Steel and wood combined box girder

A steel-wood combination and box girder technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of increased construction difficulty, increased construction cost, insufficient cleanliness, etc., to achieve convenient construction, good bending and torsion resistance of beams, enhanced The effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

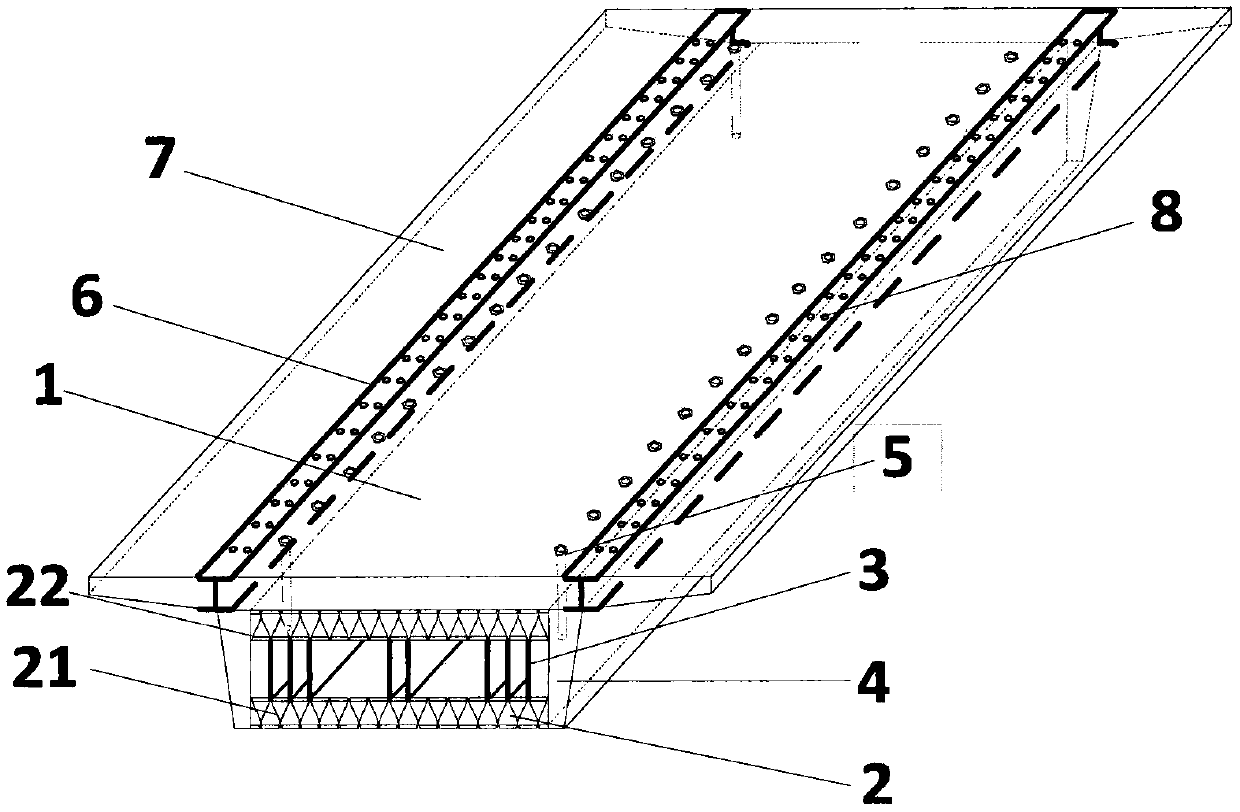

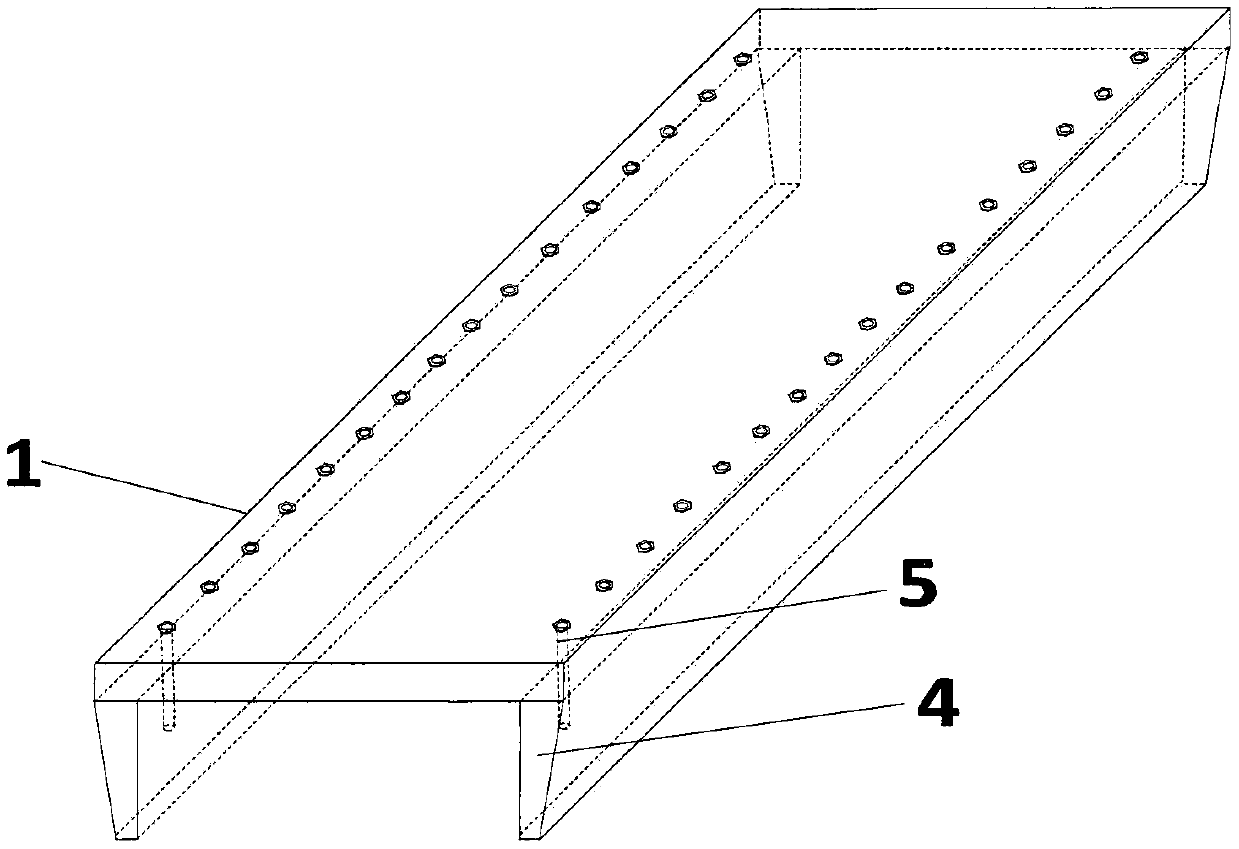

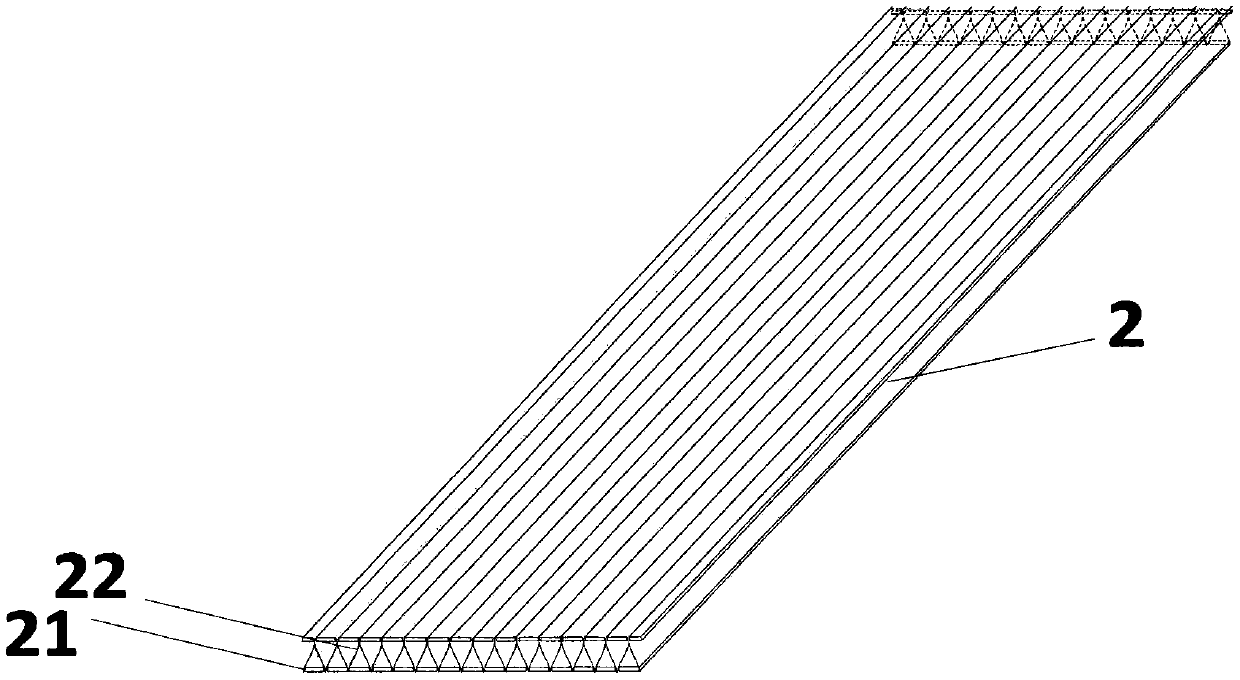

[0025] Such as Figure 1-8 , the described steel-wood composite box girder comprises CLT bridge deck 1, steel-wood composite box girder block 2, steel web 3, CLT edge web 4, screw 5, H-shaped steel 6, flange plate 7, bolt 8.

[0026] Described a kind of steel-wood composite box girder, CLT bridge deck, H-shaped steel and flange plate are provided with bolt holes, and CLT bridge deck and flange plate are respectively overlapped in H-shaped steel channel and anchored with bolts; CLT bridge deck 1 and The CLT side web 4 is connected by screws 5, the CLT side web 4 and the steel-wood composite box girder block 2 are bonded by E1 grade phenolic glue, and the lower part of the CLT bridge deck 1 and the upper part of the steel-wood composite box girder block 2 are bonded by E1 grade phenolic glue. glue for bonding, and the steel web 3 and the steel-wood composite box girder block 2 are connected together by welding.

[0027] The steel-wood composite box girder block 2 is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com