Ring beam rivet weld device for mining dumper

A technology of dump truck rim and riveting welding, applied in the field of welding tooling, can solve the problems of large error of rear rim beam, difficulty in guaranteeing casting quality, waste of manpower, etc., and achieve the effect of reducing welding error, ensuring welding quality and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

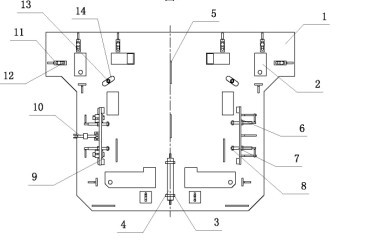

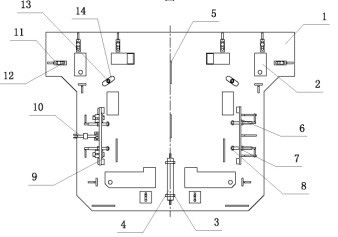

[0022] Embodiment one: see figure 2 As shown, a mine dump truck ring beam riveting and welding device includes an installation platform 1 matched with the ring beam structure. On the installation platform, there are two steel castings corresponding to the middle of the ring beam located on the center line of the installation platform. Vertical plate 3, the center of the vertical plate is provided with a through hole, a center positioning rod 4 is provided through the through holes of the two vertical plates, two measuring plates 5 are arranged above the central positioning rod, and one side of the measuring plate In order to measure the reference plane, the measurement reference plane coincides with the center line, and the right side of the measurement plate is provided with a first positioning block 6, and the lower part of the first positioning block is connected to the installation platform 1 through a steel pipe. Two through holes are symmetrically opened on the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com