Self-Locking Fastener

a self-locking and fastener technology, applied in the direction of snap fasteners, buckles, transportation and packaging, etc., can solve the problems of economic inability, poor product image, and welding machine to weld two pieces together, so as to enhance the connection of the buckle base, facilitate and facilitate use and operation, the effect of reducing the packing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

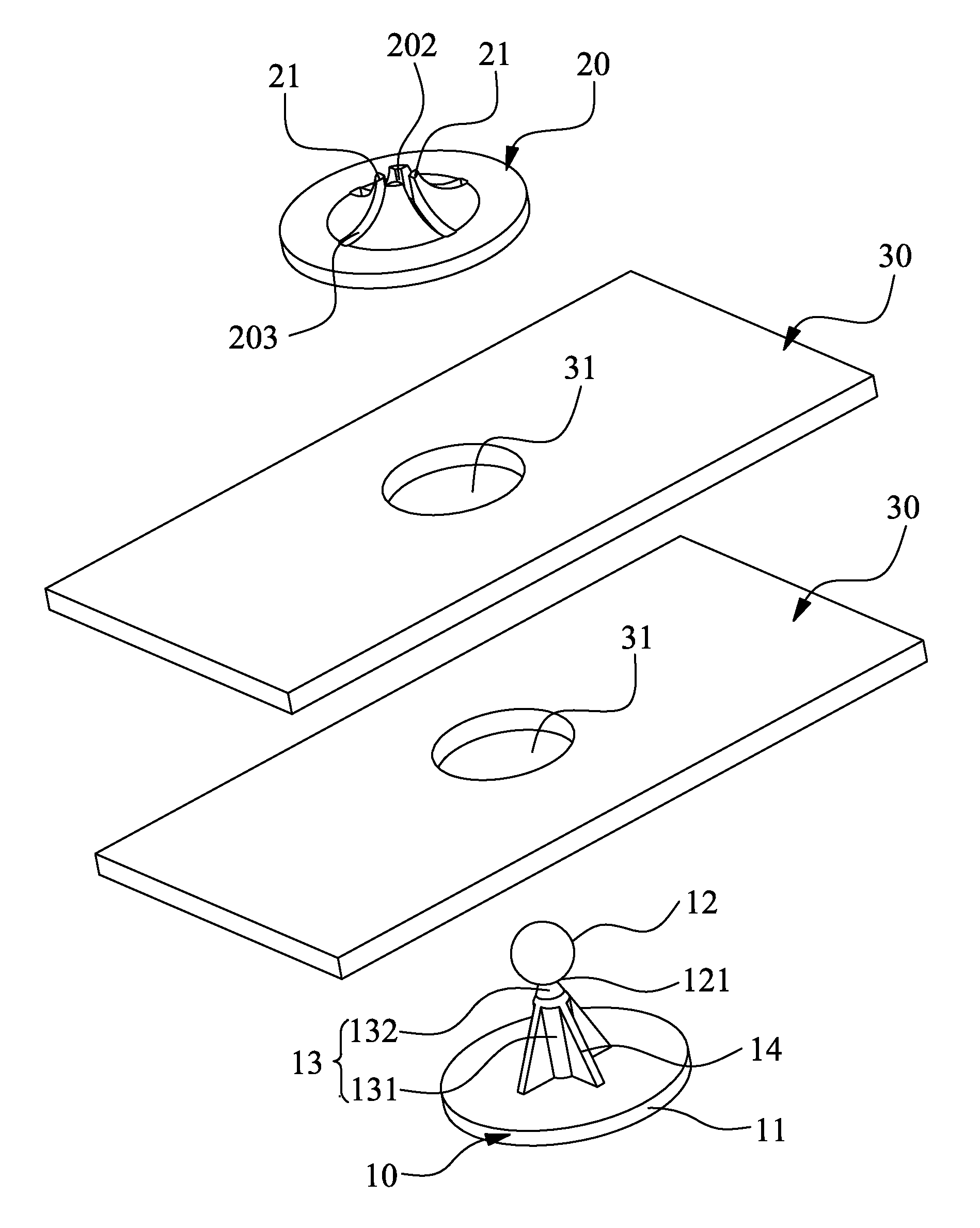

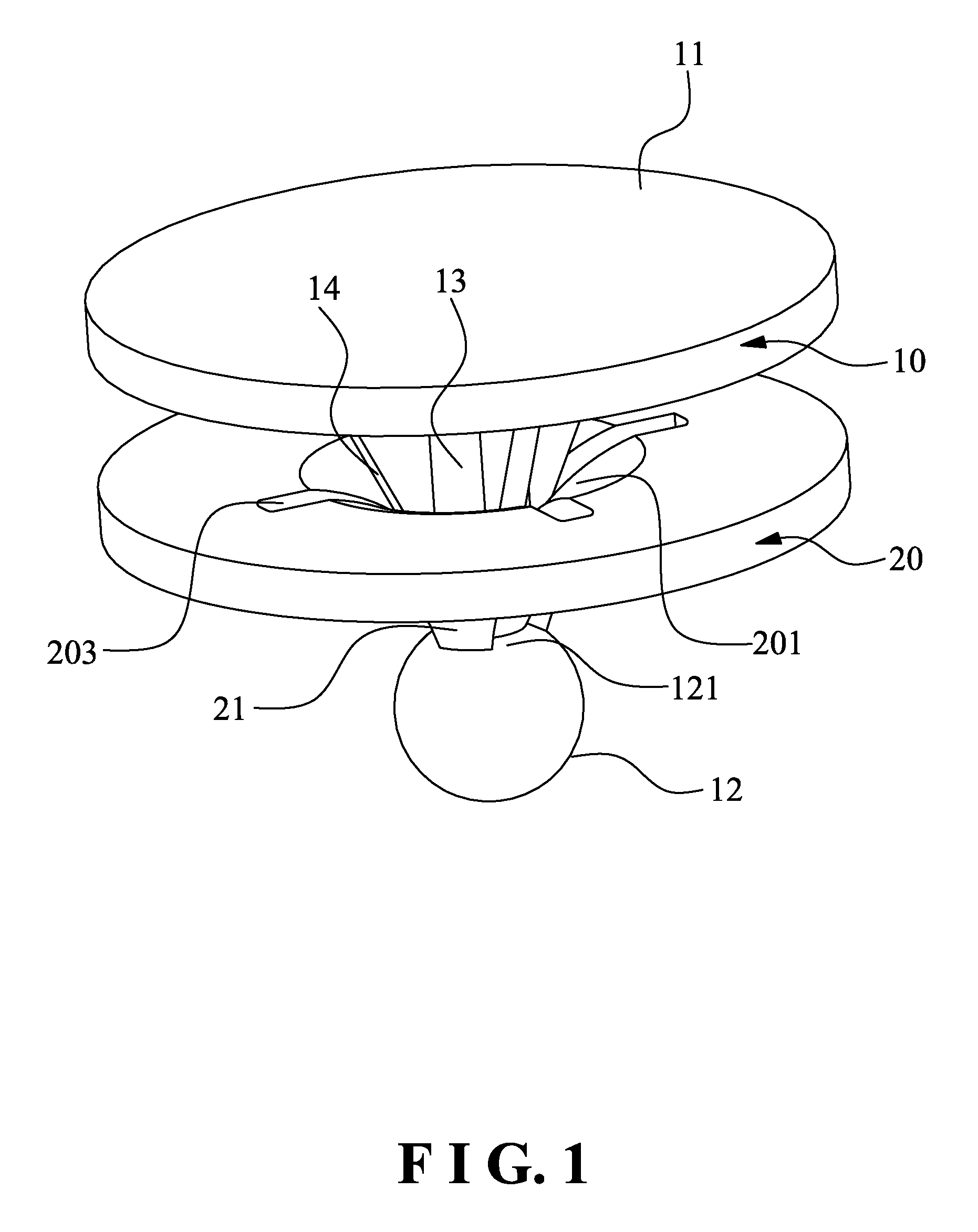

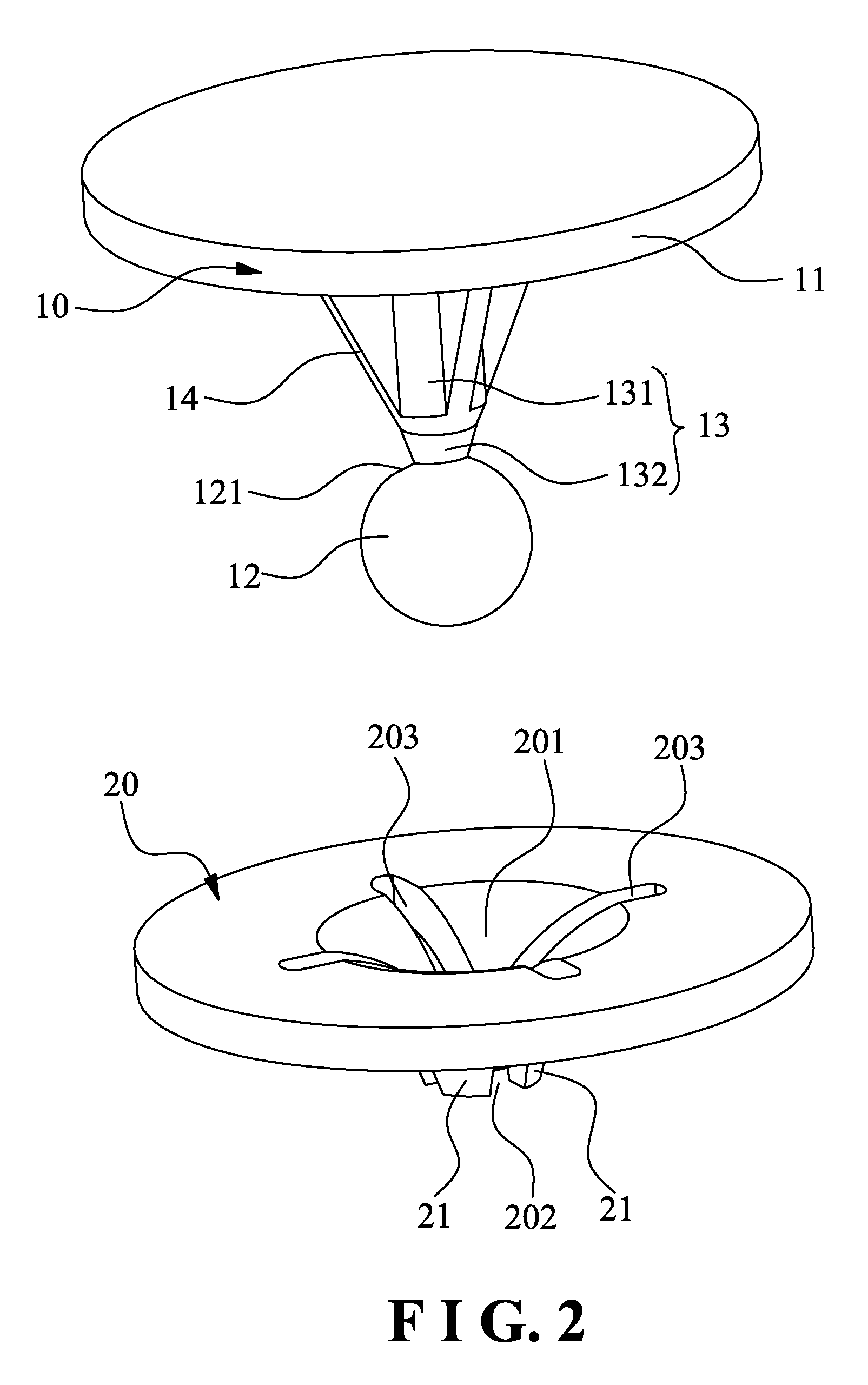

[0028]As shown in FIG. 1 through FIG. 5, the self-locking fastener according to a preferred embodiment of the present invention comprises a base member 10 and a clip member 20 mounted to the base member 10.

[0029]As shown in FIG. 1 and FIG. 2, the base member 10 is made of plastic. The base member 10 comprises a buckle base 11, a buckle point 12, and a buckle pin 13 which is connected between the buckle base 11 and the buckle point 12. The buckle base 11 is in a disk shape. The buckle point 12 is a sphere. The shape of the buckle point 12 is not limited to a sphere, which can be a cone or other shapes. The spherical buckle point 12 is conveniently mounted to the clip member 20. The buckle pin 13 has a base portion 131 and a connection portion 132 which extends from the base portion 131 and is tapered toward the buckle point 12. The base portion 131 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com