Device and method for accurate compression molding of test piece during similar material confecting process

A material molding and compression molding technology, applied in the field of model testing, can solve the problems of too large difference in mechanical test parameters, aggravating the difficulty of material preparation, and uneven compaction of the test piece, so as to ensure the compactness of the test piece and reduce the mechanical Parameter difference, small volume error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

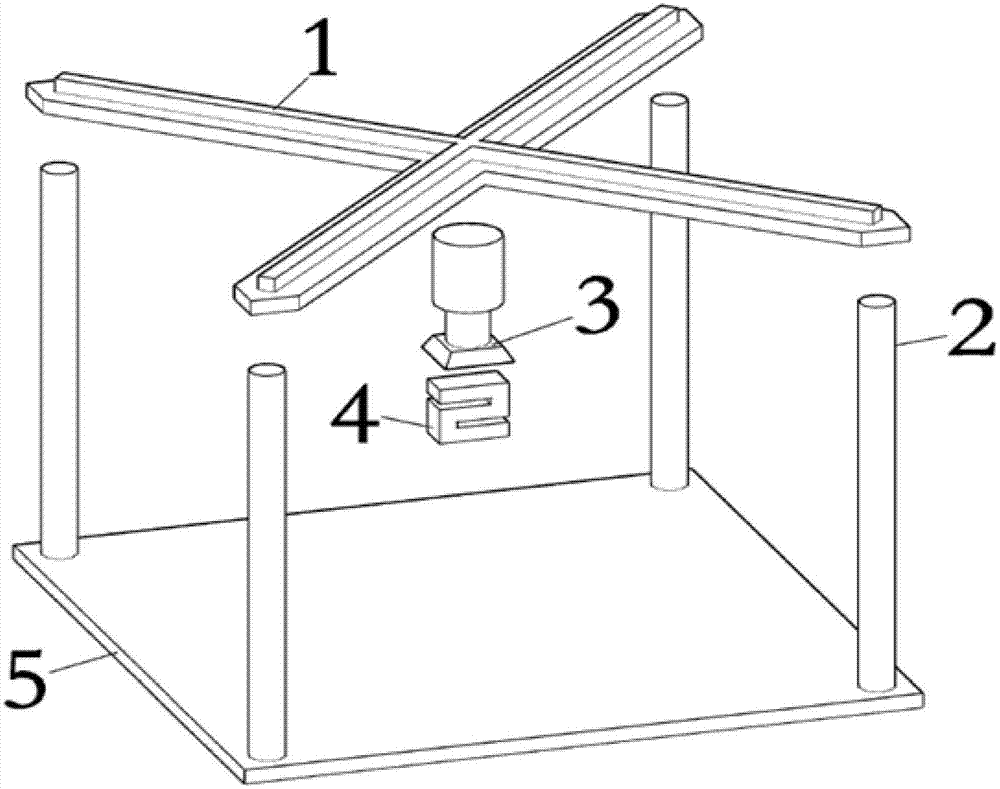

[0025] figure 1 , figure 2 Among them, a device for precise compression molding of test pieces in the process of similar material preparation, including material molding dies and precise pressure control system. The material forming mold can be disassembled and assembled, which is convenient for the brushing of the release agent in the early stage and the demoulding of the test piece in the later stage. The precise pressure control system can display the pressure and set the pressure to be applied to press the test piece.

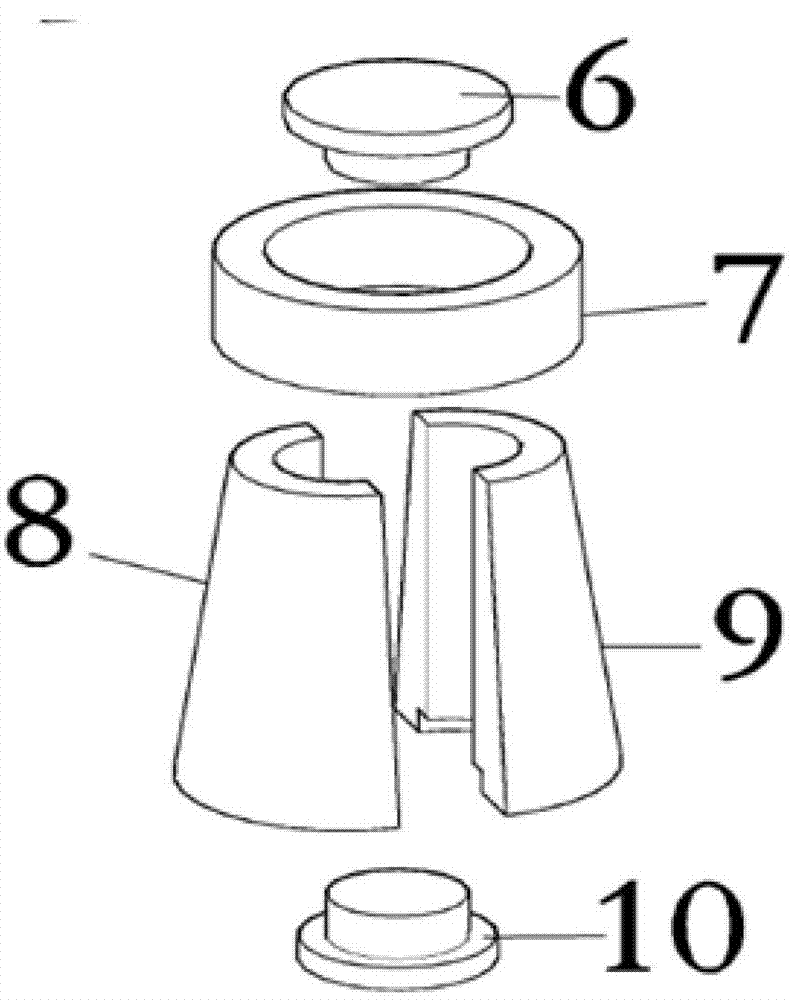

[0026] The material forming mold is precisely processed by high-strength steel. It includes side mold a8 and side mold b9 on both sides, the bottom of both is installed on the mold base 10, the mold hoop 7 is installed on the top, and the mold top cover 6 is installed in the mold hoop 7.

[0027] The precise pressure application...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com