Prefabricated lattice type wind power tower drum

A technology of prefabrication and assembly of wind power towers, which is applied in wind power generation, installation/support of wind turbine configuration, final product manufacturing, etc. It can solve the problem of high lifting capacity, high requirements for road transportation conditions, and high proportion of cost of measures , large size of tower components, etc., to achieve the effect of reasonable force, strong anti-torsion ability, and convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

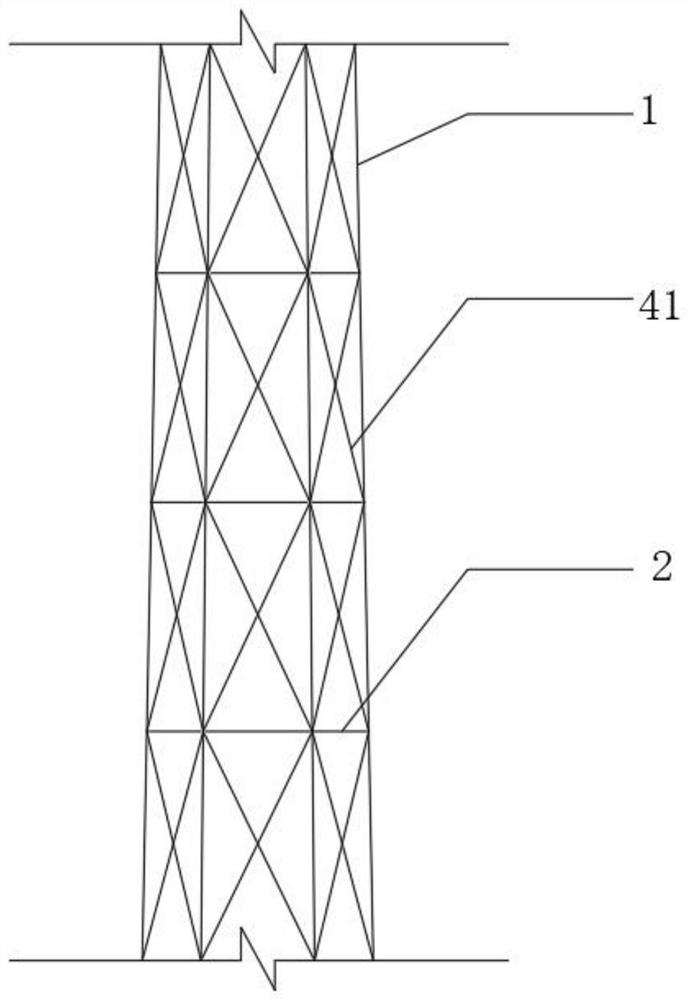

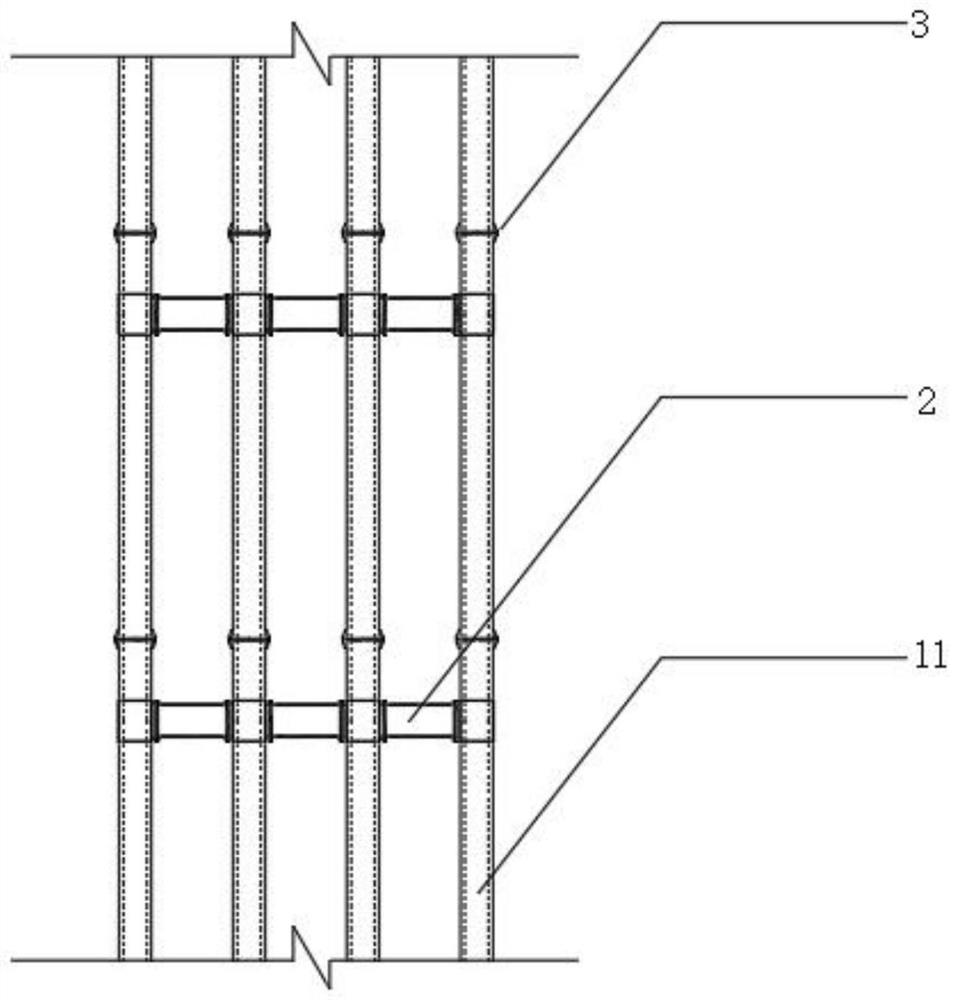

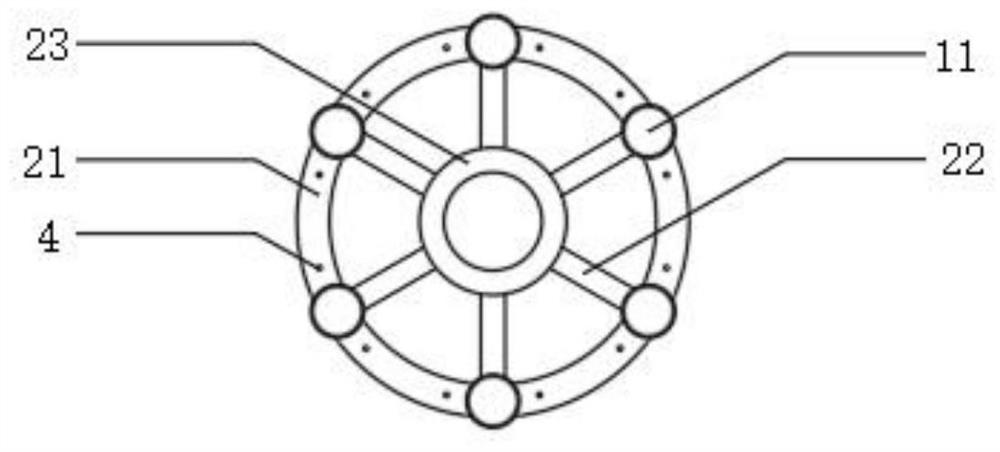

[0024] see Figure 1 to Figure 8 , a prefabricated assembly lattice type wind power tower, including several slender steel pipe concrete leg columns 1 rooted on the top surface of the foundation and arranged in a ring shape, the tops of the slender steel pipe concrete leg columns 1 are inclined towards the center of the circle to form a tower Each slender steel pipe concrete leg column 1 is spliced end to end by several short steel pipe concrete leg columns 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com