Welding clamp for heavy truck bumper assembly

A technology for welding jigs and bumpers, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as unsatisfactory welding requirements and complex bumper assembly structure, and achieve light weight, simple structure, The effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

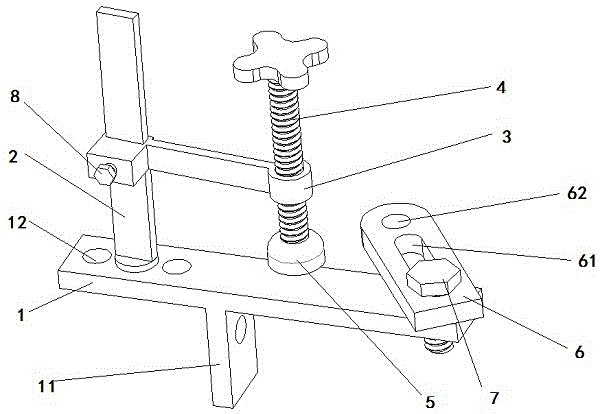

[0016] A heavy truck bumper assembly welding fixture, comprising a base 1, a support frame 2, a sliding rod 3, an adjustment screw 4, a screw disk 5, a rotating plate 6, a bolt 7, and an adjustment screw 8, and the base 1 is fixed above the welding table, The bottom of the base 1 is connected by a boss 11, the boss 11 is fixed on the side of the welding table, a number of positioning holes 12 are arranged above the base 1, the positioning holes 12 on the left side of the base 1 are provided with a support frame 2, and the support frame 2 A sliding rod 3 that can slide up and down is provided, and its specific position is adjusted by an adjusting screw 8. The other end of the sliding rod 3 is provided with a vertically penetrating adjusting screw 4, and a screw 5 is connected below the adjusting screw 4. The positioning hole 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com