Vacuum packing method, vacuum packing treatment device and treatment method of vacuum packing treatment device

A vacuum packaging and processing device technology, applied in vacuum/special atmosphere packaging, packaging, transportation packaging, etc., can solve the problem of the decrease of the flatness and aesthetics of vacuum packaging of materials, reduce the packaging speed of vacuum packaging machines, and prolong the waiting time of vacuum packaging and other problems, to achieve the effects of shortening the waiting time, ensuring pressure, good bending resistance and torsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

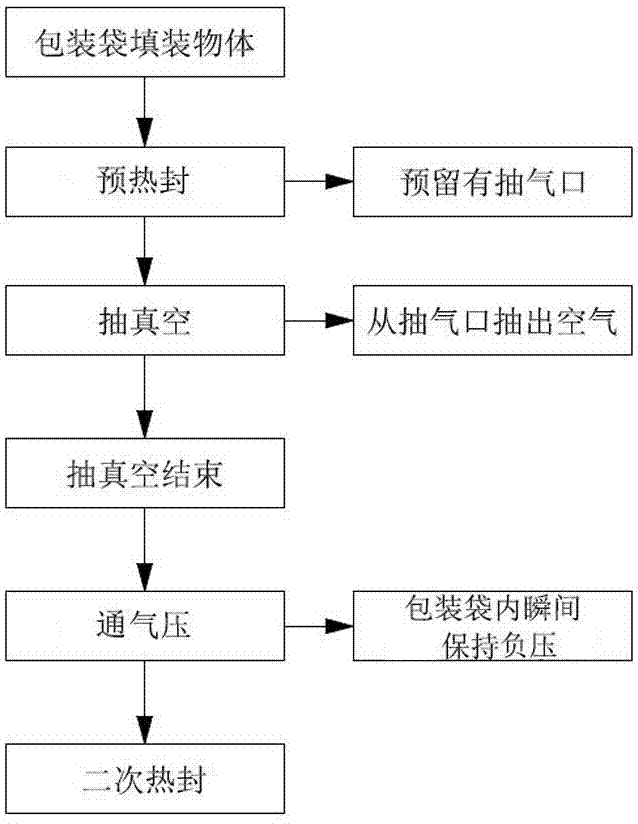

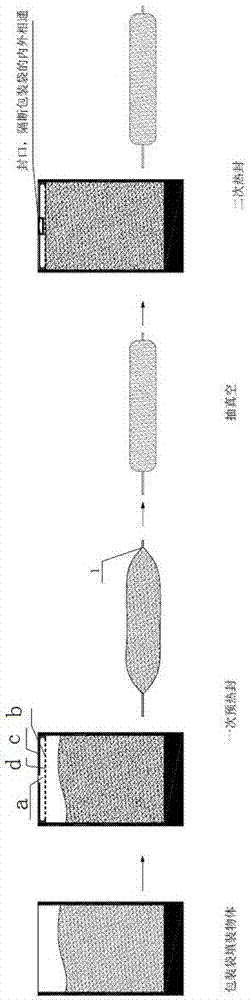

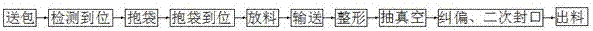

[0043] Such as Figure 1~2 Shown, a kind of vacuum packaging method comprises the following steps:

[0044] Step S1: After the packaging bag is filled with objects, perform a pre-heat seal at the filling port, form a heat-sealing line at the filling port of the packaging bag, and leave a suction port at the pre-heat sealing position of the packaging bag, only Leave the air outlet to communicate the air inside and outside the packaging bag;

[0045] Step S2: Place the preheat-sealed packaging bag in a vacuum chamber connected to the vacuum mechanism, turn on the vacuum mechanism, and use negative pressure to draw out the air in the packaging bag from the suction port. At this time, the pressure in the packaging bag is the same as The pressure in the vacuum chamber is equal;

[0046] Step S3: Connect the vacuum chamber to the outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com