Sprayer with remotely pivotable and selectively lockable nozzle

A sprayer, nozzle technology applied in the field of sprayers with nozzles pivotable at the distal end and selectively lockable, able to solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following descriptions of various embodied fluid sprayers are illustrative in nature and are not intended to limit the application of the invention or its use. Accordingly, the various embodiments, aspects, versions and examples described in the Summary and Detailed Description are non-limiting examples in nature which fall within the scope of the appended claims and are not intended to limit the broadest scope of the claims .

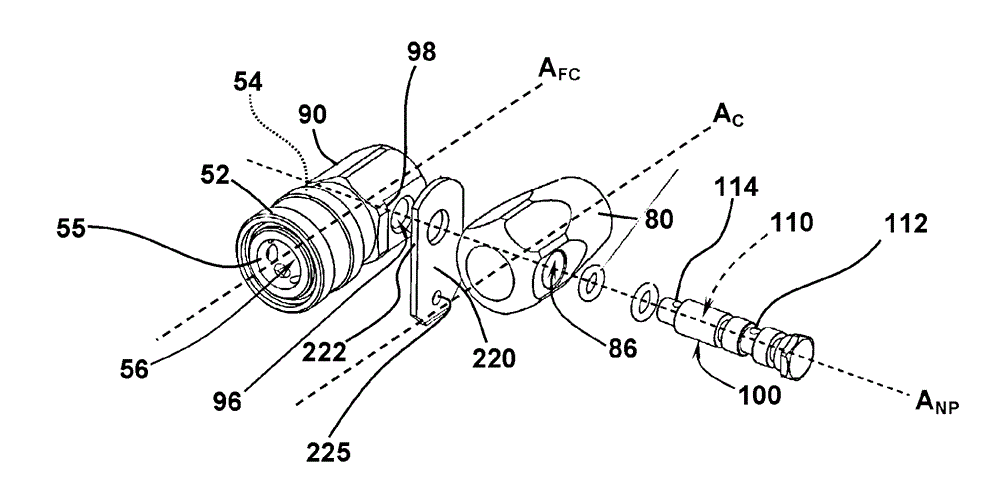

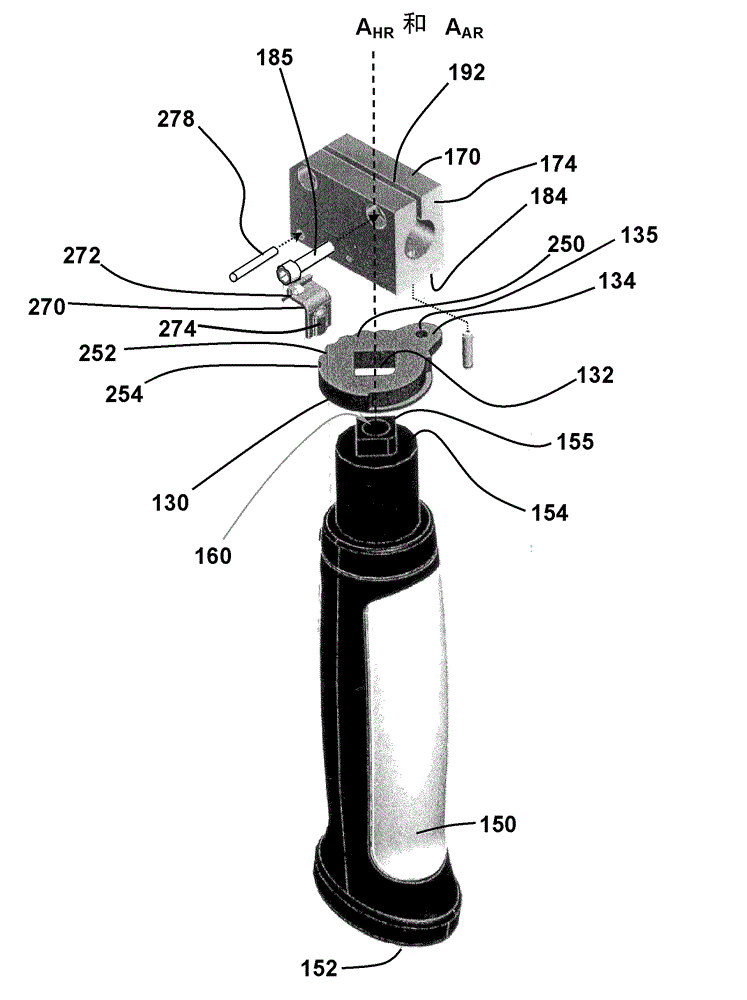

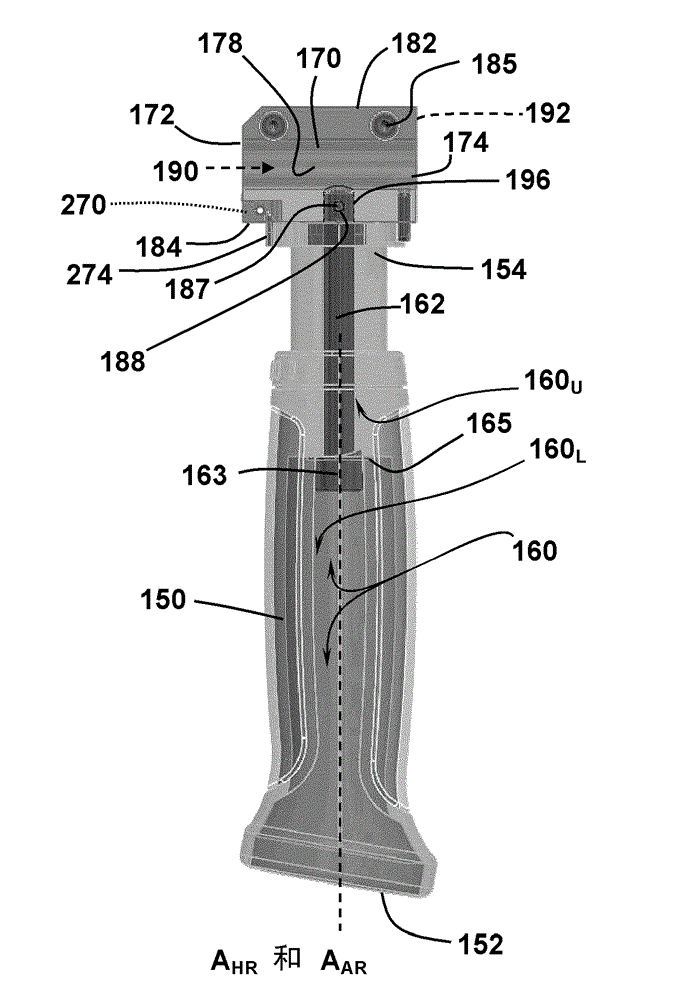

[0024] see figure 1 , the illustrative nebulizer 10 includes a rigid fluid conduit 20 along the conduit axis A C Extends between longitudinally opposite first and second conduit ends 22 , 24 . The conduit sidewall 26 has an outer surface 27 and an inner surface 28 that define an inner fluid passageway 40 extending between the first conduit end 22 and the second conduit end 24 . First conduit end 22 and second conduit end 24 respectively include a fluid inlet opening 42 through which fluid can be introduced into fluid passageway 40 and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com