Fairing structure for pylon of aircraft with wing-mounted layout

A fairing and layout technology, which is applied in the field of aircraft aerodynamic shape design, can solve problems such as adverse effects of airflow, inability to reflect practical value, and inability to achieve deflection of hanging cross-sections, so as to reduce adverse effects, avoid airframe structure weight, reduce The effect of aircraft manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure of the fairing suspended in the aircraft with wing suspension layout according to the present invention will be specifically described below. In the following detailed description, directional terms, such as up, down, left, right, etc., are used with reference to the directions described in the drawings, and these directional terms are only for illustration rather than limitation. The exemplary structural design drawings and the following description of the embodiments of the present invention combined are not intended to exhaust all embodiments according to the present invention.

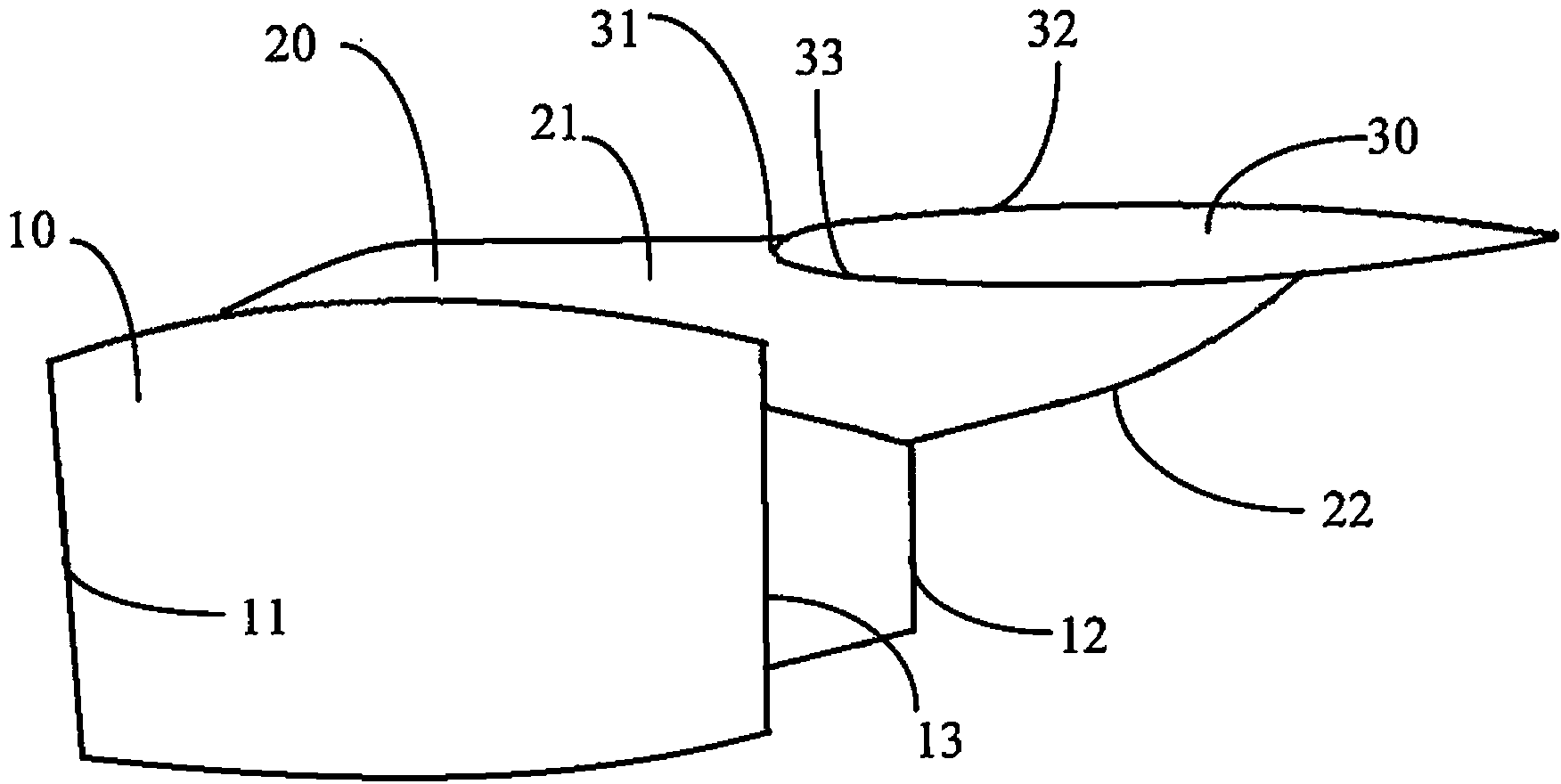

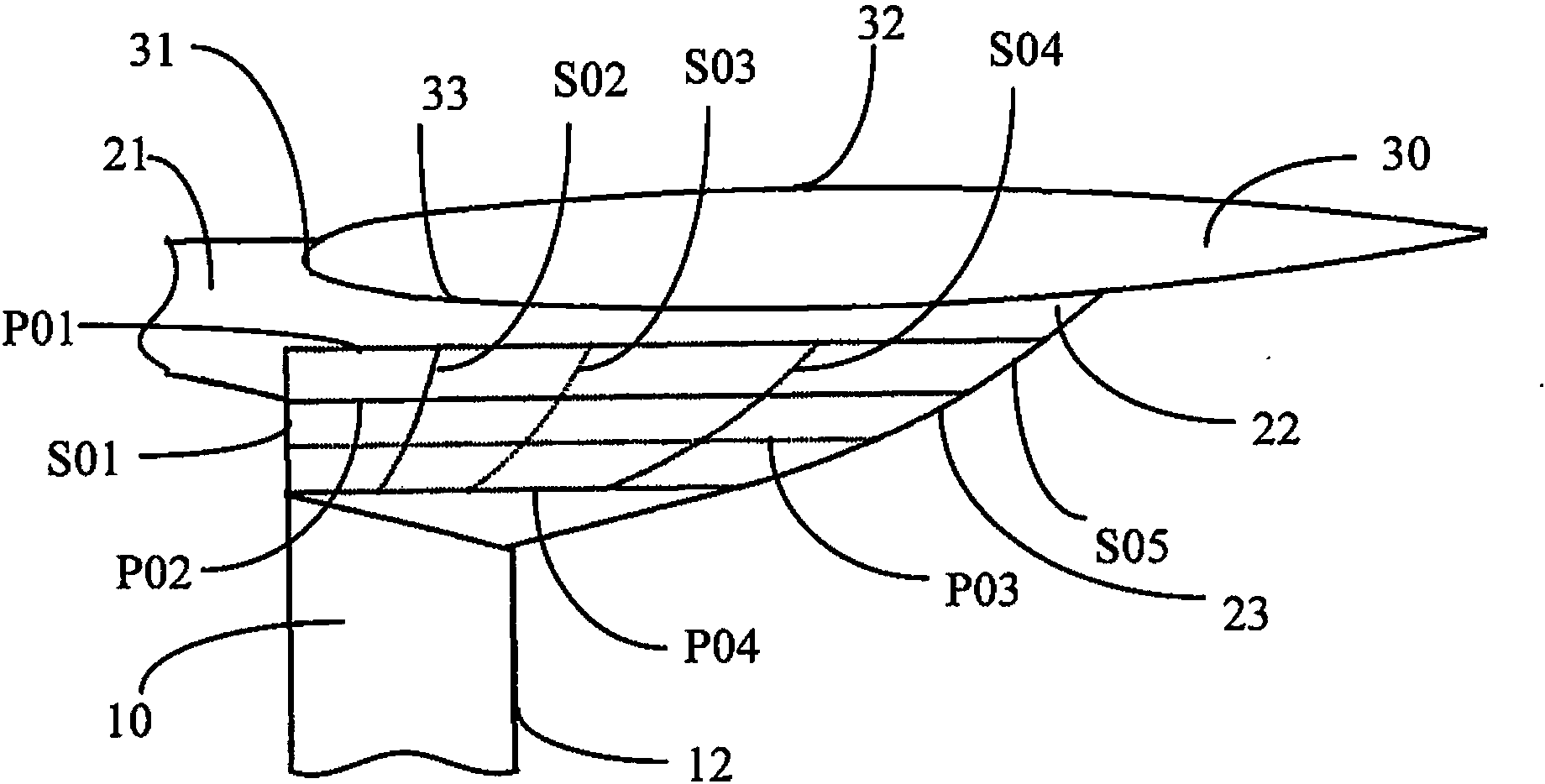

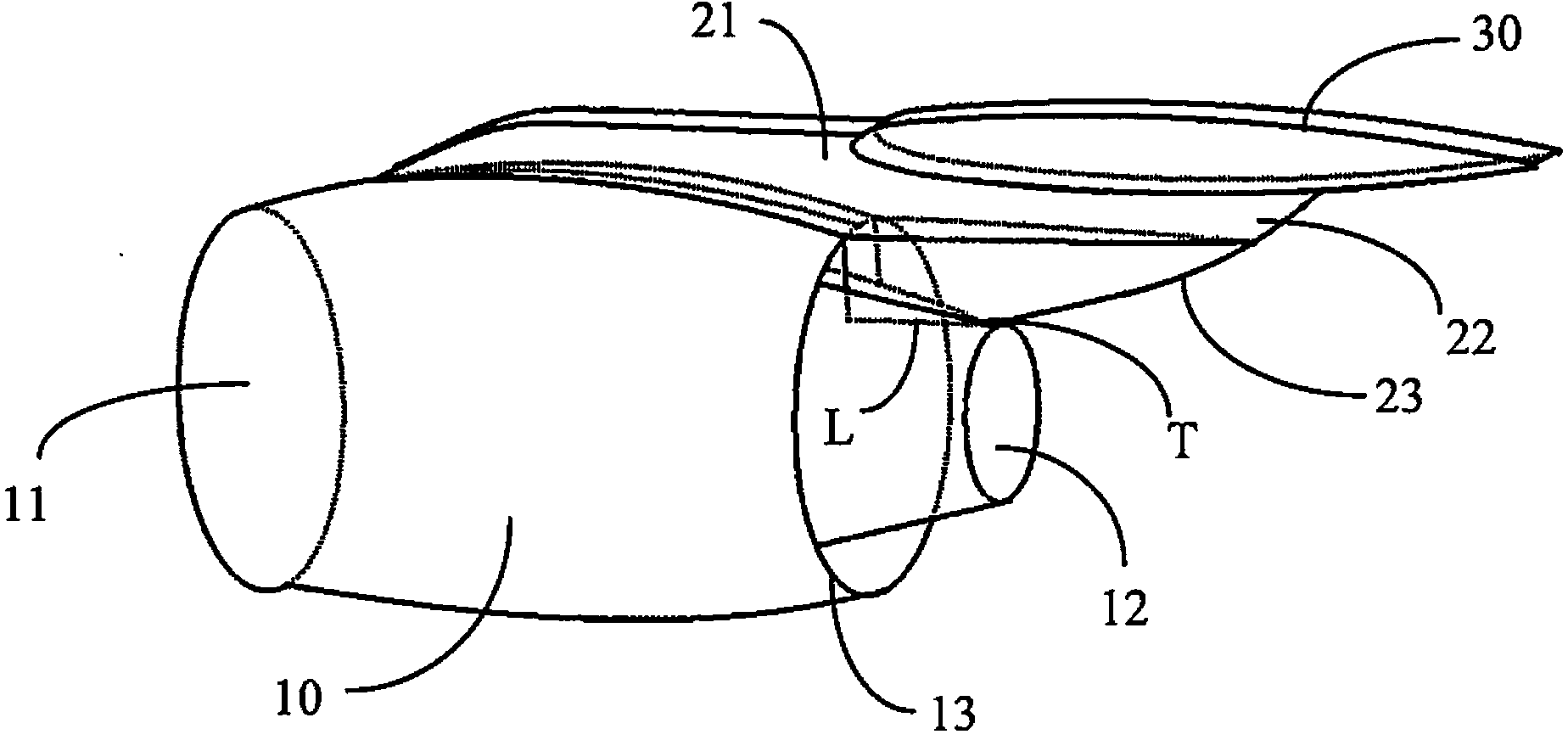

[0021] combine figure 1 and figure 2 As shown, in a preferred embodiment of the present invention, the improved design of the suspended fairing structure is realized by modeling at least a part of the suspended rear fairing using section control lines. For those skilled in the art, the modeling and shaping technology should be well known, and will not be repeated here. Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com