Dedicated flatcar body for railway container and container conveying system

A container and container lock technology, which is applied to railway car body parts, transport passenger cars, transportation and packaging, etc., can solve the problems of poor vehicle dynamics, small moment of inertia, weak anti-torsion ability, etc., and achieve large assembly space, longitudinal The effect of reasonable force transmission path and strong anti-torsion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

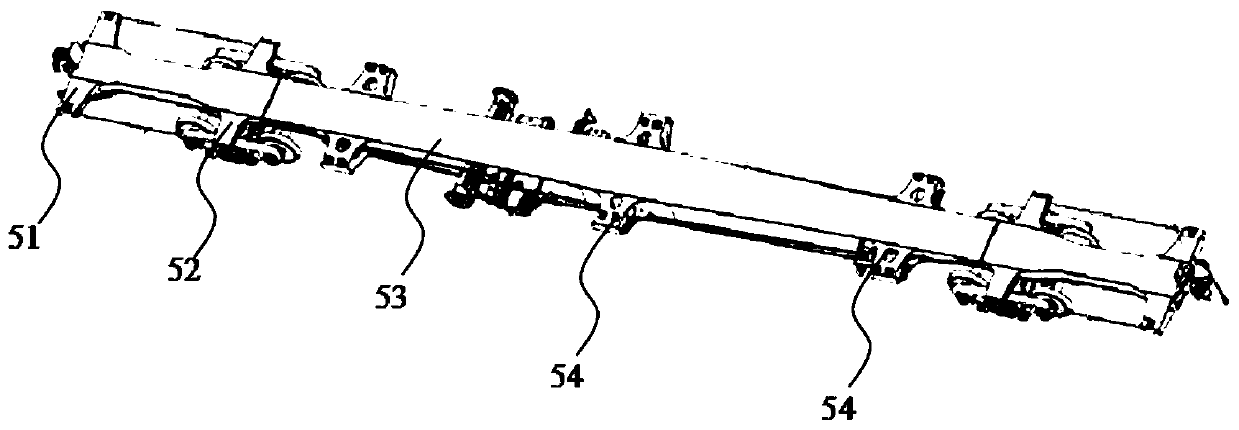

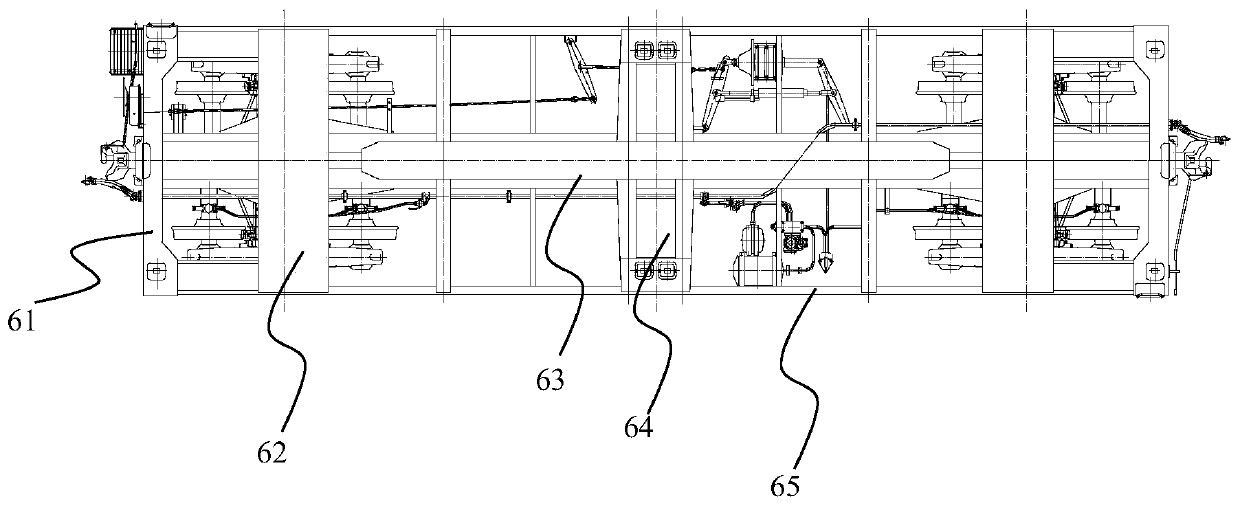

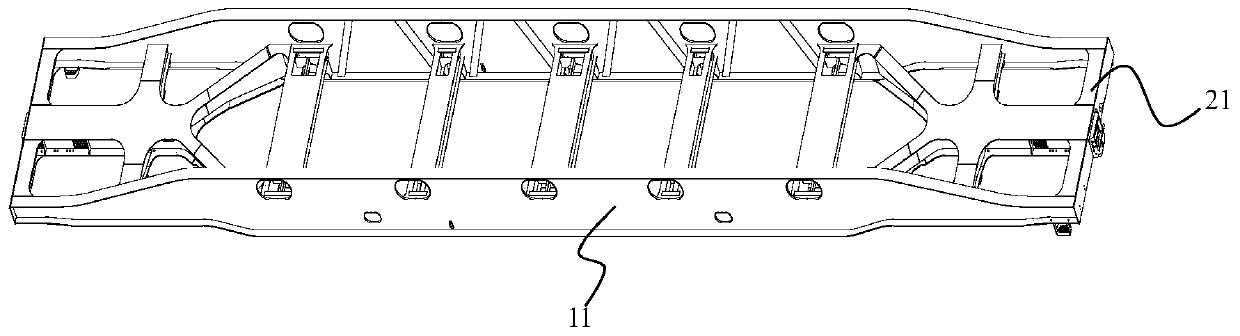

[0078] image 3 It is a schematic structural view of the special flat car body for railway containers provided by the embodiment of the present invention, Figure 4 and Figure 5 respectively image 3 The schematic diagram of the front view and the top view of , refer to Figure 3-5 As shown, the body of the flat car dedicated to railway containers provided by the embodiment of the present invention has a front-rear symmetrical structure and a left-right symmetrical structure, which are symmetrical about the longitudinal centerline and the transverse centerline. The special flat car body for railway containers provided by the embodiment of the present invention includes two side beams 11 and two end beams 21. The end beams 21 are arranged at intervals and in parallel, and are respectively located at the two ends of the side beams 11. The end beams 21 are located between the two side beams 11. The beams 21 at both ends constitute a rectangular frame structure. This rectang...

Embodiment 2

[0091] An embodiment of the present invention provides a container transport system, including several containers and the special flat car body for railway containers in Embodiment 1, and the container is fixed above the flat car body. The container transportation system of this embodiment can load containers of different sizes according to needs, so as to achieve maximum transportation efficiency. Several different transport conditions will be described in detail below.

[0092] Figure 9 The schematic diagram of loading two 40-foot containers on the special flat car body of railway containers provided by the embodiment of the present invention, refer to Figure 9 As shown, the body length of the special flat car for railway containers in the present embodiment is 80 feet, and can simultaneously load two 40-foot containers 31, and the two 40-foot containers 31 are horizontally distributed, and one is placed on the left and right sides. Compared with the special flat car bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com