Needle plate girder of high-speed needling machine

A needle loom and needle beam technology, which is applied in the field of non-woven production, can solve the problems that the assembly strength of the needle beam is not as good as that of steel parts, the quality of the aluminum alloy needle beam is not reduced, and the high-frequency and high-speed limitations of the acupuncture machine, etc. Achieve the effect of overcoming quality uncertainty, neat and beautiful appearance, and small bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

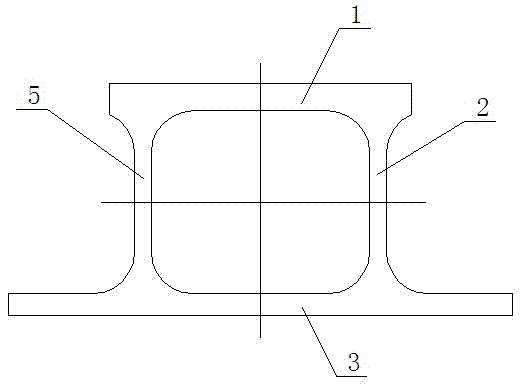

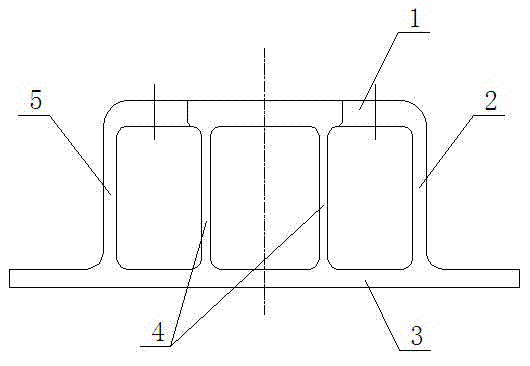

[0014] Such as image 3 As shown, it is the needle plate beam of the high-speed acupuncture machine, including the top side plate 1, the bottom side plate 3, the left side plate 5 and the right side plate 2, and two reinforcements are set between the left side plate 5 and the right side plate 2 Rib 4 , the upper end of each reinforcing rib 4 is fixedly connected with the top side plate 1 respectively, and the lower end of each reinforcing rib 4 is fixedly connected with the bottom side plate 3 respectively. The top side plate 1 and the left side plate 5 are connected by circular arc transition, the top side plate 1 and each rib 4 are respectively connected by circular arc transition, and the top side plate 1 and the right side plate 2 are connected by circular arc transition connection; the bottom side plate 3 and the left side plate 5 are connected through a circular arc transition, the bottom side plate 3 and each rib 4 are respectively connected through a circular arc trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com