Patents

Literature

66results about How to "Good anti-torsion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

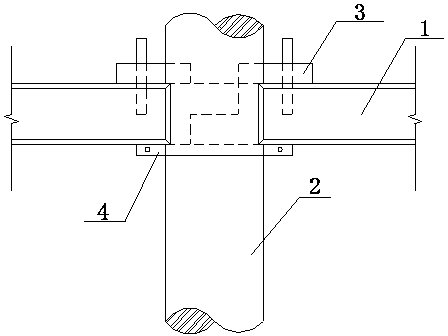

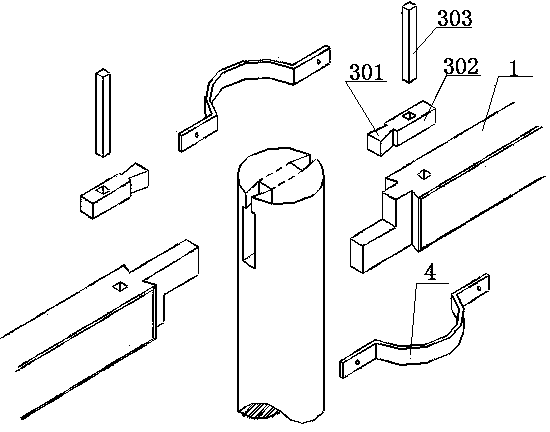

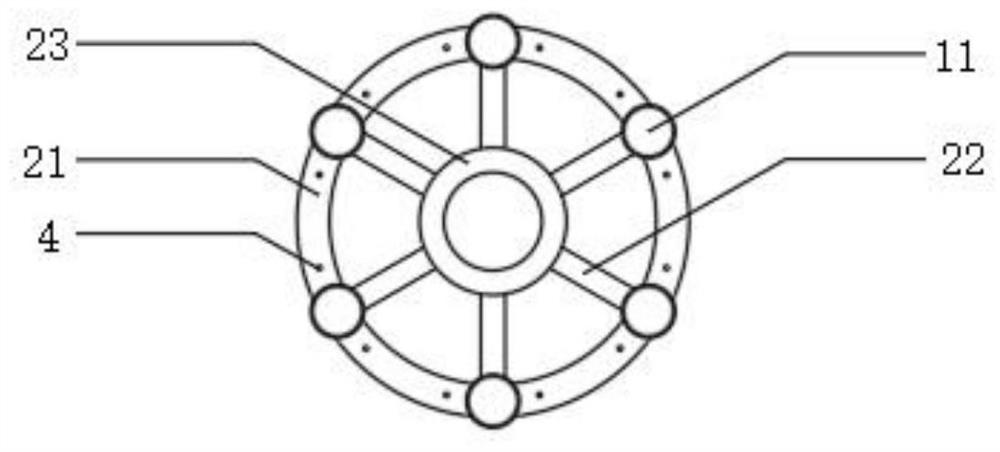

Steel-wood composited reinforcement device for ancient wood frames

InactiveCN103835525AImprove integrityImprove seismic performanceBuilding repairsMortise and tenonShock resistance

Disclosed is a steel-wood composited reinforcement device for ancient wood frames. The steel-wood composited reinforcement device needs not to be fixed with iron cramps or angle steel, horizontal displacement of mortises and tenons can be prevented through wood components, and bending resistance of beams and columns can be improved through steel fasteners. The steel-wood composited reinforcement devcie is high in flexibility, shock resistance and twisting resistance; with the reinforcement technology, maintenance and replacement can be achieved, and protection and renovation of the wood structure is benefited.

Owner:LUOYANG INST OF SCI & TECH

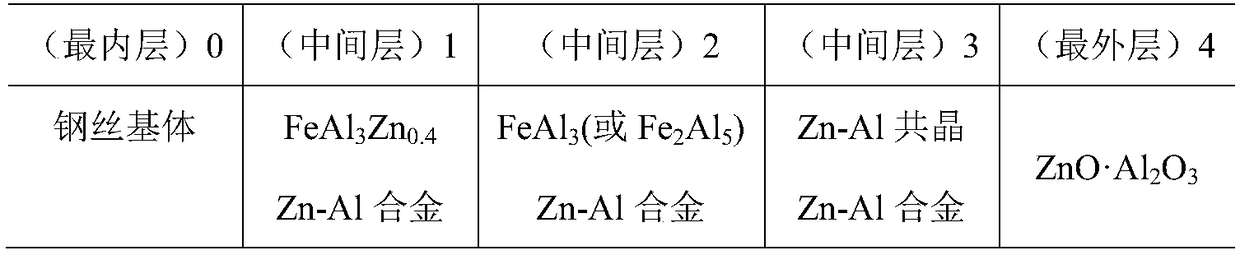

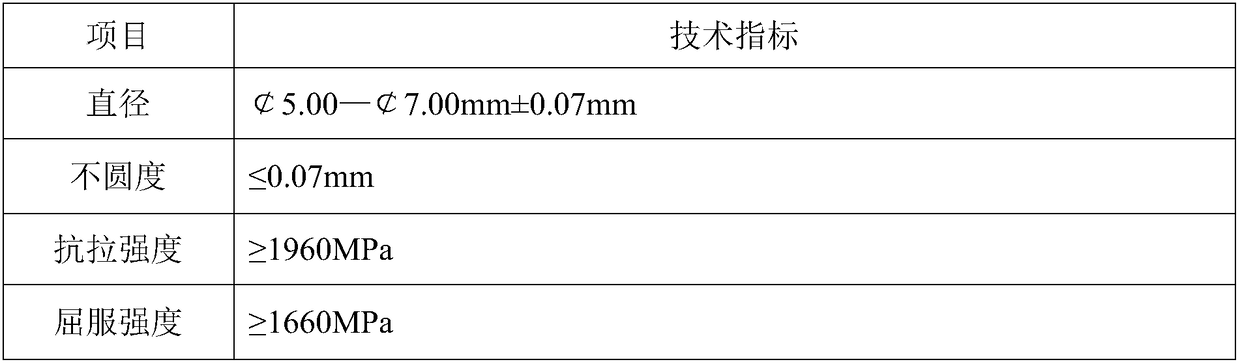

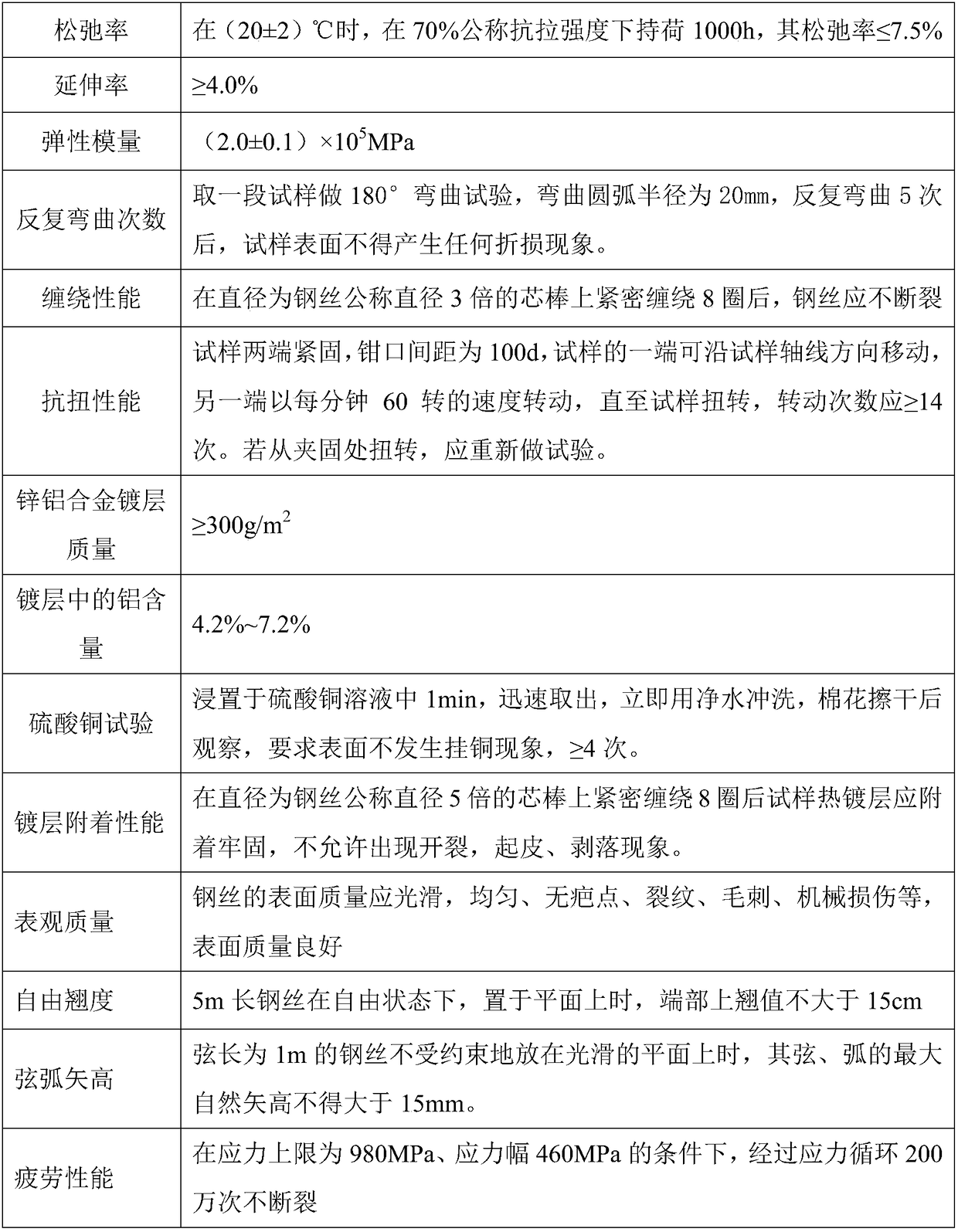

High-strength and ductility durable type large-diameter 1960 MPa stage zinc-aluminum alloy coating steel wire for bridge cable

InactiveCN108239735AHigh strengthIncreased durabilityHot-dipping/immersion processesWater bathsHigh carbon

The invention relates to a high-strength and ductility durable type large-diameter 1960 MPa stage zinc-aluminum alloy coating steel wire for a bridge cable. A steel wire rod is an ultra-pure hyper-eutectoid steel high-carbon steel wire rod obtained after sorbite treatment (water bath, lead bath and salt bath), the strength of extension is larger than or equal to 1290 MPa, the area reduction rate is larger than or equal to 30%, and the elongation is larger than or equal to 10%; and the steel wire rod is drawn into a bright steel wire with the diameter ranging from 4.90 mm to 6.90 mm, then hot galvanizing zinc-aluminum alloy coating is carried out, and technological processes include lead bath degreasing, hot water washing, chlorohydric acid pickling, hot water washing, weak base washing, hot water washing, ammonium chloride and zinc chloride solvent plating assisting, hot-dip galvanizing-nitrogen smearing, zinc-aluminum alloy hot galvanizing, nitrogen smearing and wire collecting. The steel wire rod is subject to stabilization treatment, and the strength, the linearity, the relaxation rate and the steel wire axial homogeneity of the large-diameter ultrahigh-strength Zn95Al5 alloy coating steel wire are guaranteed.

Owner:JIANGSU FASTEN STEEL CABLE CO LTD +1

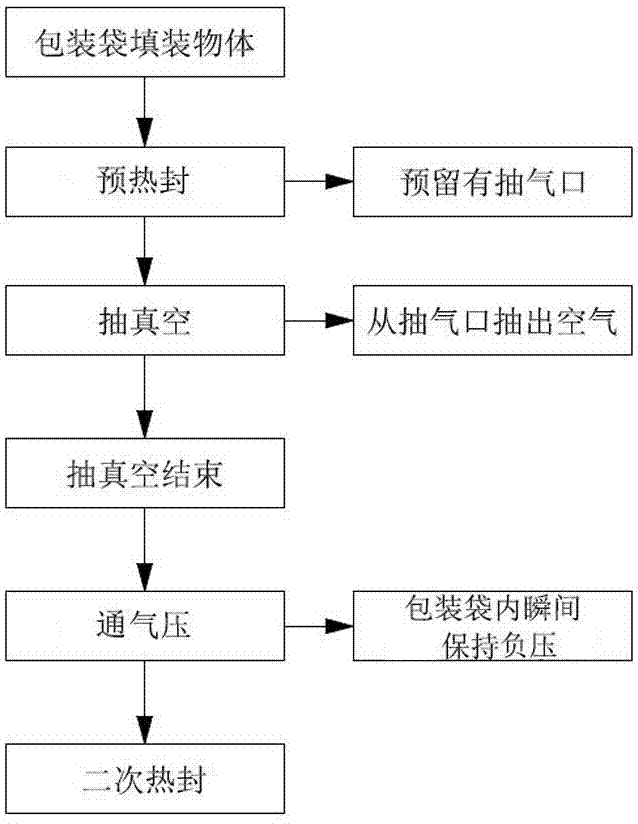

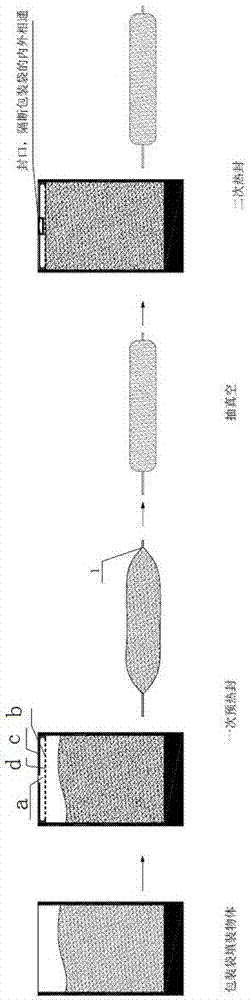

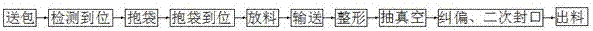

Vacuum packing method, vacuum packing treatment device and treatment method of vacuum packing treatment device

ActiveCN107878846AImprove stabilityIncrease success ratePackaging under vacuum/special atmosphereWrapper twisting/gatheringEngineeringWaiting time

The invention relates to a vacuum packing method, a vacuum packing treatment device and a treatment method of the vacuum packing treatment device. The vacuum packing treatment device comprises a shaping mechanism for a shaping station and a vacuumizing mechanism for a vacuumizing station, and the shaping mechanism comprises a shaping mechanism lifting air cylinder, a shaping mechanism mounting plate, an upper shaping plate connecting plate and a shaping plate. The shaping mechanism lifting air cylinder is mounted on the shaping mechanism mounting plate, the movable end of the shaping mechanismlifting air cylinder is hinged to the upper shaping plate connecting plate, and a balancing guiding shaft is arranged between the shaping mechanism mounting plate and the upper shaping plate connecting plate. The upper shaping plate connecting plate is connected with the shaping plate through an elastic cushion block, and a vibrating air cylinder is arranged on the shaping plate. According to thevacuum packing method, the vacuum packing treatment device and the treatment method of the vacuum packing treatment device, secondary hot sealing and vacuum packing are ingeniously combined, the stability is improved, the success rate is increased, and the traditional waiting time is shortened; and the shaping mechanism and the vacuumizing mechanism can be separately arranged so as to improve thepacking efficiency, flatness and beauty, and the structure is stable and reliable.

Owner:ZHANGZHOU JIALONG TECH INC

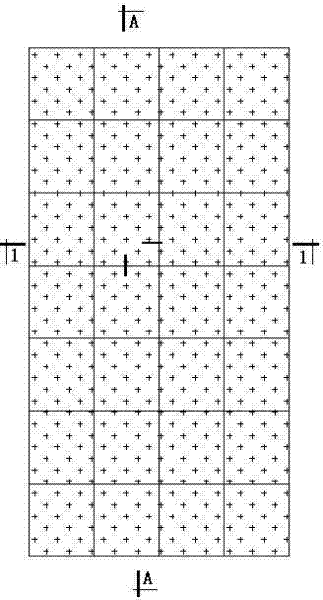

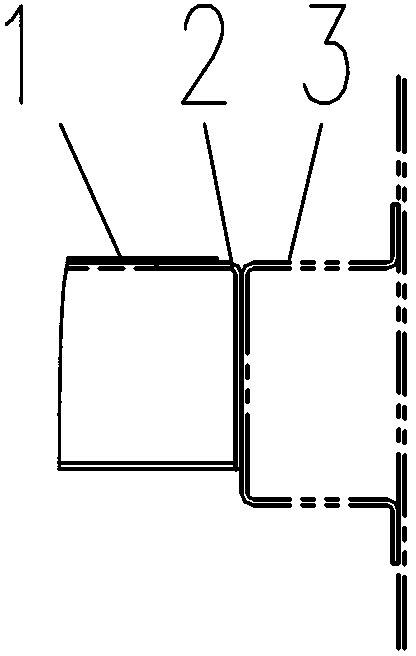

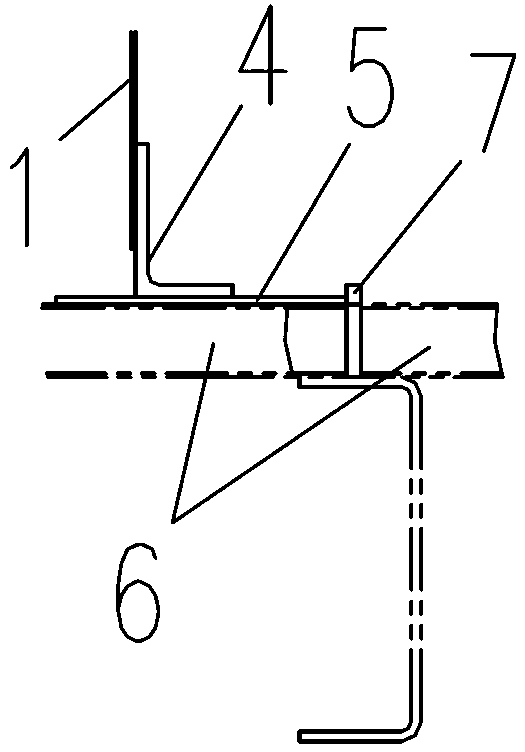

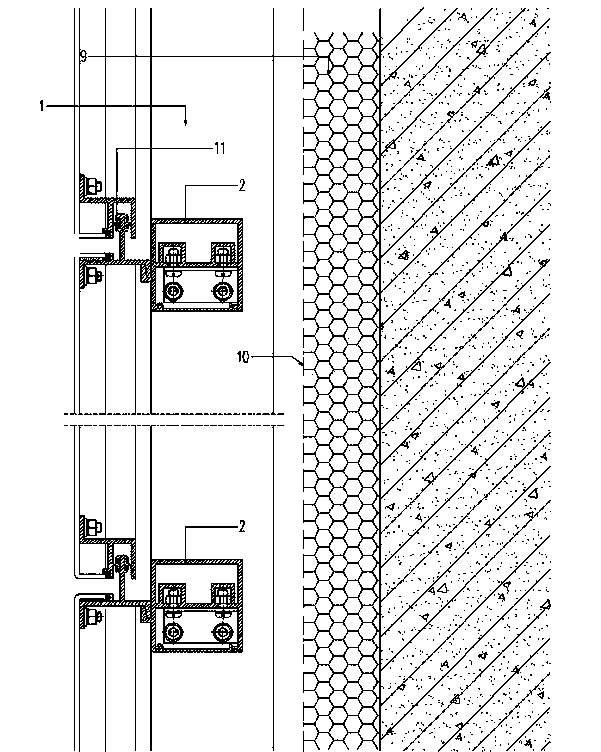

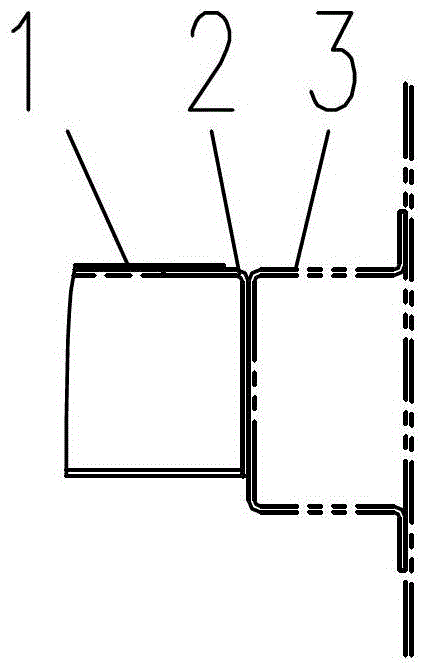

Open type aluminum plate curtain wall

The invention discloses an open type aluminum plate curtain wall, which is characterized in that: the open type aluminum plate curtain wall comprises vertical columns, horizontal beams, aluminum single plates and aluminum alloy secondary frames; the horizontal beams are fixed to the vertical columns by bolts running through the vertical columns; the aluminum alloy secondary frames comprise secondary frame main parts with hook grooves in the middle, and hook plates hooked in the hook grooves; one ends of the secondary frame main parts are fixedly connected with the vertical columns by the bolts, while the other ends of the secondary frame main parts are parallel to one ends of the hook plates far away from the hook grooves; one ends of the secondary frame main parts parallel to each other and one ends of the hook plates are fixedly connected with two adjacent aluminum single plates by the bolts respectively; and one ends of the secondary frame main parts parallel to each other and one ends of the hook plates are formed with open type space. The open type installation method meets needs of seeking different effects, so that the open type aluminum plate curtain wall is more beautiful; in addition, the non rigid connection method is more favorable for expansion and contraction among the plates, so that the open type aluminum plate curtain wall is improved in structural stability.

Owner:无锡金城幕墙装饰工程有限公司

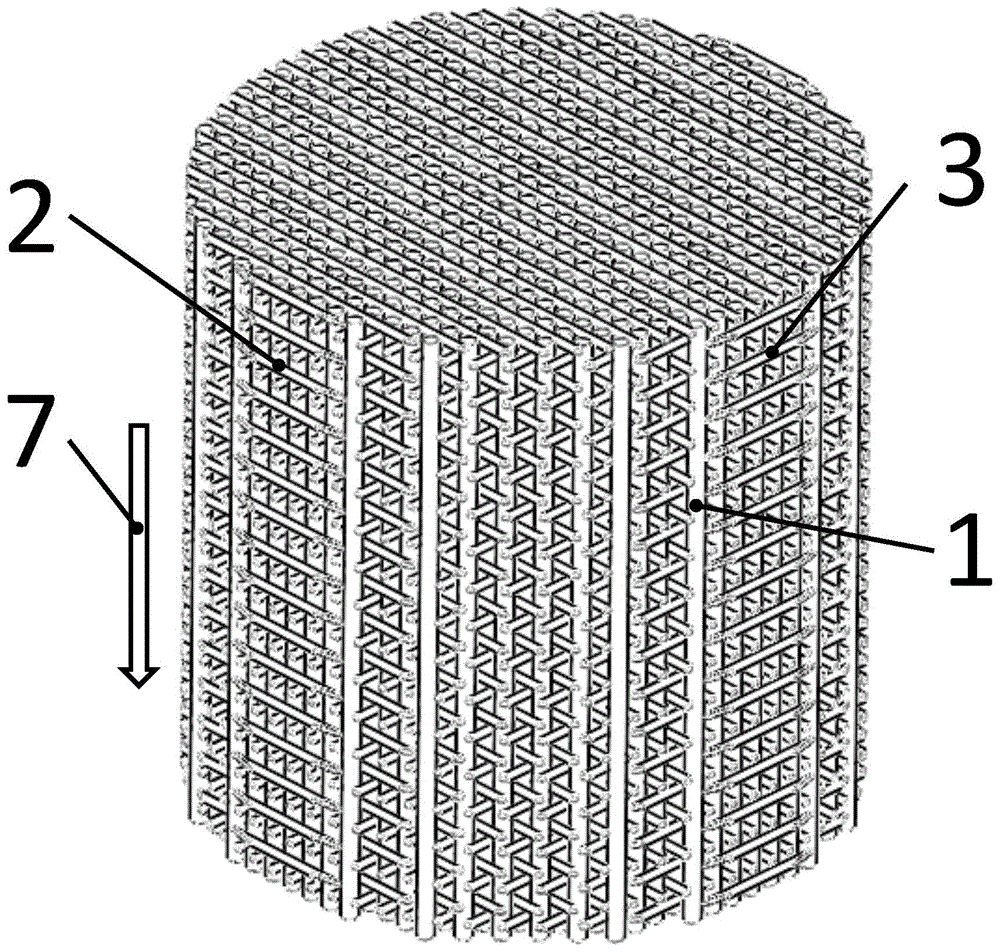

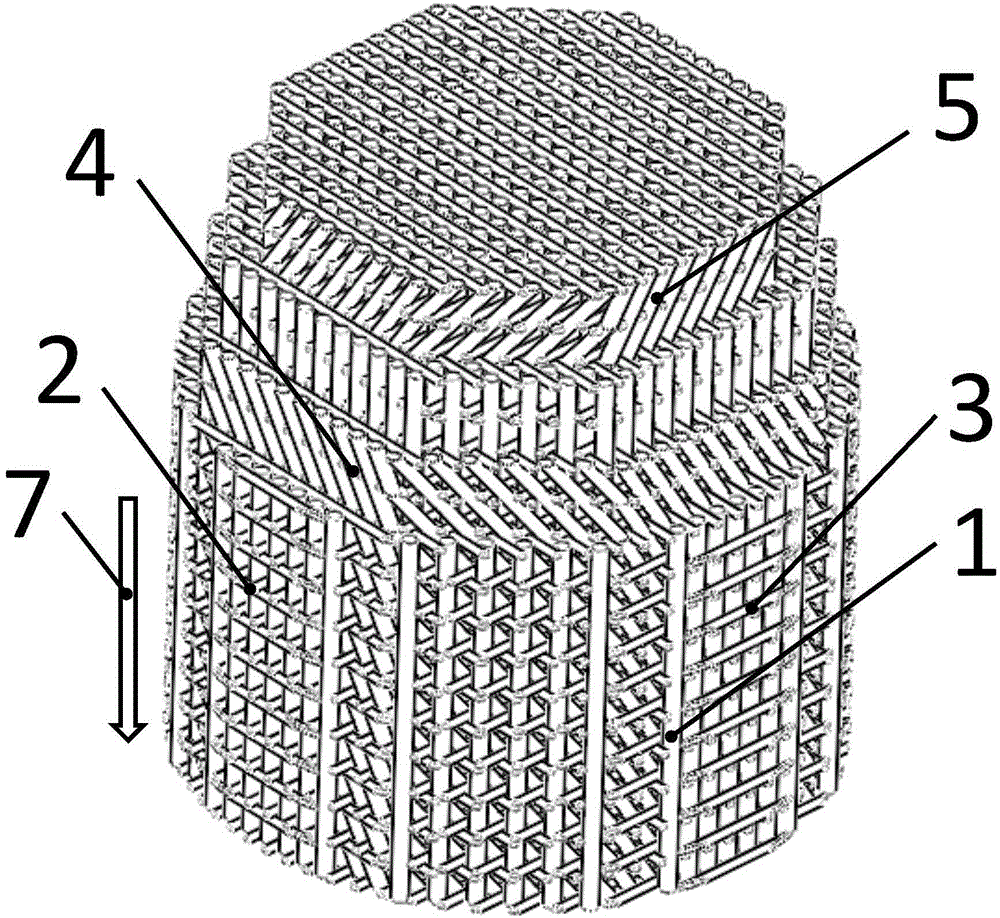

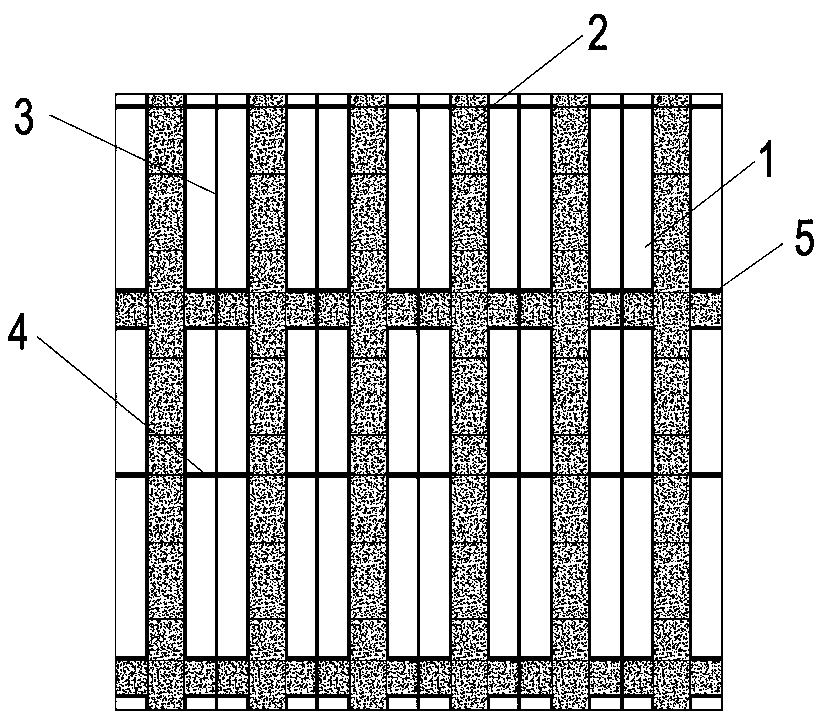

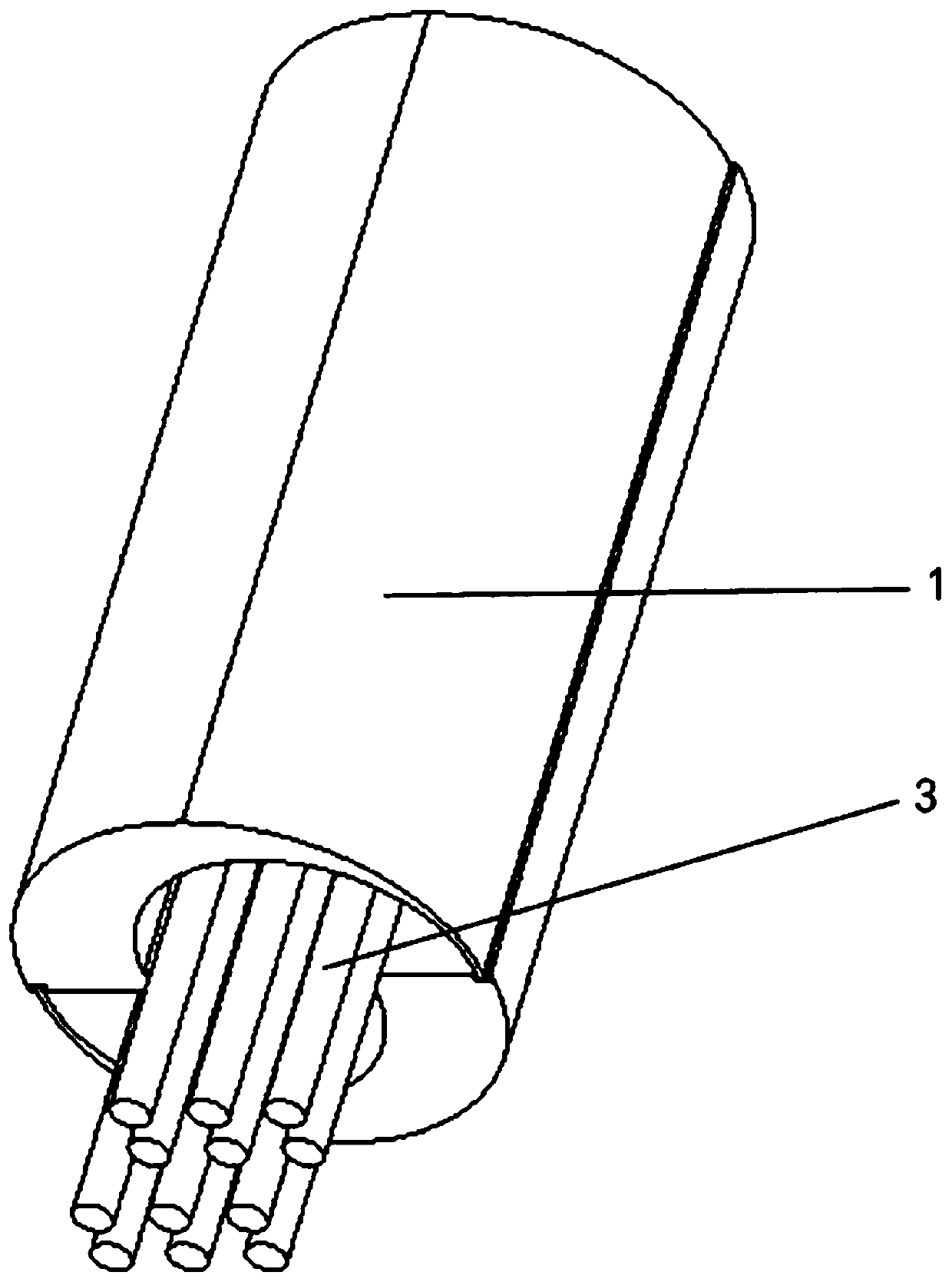

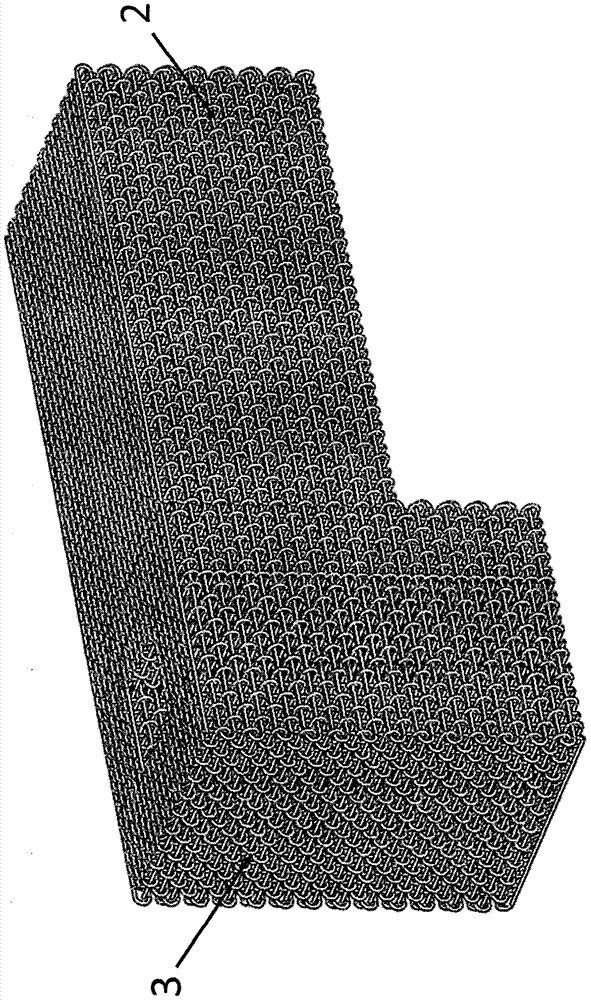

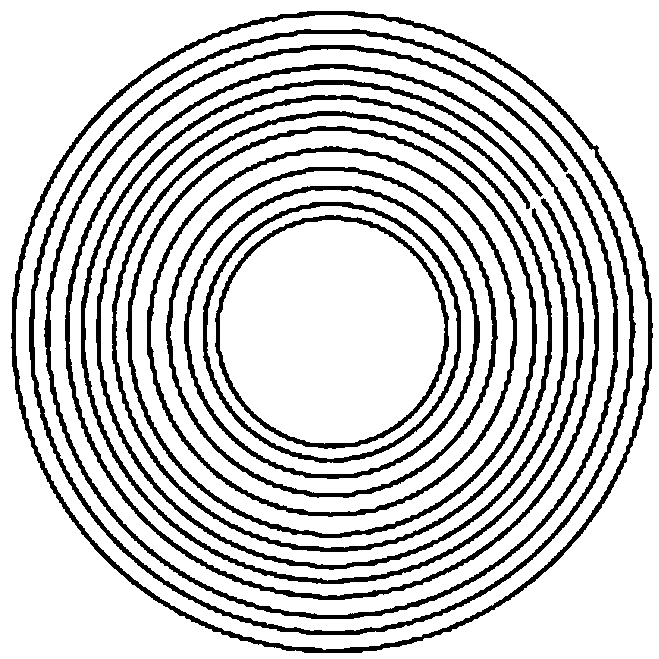

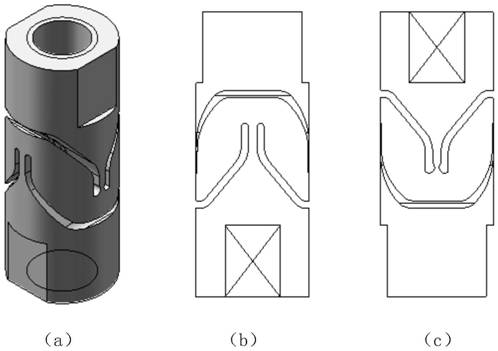

Solid cylindrical fabric and weaving method thereof

ActiveCN104947293AGood anti-torsion performanceStrong designability of mechanical propertiesWoven fabricsPrismYarn

The invention discloses a piece of solid cylindrical fabric and a weaving method thereof. The fabric comprises a warp system, a weft system and a normal yarn system which are perpendicularly crossed; the fabric is characterized by at least further comprising one of a plus theta oblique yarn system and a minus theta oblique yarn system, wherein the plus theta oblique yarn system rotates around the axis of the fabric in the anticlockwise direction to form a regular eight-angular prism left-hand screw shape and is interwoven with the warp system, the weft system and the normal yarn system, and the included angle plus theta formed by plus theta oblique yarn and the length direction of the fabric ranges from 10 degrees to 80 degrees; the minus theta oblique yarn system rotates around the axis of the fabric in the clockwise direction to form a regular eight-angular prism right-hand screw shape and is interwoven with the warp system, the weft system and the normal yarn system, and the included angle minus theta formed by minus theta oblique yarn and the length direction of the fabric ranges from minus 10 degrees to minus 80 degrees. The weaving method is characterized in that the oblique yarn system is introduced through movement of an oblique yarn spindle along a regularly octagonal track.

Owner:TIANJIN POLYTECHNIC UNIV

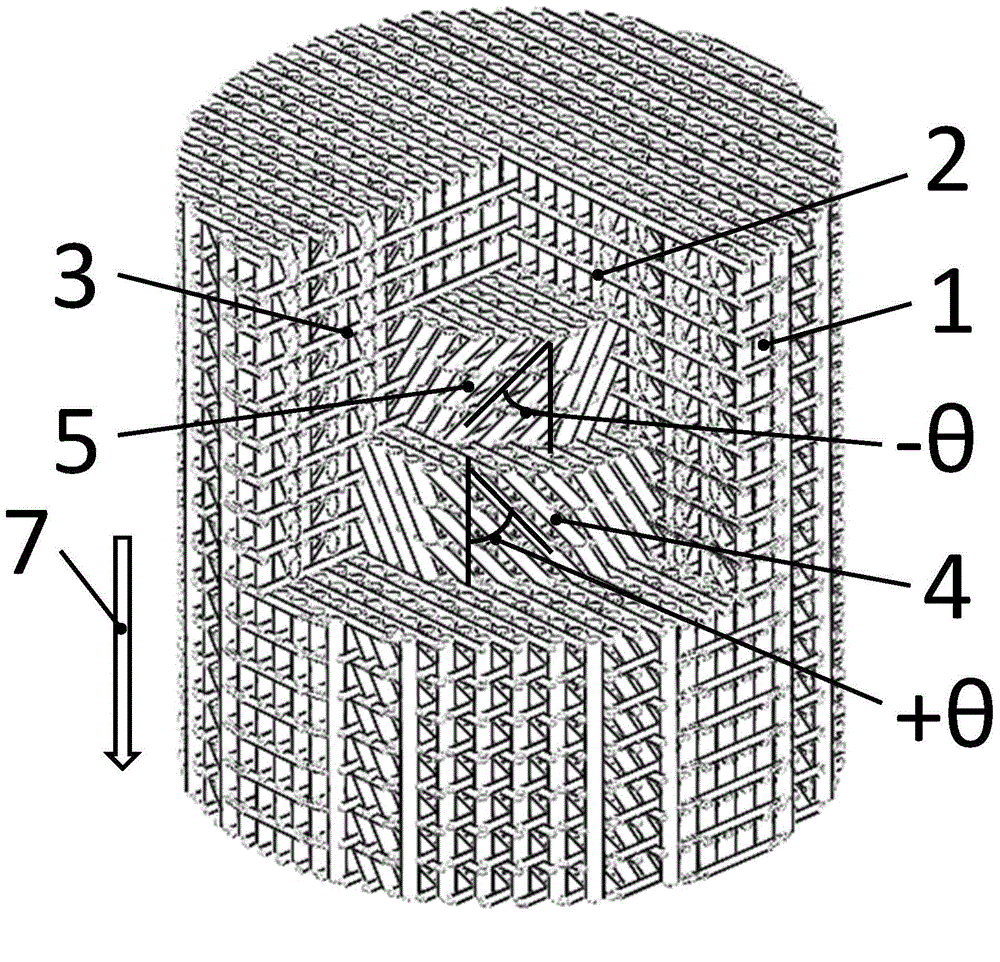

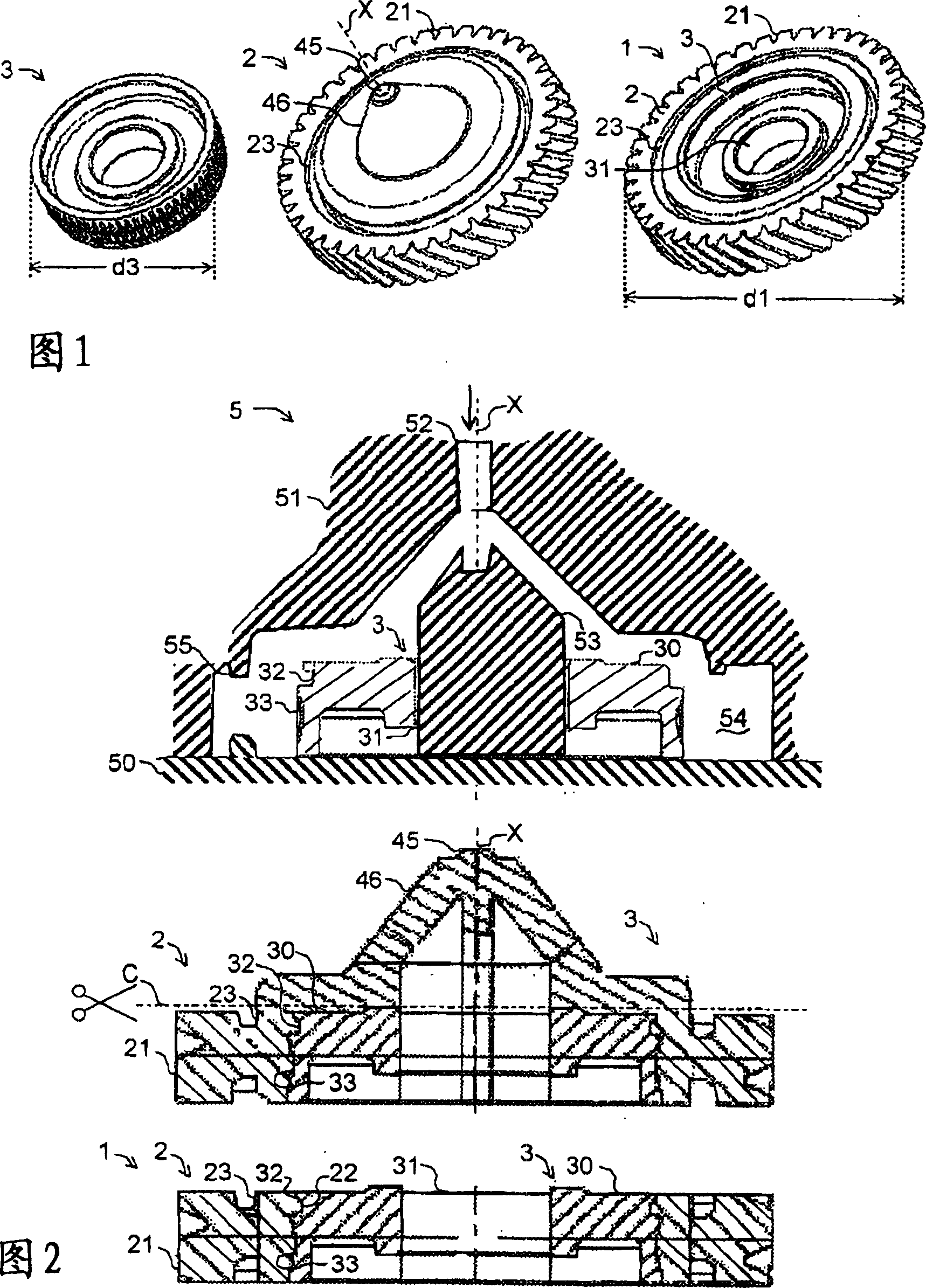

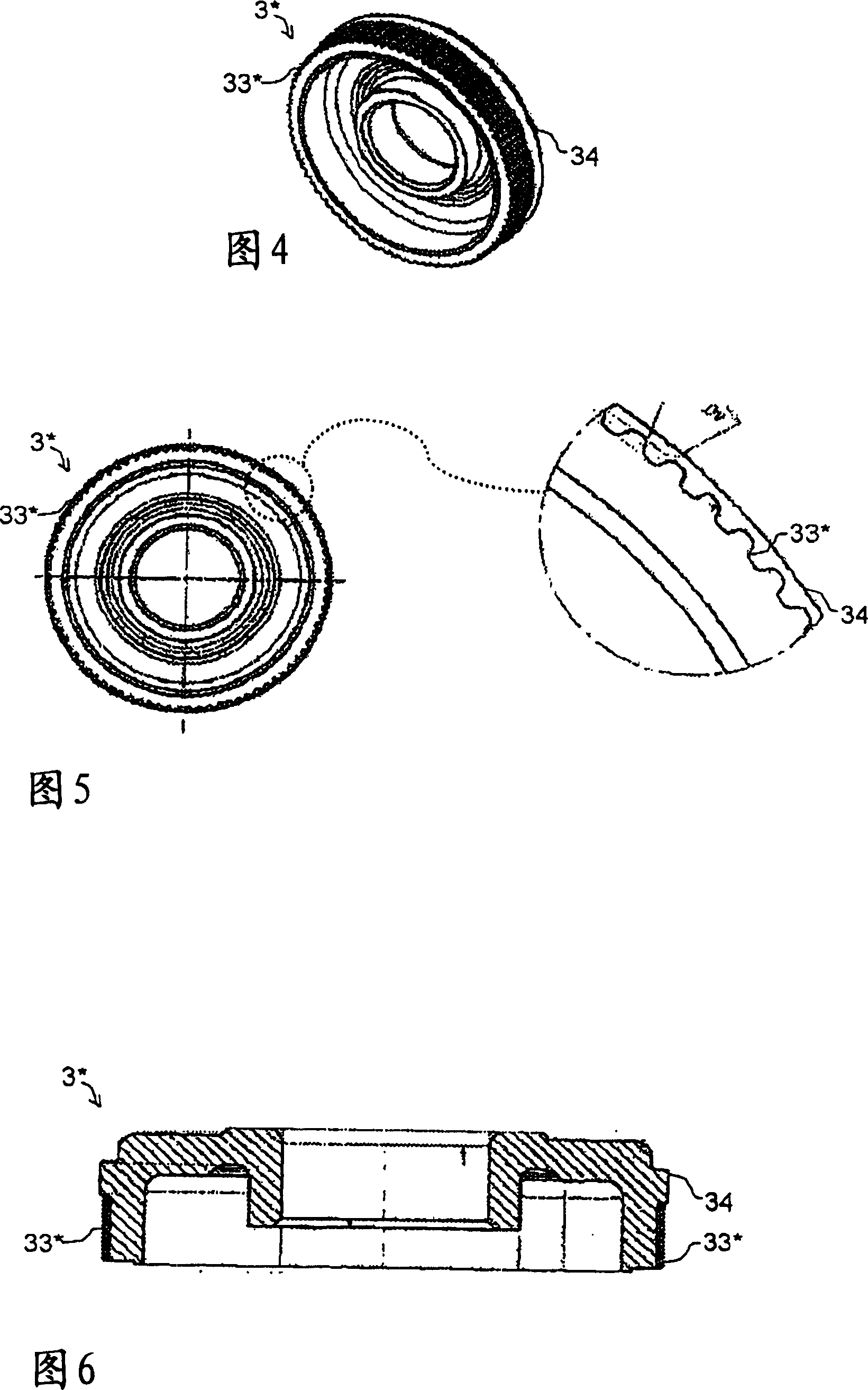

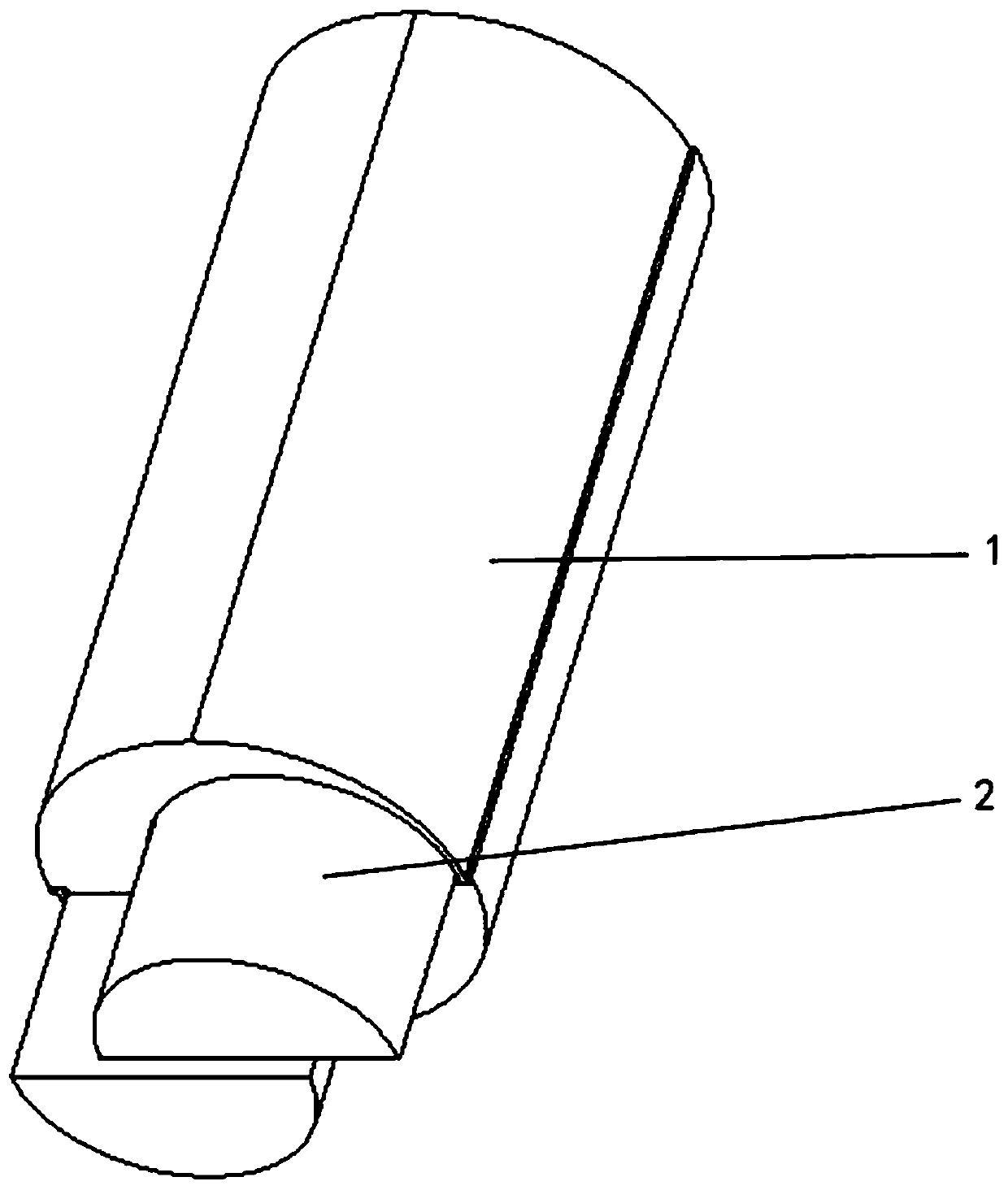

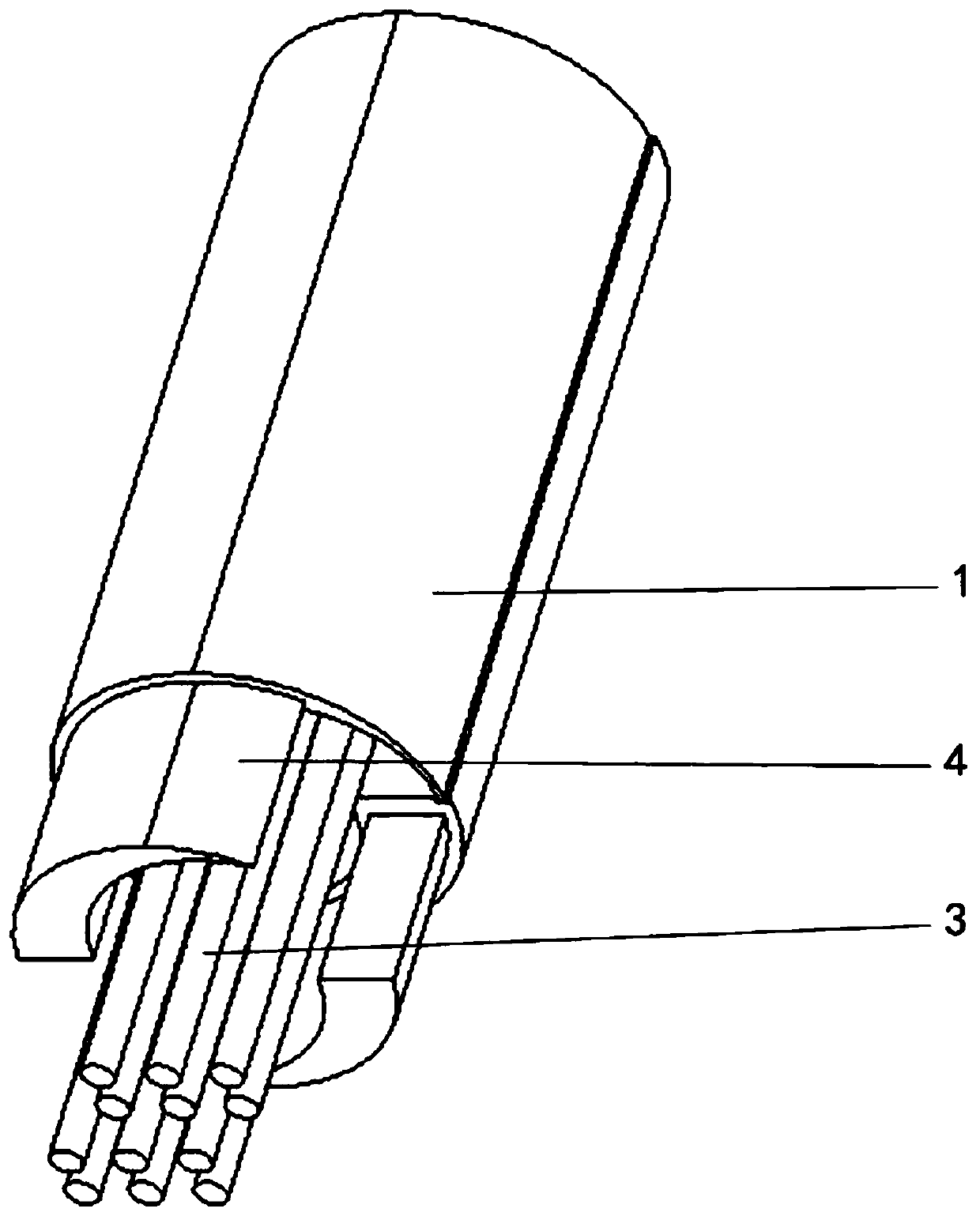

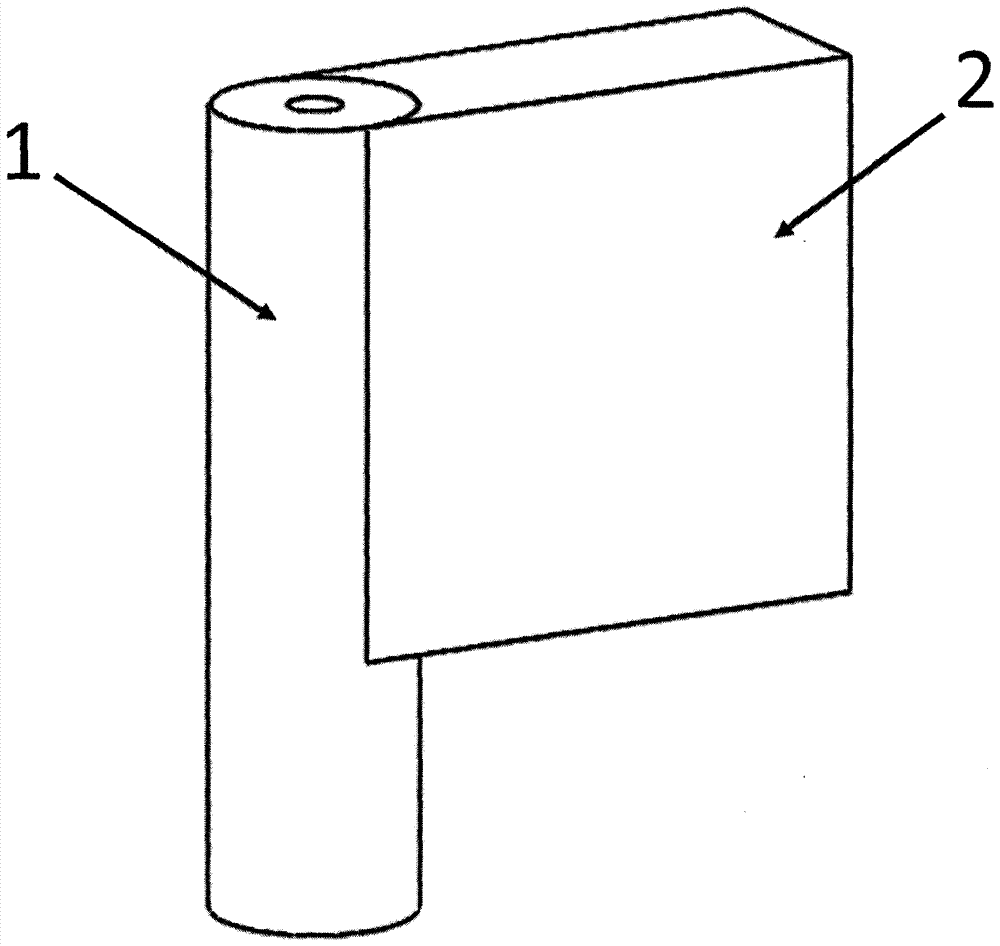

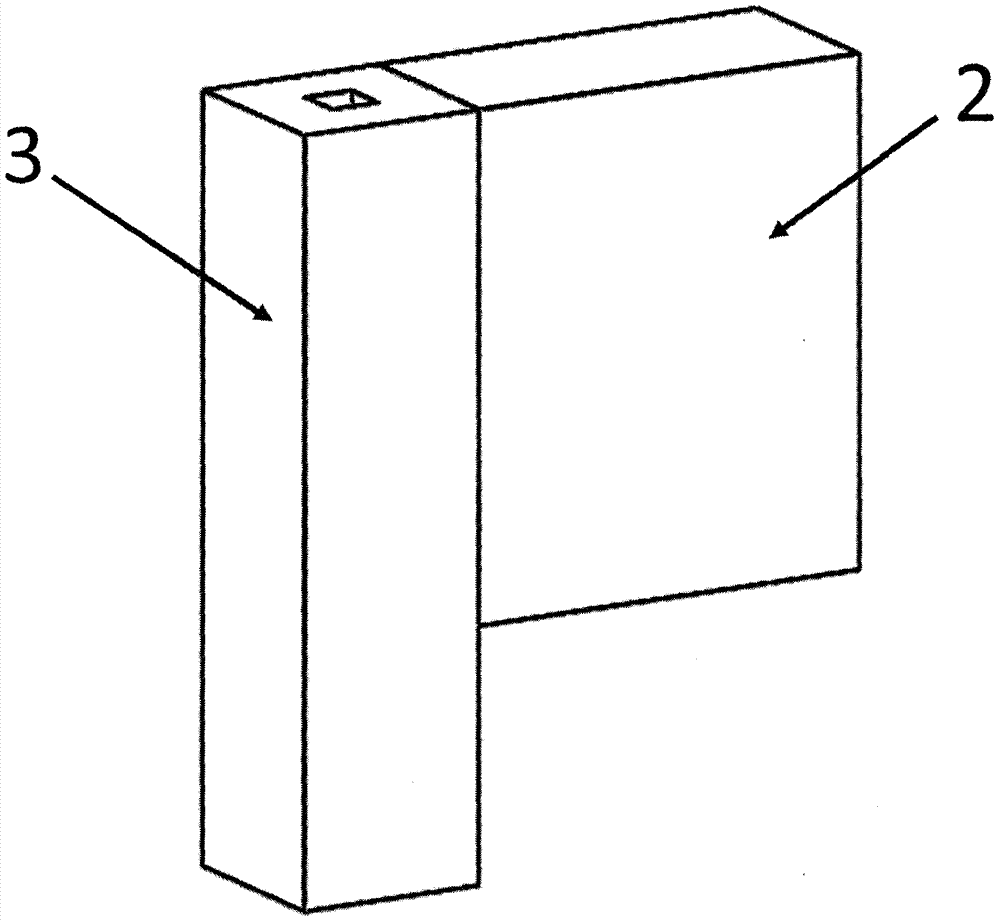

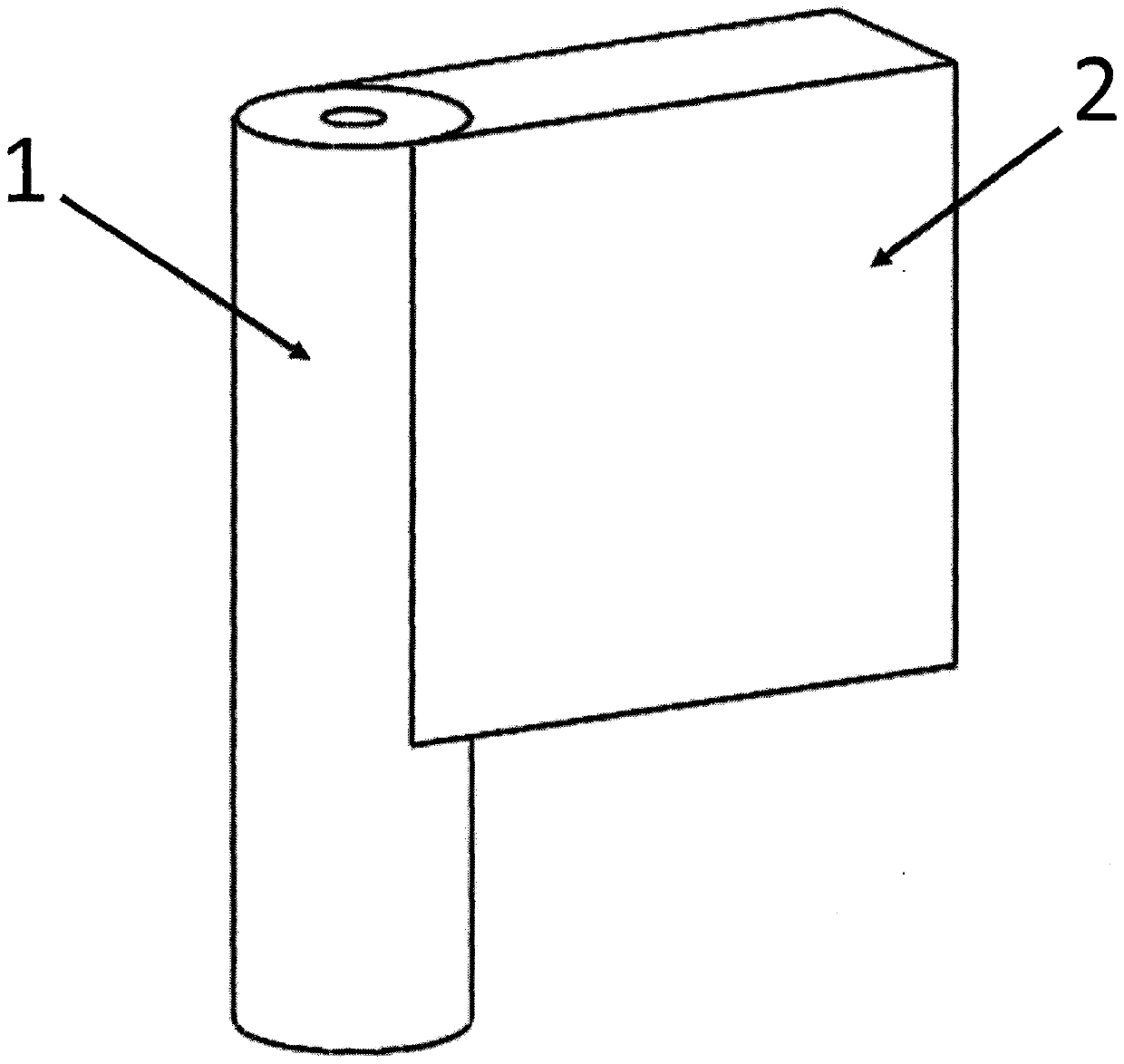

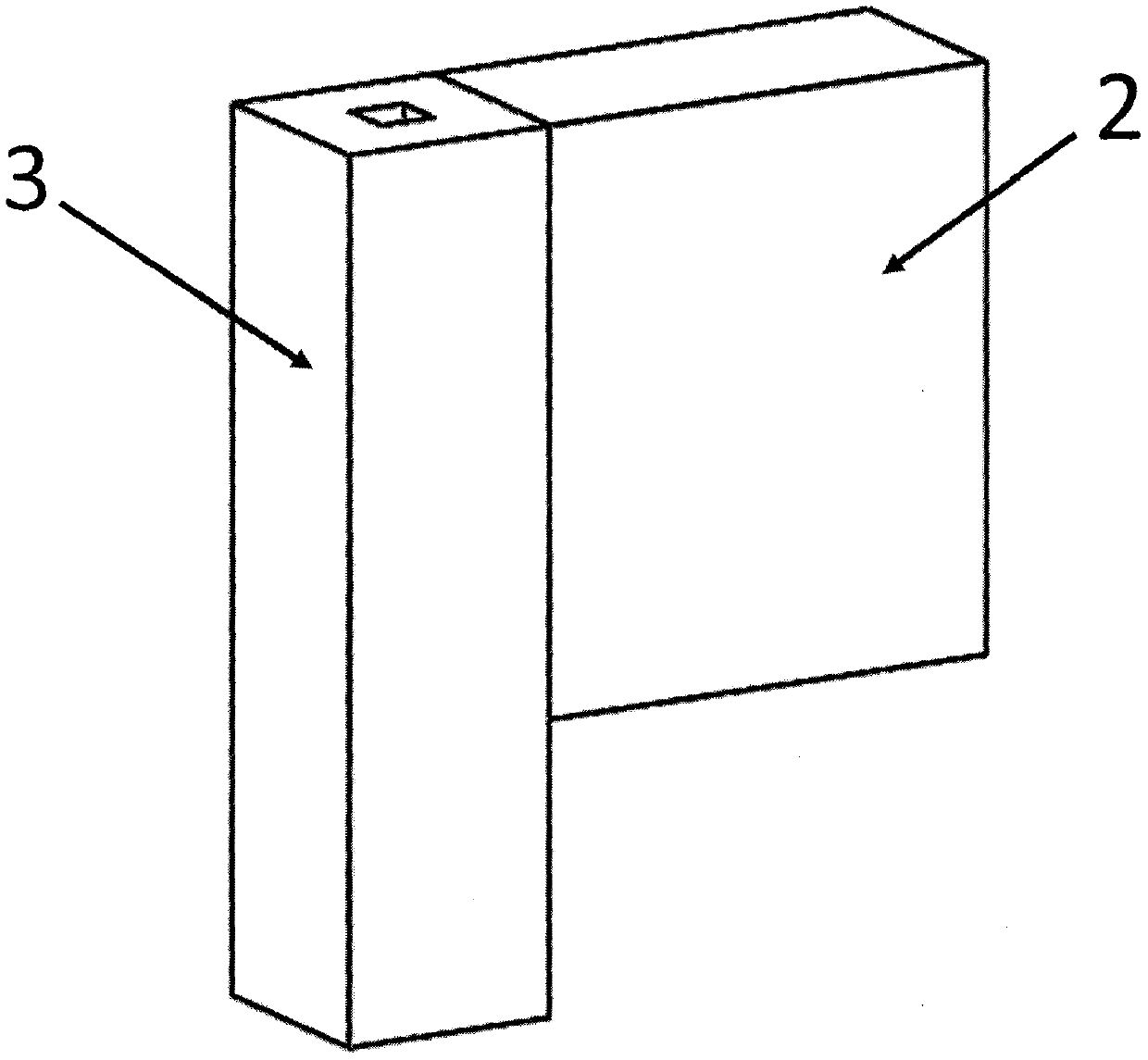

Gear and manufacturing method for a gear

InactiveCN101016943AAchieve connectionGood anti-torsion performancePortable liftingGear wheelsInjection molding processGear tooth

The invention concerns a gearwheel ( 1 ) with a gear rim ( 2 ) and an insert ( 3 ) whose external diameter (d 3 ) is greater than half of the external diameter (d 1 ) of the gearwheel ( 1 ), wherein the insert ( 3 ) is surrounded by injection molding by means of a cone mold during the manufacture of the gearwheel. In particular, the gear rim ( 2 ), including gear teeth on the external circumference, is formed at the same time during the injection molding process.

Owner:IMS GEAR SE & CO KGAA

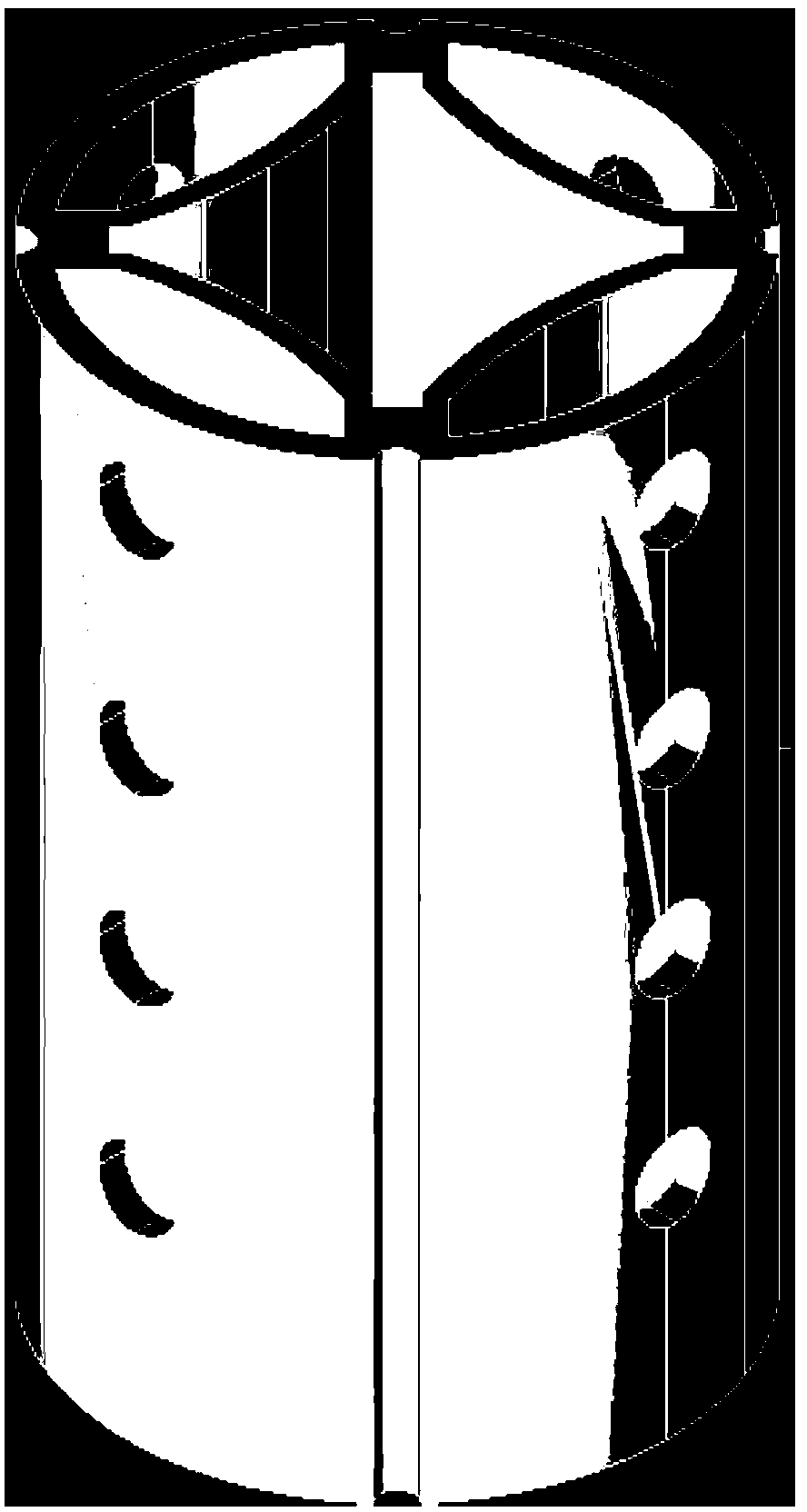

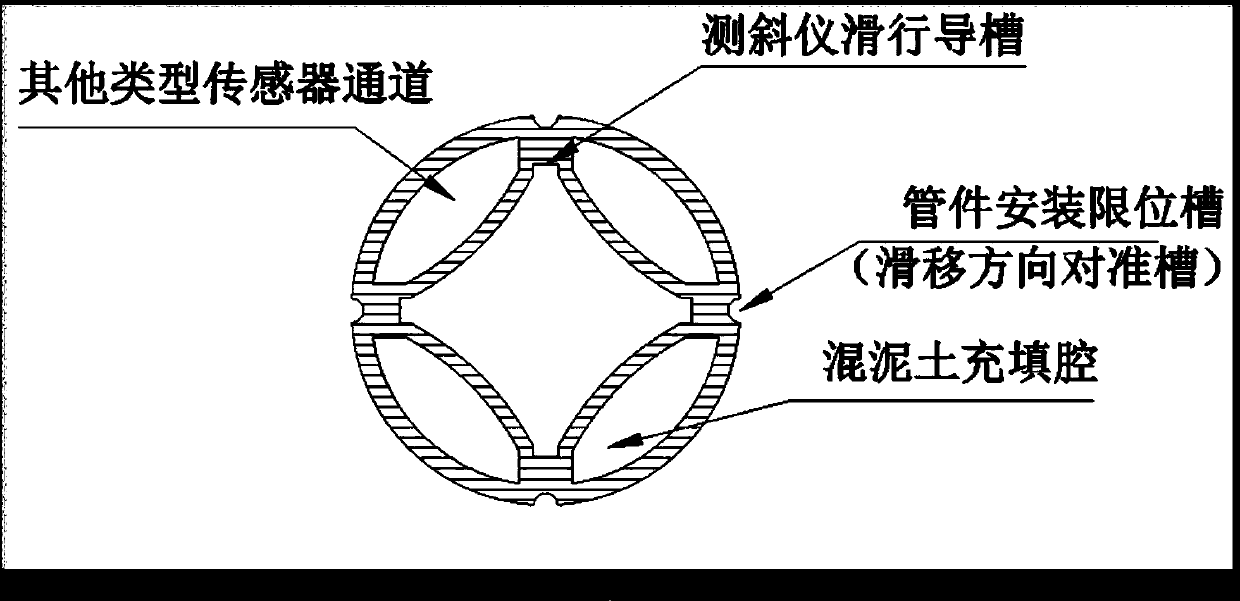

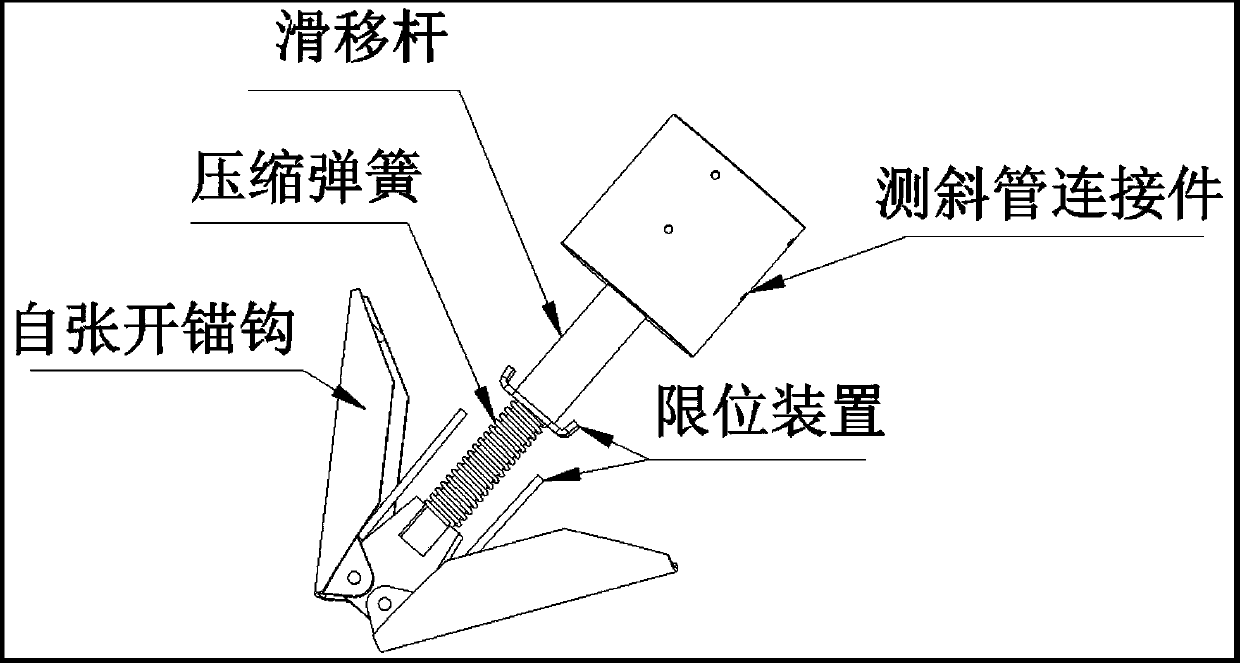

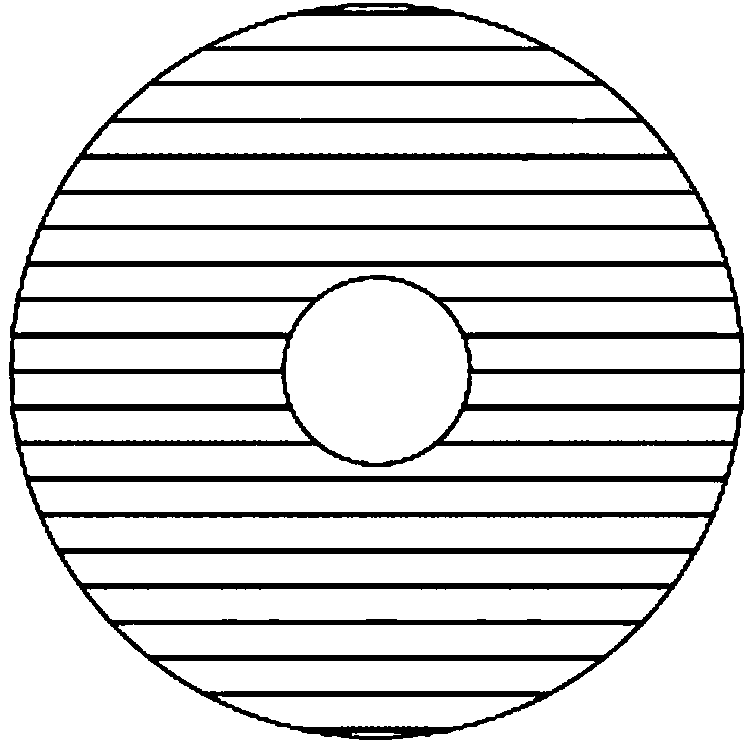

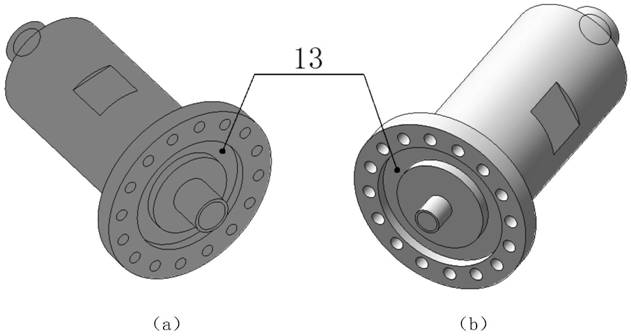

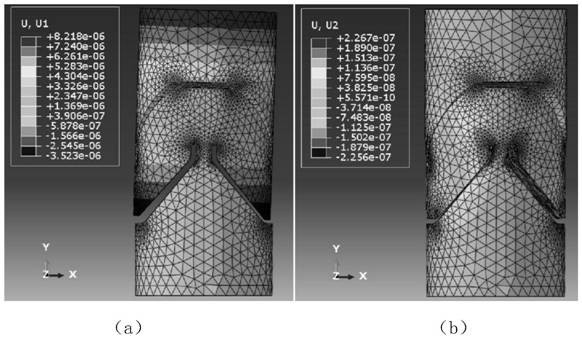

High-strength double-wall inclinometer casing for inclined displacement measurement

ActiveCN103882848AHigh mechanical strengthStrong bending resistanceFoundation testingIn situ soil foundationAxial pressurePipe fitting

The invention relates to a high-strength double-wall inclinometer casing for inclined displacement measurement. The high-strength double-wall inclinometer casing comprises a plurality of measuring pipe fittings, a plurality of pipe fitting connecting pieces and an axial pressure trigger self-opening type anchor hook base. The measuring pipe fittings are connected through the pipe fitting connecting pieces, the axial pressure trigger self-opening type anchor hook base is connected with the measuring pipe fitting which firstly conducts hole sinking, the measuring pipe fittings are provided with inner walls and outer walls, four concrete filling cavities of inner and outer pair arc structures are formed by the inner walls and the outer walls, a plurality of holes are formed in the outer walls, when the inclinometer casing is submerged in the bottom of drilled holes, pressure is exerted in the axial direction, the axial pressure trigger self-opening type anchor hook base is opened and is anchored to the pedestal rock, and when back filling is carried out on concrete, cement paste enters the concrete filling cavities through the holes. The inclinometer casing has the strong capability of resisting tension and pressure, resisting bending and resisting torsion, the compatible deformation capability of the inclinometer casing and the surrounding rock-soil layer is improved, the upward buoyancy of serous fluid on the inclinometer casing is reduced, and a base of the inclinometer casing and the bed rock are in the fixed connection state all the time.

Owner:BEIJING ZHONGLI ZHIYAN INTERNET OF THINGS TECH CO LTD

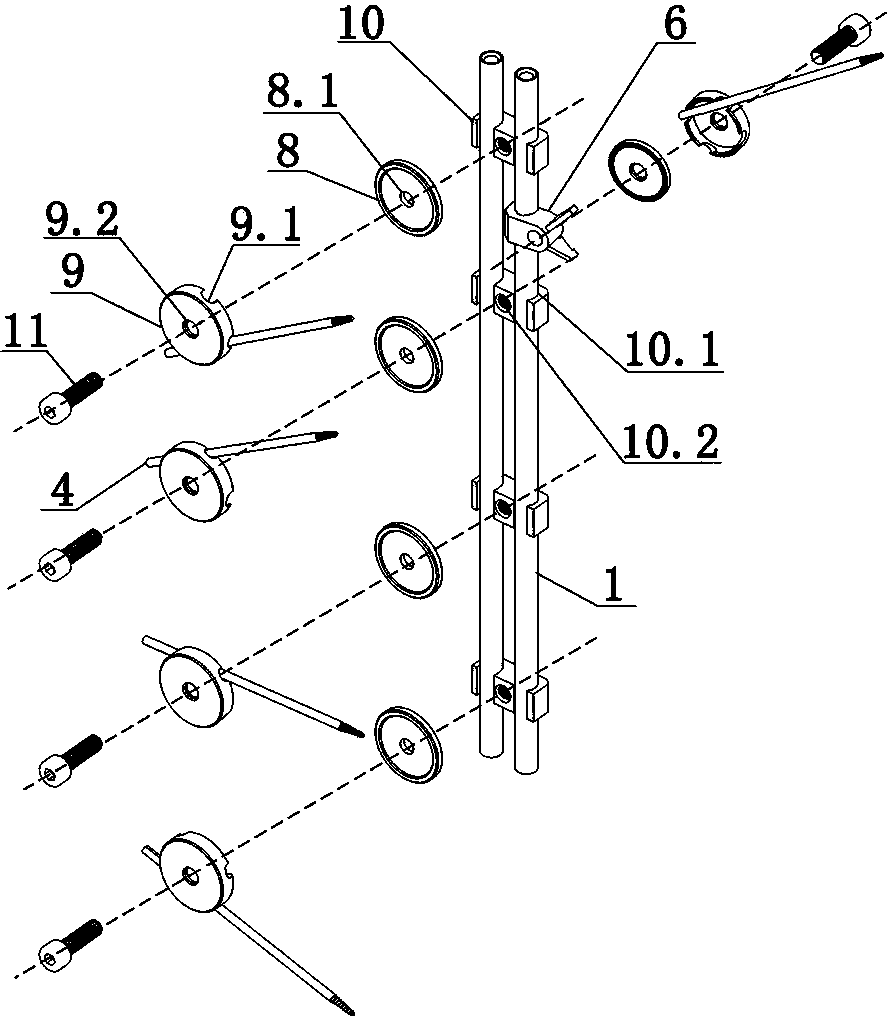

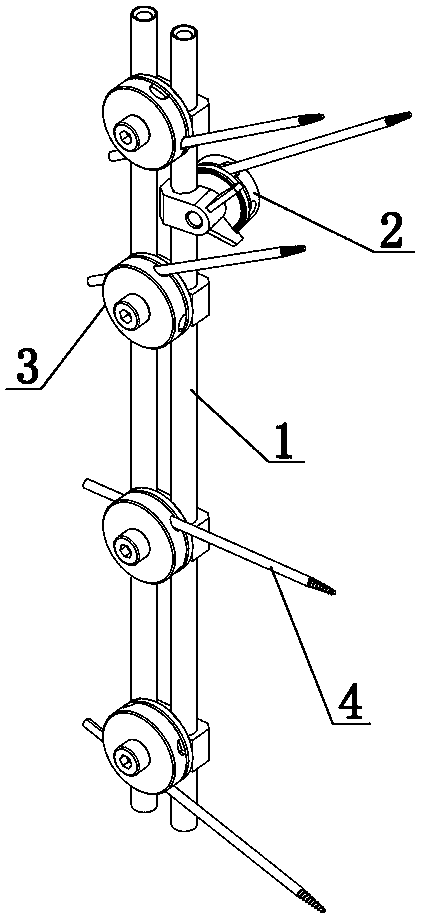

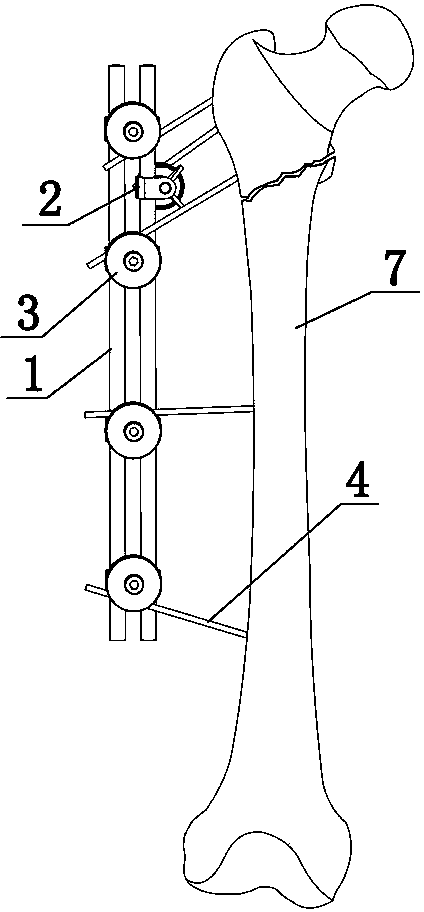

Tubular connecting rod device and outer-bone fixing device

Owner:JIANGSU GUANGJI MEDICAL TECH

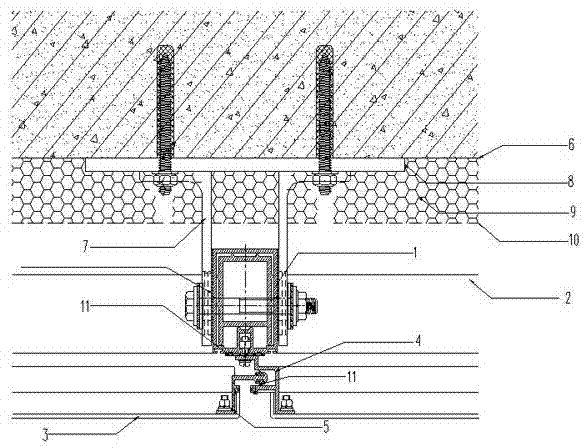

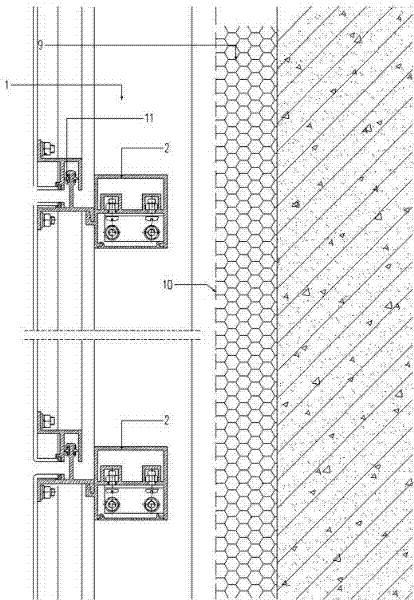

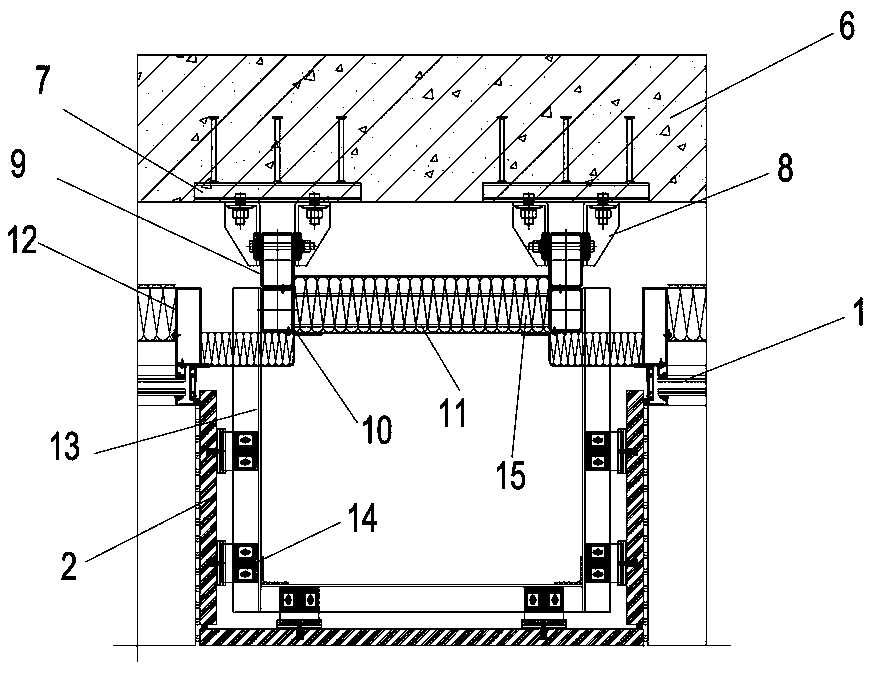

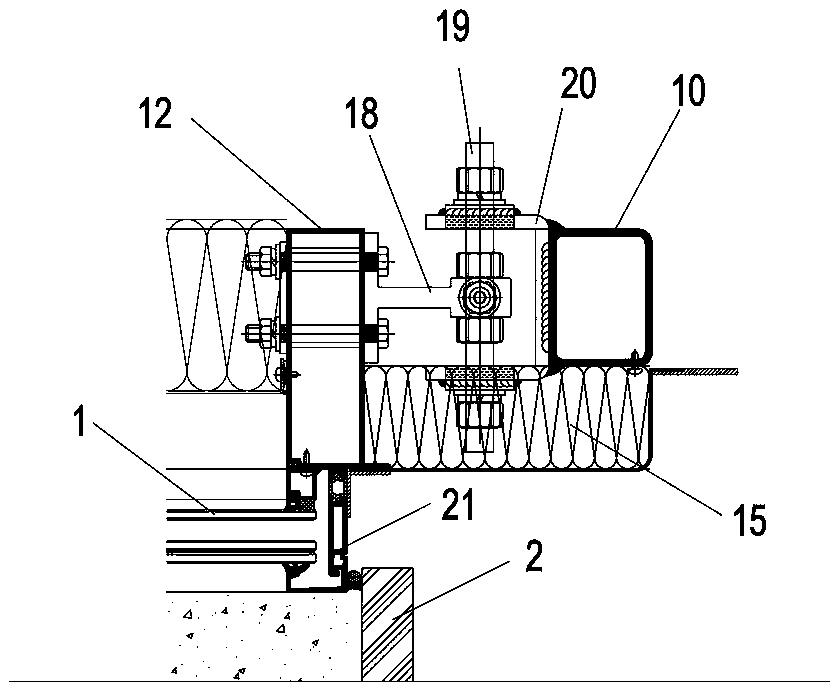

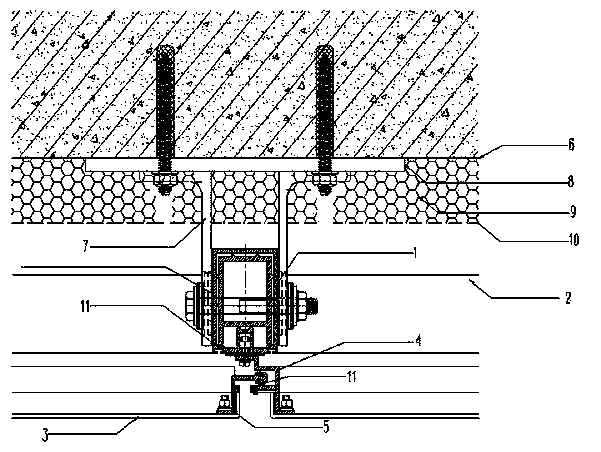

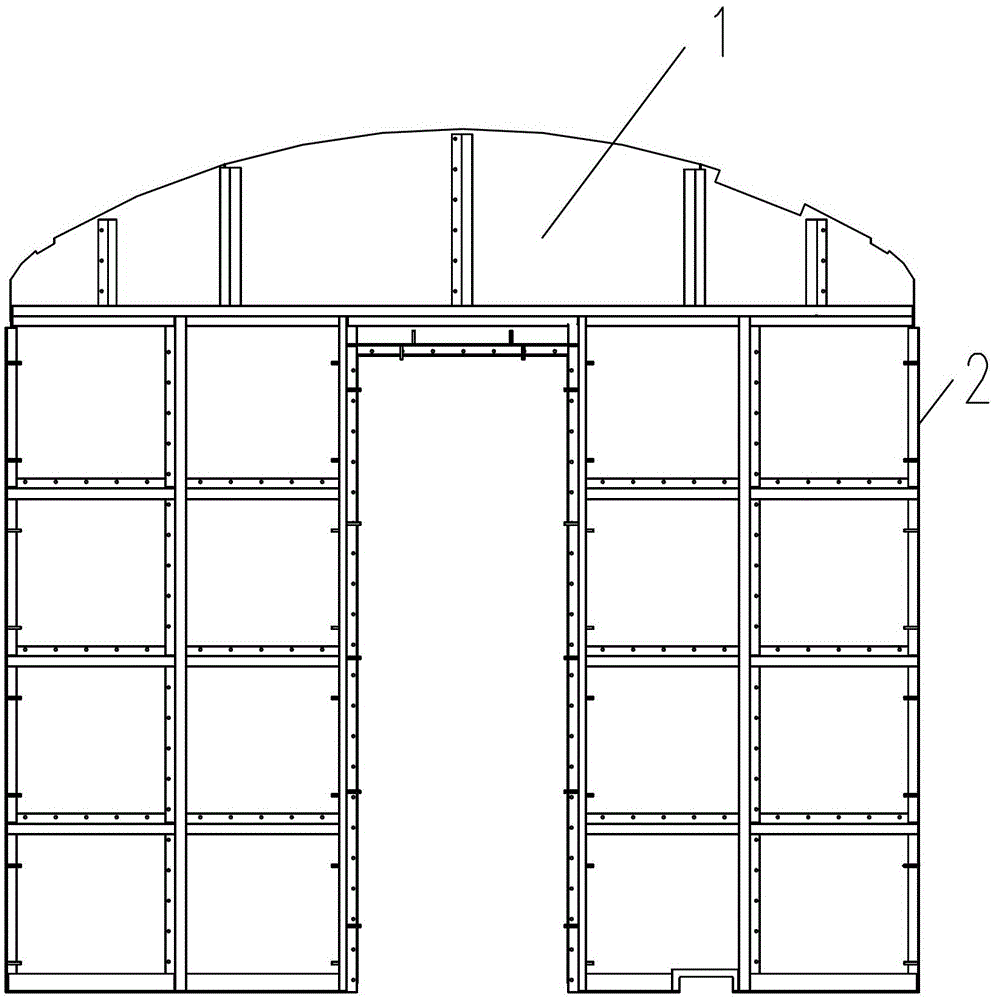

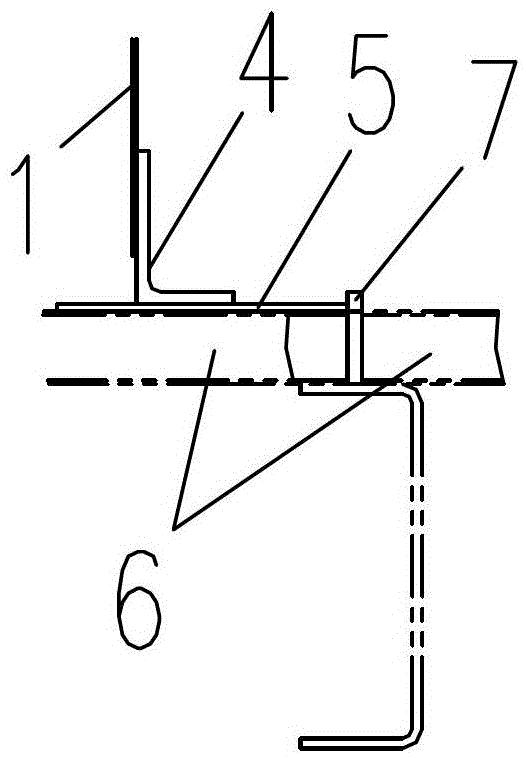

Assembly type low energy consumption curtain wall system and construction method thereof

PendingCN109853800ABoth installationShorten construction timeWallsClimate change adaptationThermal insulationButt joint

An assembly type low energy consumption curtain wall system and a construction method thereof are disclosed. The curtain wall system comprises a unit glass curtain wall and a stone curtain wall, whichare staggeredly distributed in a transverse direction and connected by a corner piece, and the unit glass curtain wall and \the stone curtain wall are connected to a main body structure through an adapter assembly; the unit glass curtain wall is connected to a second rectangular framework column in the adapter assembly through a hanging connection assembly, and the stone curtain wall is connectedto a second rectangular framework column in the adapter assembly through a connection assembly; and longitudinally adjacent glass curtain walls are in butt joint by a cross beam, and transversely adjacent glass curtain walls are connected to a same upright column. The system facilitates installation and disassembly, and has three-dimensional beauty by unitized design of the glass curtain wall andhanging connection of a U-shaped piece to the stone curtain wall; and the employed upright column and the cross beam form a closed drainage system, components and a thermal insulation board are connected, a construction method that combines heat preservation and drainage is employed, and the versatility of energy conservation and low energy consumption of the system is presented.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

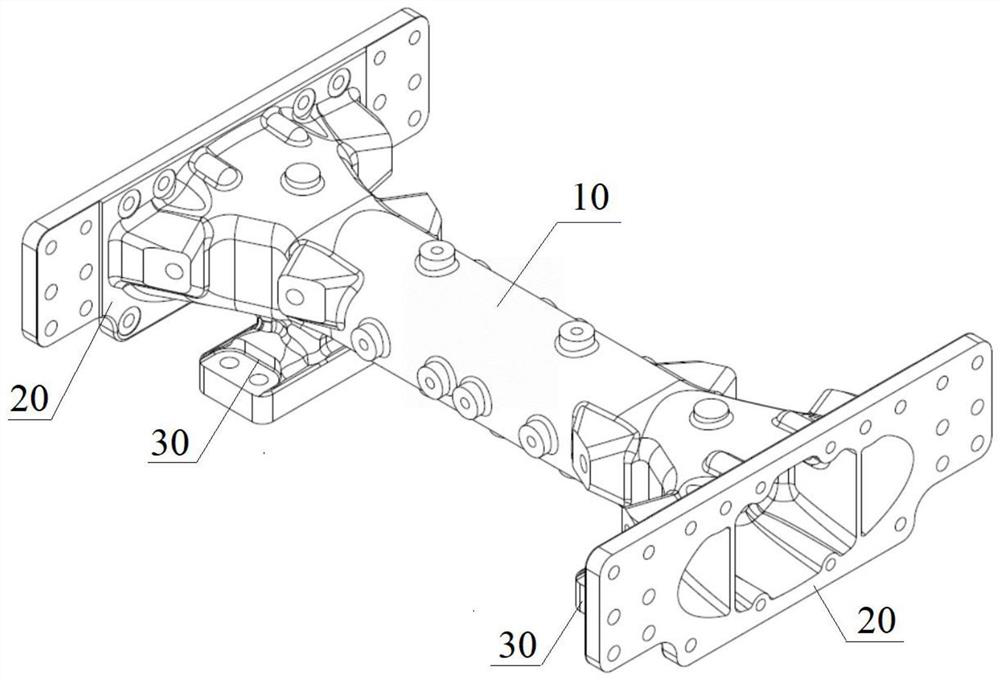

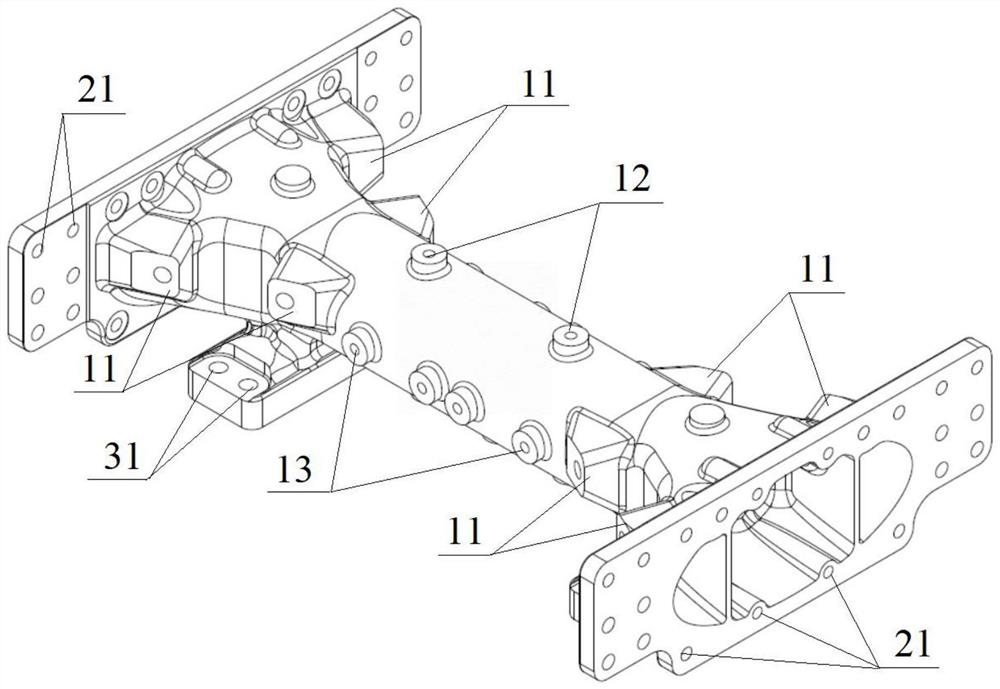

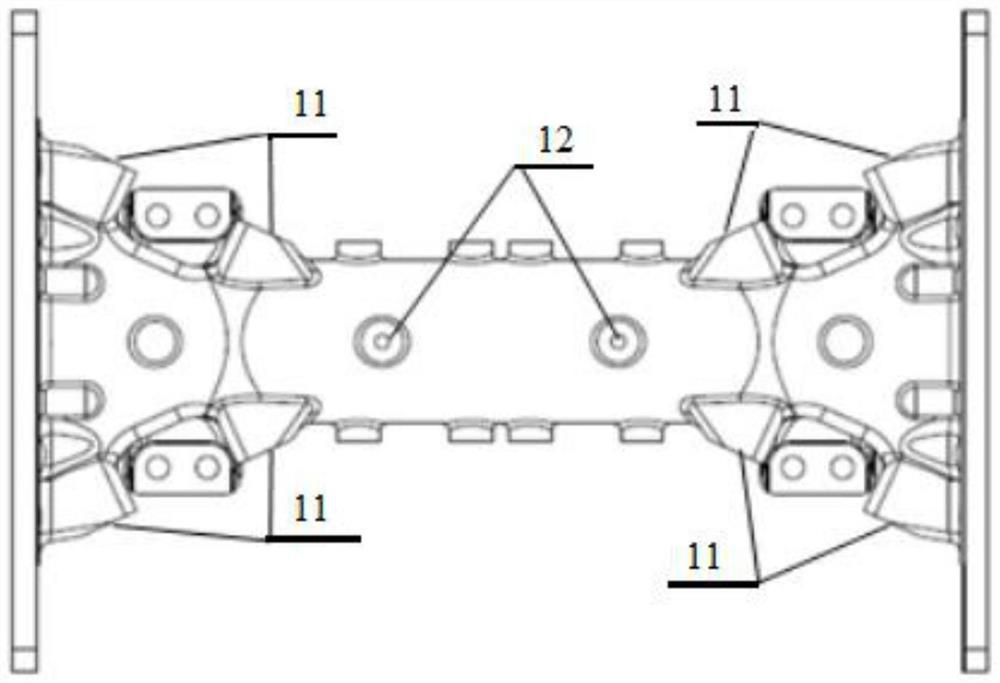

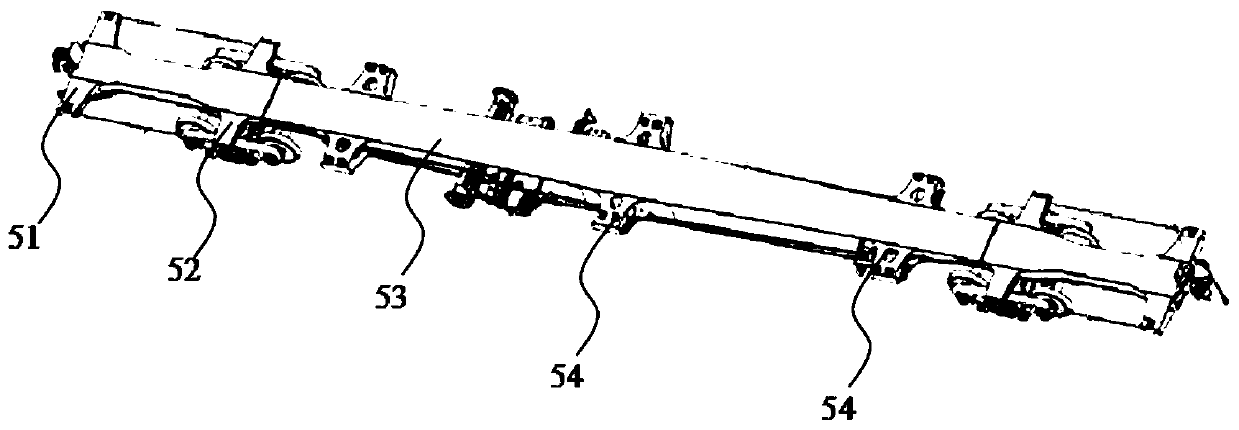

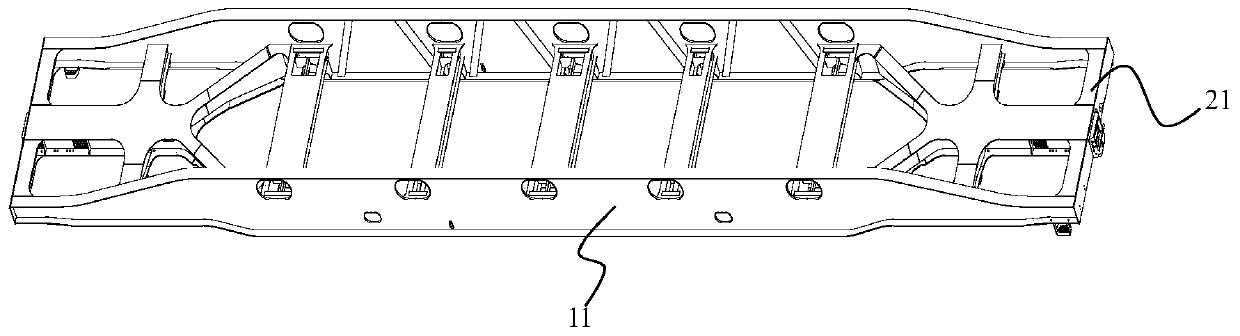

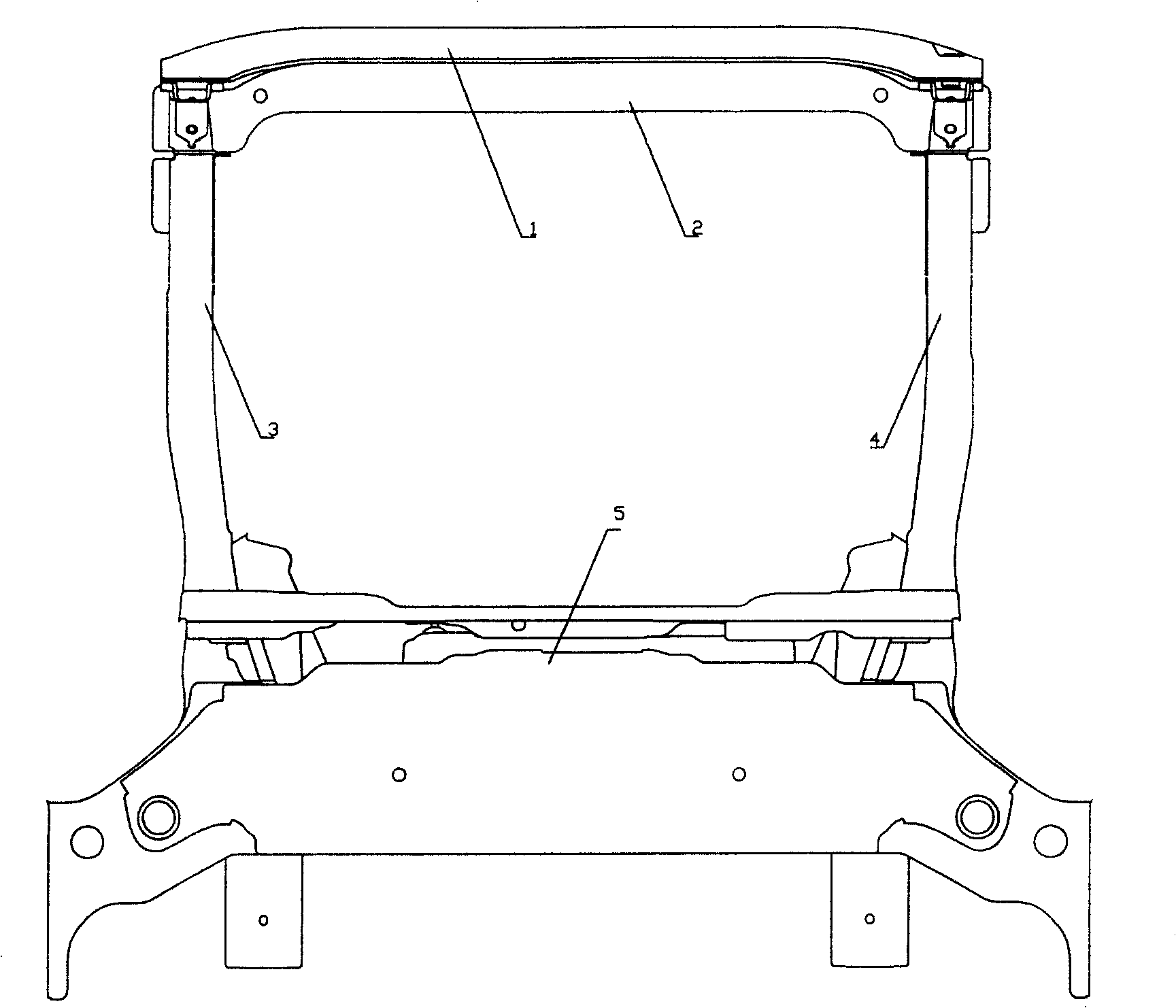

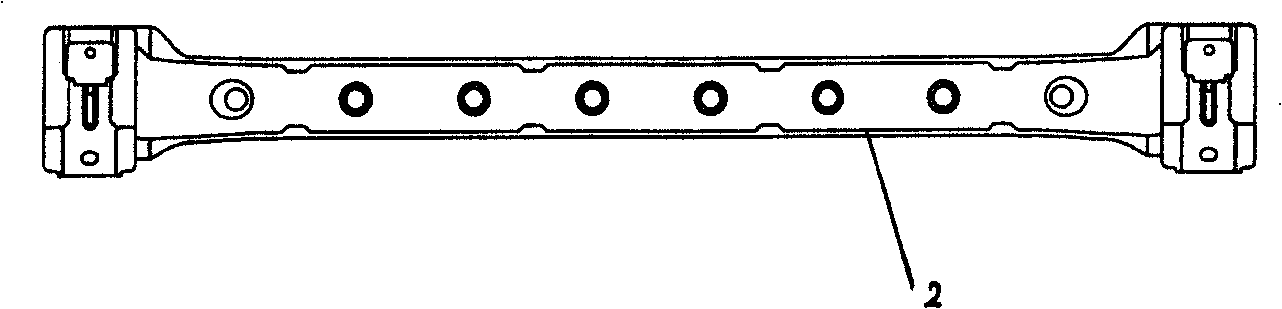

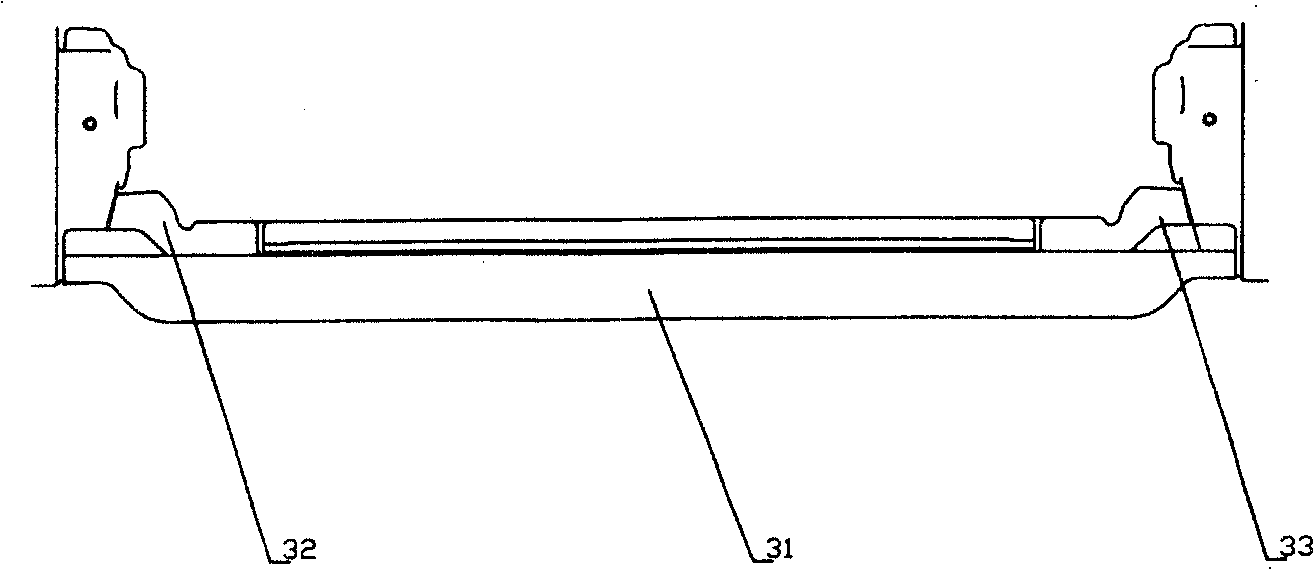

Integrally-formed lightweight cast cross beam assembly

PendingCN111791953AImprove fuel economyEven by forceUnderstructuresSuspension (vehicle)Vehicle frame

The invention discloses an integrally-formed lightweight cast cross beam assembly comprising a cross beam part, a longitudinal beam connecting end panel and a balanced suspension connecting bottom panel that are integrally formed through a casting process. The cross beam part is transversely arranged in a length direction, the longitudinal beam connecting end panel is formed on the end faces of the two transverse sides of the cross beam part, and the balanced suspension connecting bottom panel is formed below the bottom face of the cross beam part. Compared with a stamped metal plate cross beam, the integrally-formed lightweight cast cross beam assembly is lighter and more convenient, and the fuel economy of a vehicle can be better improved; compared with a stamped metal plate cross beam,the stress is more uniform, and the torsion resistance is higher; the integrated and light-weight design is adopted, the longitudinal beam connecting end panel and the balanced suspension connecting bottom panel are integrated on the transverse beam part, so that mounting supports of a front-end mounting system are reduced, the self weight of the frame can be reduced, and the design, manufacturingand management cost is also reduced.

Owner:DONGFENG COMML VEHICLE CO LTD

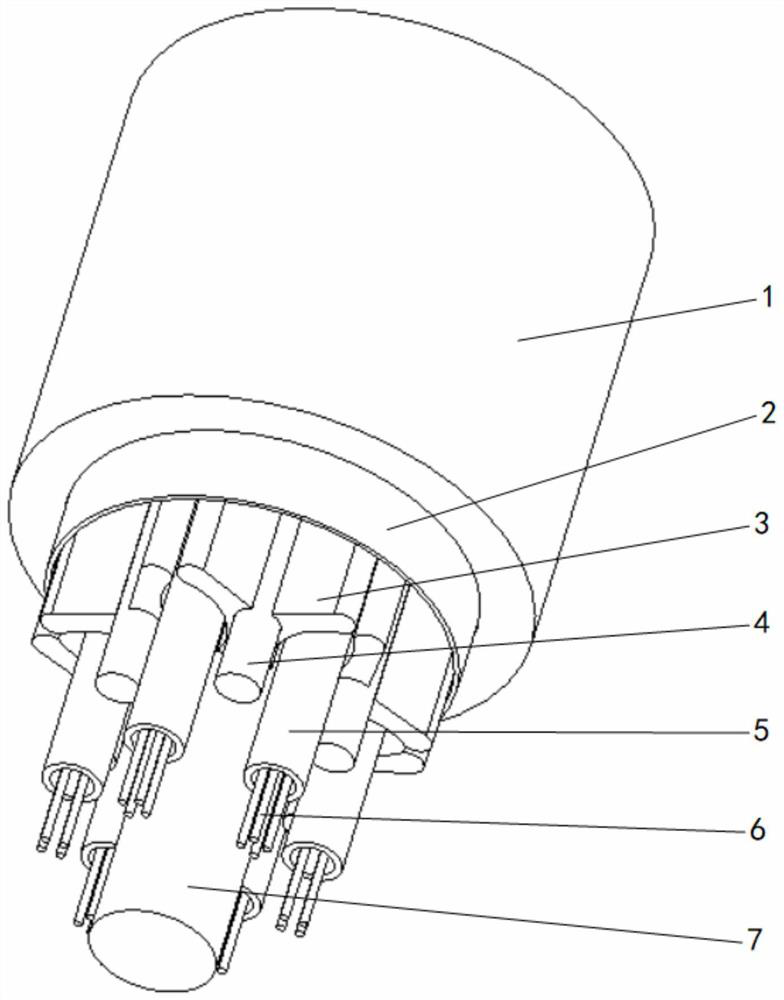

Optical cable with special-shaped filling ropes

PendingCN111830653AGood anti-torsion performanceEasy to take outInsulated cablesFibre mechanical structuresEngineeringOptical communication

The invention belongs to the field of cables and particularly relates to a special-shaped filling rope. The cable is provided with an outer protective layer, a belting layer, a central reinforcing member and at least three loose tubes, wherein at least one optical communication component is arranged in each loose tube, the cable is characterized in that a filling rope is further arranged between every two adjacent loose tubes, the filling rope is composed of a base and two branched supporting plates located at the top of the base, an accommodating cavity is formed between the two support plates towards the inside of the base, an embedding opening is formed in the top of the accommodating cavity, the bottom of the base is arc-shaped and is attached to the surface of the central reinforcingpiece, the base of the previous filling rope, the supporting plate on the left side and the base of the next filling rope are close to each other in the clockwise direction to form an oval loose tubecontaining cavity, the loose tube is located in the loose tube containing cavity, and an electric unit is arranged in the containing cavity. The cable has advantages of being simple in structure, goodin heat dissipation performance, resistant to side pressure, shock and torsion, easy to construct and the like.

Owner:CHANGSHU GAOTONG INTELLECT EQUIP CO LTD

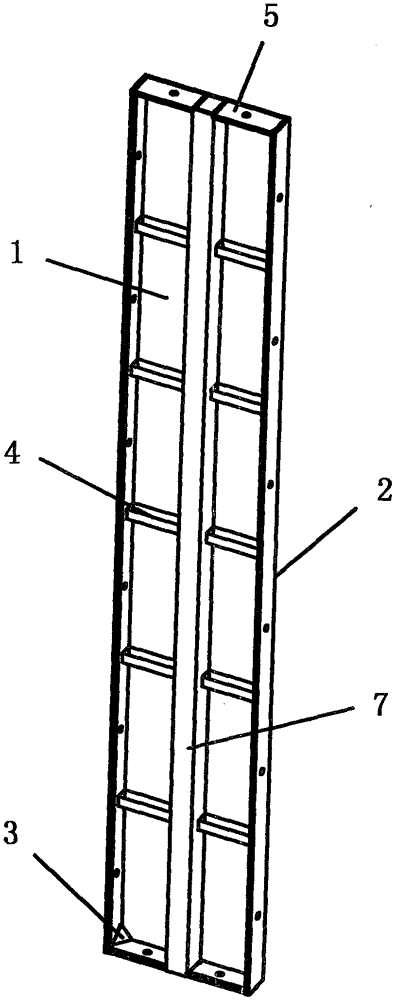

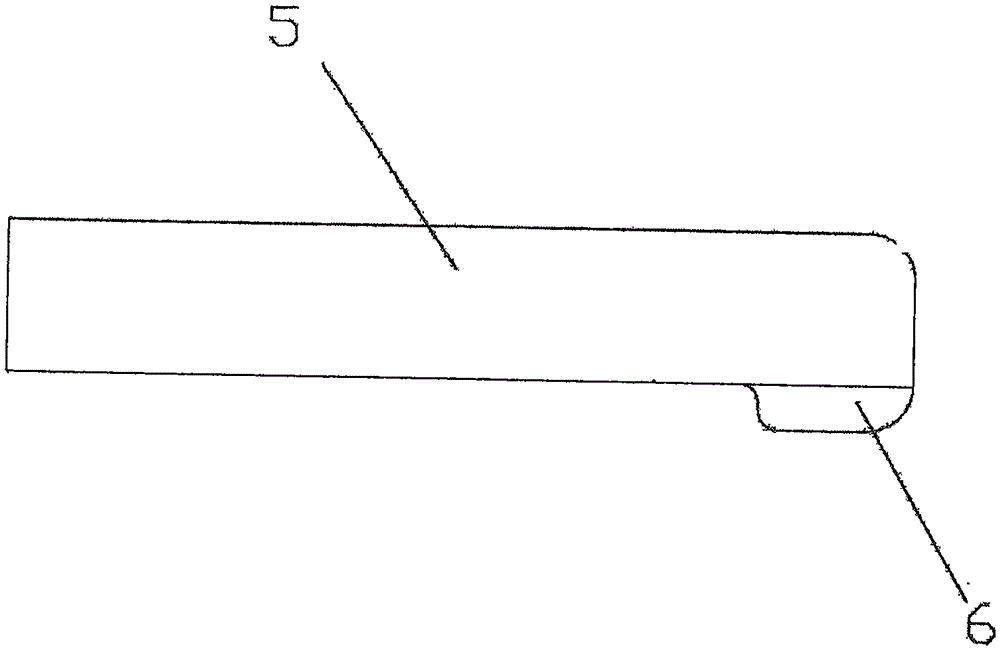

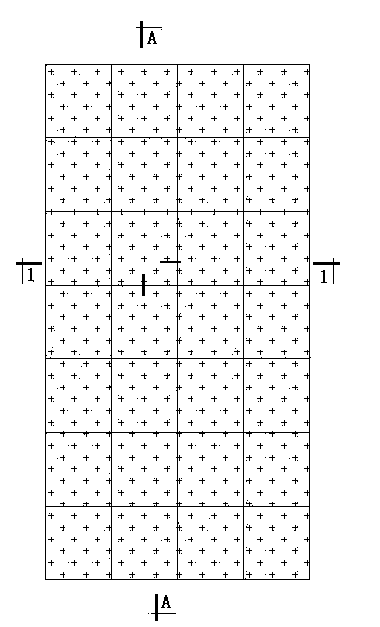

Reinforced plastic formwork for construction and manufacturing method thereof

InactiveCN105237916AStrong impact resistanceGood anti-torsion performanceForming/stuttering elementsNational standardStructural engineering

The invention discloses a reinforced plastic formwork for construction. The reinforced plastic formwork comprises a panel, side edge vertical ribs are arranged at the two sides of the panel, at least one hollow middle vertical rib is arranged in the middle of the panel, the middle vertical rib and the side edge vertical ribs are arranged in parallel in an equidistance mode, multiple middle cross ribs in parallel are vertically arranged between the side edge vertical ribs and the middle vertical rib, side edge cross ribs are arranged at the two ends of the side edge vertical ribs, first stiffeners are arranged at the tops of the side edge vertical ribs and the tops of the side edge cross ribs, and second stiffeners are arranged at the connecting positions of the side edge vertical ribs, the side edge cross ribs and the panel. The invention further discloses a manufacturing method of the reinforced plastic formwork for construction. Defects in the prior art can be overcome, the planeness and the straightness of the panel and the vertical ribs are achieved, the concrete pouring quality is guaranteed, and the corresponding national standard is met. The strength and stiffness of the formwork are improved, the labor intensity of operators is relieved, and the construction cost is greatly reduced.

Owner:保定市裕升建筑安装股份有限公司

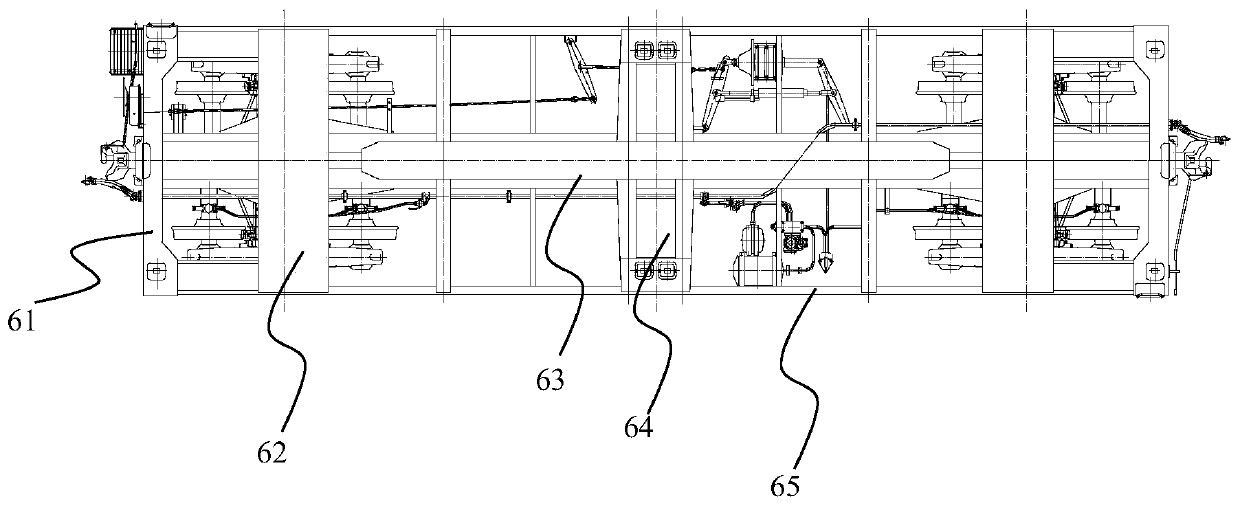

Dedicated flatcar body for railway container and container conveying system

InactiveCN110466544AEfficient transportIncrease the moment of inertiaWagons/vansVehicle dynamicsTransit system

Owner:CRRC QIQIHAR ROLLING CO LTD

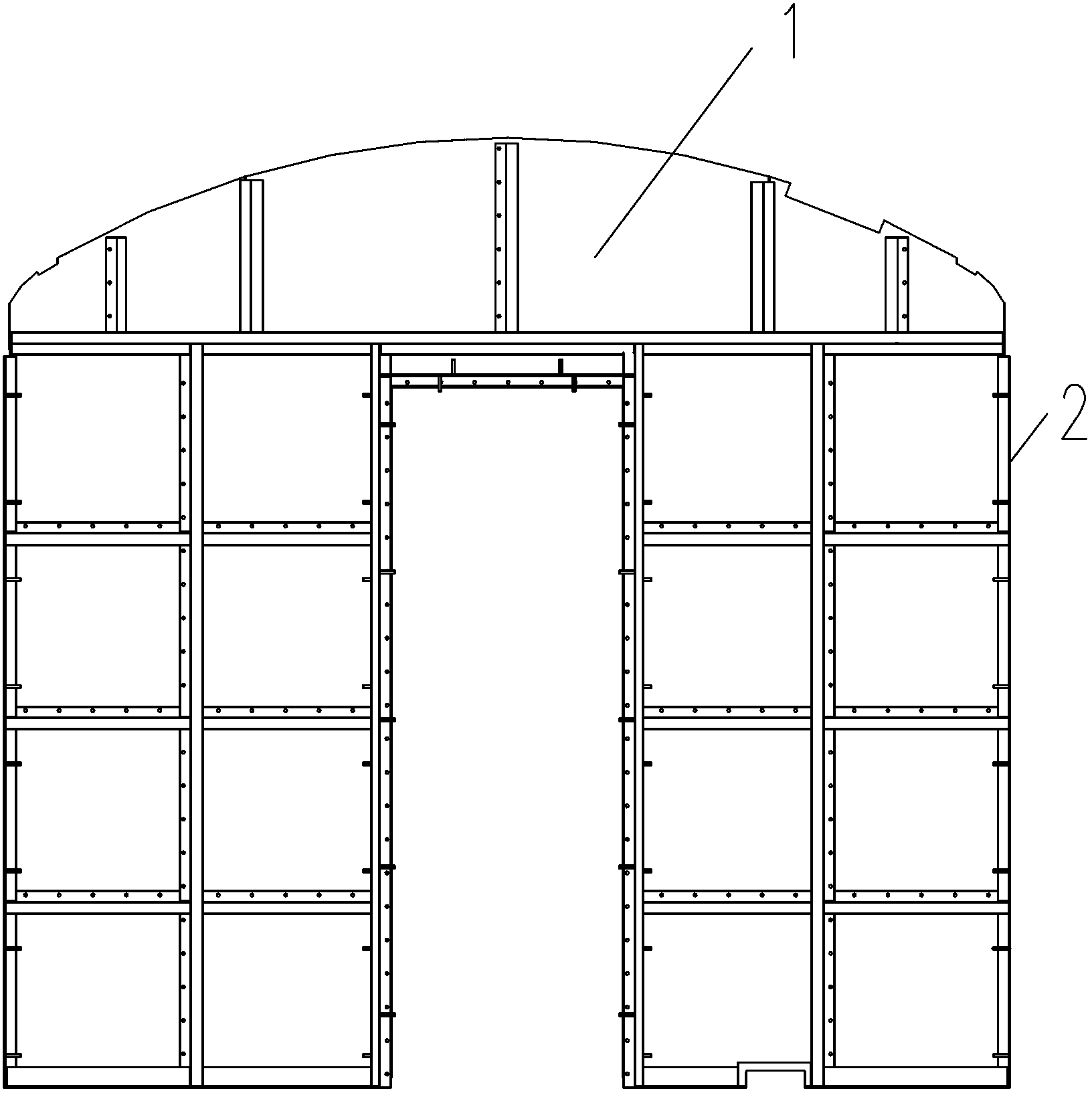

Engine room soundproof wall mounting structure for railway vehicle

ActiveCN103318204AImprove torsion resistanceEasy to adjustAxle-box lubricationRailway bodiesButt jointSpot welding

The invention relates to an engine room soundproof wall mounting structure for a railway vehicle. Angle-form vertical columns are connected to two sides of a soundproof wall by means of full-length welding. One side of the outer vertical face of each angle-form vertical column is connected with a side wall vertical column by means of full-length welding, and the other side of the outer vertical face of each angle-form vertical column is connected with the side wall vertical column through segment welding or dense point welding. A reinforcement plate is connected below a lower crossbeam of the soundproof wall by means of full-length welding. One side of the reinforcement plate is connected with a butt joint vertical plate between corrugated floors by means of full-length welding. The upper end of the soundproof wall is connected with a vehicle-top bent beam by means of full-length welding. By the two angle-form vertical columns added on two sides of the soundproof wall, torsion-resistant performance of the soundproof wall is increased, the position of the soundproof wall can be adjusted conveniently during assembling, and assembling difficulty of the soundproof wall is lowered. By the structure that the added angle-form vertical columns are connected with partition plates and side wall vertical columns by means of full-length welding, the reinforcement plate is welded at the butt joint position of the corrugated floors of a base frame and connected with the butt joint vertical plate by means of full-length welding, the lower crossbeam of the soundproof wall is connected with the reinforcement plate by means of full-length welding, and the soundproof wall is connected with a vehicle top by means of full-length welding, soundproof performance of the soundproof wall is increased.

Owner:CRRC NANJING PUZHEN CO LTD

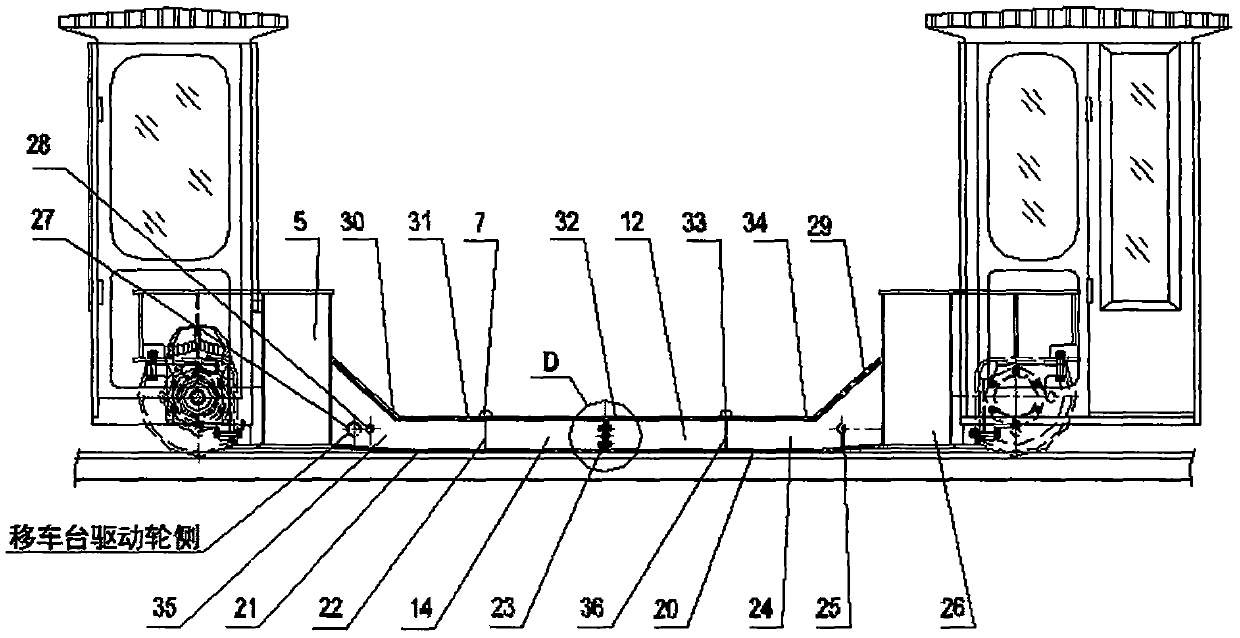

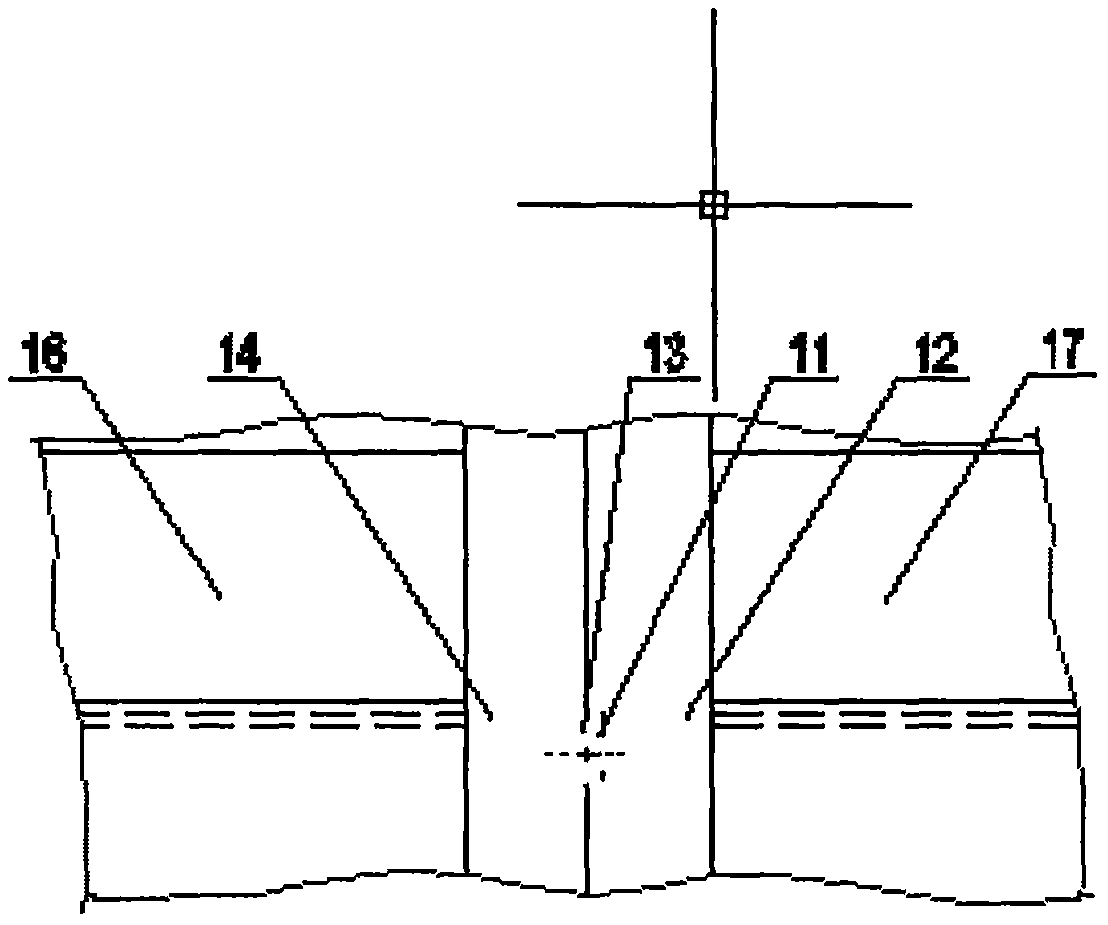

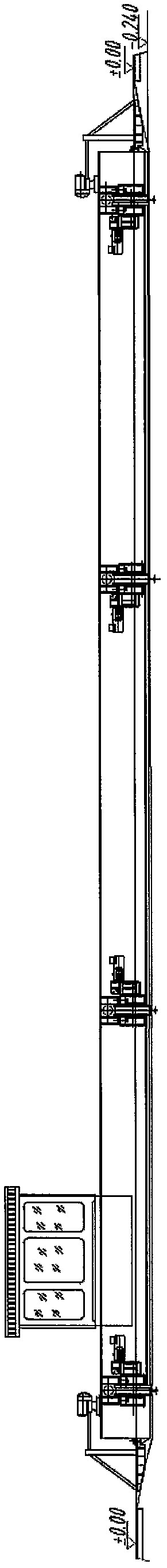

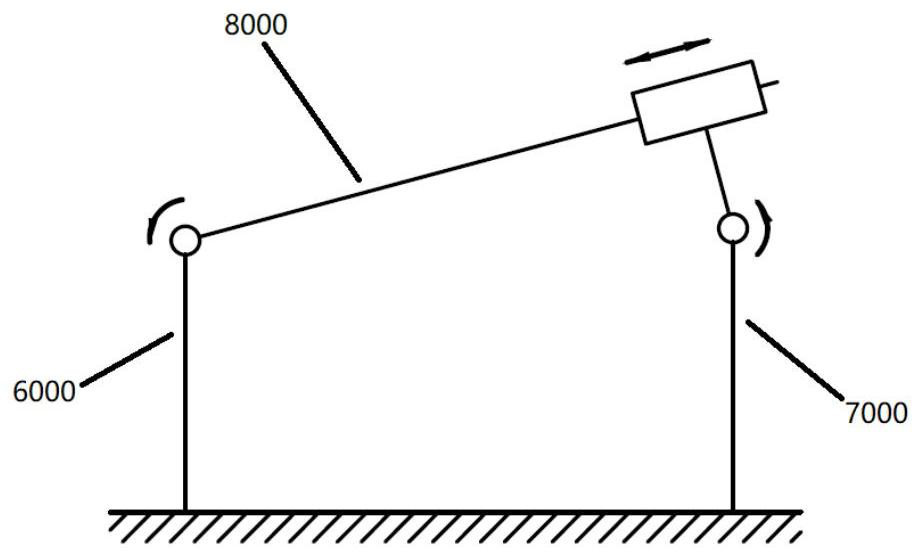

Integral locomotive moving platform

The invention relates to a special maintenance device for realizing locomotive shunting operation at a railway locomotive maintenance field and the special maintenance device allows railway locomotives to complete parallel shunting operation. A locomotive moving platform is a large and medium device in the rail transit industry and has a large size. According to a traditional manufacturing method,parts can only be produced in factories and transported to the field to be assembled and welded for forming, so the mutual parallelism and perpendicularity of wheelsets of a walking part of the locomotive moving platform can not be ensured resulting in rail gnawing, deviation and other situations during the operation process of the locomotive moving platform and an influence on the safe and reliable operation of the locomotive moving platform. An integral locomotive moving platform of the invention adopts the integral manufacturing in a manufacturing plant to ensure the parallelism, perpendicularity and stable operation of the wheelsets during the operation process of the integral locomotive moving platform assembled on site and the avoidance of hunting, rail gnawing and other situations,and can achieve the reliable bidirectional connection of rails of the integral locomotive moving platform. By virtue of the integral manufacturing, disassembled transportation, fixing pins for fixingpositions, bolts for jointing and assembling and welding for forming, the integral locomotive moving platform reduce the on-site workload, shorten the assembling time and improve the installation efficiency. The integral locomotive moving platform has a neat and delight exterior, and the wiring is safe and reliable.

Owner:CHINA RAILWAY HUATIE ENG DESIGN GRP CO LTD

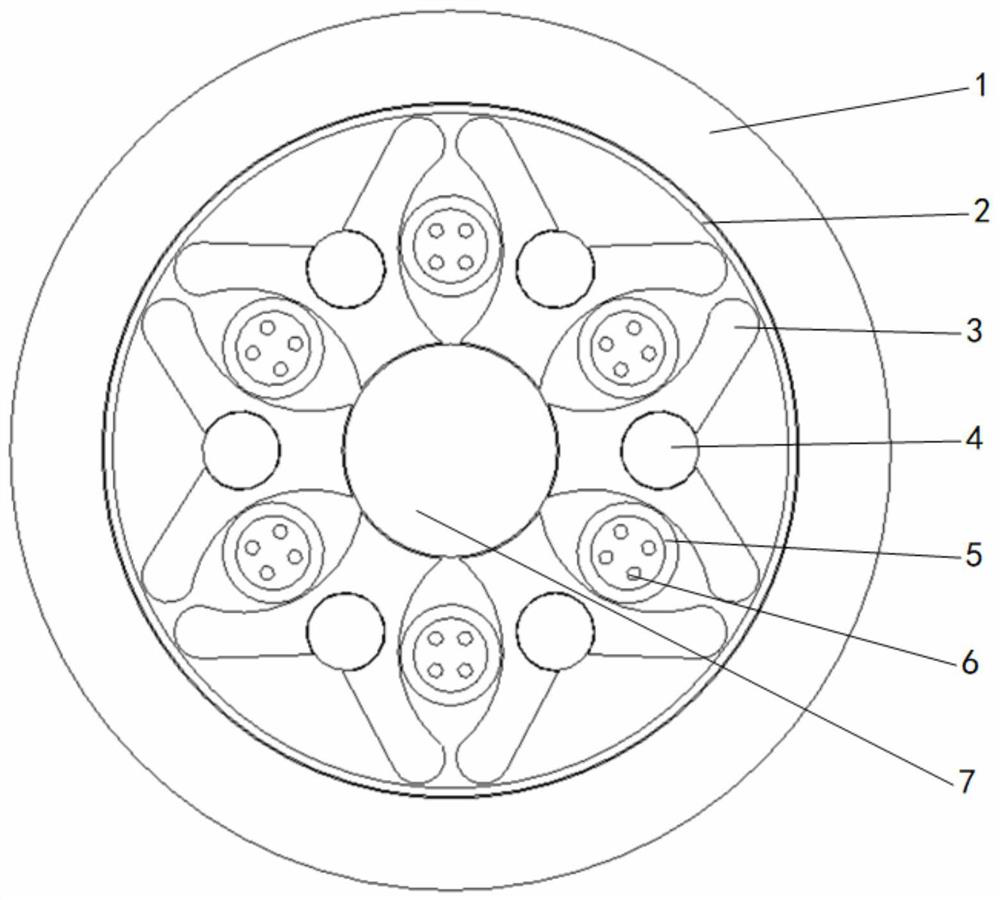

Double-tube cable or optical cable

InactiveCN111180125ASimple structureEasy maintenanceInsulated cablesFibre mechanical structuresDouble tubeStructural engineering

The invention belongs to the field of cables, in particular to a double-tube cable. The cable comprises an outer protective layer and a plurality of electric units, and is characterized in that the outer protective layer is composed of two outer protective layer main bodies and a connecting part; the outer protective layer main body has a large head part and a small tail part; a clamping groove isformed in the head part of the outer protective layer main body; the tail part is provided with a clamping part; the head part and the tail part of the two outer protective layer main bodies are respectively connected with the tail part and the head part of the other outer protective layer main body in a clamping way through clamping grooves and the clamping parts, two staggered semicircular accommodating cavities are formed between the two outer protective layer main bodies and one connecting part, and at least one electric unit is arranged in each accommodating cavity. The invention also discloses a double-tube optical cable. The problems that a double-core cable or an optical cable is poor in tensile and compression resistance and inconvenient to maintain a broken circuit are solved; and the cable has the beneficial effects of being simple in structure, easy to maintain, good in compression resistance, good in tensile property, good in torsion resistance and the like.

Owner:CHANGSHU YUTONG PHOTOELECTRIC TECH CO LTD

Open type aluminum plate curtain wall

The invention discloses an open type aluminum plate curtain wall, which is characterized in that: the open type aluminum plate curtain wall comprises vertical columns, horizontal beams, aluminum single plates and aluminum alloy secondary frames; the horizontal beams are fixed to the vertical columns by bolts running through the vertical columns; the aluminum alloy secondary frames comprise secondary frame main parts with hook grooves in the middle, and hook plates hooked in the hook grooves; one ends of the secondary frame main parts are fixedly connected with the vertical columns by the bolts, while the other ends of the secondary frame main parts are parallel to one ends of the hook plates far away from the hook grooves; one ends of the secondary frame main parts parallel to each other and one ends of the hook plates are fixedly connected with two adjacent aluminum single plates by the bolts respectively; and one ends of the secondary frame main parts parallel to each other and one ends of the hook plates are formed with open type space. The open type installation method meets needs of seeking different effects, so that the open type aluminum plate curtain wall is more beautiful; in addition, the non rigid connection method is more favorable for expansion and contraction among the plates, so that the open type aluminum plate curtain wall is improved in structural stability.

Owner:无锡金城幕墙装饰工程有限公司

Soaking solution capable of modifying and toughening juncus effusus

InactiveCN105936086ATough enoughImprove bending resistanceReed/straw treatmentWood impregnation detailsIllicium verumAdditive ingredient

The invention provides a soaking solution capable of modifying and toughening juncus effusus. The soaking solution comprises the following raw components in parts by weight: 40-48 parts of edible vinegar with a concentration of 5.3%, 1-2 parts of rhizoma kaempferiae, 0.4-0.8 part of sodium chloride, 0.1-0.5 part of alpha-olefin sulfonate, 0.1-0.5 part of isopropyl myristate, 10-15.6 parts of morning glory root, 3.4-5.2 parts of illicium verum, 10-15.6 parts of bitter orange blossom, 0.3-0.6 part of sodium dodecyl benzene sulfonate, 4-7 parts of an aloe extract; 5-10 parts of mugwort, 2-4 parts of hydroxyl fluorosilicone oil and 12-17 parts of a toughening preparation. The soaking solution provided by the invention is free from toxic stimulus chemicals, and thus no ingredients being harmful to the human body remain after the soaking; the soaked juncus effusus is still sufficient in toughness, and very good in anti-bending capability and anti-torsion capability; meanwhile, the specific herbal fragrance of the juncus effusus is prevented from being eliminated in the soaking process; and after the soaked juncus effusus is placed in an oxygen-rich and wet environment for 5 years, the color and luster is still unchanged.

Owner:阜南县黄岗利达工艺品有限公司

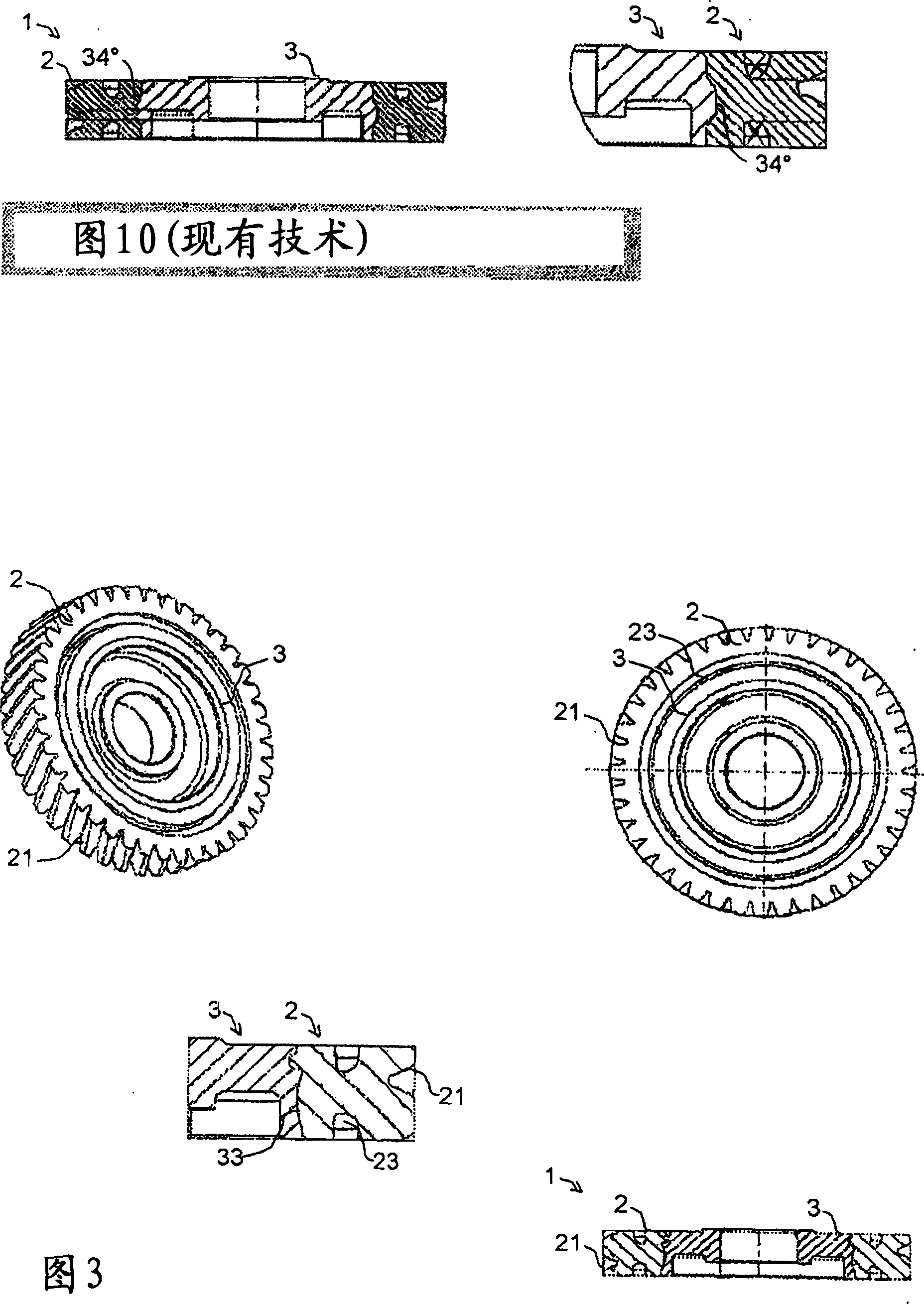

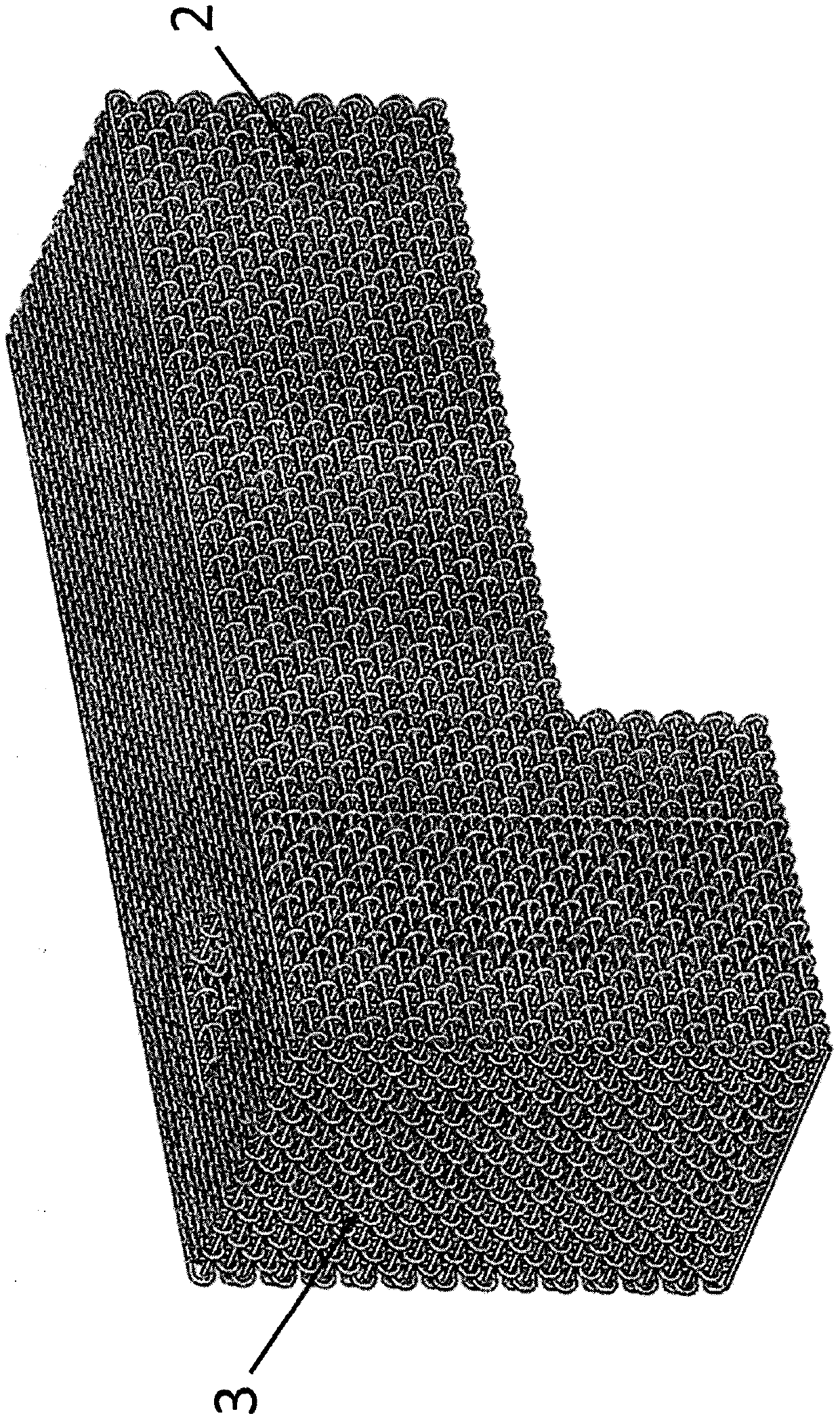

Integrated rudder-enhancing textile and knitting method thereof

ActiveCN106987978AMeet different performance requirementsGood anti-torsion performanceWoven fabricsEngineeringRudder

The invention discloses an integrated rudder-enhancing textile and a knitting method thereof. The textile is a textile of a coupled structure and includes a rudder shaft area and a rudder face area, a rudder shaft area textile body is of a multi-directional interwoven structure, a rudder face area textile body is of a three-directional interwoven structure, the two structures are in seamless connection through a weft yarn system penetrating through the width direction and form the integrated textile. The multi-directional interwoven structure of the rudder shaft area textile body includes slant yarn which is spirally oriented around the central line of a rudder shaft, and the torsion resistance performance of the rudder shaft can be effectively improved. Meanwhile, the three-directional interwoven structure of the rudder face area textile body includes warp yarn and weft yarn which are straight oriented along a rudder plane, and the bending resistance performance of a rudder face is ensured. According to the knitting method of the integrated rudder-enhancing textile, on the basis of a current three-dimensional textile kitting method, through the multi-directional motion design of a spindle, the motion of the spindle is controlled flexibly, the knitting of the coupled structure is achieved, and the knitting method of the integrated rudder-enhancing textile is simple in process and high in maneuverability.

Owner:TIANJIN POLYTECHNIC UNIV

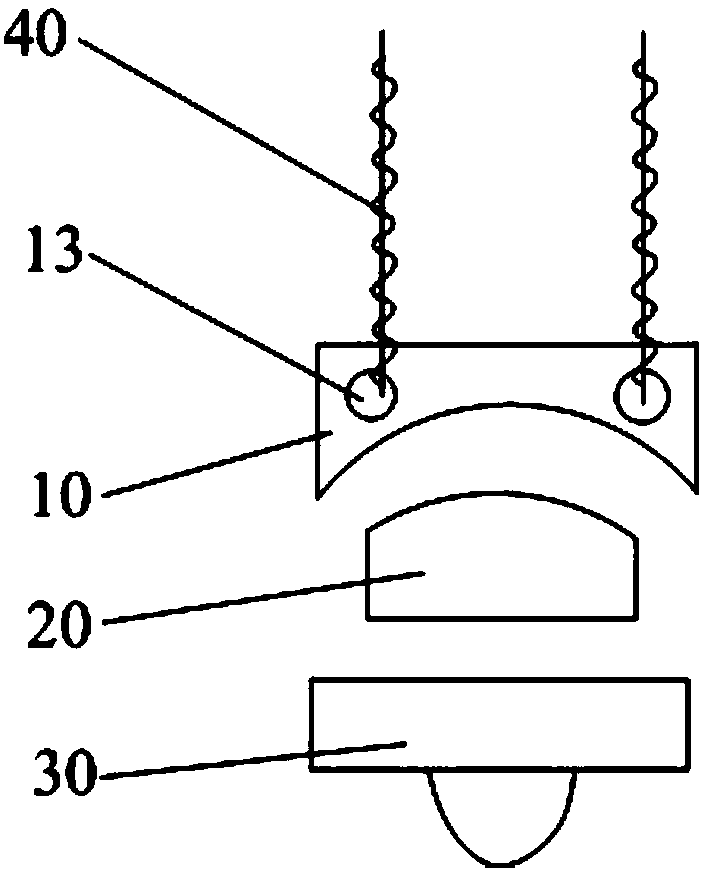

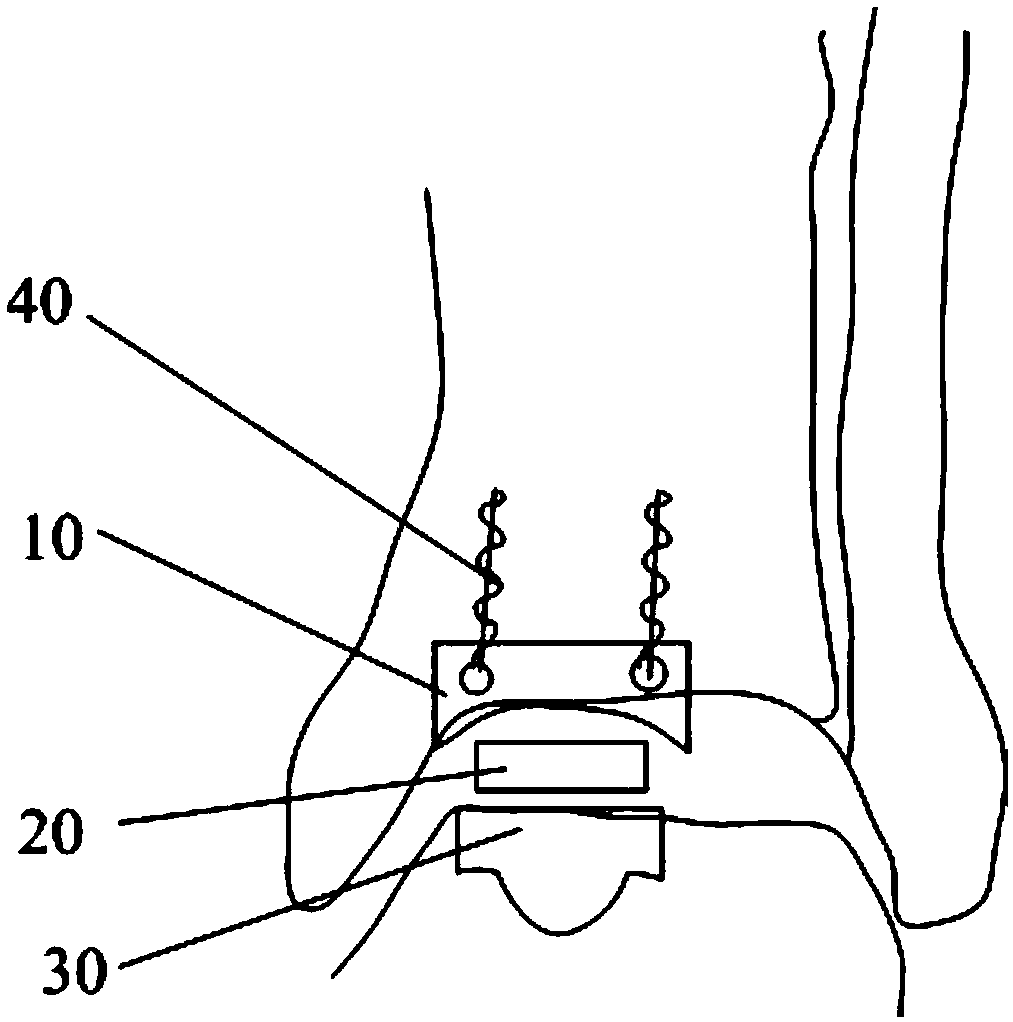

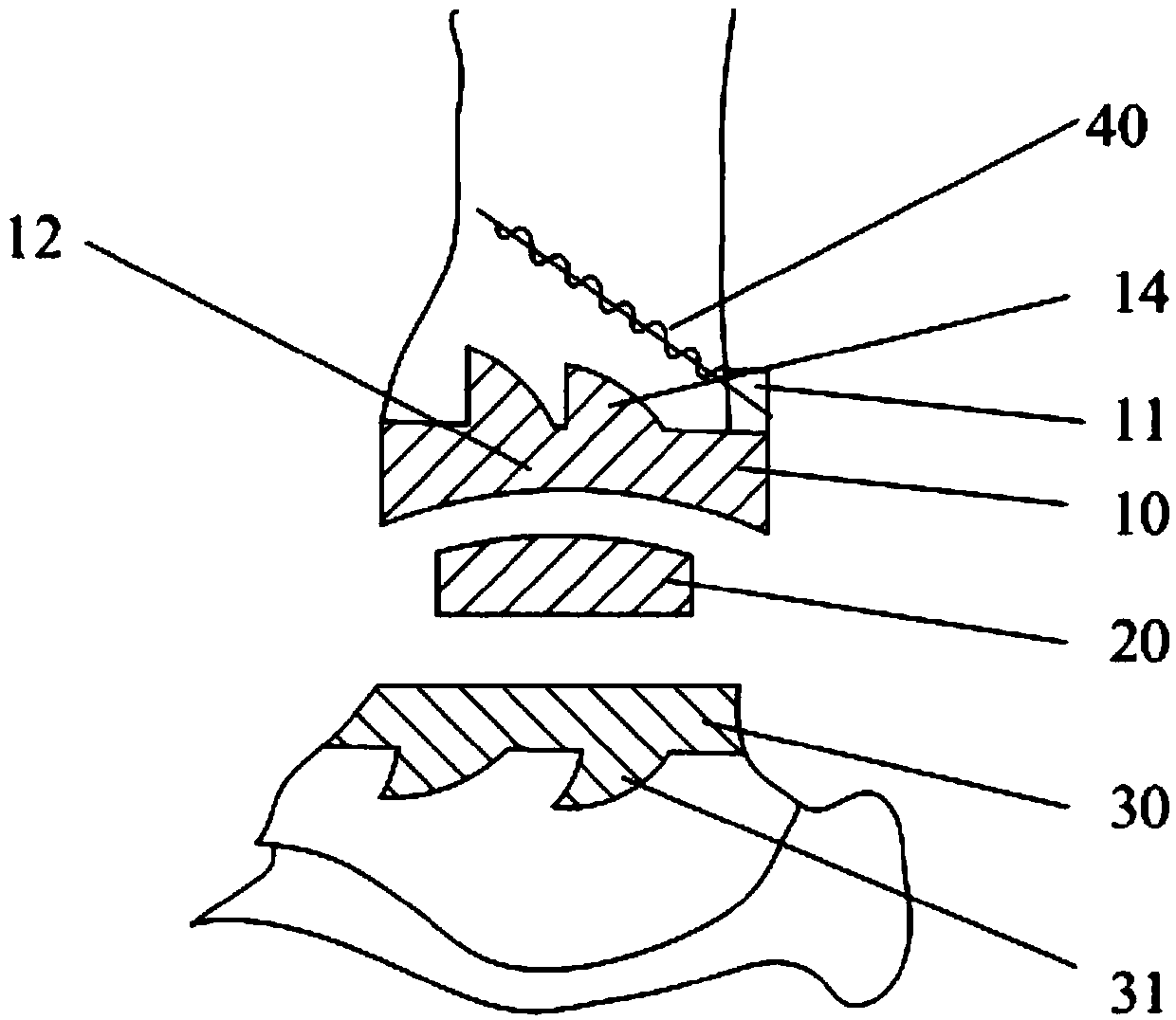

Single ankle joint surface replacement system

ActiveCN109620483AImprove anti-rotationImprove torsion resistanceWrist jointsAnkle jointsKeelConvex side

The invention provides a single ankle joint surface replacement system, which consists of a shin side face, a rotating core and a calcar side face, wherein the shin side face and the calcar side faceare made of metal or alloy materials, and the rotating core is made of polyethylene abrasion-resistant material. By using the structure, single ankle joint surface replacement can be achieved. The front part of the shin side face is connected with a sagittal position of the body at an angle, and the top part of the shin side face is a rough spraying surface or a non-polished metal surface; the bottom of the shin side face is a polished smooth surface. And the middle part of a body part is provided with a double-fin keel. The left diameter and right diameter and the front diameter and back diameter of the rotating core are smaller than that of the shin side face; the top of the rotating core is convex in sagittal position and coronal position, and the bottom of the rotating core is horizontal smooth plane. The polished horizontal smooth surface is arranged at the top part of the calcar side face, the non-polished metal surface is arranged at the bottom part, and the double-fin keel is arranged at the middle part of the bottom part. The system has the advantages of simple structure, convenient use, good ankle joint function, effective bone retention, effective improvement of initialstability and reduction of refurbishment rate.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Miniature car front frame skeleton structure

InactiveCN100411935CExtended service lifeGood anti-torsion performanceUnderstructuresMonocoque constructionsHead-on collisionSheet steel

The invention relates to a micro car front framework structure, composing a complete bearing frame by left and right carling welded assembly and multiple beam welded assembly, where the left and right carling welded assembly is of a 'Z'-shaped structure, and the multiple beam weled assembly comprises front collision beam welded assembly, front beam welded assembly and front wallboard support beam welded assembly, the front collision beam welded assembly is arranged in front of the front beam welded assembly and connected by bolt, the front collision beam welded assembly and the front beam welded assembly both adopt closed section, and the front wallboard support beam welded assembly comprises front wallboard support beams and front wallboard front plate reinforcing beams by welding. And it has better intensity and rigidity, and strong anti-head on collision and anti-side collision and antitorque abilities, and the main parts adopt high intensity steel plate, the structural section size is smaller, able to save materials and room, and prolong automobile's service life.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

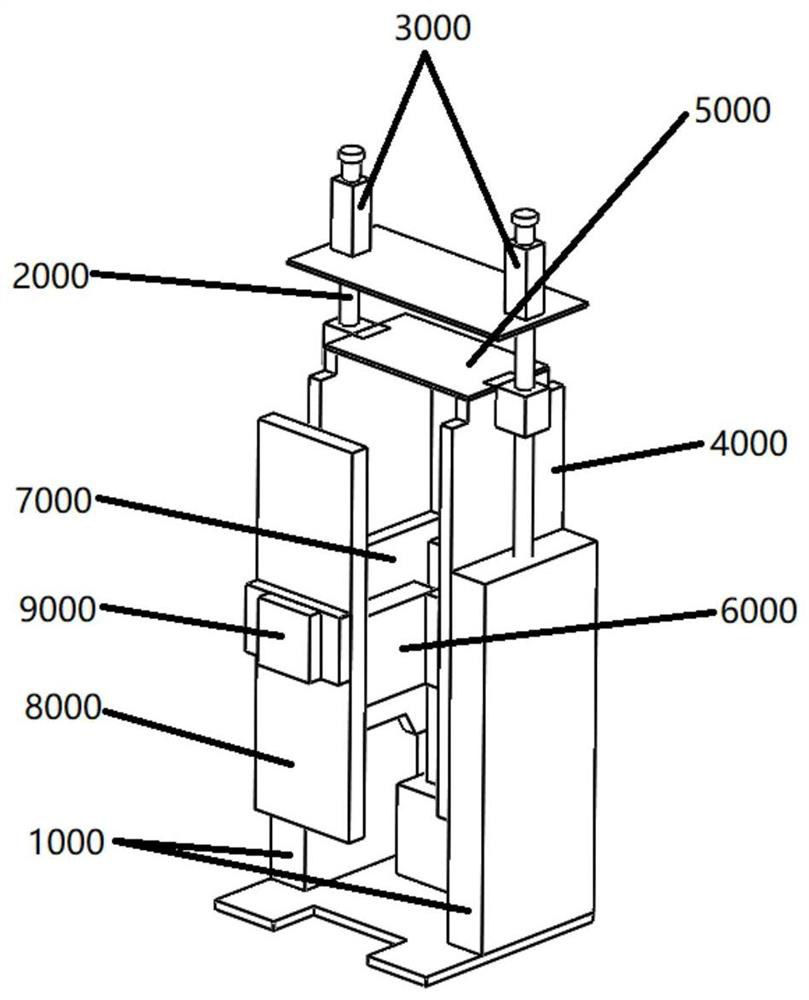

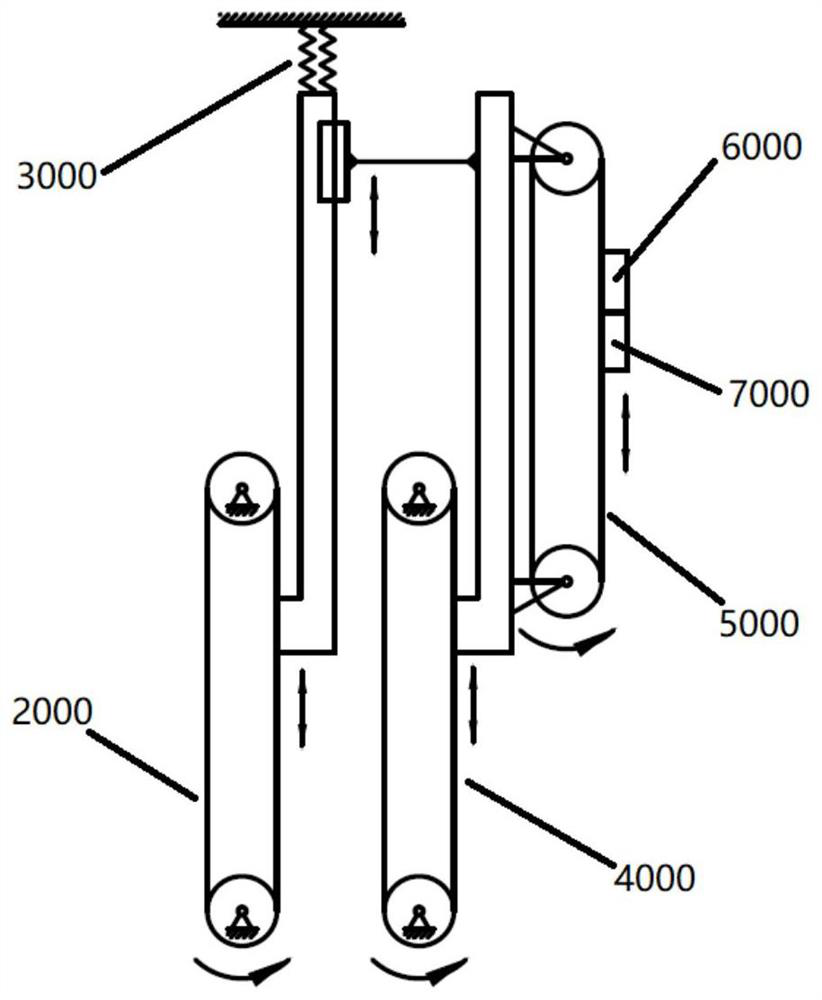

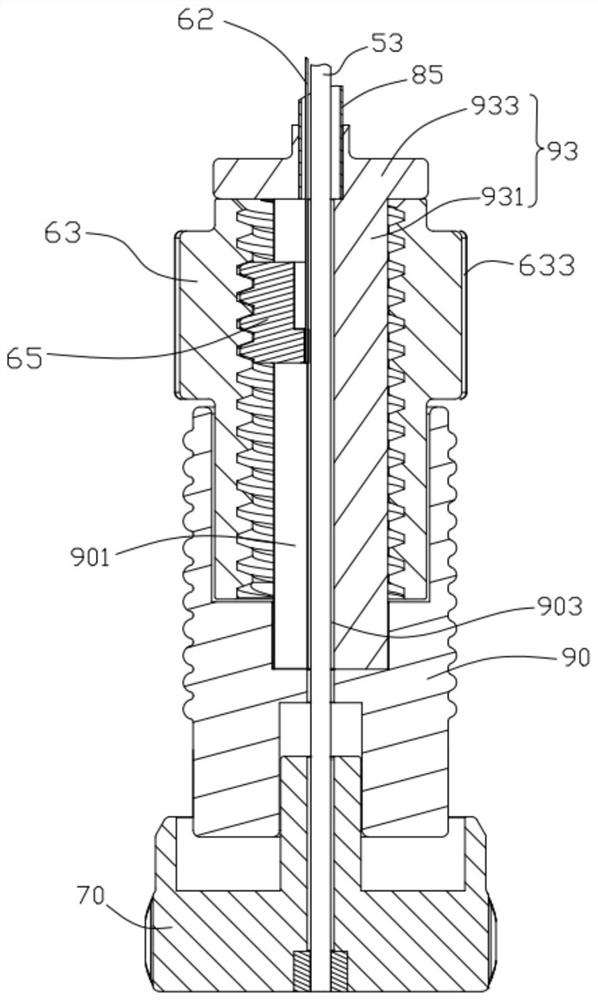

Automatic lifting mechanism

ActiveCN112239183AGood anti-torsion performanceHigh linear precisionLifting devicesStructural engineeringControl theory

The invention provides an automatic lifting mechanism. The automatic lifting mechanism comprises a first-stage lifting device, wherein the first-stage lifting device can conduct lifting movement in avertical direction, and can be supported on a ceiling; a second-stage lifting device arranged on a frame conducts lifting movement in the vertical direction of the frame, and the upper end portion ofthe second-stage lifting device is connected with the first-stage lifting device through a sliding pair, so that the rigidity of second-stage lifting device is improved; a third-stage lifting device conducts synchronous lifting movement along with the second-stage lifting device; left and right arms arranged on the third-stage lifting device conduct synchronous lifting movement along with the third-stage lifting device, and conduct forward or backward telescopic movement in the vertical direction of the third-stage lifting device respectively; a fourth-stage lifting device conducts synchronoustelescopic movement and angle adjustment along with the left arm and / or the right arm, and conducts lifting movement in the vertical direction; and a translation device conducts synchronous telescopic movement and / or lifting movement along with the fourth-stage lifting device. The automatic lifting mechanism is high in precision, high in rigidity, high in carrying capacity and high in freedom degree, and multi-degree-freedom high-precision controllable movement in other directions is achieved at the same time.

Owner:上海蔚建科技有限公司

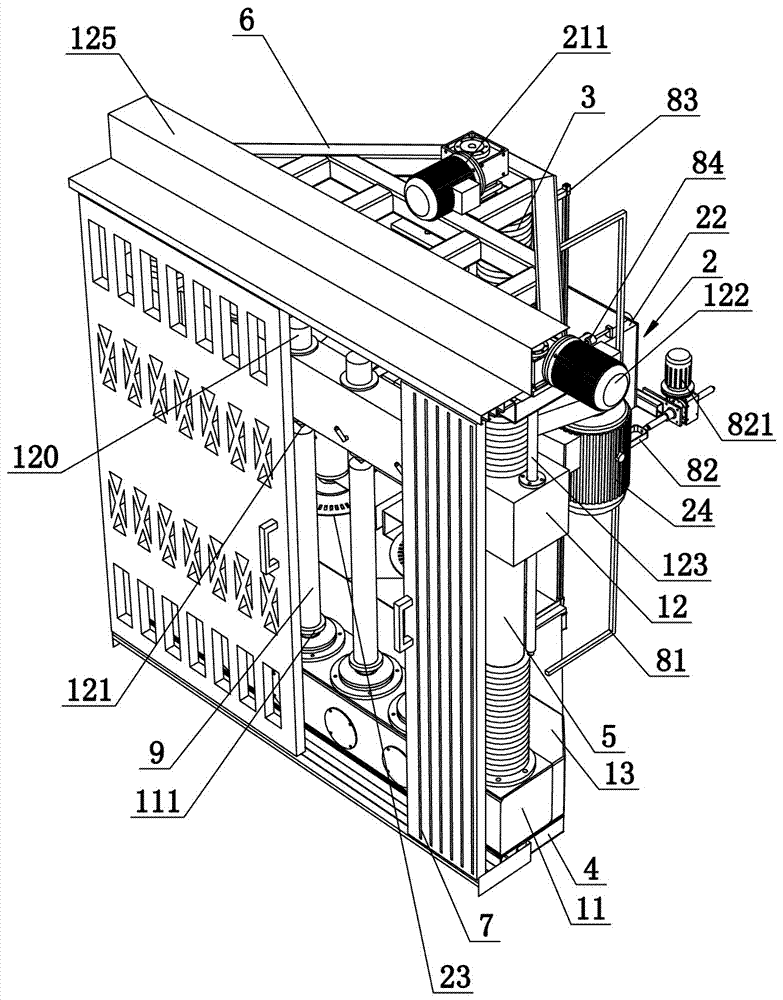

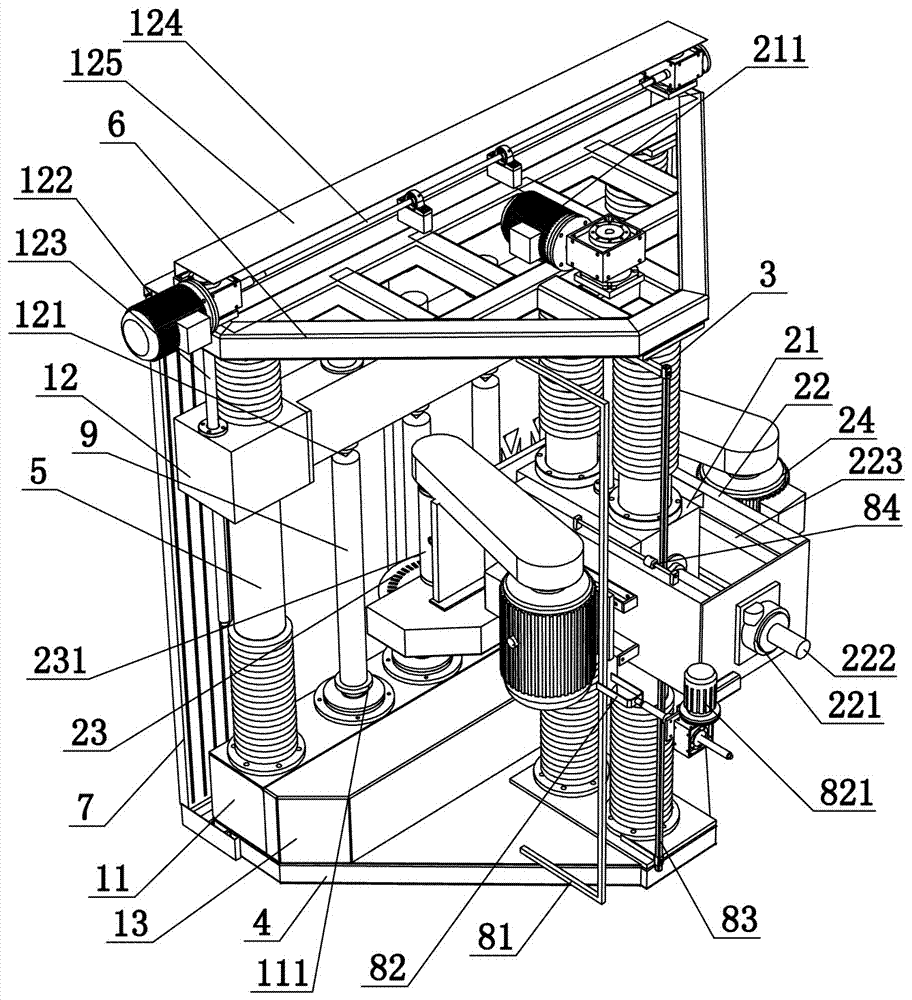

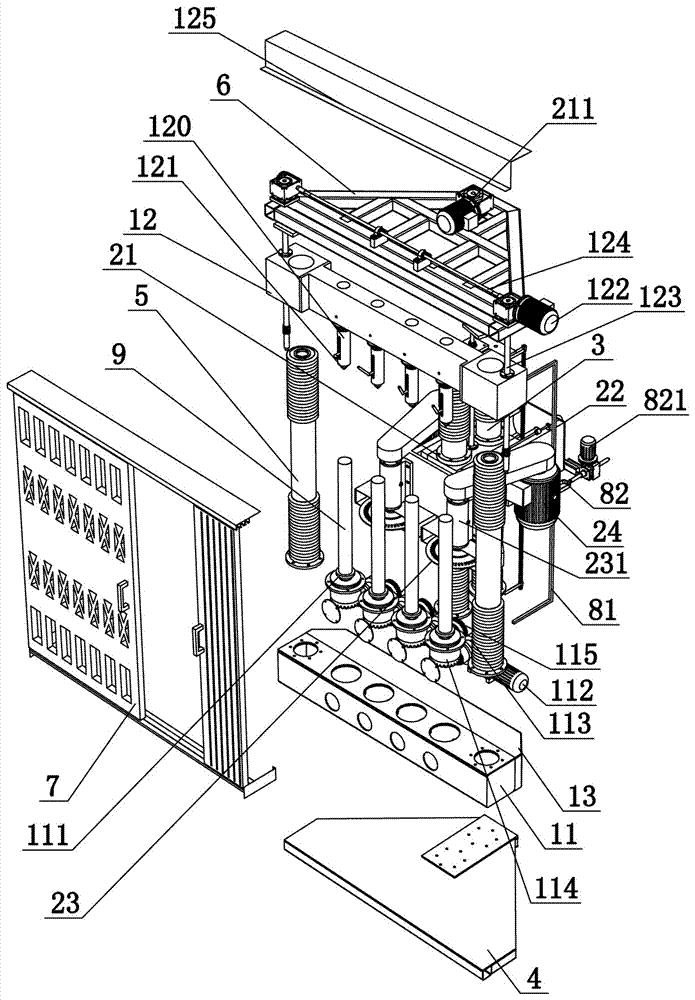

Multi-head vertical stone processing equipment

ActiveCN107379288AReduce shockGood product identityWorking accessoriesStone-like material working toolsEngineering

The invention relates to multi-head vertical stone processing equipment which comprises a worktable, a cutting mechanism and cutting upright columns. The worktable is used for vertically arranging a plurality of stone workpieces, the stone workpieces are positioned on the same plane, the cutting mechanism is used for simultaneously processing the stone workpieces and is assembled on the cutting upright columns in such a manner that the cutting mechanism can move along the cutting upright columns, and the stone workpieces and the cutting upright columns can extend along the vertical directions. The cutting upright columns are arranged on the plane where the stone workpieces are positioned, the projection of the cutting upright columns on the plane where the stone workpieces are positioned is positioned in the middles of the arrangement distances of the stone workpieces. The multi-head vertical stone processing equipment has the advantages that the multi-head vertical stone processing equipment is stable in structure and comprises few transmission structures (such as lifting driving mechanisms of lifting sliders) of various inner driving mechanisms, accordingly, the running stability of the multi-head vertical stone processing equipment can be improved, the durability of the multi-head vertical stone processing equipment can be enhanced, and the market competitiveness of the multi-head vertical stone processing equipment can be enhanced.

Owner:QUANZHOU MINYAN STONE MACHINERY CO LTD

Method for manufacturing enhanced thick-walled composite tube

InactiveCN104175703ANo stratificationEasy to makeLaminationLamination apparatusUltimate tensile strengthBond strength

The invention provides a method for manufacturing an enhanced thick-walled composite tube. A traditional dry-process laminating and rolling method is changed into the laminating-cutting-punching three-step manufacturing method, and the problems of low interlaminar bond strength caused by inconsistent tension and pressure during rolling, layering, cracking and the like are solved. The manufacturing method is simple, the manufacturing time is short, and the manufactured enhanced thick-walled composite tube is free of a layering phenomenon and has excellent torsion resistance.

Owner:MIANYANG TENGYANG ELECTROMECHANICAL PROD

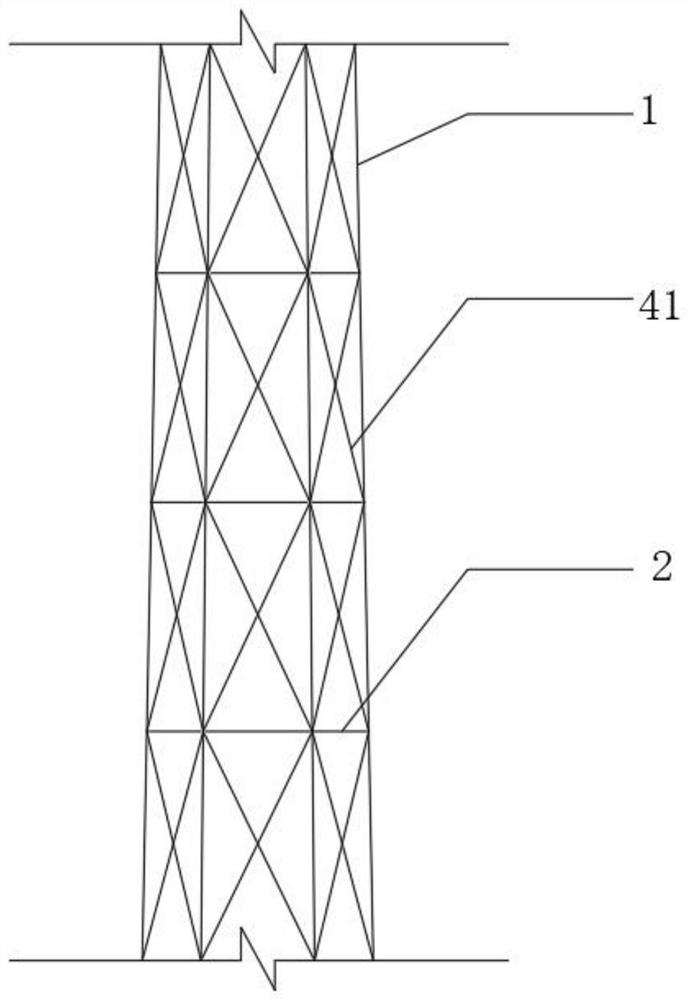

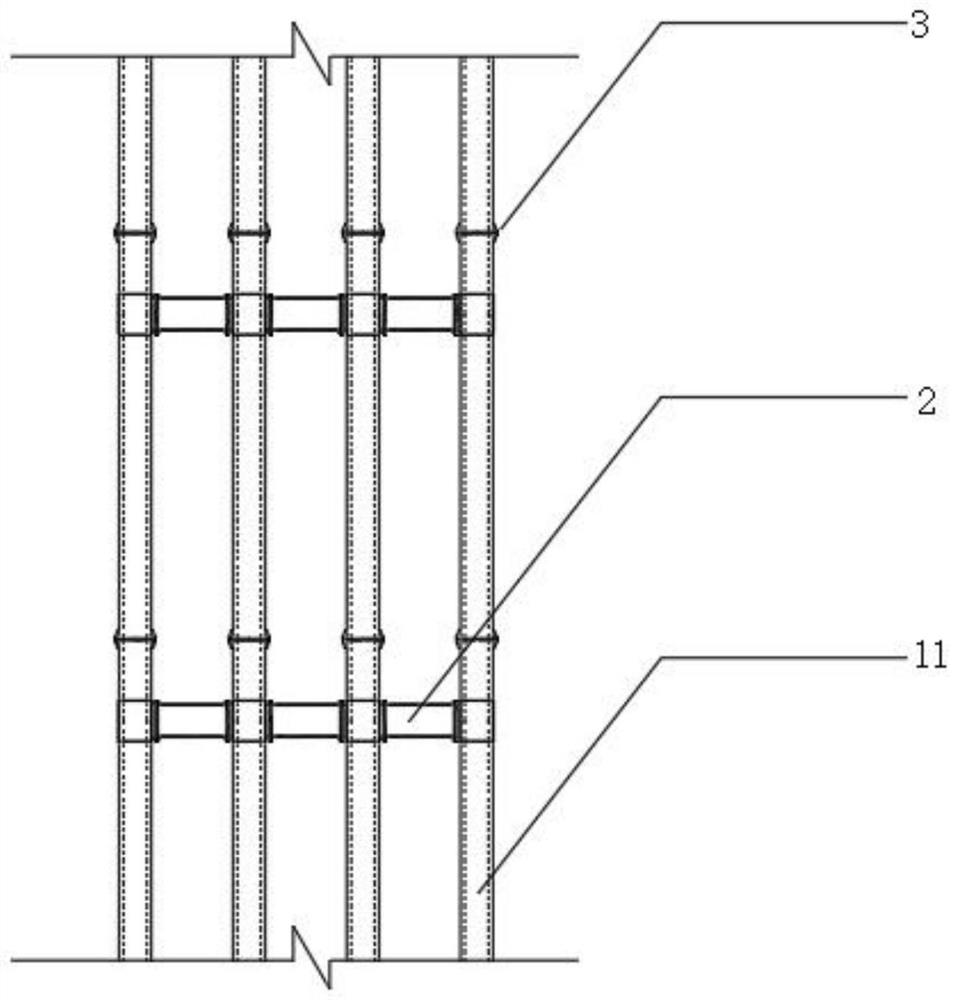

Prefabricated lattice type wind power tower drum

PendingCN113847210AEasy constructionEasy to replaceFinal product manufactureWind motor supports/mountsSteel tubeArchitectural engineering

The invention relates to a prefabricated lattice type wind power tower drum, in particular to the technical field of wind power generation, and comprises a plurality of long and thin steel pipe concrete limb columns which are rooted on the top surface of a foundation and are arranged into a ring shape, and the top ends of the long and thin steel pipe concrete limb columns incline towards the circle center to form a tower shape; each long and thin steel pipe concrete limb column is formed by splicing a plurality of short steel pipe concrete limb columns end to end, the adjacent short steel pipe concrete limb column sections are connected through longitudinal flanges, the long and thin steel pipe concrete limb columns are fixed through a plurality of parallel connection structures, and external prestressing tendons are arranged between the adjacent long and thin steel pipe concrete limb columns in a crossed mode; and anchoring ends of the external prestressing tendons are arranged at the bottom and the top of the tower drum respectively, and the external prestressing tendons are arranged at the corresponding positions of the parallel connection structures in a penetrating mode through a steering mechanism. The prefabricated lattice type wind power tower drum provided by the invention has the technical effects that a replaceable in-vitro non-adhesive prestress system is adopted, the assembly is convenient to manufacture, transport and hoist, and the formed spatial net surface structure is reasonable in stress and high in torsion resistance.

Owner:江苏砺诚交通科技有限公司

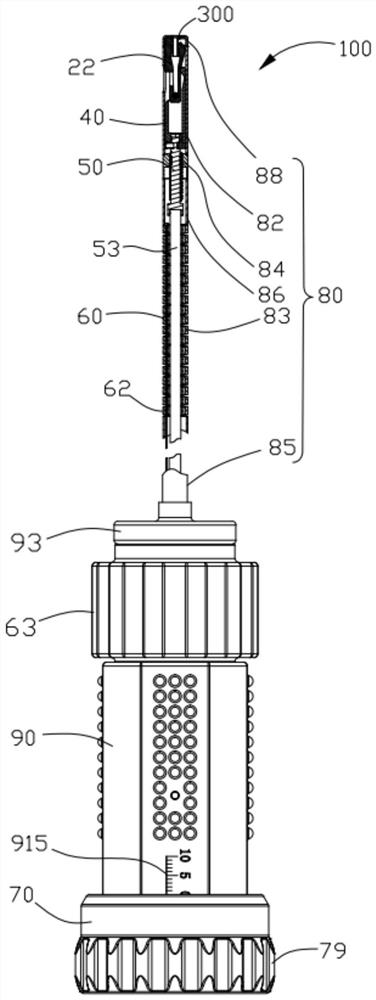

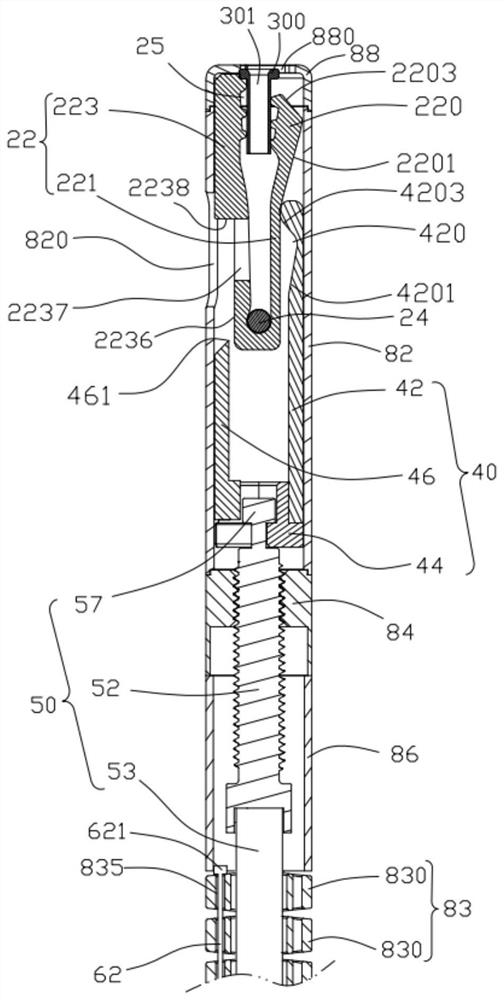

Bending-adjustable suture line locking device

PendingCN113892986AGood anti-torsion performancePrevent twistingSuture equipmentsAnnuloplasty ringsStructural engineeringMechanical engineering

The invention provides a bending-adjustable suture line locking device. The bending-adjustable suture line locking device comprises a clamping head, a locking nail contained at the far end of the clamping head, a push rod assembly arranged outside the clamping head, an outer supporting pipe assembly arranged outside the push rod assembly in a sleeving mode and a bending adjusting mechanism; the outer supporting pipe assembly comprises a bending adjustable section and a flexible outer pipe connected with the near end of the bending adjustable section, the bending adjustable section comprises a plurality of unit sections, and every two adjacent unit sections are rotationally connected; and the bending adjusting mechanism at least comprises one traction piece connected with the bending adjustable section, and the traction piece is axially pulled so that the bending adjustable section can be bent towards the side where the traction piece is located. The bending adjustable section has good anti-torsion performance in a bending state and is sufficient to resist acting force on the bending adjustable section when driving a push rod to enable the clamping head to be closed or opened, the bending adjustable section is prevented from twisting or swinging, and therefore the phenomena that the locking nail and a locking point are staggered and a suture line is pulled are avoided.

Owner:HANGZHOU VALGEN MEDTECH CO LTD

A kind of integral rudder reinforcement fabric and weaving method thereof

ActiveCN106987978BMeet different performance requirementsGood anti-torsion performanceWoven fabricsEngineeringRudder

Owner:TIANJIN POLYTECHNIC UNIV

Installation structure of sound insulation wall in railway vehicle engine room

ActiveCN103318204BImprove torsion resistanceEasy to adjustAxle-box lubricationRailway bodiesButt jointEngineering

The invention relates to an engine room soundproof wall mounting structure for a railway vehicle. Angle-form vertical columns are connected to two sides of a soundproof wall by means of full-length welding. One side of the outer vertical face of each angle-form vertical column is connected with a side wall vertical column by means of full-length welding, and the other side of the outer vertical face of each angle-form vertical column is connected with the side wall vertical column through segment welding or dense point welding. A reinforcement plate is connected below a lower crossbeam of the soundproof wall by means of full-length welding. One side of the reinforcement plate is connected with a butt joint vertical plate between corrugated floors by means of full-length welding. The upper end of the soundproof wall is connected with a vehicle-top bent beam by means of full-length welding. By the two angle-form vertical columns added on two sides of the soundproof wall, torsion-resistant performance of the soundproof wall is increased, the position of the soundproof wall can be adjusted conveniently during assembling, and assembling difficulty of the soundproof wall is lowered. By the structure that the added angle-form vertical columns are connected with partition plates and side wall vertical columns by means of full-length welding, the reinforcement plate is welded at the butt joint position of the corrugated floors of a base frame and connected with the butt joint vertical plate by means of full-length welding, the lower crossbeam of the soundproof wall is connected with the reinforcement plate by means of full-length welding, and the soundproof wall is connected with a vehicle top by means of full-length welding, soundproof performance of the soundproof wall is increased.

Owner:CRRC NANJING PUZHEN CO LTD

A piezoelectric actuator protection device

ActiveCN112910307BAvoid Fracture FailurePrecise linear output characteristicsPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

The invention discloses a piezoelectric actuator protection device. One end of the piezoelectric actuator is connected to the top connecting rod through a flexible hinge, and an inner shaft sleeve is set on one end of the piezoelectric actuator and the flexible hinge; The other end of the actuator is connected to the bottom connecting rod, the piezoelectric actuator and the inner bushing are covered with an outer bushing, the inner bushing is connected to the top connecting rod, and the outer bushing and the bottom connecting rod are tightly connected to form a piezoelectric actuator. Actuator protection device. The protection device of the present invention can be used without changing the structure of the original piezoelectric actuator, and has the advantages of simple structure, light weight, easy disassembly and installation, high reliability, and strong temperature adaptability, and does not affect the original piezoelectric actuator. The displacement output performance of the device.

Owner:XI AN JIAOTONG UNIV

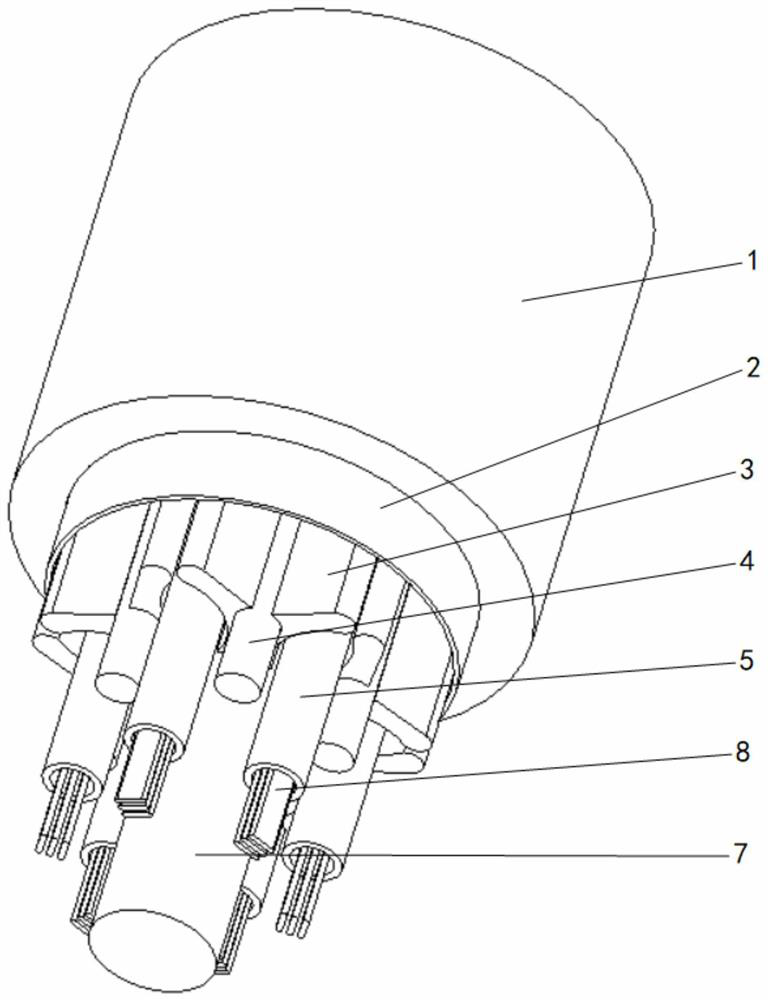

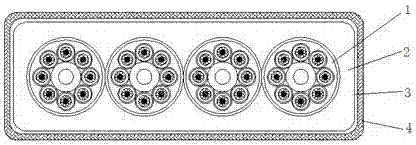

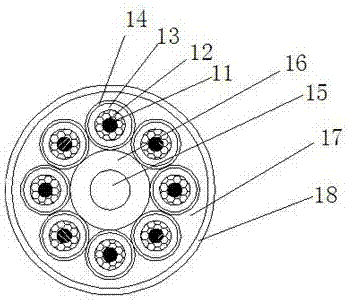

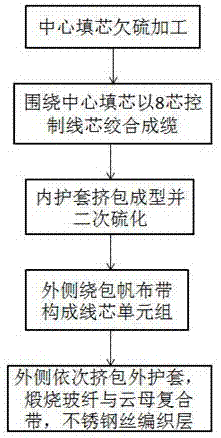

Reel control cable and preparation method thereof

ActiveCN105206328BPrevent splashGood anti-torsion performanceFlat/ribbon cablesCable/conductor manufactureGlass fiberSteelmaking

The invention provides a reel control cable and its production method. The reel control cable includes a wire core unit group, an outer sheath, a calcined glass fiber and mica composite tape and a stainless steel braid layer; the wire core unit group includes an 8-core control wire Core, center core, inner sheath and canvas reinforcement layer, the control wire core is twisted around the center core core to form a cable, the outer side is extruded with an inner sheath, and the outer side of the inner sheath is wrapped with a canvas reinforcement layer; there are 4 core unit groups in parallel Place it evenly, extrude the outer sheath on the outside, wrap the calcined glass fiber and mica composite tape on the outside of the outer sheath, and wrap the stainless steel wire braid on the outside of the calcined glass fiber and mica composite tape, and the cross section of the reel control cable is flat. The above-mentioned cables are processed through the steps of filling the core with insufficient sulfur, twisting into a cable, extruding the sheath, and secondary vulcanization. The reel control cable provided by the invention has excellent temperature-resistant and wear-resistant properties, effectively prevents molten steel from splashing, and is widely used in industrial mobile machinery such as transporting molten steel tanks in large-scale steelmaking plants.

Owner:江苏通光德柔电缆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com