Welding and carrying integrated welding gun device

A welding torch and integrated technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as affecting welding accuracy, potential safety hazards, and bad parts bumping, and achieve improved welding quality, stable fixed state, and accelerated handling. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

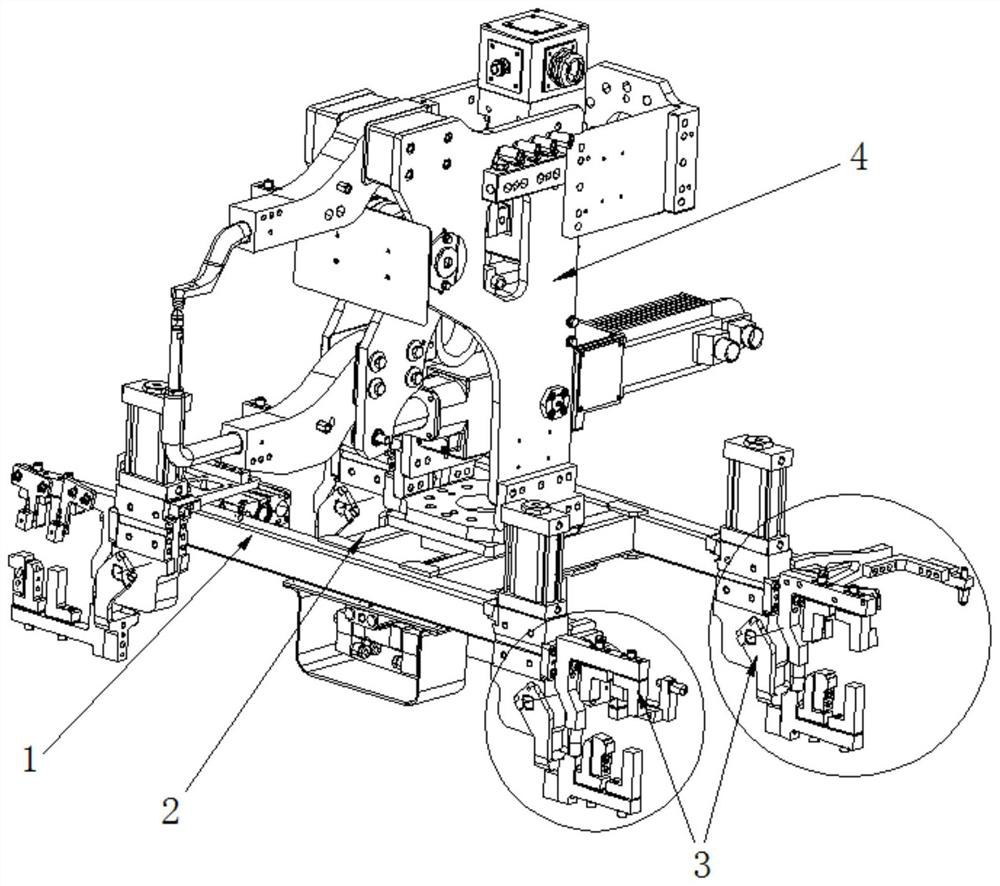

[0024] Such as Figure 1 to Figure 3 As shown, a welding torch device integrating welding and handling includes:

[0025] The double horizontal frame 1 is fixedly connected by the reinforcement 2 between the double horizontal frame 1; the double horizontal frame 1 can be understood here as two parallel and transversely arranged support frames. At this time, the reinforcement 2 is generally perpendicular to the double horizontal frame 1 ; Of course, the double horizontal frame 1 and the reinforcing member 2 can be other supporting frame structures that can be fixed to each other laterally.

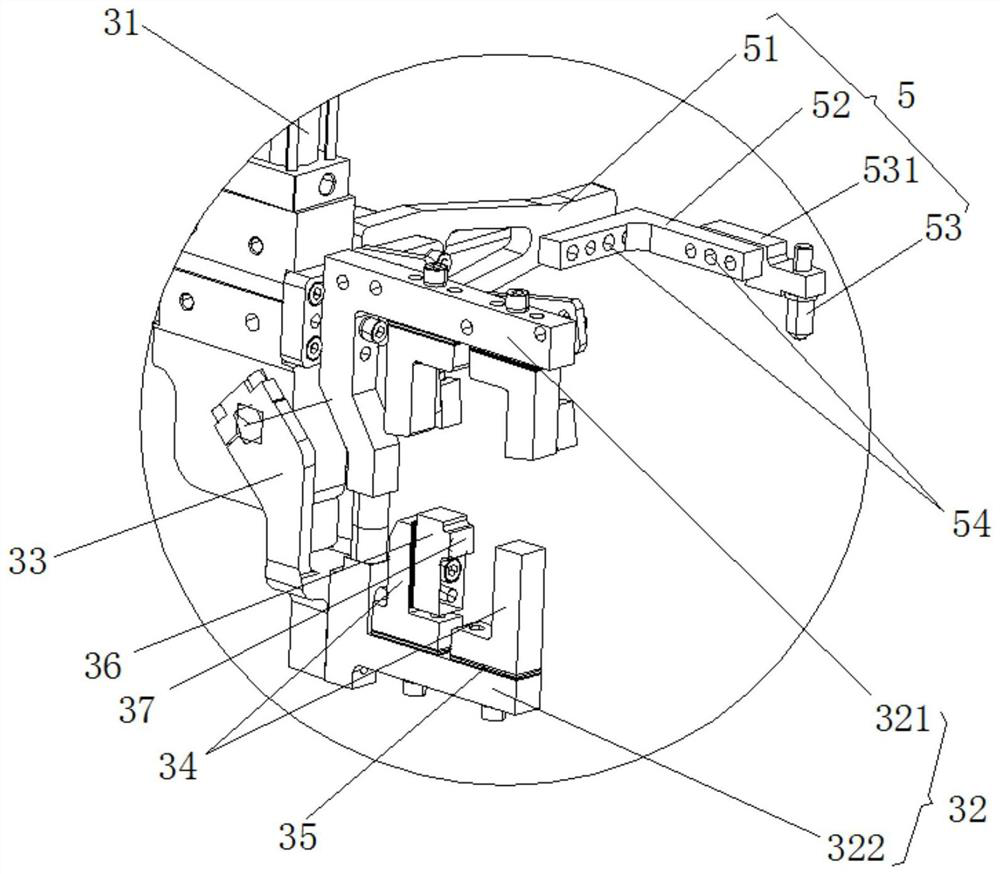

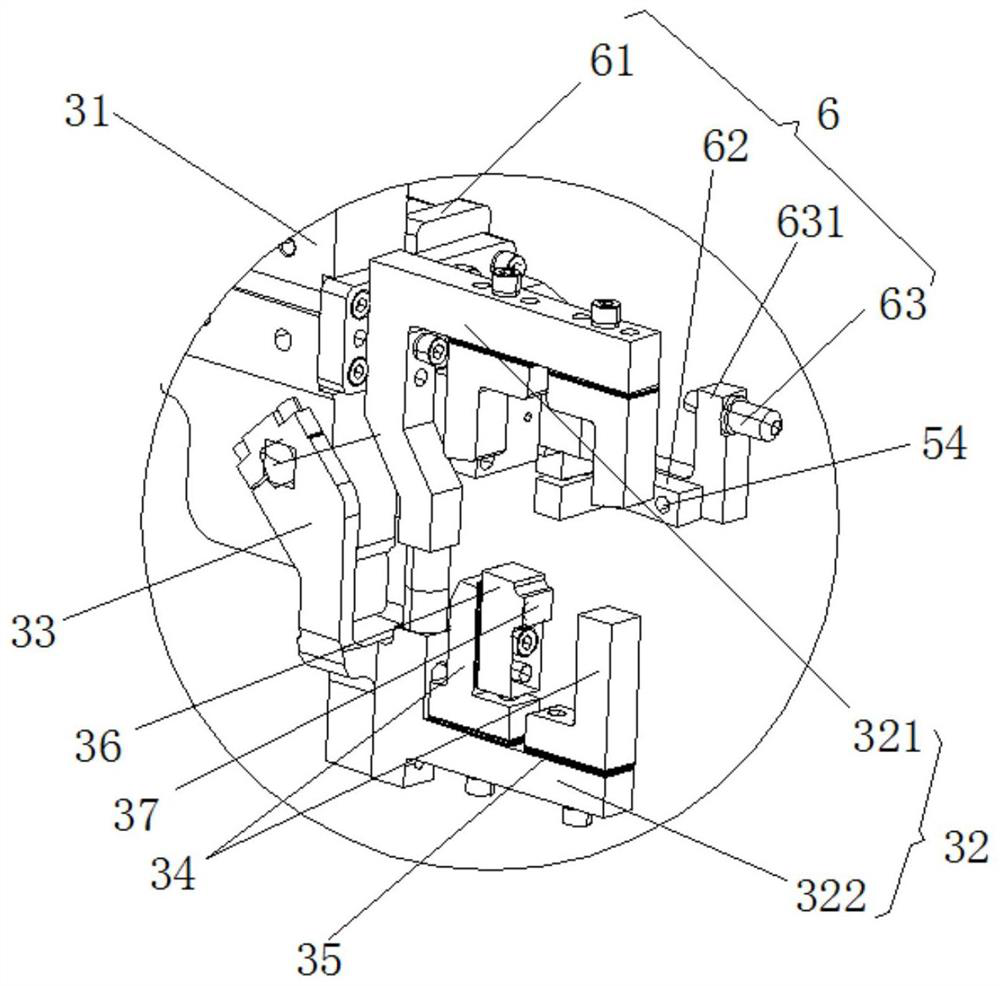

[0026] The grabbing part 3, the grabbing part 3 is arranged at the end of the double cross frame 1, the grabbing part 3 includes a corner cylinder 31 and a clamping part 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com