Biological sample dividing machine and biological sample dividing method

A technology of biological samples and dividing machines, applied in the field of machinery, can solve problems such as difficult fixation, difficult cutting, and large sample size errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

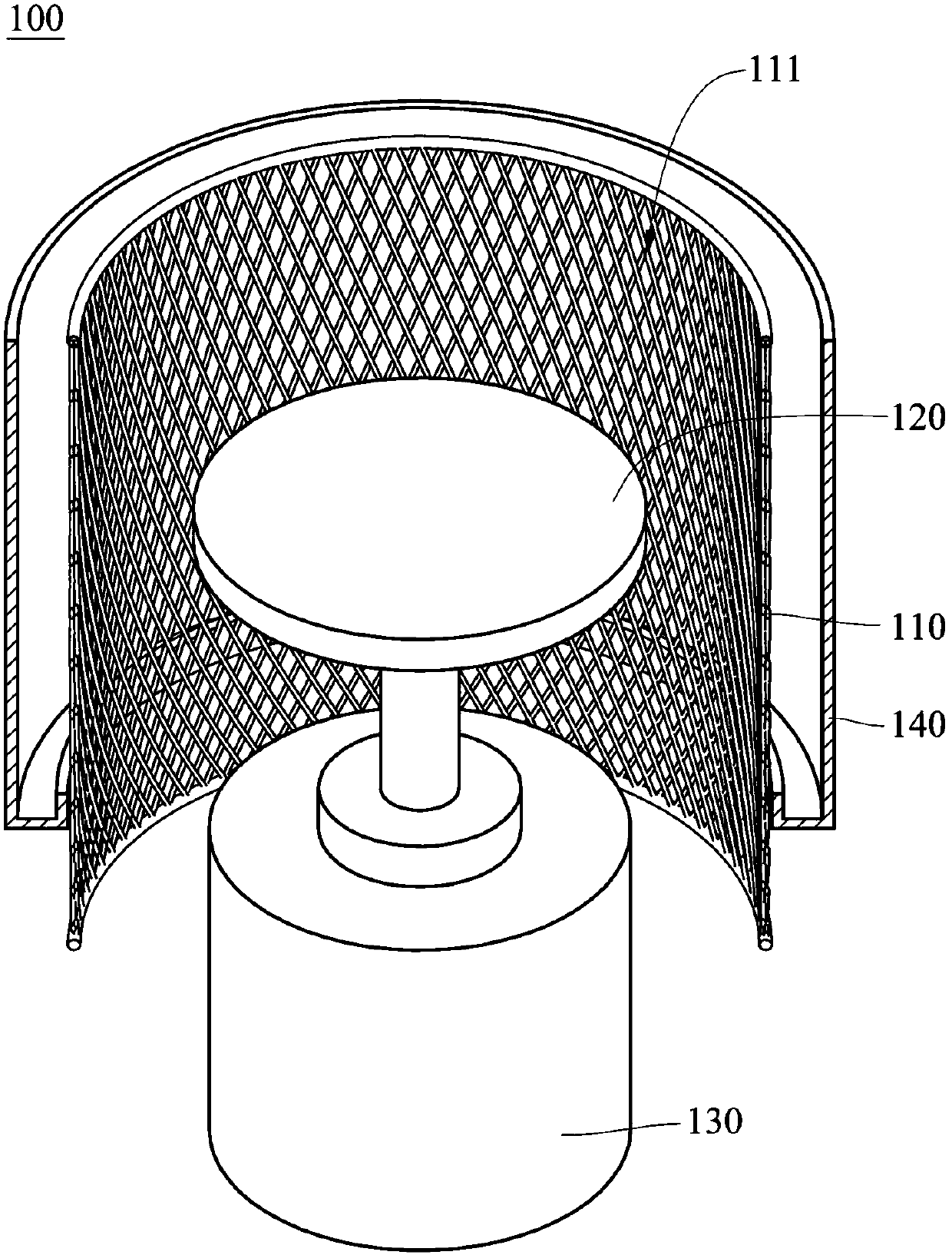

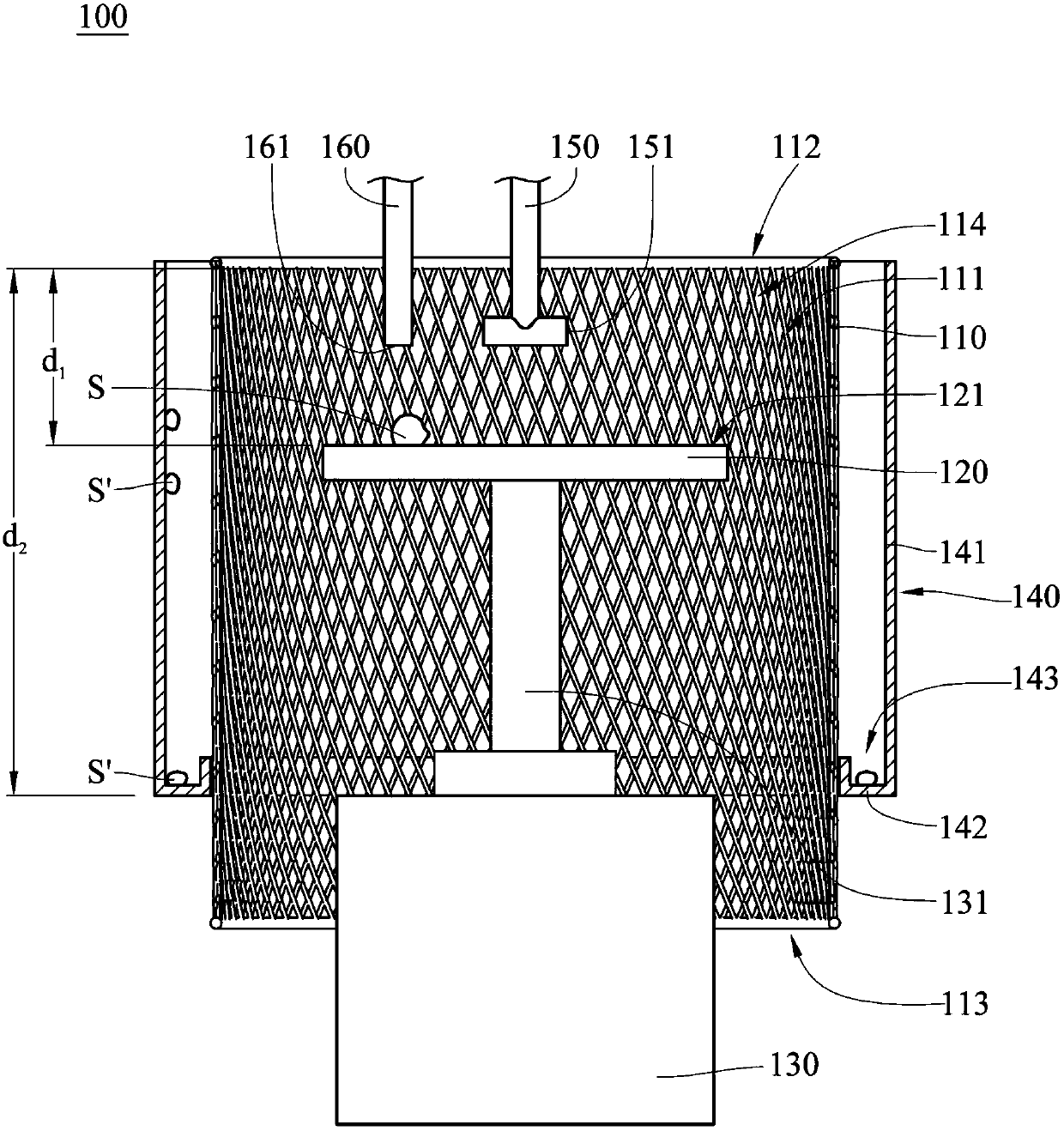

[0052] figure 1 Is a partial cross-sectional view of the three-dimensional structure of the biological sample dividing machine in the first embodiment of the present invention, figure 2 It is a cross-sectional view of the biological sample dividing machine in the first embodiment of the present invention, such as figure 1 versus figure 2 As shown, the biological sample dividing machine 100 of the first embodiment of the present invention includes a dividing net 110, a rotating stage 120, a rotating driving device 130, a collector 140, an air jet 150, and a liquid jet 160. The dividing net body 110 surrounds an accommodating space 111, and a first opening 112 and a second opening 113 located on two opposite sides of the accommodating space 111 and communicating with the accommodating space 111. In the first embodiment of the present invention, the dividing net body 110 is a hollow columnar structure with two openings, but it is not limited to this. In other embodiments of the p...

Embodiment 2

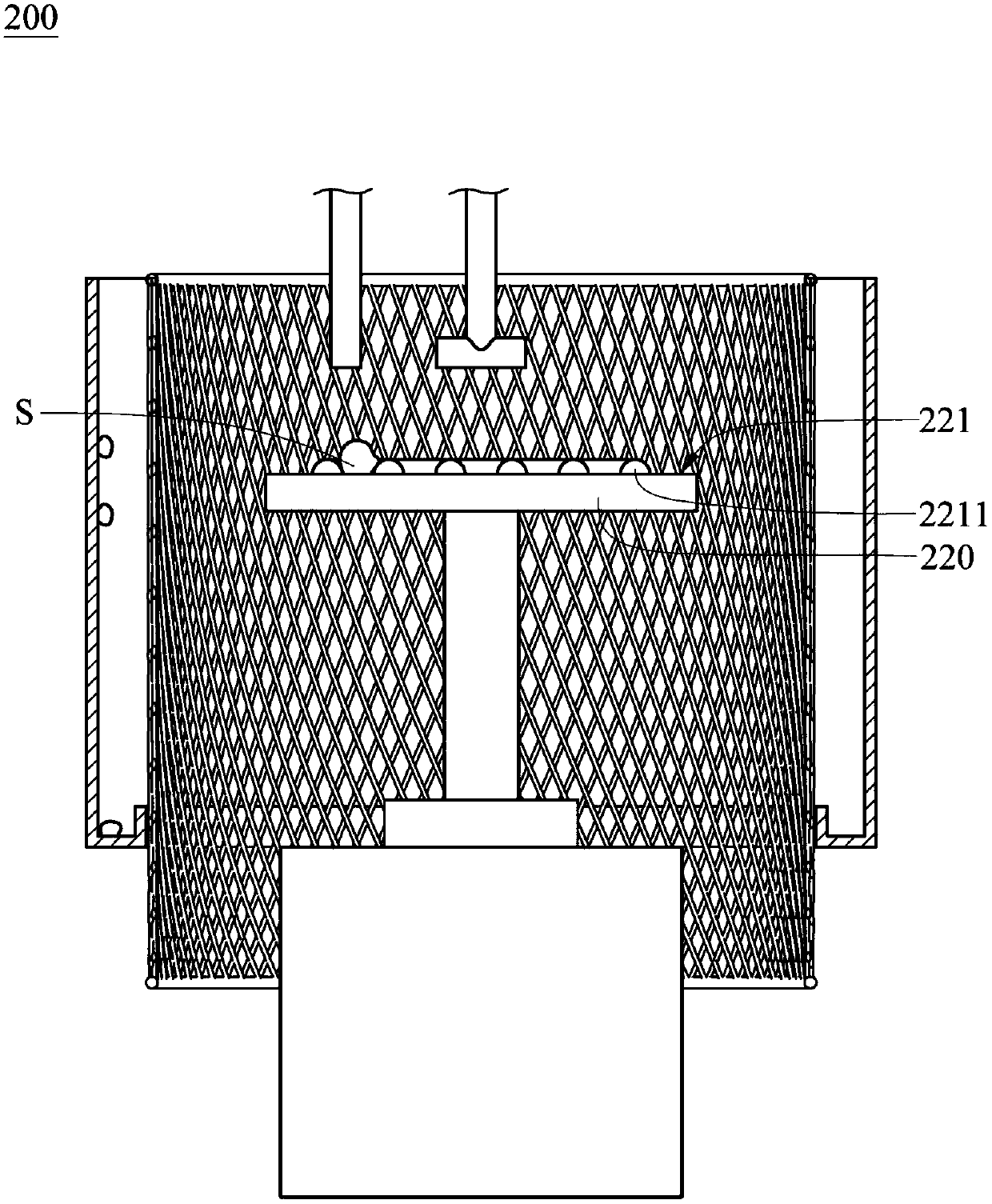

[0064] image 3 Is a cross-sectional view of the biological sample dividing machine in the second embodiment of the present invention, such as image 3 As shown, the second embodiment of the present invention is similar to the first embodiment, and only the differences are described below, and the similarities are not repeated here.

[0065] In the biological sample dividing machine 200 of the second embodiment of the present invention, the bearing surface 221 of the rotating stage 220 has a plurality of protruding structures 2211. The plurality of protruding structures 2211 can increase the frictional force between the biological sample S and the bearing surface 221, and prolong the time that the biological sample S rotates with the bearing surface 221, so that the biological sample S bears greater centrifugal force when it is separated from the bearing surface 221 and has Greater speed. In this way, a better cutting effect can be obtained when the biological sample S hits the d...

Embodiment 3

[0067] Figure 4 Is a cross-sectional view of the biological sample dividing machine in the third embodiment of the present invention, such as Figure 4 As shown, the third embodiment of the present invention is similar to the first embodiment, and only the differences are described below, and the similarities are not repeated here.

[0068] In the biological sample dividing machine 300 of the third embodiment of the present invention, the thickness of the center area of the rotating stage 320 is smaller than the thickness of the edge area, so that the bearing surface 321 is disk-shaped. The disc-shaped bearing surface 321 makes the centrifugal force only the component of the centrifugal force directed from the center area of the rotating stage 320 to the edge area to drive the biological sample S to move away from the bearing surface, extending the time for the biological sample S to rotate with the bearing surface 321 Therefore, the biological sample S has a greater speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com