Integral locomotive moving platform

A car transfer platform, integrated technology, applied in the direction of transfer platform/car transfer platform, railway car body parts, transportation and packaging, etc. The problem of reliable operation of the platform and the rail of the moving platform can achieve the effect of large structural safety reserve, good overall stability and anti-torsion performance, and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

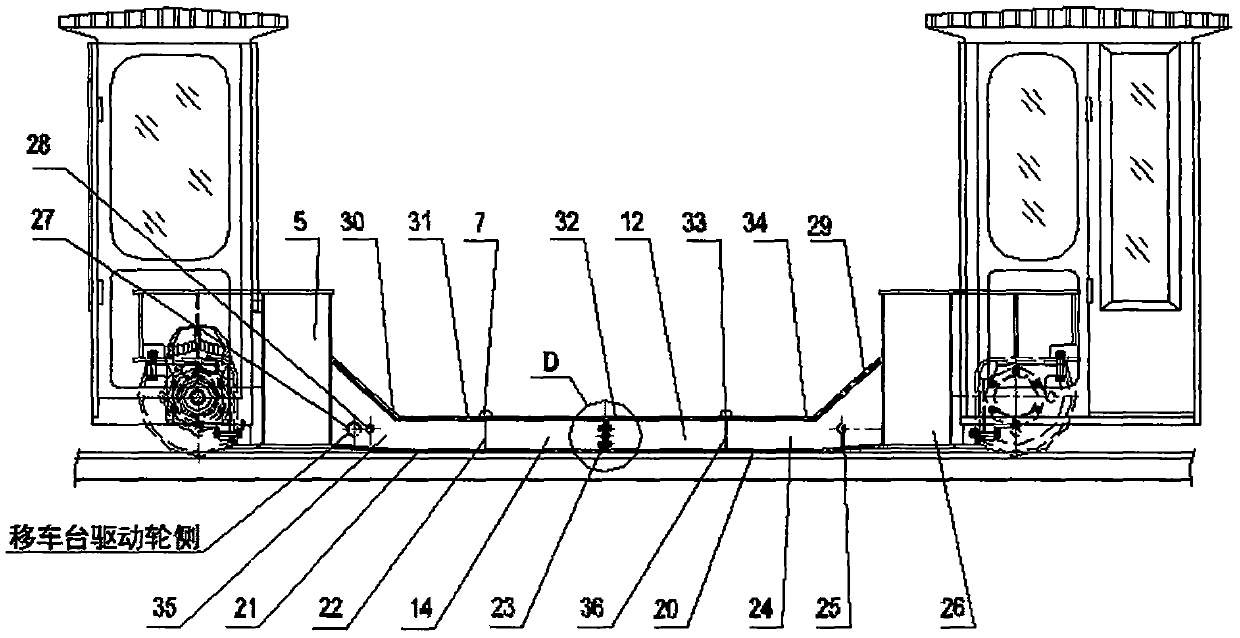

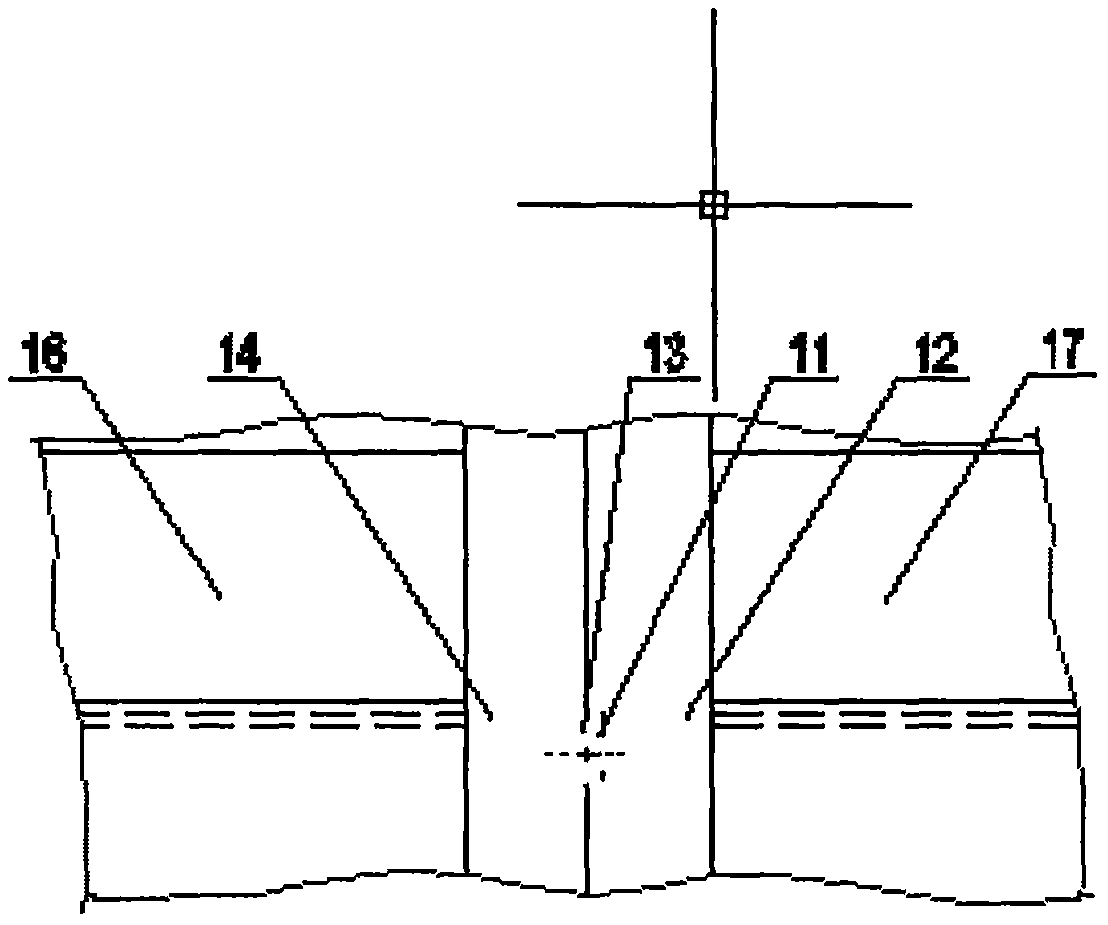

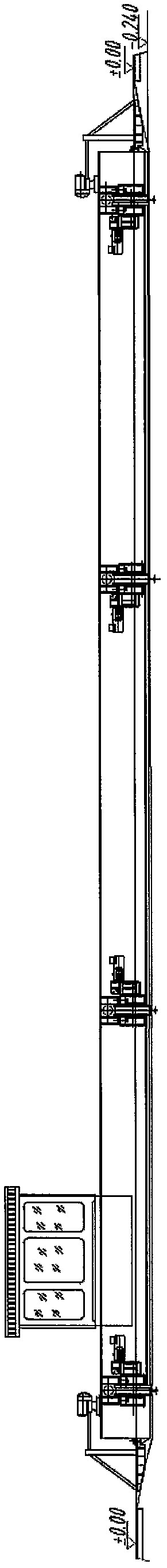

[0024] Embodiments of the present invention are described in conjunction with the accompanying drawings

[0025] Figures: 1, 2, 3, 4, 5

[0026] The integral vehicle moving platform is composed of the overall bearing structure of the space plate beam, the driving wheel drive device, the driven wheel device, the power supply part, the safety warning system, the ferry bridge, the main (auxiliary) driver's cab, and the electric control system. It consists of 4 groups The drive wheel drive device 2 and the 4 sets of driven wheel drive devices 3 are installed on the angular bearing box support on the side of the left main beam 5 and the right main beam 26, and the four sets of drive wheel bidirectional motors are controlled by the inverter system to run synchronously, and the induction system senses The position of the shifting platform is determined by calculation to determine the start and braking curves of the frequency converter, so as to achieve precise alignment of the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com