Optical cable with special-shaped filling ropes

A technology for filling ropes and optical cables, which can be applied to cables, optics, light guides, etc., and can solve the problems of increasing the weight of optical cables, inconvenient construction, and heavy optical cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

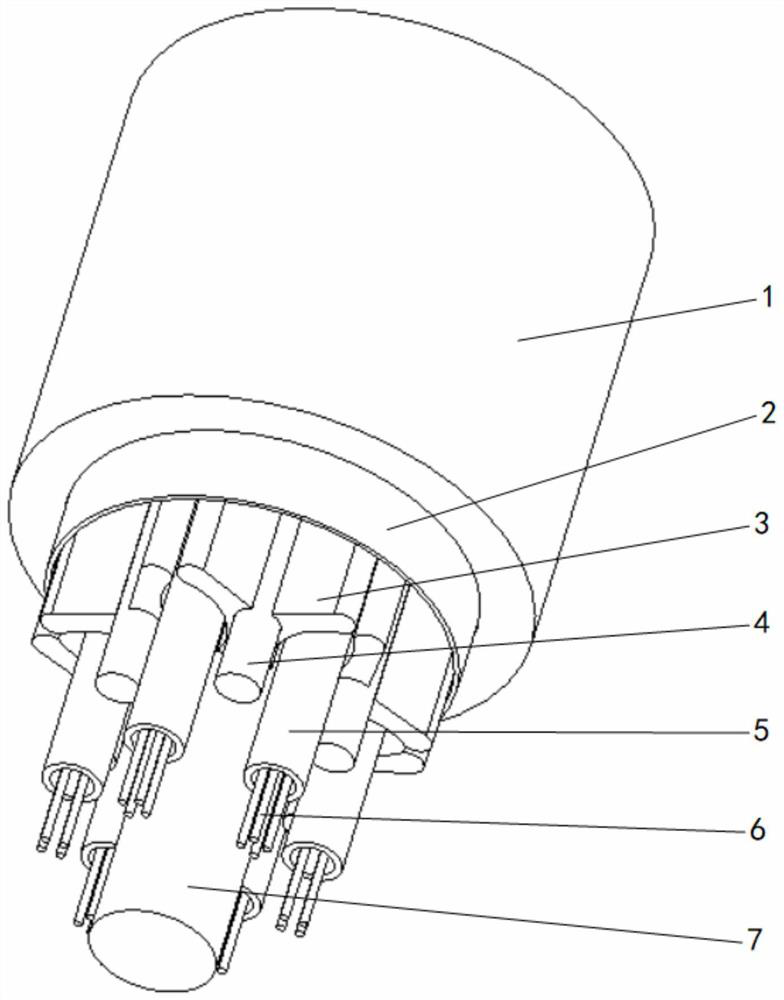

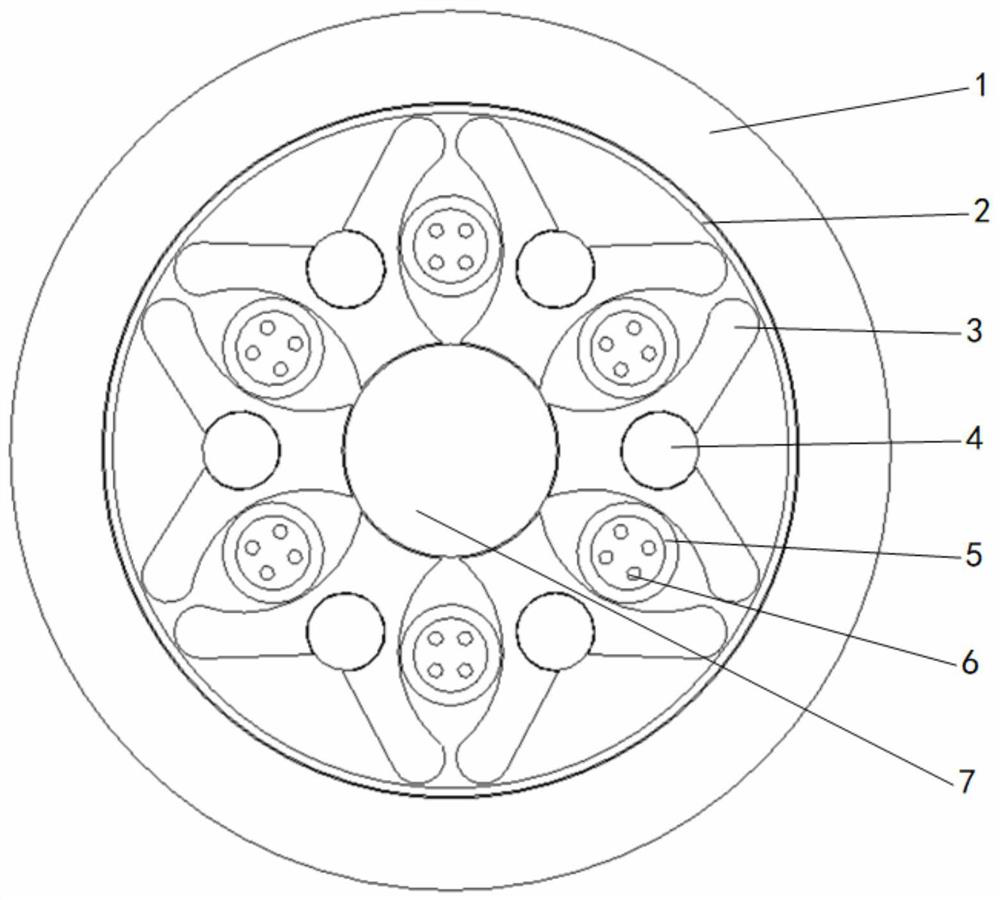

[0031] please see figure 1 , figure 2 and Figure 5 , an optical cable with a special-shaped filling rope, which has an outer sheath 1, a tape layer 2, a central strength member 7 and at least three loose tubes 5, each loose tube is provided with at least one optical fiber 6, and the loose tube 5 Located outside the central reinforcement 7, the tape layer 2 is located outside the loose tube 5, and the outer sheath 1 is extruded outside the tape layer 2, and it is characterized in that there is also a set between the two adjacent loose tubes 5 A filling rope 3, the filling rope 3 is composed of a base 34 and two bifurcated support plates 31 at the top of the base 34, a cavity 33 is formed between the two support plates 31 in the base 34, the cavity 33 top forms an embedding opening 32, the bottom of the base 34 is arc-shaped, and is bonded to the surface of the central reinforcement 7, clockwise, the base 34 of the previous filling rope 3 and the support plate 31 on the left...

Embodiment 2

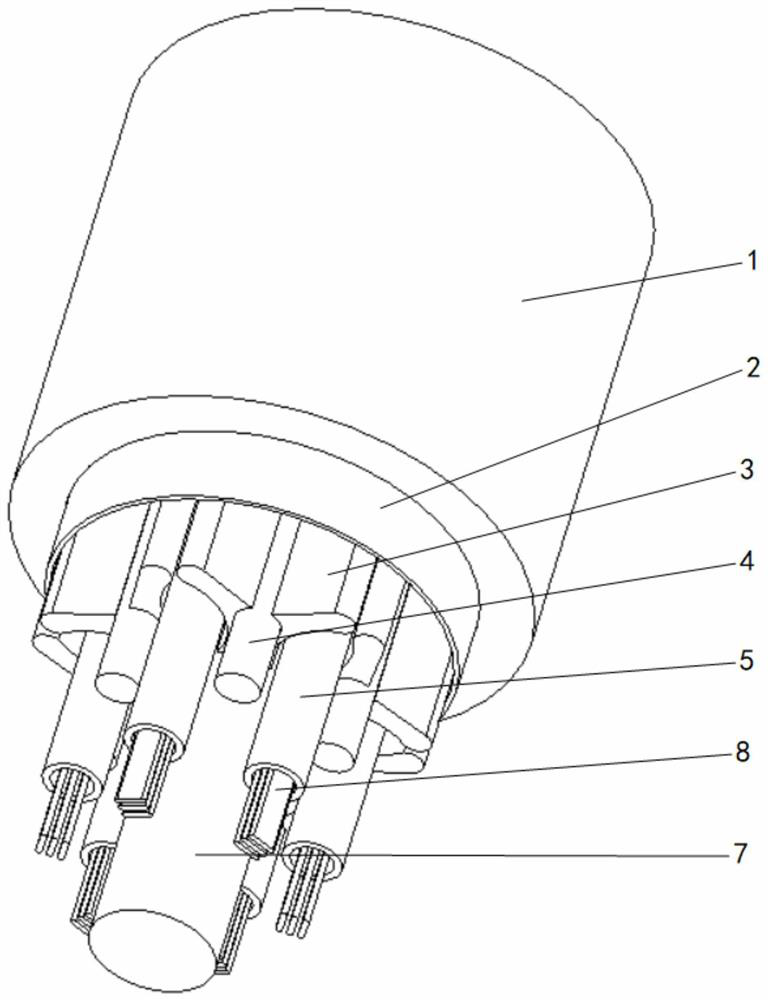

[0033] please see image 3 , Figure 4 and Figure 5 , an optical cable with a special-shaped filling rope, which has an outer sheath 1, a tape layer 2, a central strength member 7 and at least three loose tubes 5, each loose tube is provided with at least one optical fiber ribbon 8, and the loose tube 5 is located outside the central reinforcement 7, the wrapping layer 2 is located outside the loose tube 5, and the outer sheath 1 is extruded outside the wrapping layer 2, which is characterized in that two adjacent loose tubes 5 are also provided with There is a filling rope 3, and the filling rope 3 is composed of a base 34 and two bifurcated support plates 31 located at the top of the base 34, and a cavity 33 is formed between the two support plates 31 to the base 34 to accommodate An embedding opening 32 is formed at the top of the cavity 33, and the bottom of the base 34 is arc-shaped, and is attached to the surface of the central reinforcing member 7. In a clockwise dir...

Embodiment 3

[0035] please see Figure 6 , Figure 7 , Figure 8 and Figure 9, an optical cable with a special-shaped filling rope, which has an outer sheath 1, a tape layer 2, a central strength member 7 and at least three loose tubes 5, each loose tube is provided with at least one optical fiber 6, and the loose tube 5 Located outside the central reinforcement 7, the tape layer 2 is located outside the loose tube 5, and the outer sheath 1 is extruded outside the tape layer 2, and it is characterized in that there is also a set between the two adjacent loose tubes 5 A filling rope 3, the filling rope 3 is composed of a base 34 and two bifurcated support plates 31 at the top of the base 34, a cavity 33 is formed between the two support plates 31 in the base 34, the cavity 33 top forms an embedding opening 32, the bottom of the base 34 is arc-shaped, and is attached to the surface of the central reinforcement 7, and the bottom of the base 34 also forms a limiting groove 35, and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com