Double-tube cable or optical cable

A technology of electric cables and optical cables, which is applied in the field of double-tube cables or optical cables, can solve problems such as inconvenient maintenance of broken circuits, poor tensile and compressive properties, and achieve the effects of simple structure, good compressive properties, and good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

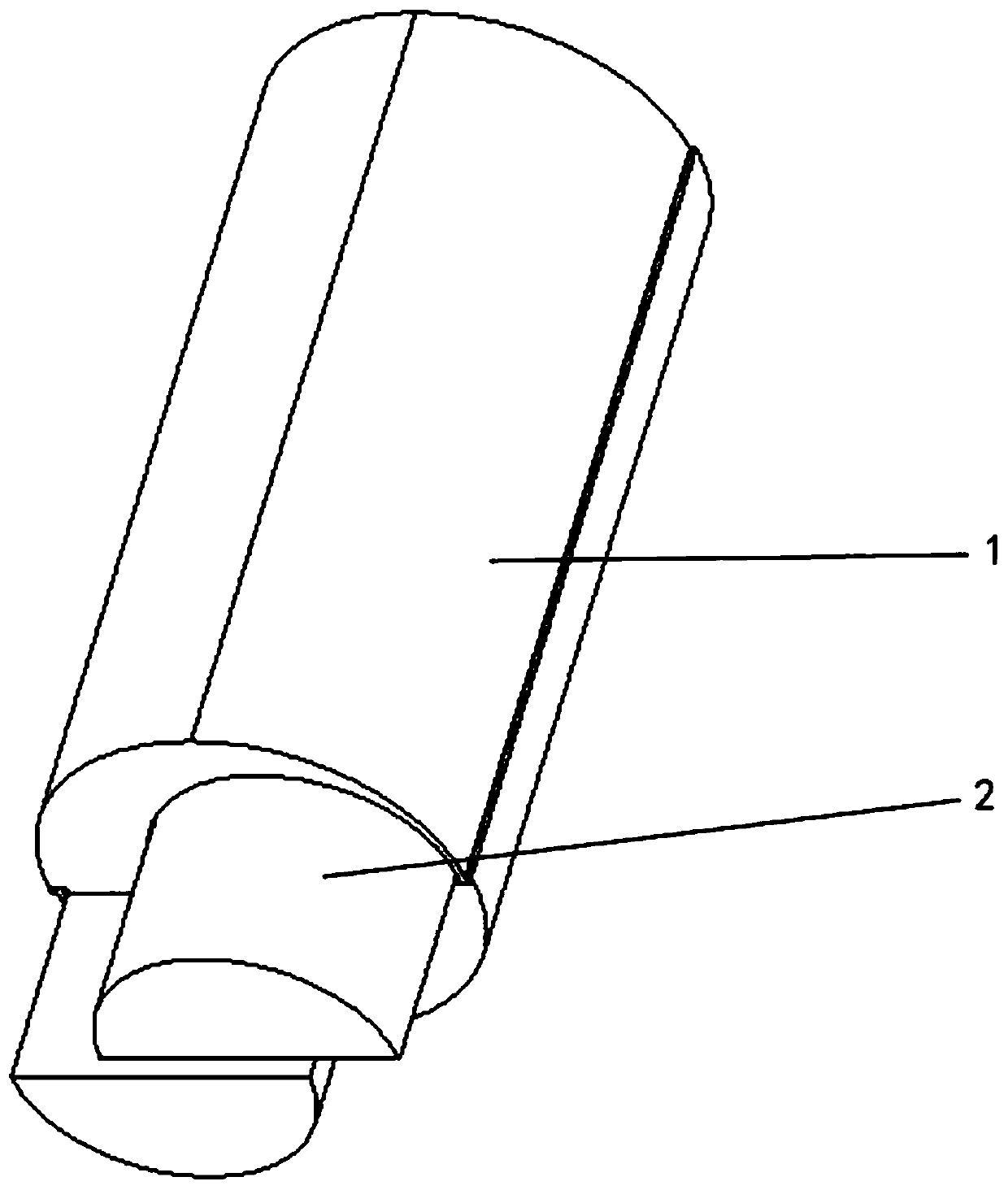

[0029] please see figure 1 , Figure 5 and Figure 6 , a double-tube cable with an outer sheath 1 and two electrical units 2, the electrical unit 2 is semicircular, characterized in that the outer sheath 1 consists of two outer sheath main bodies 11 and a connecting part 12, the head of the outer sheath main body 11 is large and the tail is small, the head of the outer sheath main body 11 forms a clamping groove 112, and the tail is provided with a clamping part 111, the two outer sheath main bodies 11 The head and the tail are respectively connected to the tail and the head of another outer sheath main body 11 through the snap-in groove 112 and the snap-in part 111, and two dislocations are formed between the two outer sheath main bodies 11 and one connecting part 12. A semicircular cavity 13, the electric unit 2 is located in the cavity 13.

[0030] The double-tube cable described in the above embodiment is characterized in that the electrical unit 2 is composed of a cond...

Embodiment 2

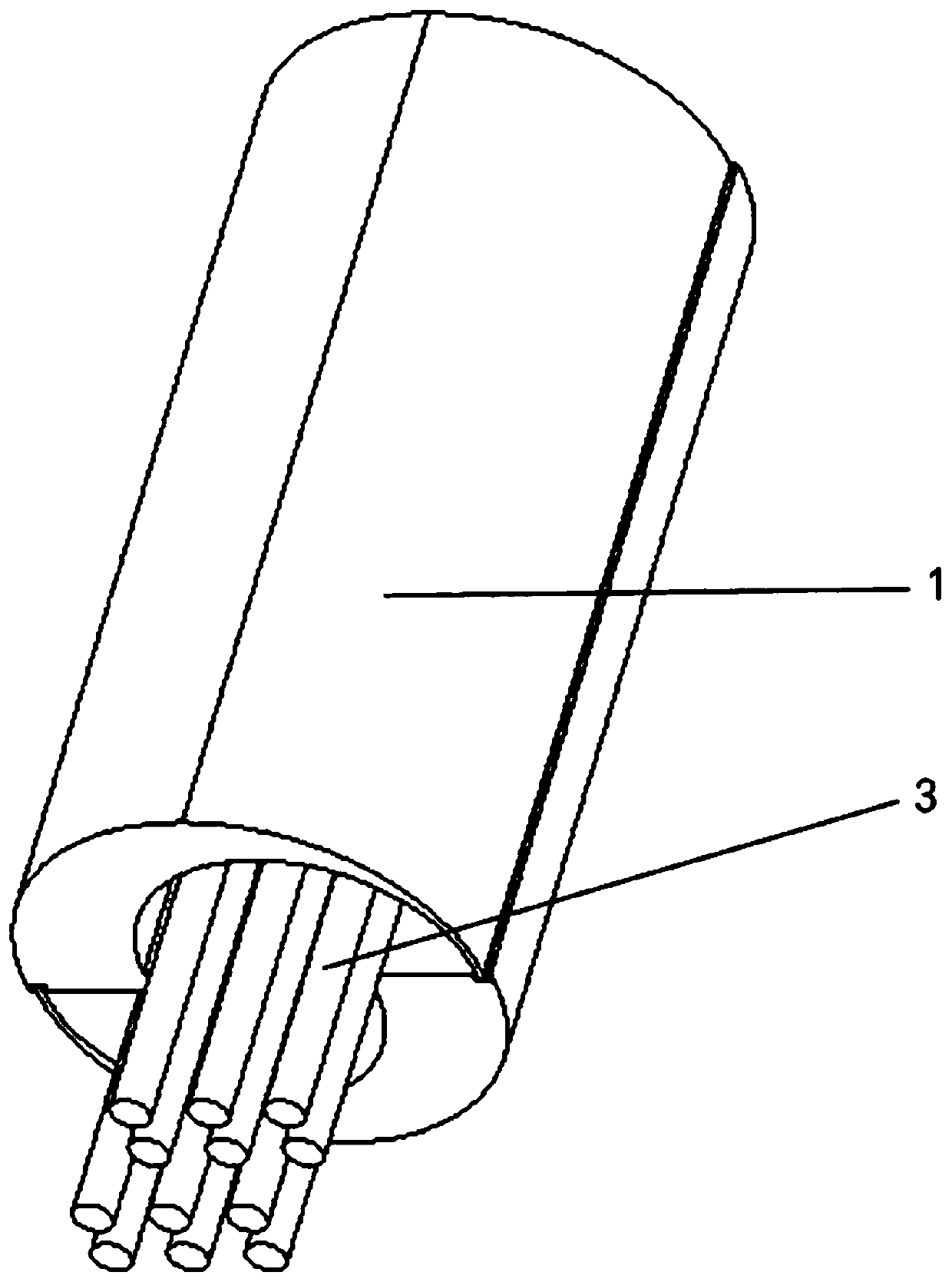

[0035] please see figure 2 , Figure 5 and Figure 6 , a double-tube optical cable with an outer sheath 1 and a plurality of optical communication components 3, characterized in that the outer sheath 1 is composed of two outer sheath main bodies 11 and one connecting part 12, the outer sheath main body 11. The head is large and the tail is small. The head of the outer sheath main body 11 forms a clamping groove 112, and the tail is provided with a clamping part 111. The heads and tails of the two outer sheath main bodies 11 are respectively connected with the other outer sheath The tail and the head of the sheath main body 11 are connected to each other through the snap-in groove 112 and the snap-in part 111, and two semicircular cavities 13 are formed between the two outer sheath main bodies 11 and one connecting part 12. The cavities 13 At least one optical communication component 3 is provided.

[0036] The double-tube optical cable described in the above embodiment is ...

Embodiment 3

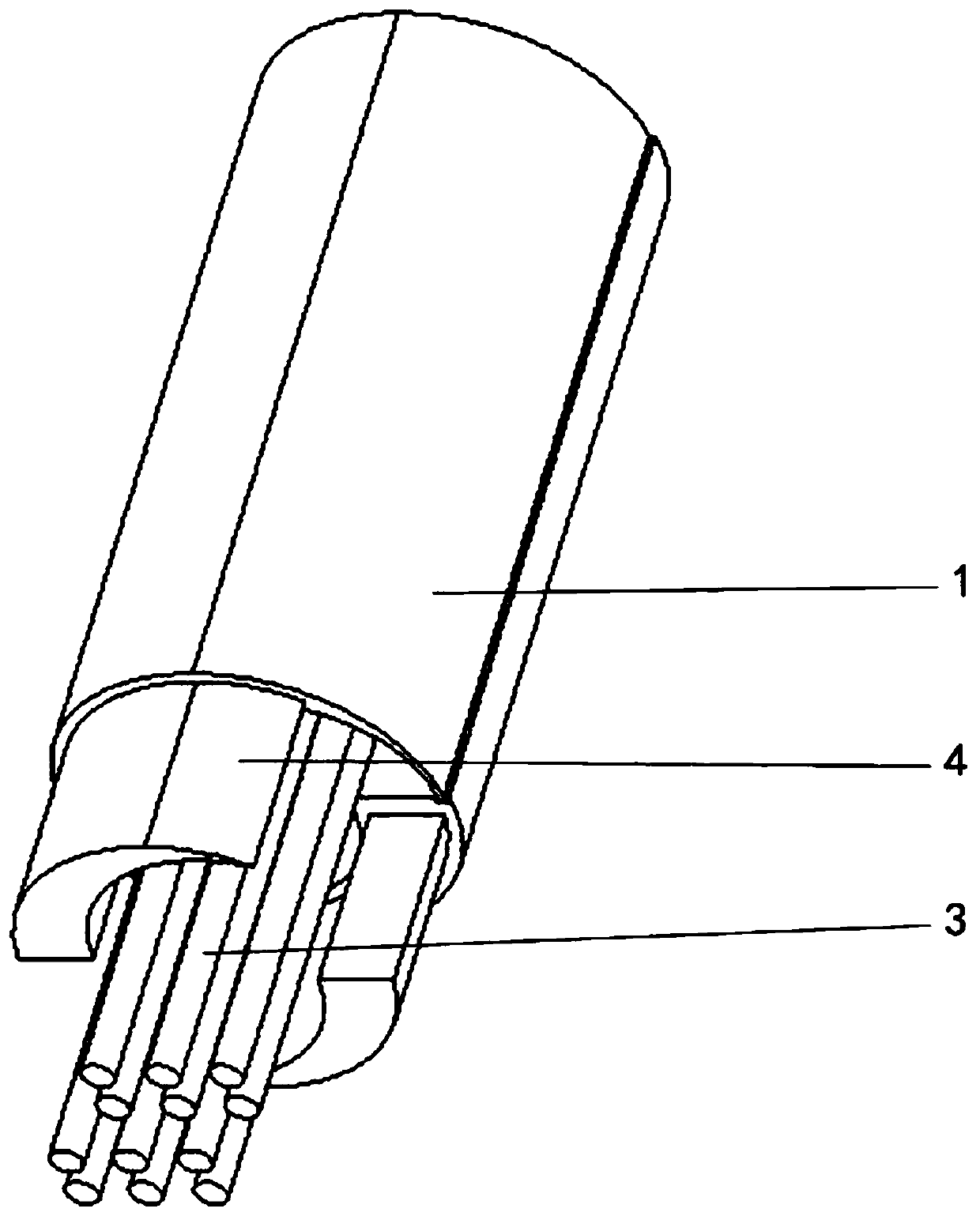

[0038] please see image 3 and Figure 6 and refer to Figure 5 , a double-tube optical cable with an outer sheath 1 and a plurality of optical communication components 3, characterized in that the outer sheath 1 is composed of two outer sheath main bodies 11 and one connecting part 12, the outer sheath main body 11. The head is large and the tail is small. The head of the outer sheath main body 11 forms a clamping groove 112, and the tail is provided with a clamping part 111. The heads and tails of the two outer sheath main bodies 11 are respectively connected with the other outer sheath The tail and the head of the sheath main body 11 are connected to each other through the snap-in groove 112 and the snap-in part 111, and two semicircular cavities 13 are formed between the two outer sheath main bodies 11 and one connecting part 12. The cavities 13 At least one optical communication component 3 is provided, and the inside of the outer sheath main body 11 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com