Patents

Literature

72results about How to "Increase structural weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

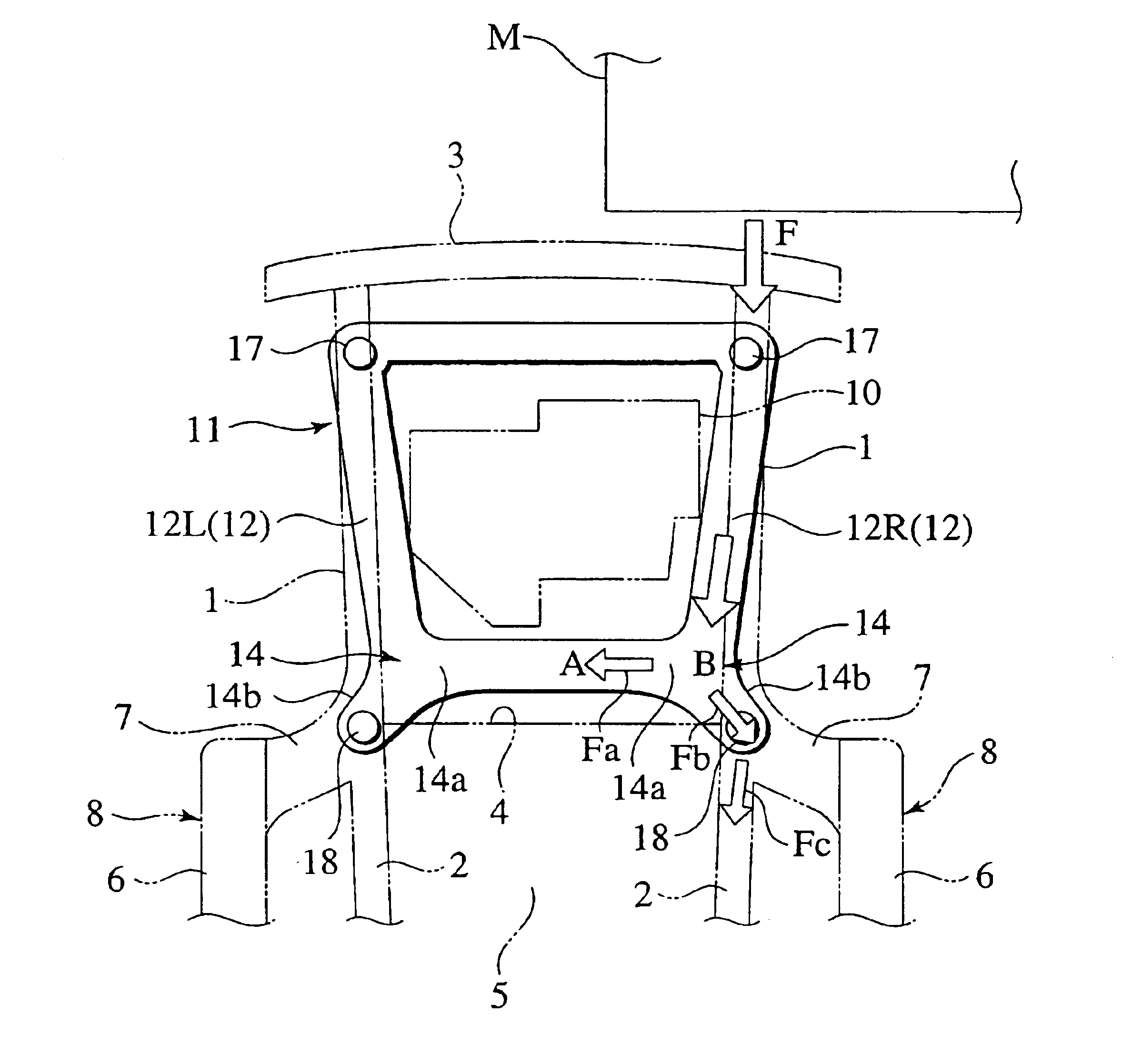

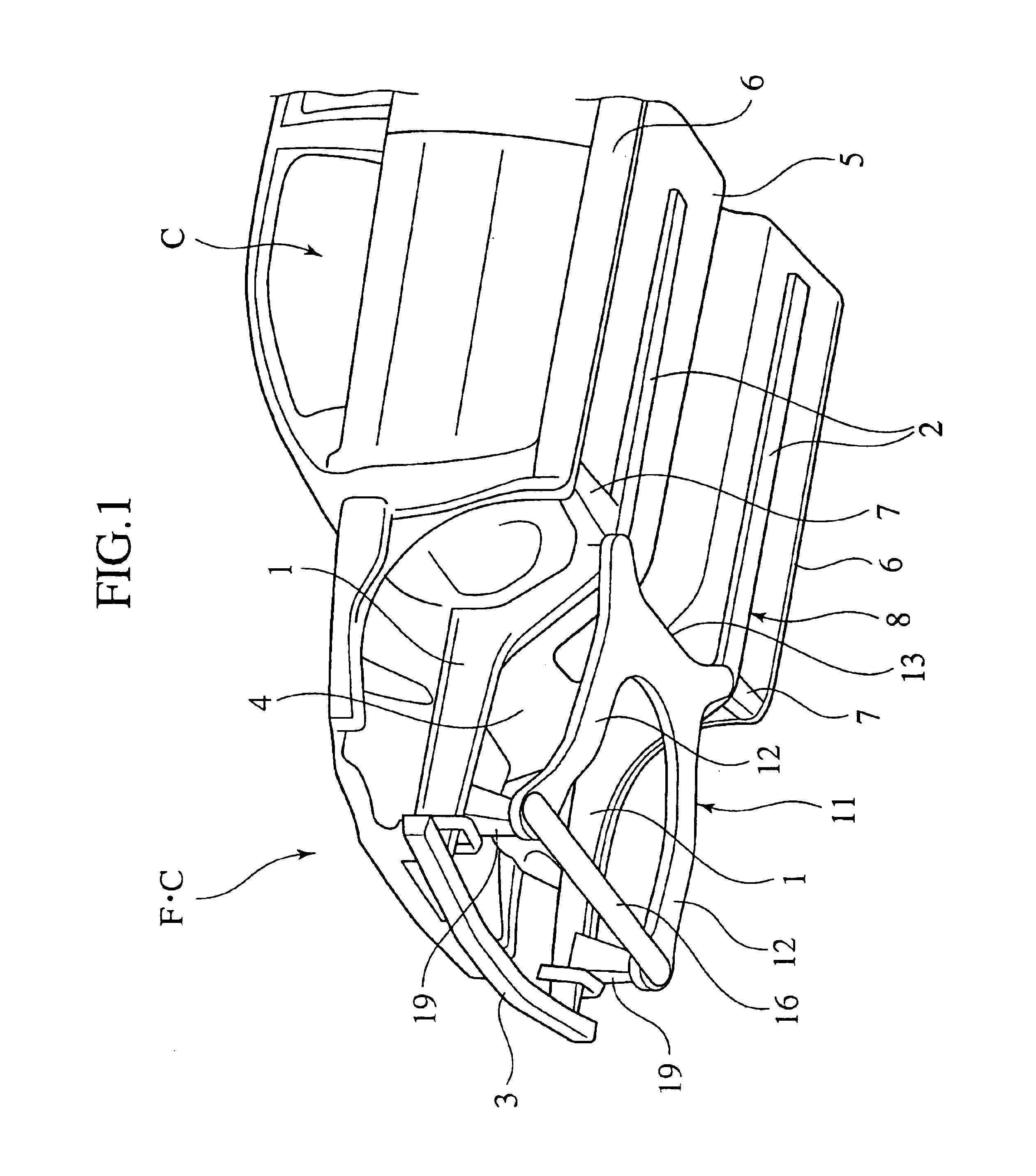

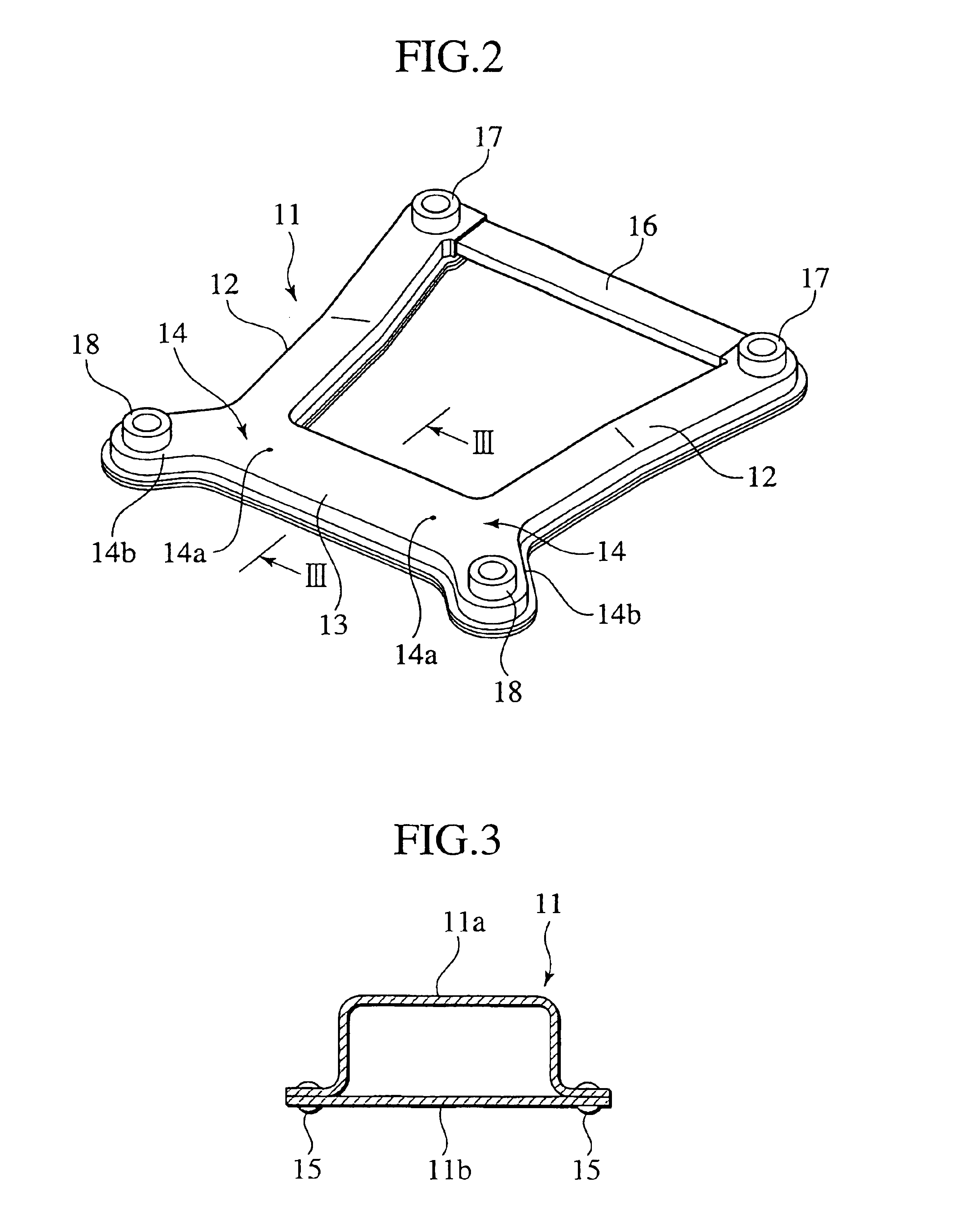

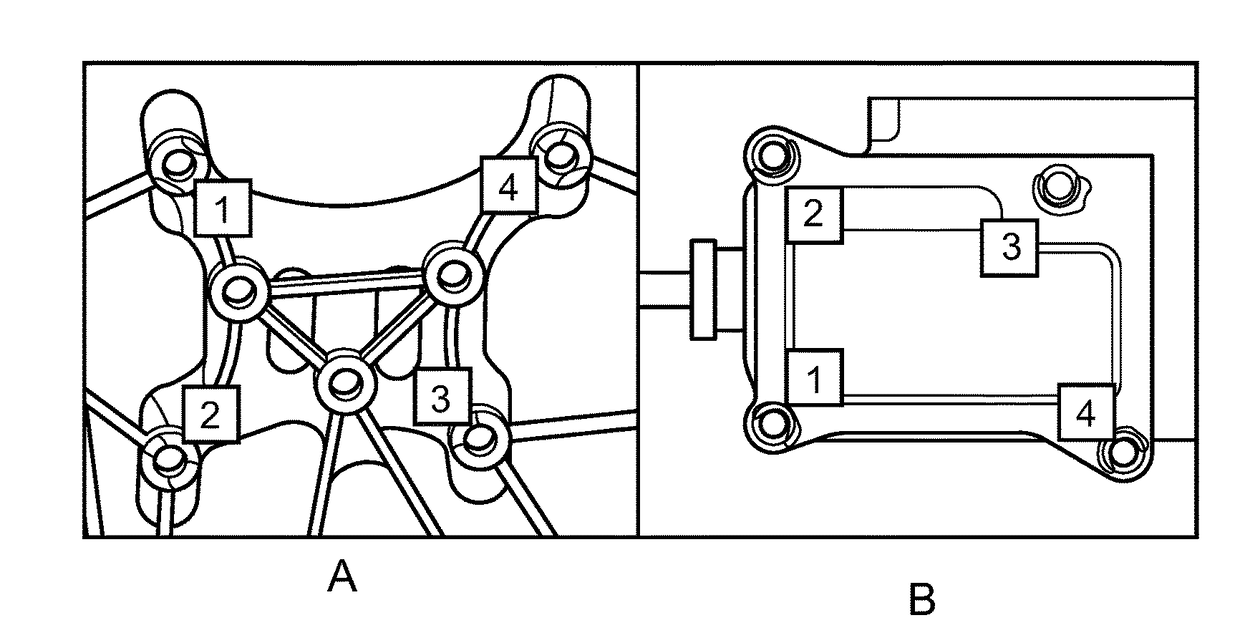

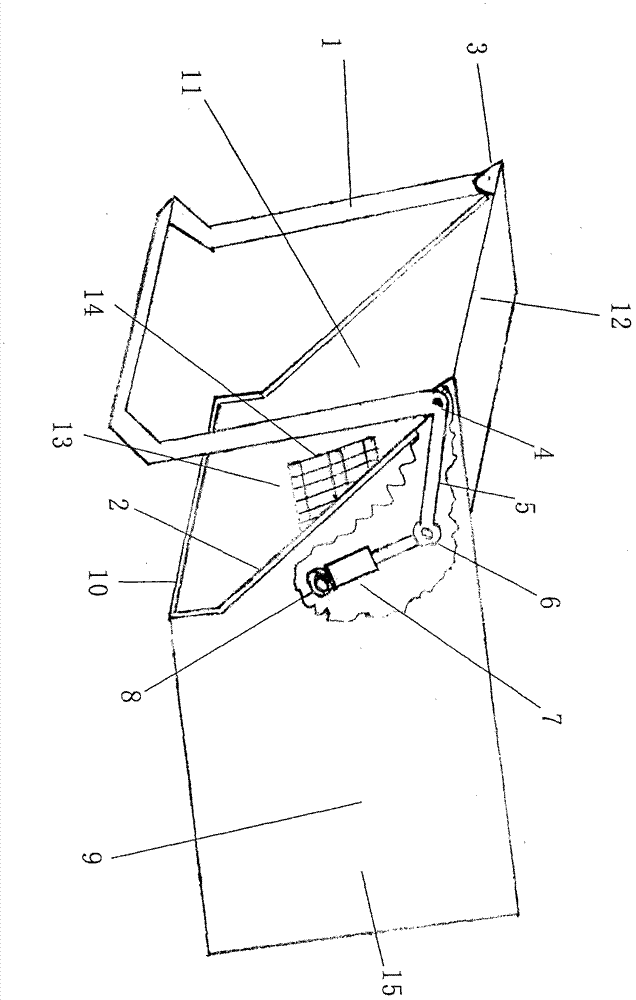

Front body structure for vehicle

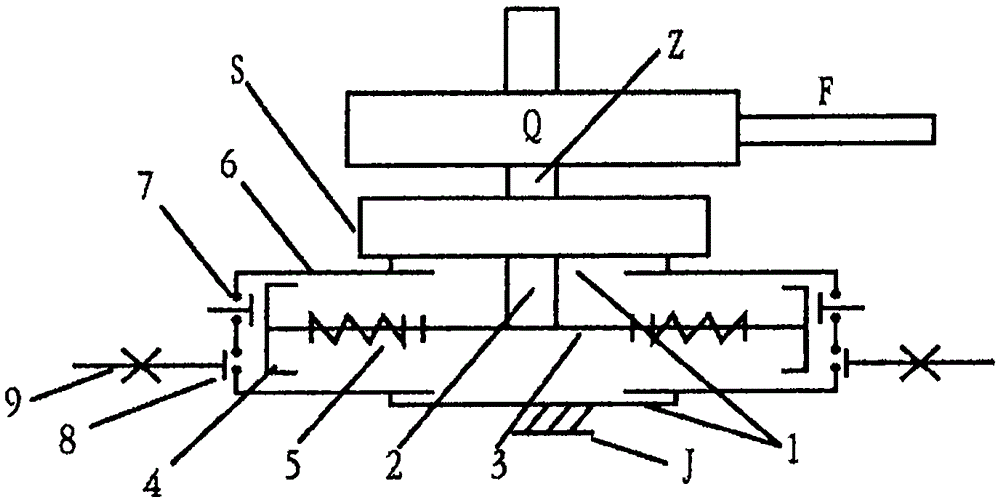

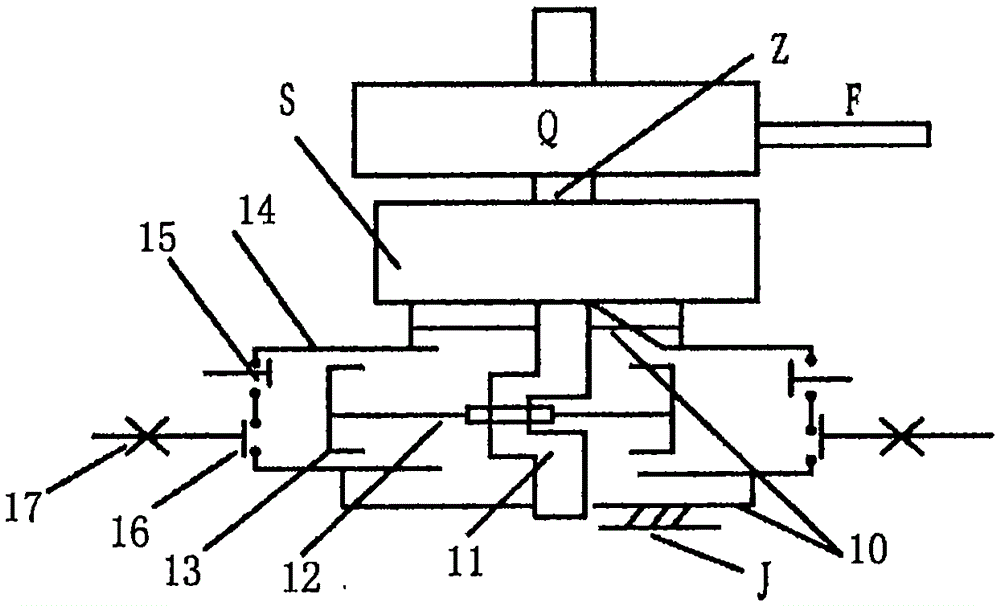

A front body structure is provided to disperse an impact load to a floor framework member through a rear end of a subframe effectively. The subframe 11 includes a left side frame 12L, a right side frame 12R and a rear frame 13. Each of the side frames 12L, 12R includes a forked part 14 having an inside branch part 14a pointing to a vehicle's inside in a width direction of the vehicle along a first route A and an outside branch part 14b pointing to a vehicle's outside in the width direction along a second route B. In operation, if an impact load F due to an offset front collision is applied on the side frame 12 in concentration, then the load F is divided into a load component Fa to be transmitted to the other side frame 12L through the inside branch part 14a and the rear frame 13 along the first route A and another load component Fb to be transmitted to the floor framework member 8 through the outside branch part 14b along the second route B.

Owner:NISSAN MOTOR CO LTD

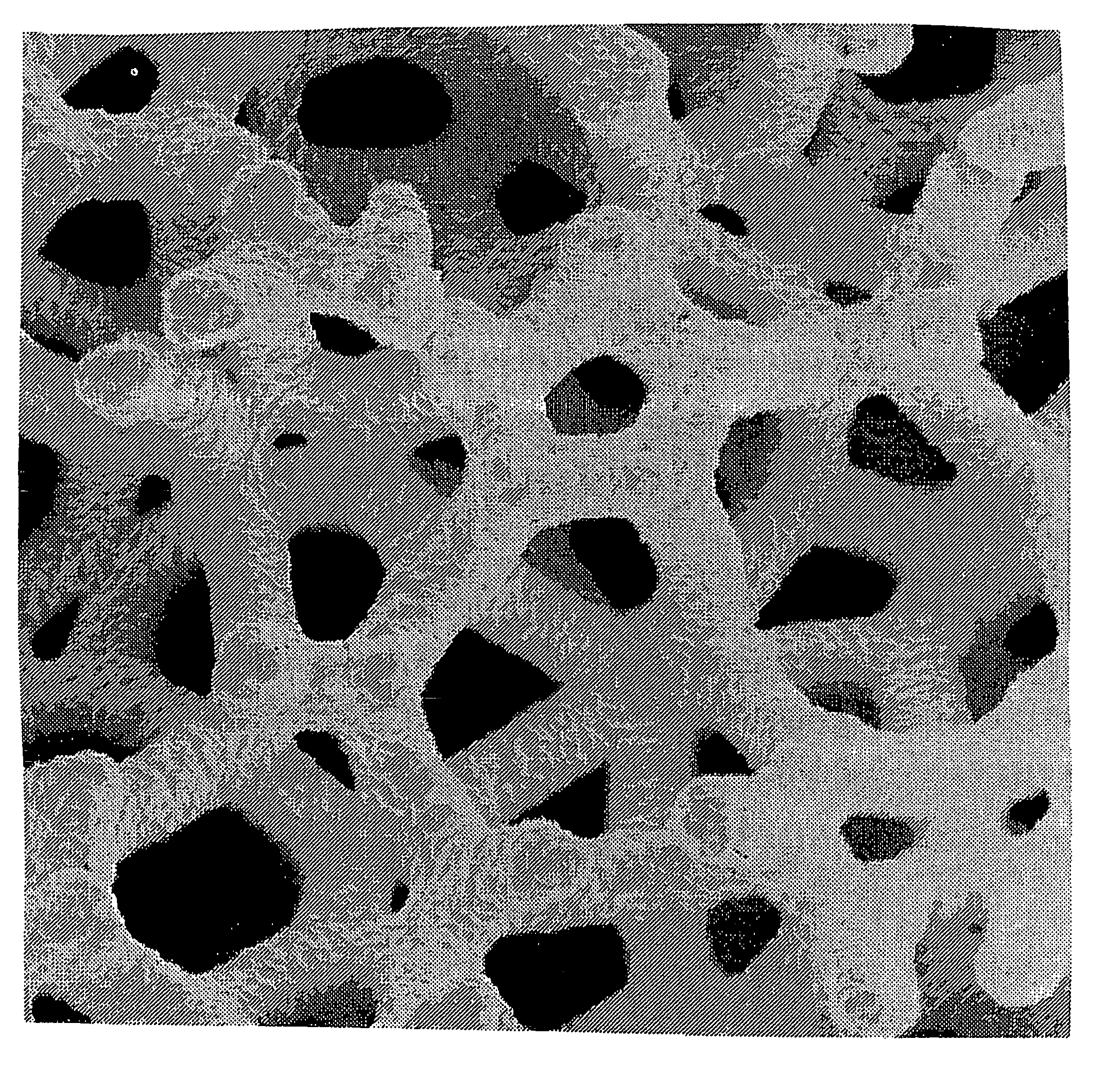

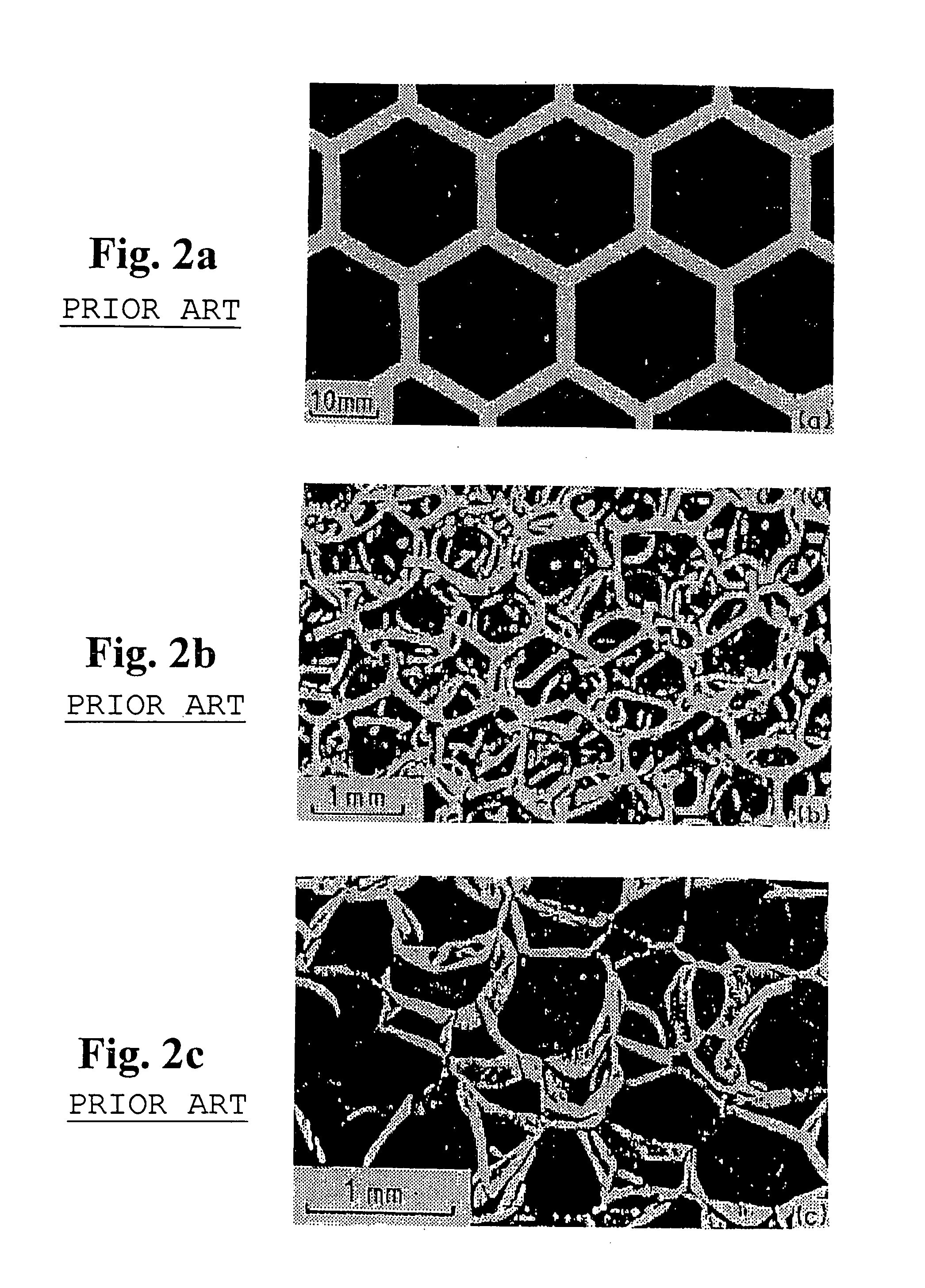

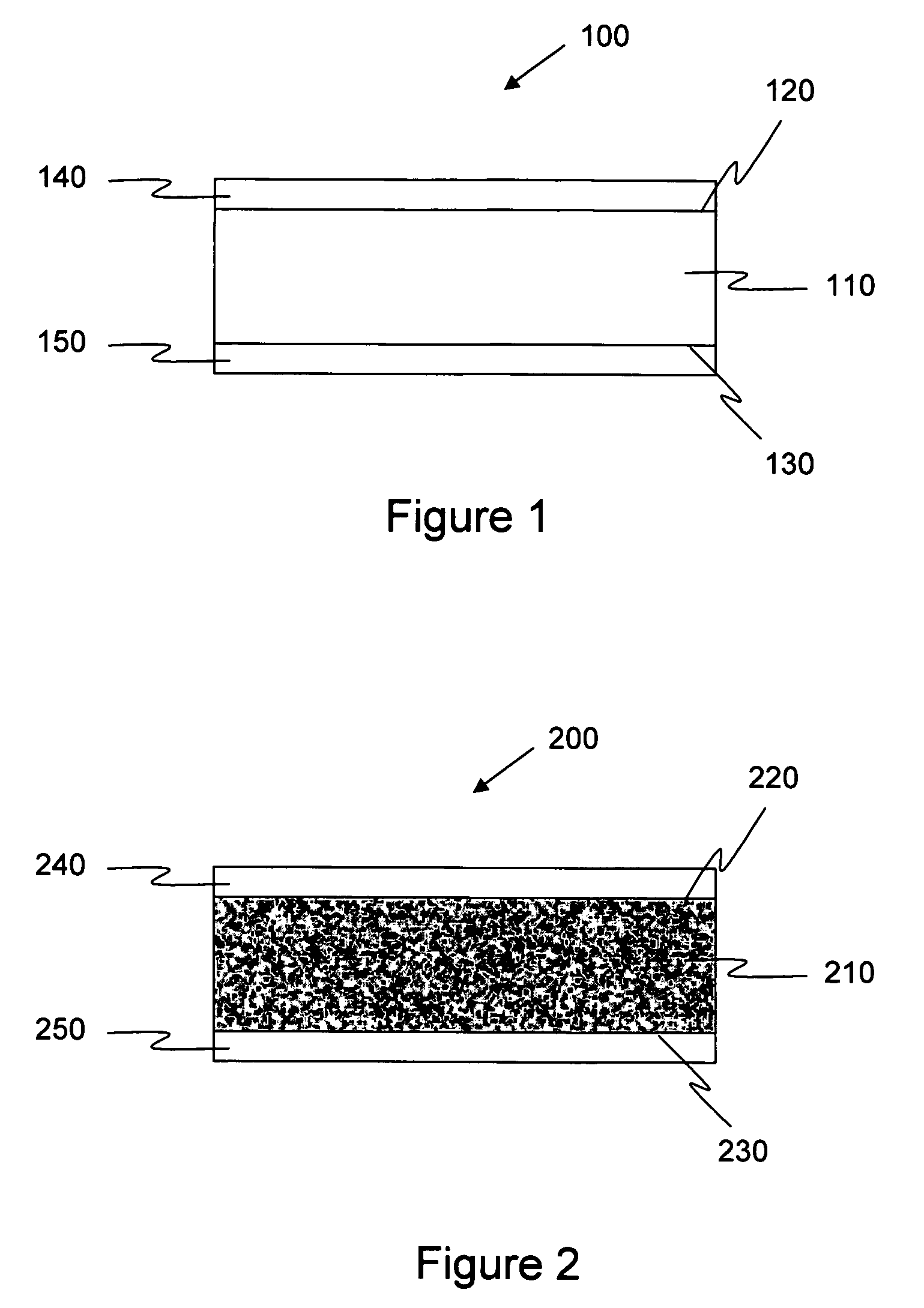

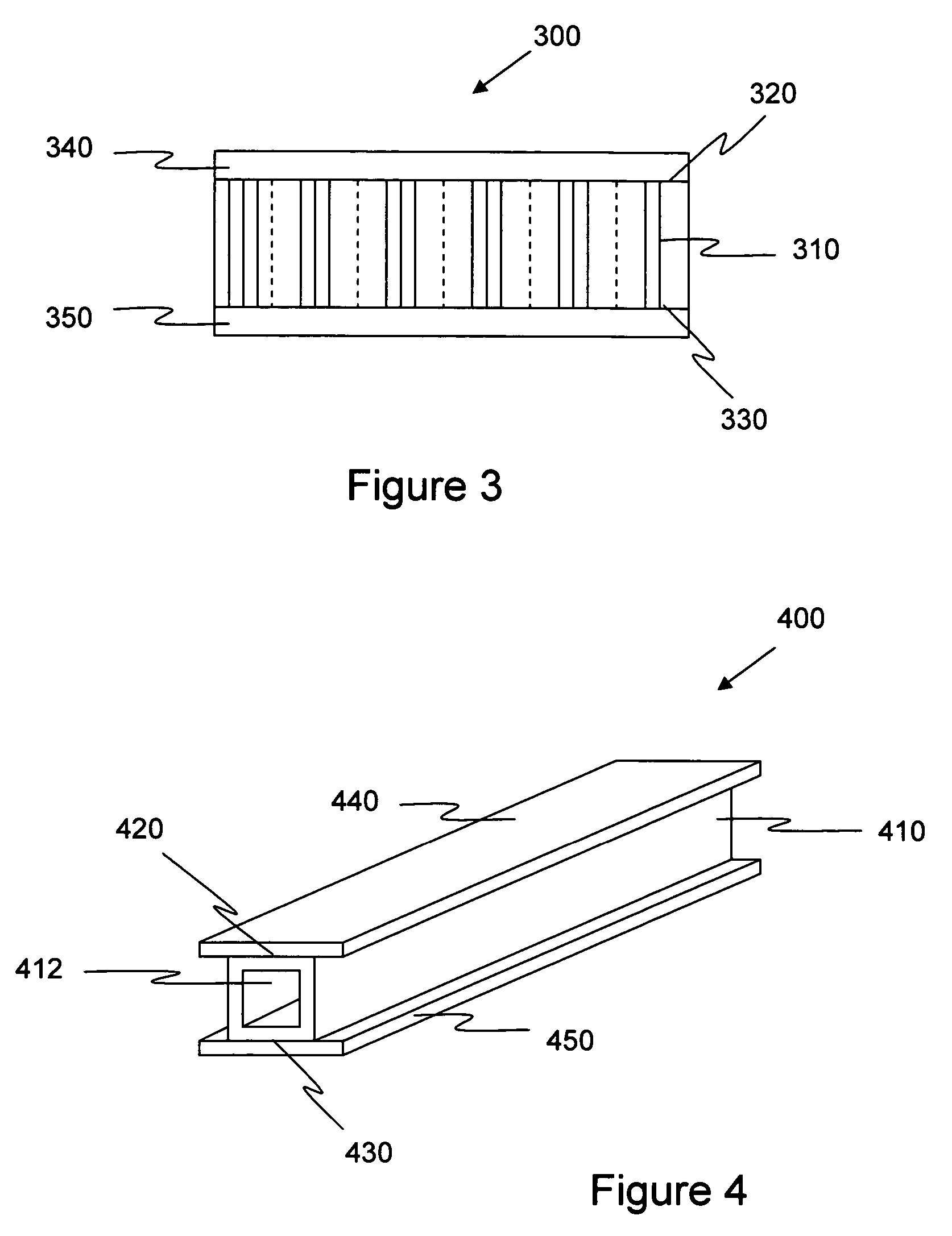

Composite foam structures

InactiveUS6929866B1Weight increaseReduce porosityMolten spray coatingCeramic layered productsPorous substrateThermal spraying

A composite rigid foam structure that has a skin or coating on at least one of its surfaces. The skin is formed in situ by thermal spray techniques. The skin is bonded substantially throughout the surface of the porous substrate to the peripheries of the pores. The skin on the average does not penetrate the surface of the substrate by more than the depth of about 2 to 5 pores. Thus, thermal spraying the skin onto the rigid foam produces a composite that is tightly and uniformly bonded together without unduly increasing the weight of the composite structure. Both thermal conductivity and bonding are excellent.

Owner:ULSTREETCARET

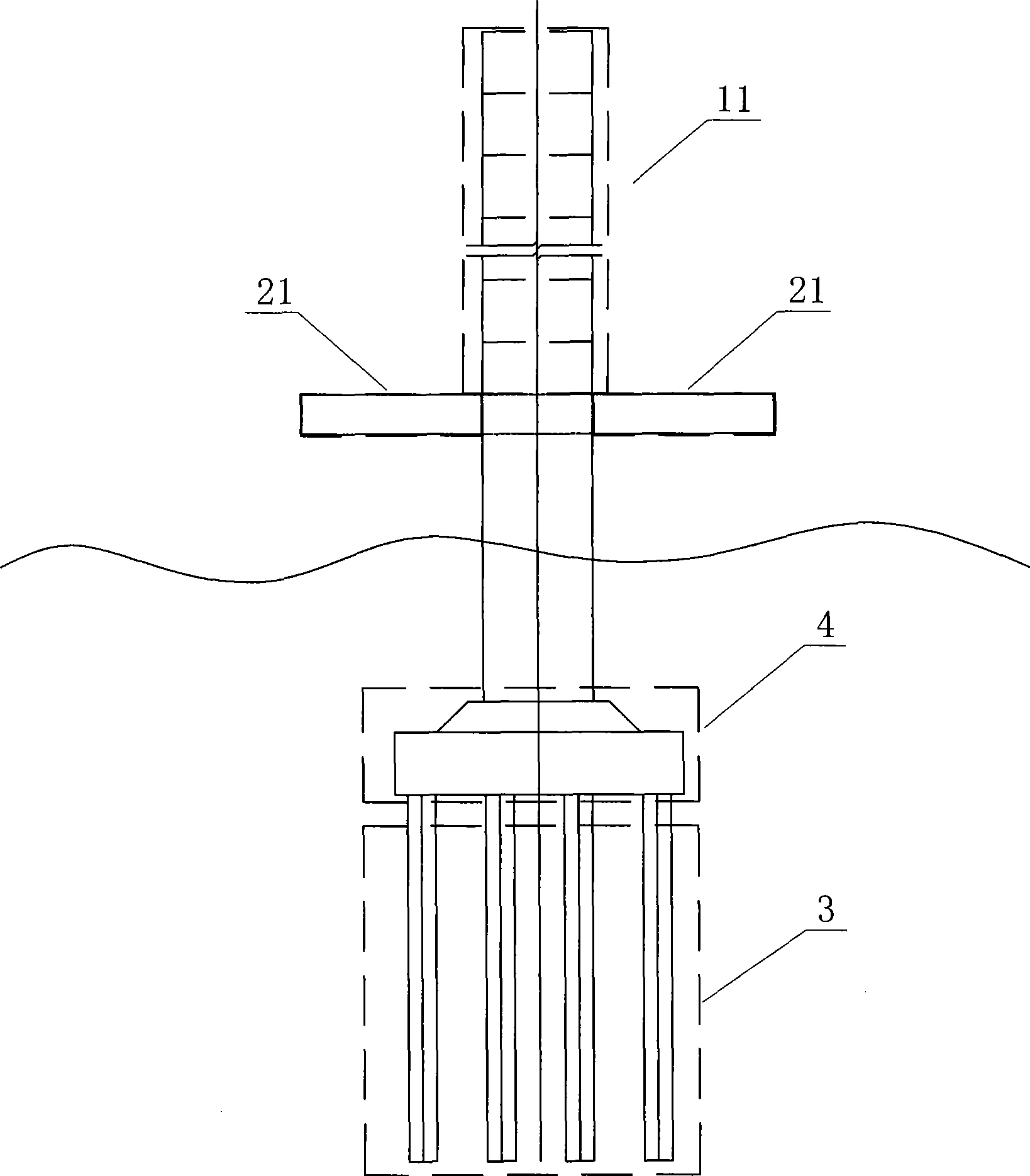

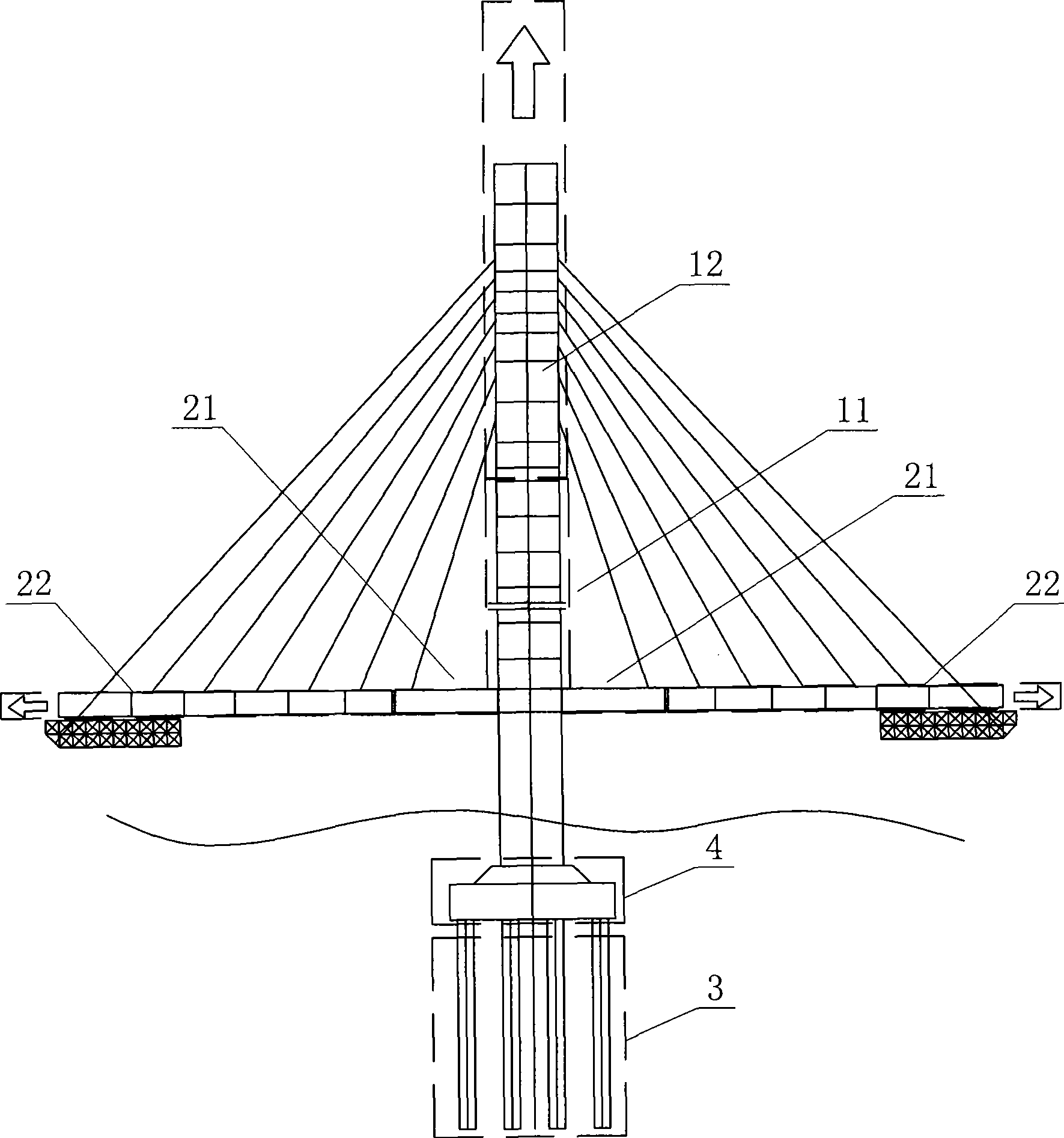

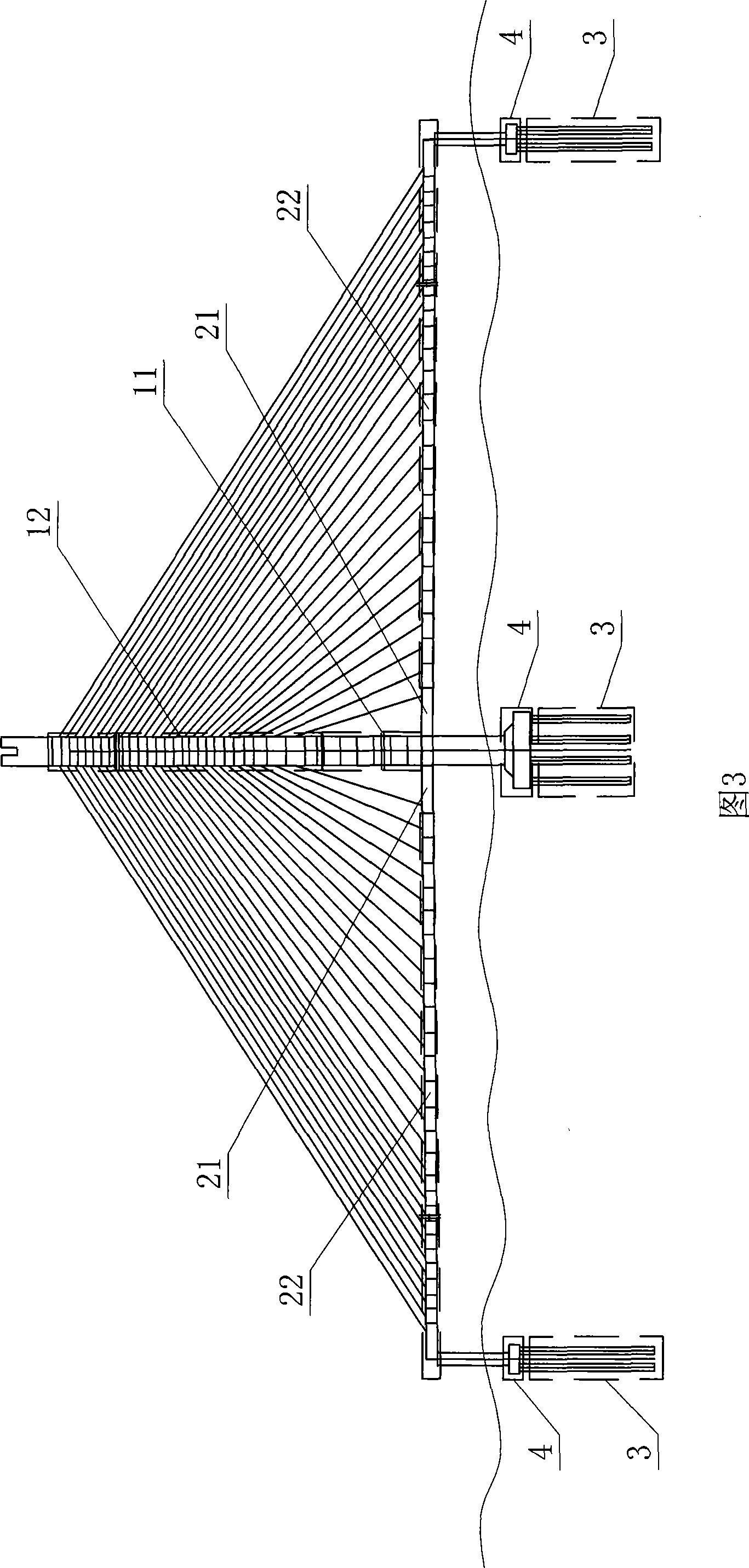

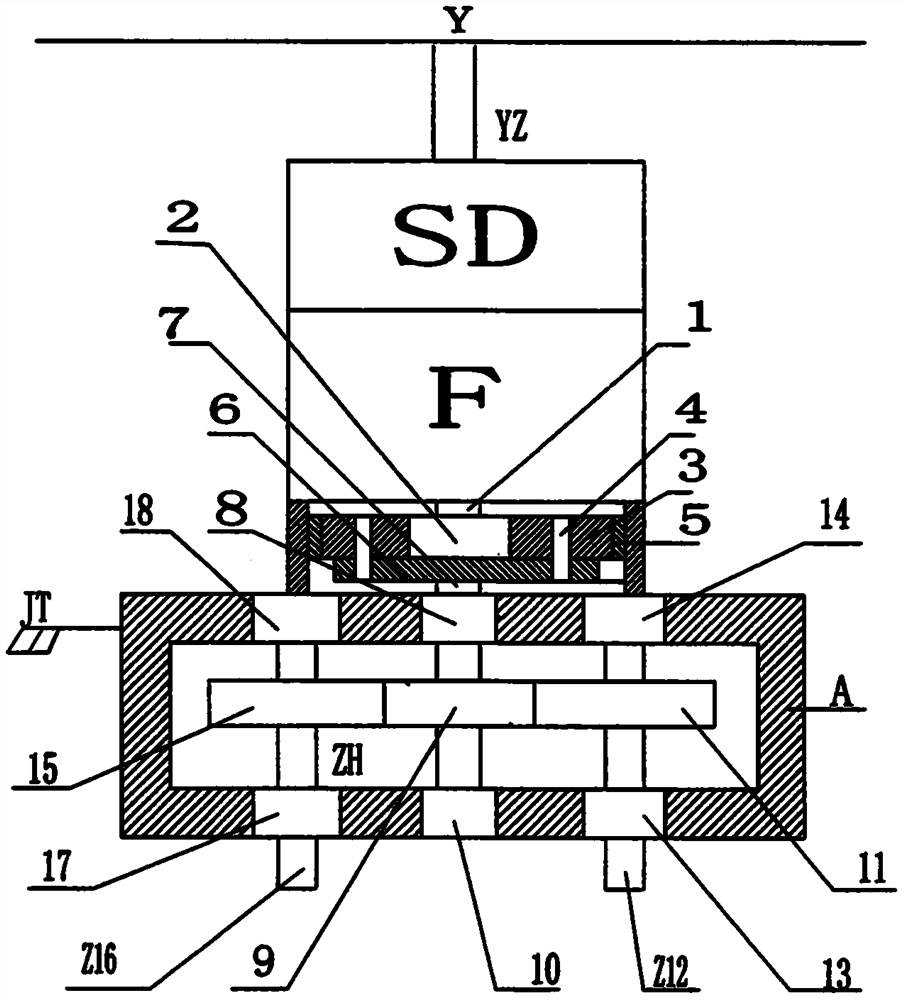

Cable stayed bridge construction method

InactiveCN101457514AImprove structural rigidityIncrease structural weightCable-stayed bridgeBridge erection/assemblyCable stayedTower

The invention relates to a construction method of a cable stayed bridge, which comprises the following steps of: firstly constructing the non-cable hanging section structure of a main tower column and simultaneously constructing the block-by-block structure of a main beam, simultaneously constructing the cable hanging section structure of the main tower column and the main beam, that is, constructing the cable hanging section structure of the main tower column along a vertical direction to be heightened in segments and simultaneously constructing the main beam block-by-block correspondingly towards both sides, and executing the one-by-one hanging and the tensioning of the stayed cables till the main tower column is completed and the main beam is folded. Due to the segmented construction of the main tower column, the construction of the hanging cable and the main beam is executed after a certain quantity of segments of the main tower column are completed and the construction conditions for hanging the stayed cable are met, and simultaneously, the main tower column is also continuously constructed in segments upwards so as to achieve the simultaneous construction of the main tower column and the main beam, therefore, the tower column and the beam are simultaneously constructed so as to effectively shorten the construction period and ensure the safety of the tower column structure during the construction.

Owner:GUANGDONG FOUND ENG GRP CO LTD +1

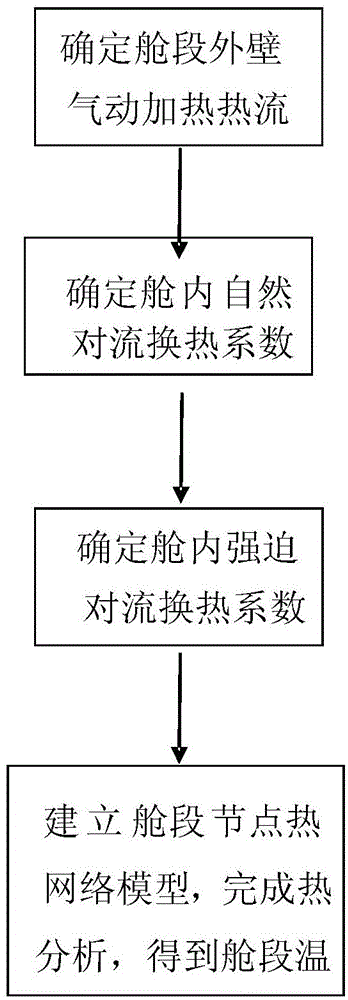

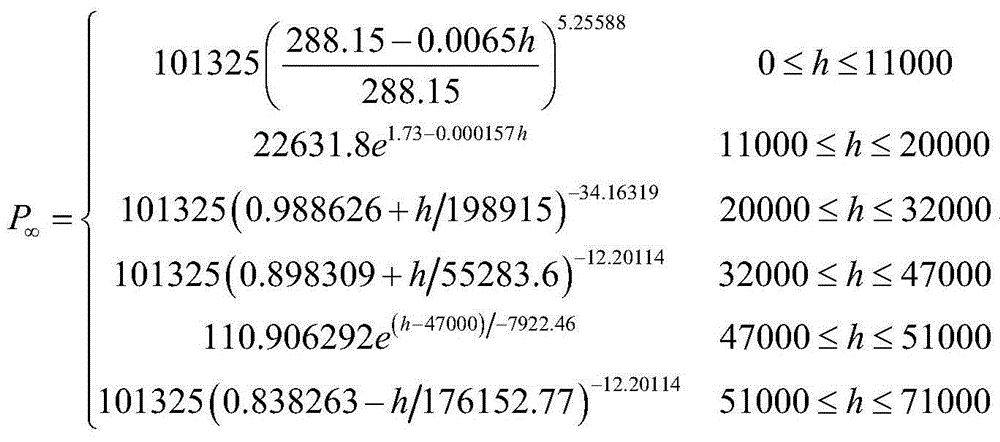

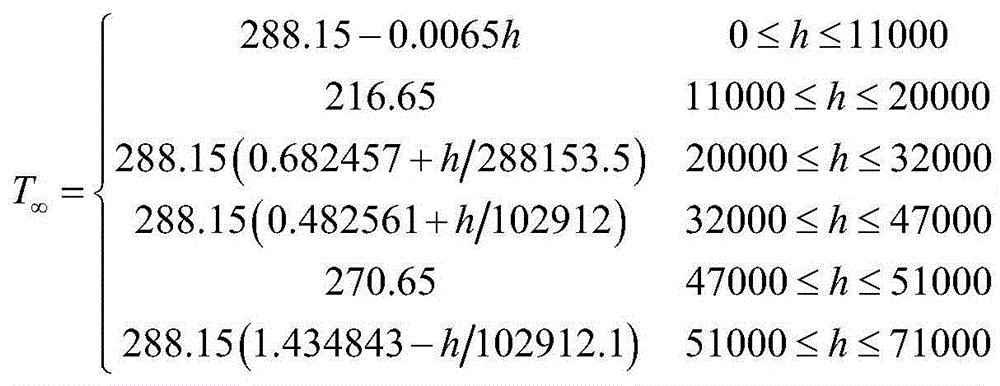

Method for determining temperature field distribution of cabin of carrier rocket in flight phase in atmospheric layer

ActiveCN104820748AIncrease structural weightReliable design basisSpecial data processing applicationsEngineeringRocket

The invention relates to a method for determining temperature field distribution of a cabin of a carrier rocket in a flight phase in an atmospheric layer. The method comprises a first step of determining an aerodynamic heating thermal flow qh changing along with the flight height and acting on the outer wall of the cabin; a second step of determining an average natural convection heat transfer coefficient alpha n of the shell surface of an instrument in a closed cavity of the cabin changing along with the flight height; a third step of determining a forced convection heat transfer coefficient alpha f of interior of the cabin caused by flight accelerated speed and constant leakage of gas in the cabin; and a fourth step of building a cabin node thermal network model, finishing thermal coupling analysis, and obtaining the cabin temperature field distribution. The method comprehensively considers the impact of aerodynamic heating outside the cabin, air natural convection in the cabin and forced convection on the cabin thermal environment, thereby effectively solving the problem of determination of temperature field distribution of the cabin of the carrier rocket in the flight phase in the atmospheric layer.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

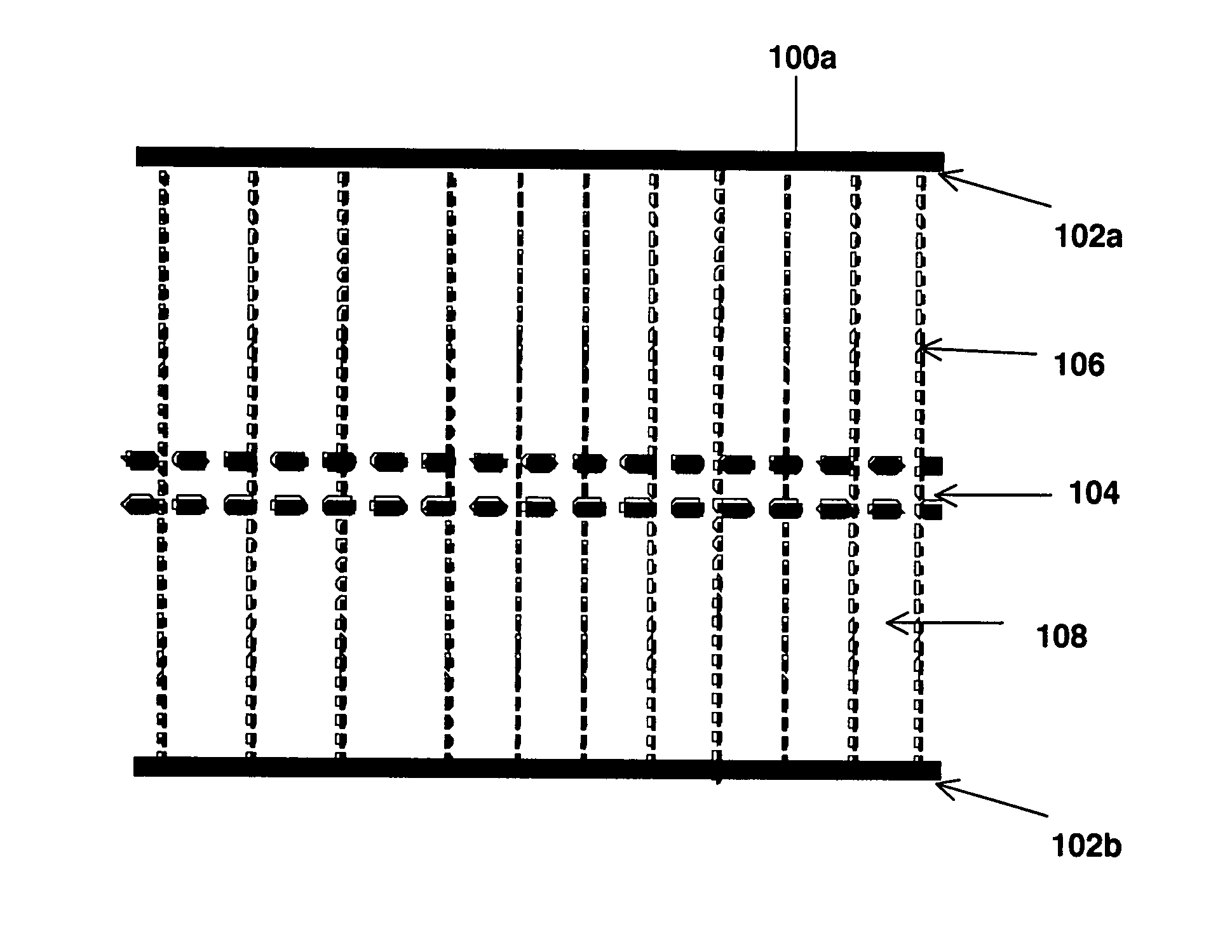

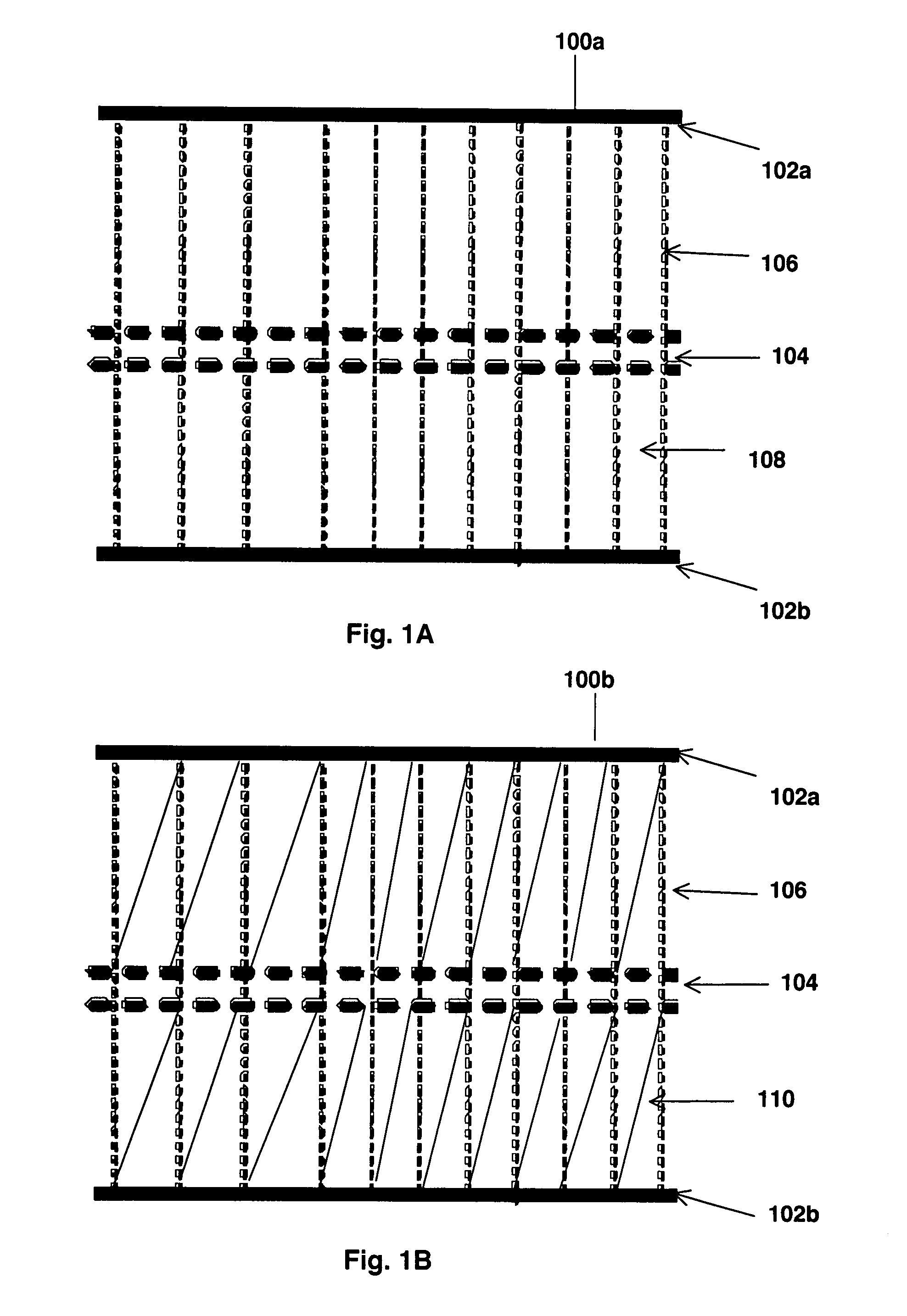

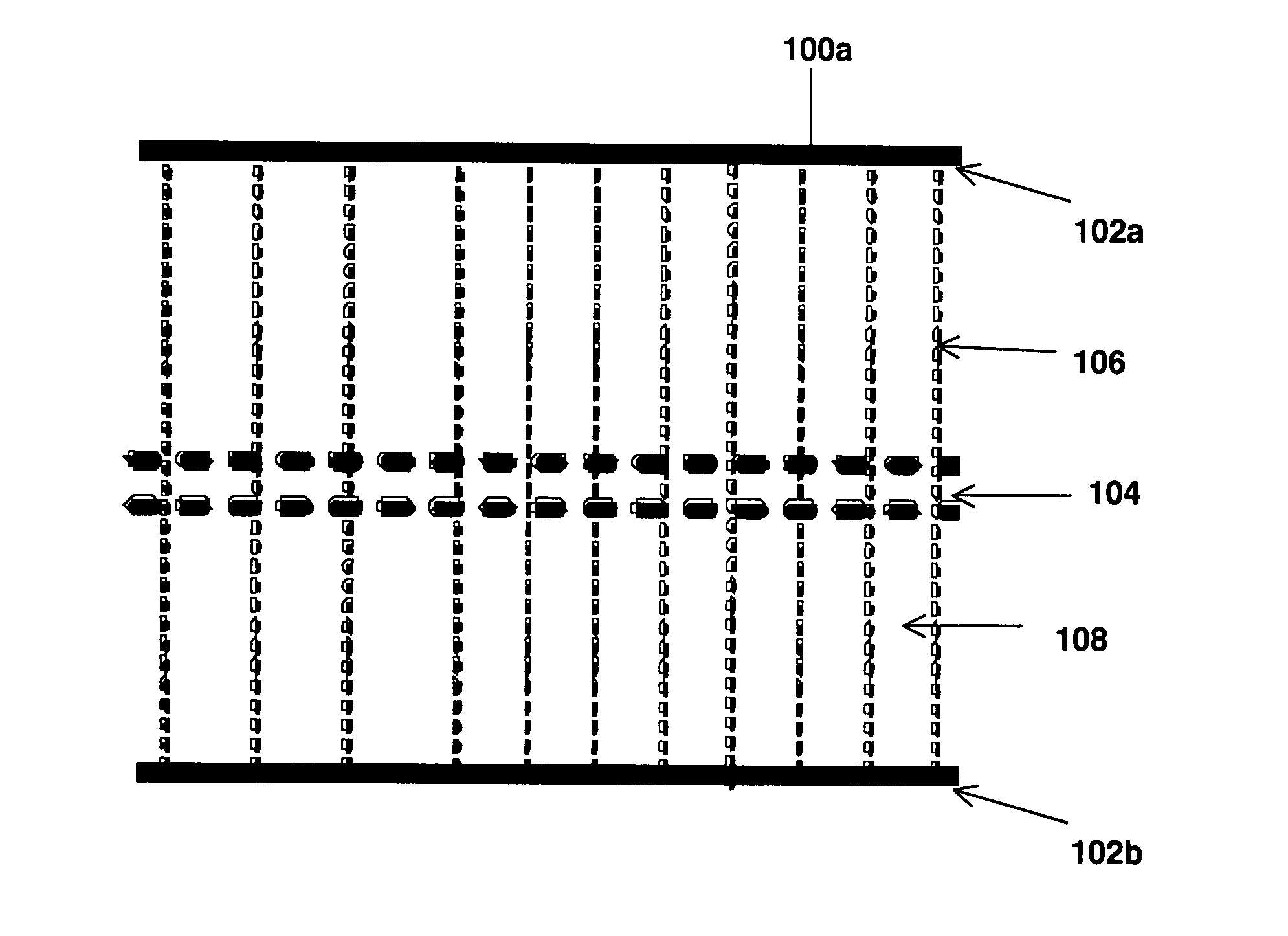

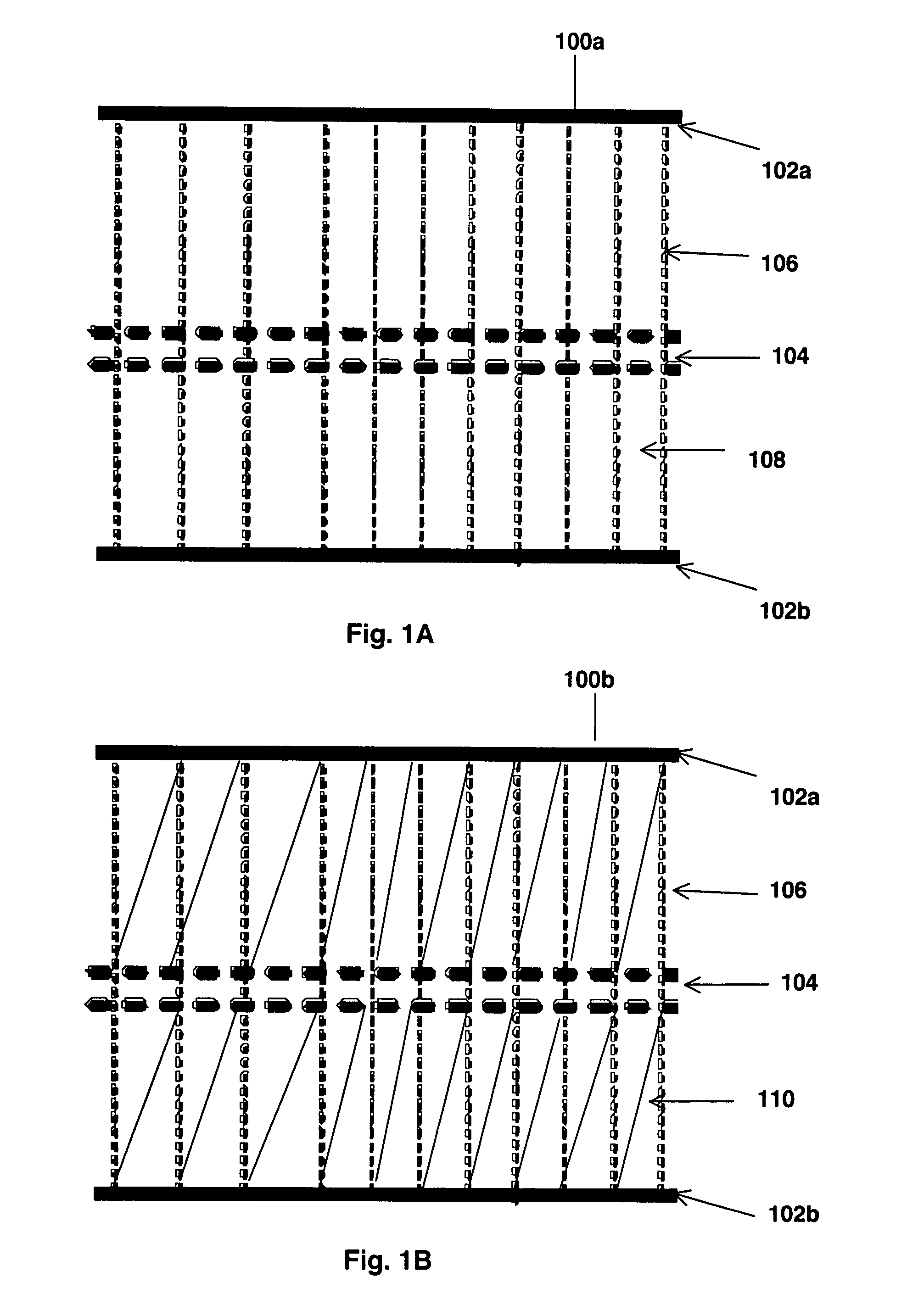

Methods and structures for sandwich panels with improved resistance to ballistic penetration

InactiveUS20110005382A1High specific strengthImprove the immunityCosmonautic vehiclesArmoured vehiclesSandwich panelBuilding construction

Provided herein methods and structures for construction of light weight sandwich panels or load-bearing panels having improved ballistic protection. The methods disclosed can facilitate construction of a hybrid core comprising ballistic fabrics and deformable pins that exhibit superior resistance to ballistic penetration. The methods and structures of the present disclosures can be advantageously used in many applications, such as armored vehicles.

Owner:MARYLAND AT BALTIMORE COUNTY UNIV OF

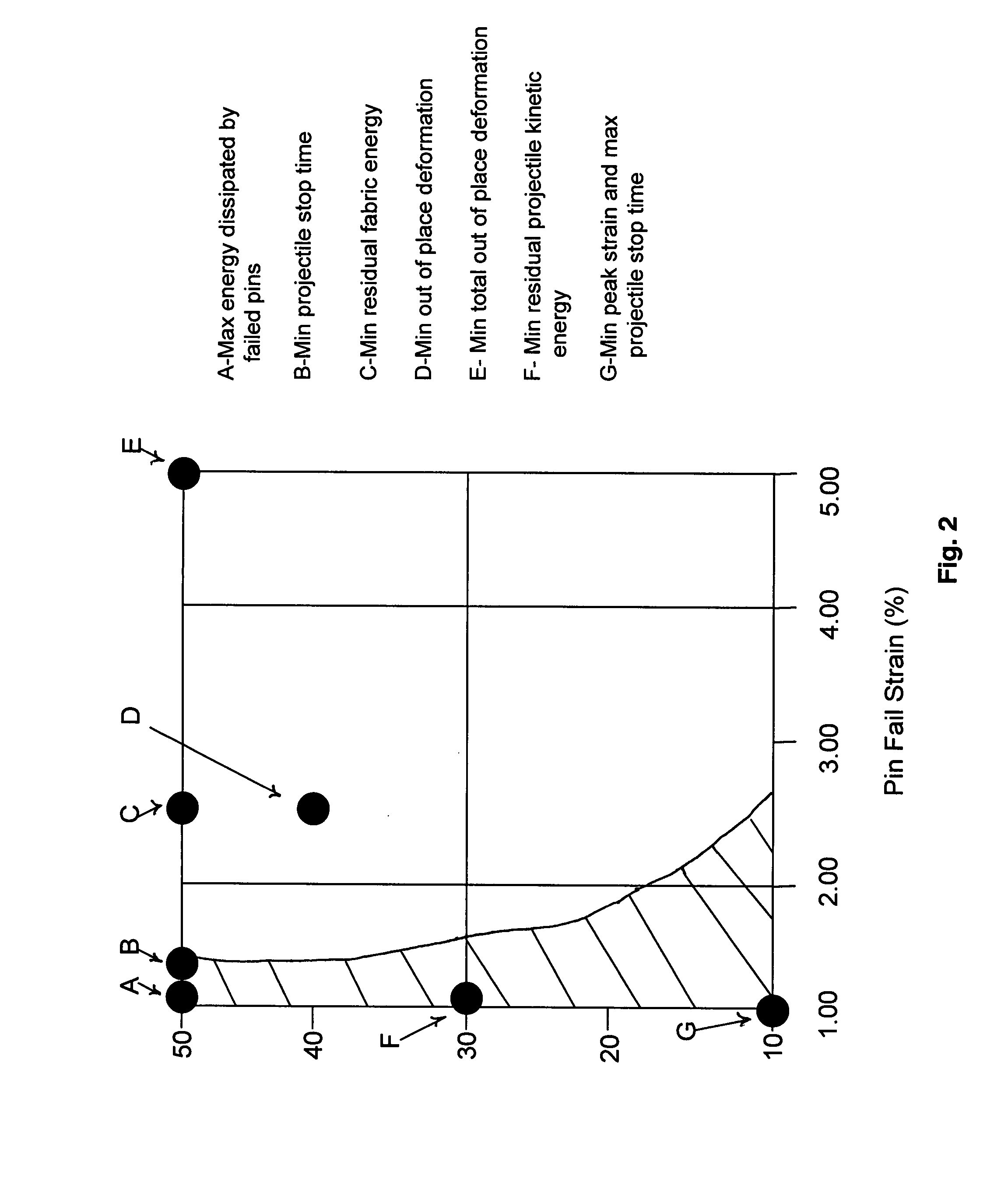

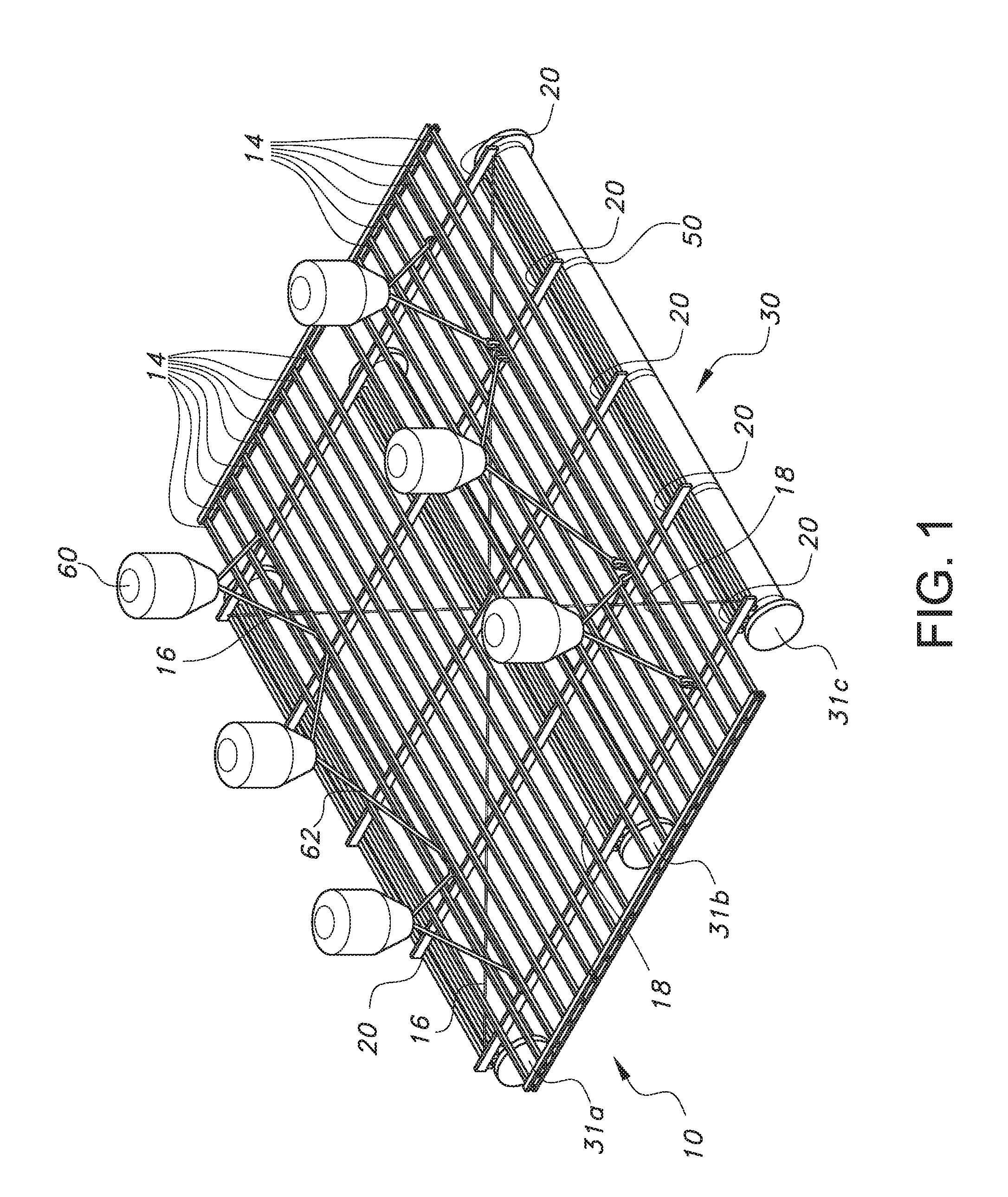

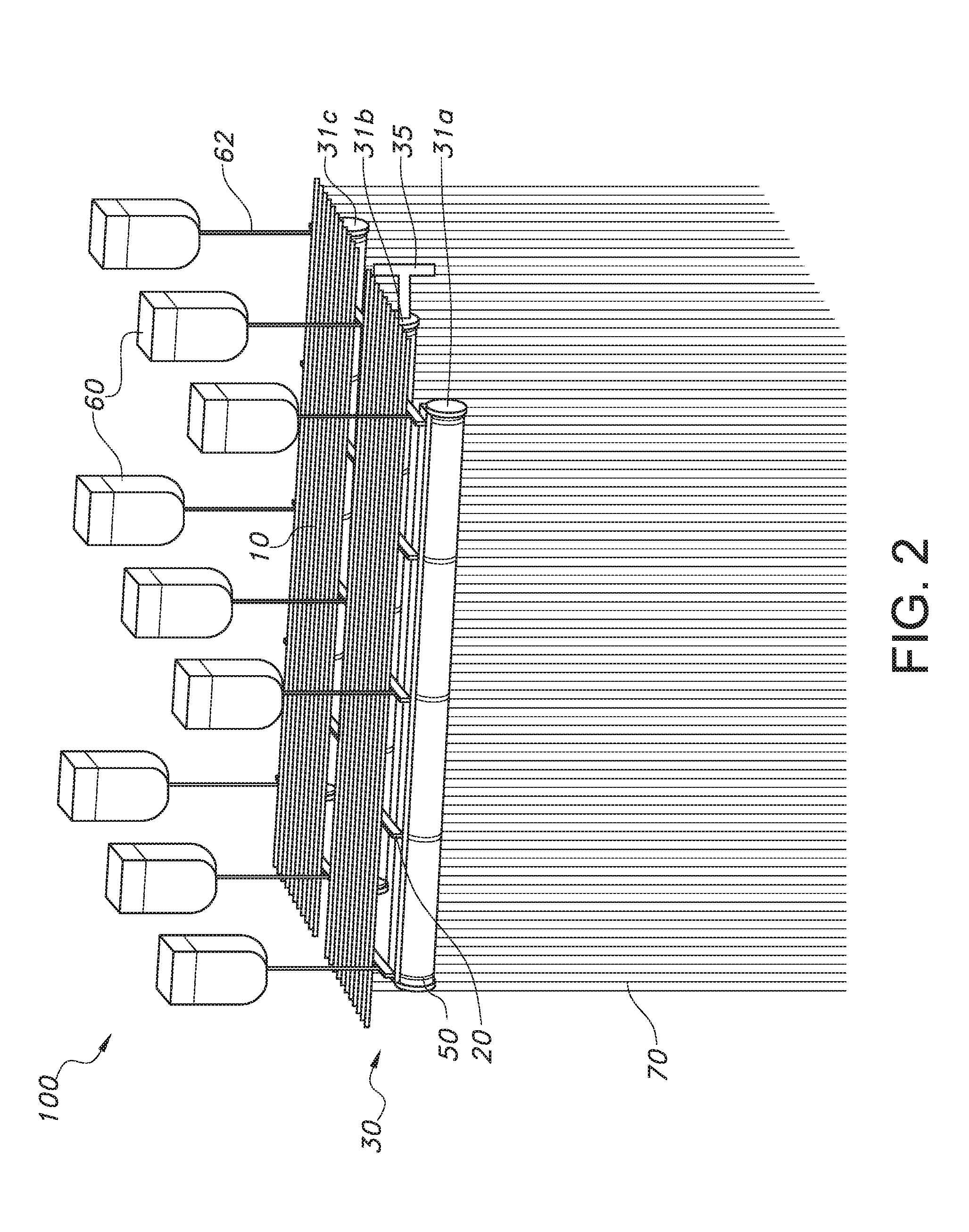

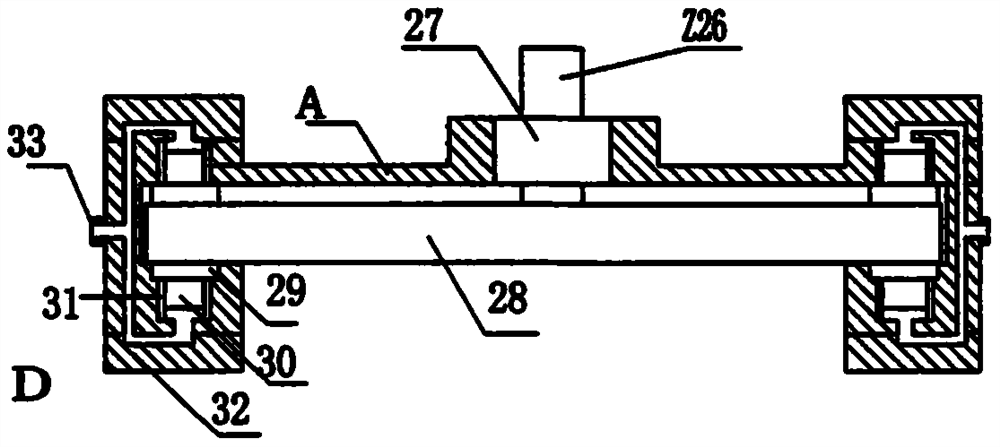

Modular submersible aquaculture raft

ActiveUS20170027136A1Avoid ice damageIncrease structural weightWaterborne vesselsClimate change adaptationControl systemEngineering

A submersible raft device that is primarily used for aquaculture farming. The raft device has a raft surface, a buoyance support structure, and a submersion control system. The buoyance support structure and the submersion control system allow the raft to be submerged to a desired depth beneath the ocean surface. When used for certain kinds of aquaculture farming, such as mussel farming, submerging the raft below the surface protects the raft, as well as the mussels growing on ropes suspended from the raft, from damage in times of hazardous sea conditions.

Owner:NEWELL CARTER

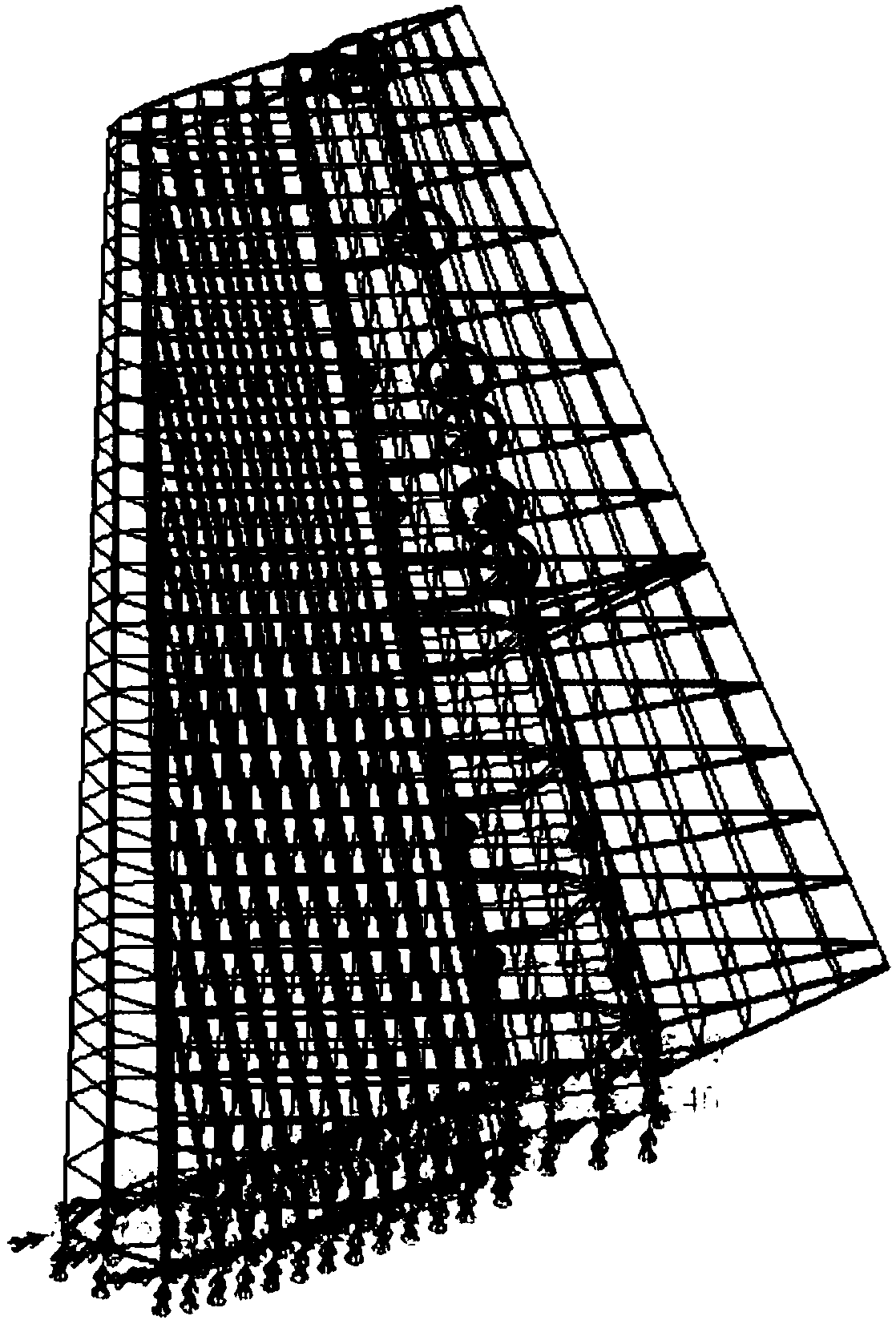

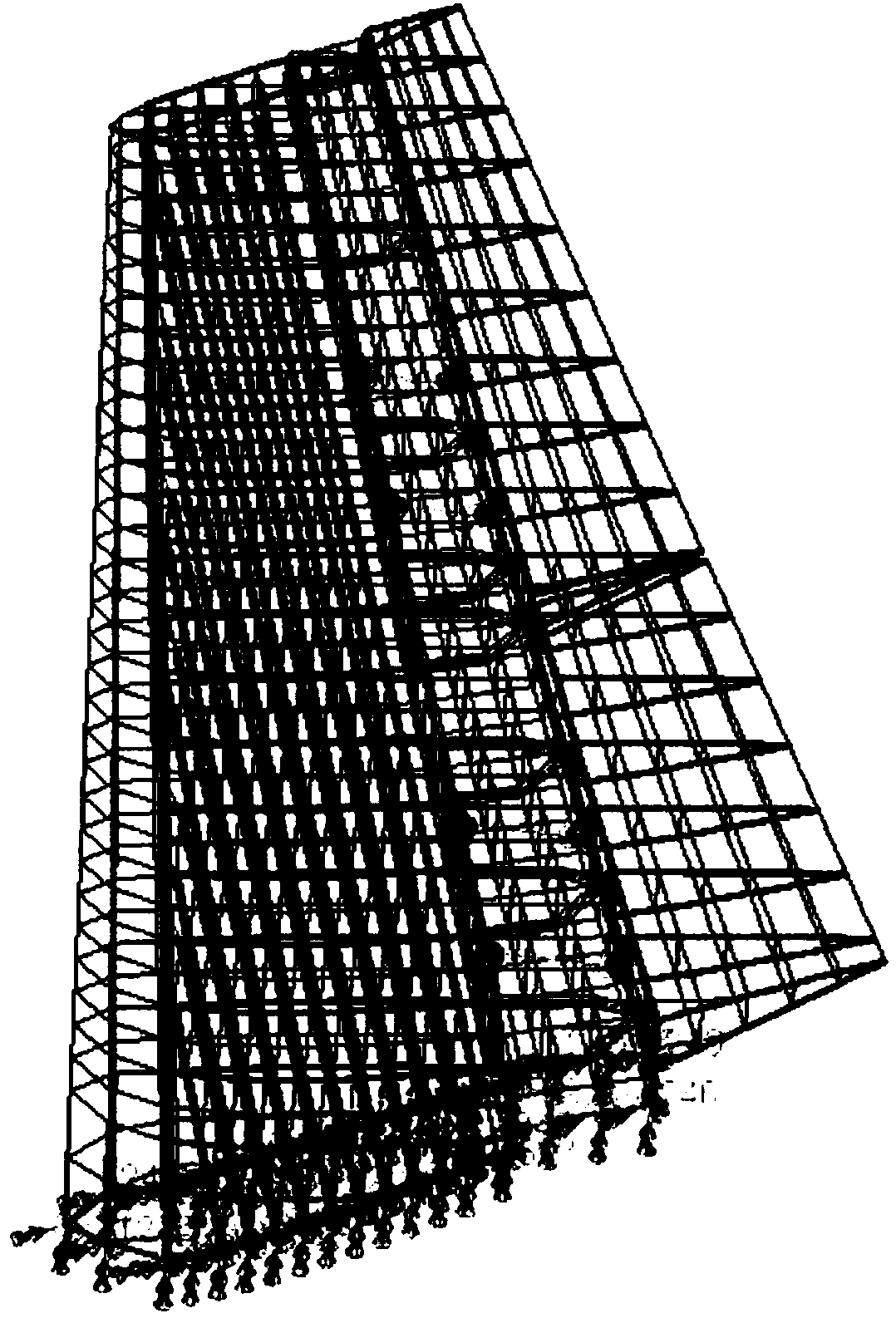

Manufacturing method of light aerofoil with super-high aspect ratio and high lift-drag ratio and aerofoil manufactured thereby

The invention discloses a manufacturing method of a light aerofoil with super-high aspect ratio and high lift-drag ratio and an aerofoil manufactured thereby. At present, some used optimized design methods for improving the strength and the rigidity of the aerofoil with the high aspect ratio have the limited improvement space; and if a method for increasing geometrical characteristic parameters of the sections of the plasmodium is adopted, the structure weight of the aerofoil needs to be increased and the effect is poor. By the manufacturing method adopted by the invention, these problems are solved. According to the overall configuration of an aircraft, the aerofoil is divided into a plurality of sections; tensile wires are arranged according to a certain mode section by section. The research result shows that the original bending function of the aerofoil is replaced by the tension of the tensile wires and the impaction of the aerofoil, and under the premise that the structure weight is basically not increased, the rigidity and the strength of the aerofoil with the high aspect ratio are greatly improved, and the pneumatic elastic deformation is reduced to be within 10 percent of the traditional aerofoil. The manufacturing method is very important for the practical application of the aerofoil with super-high aspect ratio, the cruising efficiency of the aircraft can be greatly improved, and the fuel consumption and the cost are reduced.

Owner:AERODYNAMICS NAT KEY LAB

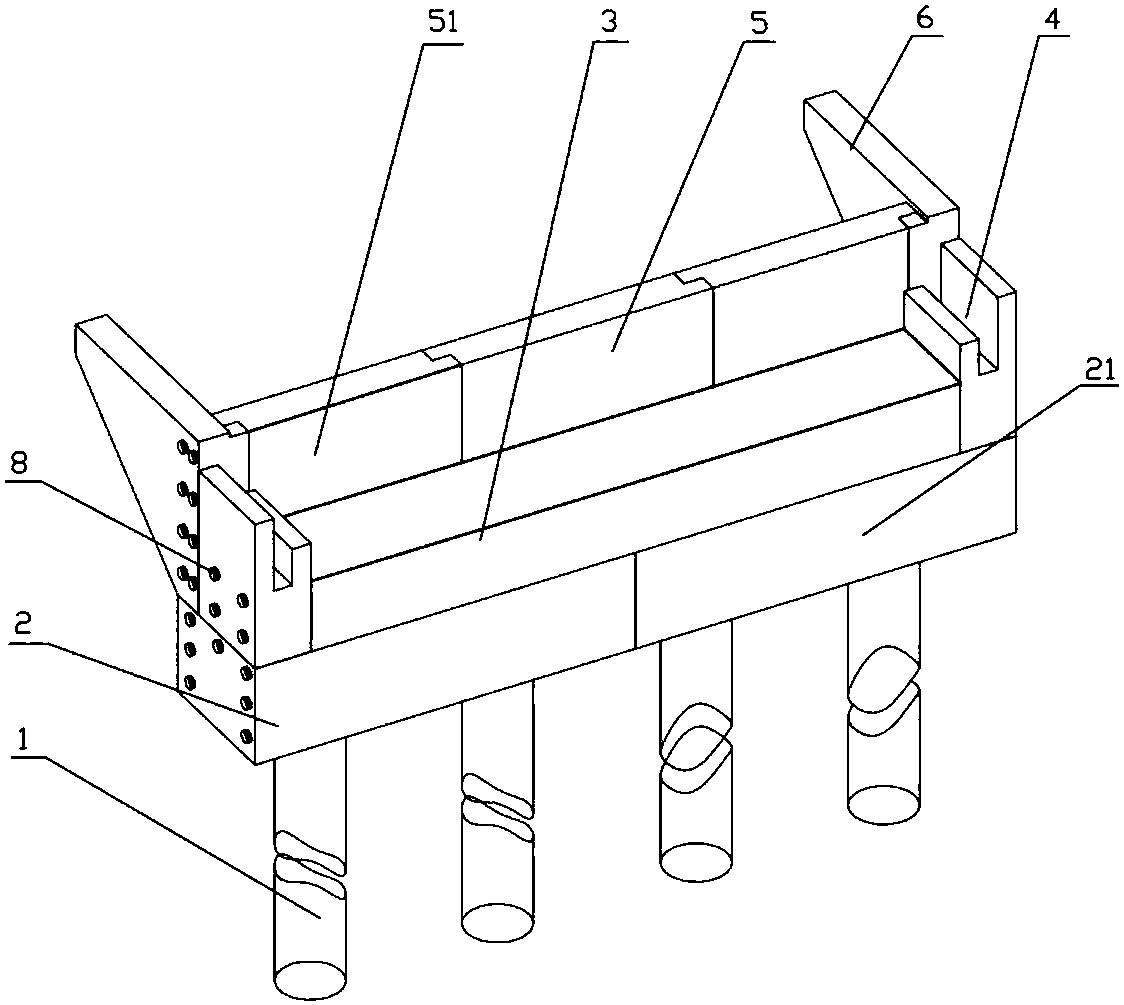

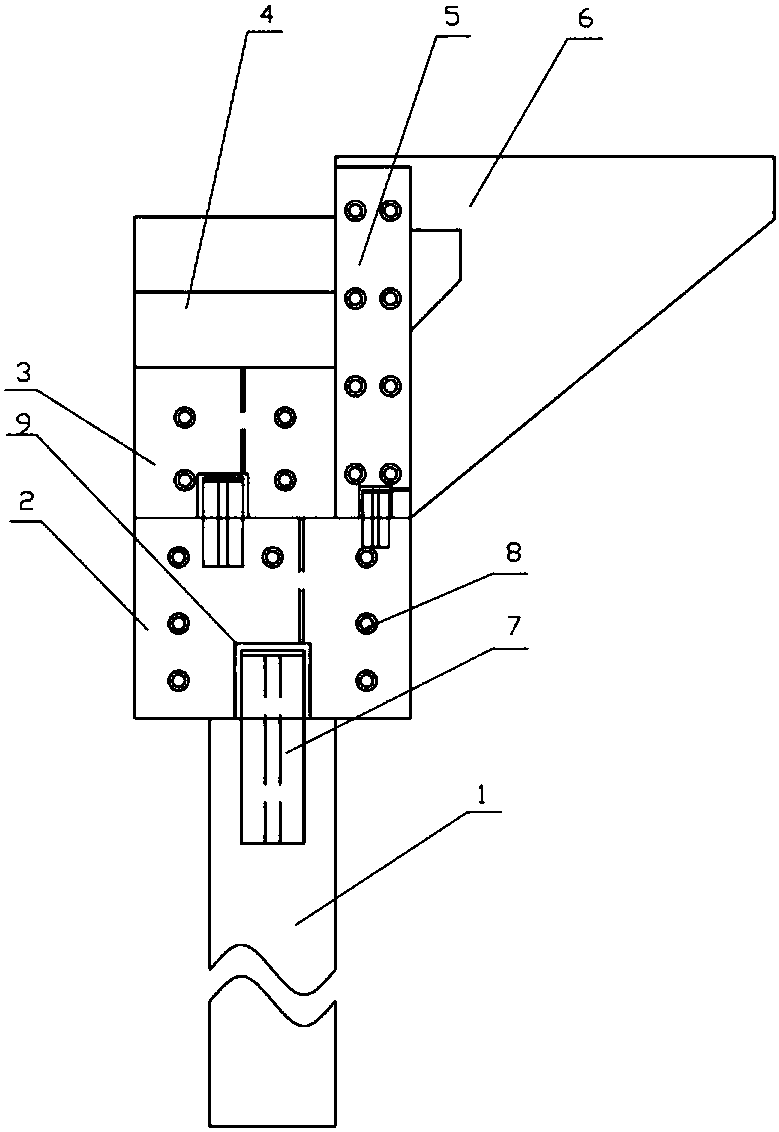

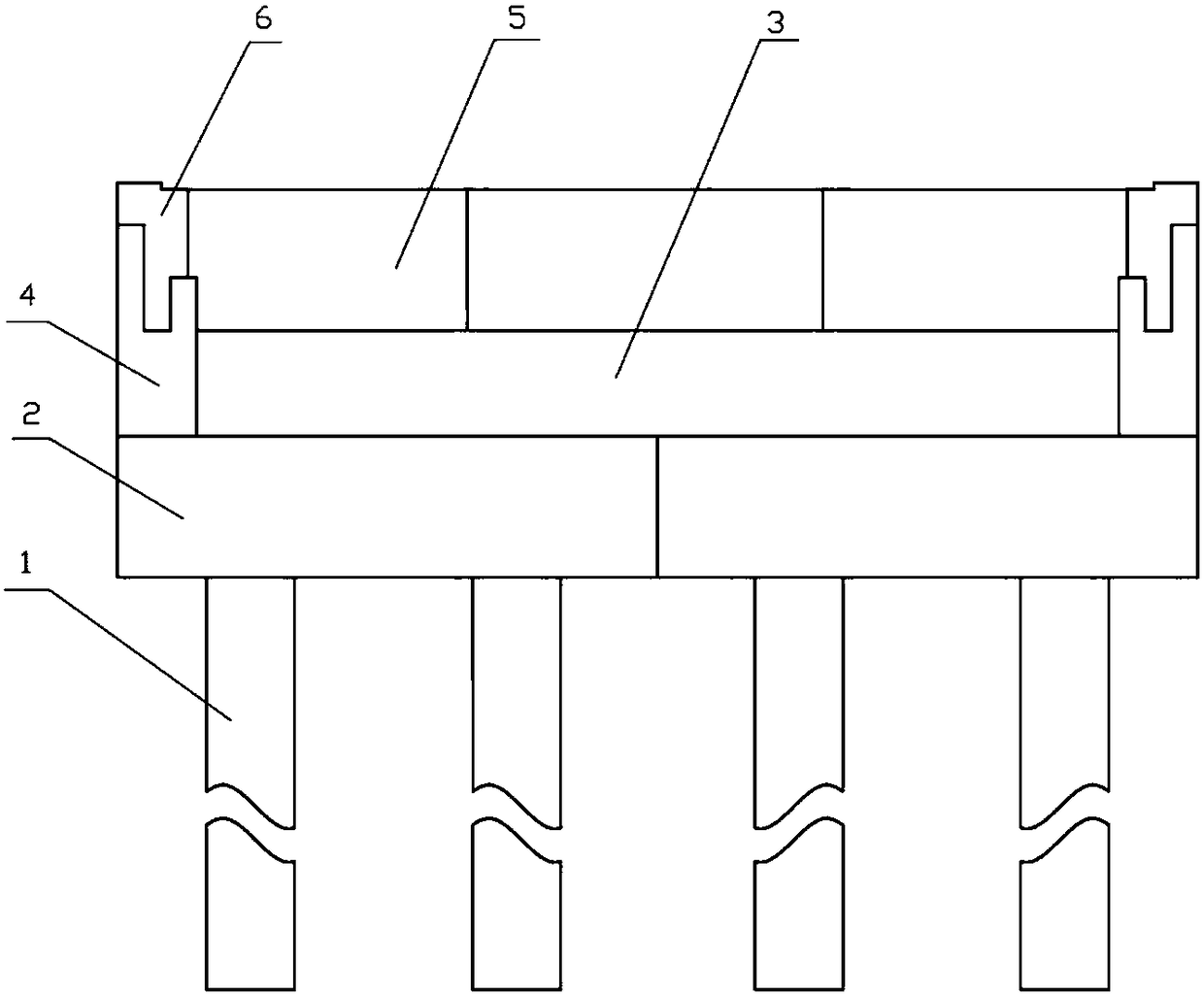

Fully assembled light abutment and construction method thereof

PendingCN108442239AHigh strengthLight weightBridge structural detailsBridge erection/assemblyPre stressAbutment

The invention discloses a fully assembled light abutment. The abutment comprises a pile foundation, a cushion cap, an abutment cap, double baffle blocks, a back wall bracket and a wing wall, the double baffle blocks are connected with the back wall bracket and installed on the cushion cap, the cushion cap, the abutment cap, the double baffle blocks, the back wall bracket and the wing wall are UHPCprefabricated components internally provided with reinforcement cages, the pile foundation is an NC prefabricated component or a UHPC prefabricated component internally provided with reinforcement cages, the cushion cap is connected with the pile foundation through an H-shaped steel plate with a sealing end cover plate, the abutment cap, the wing wall and the back wall bracket are connected withthe cushion cap through H-shaped steel plates with sealing end cover plates, the double baffle blocks are in tensile connection with the abutment cap through prestress reinforcing bars, and the back wall bracket is in tensile connection with the wing wall through prestress reinforcing bars; the construction method of the structure is included. According to the fully assembled light abutment, a fully assembled structure is adopted, the abutment has the advantages of being fast in construction speed, simple in process, easy to control in engineering project quality, less in occupation space of construction sites and the like, and the existing problem of slow construction process, the quality problem brought by hydration heat when large volume concrete construction is conducted, the problemsof large occupation space and environmental pollution and the like of traditional abutments can be effectively solved.

Owner:XIANGTAN UNIV

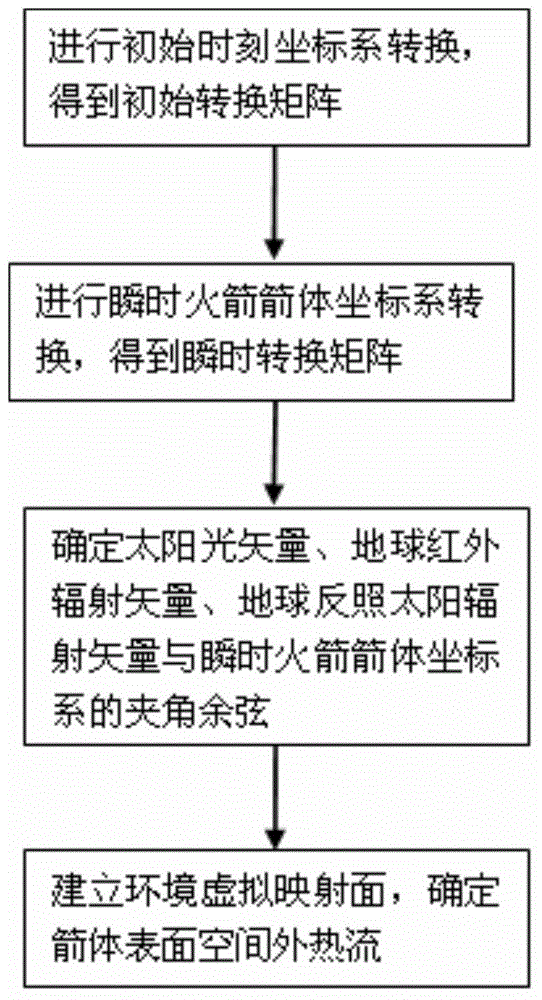

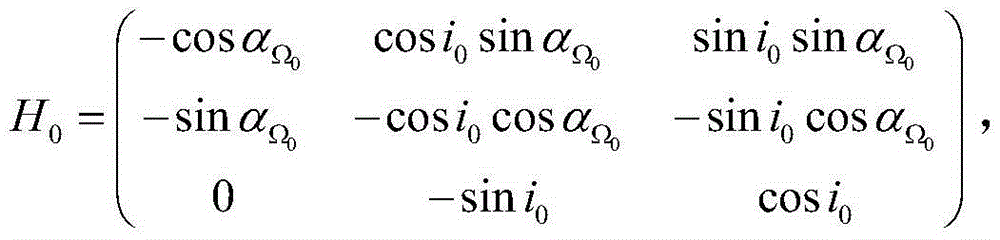

Space external heat flux calculation method for carrier rocket

ActiveCN104408279AIncrease structural weightReliable design basisSpecial data processing applicationsThermodynamicsHeat flow

The invention provides a space external heat flux calculation method for a carrier rocket. The method comprises the following steps that: (1) initial moment coordinate system conversion is carried out to obtain an initial conversion matrix; (2) instantaneous coordinate system conversion is carried out to obtain an instantaneous conversion matrix; (3) the included angle cosine of a sunlight vector, an earth infrared radiation vector, an earth light sun radiation vector and an instantaneous rocket body coordinate system is determined; and (4) an environment virtual mapping surface is built, and the rocket body surface space external heat flux is determined. The method has the advantages that the orbital dynamics and the thermodynamics are combined; the Monte Carlo method radiation heat flux calculation is used as the basis; the space external heat flux on the complicated surface of a rocket body can be finely determined; the problems of shielding and multiple times of reflection among the surfaces are effectively solved; and the coordinate conversion and mathematical calculation flow processes are simplified.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

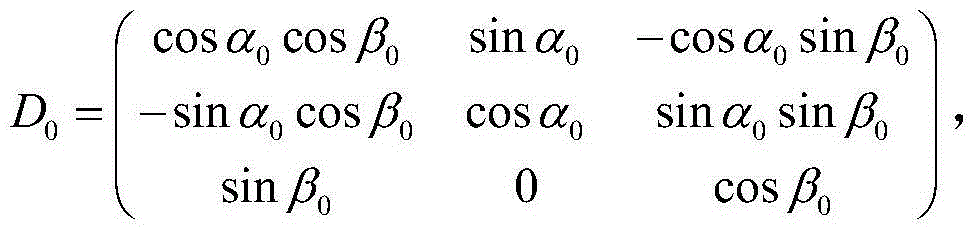

Memory-alloy driving front ducted ejector of variable-cycle engine adjustable mechanism

ActiveCN109611237AThe area is continuously adjustableReduce weightJet propulsion plantsElectricityRegulation temperature

The invention relates to a memory-alloy driving front ducted ejector of a variable-cycle engine adjustable mechanism. The memory-alloy driving front ducted ejector comprises a core driving fan case, memory alloy wire bases, pulleys, memory alloy wires, wire locking devices, gaskets, crankshafts, spherical hinge covers, spherical hinge balls, connecting rods, studs, stud supports, a valve body anda bias spring. The memory alloy wires are used as mechanism driving pieces, when the temperature is raised by external electric heating, the length is reduced due to the shape memory effect, displacement generated by the memory alloy wires is amplified by the lever effect of the crankshafts and then is transmitted to the valve body through the connecting rods to enable the valve body to be turneddown, and thus the temperature is adjusted and the flow from a core driving fan to an outer duct is controlled; when electric heating is stopped, the memory alloy is at a low-temperature phase, the bias spring pulls open the valve body, and simultaneously, the memory alloy wires are stretched to be in a loading state. The memory-alloy driving front ducted ejector can be matched with other adjustable mechanisms to convert the working state of a variable-cycle engine, and has the advantages of being small in structure weight, reliable in movement, small in influence on flow channels and the like.

Owner:BEIHANG UNIV

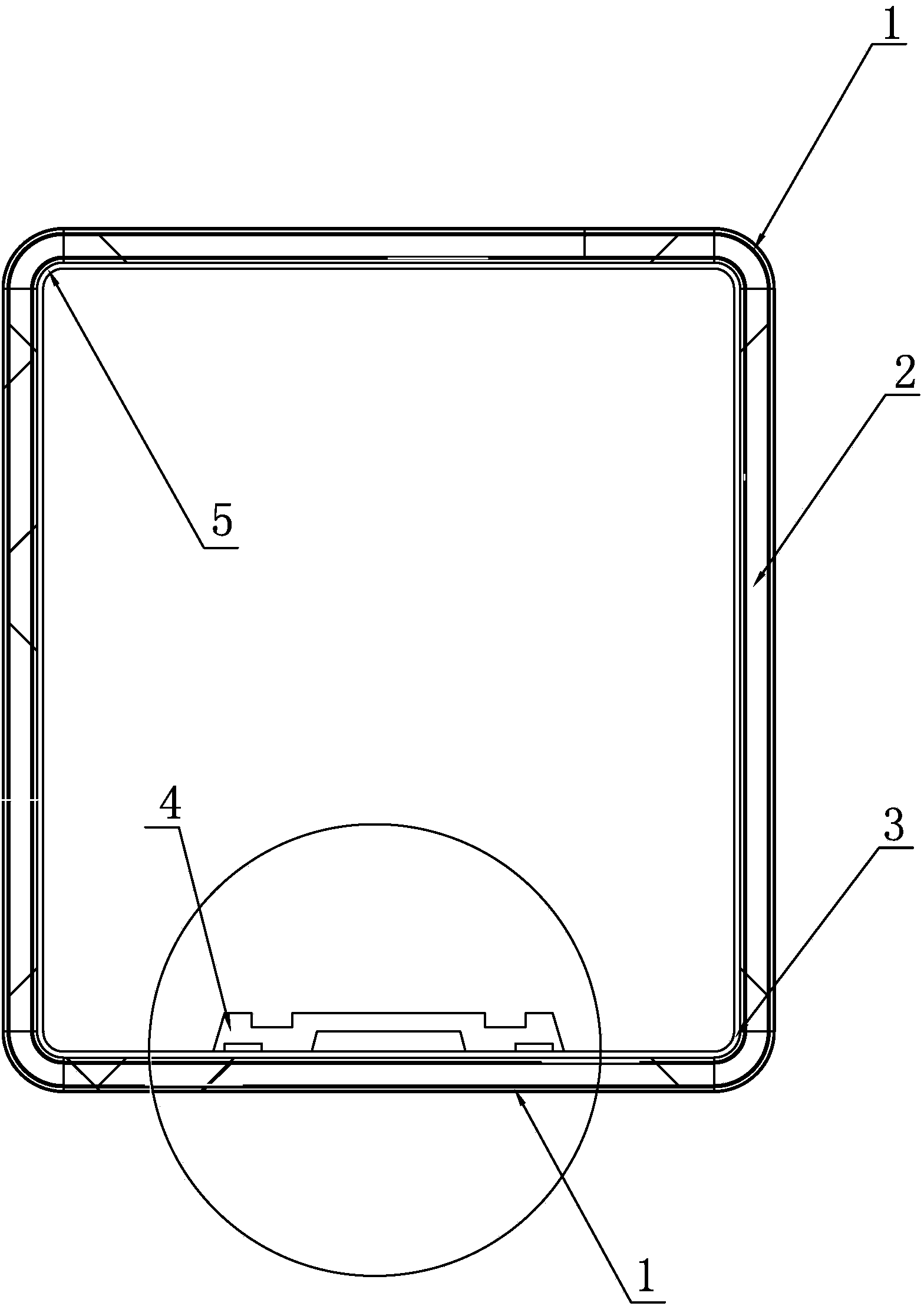

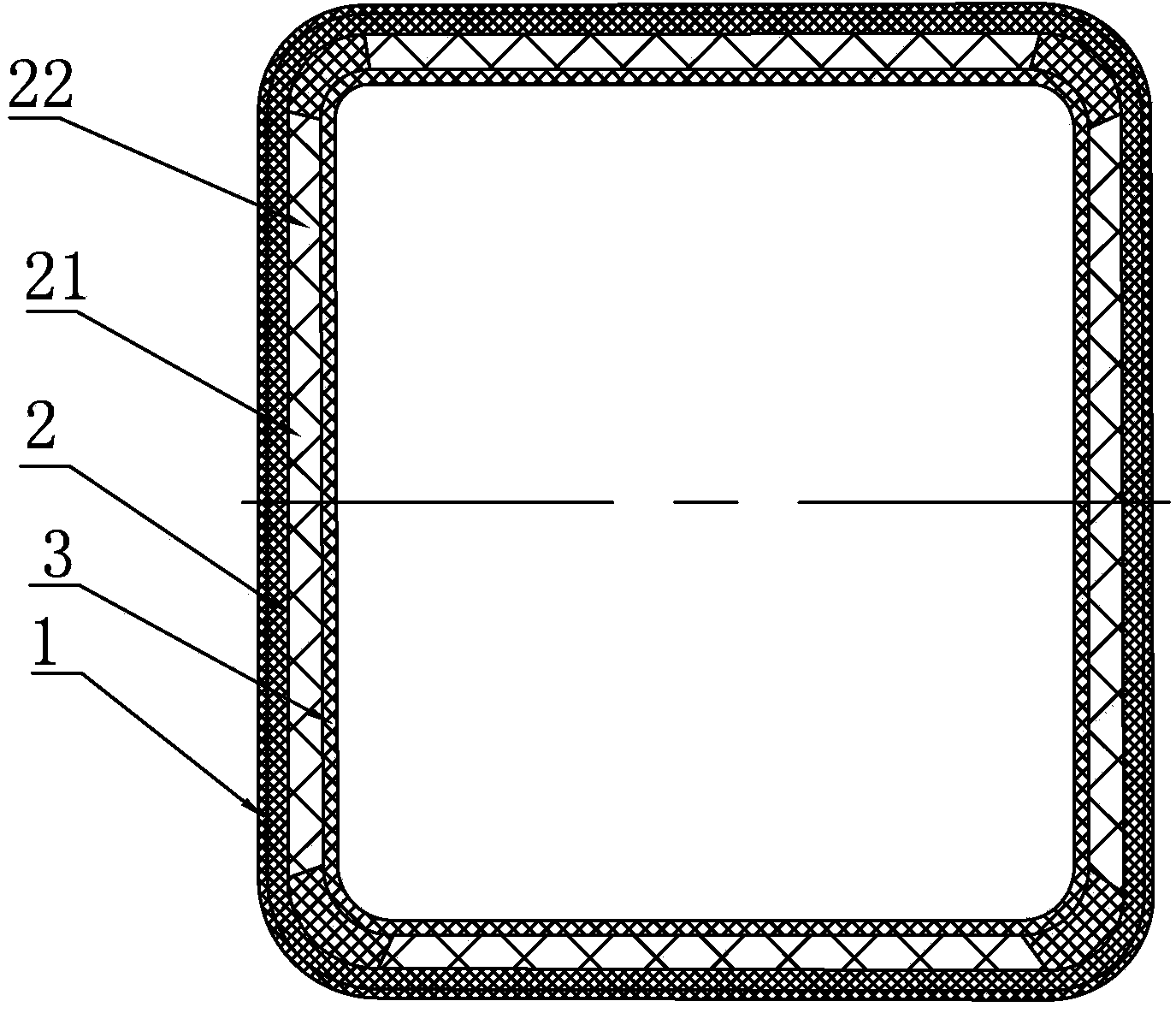

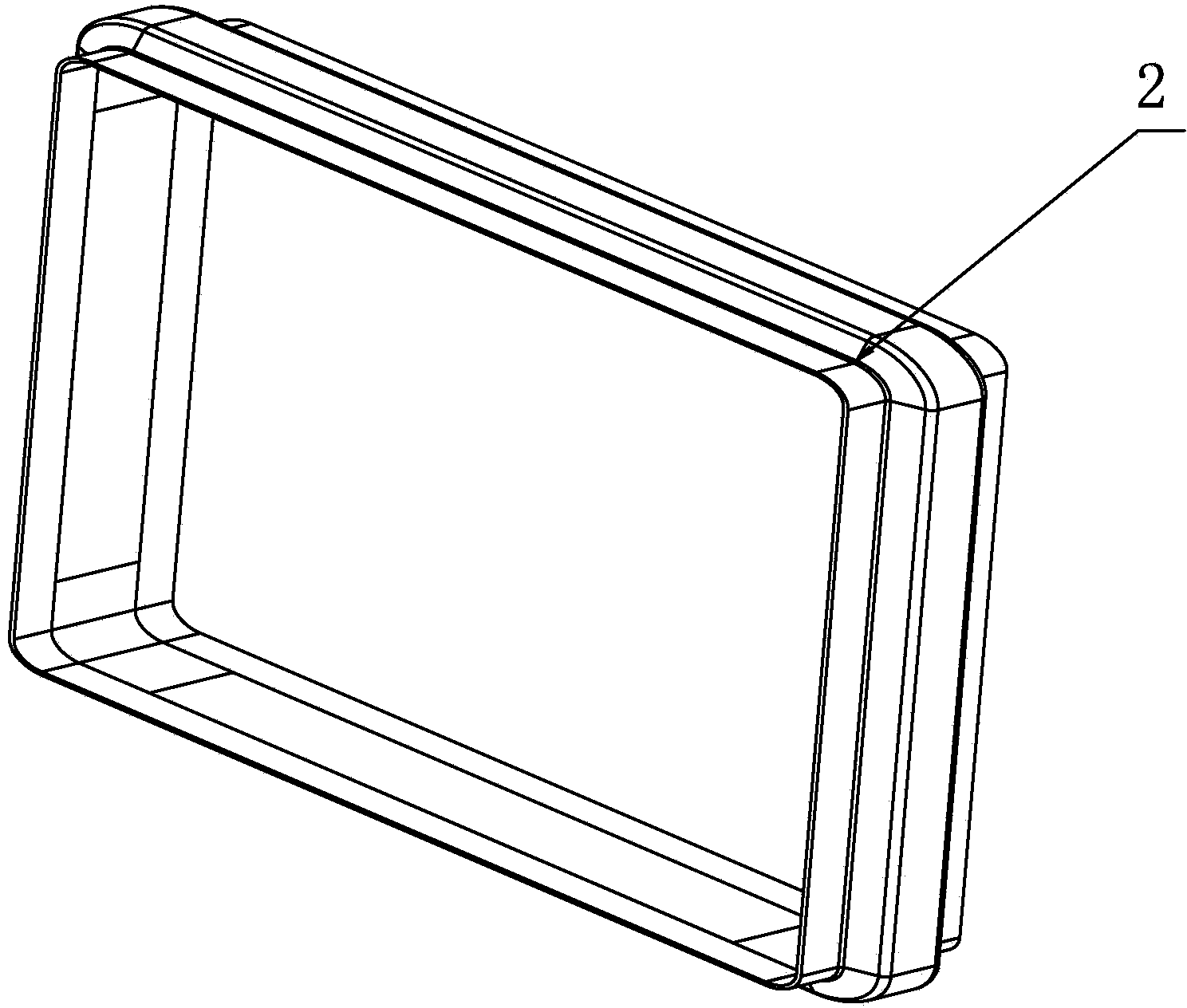

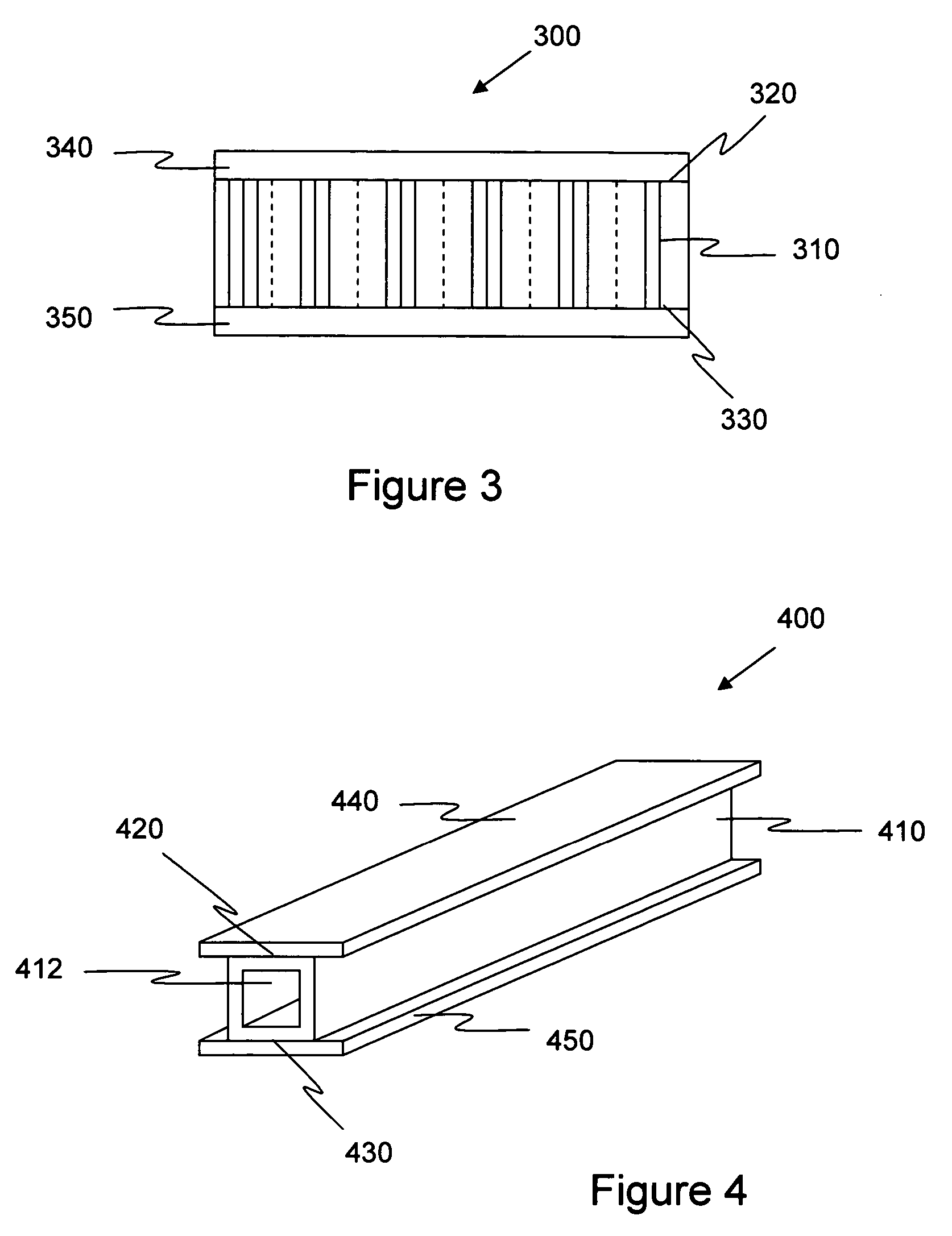

High-rigidity light launching box

The invention discloses a high-rigidity light launching box and relates to a launching box used for supporting, fixing, transporting and storing missiles. The high-rigidity light launching box is high in both circumferential rigidity and longitudinal rigidity and light and can provide large storage space for the missiles, and the stress on the corners of the launching box can be effectively diffused. The high-rigidity light launching box comprises an outer skin, an inner skin, longitudinal ribs and ring ribs evenly distributed between the outer skin and the inner skin. The ring ribs are connected with the outer skin and the inner skin through glue respectively, the ring ribs are installed on the inner skin in a sleeved mode, small rounded corners are adopted for the corners of the inner skin, the outer skin and the ring ribs, the space between the inner skin and the ring ribs is filled with a heat preserving layer, reinforcing blocks are arranged on the corners of the heat preserving layer, filling interfaces are arranged on the longitudinal ribs, a 35-degree laying layer is adopted for the inner skin, the longitudinal rib laying layers and the ring rib laying layers respectively comprise 0-degree laying layers and 90-degree laying layers, the proportion of the laying layers of the longitudinal ribs is as follows: n 0 degree: n 90 degrees= 2:1- 3:1, and the proportion of the laying layers of the ring ribs is as follows: n 90 degrees: n 0 degree= 2:1- 3:1.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

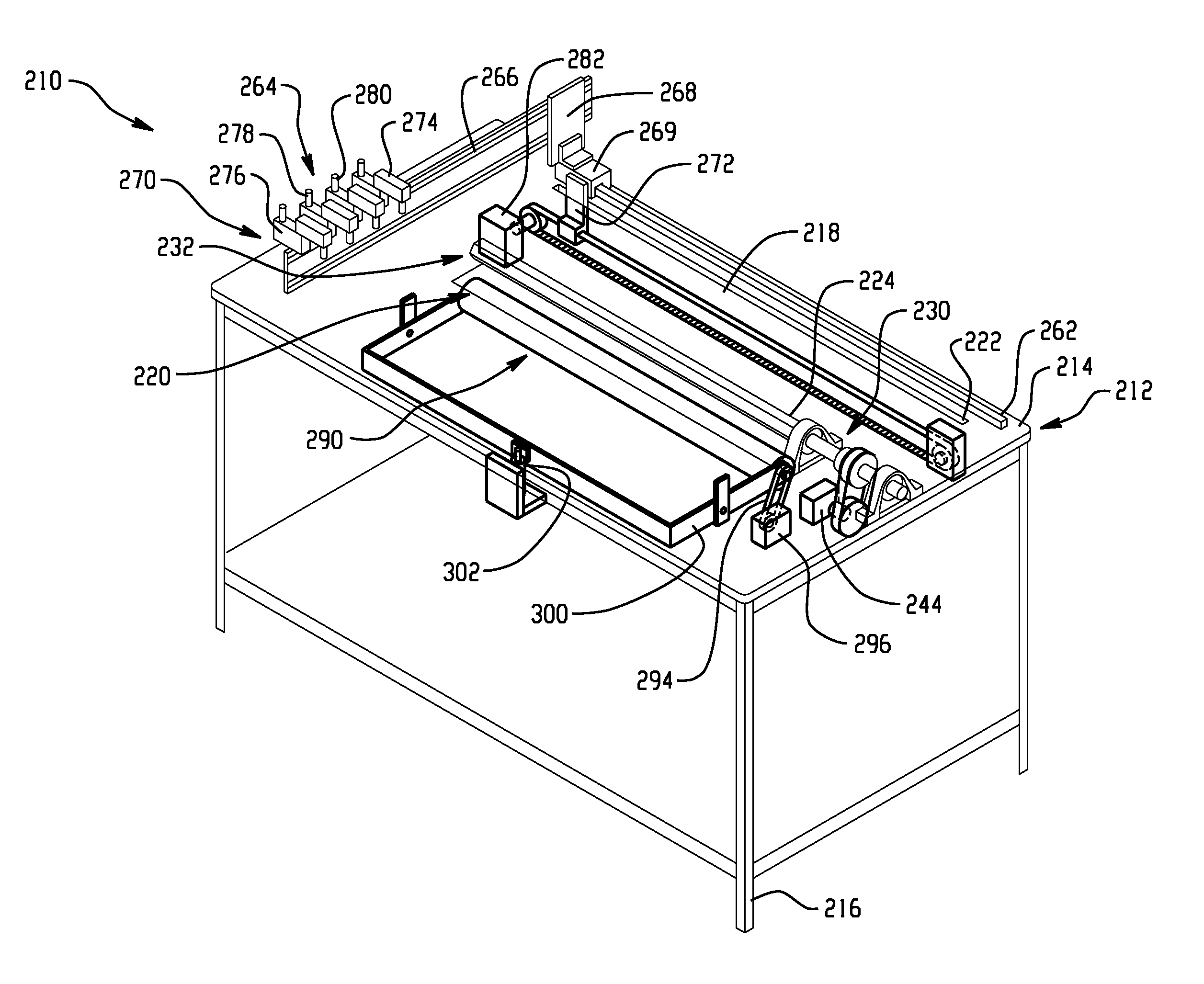

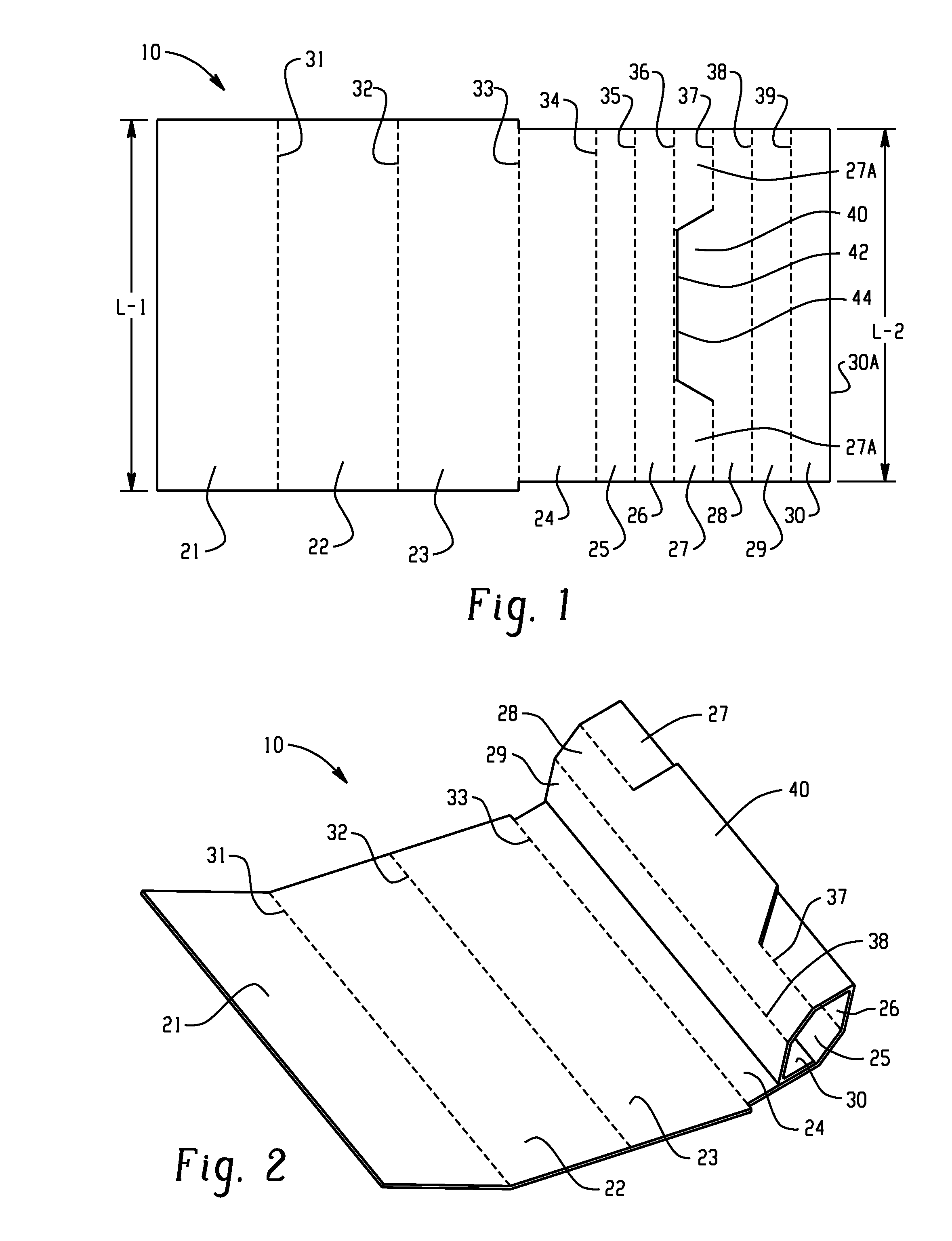

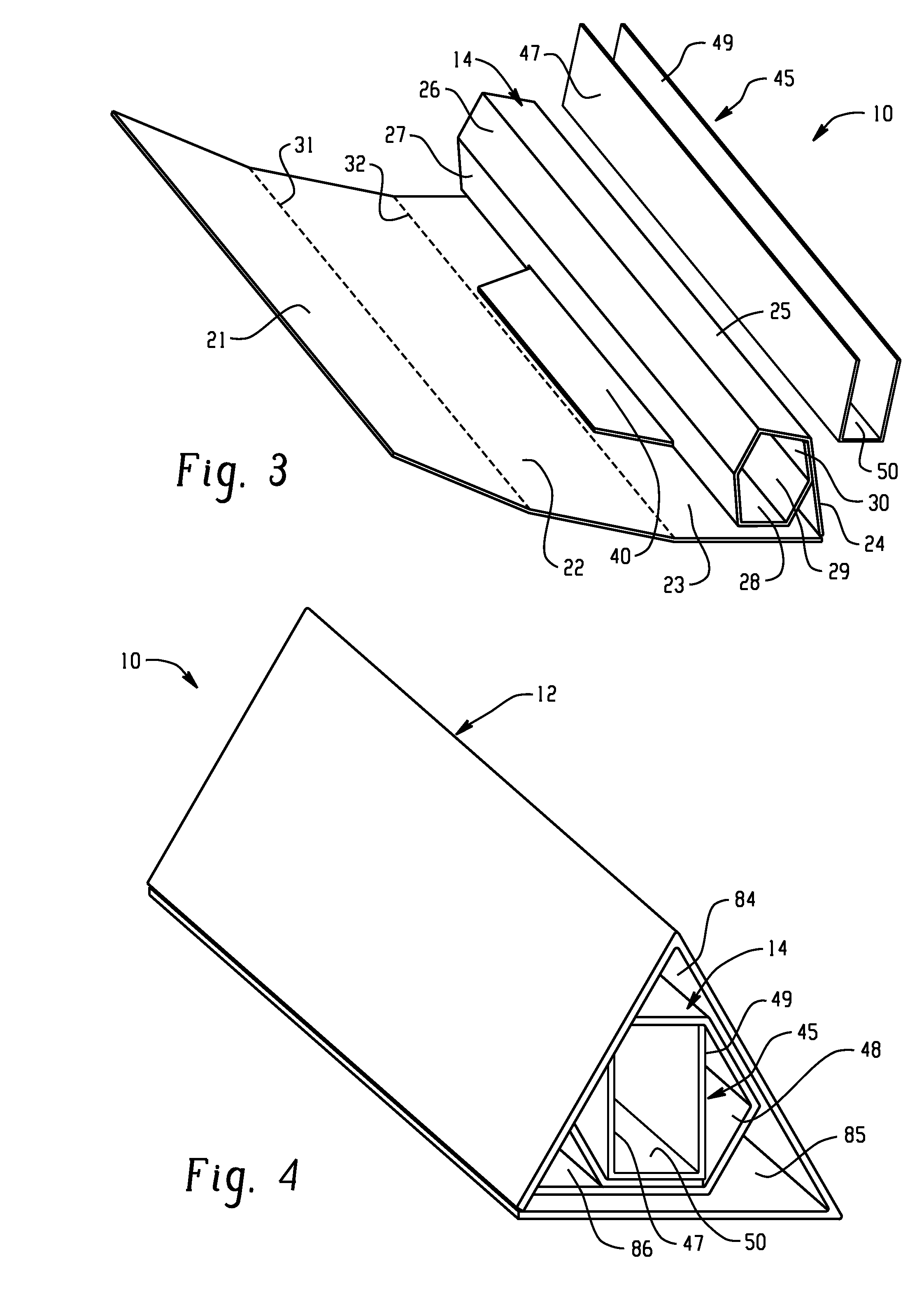

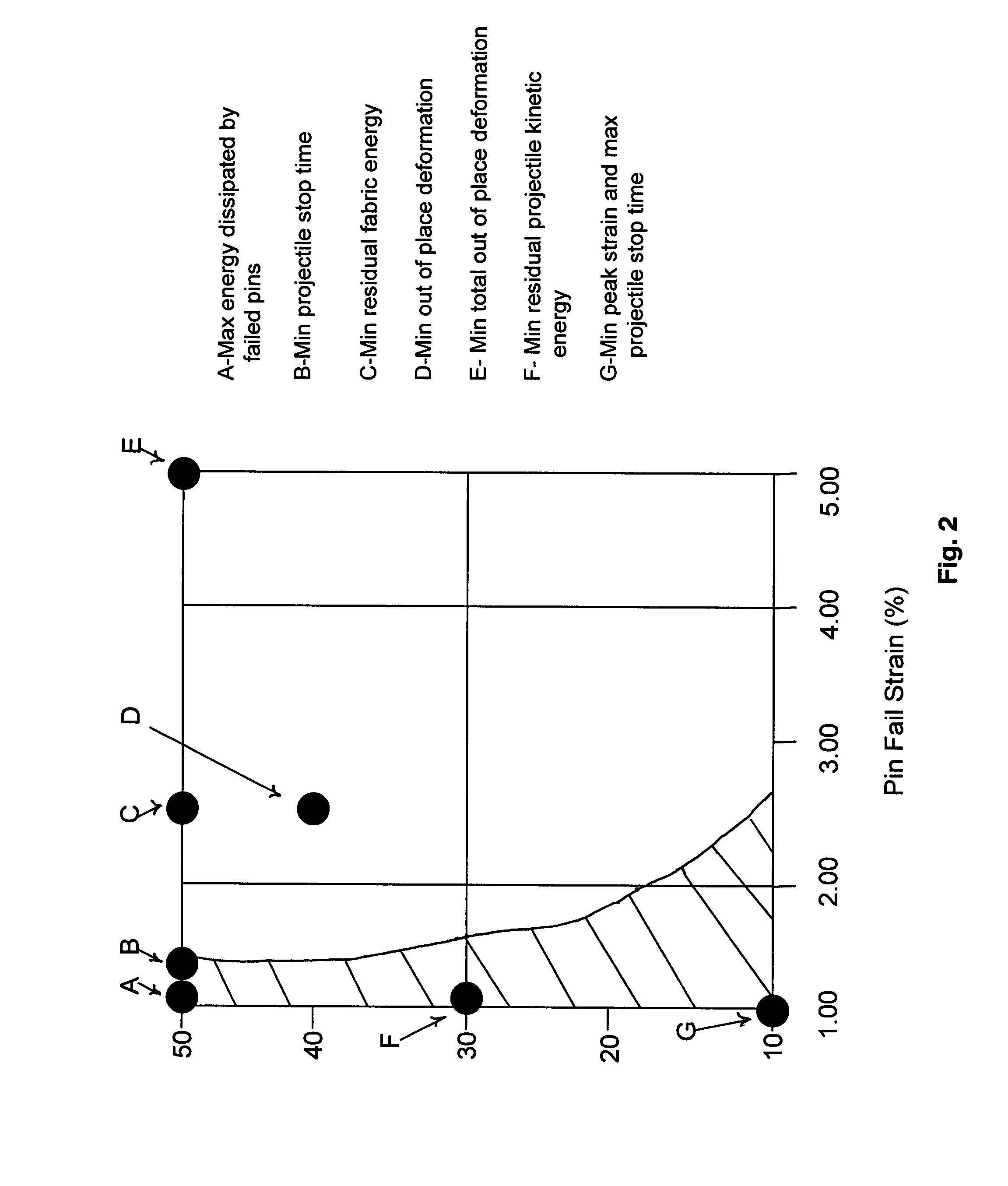

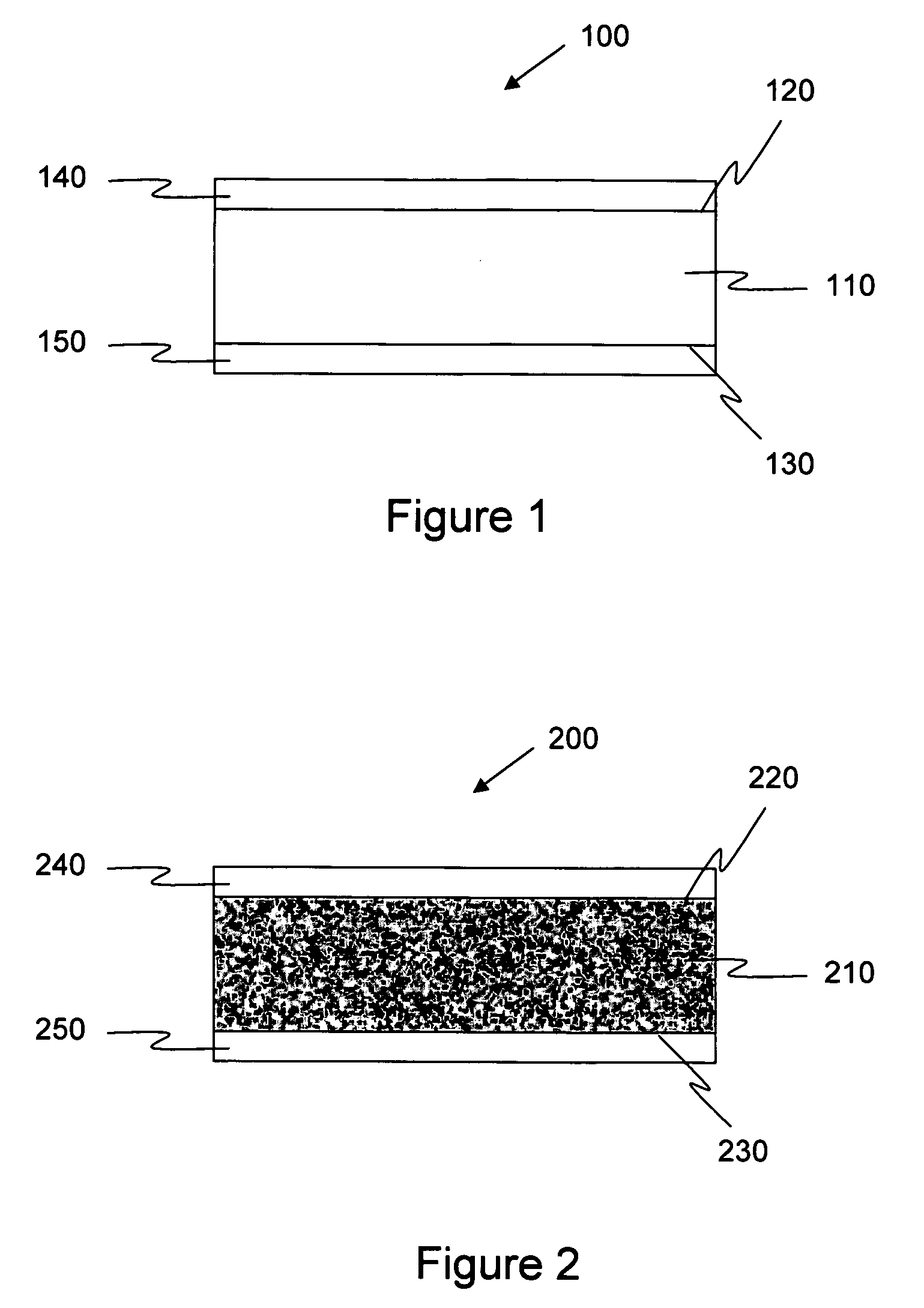

Elongate structures and devices and methods for manufacturing same

InactiveUS20130157832A1Increase beam intensityIncrease structural weightMechanical working/deformationPaper/cardboard articlesEngineeringSheet material

A device for wrapping a substantially flat piece of sheet material with a plurality of creases that define fold lines that when folded, forms an elongate structure that includes a hollow outer portion and a hollow inner portion disposed within the hollow outer portion. The device includes a mandrel, a gripper blade that releasably secures the sheet material to the mandrel, a motor that rotates the mandrel when the sheet material is secured to the mandrel, and a compressive member that releasably presses the first outer side surface of the hollow outer portion of the elongate structure against the inner portion of the elongate structure after the sheet material has been wrapped about the mandrel. The device can also include a controller that is operably associated with the motor and the compressive member.

Methods and structures for sandwich panels with improved resistance to ballistic penetration

InactiveUS8186262B2High specific strengthImprove the immunityArmourCosmonautic vehiclesSandwich panelBuilding construction

Provided herein methods and structures for construction of light weight sandwich panels or load-bearing panels having improved ballistic protection. The methods disclosed can facilitate construction of a hybrid core comprising ballistic fabrics and deformable pins that exhibit superior resistance to ballistic penetration. The methods and structures of the present disclosures can be advantageously used in many applications, such as armored vehicles.

Owner:MARYLAND AT BALTIMORE COUNTY UNIV OF

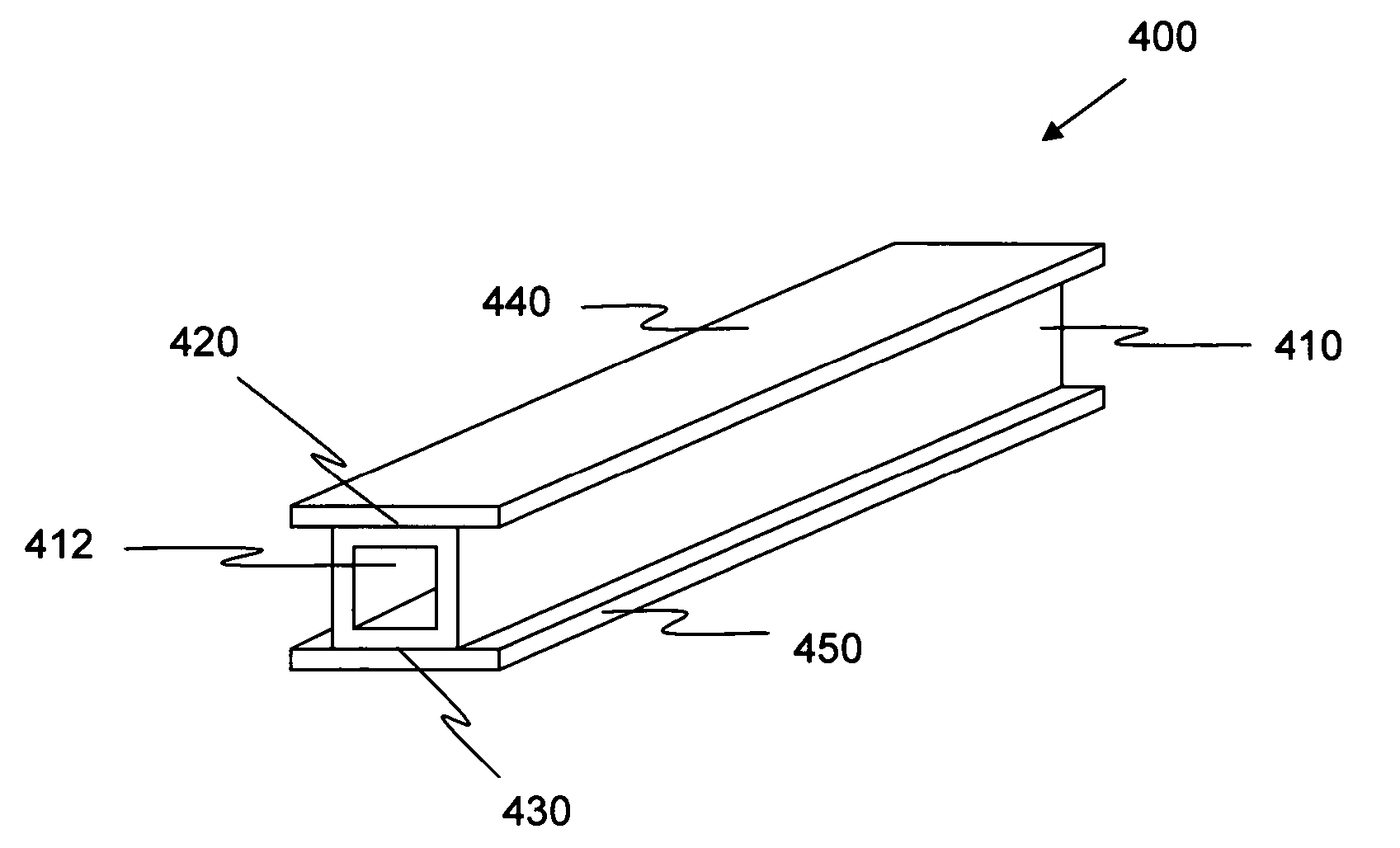

Metal matrix composite structures

InactiveUS7498077B2High strengthIncrease structural weightCeramic layered productsGlass/slag layered productsComposite constructionMetal matrix composite

A lightweight, high strength structure is described where a core material has a first and second metal matrix composite layer on surfaces of the core material. A sandwich type structure may be formed. The core material may be a solid material, a foam, a honeycomb structure, or may be a channeled material. The metal matrix composite layers may include fiber reinforced metal matrix composites.

Owner:TOUCHSTONE RES LAB

Metal matrix composite structures

InactiveUS20050238868A1High strengthIncrease structural weightCeramic layered productsGlass/slag layered productsComposite constructionHigh intensity

A lightweight, high strength structure is described where a core material has a first and second metal matrix composite layer on surfaces of the core material. A sandwich type structure may be formed. The core material may be a solid material, a foam, a honeycomb structure, or may be a channeled material. The metal matrix composite layers may include fiber reinforced metal matrix composites.

Owner:TOUCHSTONE RES LAB

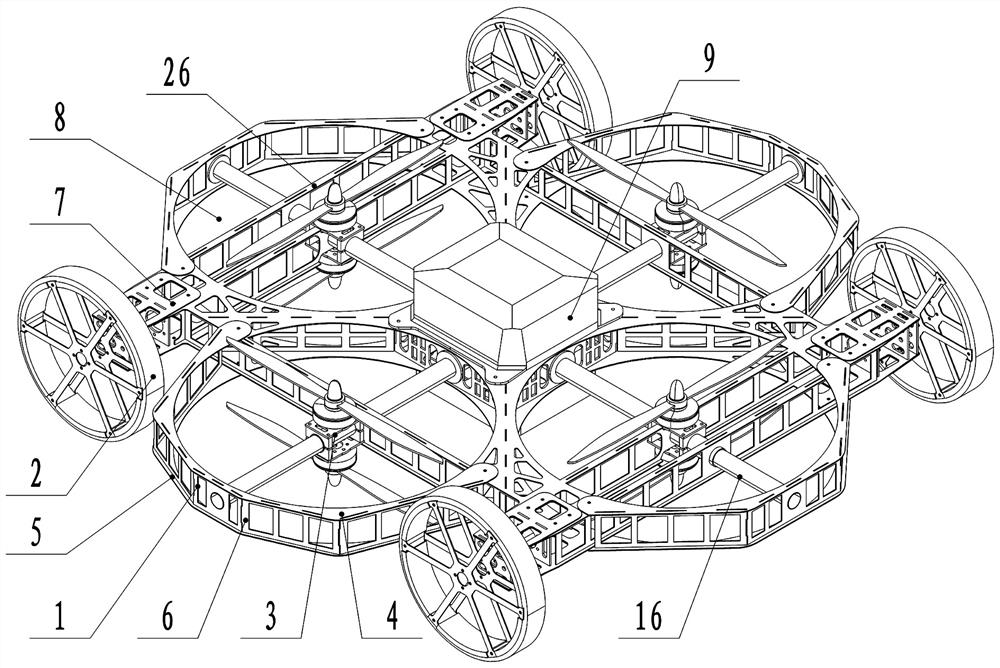

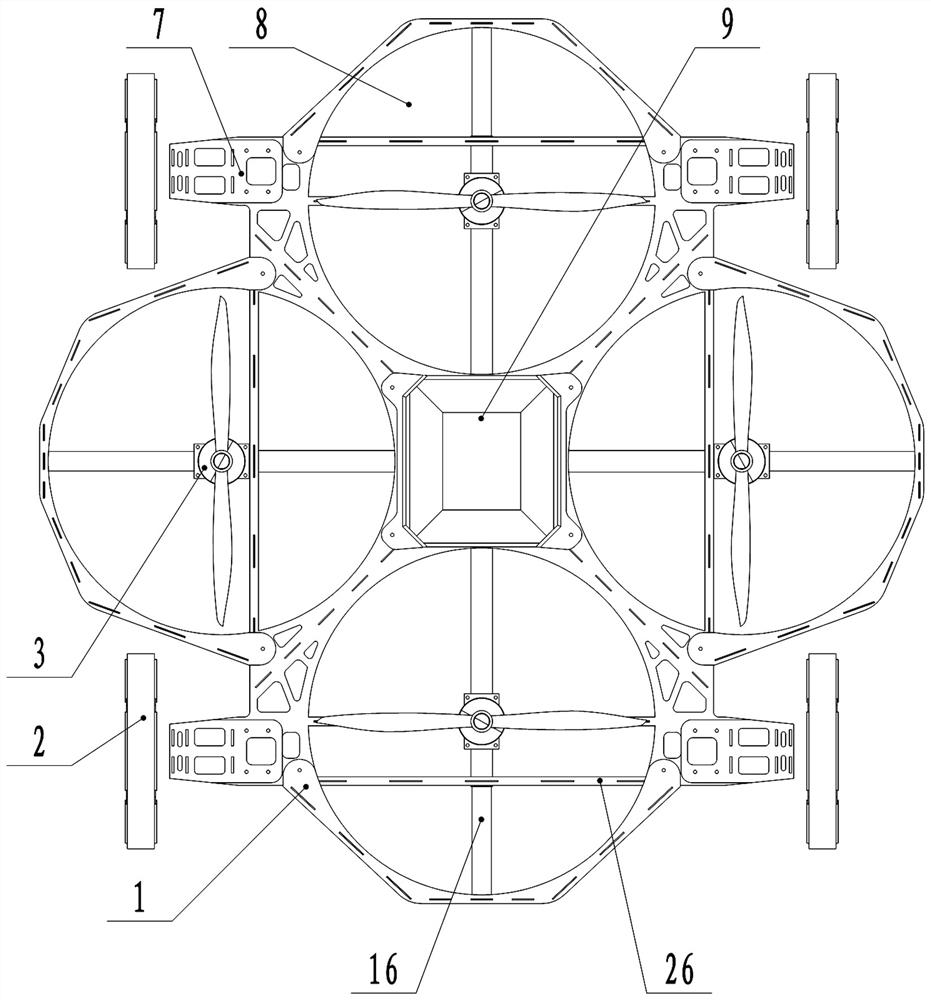

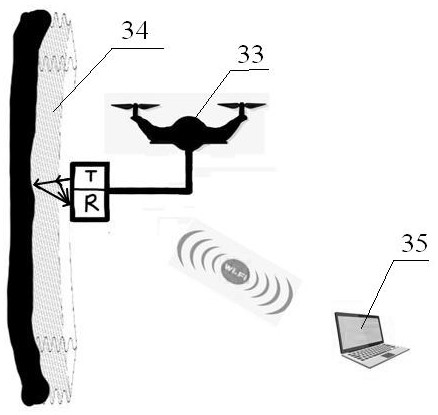

Novel air-land amphibious climbing detection robot for tunnel engineering

ActiveCN113442670AImprove efficiency and qualityImprove battery lifeMotor depositionAircraft convertible vehiclesTunnel engineeringTunnel construction

The invention belongs to the technical field of tunnel construction, and discloses a novel tunnel engineering air-land amphibious climbing detection robot which comprises a rack body, aircraft wheels and rotor wing assemblies, and the aircraft wheels and the rotor wing assemblies are arranged on the rack body. The rack body comprises an upper rack plate, a lower rack plate and a plurality of connecting plates used for connecting the upper rack plate and the lower rack plate. The aircraft wheels are arranged at four corners of the rack body and are connected with the rack body through driving connecting pieces, four rotor wing cavities used for arranging the rotor wing assemblies are uniformly arranged in the rack body, the rotor wing cavities and the aircraft wheels are arranged on the rack body in a staggered manner, a control box is arranged in the center of the rack body, and a detection radar is arranged at the bottom of the control box; and the detection radar comprises a sequential control module and a wireless data transmission module, the sequential control module is used for controlling a transmitting antenna, a receiving antenna and a signal acquisition module, and the wireless data transmission module is used for wirelessly transmitting signals acquired by the signal acquisition module to a ground computer. The structure weight is low, the operation energy consumption of the detection robot can be reduced, and the detection quality and efficiency are improved.

Owner:CHINA RAILWAY 12TH BUREAU GRP +2

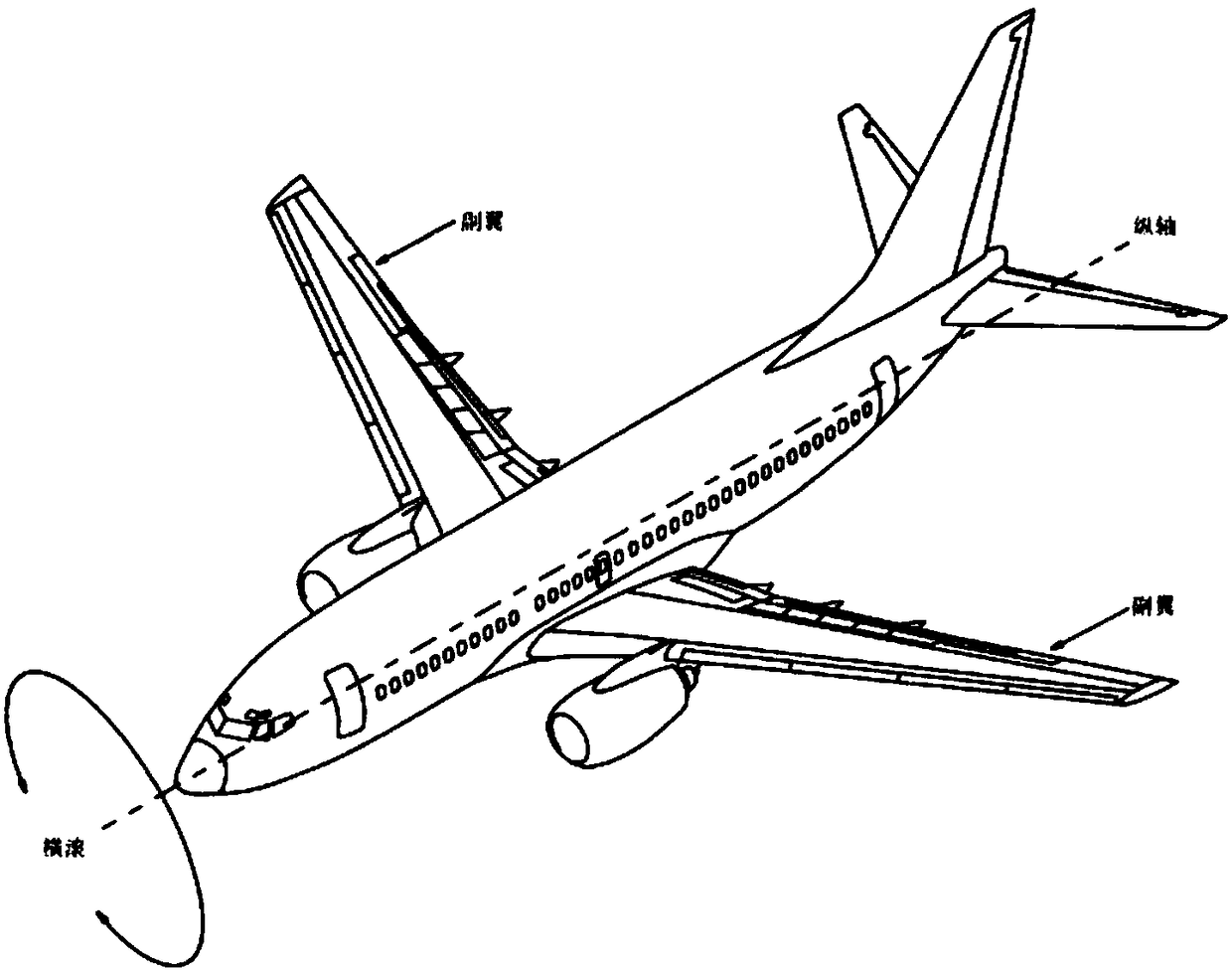

An operation efficiency increasing method based on a position change of an aileron connector

ActiveCN108163183AReduce distortionImprove operational efficiencyGeometric CADAircraft controlEngineeringAngle of attack

An operation efficiency increasing method based on a position change of an aileron connector is provided. In the method, a connector of an aileron is adopted to fix an aileron surface rotated by a servo, and the hinge position of another connector is adjusted according to the speed of incoming flow or an angle of attack, thus increasing connection rigidity of an aileron surface to allow loads on the aileron surface to be redistributed, and reducing elastic deformation of the aileron surface so as to increase the operation efficiency of the aileron. Abovementioned situations can be avoided under the premise of not increasing an operating mechanism, and the cost is reduced. The two connectors are adopted in a wing-aileron connection, the position of one of the connectors changes, and contactof the connectors is controlled by a relay. According to different flight conditions, the position of the wing-aileron connector changes to change wing-aileron connection (support) rigidity so as toredistribute (optimize) loads on the aileron surface, and aileron deformation is reduced to increase the aileron operation efficiency.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

Method for making a composite material, composite material and end product

InactiveCN102725131AImprove resistance to damageIncrease damage toleranceSynthetic resin layered productsNon-woven fabricsFiberMechanical engineering

A method is presented for making a composite material from strips comprising longitudinal fibres and a binder or resin, which material comprises a number of layer assemblies one on top of the other. Each layer assembly comprises m sets (with m at least 2) of parallel strips each extending in a different direction, Each layer assembly is manufactured by successive steps of depositing groups of parallel strips according to a well defined pattern (without longitudinally interweaving strips with previously deposited strips). Before completing a layer assembly, with the exception of the last layer assembly, by depositing its last group of parallel strips, the first group of parallel strips of the following layer assembly is already deposited. A composite material manufactured with such a method is presented too.

Owner:STICHTING NAT LUCHTEN RUIMTEVAART LABUM

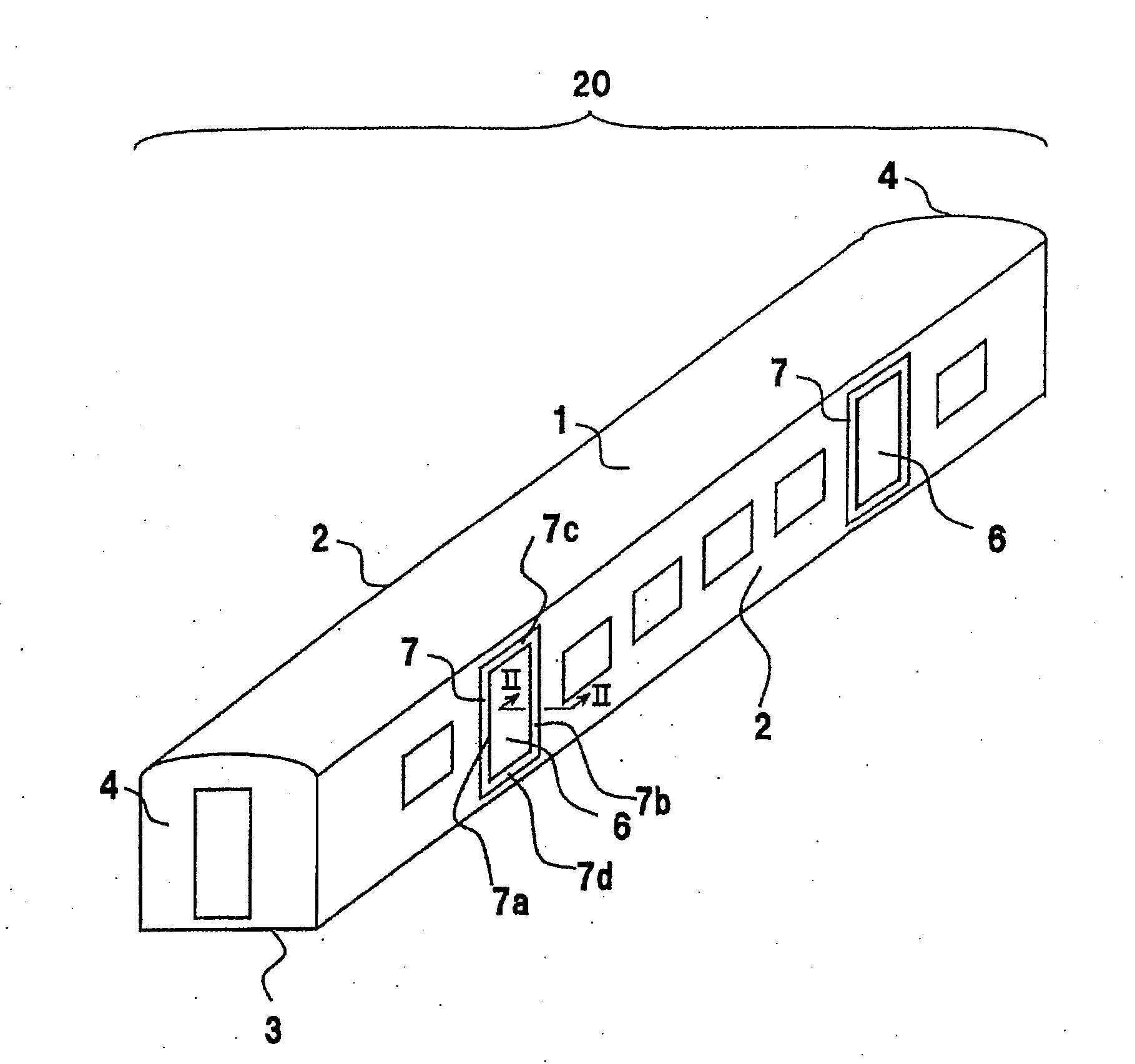

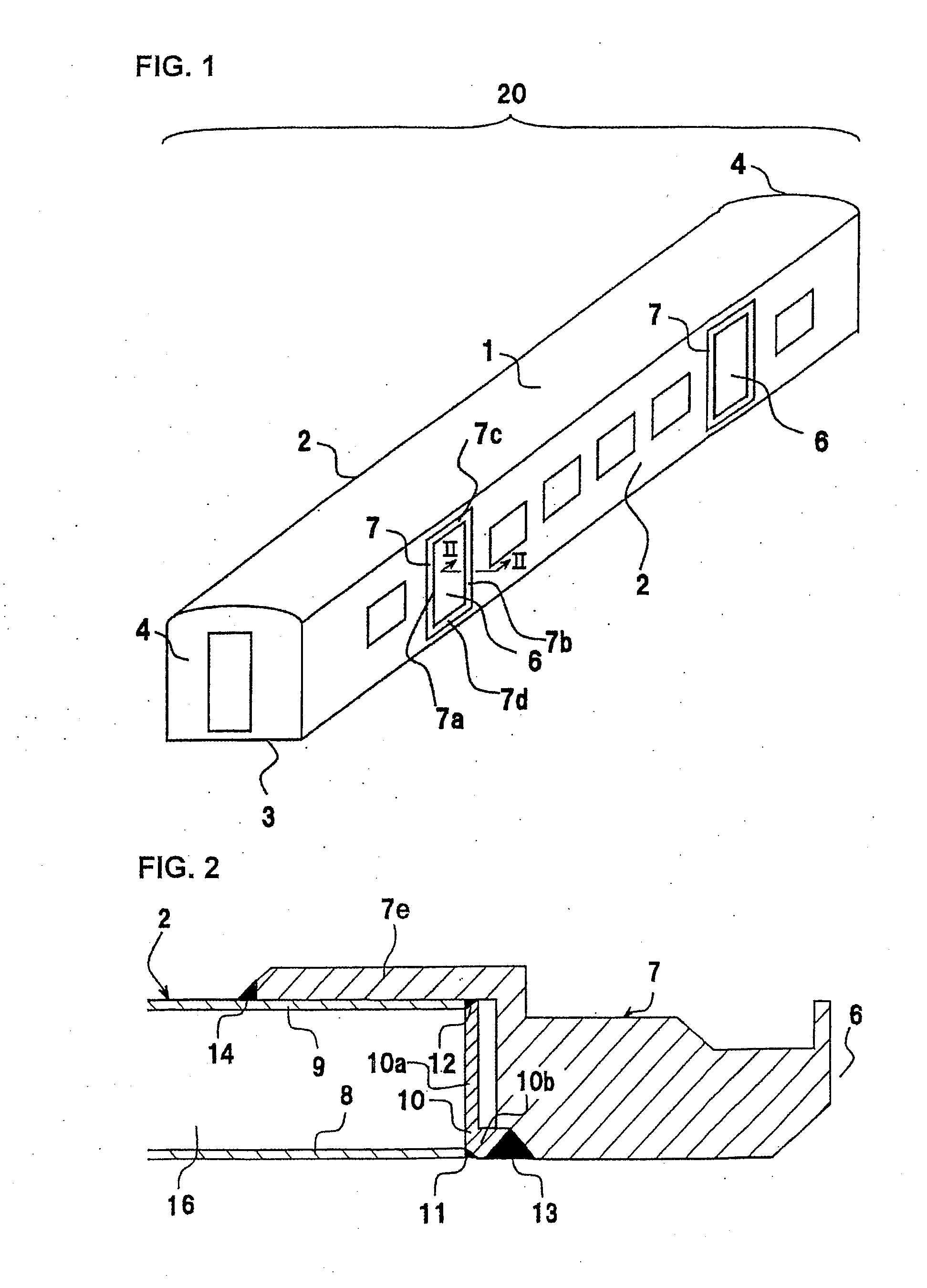

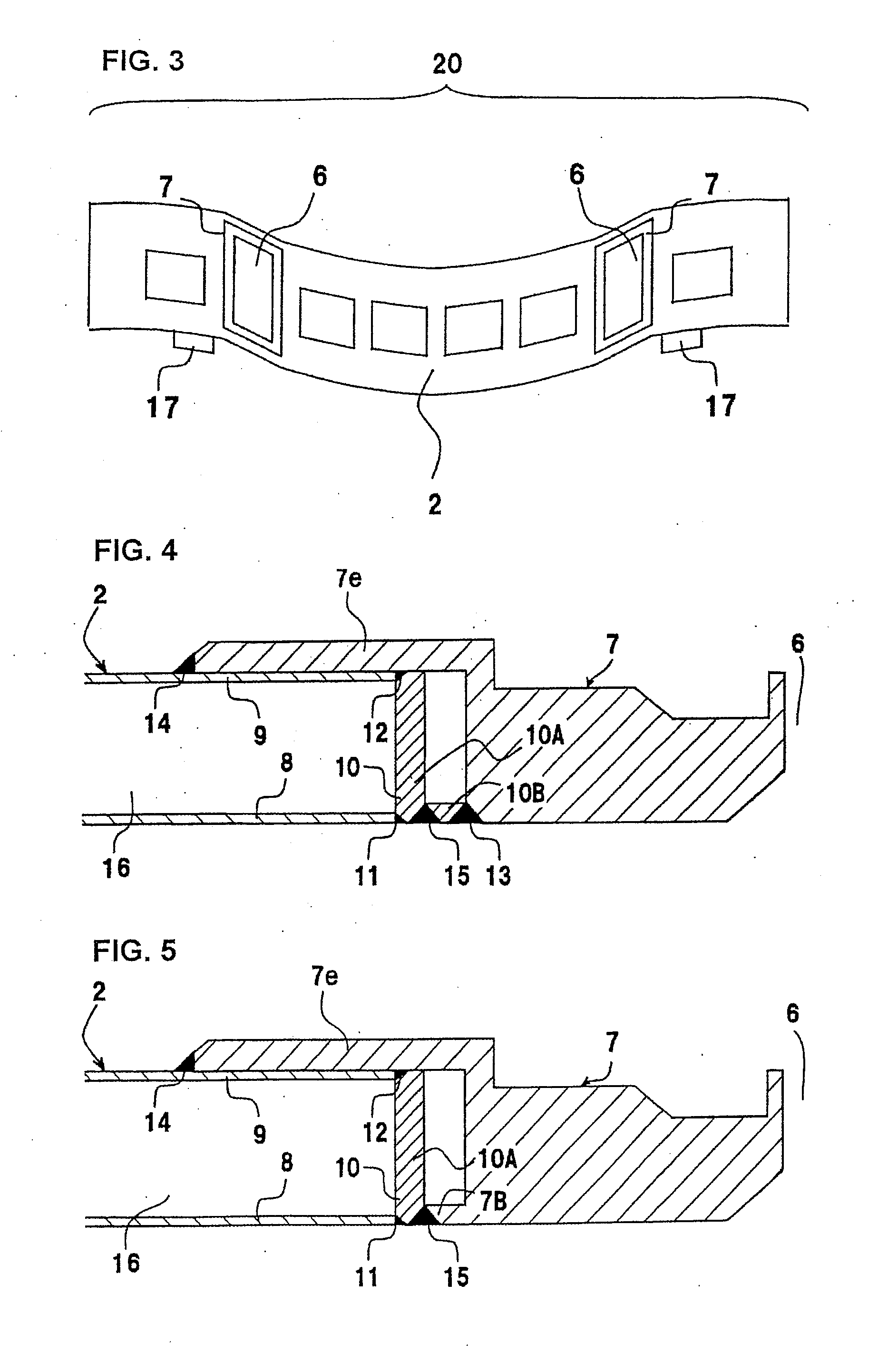

Car structure

InactiveUS20080163783A1Increase structural weightLight weightAxle-box lubricationWindow arrangementsEngineeringVertical load

A car structure is provided which has the required strength against vertical load and vibration while avoiding increase in weight of the structure. At an entrance 6 of the railroad car structure 20 in which a side structure 2 is formed by a hollow member, the side structure 2 and a frame 7 are coupled via an L-shaped fitting 10. The L-shaped fitting 10 consists of a first joint part 10a which is in the form of a plate and couples a vehicle outer face plate 8 and a vehicle inner face plate 9 and a second joint part 10b which is in the form of a plate and butt welds a part of the first joint part 10a near the vehicle outer face plate 8 and the frame 7. Plate thickness of the second joint plate 10b is larger than plate thickness of the vehicle outer face plate 8. As a result, the required strength against vertical load can be ensured without increasing the plate thickness of the vehicle outer face plate 8, in other words, with little increase in weight of the structure.

Owner:NAKAMURA HIDEYUKI +3

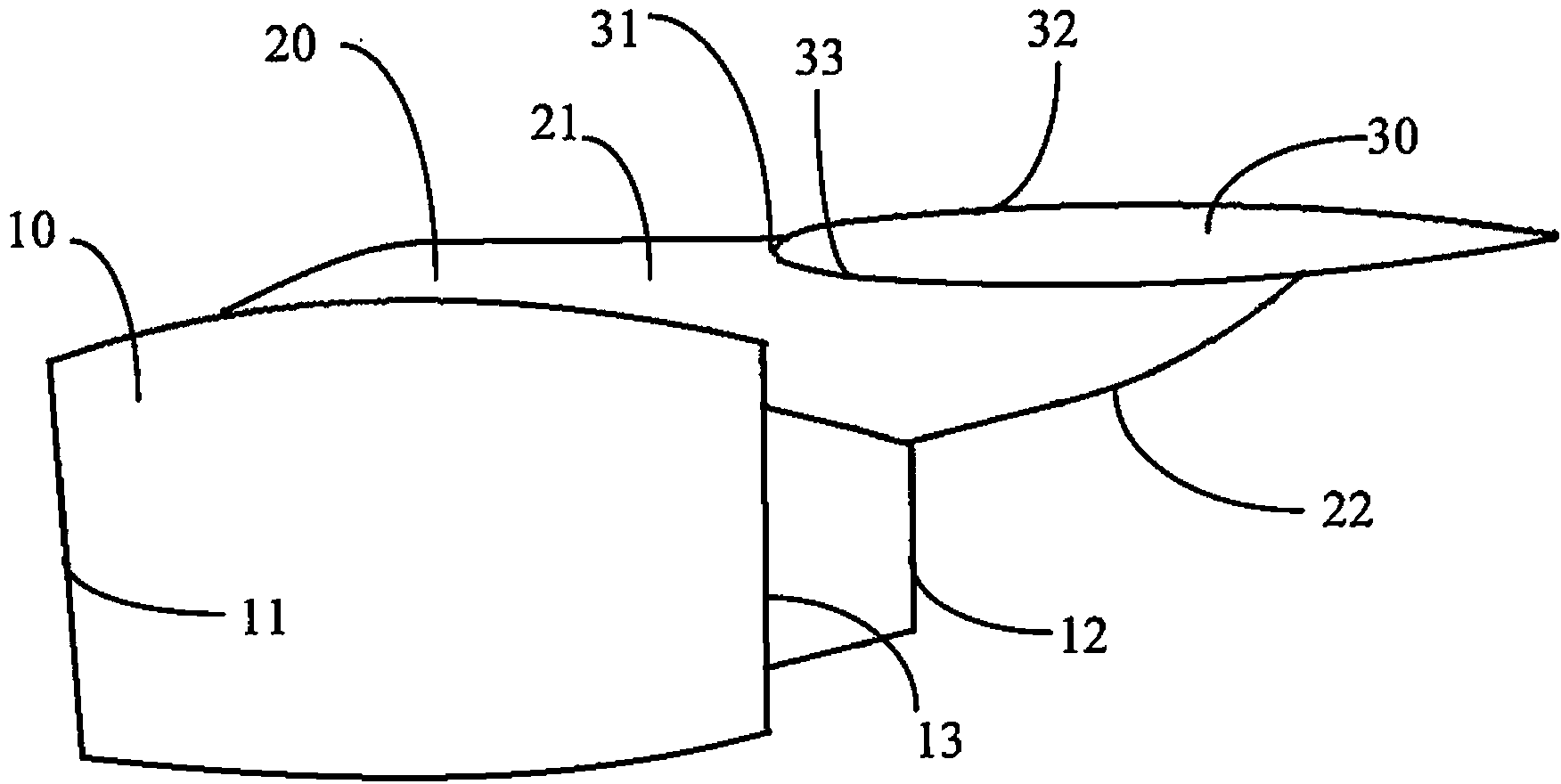

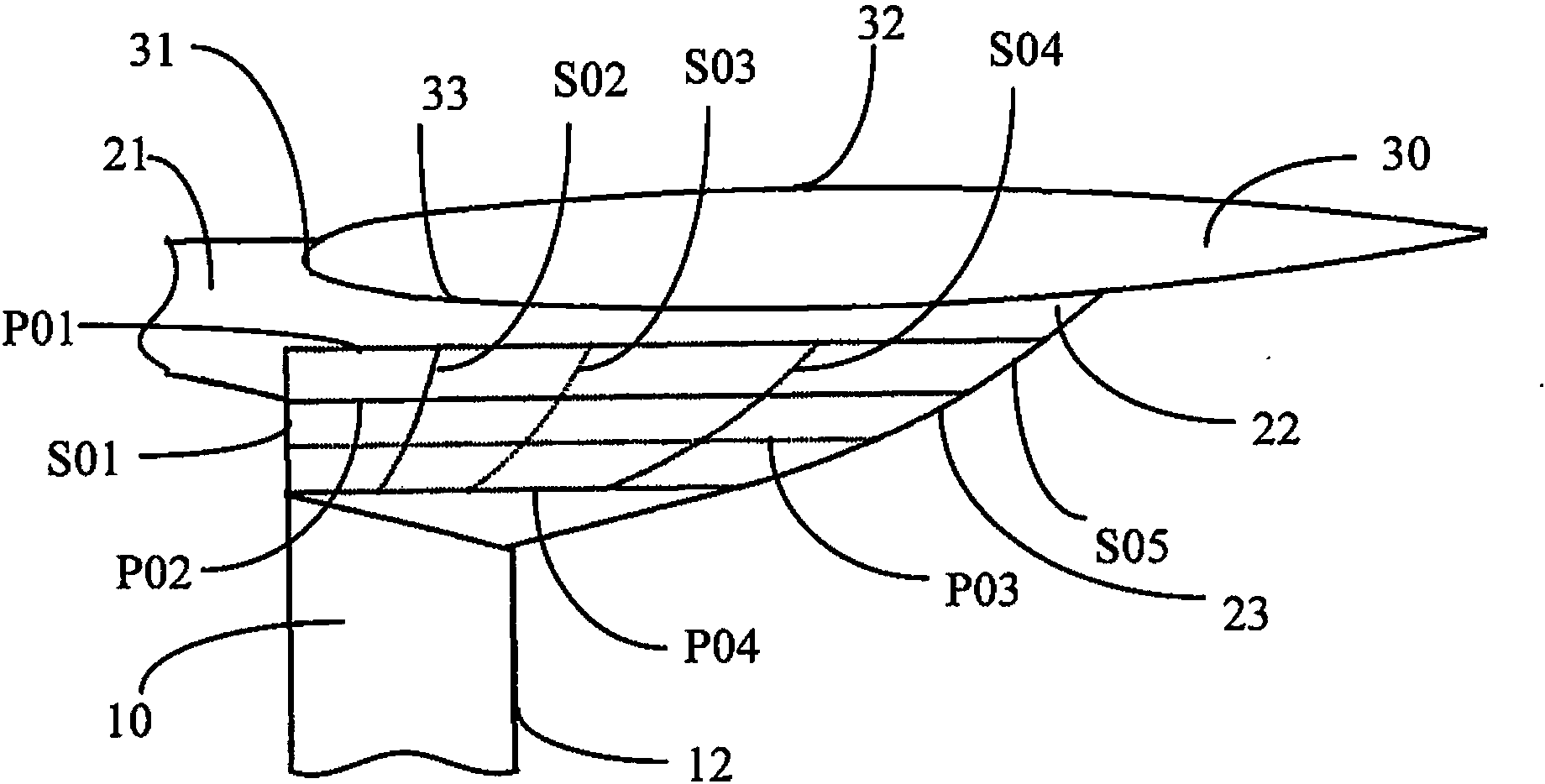

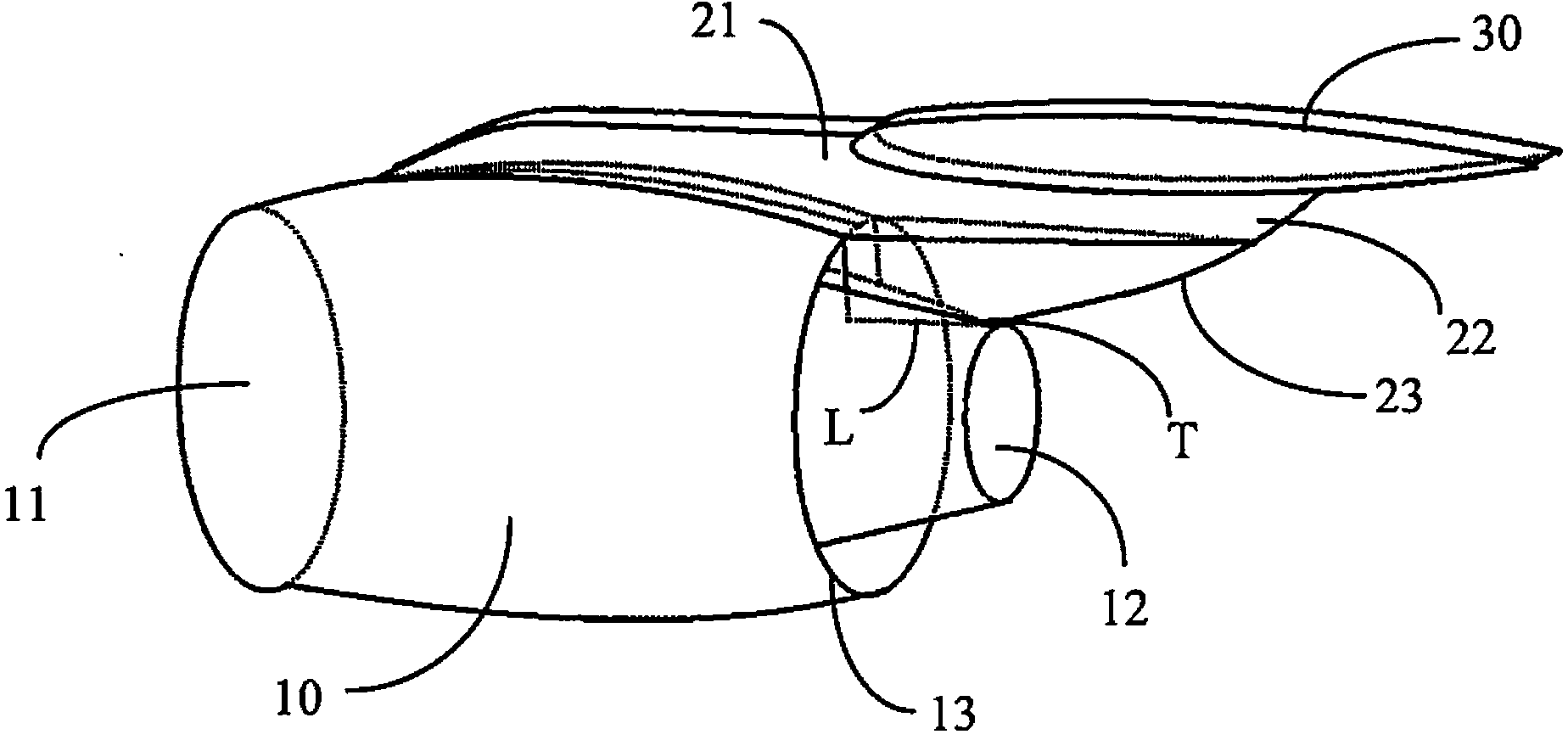

Fairing structure for pylon of aircraft with wing-mounted layout

ActiveCN103612746AIncrease the internal volumeRunner area optimizationPower plant arrangements/mountingAircraft power plant componentsLeading edgeNacelle

The invention provides a fairing structure for a pylon (20) of an aircraft with wing-mounted layout. The fairing structure comprises a front fairing (21) located in front of a wing leading edge (31) and a rear fairing (22) located behind the wing leading edge (31). The fairing structure is characterized in that at least part of the rear fairing (22) is realized by cross section control line modeling forming, and comprises at least one group of horizontal position control lines (P01, P02, P03, P04) and at least one group of longitudinal position control lines (S01, S02, S03, S04, S05). Through formation of the rear fairing of the pylon by the horizontal and longitudinal position control lines, the invention can conduct pylon design only through curvature control on the rear fairing of the pylon, and can realize optimization on flow area among the pylon / wing / engine nacelle without deflection on the rear portion of the pylon.

Owner:COMAC +1

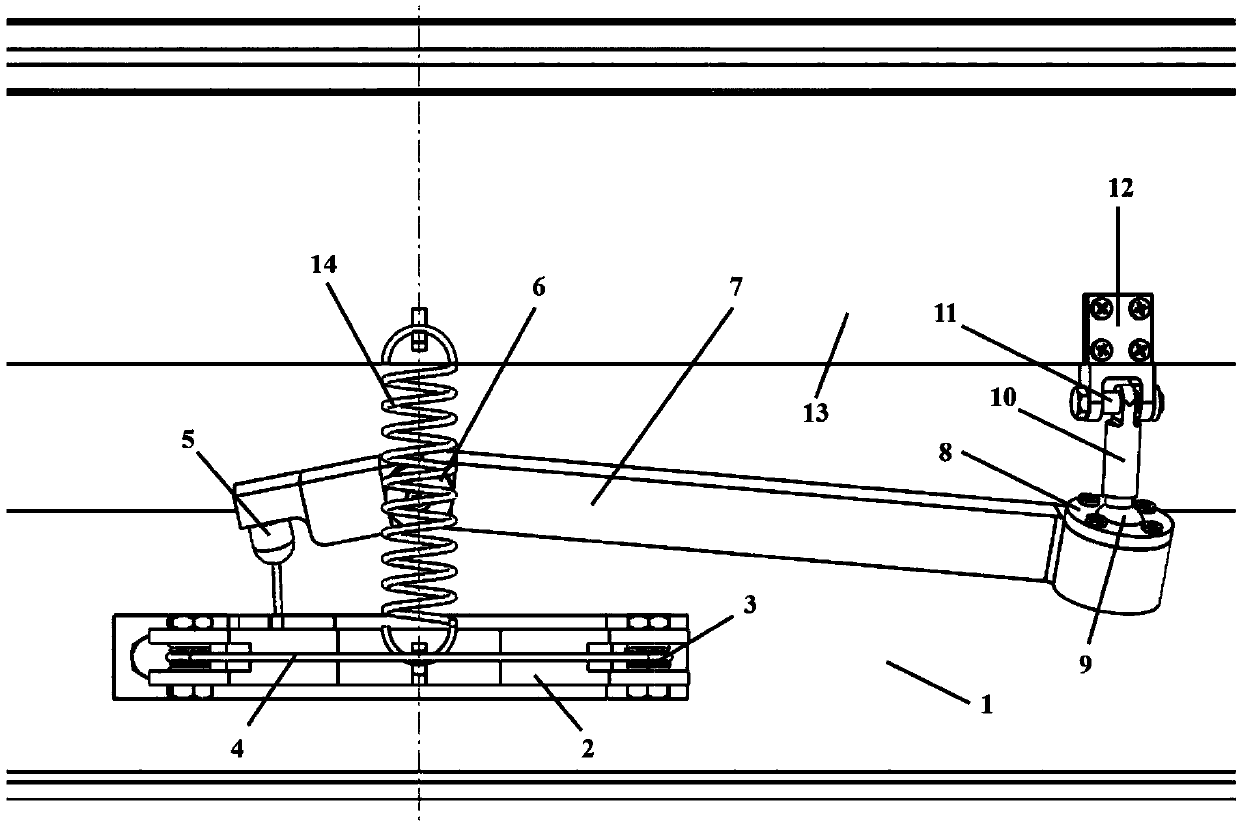

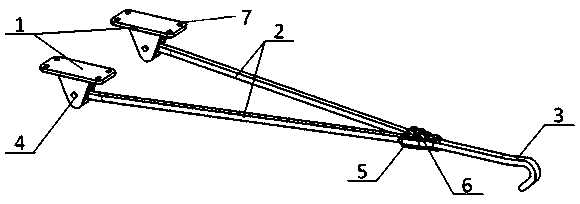

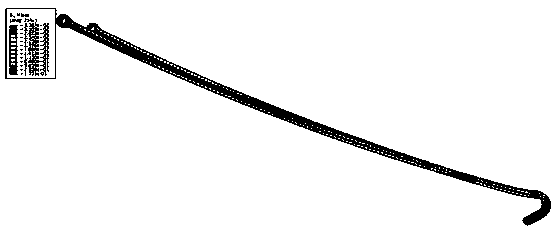

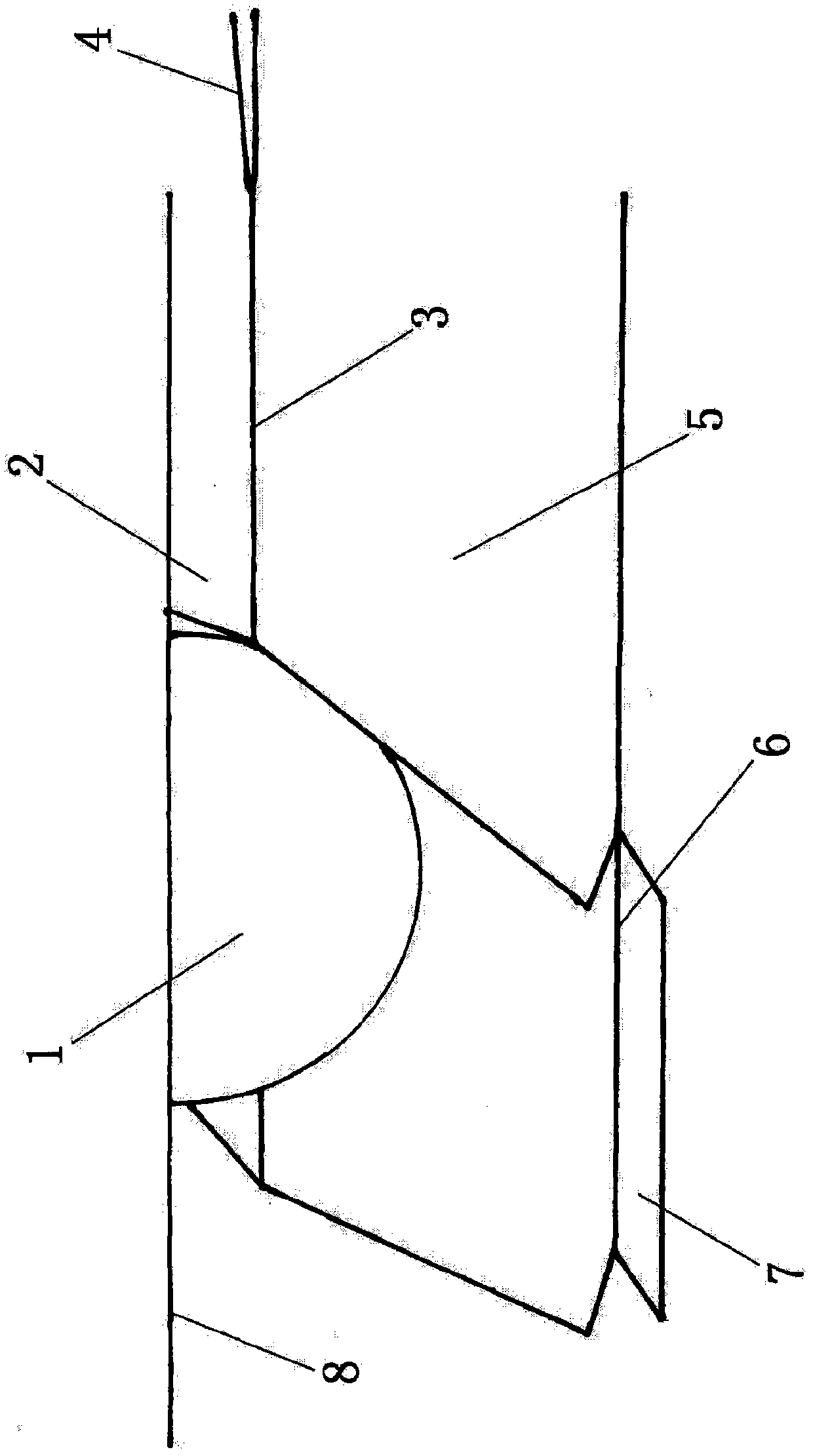

Arresting hook for unmanned aerial vehicle in gliding landing

PendingCN109552606AIncrease structural weightReduce stressArrester hooksWeight reductionMaximum levelEngineering

The invention discloses an arresting hook for an unmanned aerial vehicle in gliding landing. The arresting hook comprises a connecting seat, a V-shaped hook body and a tail hook, the V-shaped hook body is divided into two parts with left and right symmetry, the front end of the V-shaped hook body is provided with the connecting seat, the rear end sides of the left and right parts of the V-shaped hook body are fitted together, the rear end of the V-shaped hook body is connected with the tail hook, and a mounting hole for mounting and fixing the unmanned aerial vehicle is arranged in the connecting seat. By using the V-shaped arresting hook with an angle of 20 degrees, the force transmission path of the arresting hook is changed after a rope is hooked, under the condition of increasing the weight of the arresting hook structure as little as possible, the internal stress distribution and the maximum level under the same external force are greatly reduced, and the safety of landing is ensured.

Owner:AEROSPACE SHENZHOU AIRCRAFT

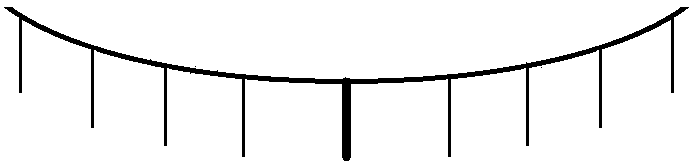

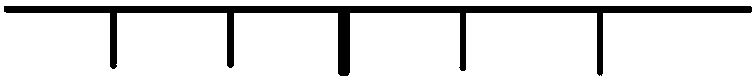

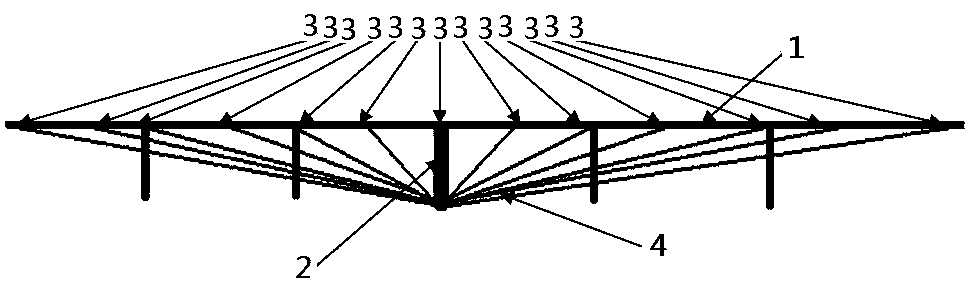

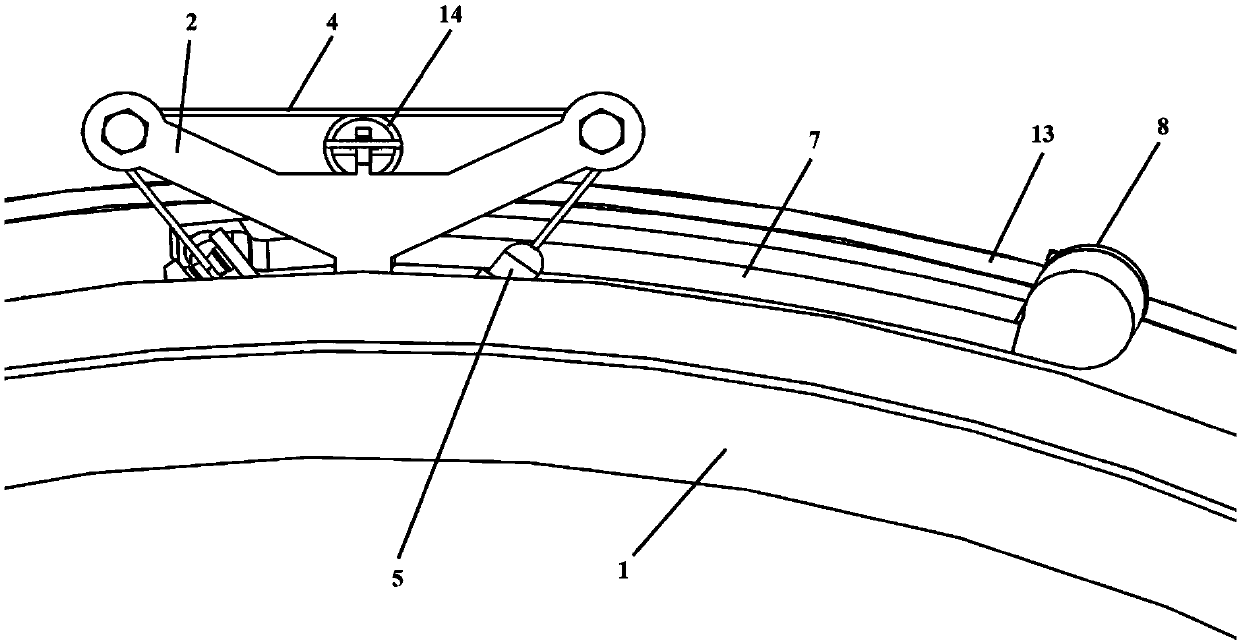

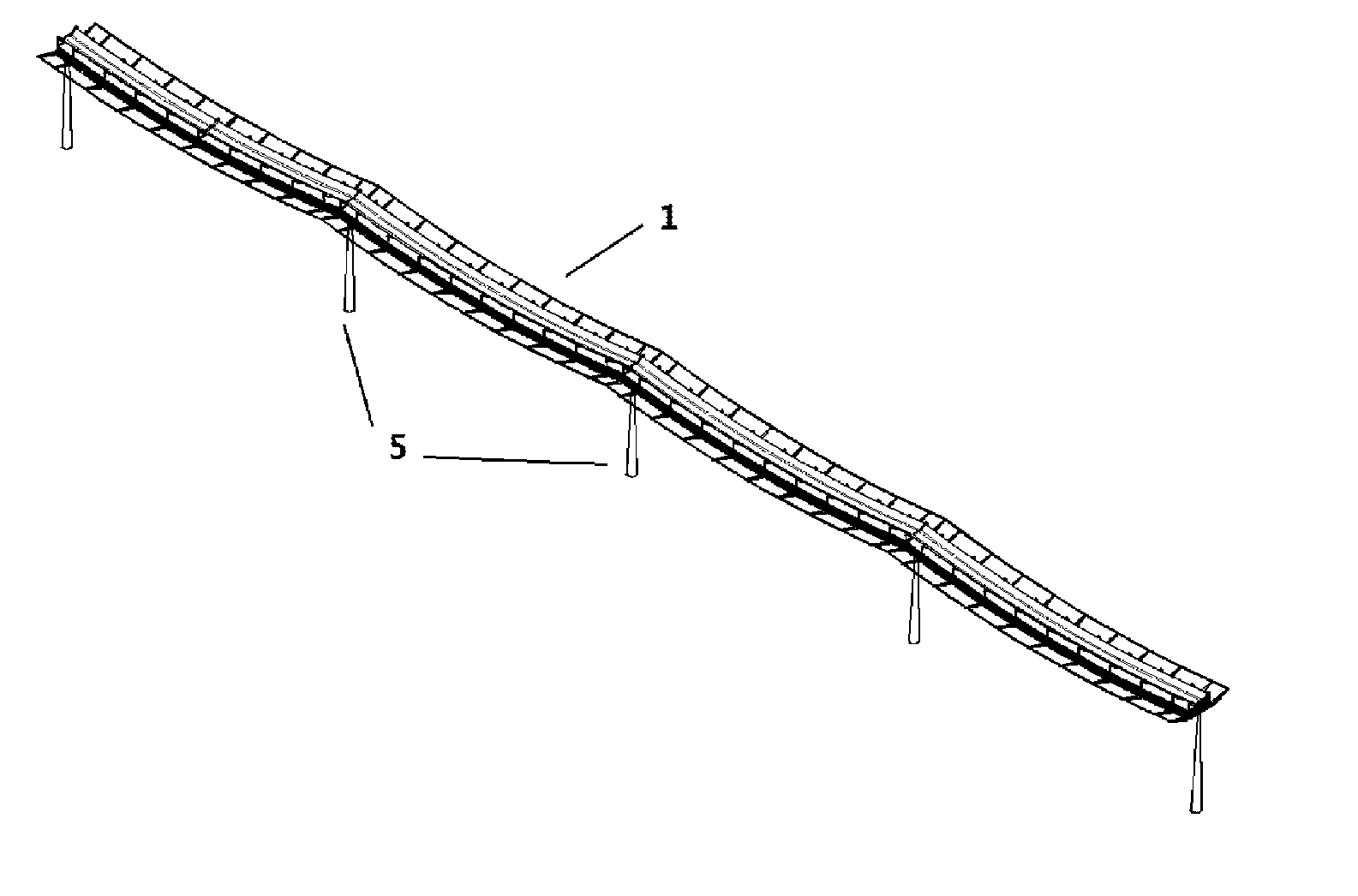

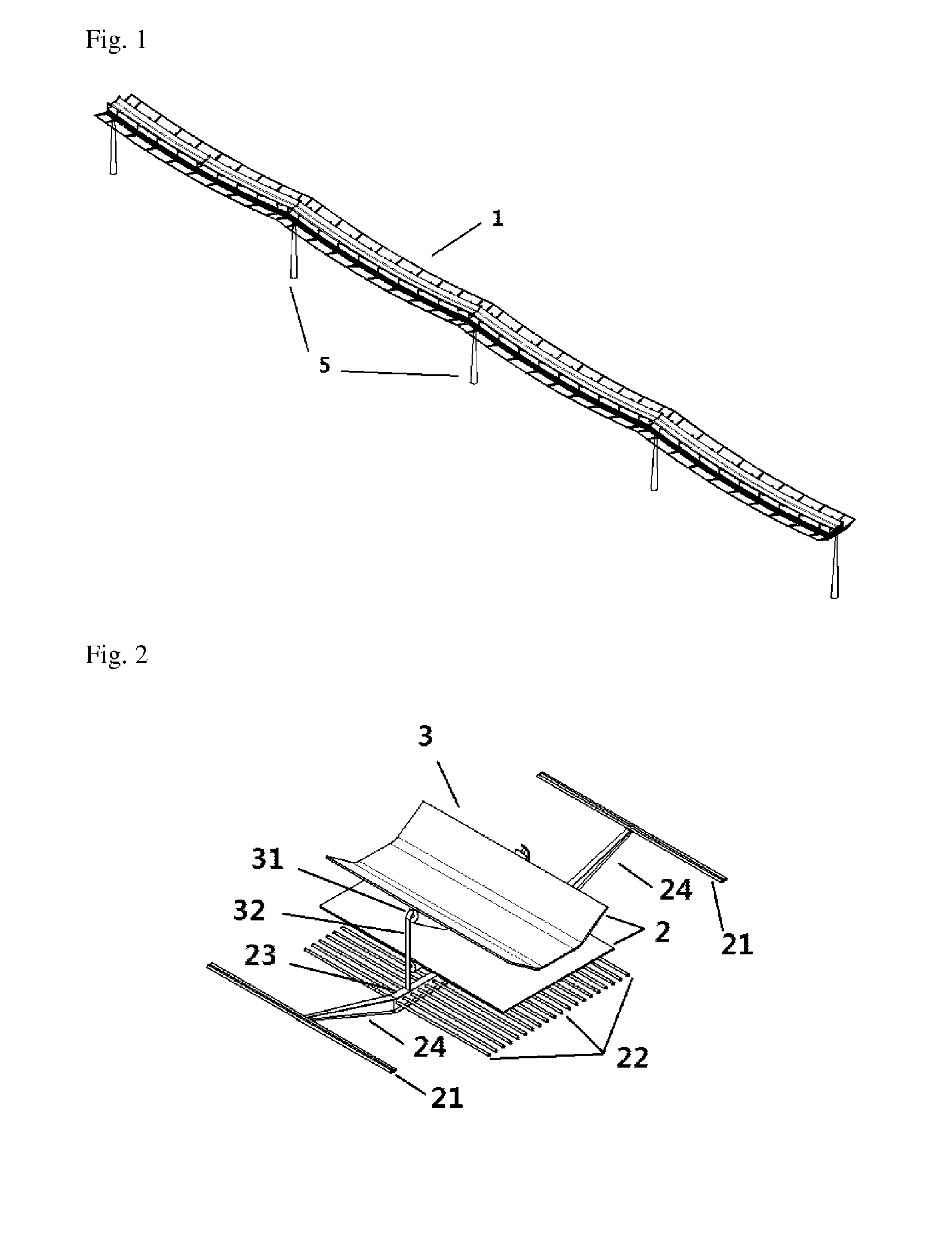

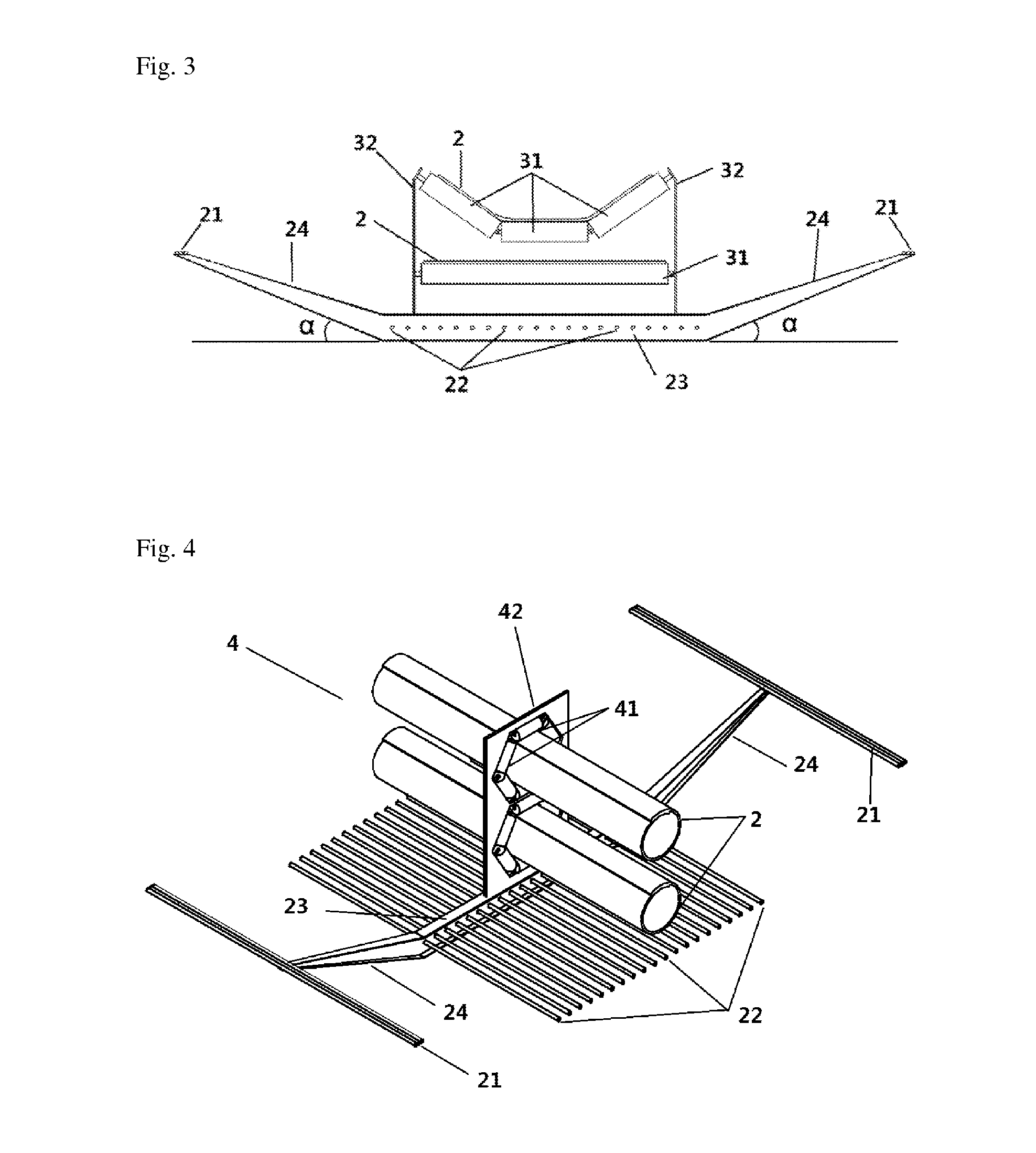

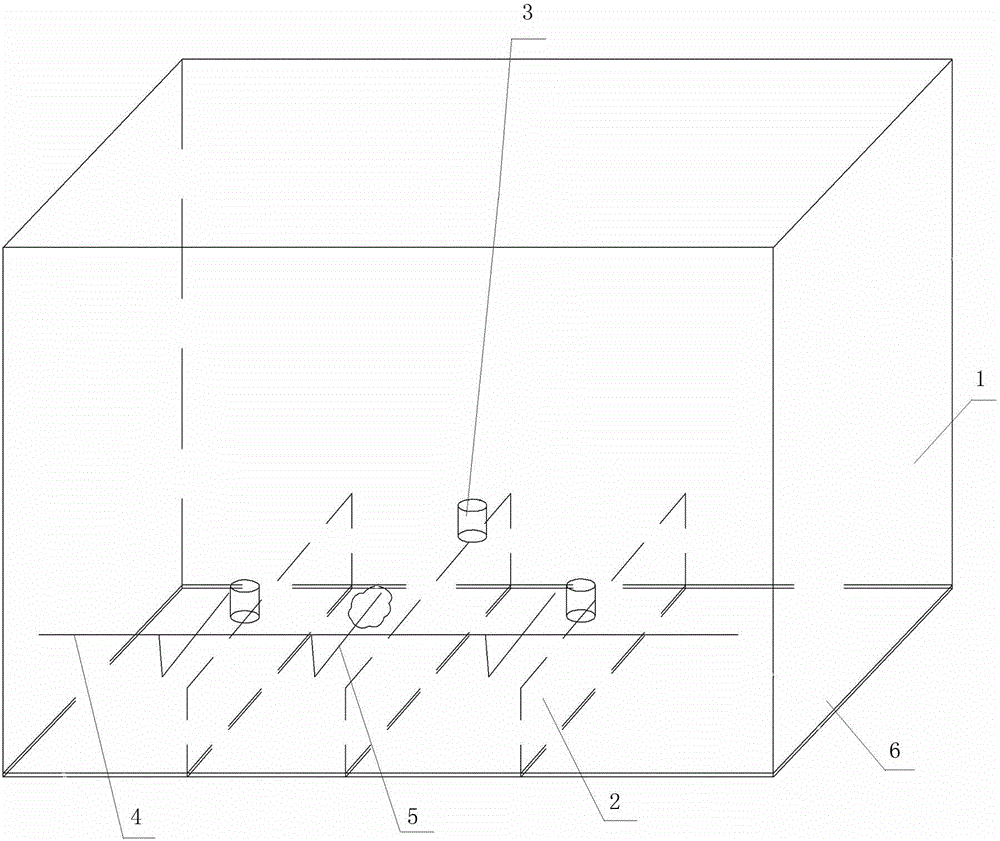

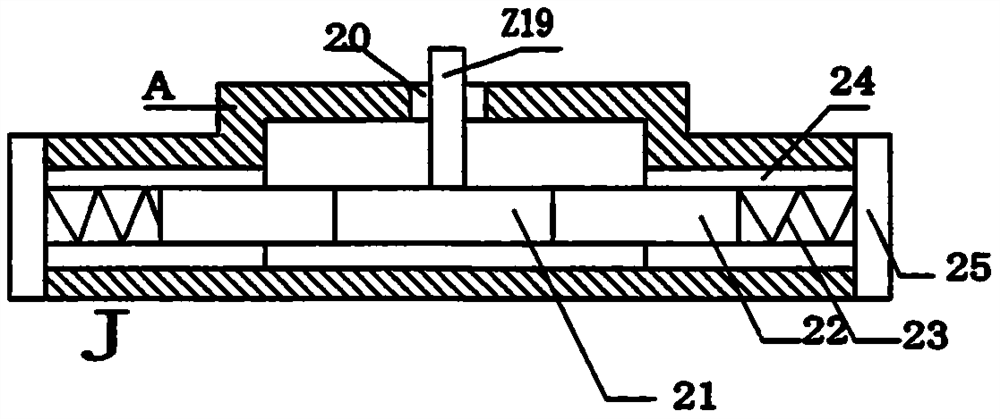

Simple suspension bridge type belt conveyor

InactiveUS20140284184A1Reduce manufacturing costImprove efficiencyConveyorsRollersSuspension bridge typesEngineering

A simple suspension bridge type belt conveyor comprises a simple suspension bridge body (1), a conveyor belt (2), a trough support roller apparatus (3) and a circular support roller apparatus (4). A plurality of supporting pillars (5) are arranged beneath the simple suspension bridge body (1); the trough support roller apparatus (3) and the circular support roller apparatus (4) are fixed on the simple suspension bridge body (1). The conveyor conveys materials on the conveyor belt (2) which is moving through the trough support roller apparatus (3) and the circular support roller apparatus (4). The simple suspension bridge type belt conveyor enables the conveyor belt (2) to pass over the pillars (5) of simple suspension bridge without overstressing the conveyor belt (2), and has lower manufacturing cost and higher conveying efficiency.

Owner:CABLE BRIDGE CONVEYOR

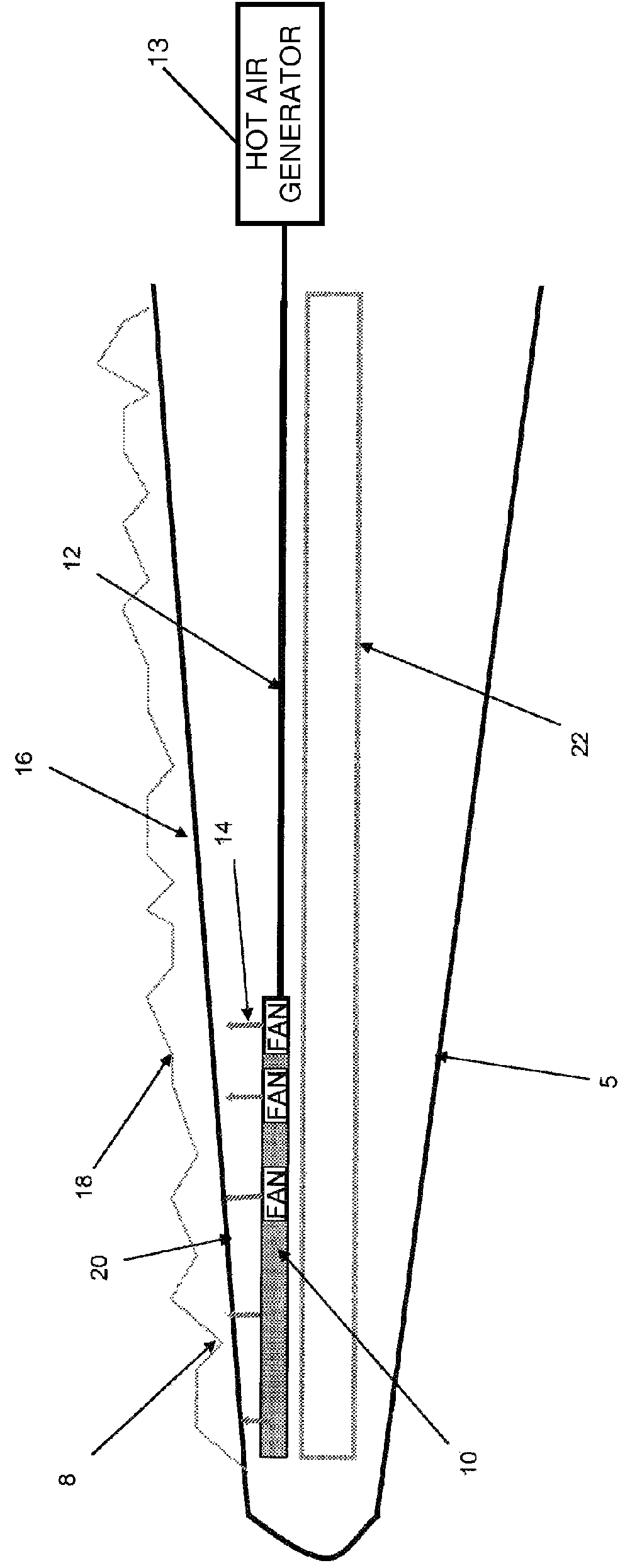

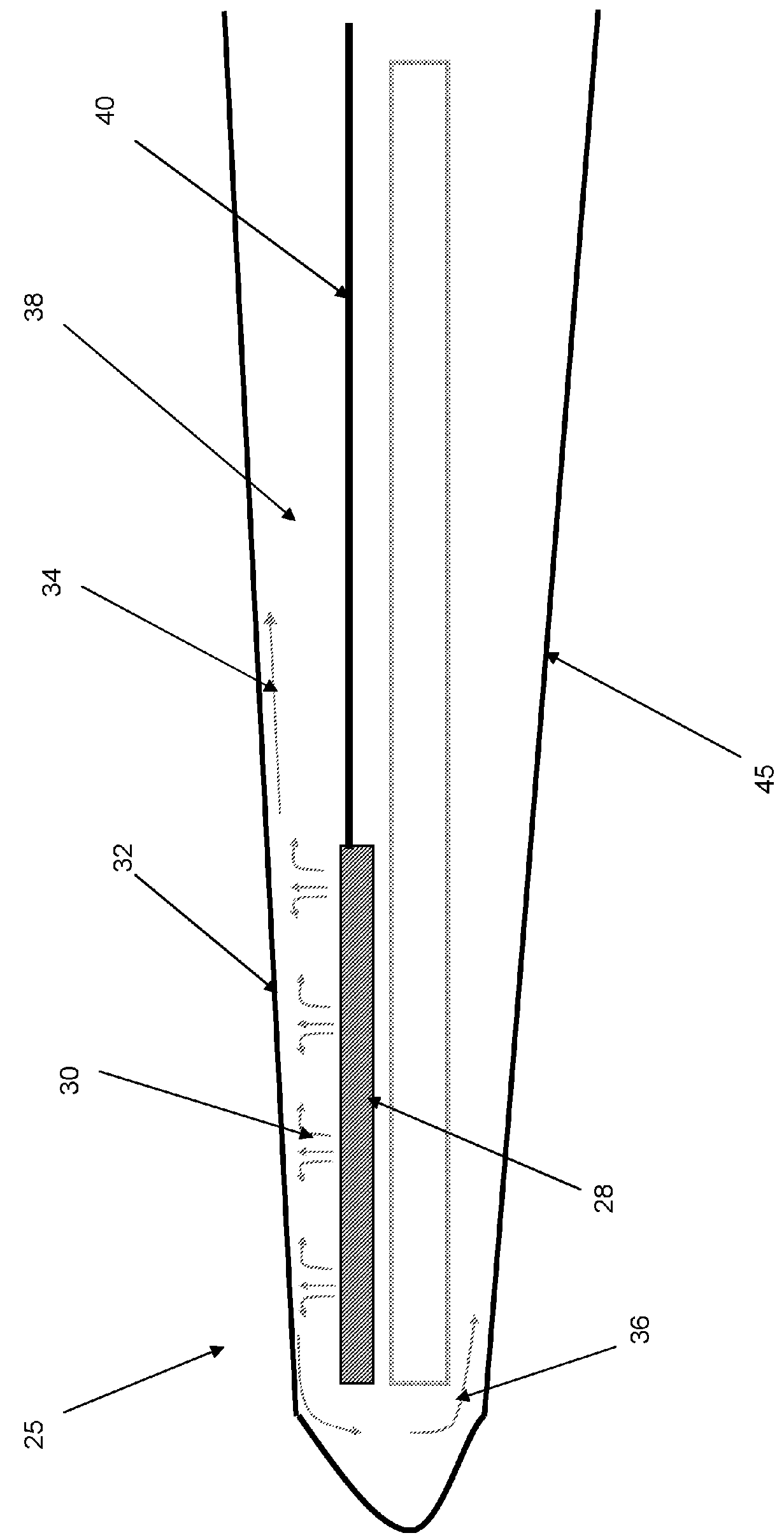

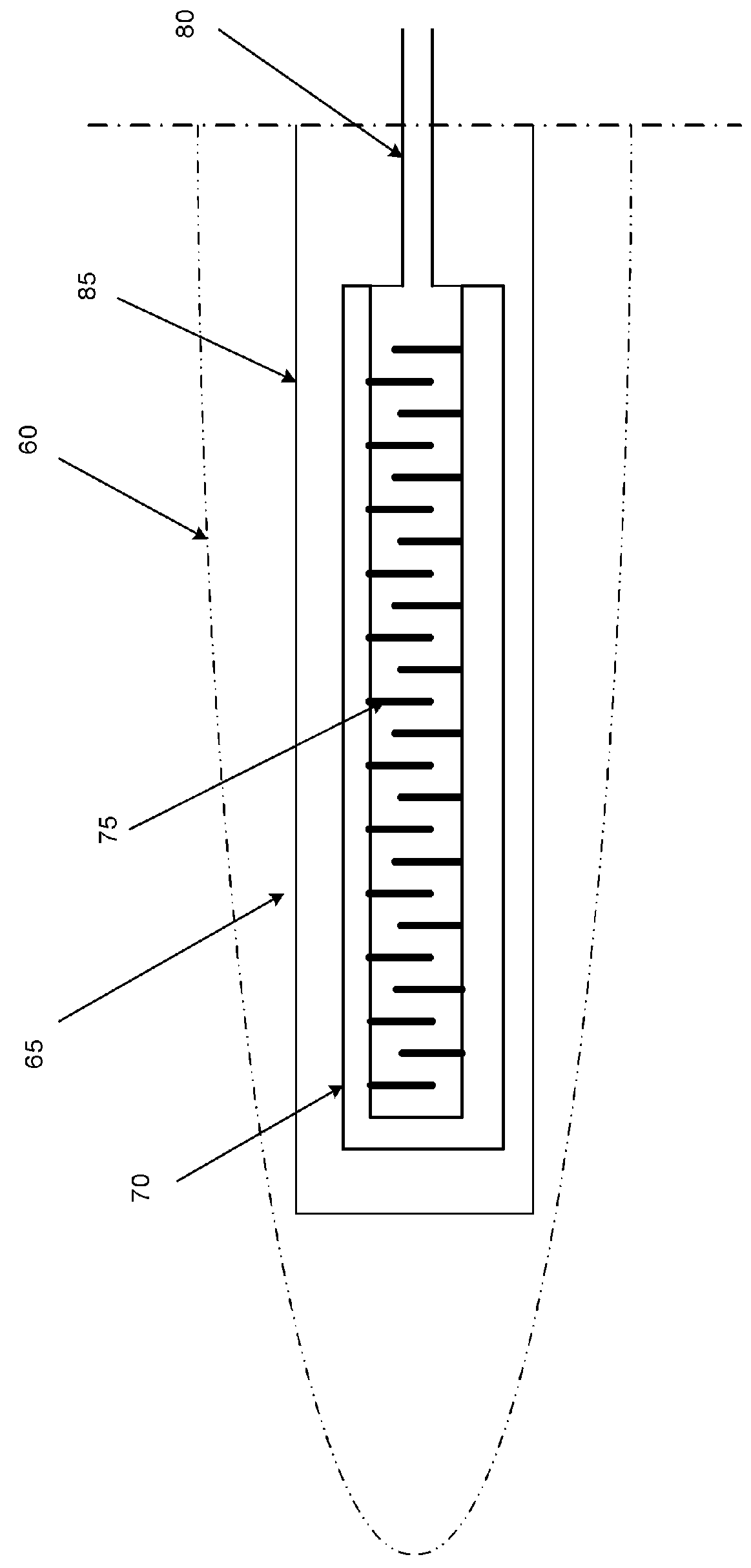

De-icing of a wind turbine blade

ActiveUS10041477B2Prevented from re-formingEffective de-icingEngine fuctionsBlade accessoriesTurbine bladeEngineering

A heating assembly for a blade of a wind turbine generator, the heating assembly comprising: a heat reservoir positioned within a cavity of the blade, the heat reservoir in communication with a heat source; the heat reservoir including a plurality of orifices for venting hot air from the heat reservoir.

Owner:VESTAS WIND SYST AS

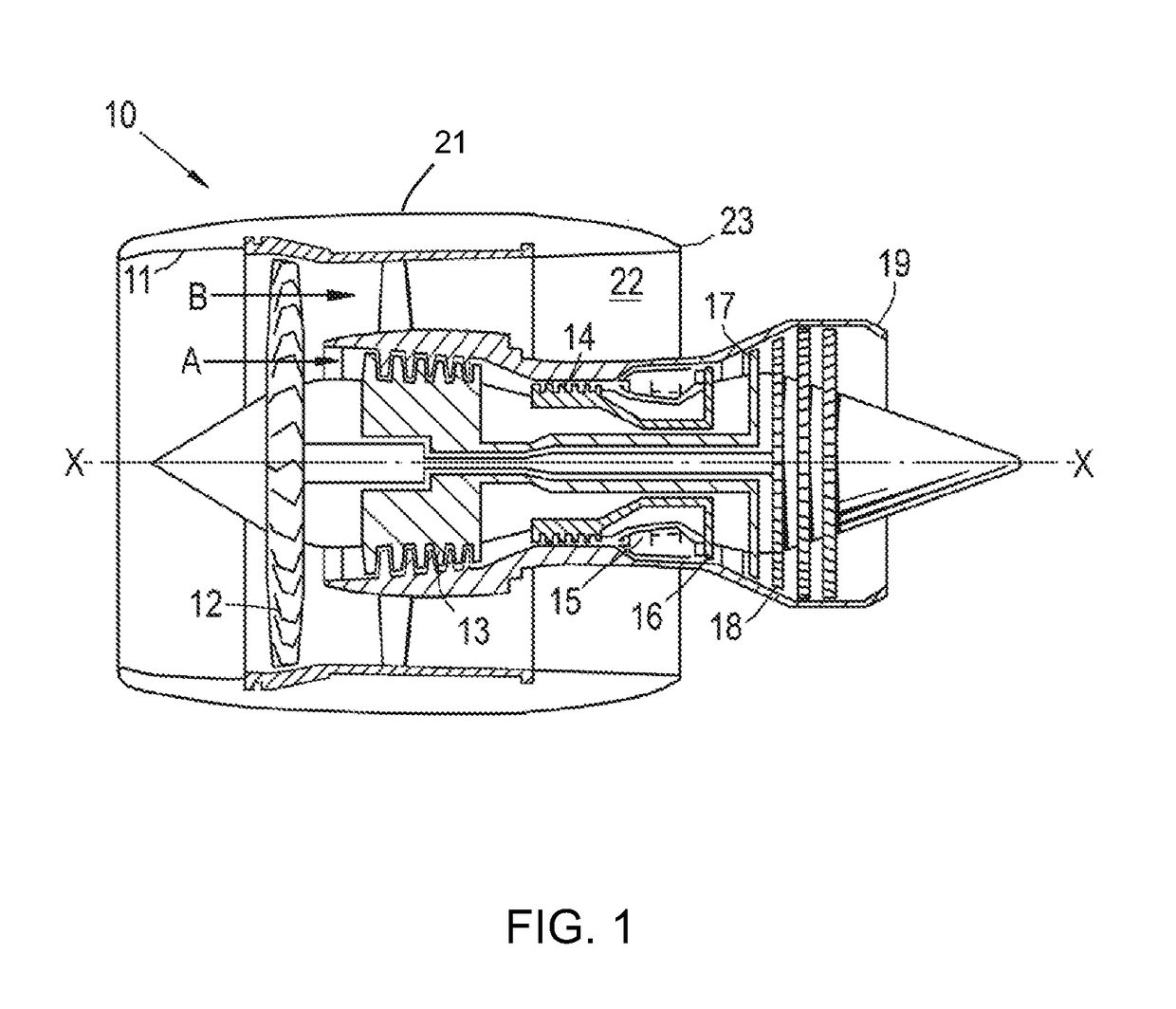

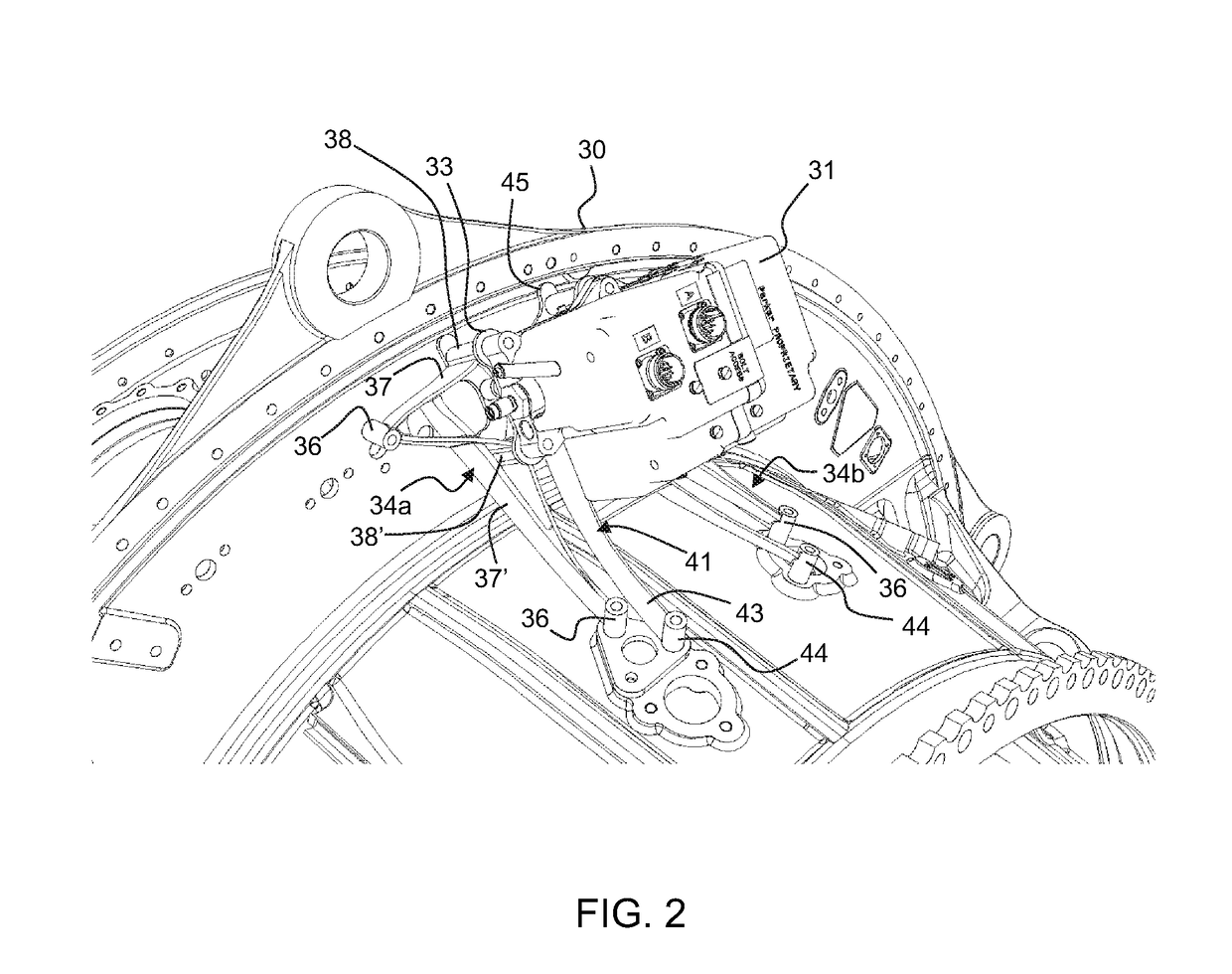

Mount structure

ActiveUS20180171876A1Increasing weight of structureReduced complianceAdditive manufacturing apparatusPower installationsGas turbinesEngineering

A mount structure for mounting an ancillary engine unit to a gas turbine engine is provided. The mount structure has plural elongate struts which each extend from a connector portion at one end of the strut to a fastening portion at the other end of the strut. The housing of the ancillary engine unit is formed of a first material having a first coefficient of thermal expansion, and the elongate struts are formed of a second material having a second coefficient of thermal expansion. Each elongate strut extends away from its connector portion in a direction which is crosswise to the direction of the hypothetical differential thermal strain at that connector portion. The mount structure further has a containment bracket which is configured to contain each connector portion.

Owner:ROLLS ROYCE PLC

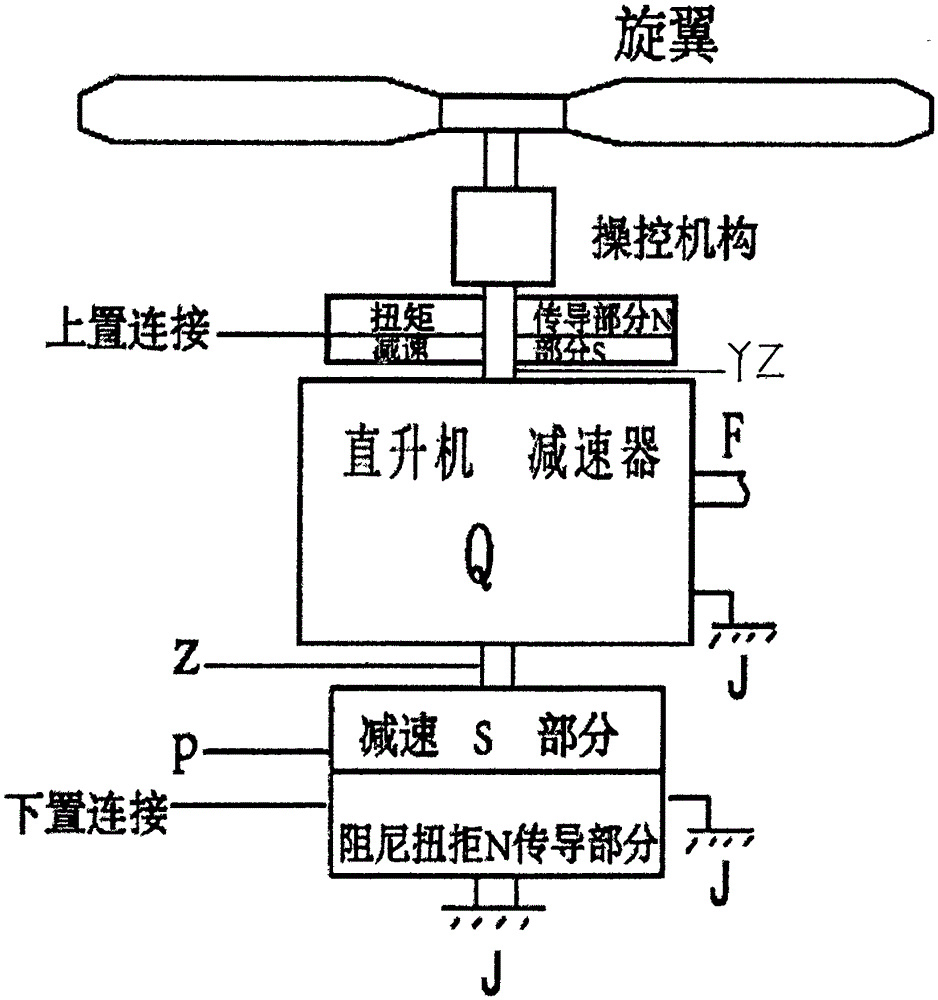

Method for balancing rotation torque of helicopter body

The invention discloses a method for balancing the rotation torque of a helicopter body. According to a traditional helicopter, a tail rotor and a duct type tail rotor are adopted, two sets of rotor wings rotate oppositely so as to generate active airflow, and the active airflow is reversely sprayed out on the tail portion, so that the rotation torque of the body of the traditional helicopter is balanced; or the body of the traditional helicopter is balanced through other methods. The rotation torque of the body of the traditional helicopter can be balanced through the methods, however, the traditional helicopter adopting the methods has certain defects. According to the method for balancing the rotation torque of the helicopter body, the structure that a torque balancer is connected to a speed reducer spindle of a helicopter so as to replace a tail rotor, one of two sets of rotor wings, and a tail airflow body rotation torque balancing structure of the traditional helicopter is used for balancing the rotation torque of the helicopter body. By the adoption of the method, a helicopter which is free of a tail rotor, a power transmission part of the tail rotor, and a tail airflow torque balancing structure and is provided with one set of rotor wings can be obtained.

Owner:王泽民

Re-improved inlet for third-generation light fighter

InactiveCN102887230AReduced reflective cross-sectional areaIncrease air intakePower plant air intake arrangementsFront edgeWorkload

The invention discloses a re-improved inlet for a third-generation light fighter, comprising an inlet side wall, an inlet lower wall and a boundary layer push bump. The front edge of the inlet lower wall is provided with an adjustable lower lip edge; the inlet side wall causes the upper edge firstly to be arranged outwards at the same horizontal position with a wing and then to be changed into an inward-retracting shape; and the bending position of the inlet side wall is provided with an obvious adjacent line. The re-improved inlet for the third-generation light fighter has the advantages that the radar cross section, flight drag, maintenance workload and structural weight of the third-generation light fighter are reduced; and the re-improved inlet allows the light fighter to fly at the speed of 2 Mach.

Owner:王长存

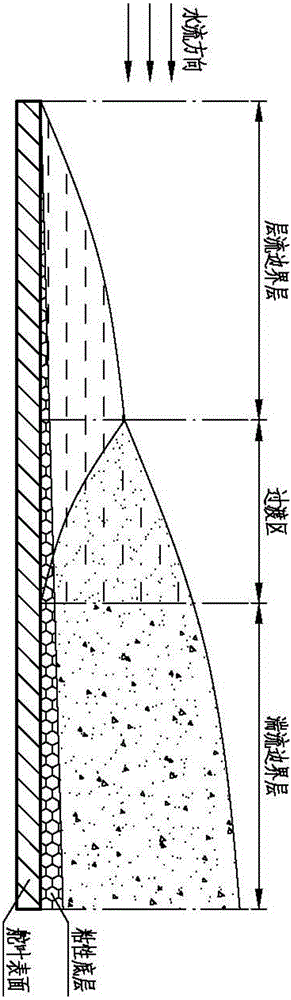

Water ballast tank anti-sediment structure

ActiveCN104527929ASimple structureImprove removal efficiencyTank vesselsHull interior subdivisionSludgeAdhesive

A water ballast tank anti-sediment structure comprises stiffeners arranged at the bottom of a water ballast tank at intervals. Multiple mud-disturbing devices used for repeatedly disturbing and breaking sedimented sediments and impurities are arranged at intervals above the stiffeners in the water ballast tank. The water ballast tank anti-sediment structure is simple in structure, low in cost, small in usage space, and can not change a ship structure or increase the weight of the ship structure, therefore the water ballast tank anti-sediment structure can be applied to any ship type, and the application range is wide. Due to the fact that the water ballast tank anti-sediment structure can directly resolve the problem that a large number of the sedimented sediments and impurities are continuously deposited on and adhesive to the water ballast tank which uses seawater as ballast water, the load capacity consumed by sludge in ship operation is reduced, and the use-cost of a ship is reduced greatly. Additionally, when the ship enters a dock for maintenance, through cleaning the water ballast tank by the anti-sediment structure, the workload of workers in cleaning the water ballast tank is reduced greatly, the ship maintenance work efficiency is improved, and the labor cost is lowered.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Third-generation heavy fighter novel gas inlet channel lip

InactiveCN102817715ALarge thrustIncrease takeoff thrustWeight reductionTurbine/propulsion air intakesLeading edgeInlet channel

The invention discloses a third-generation heavy fighter novel gas inlet channel lip. The novel gas inlet channel lip comprises a gas inlet channel lip and a boundary layer separation plate, the fixed gas inlet channel lip of a present heavy fighter is changed to a retractable movable lip, the retractable movable lip is arranged on two sides of the front portion of the boundary layer separation plate through a hinge shaft, a movable lip folding and unfolding hydraulic actuation cylinder on a mounting joint on the inside wall of the air inlet channel is connected with a folding and unfolding pull rod on the rear portion of the inner end of the movable lip through a connection bolt to realize the folding and the unfolding of the movable lip, a fixed lip having a radius larger than the radius of the movable lip is arranged on the rear portion of the movable lip, and a rectification box having a leading edge radius same with the radius of the movable lip is arranged outside the hinge shaft, and enables the third-generation heavy fighter to have relatively large engine push force on a relatively short running track such as when the third-generation heavy fighter launches on an aircraft carrier or flights in a low-altitude and low-speed manner, and to correspondingly increase the launching weight, the fighting capability and the use flexibility of the fighter.

Owner:王长存

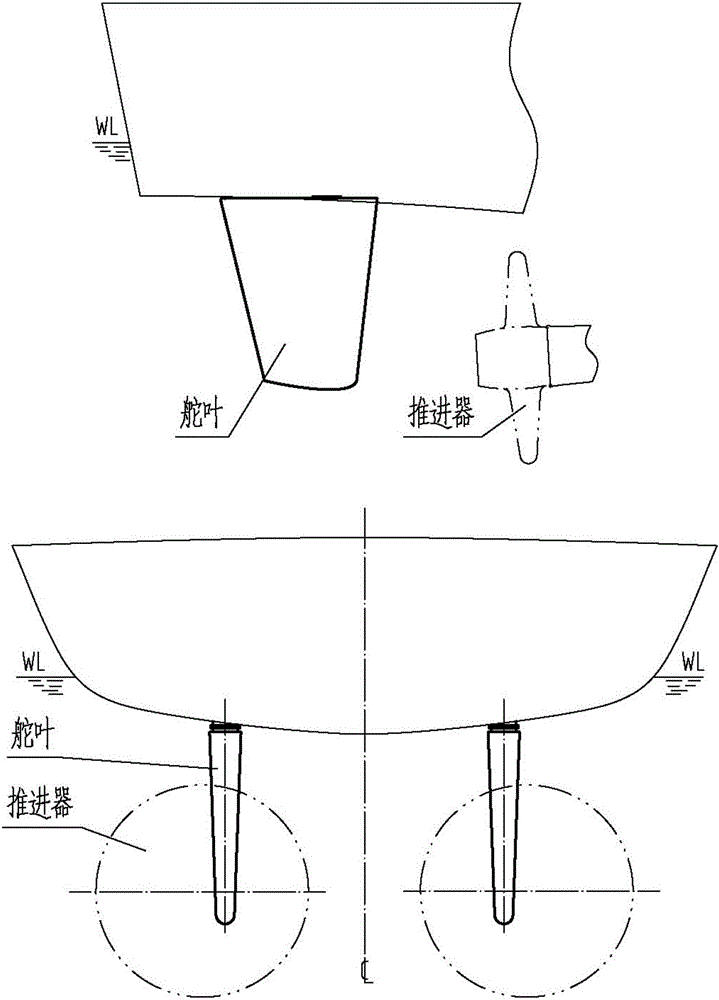

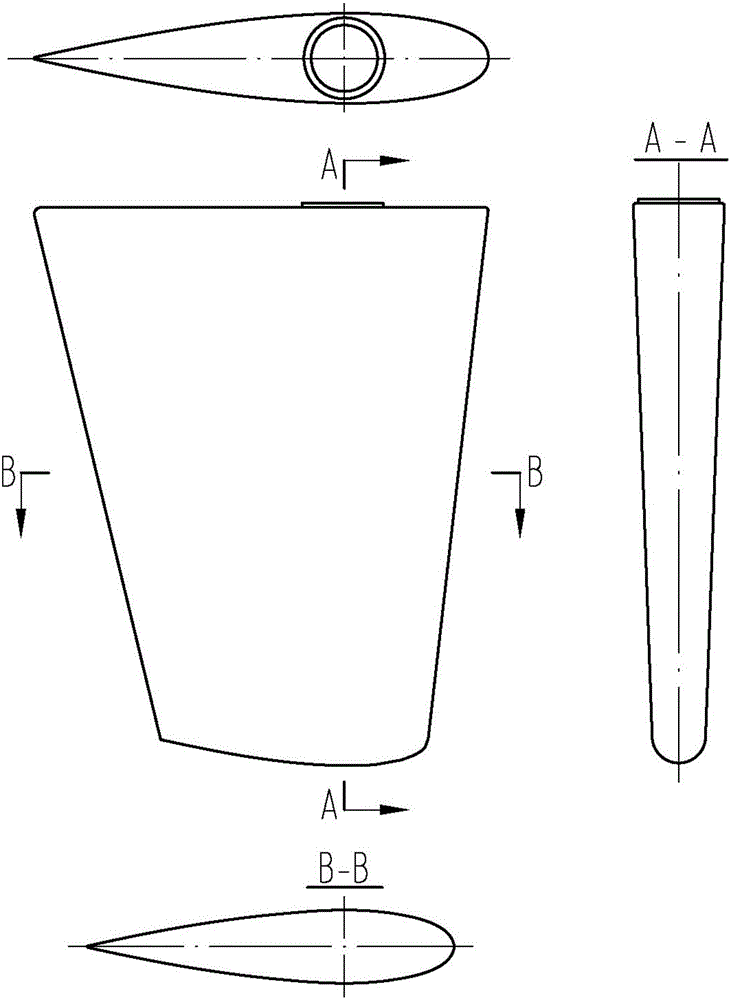

Low noise rudder blade surface structure for warship

The invention discloses a low noise rudder blade surface structure for a warship. The low noise rudder blade surface structure for the warship comprises common elastic wing panels, an elastic bow wing panel and an elastic stern wing panel, wherein the common elastic wing panels are fixedly connected with a rudder blade shell plate by virtue of mounting screws, the elastic bow wing panel is fixedly connected with the rudder blade shell plate by virtue of mounting screws, and the elastic stern wing panel is fixedly connected with the rudder blade shell plate by virtue of mounting screws; and the common elastic wing panels are connected with the elastic stern wing panel in an overlapping and leaning manner, the common elastic wing panels are mutually connected in an overlapping and leaning manner, and the elastic bow wing panel and the common elastic wing panels are connected in an overlapping and leaning manner. The low noise rudder blade surface structure for the warship has the advantages that one group of detachable elastic wing panels which are mutually matched are mounted on a rudder blade, so that the rudder blade surface structure has certain elasticity, the drastic change of water pressure, caused by turbulent flow or eddy, of a rudder blade surface is relieved, and the water flow field of the rudder blade surface is improved by virtue of surface grooves of the elastic wing panels, so that anti-cavitation and eddy reducing properties of the whole rudder blade are improved, and the fluid noise of the rudder blade is reduced.

Owner:CHINA SHIP DEV & DESIGN CENT

Power system of single-rotor helicopter without reactive torque tail rotor

InactiveCN112550687AReduce structural weightSmall structureDepending on power plant typeRotocraftBalancing machineTail rotor

Aiming at some practical defects of overlong tail, long power transmission distance, slower speed, poorer maneuverability and the like of a traditional helicopter which balances the rotating torque ofthe helicopter body by utilizing reverse torque tail paddles and mutual reverse rotation of double coaxial rotors, the invention provides a power system of a single-rotor helicopter without the reactive torque tail rotor and a power system of a helicopter with a thrust propeller or a tilting thrust propeller, the reactive torque tail rotor of the traditional helicopter is replaced, one rotor in the double coaxial rotors is used for balancing the rotating torque of the helicopter body, and the flying speed and maneuverability of the helicopter are improved.

Owner:王泽民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com