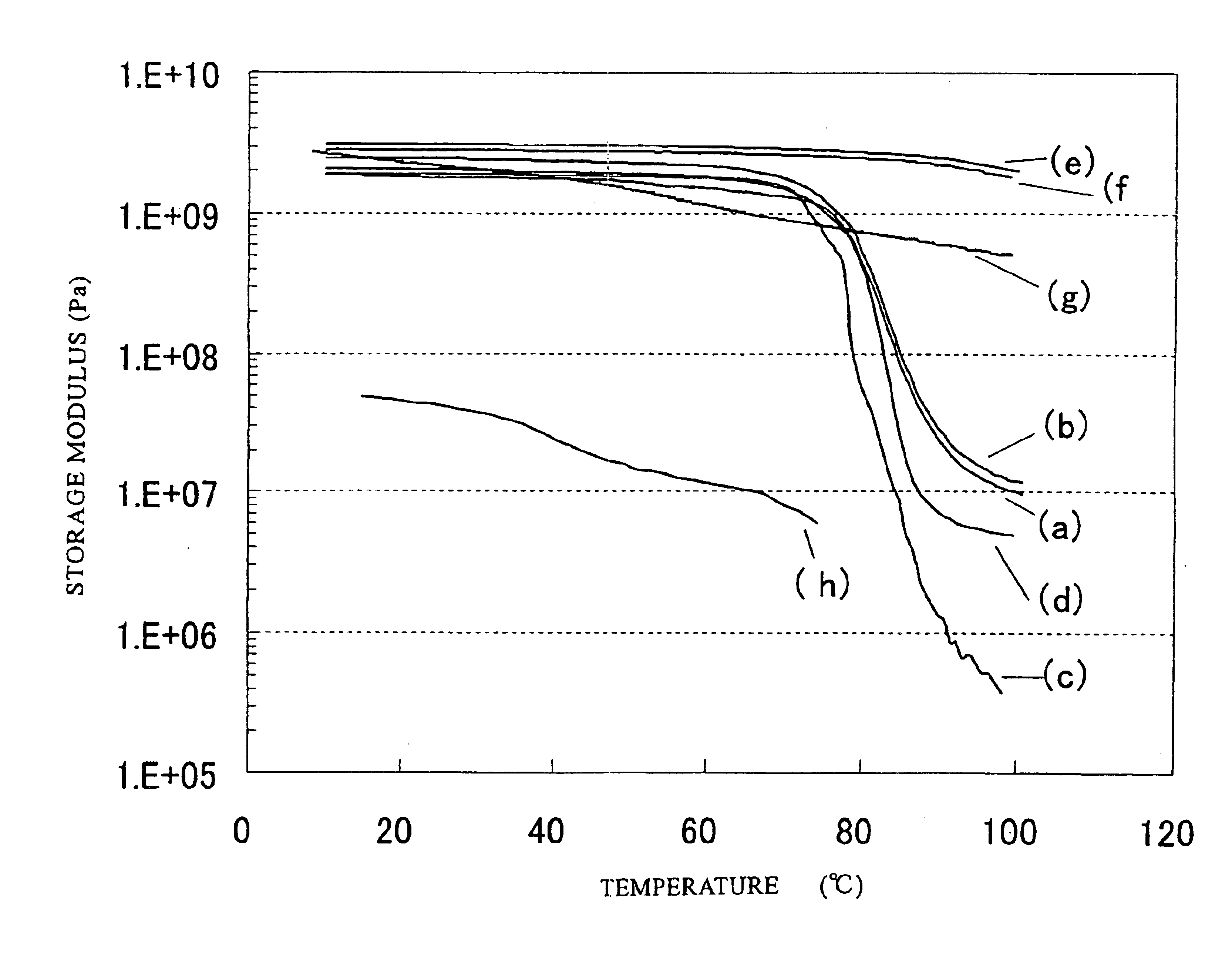

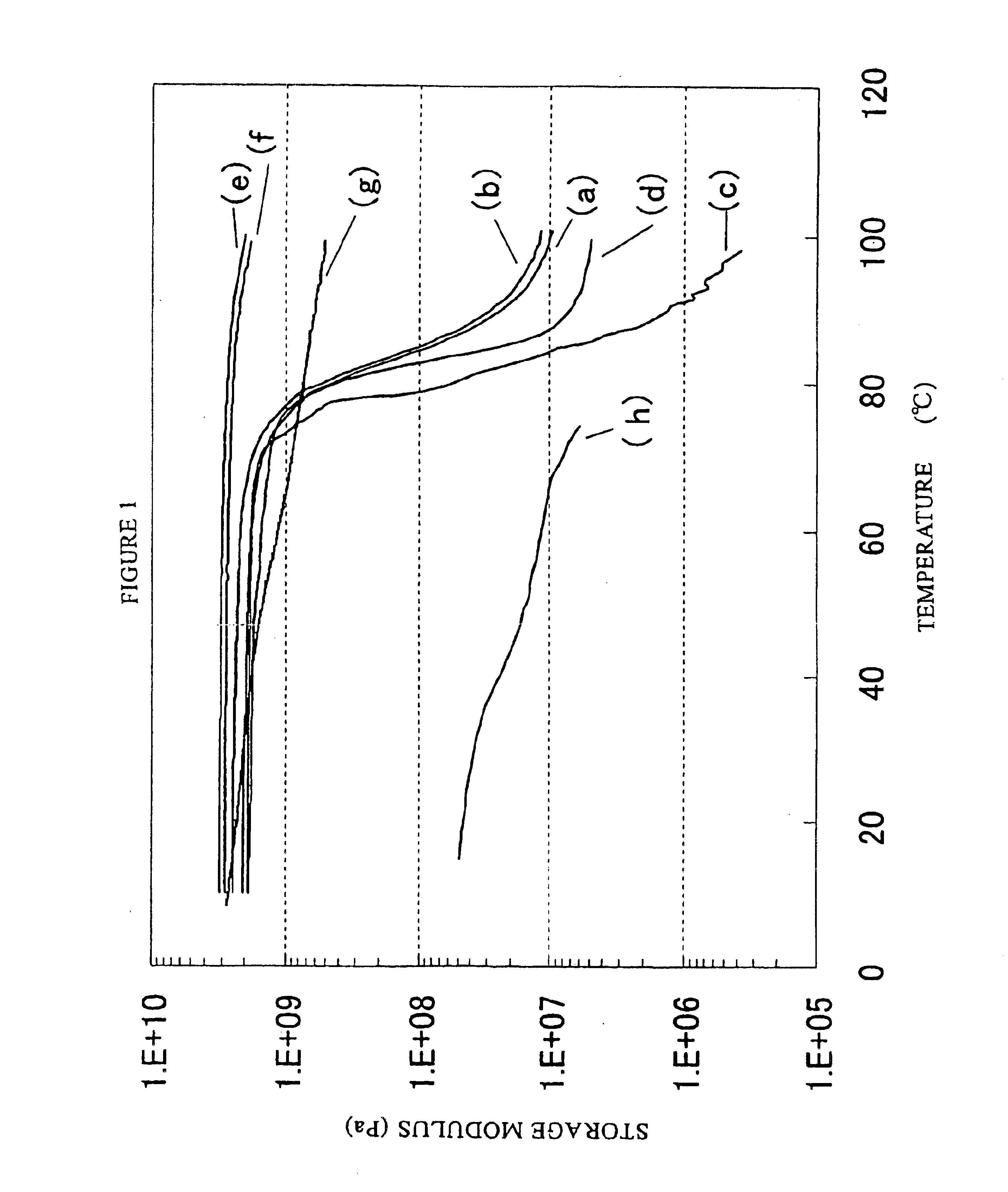

An adhesive film for protecting the surface of a semiconductor wafer wherein the adhesive layer is formed on one surface of a substrate film, the substrate film comprising at least one layer which satisfies the following requisites (A) and at least one of (B) or (C):requisite (A): high elastic modulus properties in which the storage modulus is 1×109 Pa to 1×1010 Pa under the total temperature range of from 18 to 50° C.requisite (B): high elastic modulus properties in which the storage modulus within at least part of the temperature range of from 50 to 90° C. is not more than 1×108 Pa.requisite (C): high elastic modulus properties with expansibility by water absorption in which the size-changing ratio by absorbing water for four hours is 0.05 to 0.5% at 23° C. and 90% RH.

Owner:MITSUI CHEM TOHCELLO INC

Pressure-sensitive adhesive, pressure-sensitive adhesive layer, and pressure-sensitive adhesive sheet

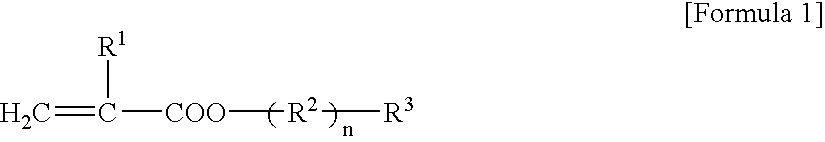

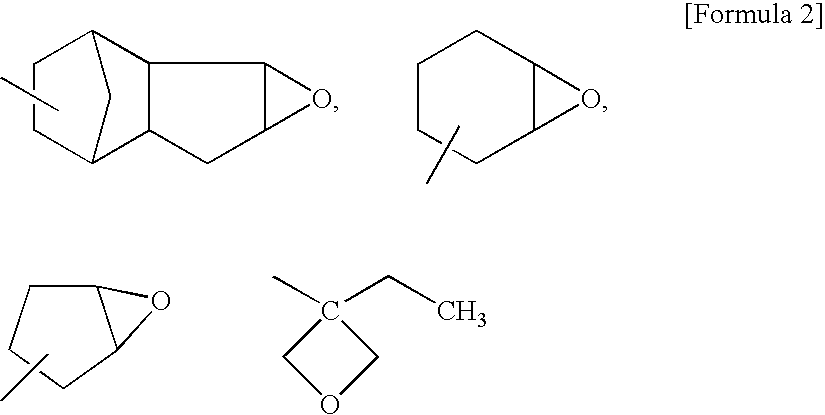

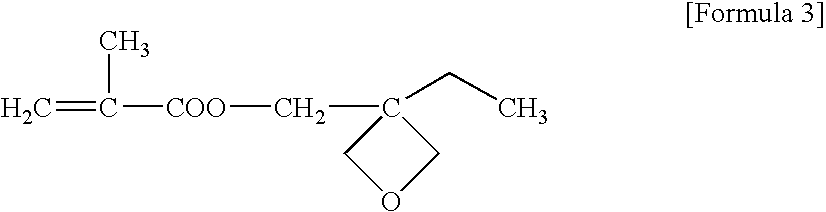

InactiveUS20130251990A1Low dielectric constantSatisfactory level of adhesive performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMeth-Pressure sensitive

A pressure-sensitive adhesive of the invention includes a (meth)acryl-based polymer obtained by polymerization of a monomer component including: an alkyl(meth)acrylate (a1) having a branched alkyl group of 8 to 24 carbon atoms at an ester end; and an alkyl(meth)acrylate (a2) having a linear alkyl group of 8 to 24 carbon atoms at an ester end. The pressure-sensitive adhesive can has a satisfactory level of adhesive performance and can form a pressure-sensitive adhesive layer with a lower dielectric constant.

Owner:NITTO DENKO CORP

Double-sided pressure-sensitive adhesive sheet

InactiveUS20120208955A1Avoid exhaustionReduced adherend selectivityPolyureas/polyurethane adhesivesFilm/foil adhesives without carriersPolyesterDimer acid

A double sided pressure-sensitive adhesive sheet includes a pressure-sensitive adhesive layer made from a polyester-based pressure-sensitive adhesive composition containing a polyester including at least a lactic acid unit, a dibasic acid unit, and a glycol unit, a tackifier resin, and a crosslinking agent. The dibasic acid unit includes a dimer acid, the polyester has a weight average molecular weight of 20,000 to 200,000 and a glass transition temperature of −70 to −20° C. as measured using a differential scanning calorimeter at a temperature rise rate of 20° C. / minute, the polyester has a hydroxyl value of 1 to 60 mgKOH / g, the adhesive composition contains 10 to 70 parts by weight of the tackifier resin based on 100 parts by weight of the polyester, and the pressure-sensitive adhesive layer has a gel fraction of 50 to 90% by weight.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com