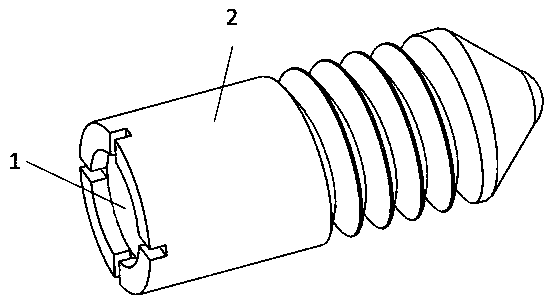

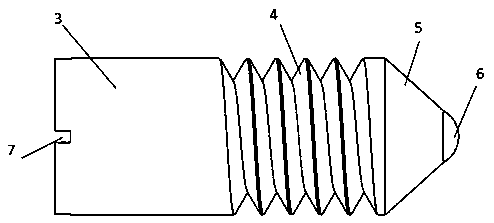

Degradable screw and manufacturing method thereof

A screw and thread technology, applied in the field of degradable screws and their manufacturing, can solve the problems of unsatisfactory bending resistance and poor bonding performance of solid structures, achieve good biocompatibility and osteoinductivity, low manufacturing cost, The effect of broad clinical application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

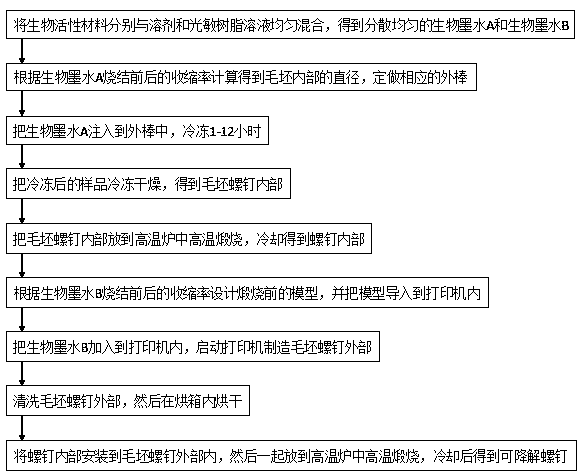

[0065] 1) According to the mass percentage of 55% calcium magnesium silicate powder, 2.5% polyvinyl alcohol and 42.5% deionized water to prepare uniformly dispersed bio-ink A, according to the mass percentage 1:1 calcium magnesium silicate powder The body was uniformly mixed with the photosensitive resin solution to obtain uniformly dispersed bio-ink B.

[0066] 2) According to the shrinkage rate of bio-ink A before and after sintering, the inner diameter of the blank is calculated, and an outer rod with an inner diameter of 5.2 mm and a wall thickness of 1.5 mm is customized.

[0067] 3) Inject the bio-ink A in step 1) into the outer rod, and then at -60 o Quick freezing in the environment of C for 4-5 hours.

[0068] 4) Freeze-dry the frozen sample to obtain the inside of the blank screw.

[0069] 5) Put the inside of the blank screw into the high temperature furnace, after 1100 o After calcining at high temperature for 3-4 hours, cool to obtain the inside of the screw wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com