Multi-level energy absorbing tube

An energy-absorbing tube, multi-level technology, applied in shock absorbers, mechanical equipment, transportation and packaging, etc., can solve problems such as unstable deformation modes, improve structural energy absorption, save manufacturing costs, and achieve high energy absorption efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

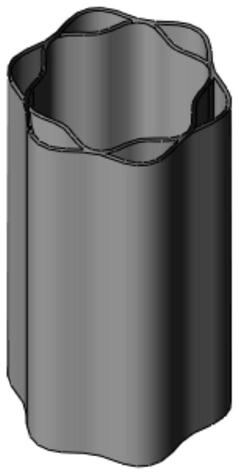

[0036] Such as Figure 2a , Figure 2b The two-layer energy absorbing tube shown (referred to as a type of energy absorbing tube in the present invention) has two sinusoidal waves spliced in its cross section. The trough of the outer sinusoidal corrugation is tangent to the peak of the inner sinusoidal corrugation. A sine wave corresponding to the sine function has the same amplitude A and wave number N, and the basic nominal radius R 0 Different, in this embodiment, the basic nominal radius R of the outer tube is maintained 0 To set a value of 25mm, change the value of the basic nominal radius of the inner tube so that the trough of the sinusoidal corrugation of the section of the outer tube is tangent to the peak of the sinusoidal corrugation of the section of the inner tube. Among them, the tube length L in this embodiment is 100 mm.

Embodiment 2

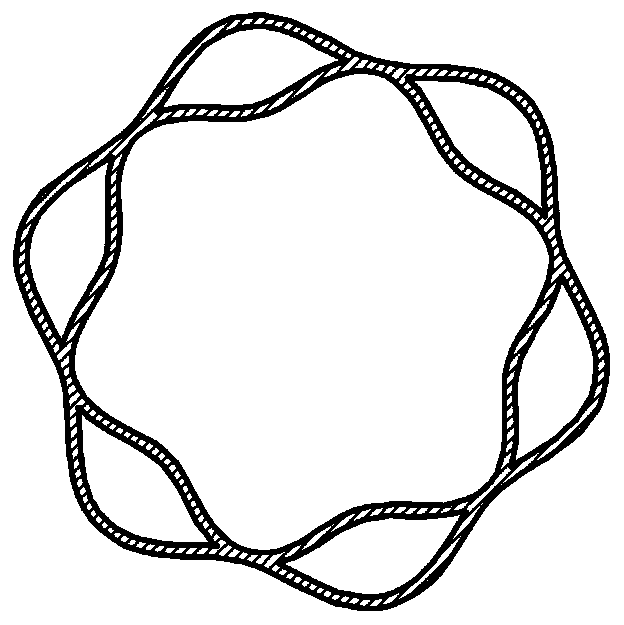

[0038] Such as image 3 Shown is another type of two-layer energy absorbing tube structure (referred to as the second type of energy absorbing tube in the present invention). The crests and troughs of the two sinusoidal corrugations spliced in the cross section are directly opposite, and the two sinusoidal corrugations correspond to Sine function amplitude A, ripple number N, basic nominal radius R 0 The same respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com