Coupling structure and use method of combined type trolley case

A technology of connecting structures and trolley cases, applied in applications, luggage, clothing, etc., can solve problems such as low efficiency, high rework rate, easy confusion, etc., to reduce deformation and damage, reduce packaging and transportation costs, and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

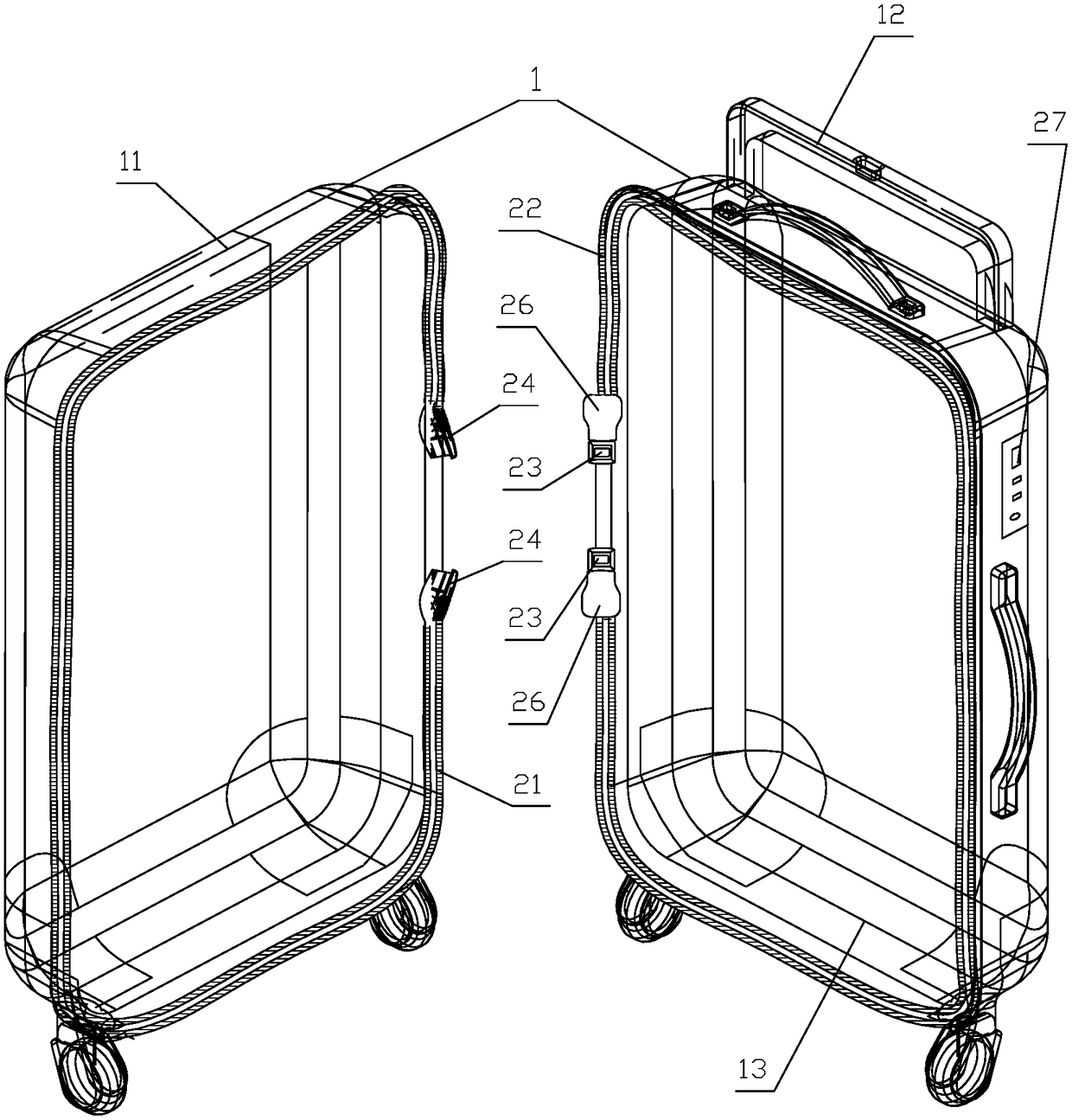

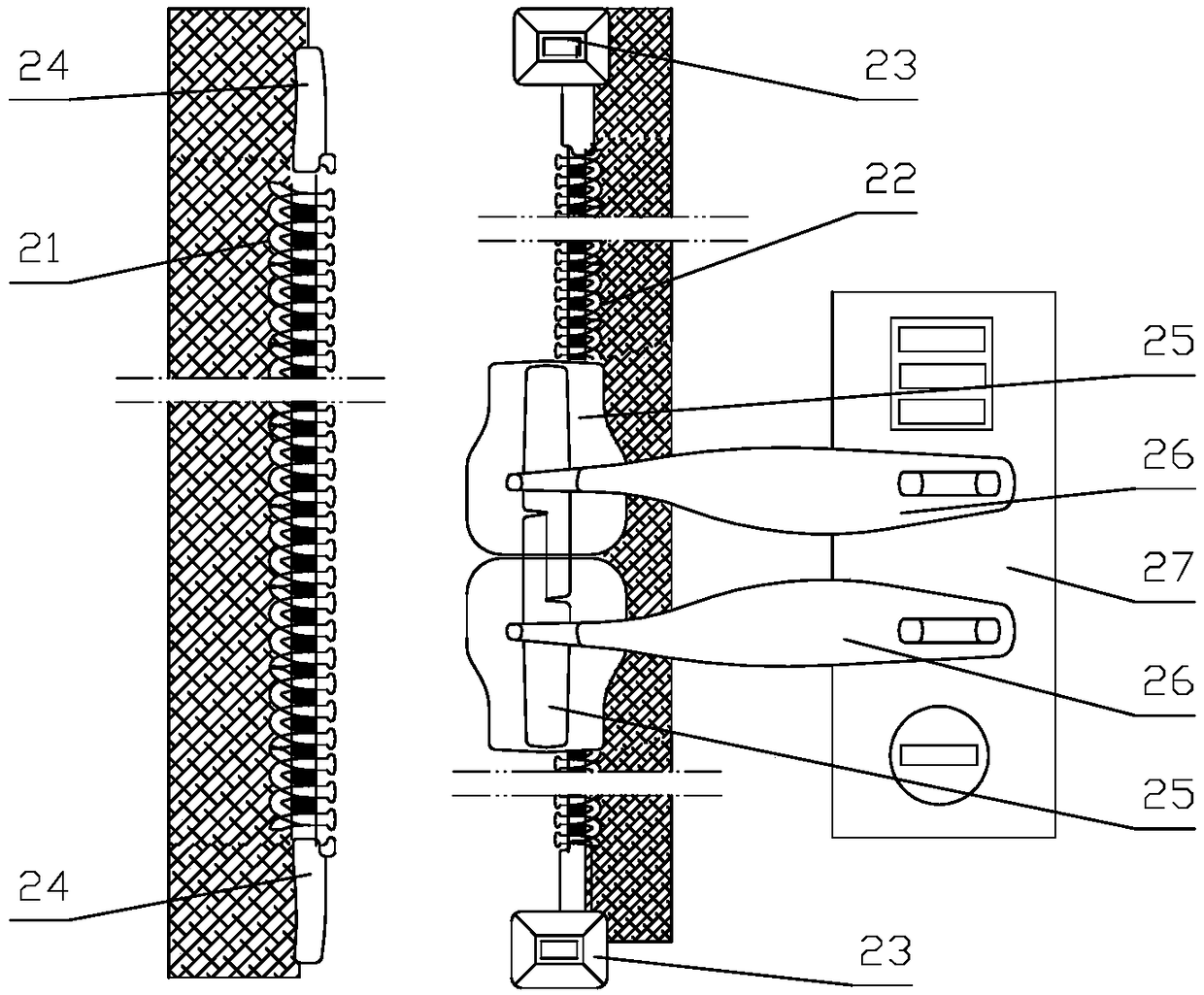

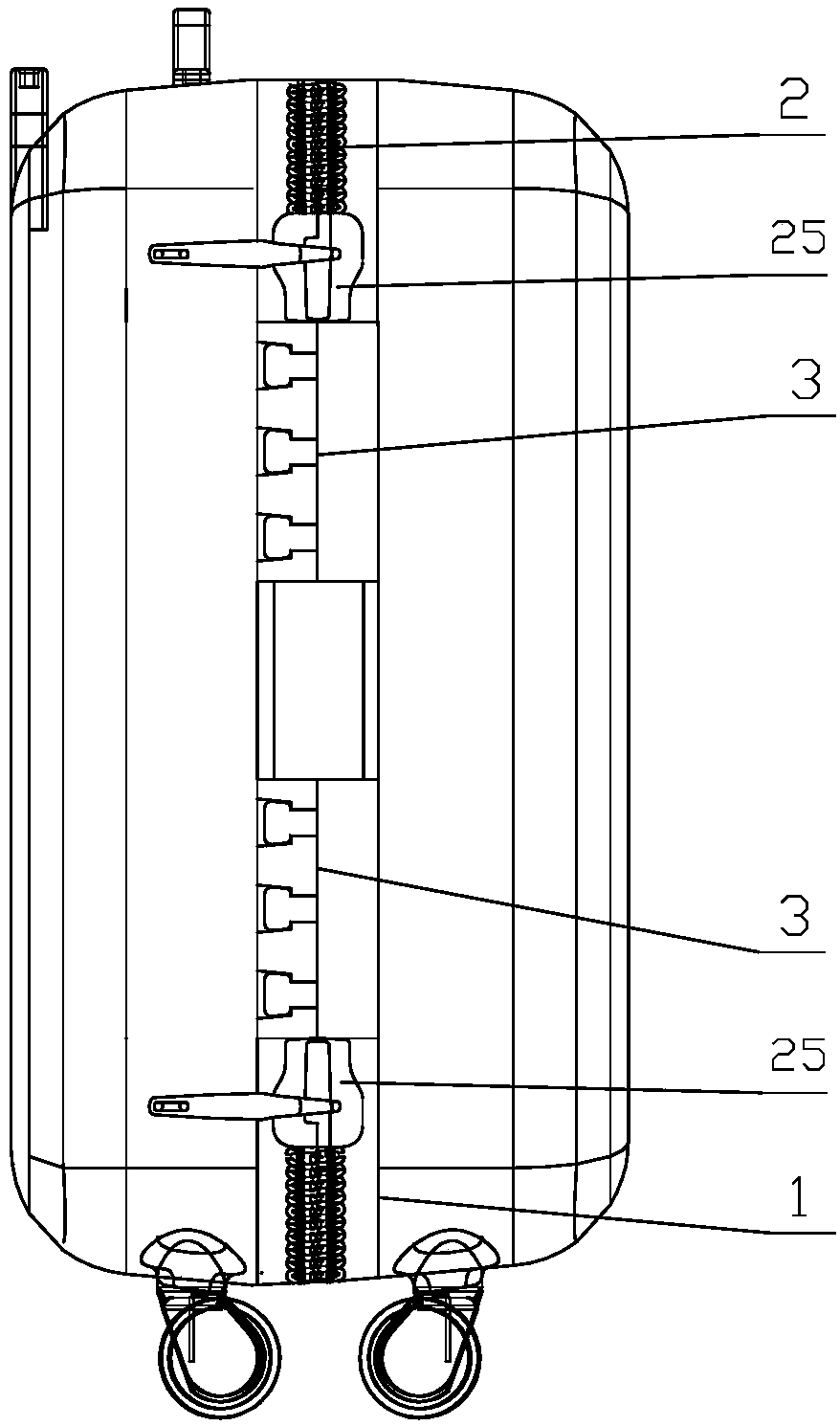

[0044] A connection structure of a combined trolley case, which comprises a soft cloth case or an upper case 11 of a hard case 1 and a lower case 13 equipped with a pull rod 12, the upper case 11, the lower case 13 is sewn around the mouth edge of the zipper 2 at both ends with the single-side chain belt A21 and the single-side chain belt B22 respectively, wherein the single-side chain belt B22 is sewn on the lower box shell 13, as shown in Figure 1 . And the two ends of described unilateral chain belt B22 are all equipped with lower gear 23, and the two ends of unilateral chain belt A21 are all installed with the latch 24 that matches lower gear 23; The slider 25, and the pull tab 26 on the slider 25 can turn to the side of the customs lock 27 and lock with the customs lock 27, as shown in FIG. 2 . Two detachable and mutually fastening soft fastening components 3 are respectively sewn and fixed on the two ends of the upper box shell 11 and the lower box shell 13 connecting p...

Embodiment 2

[0047] For the upper box shell 11 between the two fastening components 3 in embodiment 1, the lower box shell 13 is sewed with a disengagement hinge 4, it is also possible to adopt another coupling structure of a combined drawbar box, and its remaining structures are the same as The above-mentioned Example 1 is the same. And at the two ends of the upper box shell 11, the lower box shell 13 connection parts are respectively fixed with two detachable and snap-fit soft fastening components 3, and between the two fastening components 3, the upper box shell 11, The lower box shell 13 is fixed with a detachable hinge 5 such as Figure 15 , Figure 16 As shown, the upper box shell 11 and the lower box shell 13 are connected together, and the described detachable hinge 5 is as Figure 17 , Figure 18 Shown to comprise two back-to-back flexible L-shaped connecting pieces 51, the top of the two connecting pieces 51 is covered with a П-shaped umbrella cover 52, a supporting plate 53...

Embodiment 3

[0049] Since the upper case 11 and the lower case 13 can be conveniently disassembled structurally, in order to increase the volume of the trolley case 1, an annular thickening can also be connected between the above-mentioned upper case 11 and the lower case 13 by a zipper. Case 6 such as Figure 19 shown. Described thickened case shell 6 is as Figure 20 Shown is an annular ring 61 with the same shape as the mouth of the upper case 11 or the lower case 13, and the two sides of the annular ring 61 are respectively sewn with the unilateral chain belt on the upper case 11 and the lower case 13. A21 and unilateral chain belt B22 matching unilateral chain belt B22 and unilateral chain belt A21, and use two sliders 25 to open and close the zipper 2 at both ends of the thickened box shell 6 sides and the upper box shell 11 and the lower box shell 13 connections. Of course, the thickness (or width) S of the thickened box shell 6 can be designed to have a variety of thickness S va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com