Side impact energy-absorbing high-rigidity all-aluminum light-weight door sill structure for automobile

A technology for sill beam and vehicle side, which is applied to the superstructure, superstructure sub-assemblies, vehicle parts, etc., can solve the problem of not being able to meet the requirements of lightweight design and collision safety design at the same time, and the overall deformation of the reinforced area and the non-reinforced area. Can not meet the requirements of lightweight design of automobiles, and achieve the effect of improving driving comfort, attenuating noise, reducing side impact intrusion and personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

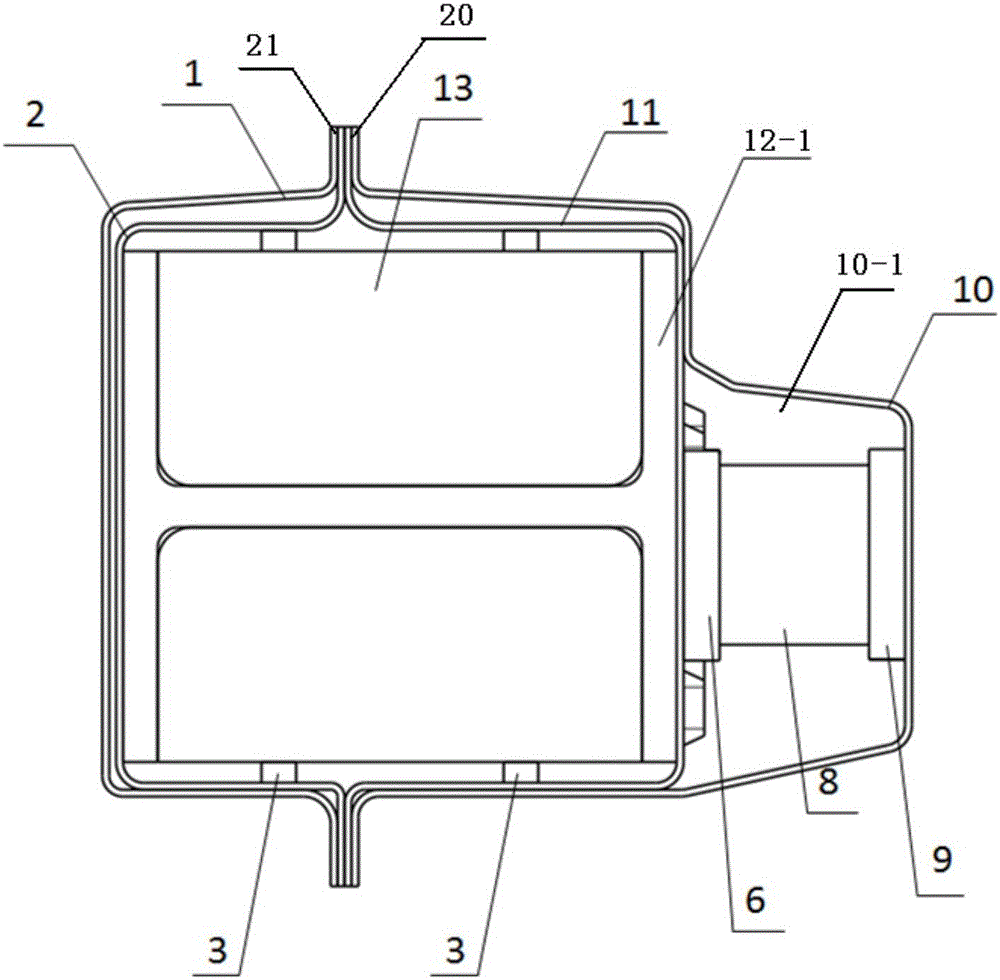

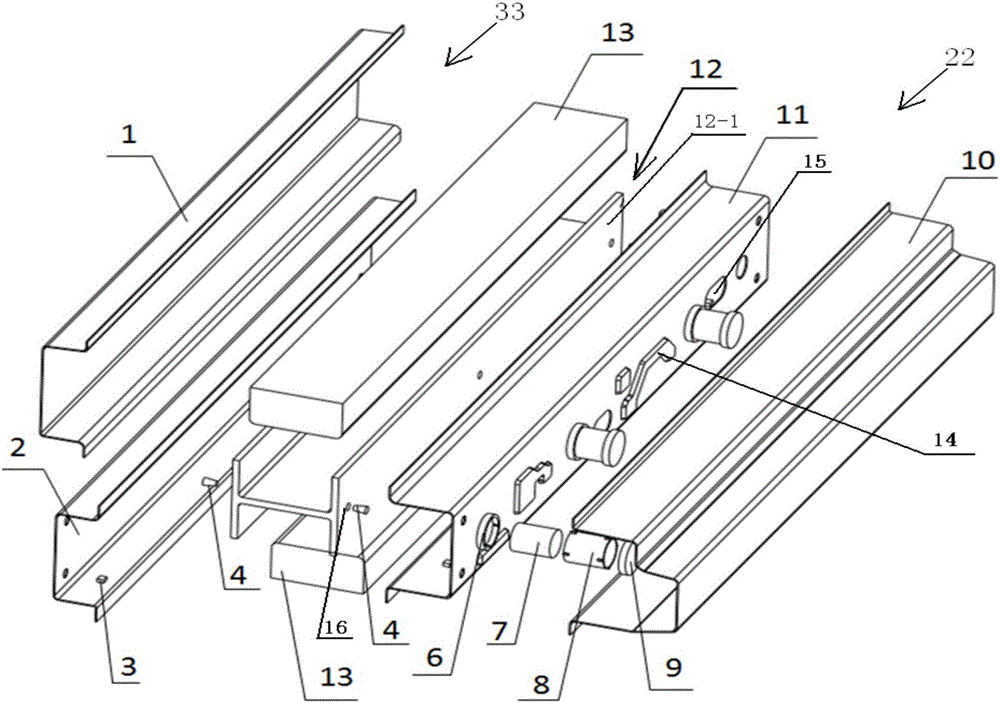

[0032] like Figures 1 to 4 shown. The invention discloses an automobile side collision energy-absorbing high-rigidity all-aluminum lightweight threshold beam structure, comprising a threshold beam frame and an I-shaped composite beam 12 wrapped in the threshold beam frame; the I-shaped composite beam 12 Aluminum foam columns 13 are respectively arranged in the upper and lower grooves; the aluminum foam columns 13 are formed by wire cutting, and the corresponding chamfers are processed, and the aluminum foam columns 13 and the grooves can be glued together. fixed. The I-shaped composite beam 12 is made of aluminum alloy.

[0033] The threshold beam frame includes an outer panel shell assembly 22 and an inner panel shell assembly 33, and the threshold beam frame is formed by combining the outer panel shell assembly 22 and the inner panel shell assembly 33, and the threshold beam frame wraps the I-shaped composite beam 12 The shells of the outer plate shell assembly 22 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com