Patents

Literature

53results about How to "Simple and quick assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

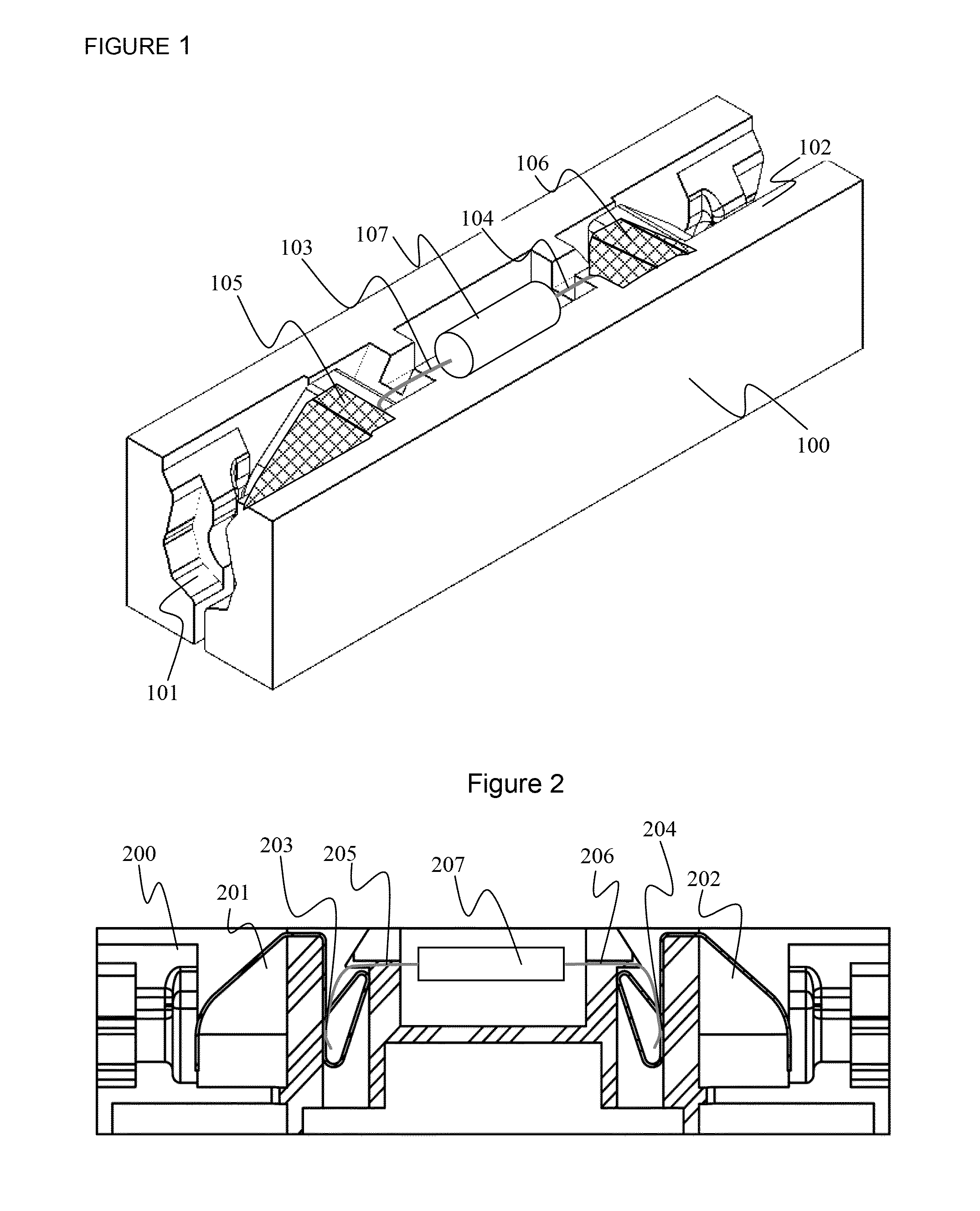

Three-dimensional structures with electronic circuit paths and safety circuits

Owner:ELENCO ELECTRONICS

Three-dimensional structures with electronic circuit paths and safety circuits

ActiveUS20110143629A1Eliminate circuit errorEliminate shorted power sourceToysComputer moduleEngineering

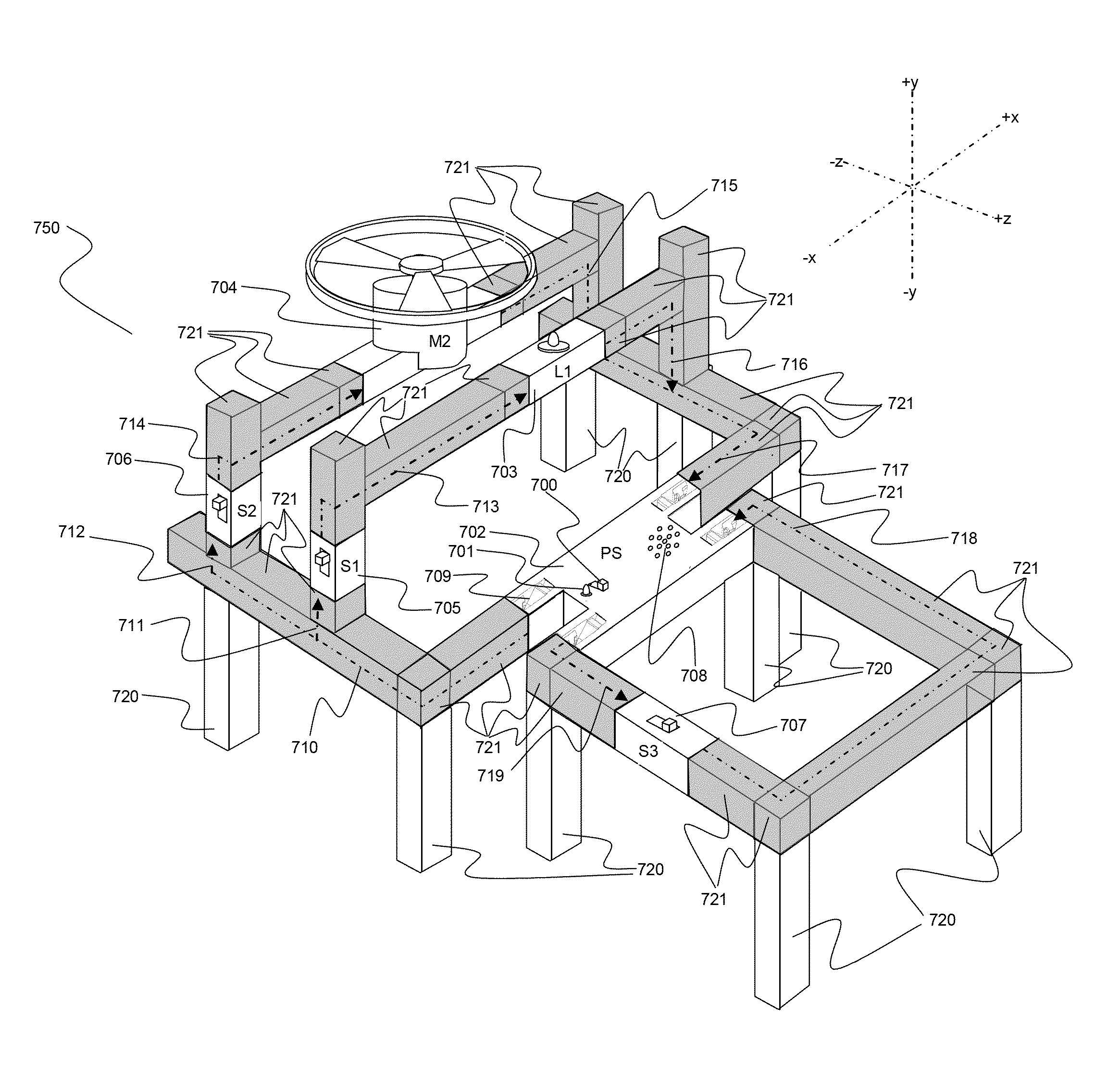

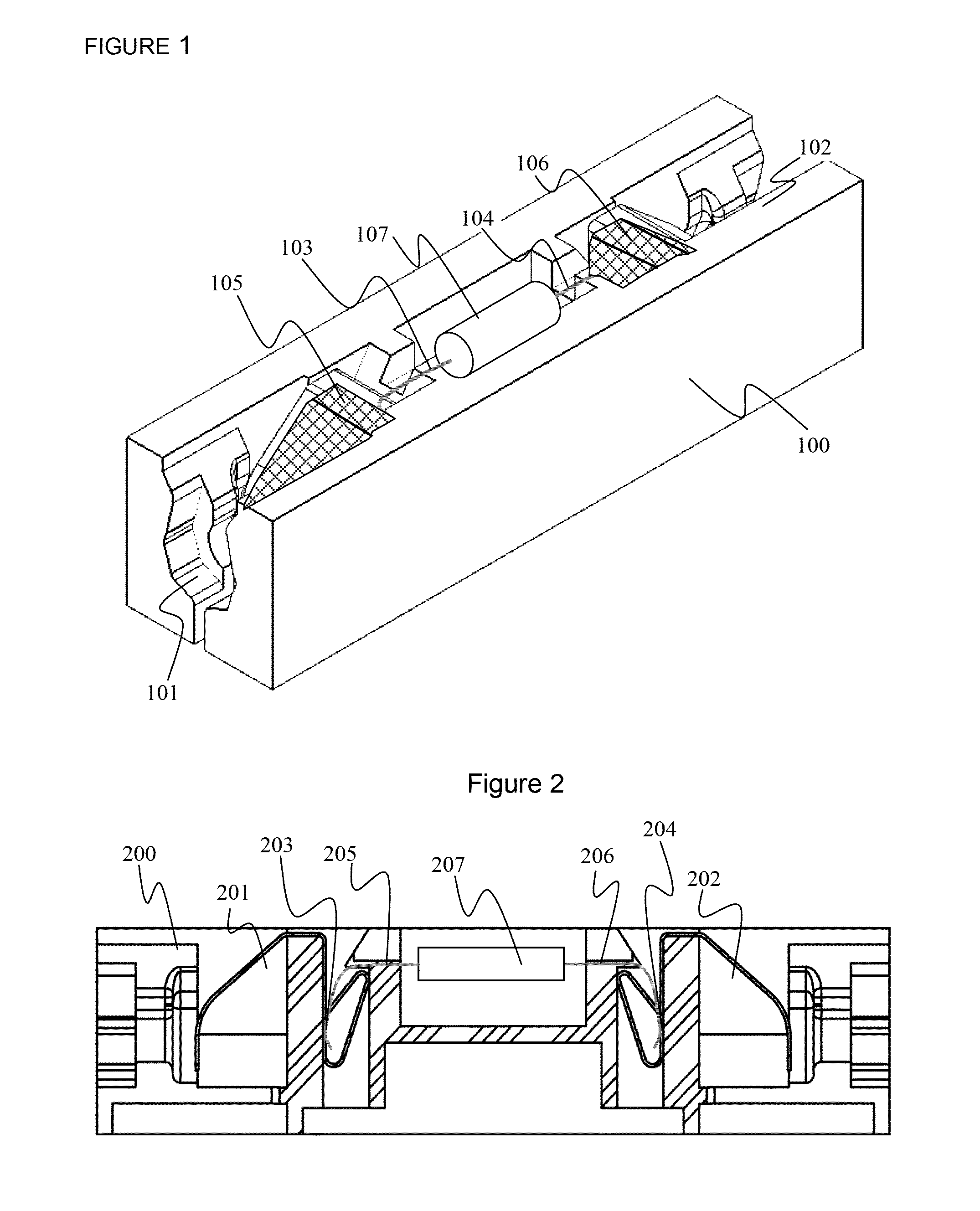

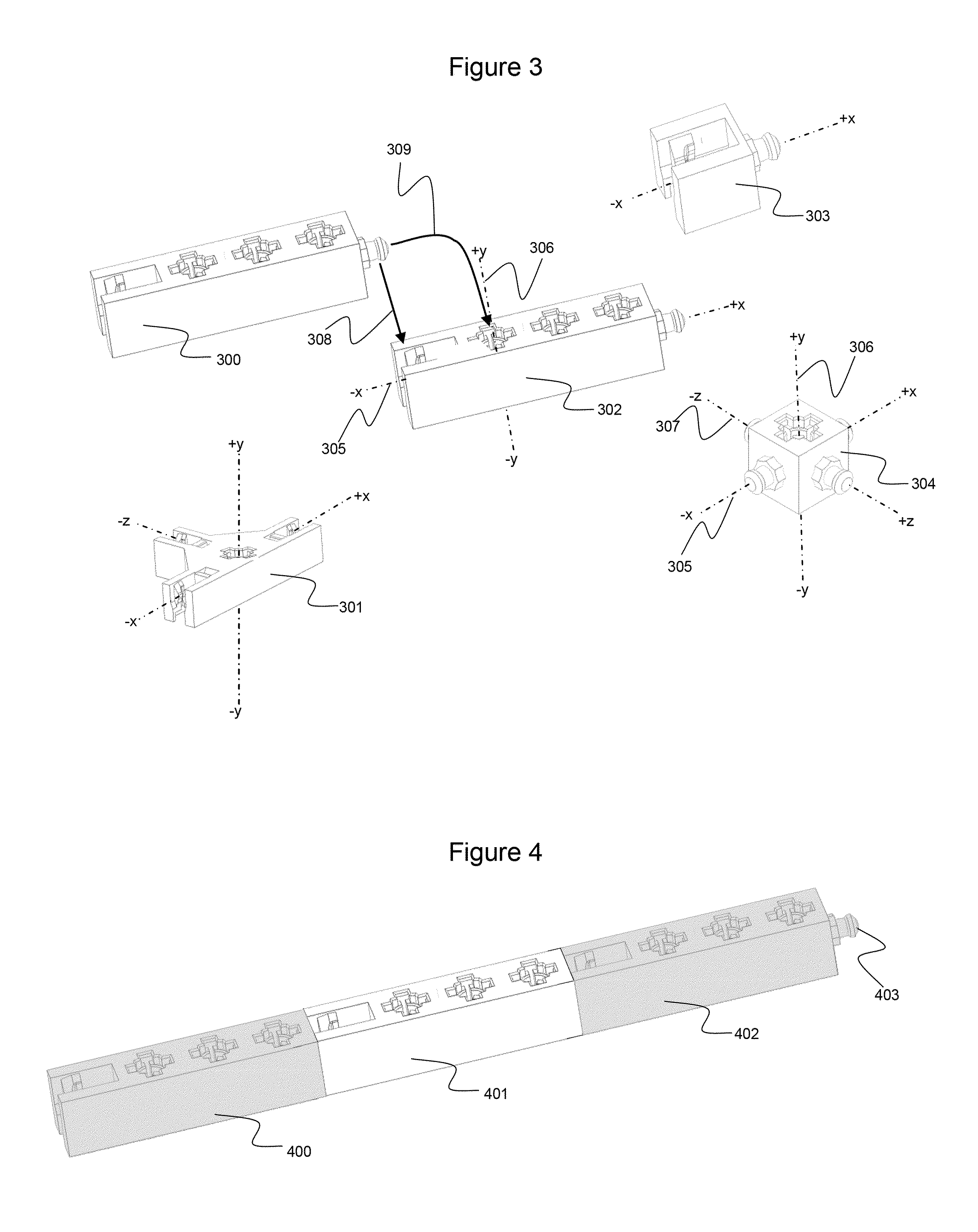

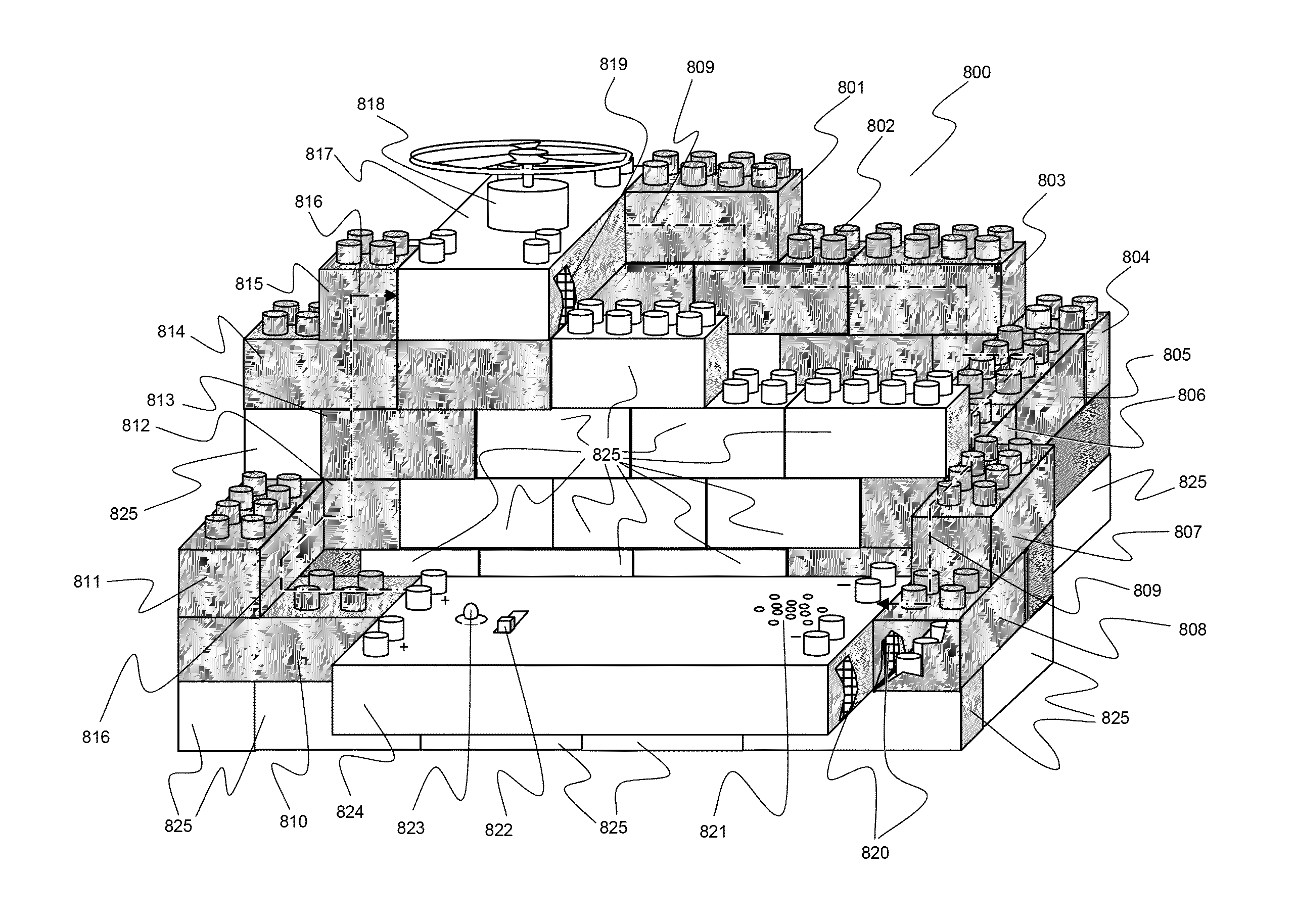

A three-dimensional electro-mechanical system for making mechanical structures using snap-together parts or building blocks that easily demonstrate the principles required in making three-dimensional electronic circuits incorporated in the mechanical structures. A reusable electronic module that contains batteries or other power sources and has means for attaching to other electronic modules to power these three-dimensional circuits and prevent and warn the user of excessive current.

Owner:ELENCO ELECTRONICS

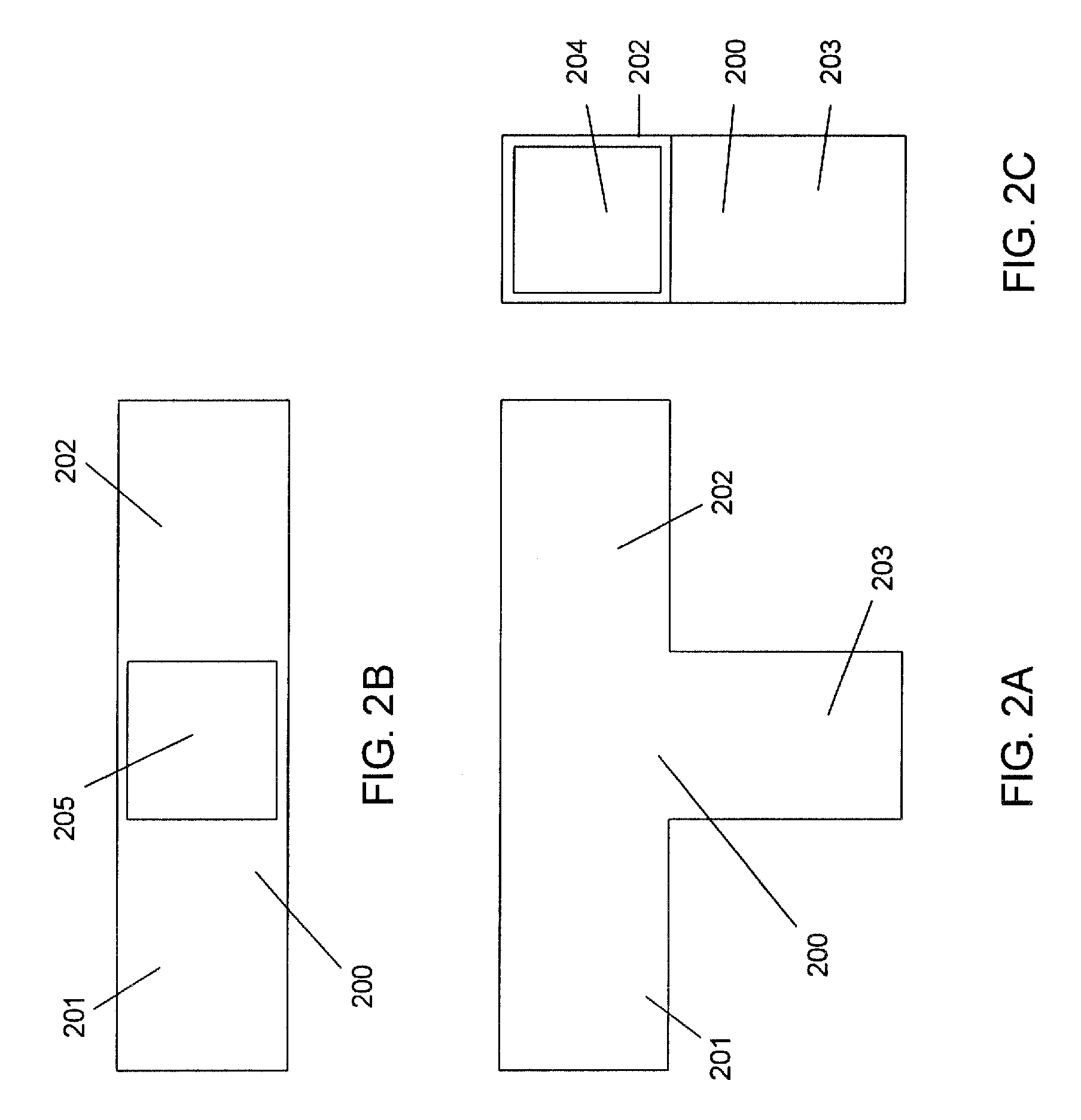

Self-Locking Fastener

InactiveUS20130031756A1Easy and convenient to useEasy and convenient to and operateSnap fastenersFlexible elementsEngineeringSelf locking

Owner:DONGGUAN MASTER INK CO LTD

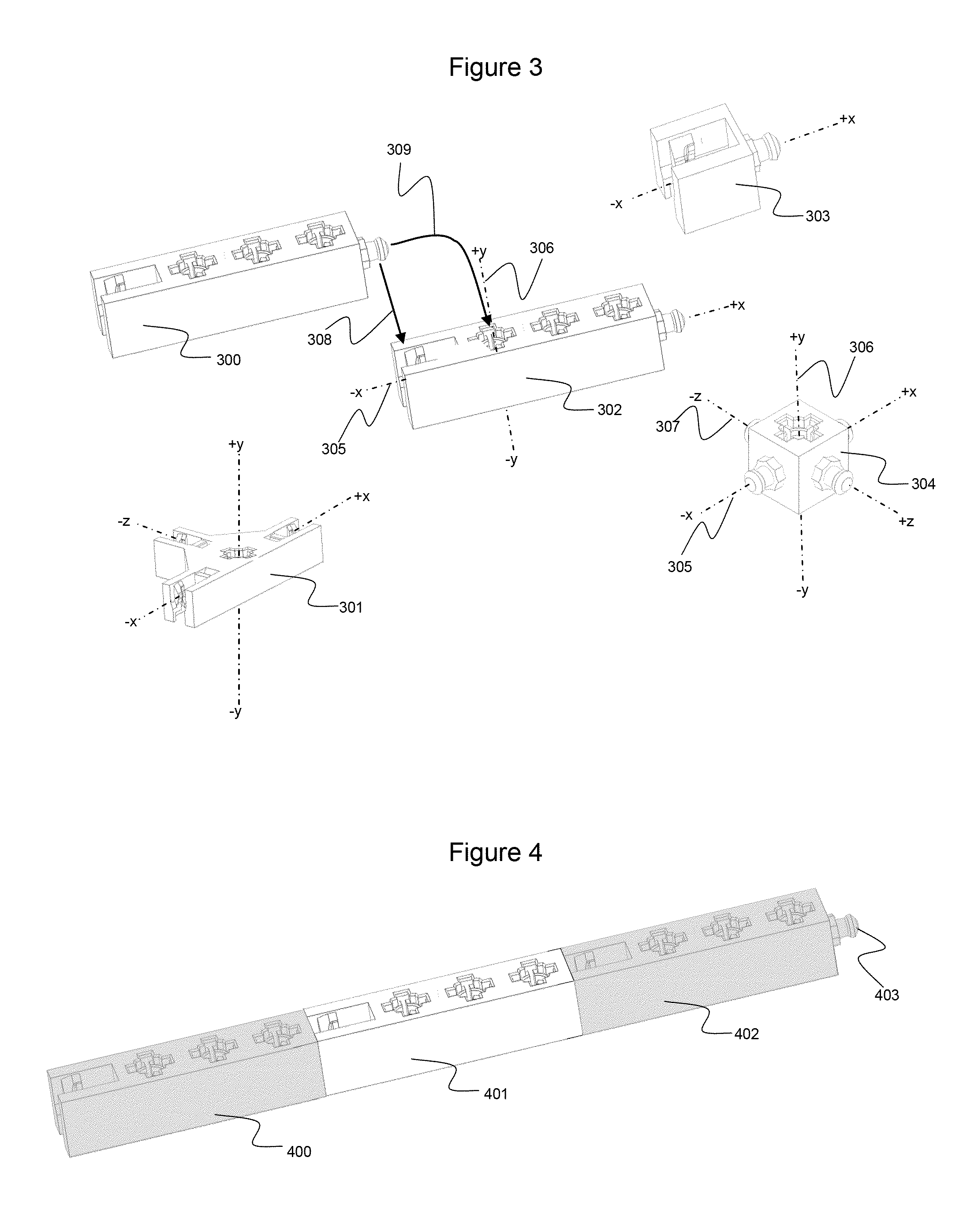

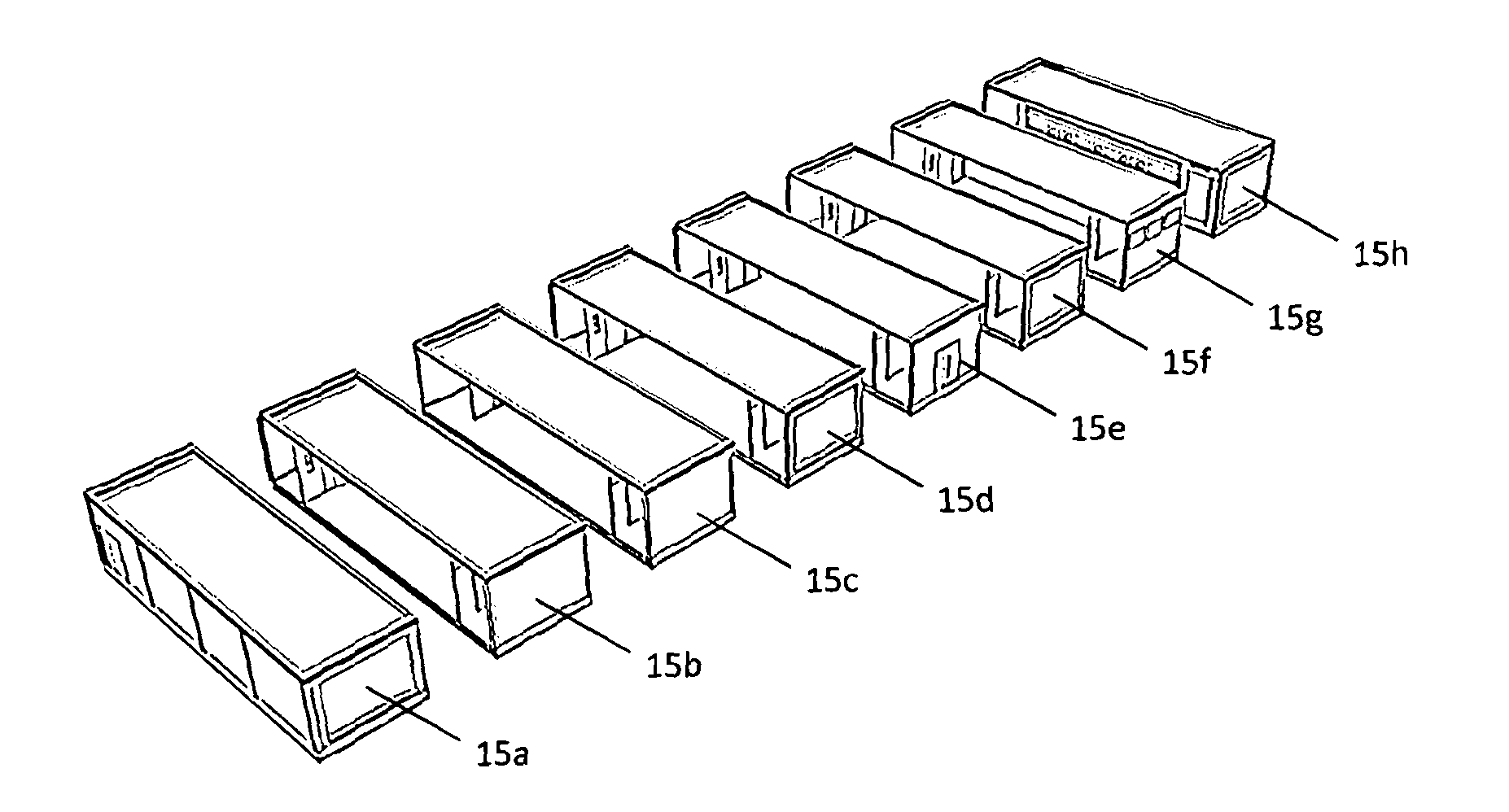

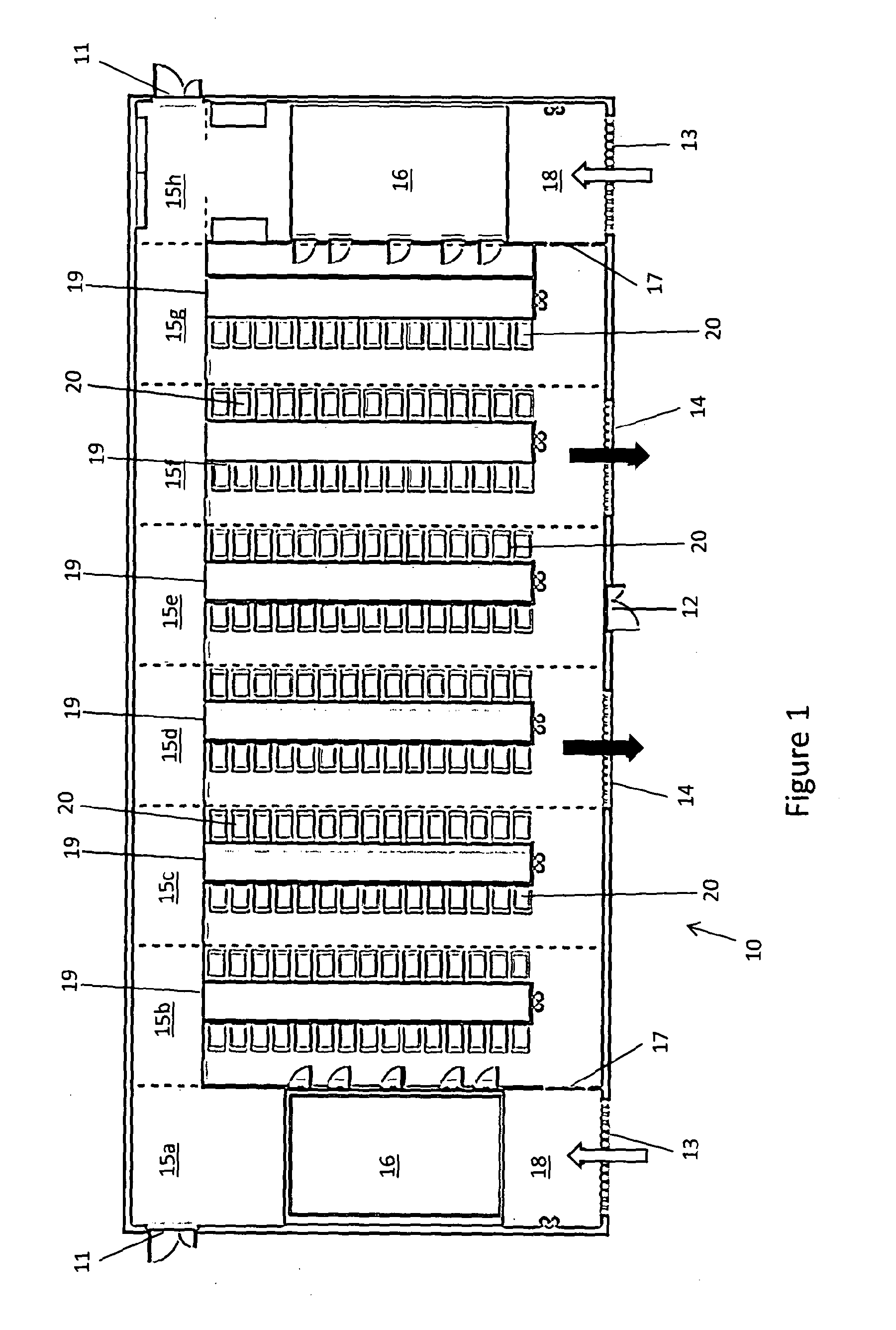

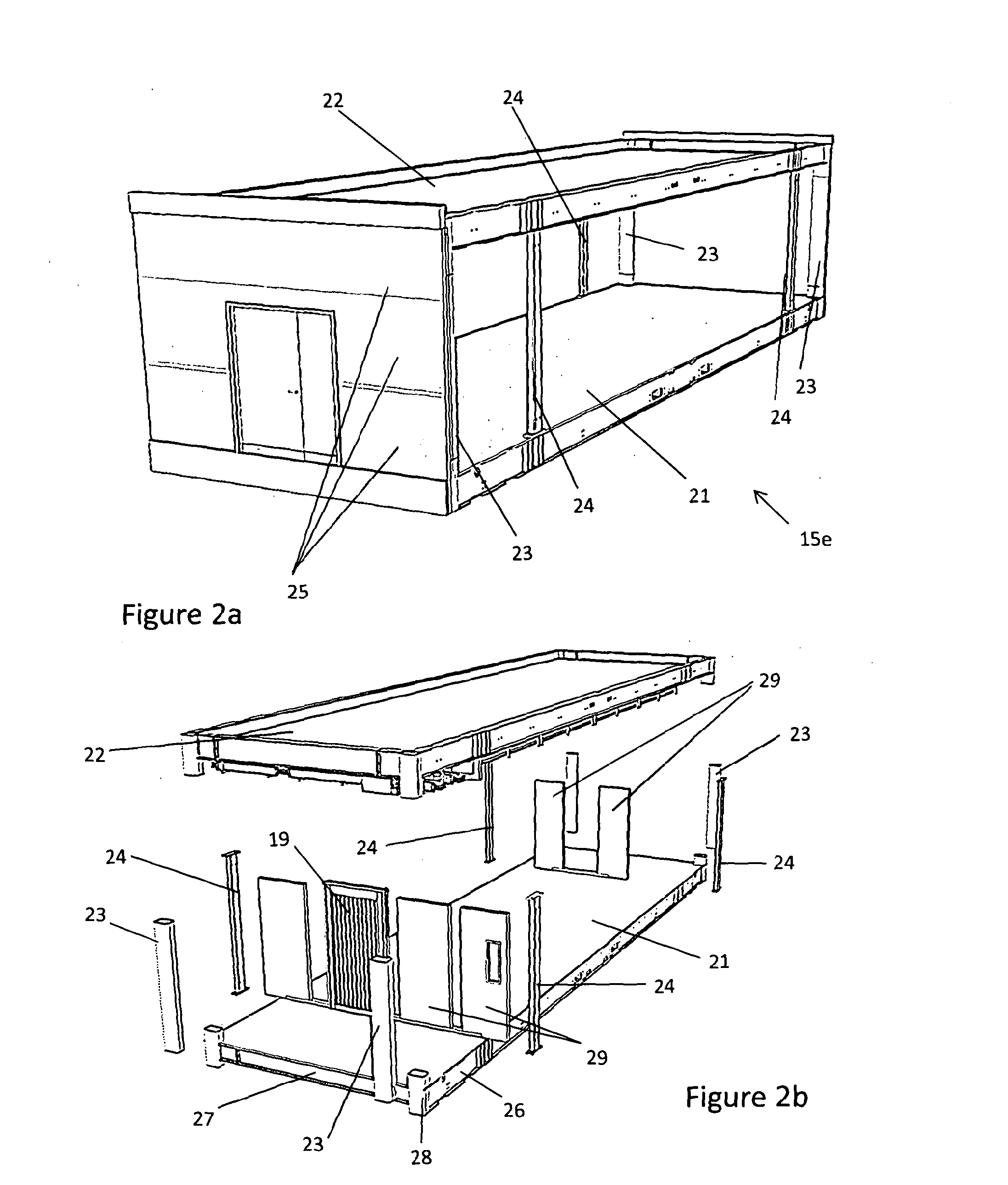

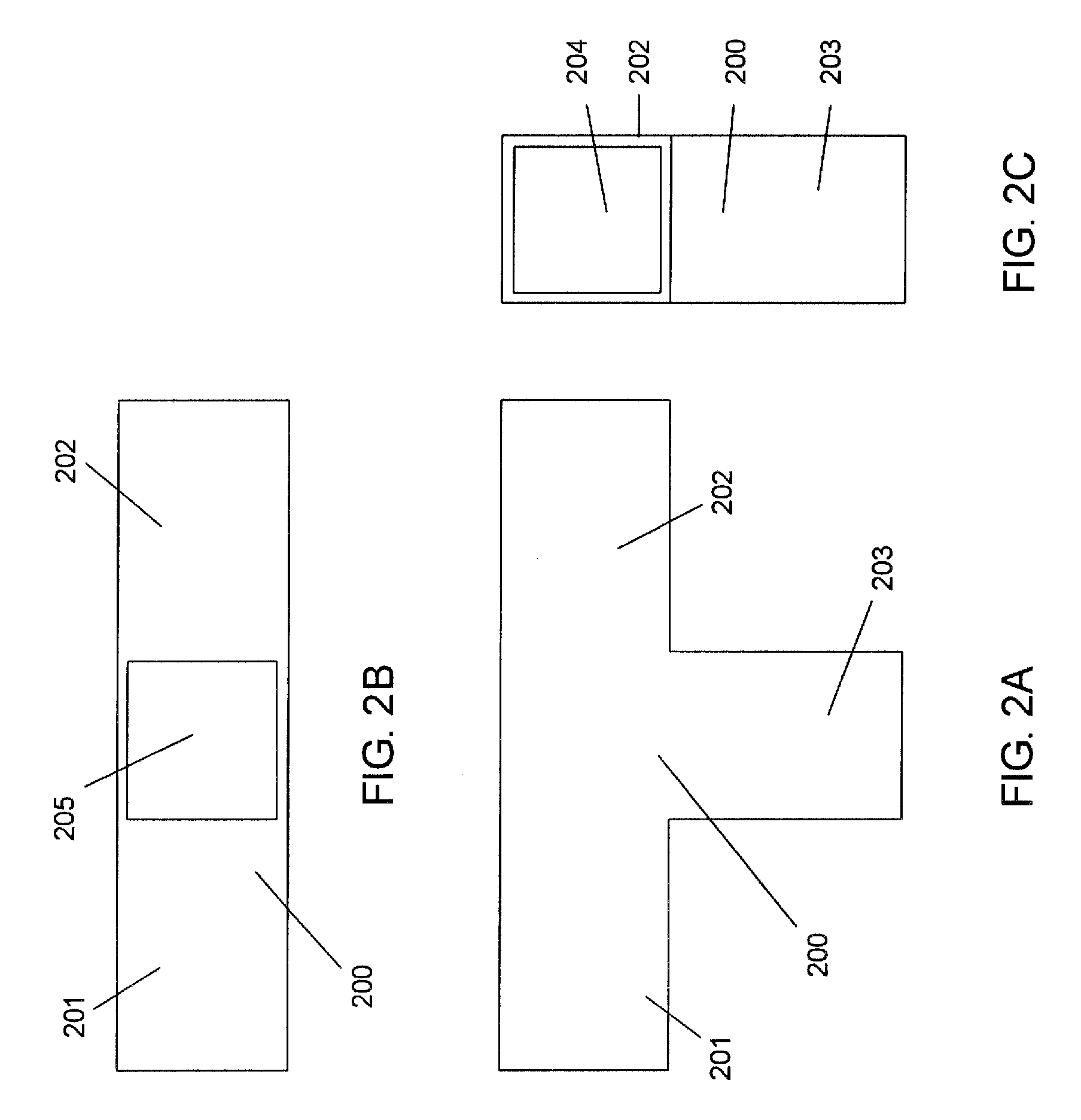

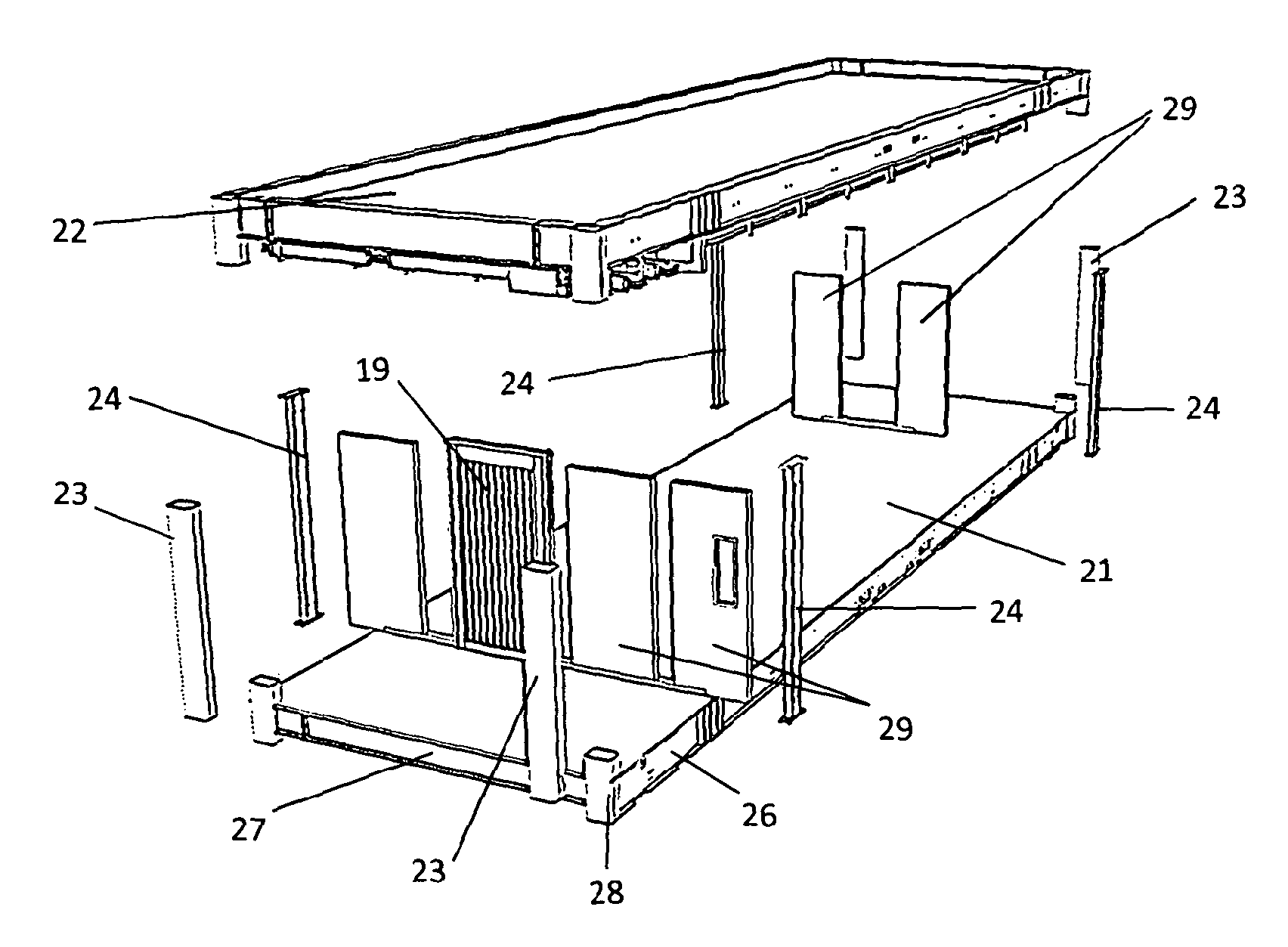

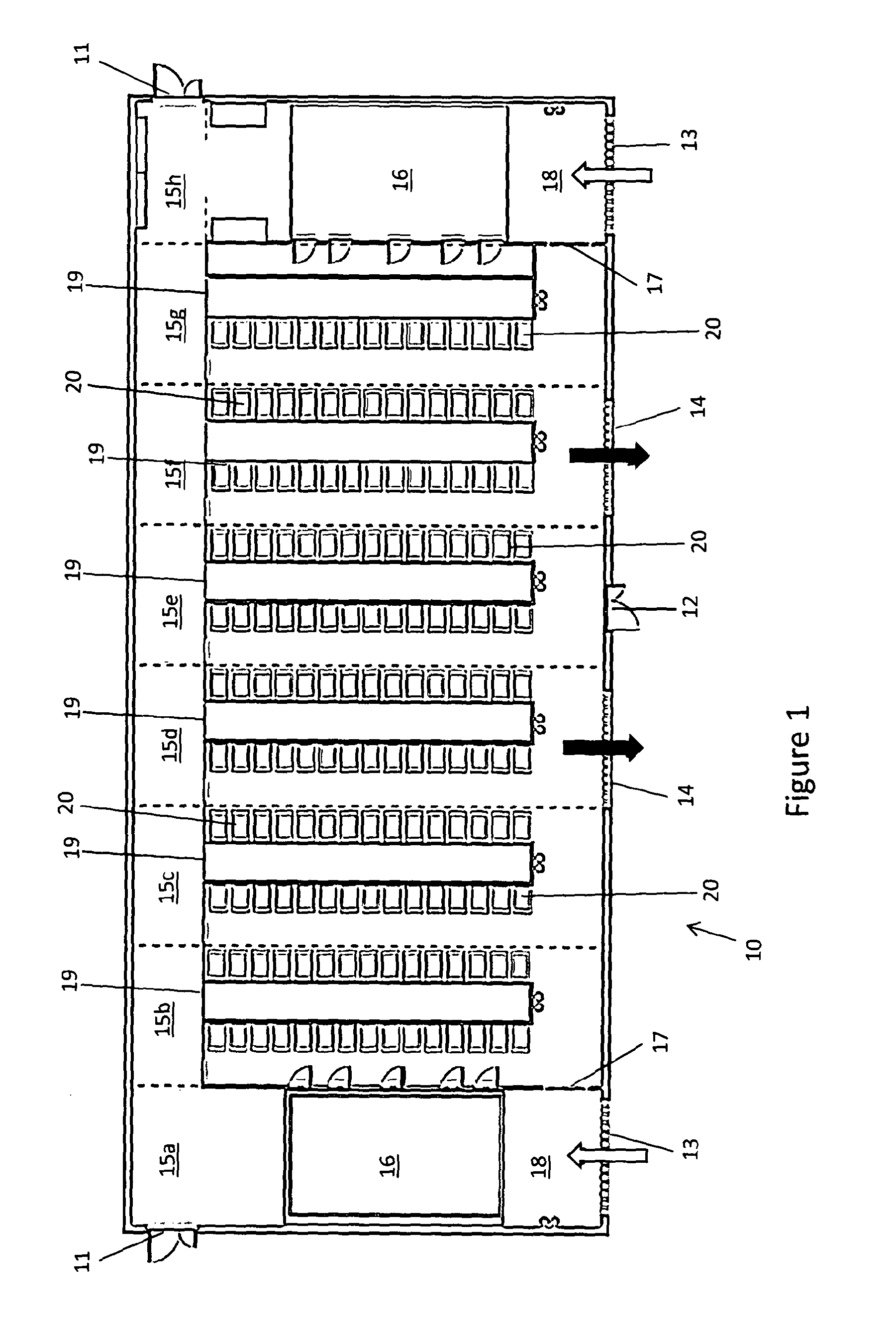

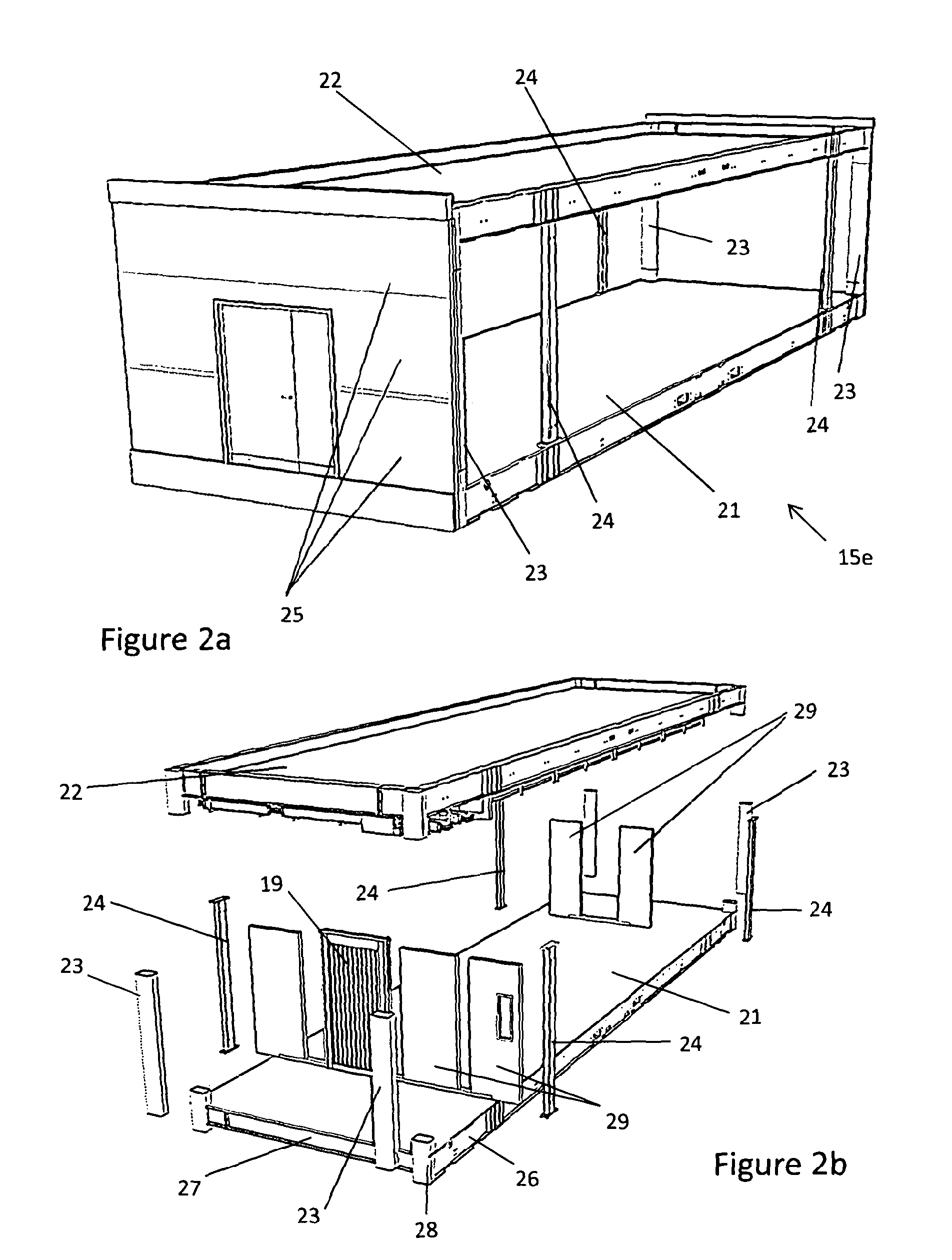

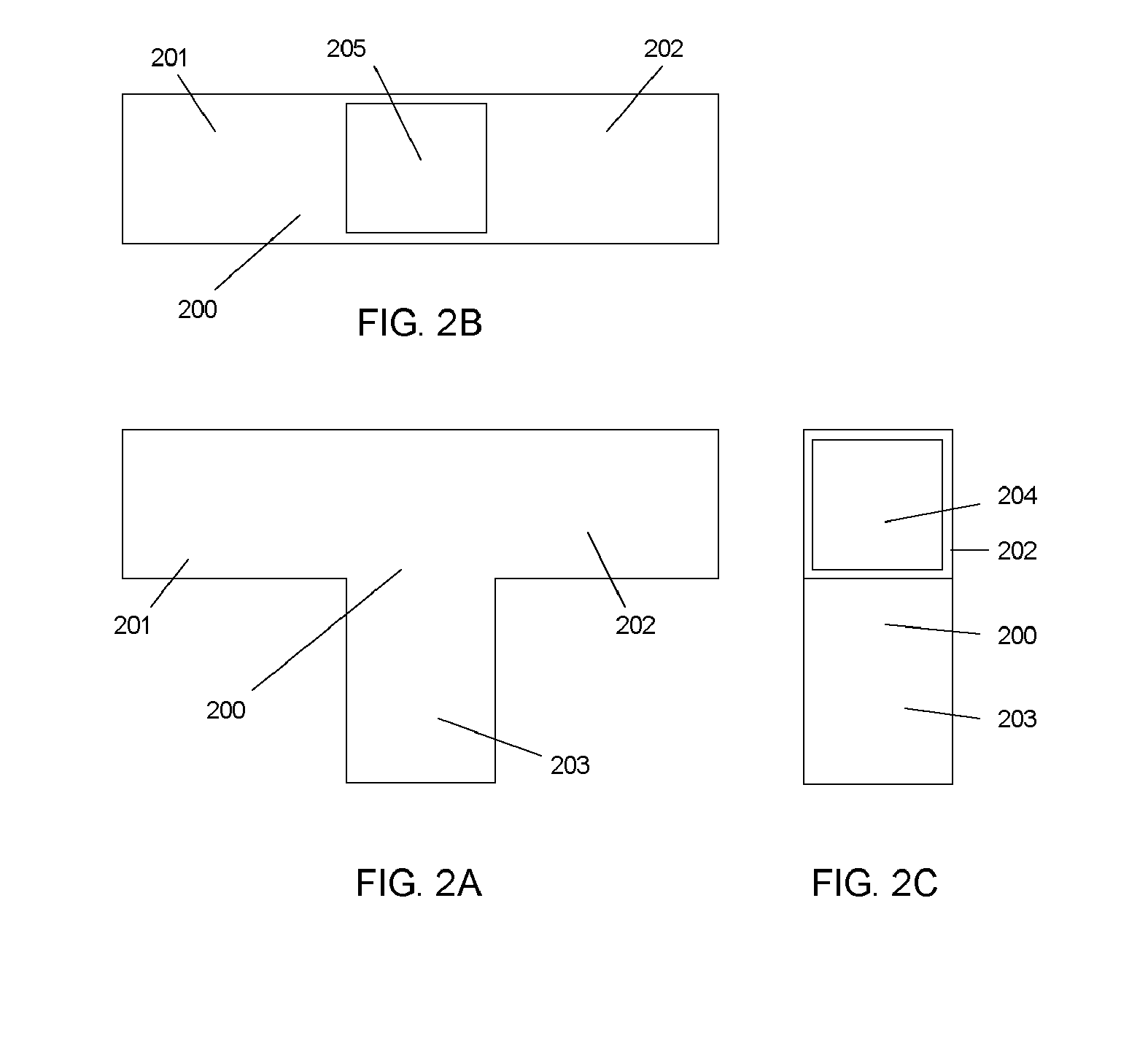

Data Centre

ActiveUS20140298734A1Extended production lineReduce construction costsServersPublic buildingsData centerEngineering

A data centre comprises a plurality of sections (15a-15h) assembled together to define a unitary structure (10) such that there exists at least one personnel area that spans at least two sections; wherein the sections comprise a first section with which there is associated a first service—carrying chassis (40, 50, 60, 70) and a second section with which there is associated a second service—carrying chassis 40, 50, 60, 70), each of the first and second service—carrying chassis comprising a frame (41, 51, 61, 71) onto which is mounted components of at least two different services (42-44, 46); the first and second chassis are connected to each other by means of a junction (47) between the first and second chassis; and the first and second sections each include a ceiling (22) and the first service carrying chassis is mounted on the ceiling of the first section and the second service carrying chassis is mounted on the ceiling of the second section.

Owner:BRIPCO

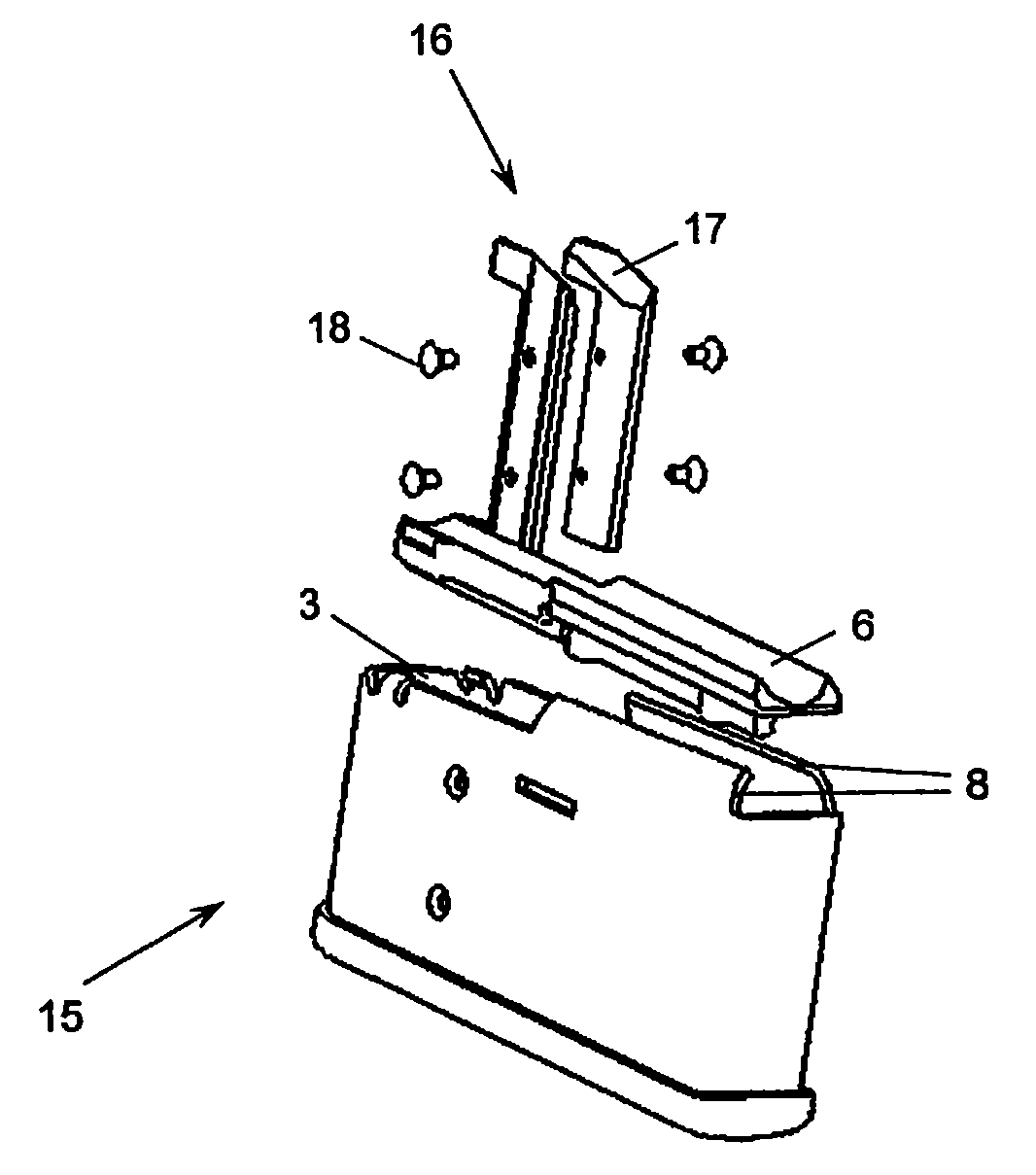

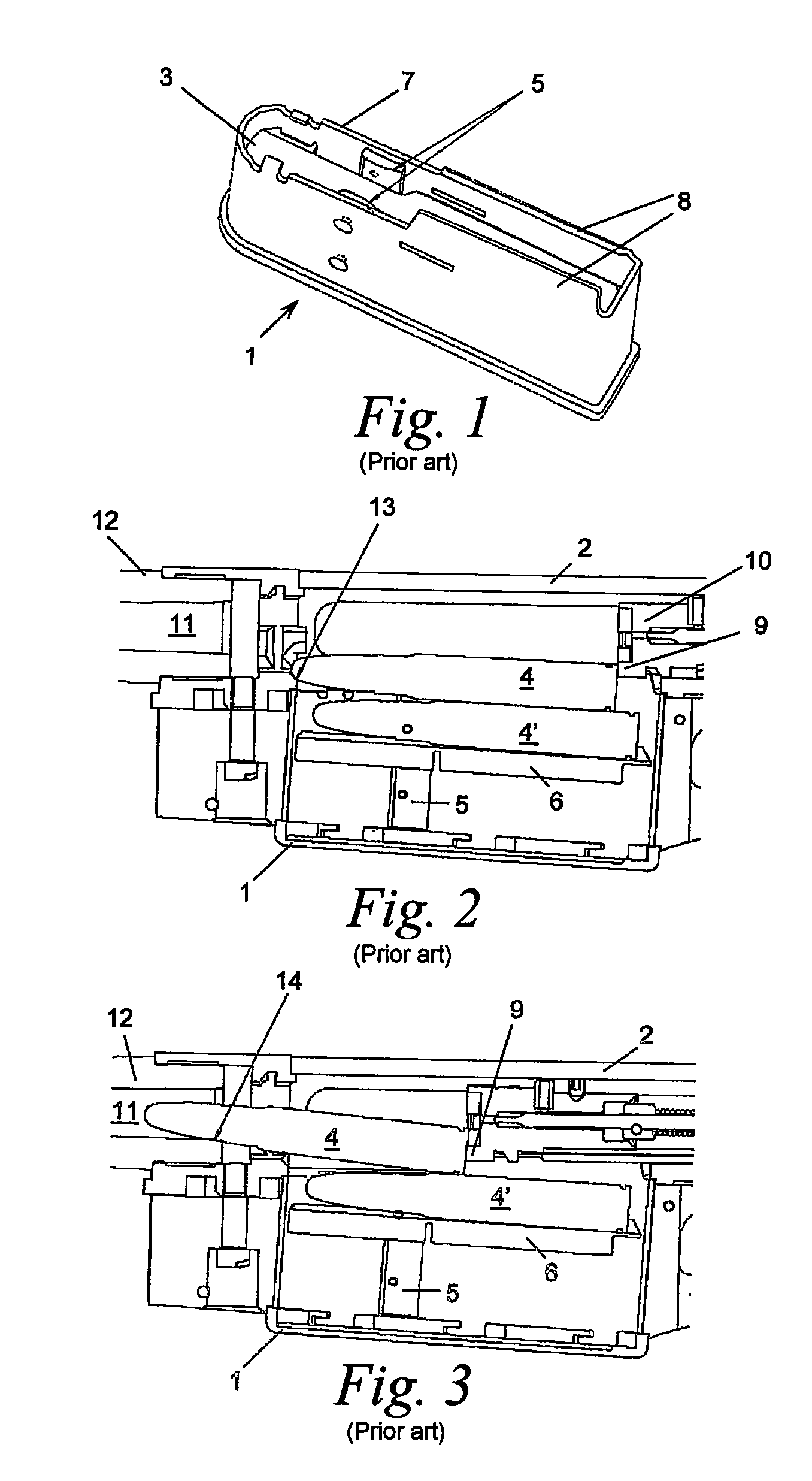

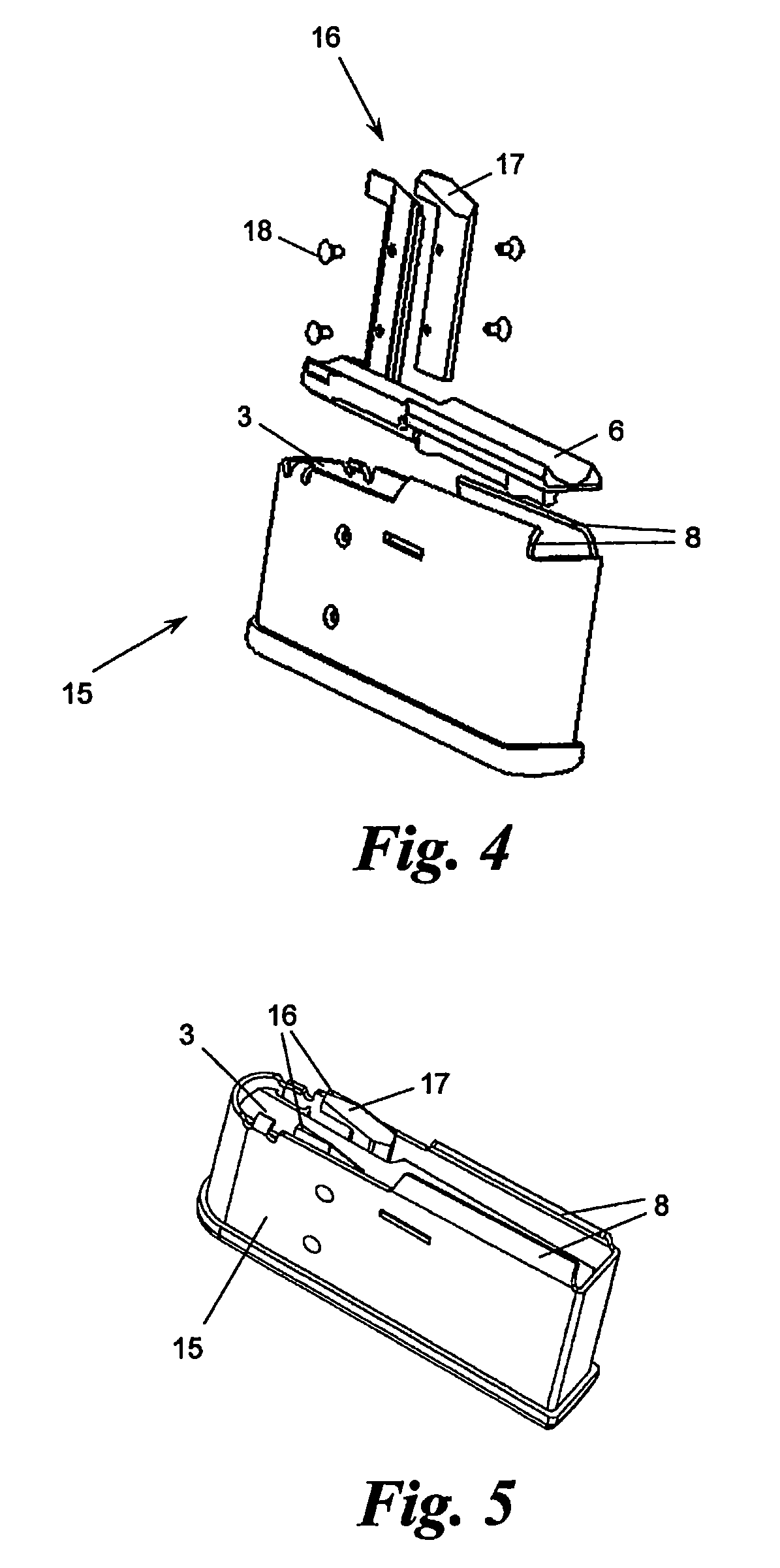

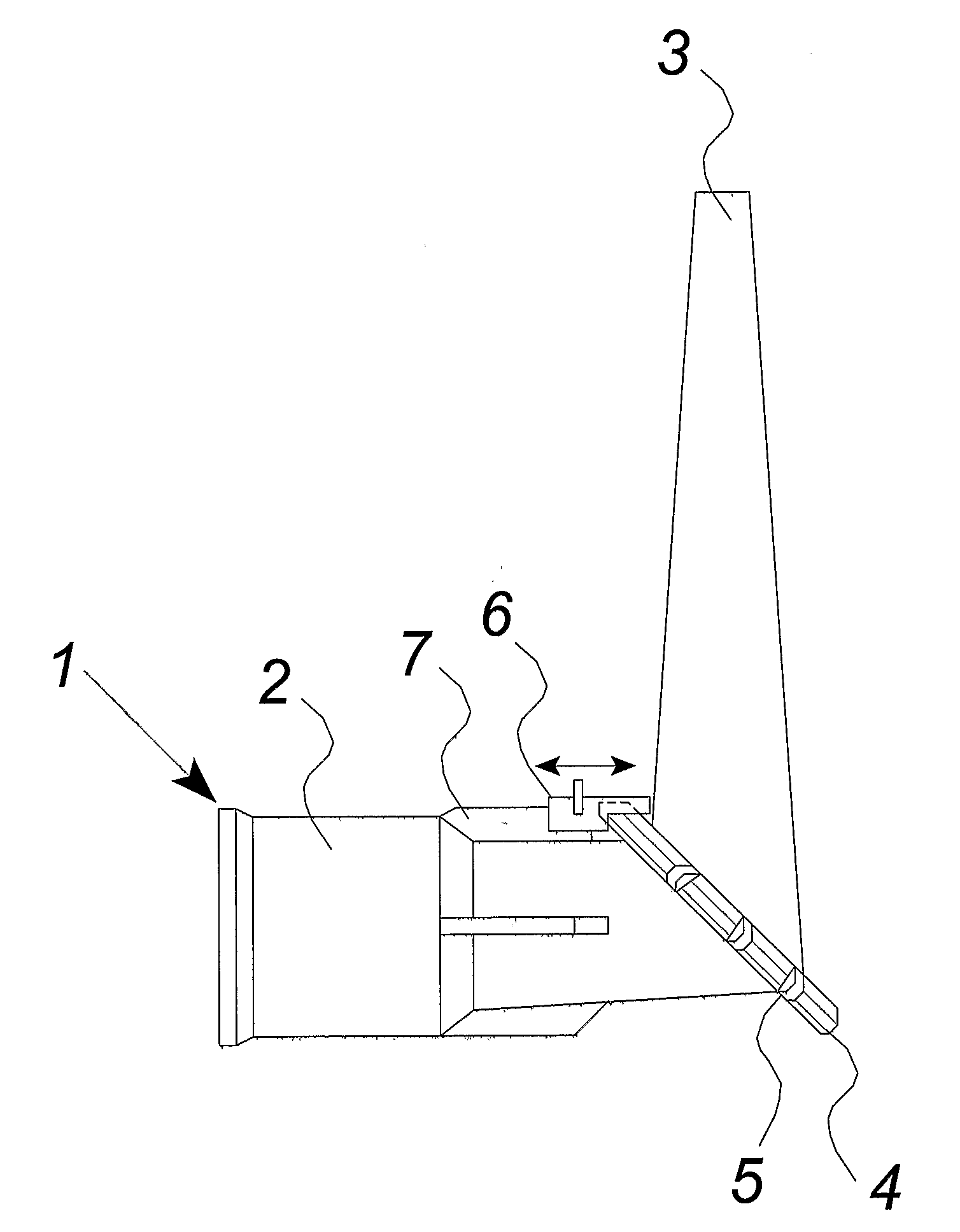

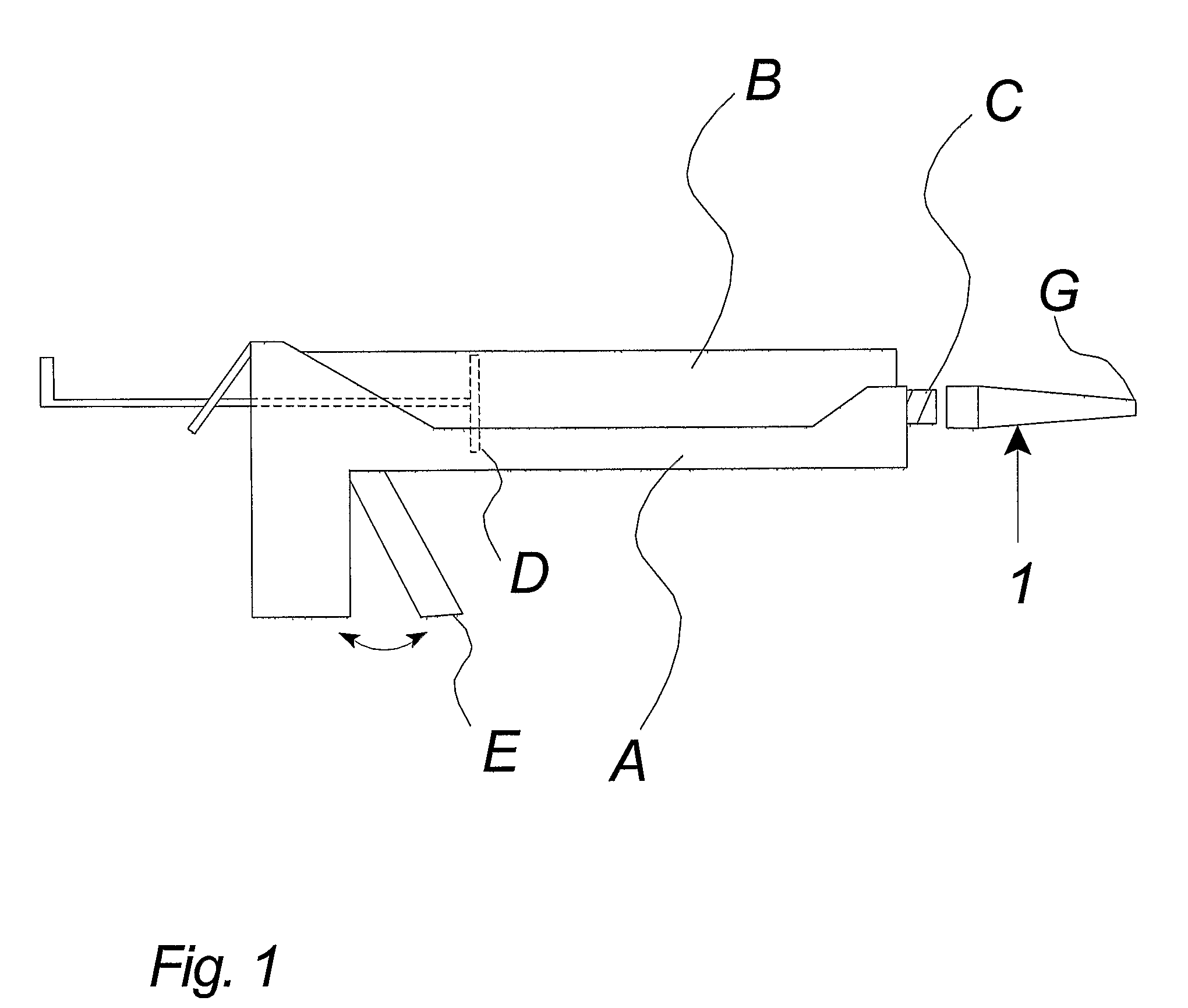

Box magazine for a firearm

InactiveUS7698844B2Avoid deformationSimple and quick assemblyAmmunition loadingEngineeringMechanical engineering

Rod magazine for a firearm, having a channel for holding cartridges in a stack, and having a feed for feeding the stack to a channel end which is clasped by magazine lips, which hold the top cartridge in the stack back in the channel direction, but allow its movement approximately transversely with respect to the channel direction beyond the rod magazine, with the channel being equipped with guide strips, which run in the channel direction, for the shoulders of the cartridges, and with the guide strips projecting beyond the channel end and into the movement path, which is located in front of the magazine lips, of the top cartridge.

Owner:STEYR MANNLICHER

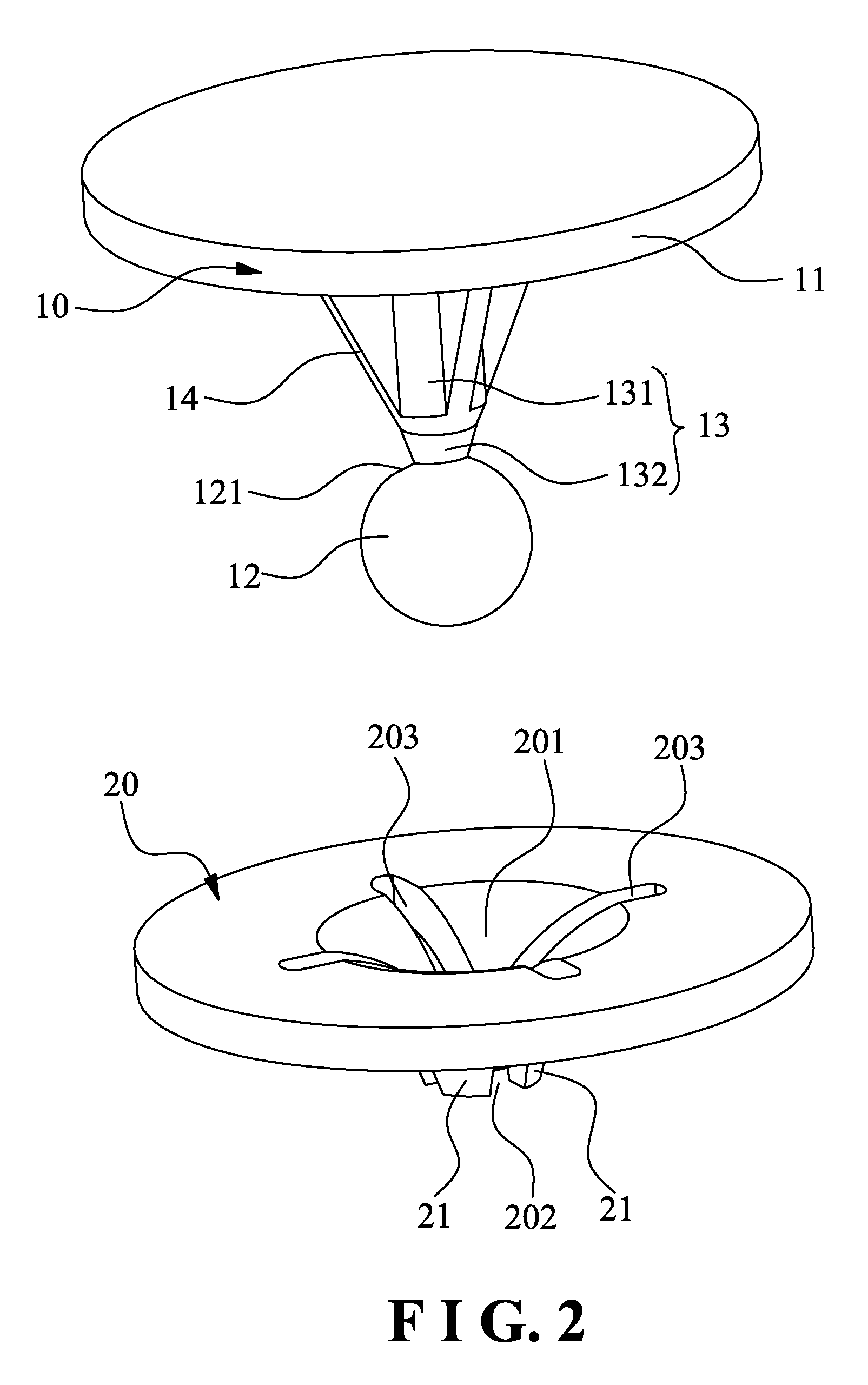

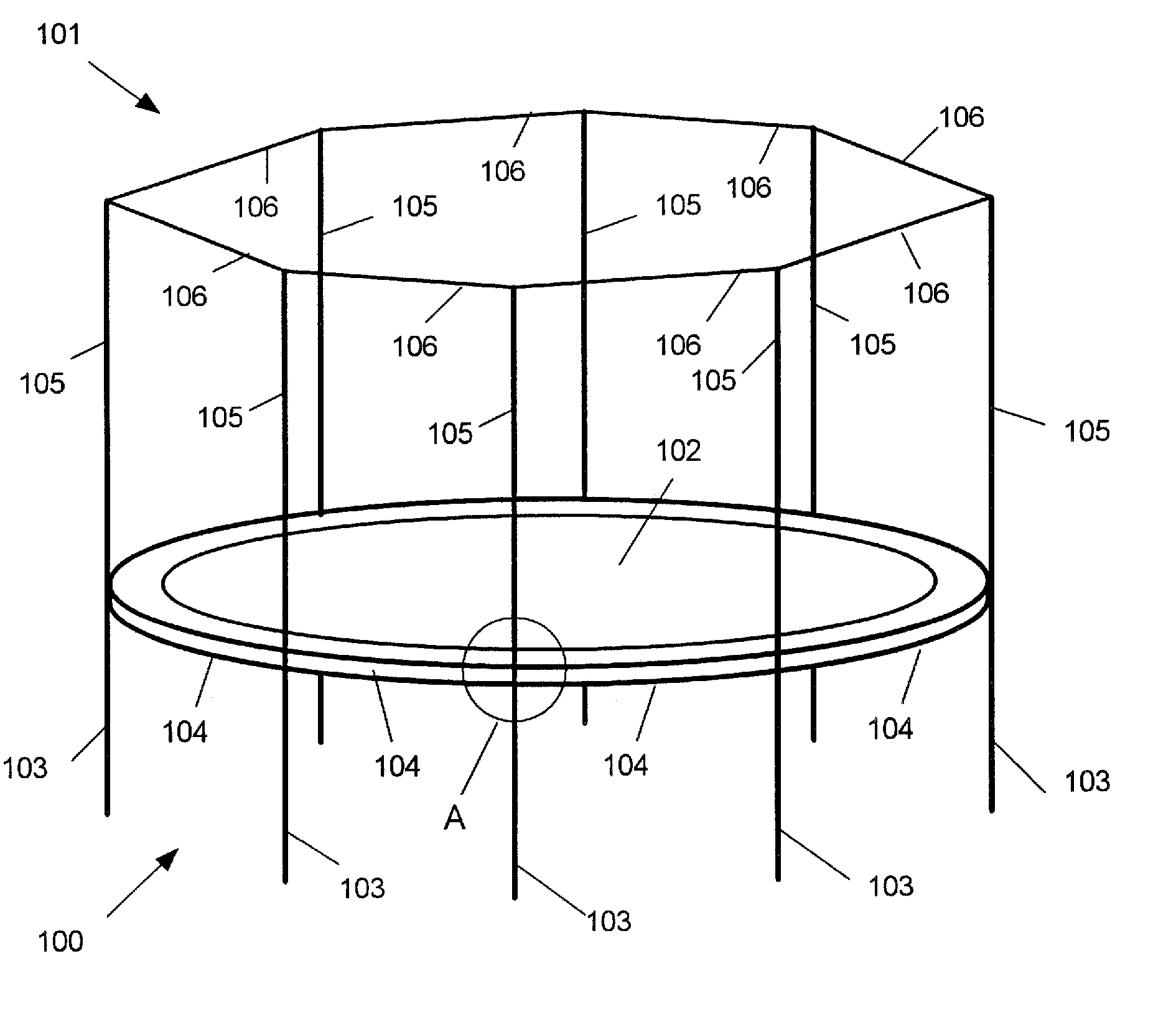

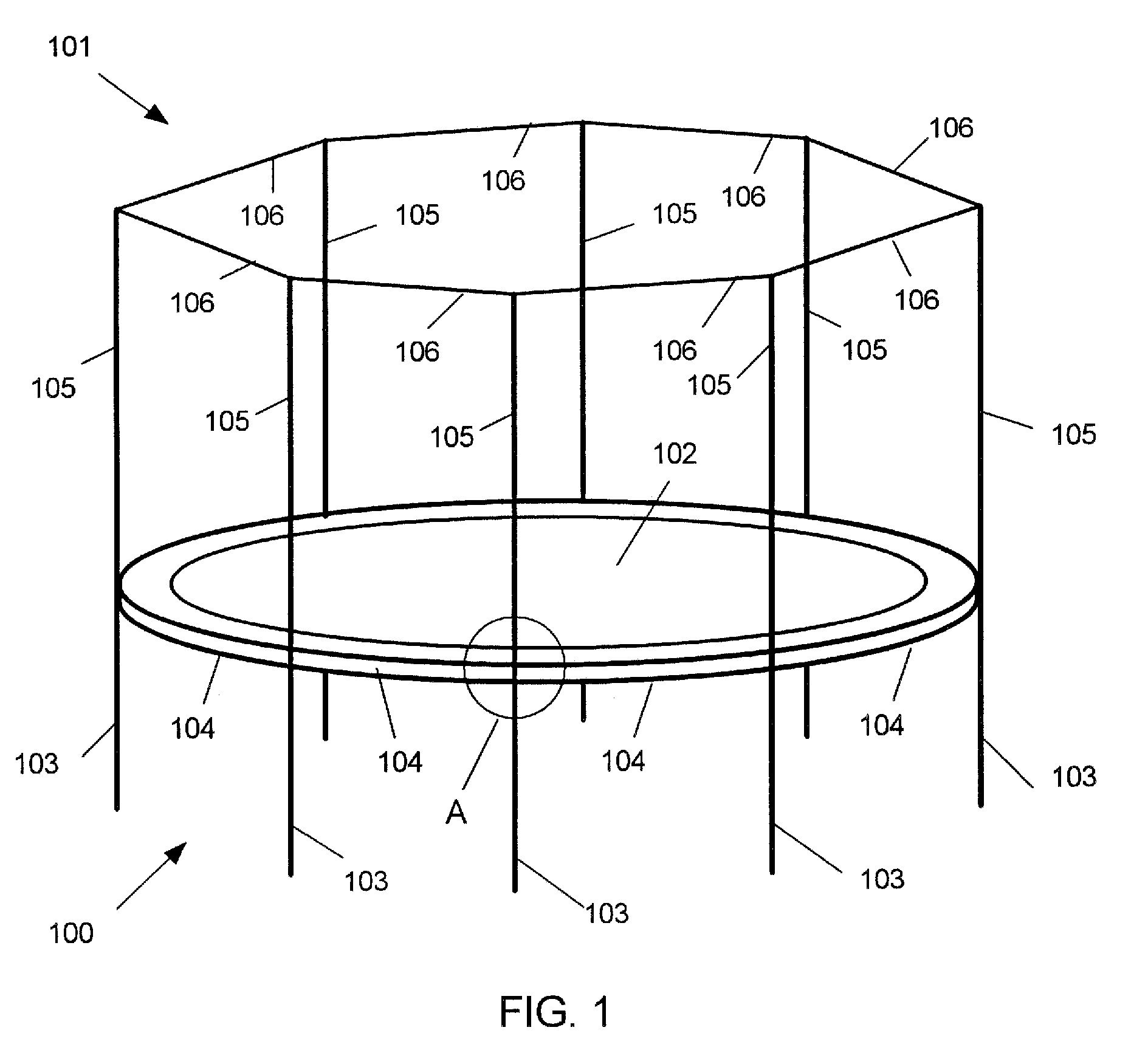

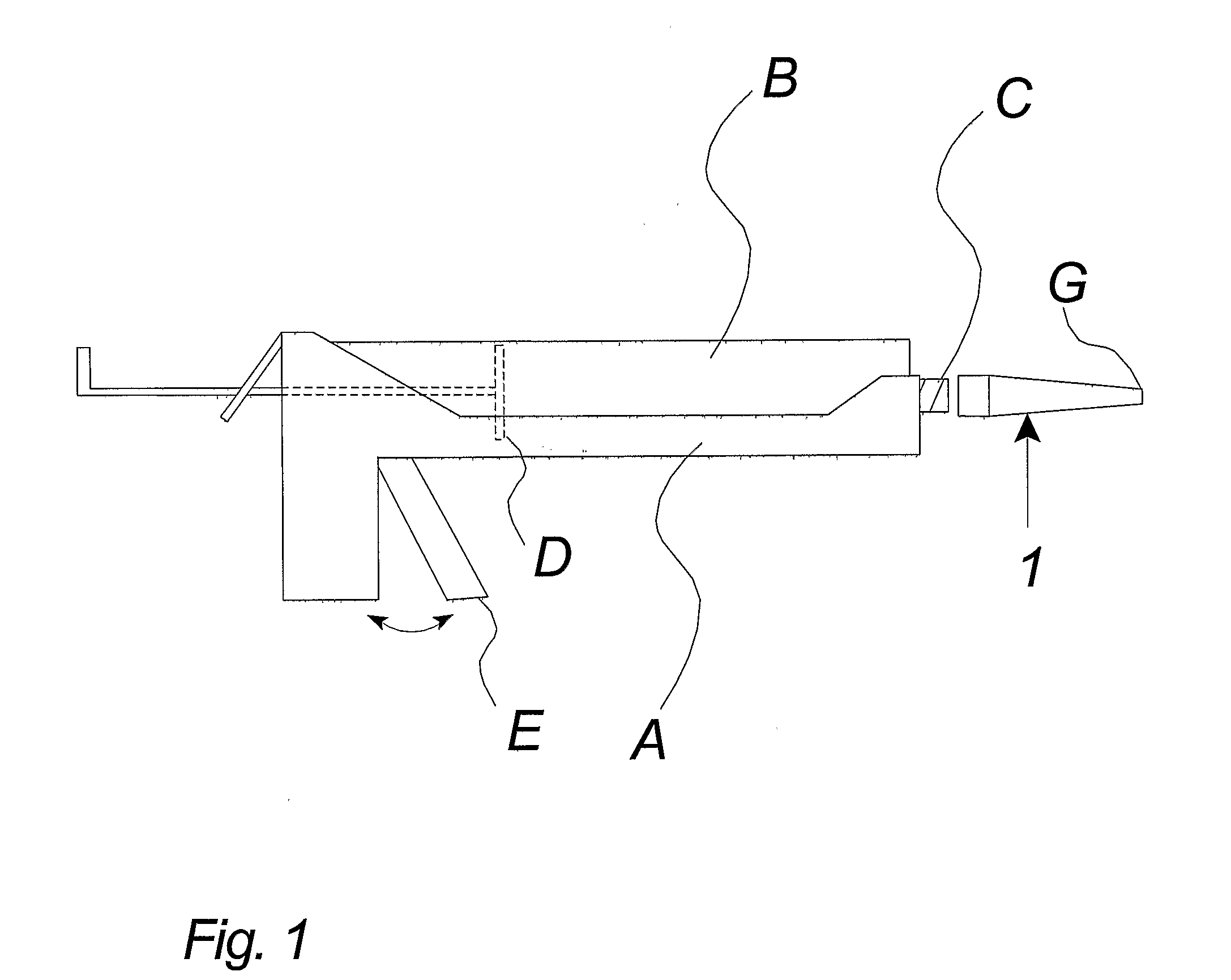

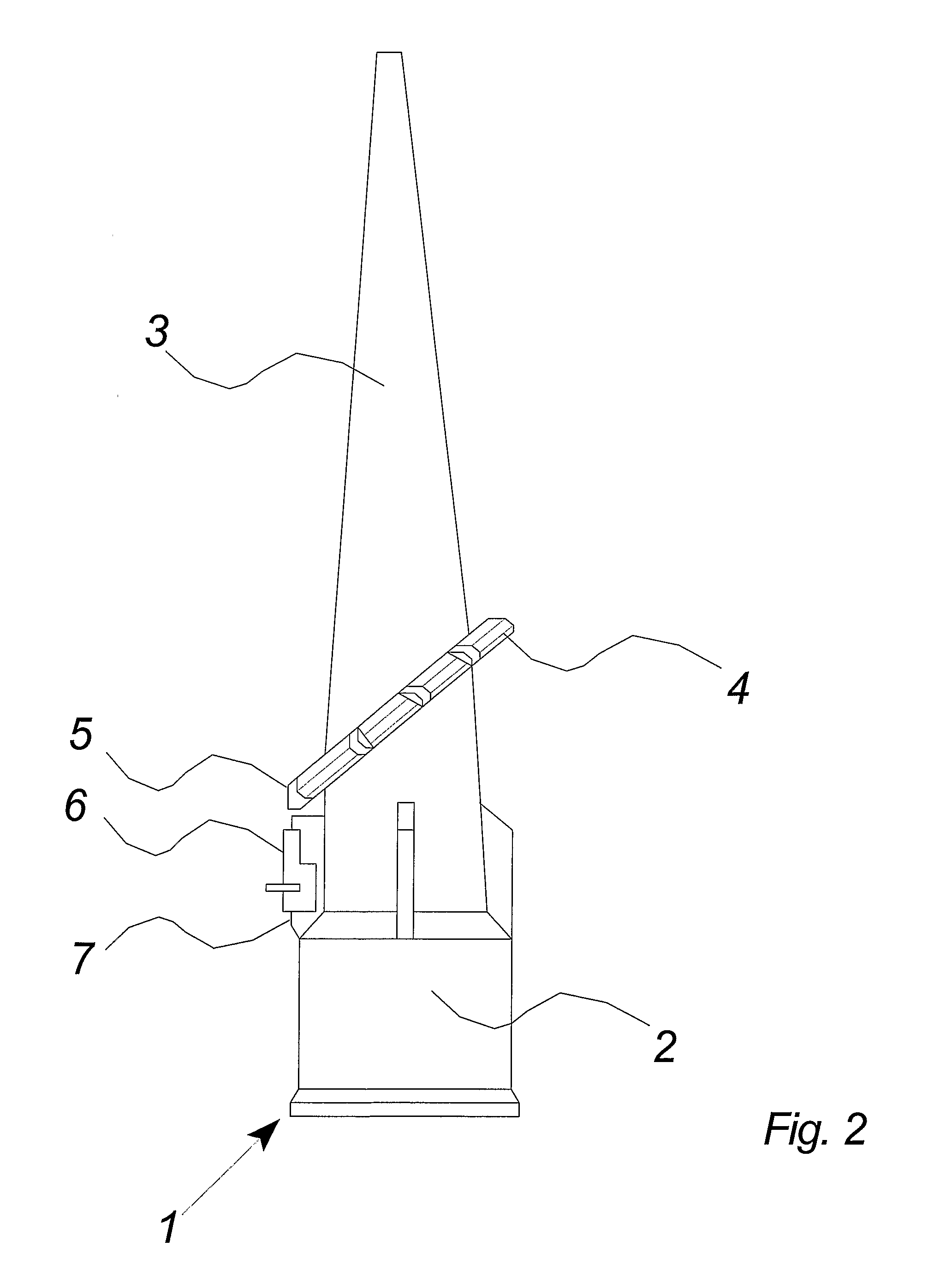

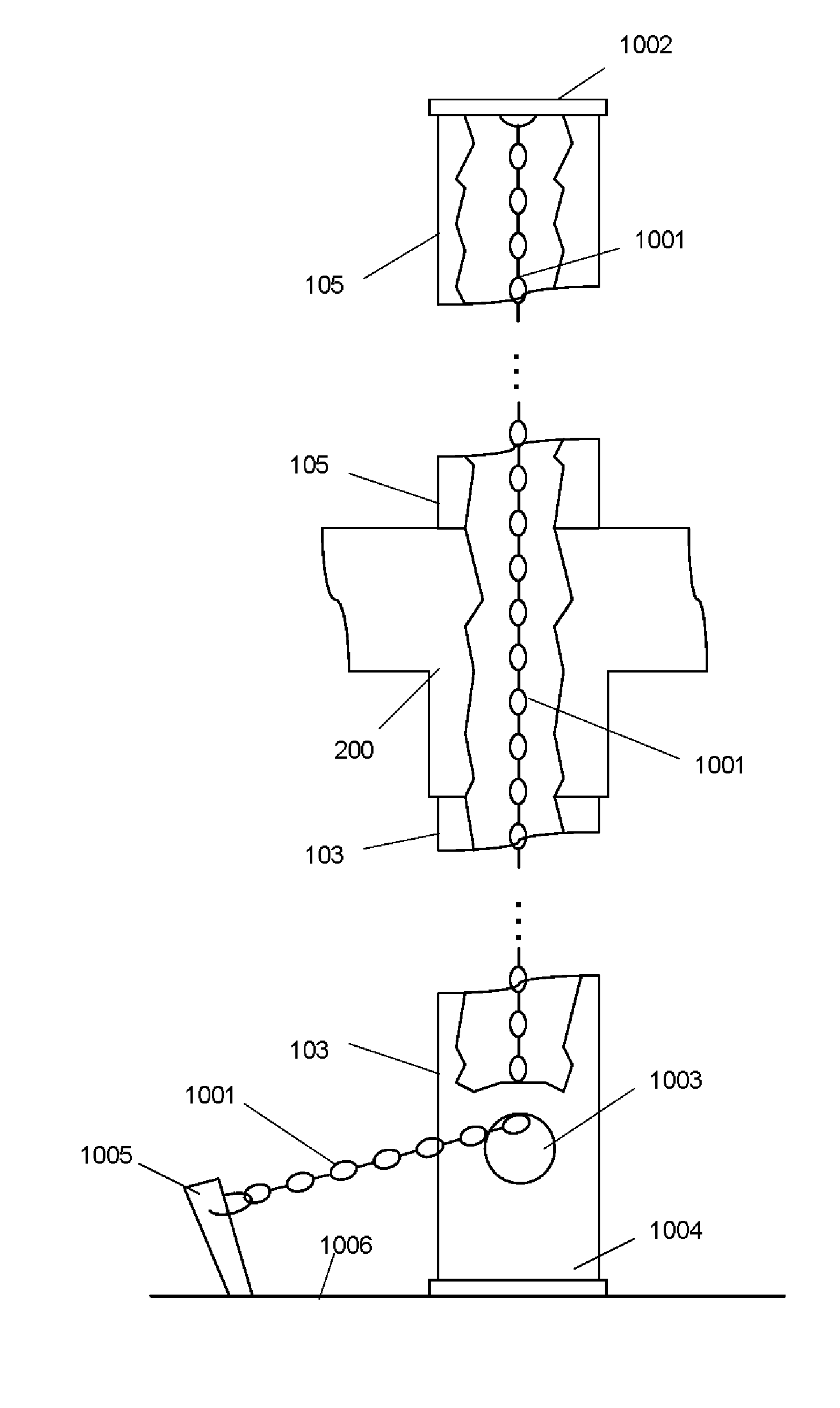

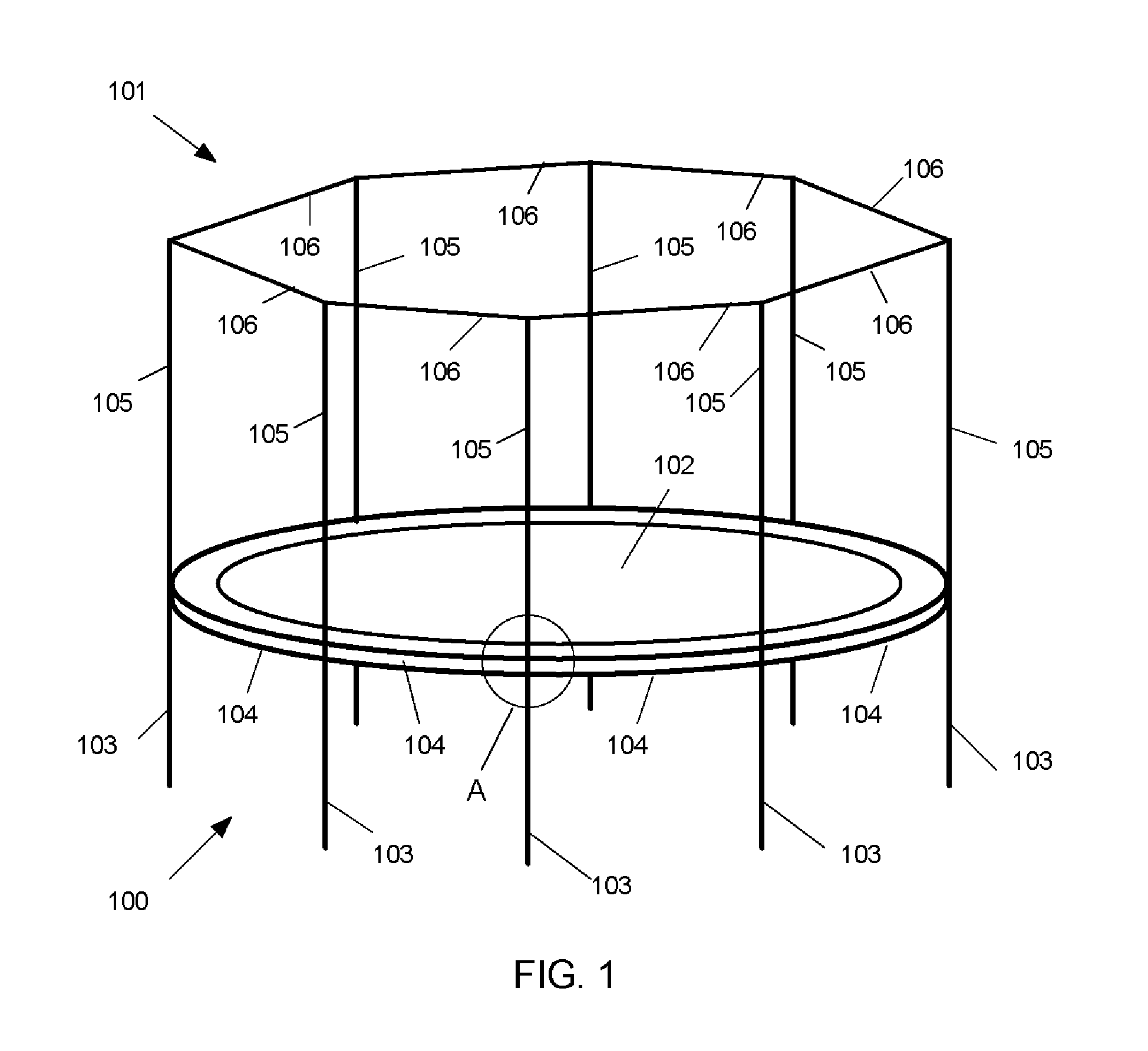

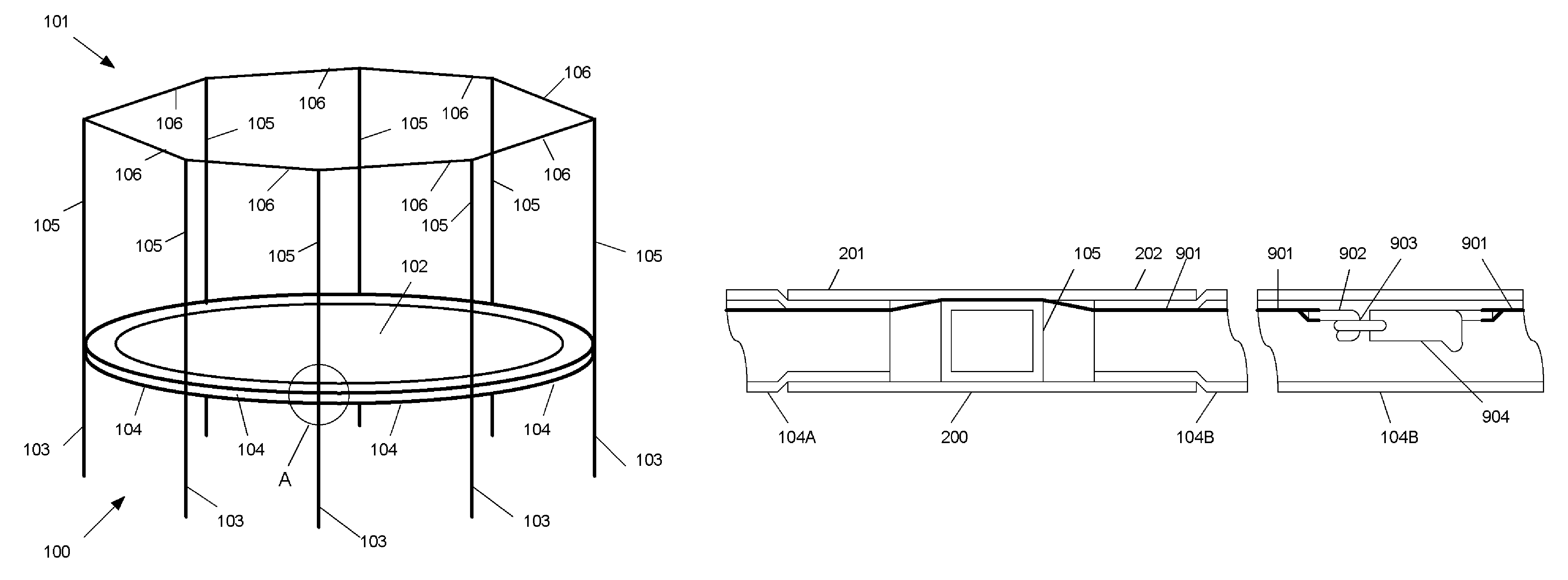

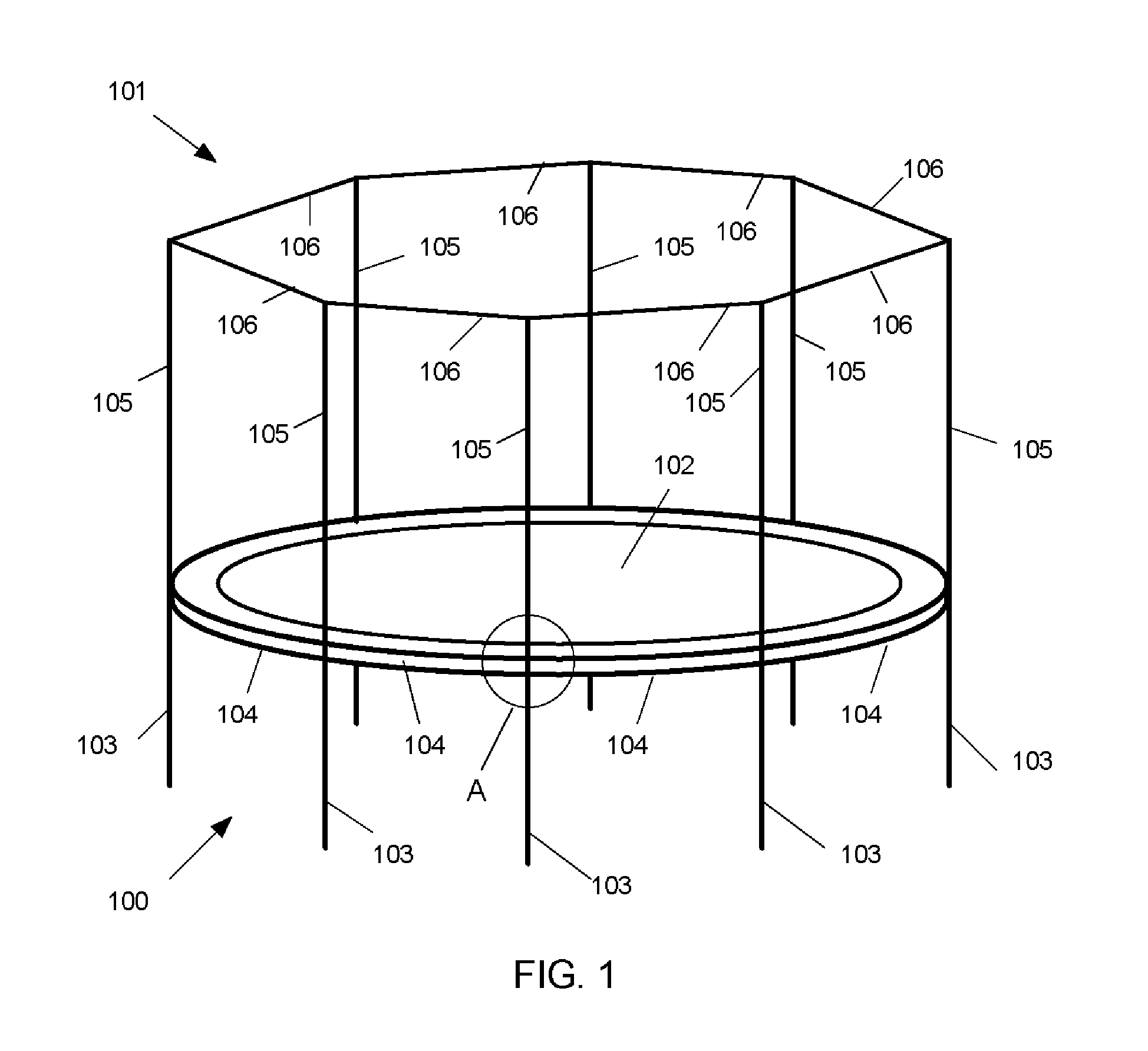

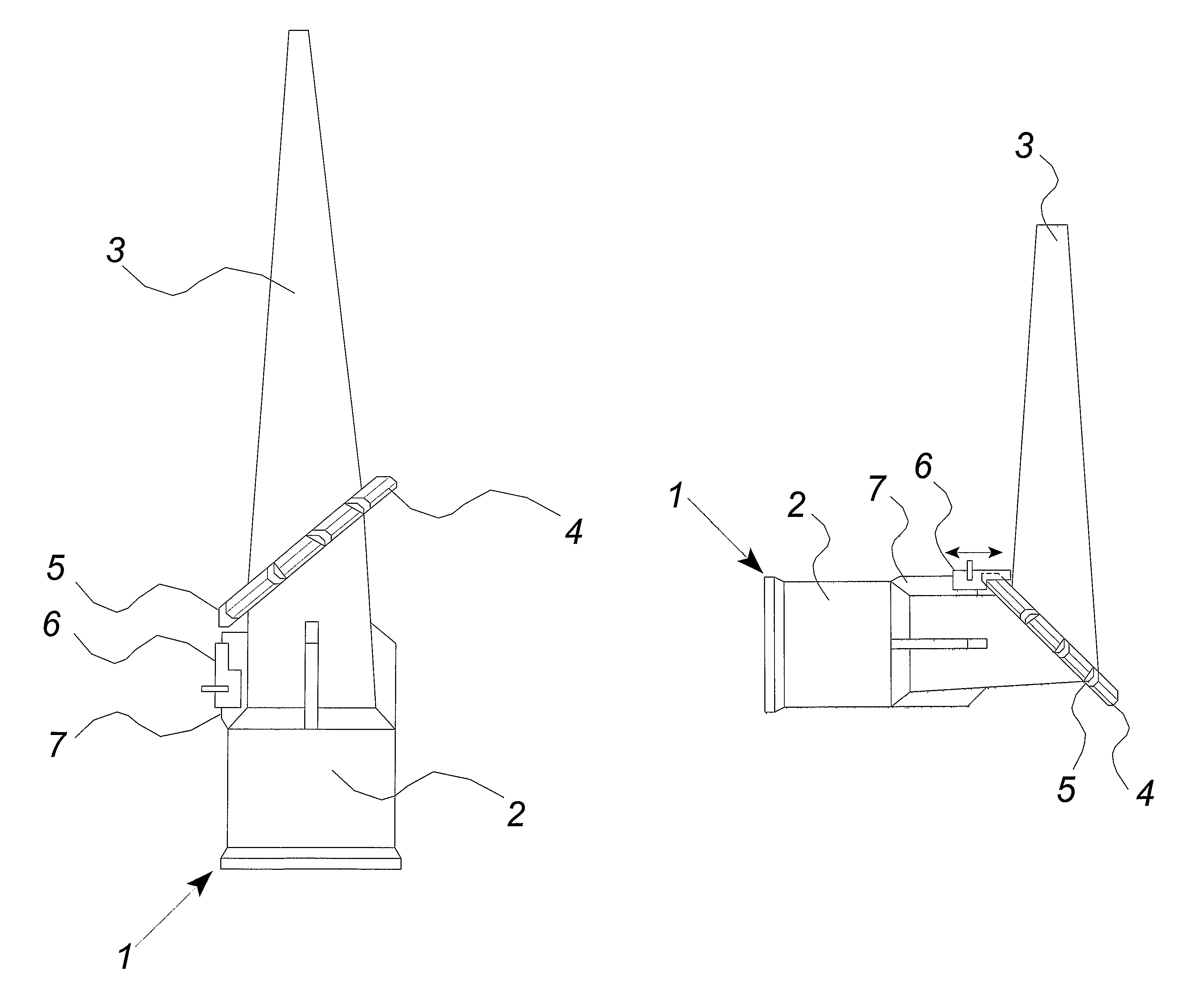

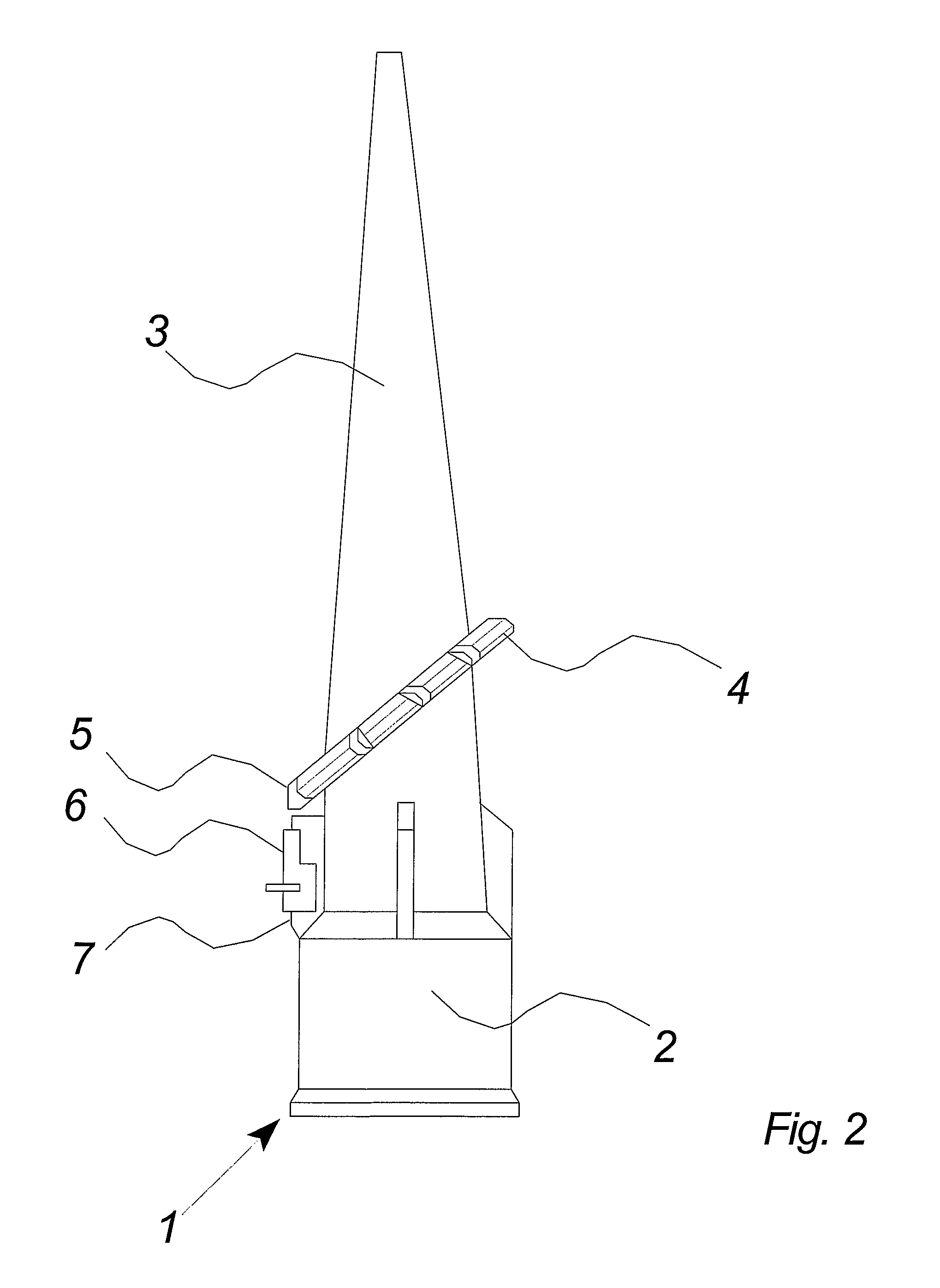

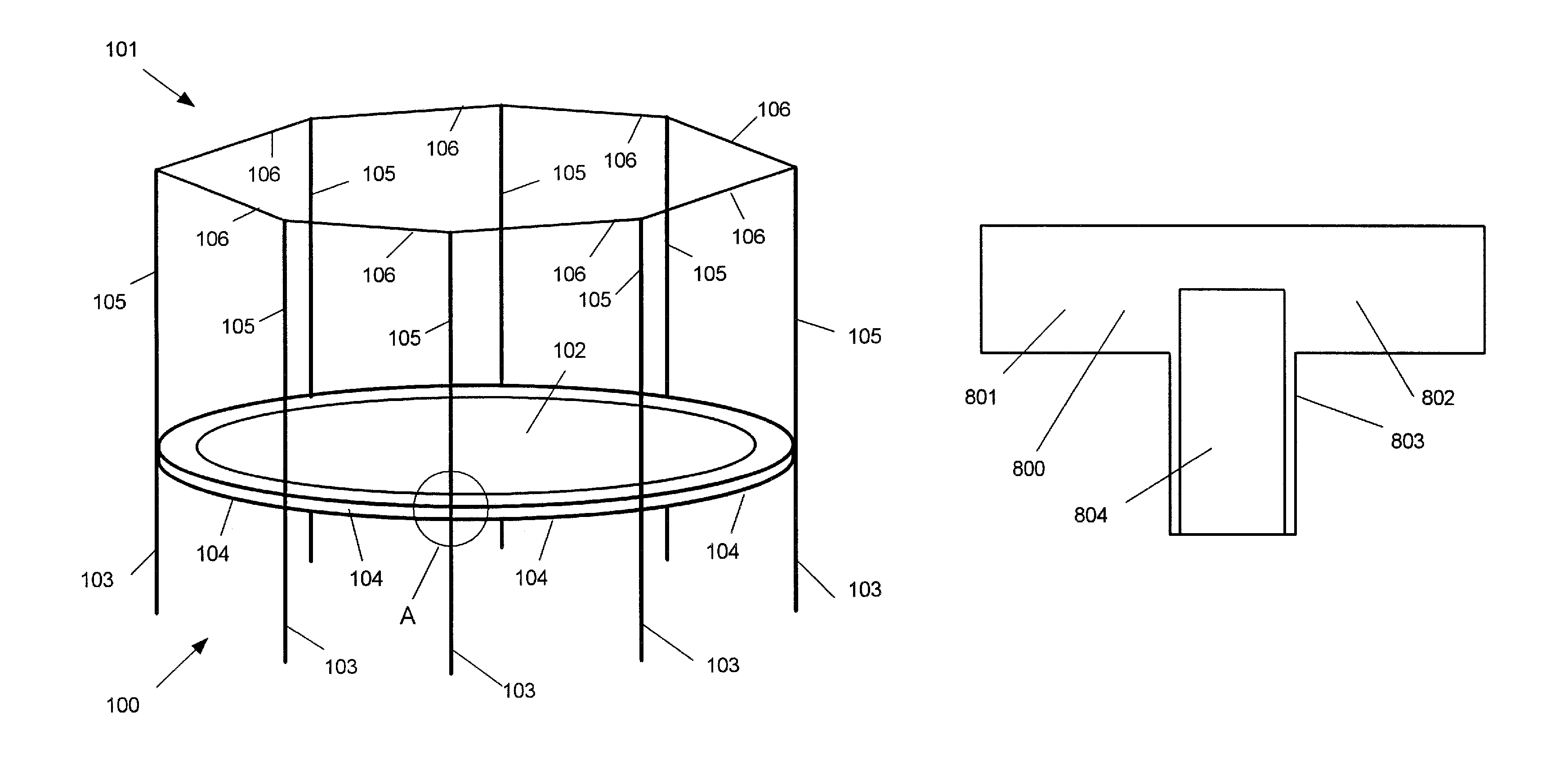

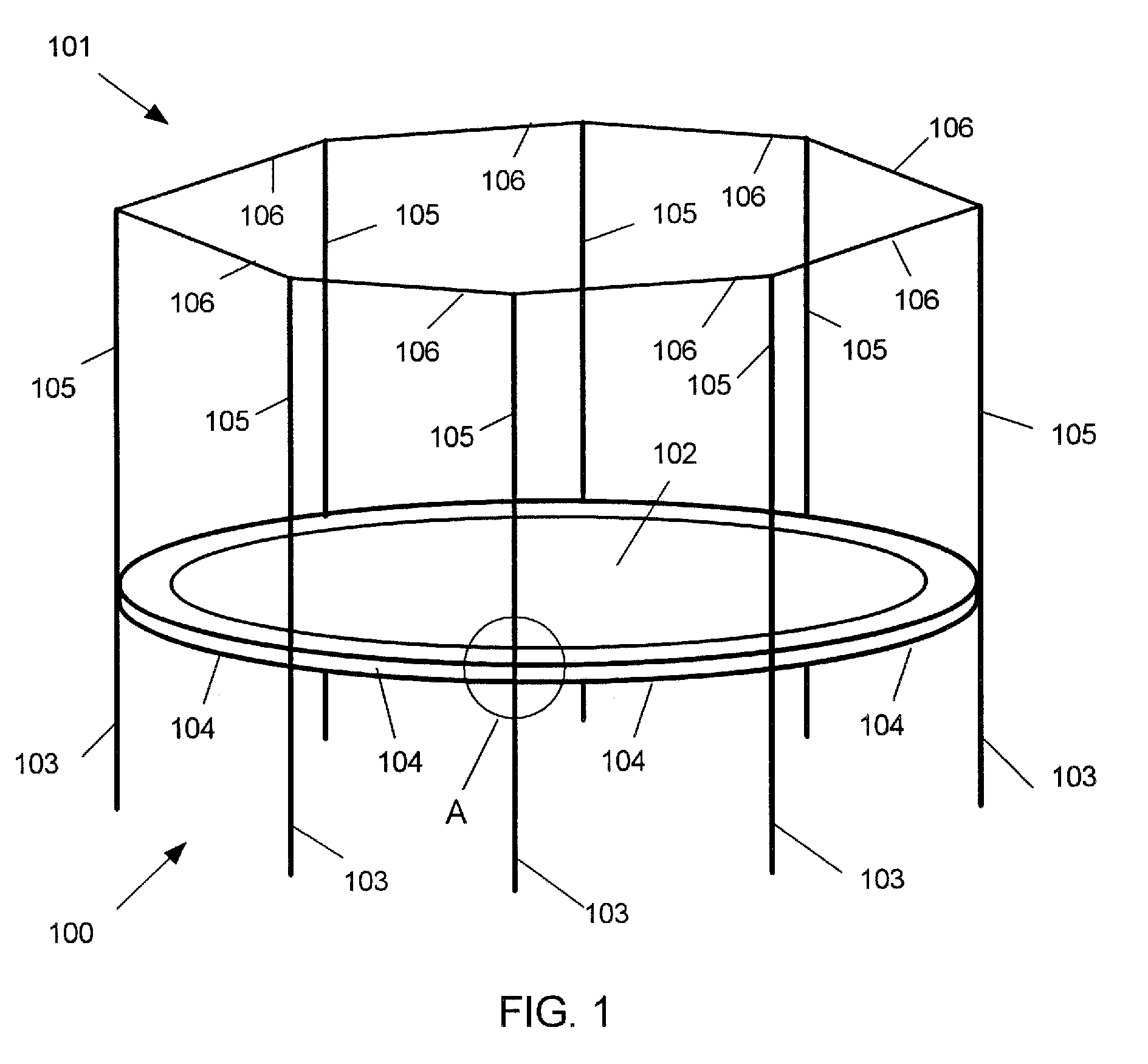

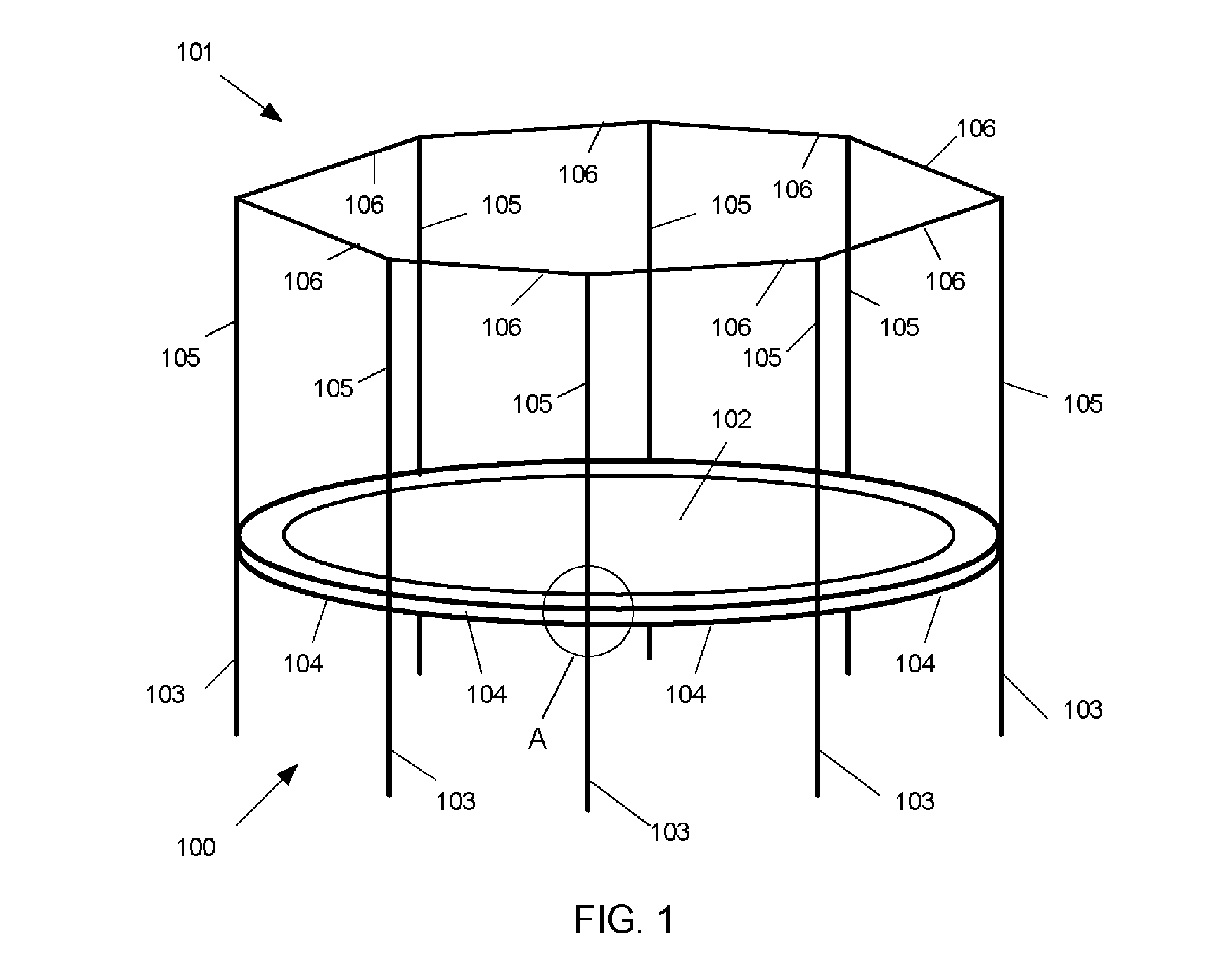

Recreational structure using a coupling member

InactiveUS20060189441A1Simple assemblyQuickly assembleGymnastic climbingSpring boardsMechanical engineeringFlange

A recreational structure, such as a trampoline frame, can be quickly and reliably assembled using a coupling member generally having a “T” configuration. A first arm member and a second arm member are disposed in an opposite relationship with each other. The first and second arm members each receive one end of a horizontal frame member of the recreational structure. The third arm member includes flange members that receive one end of a vertical frame member of the recreational structure and one end of a vertical pole member of, for example, a safety enclosure.

Owner:CA06

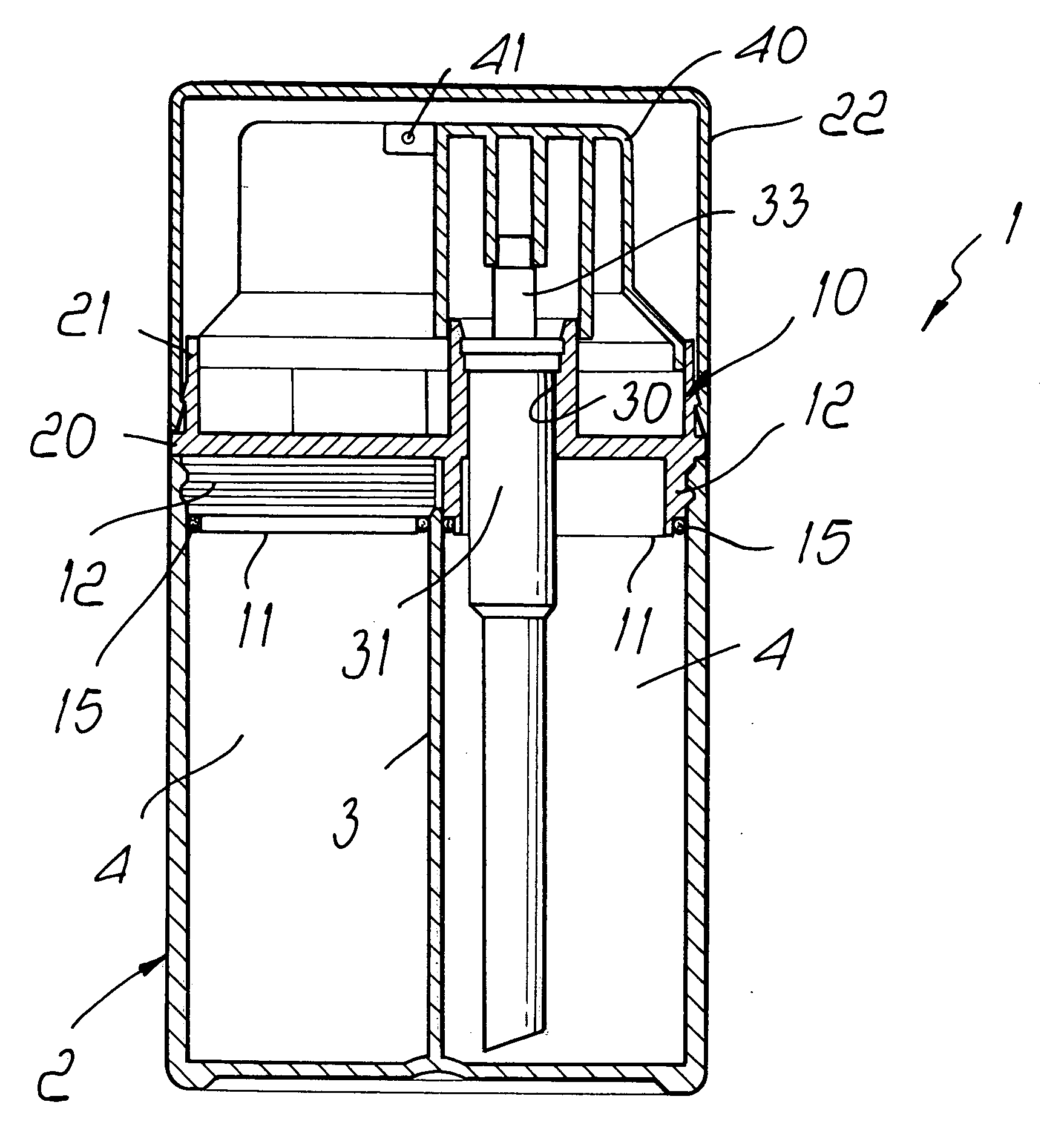

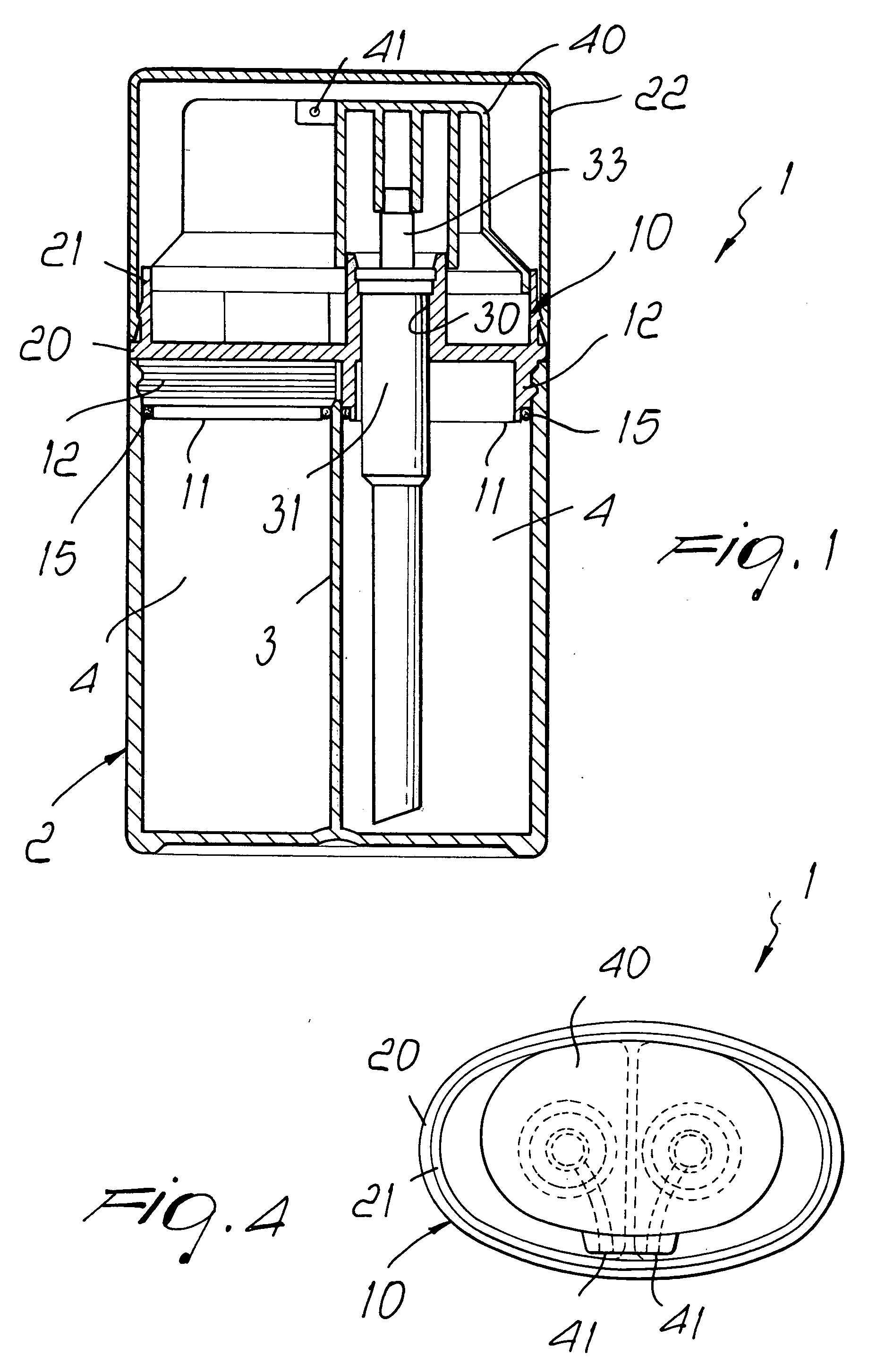

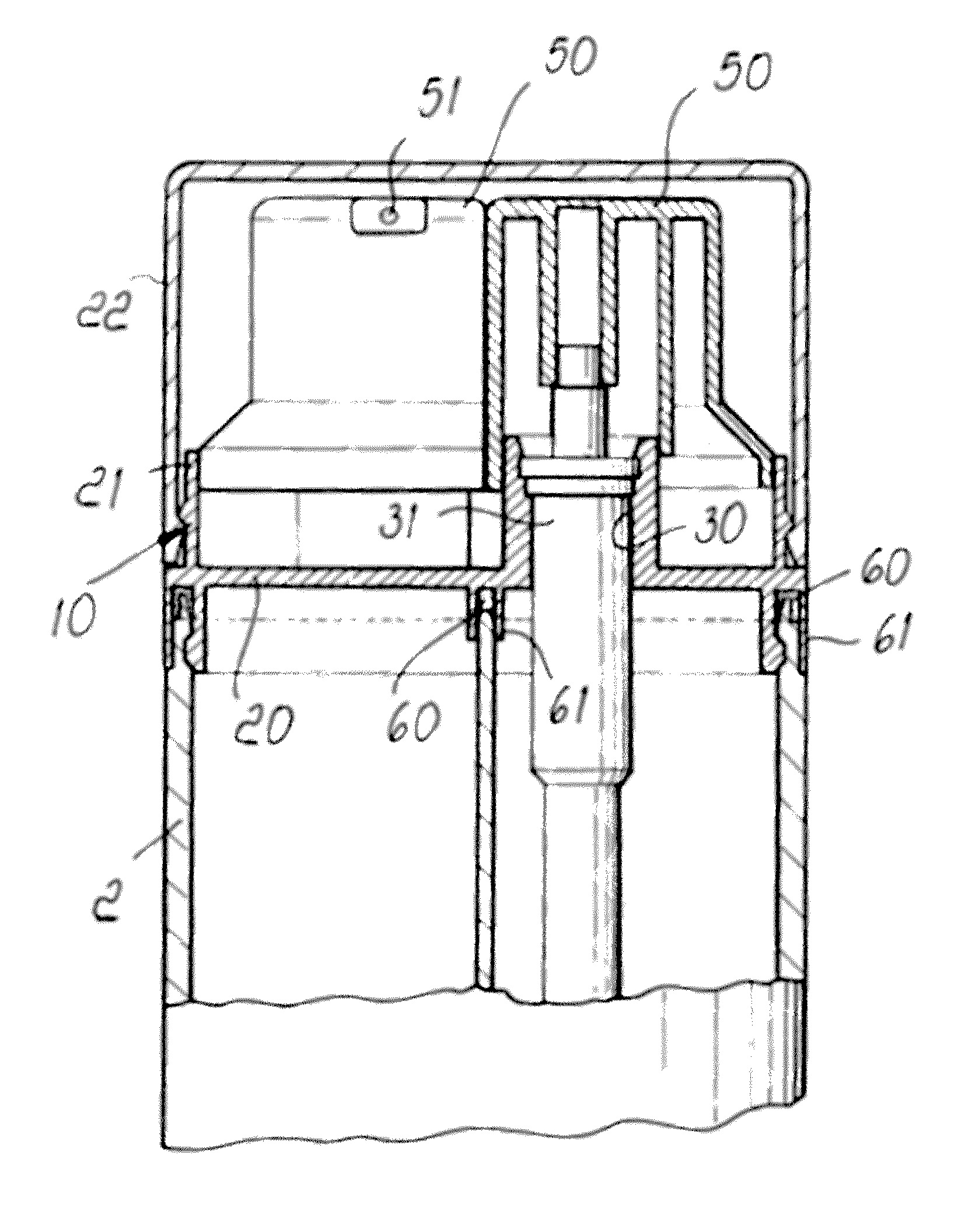

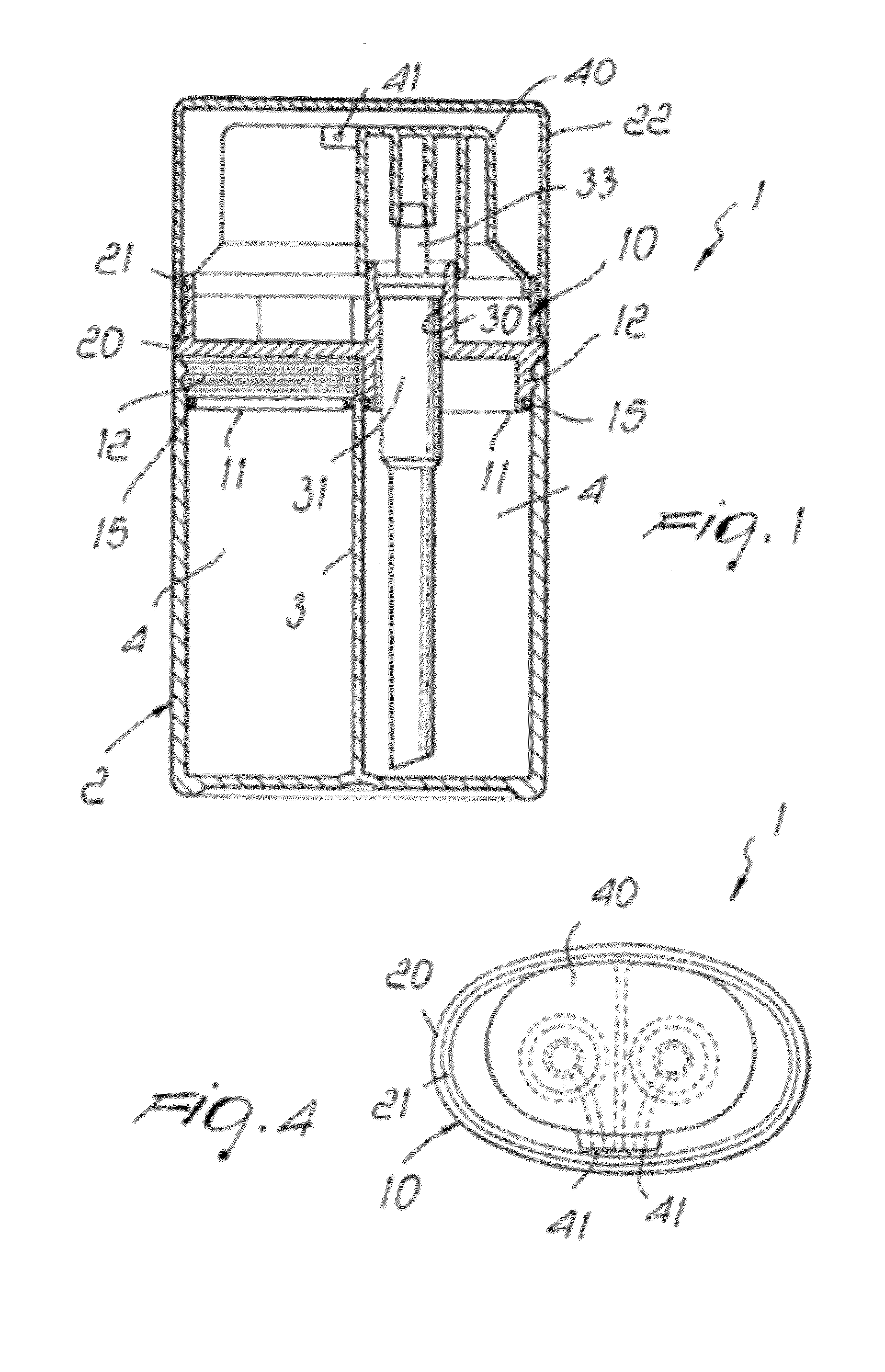

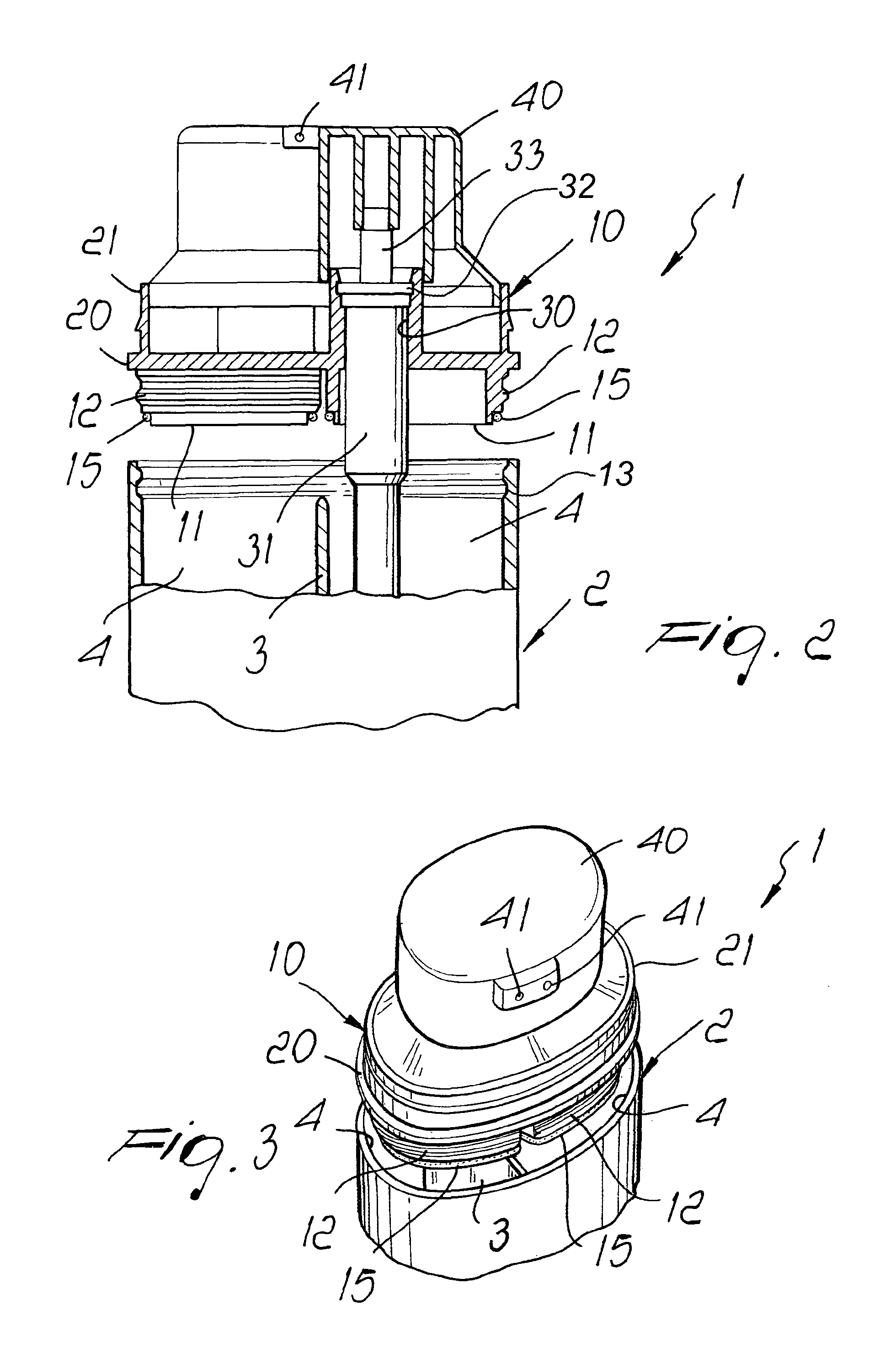

Container for dispensing separate products

InactiveUS20050127100A1Easy to manufactureSimple and quick assemblyLarge containersCosmetic containersVALVE PORT

Owner:REGGIANI

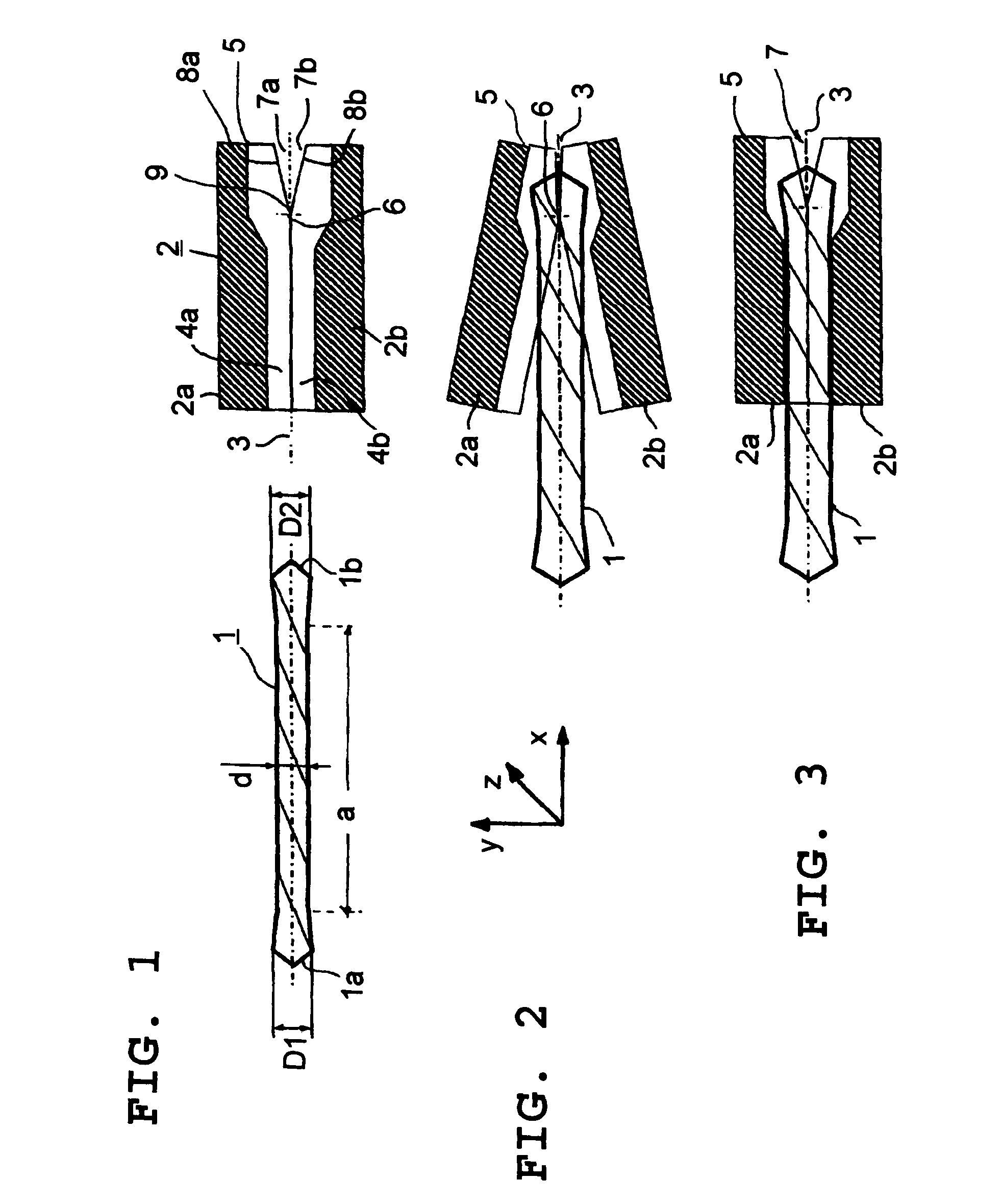

Nozzle for Use in Connection with Dosing of a Material from a Container, Method and Use Thereof

InactiveUS20080264981A1Low production costEasy to useLiquid surface applicatorsLiquid flow controllersEngineeringMechanical engineering

The invention relates to a nozzle (1) for use in connection with the providing of a fluid material from a container, where the nozzle comprises a first nozzle base part (2), a nozzle tip part and a link (4) connecting the nozzle parts (2, 3). The link (4) has a first pivotal state and a second locked state when the link is under pressure by the material flow The link (4) has a first surface (8) and second surface (10), the surfaces being pivotally connected to each other, and where said surfaces (8, 10) are angled in relation to the longitudinal center axis of the nozzle. The invention also relates to a use of the nozzle (1).

Owner:CLAUS LEONHARDT JENSEN & FINN HOLME HJORT

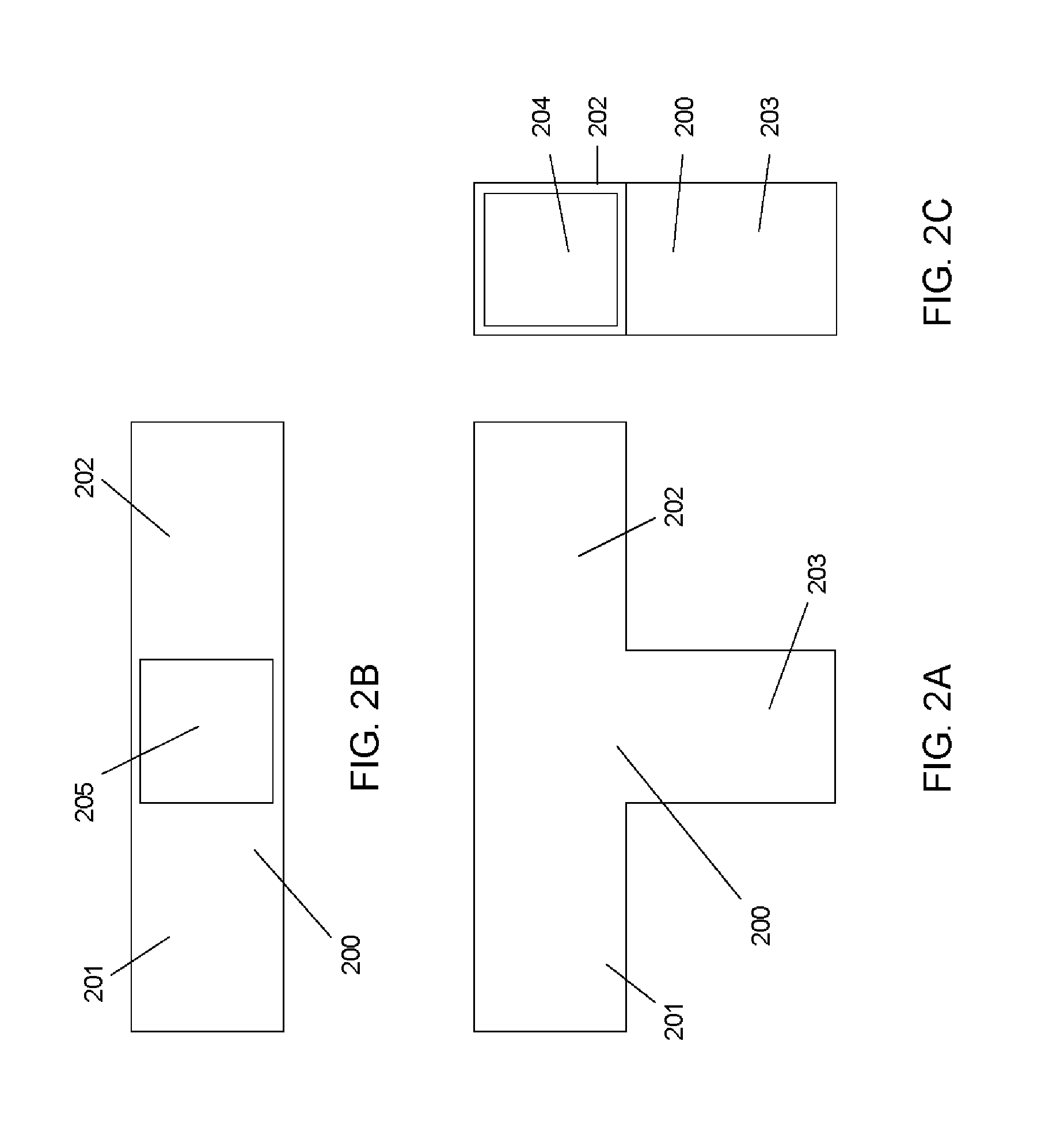

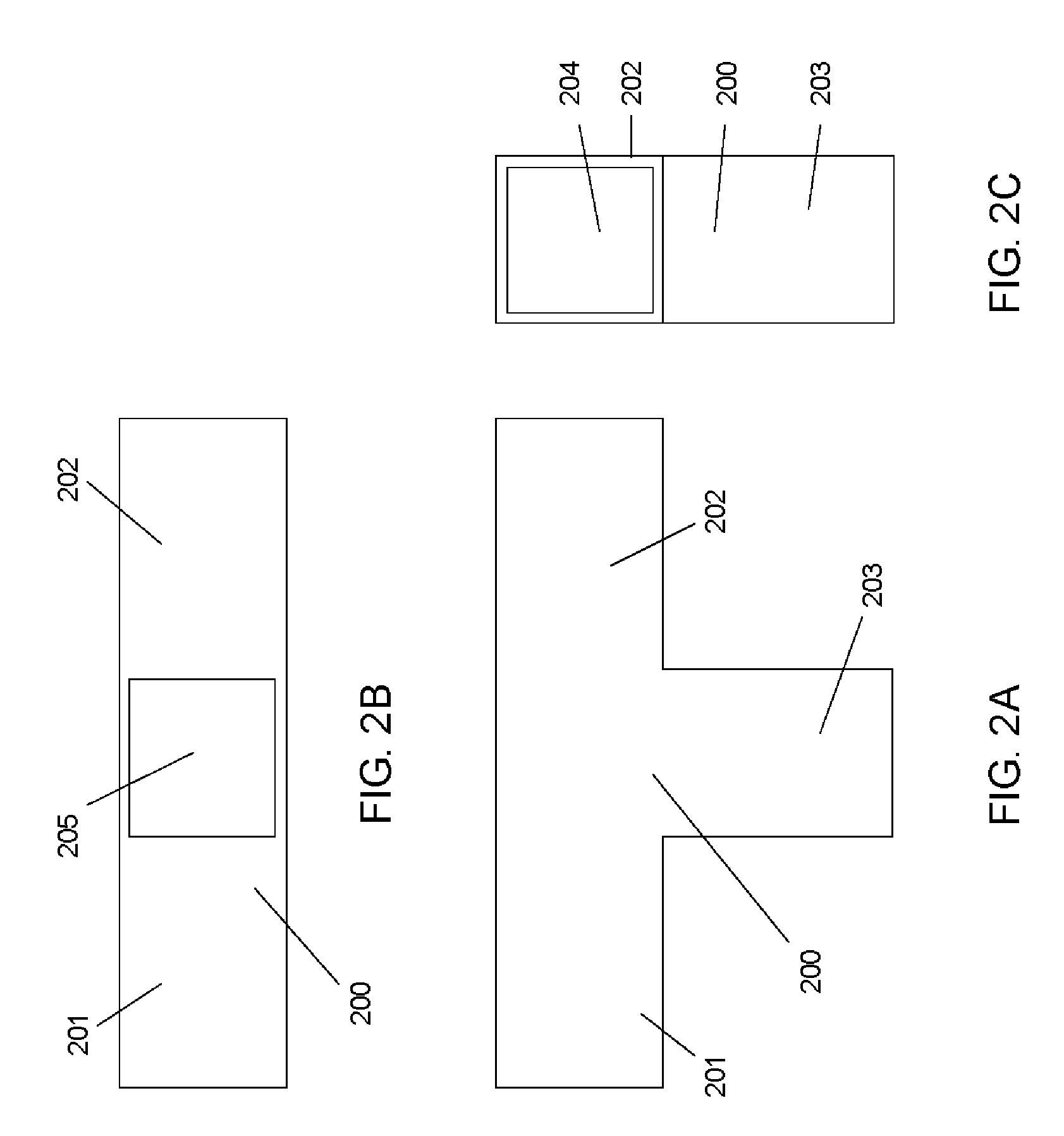

Recreational structure using a sleeve-joint coupling

InactiveUS20060128529A1Simple and quick assemblyStable structureGymnastic climbingSpring boardsCouplingTension member

A recreational structure, such as a trampoline frame, can be quickly and reliably assembled using a sleeve-joint coupling having a “T” configuration. A first arm member and an aperture that is formed in the sleeve-joint coupling are disposed in an opposite relationship. A second arm member and a third arm member are disposed in an opposite relationship with each other. The first arm member receives one end of a vertical frame member of the recreational structure, while the aperture receives one end of a vertical pole member of, for example, a safety enclosure. The second and third arm members each receive one end of a horizontal frame member of the recreational structure. A tension member applies a force between a vertical frame member and a corresponding vertical pole member that compresses the vertical frame member toward the corresponding vertical pole member.

Owner:CA06

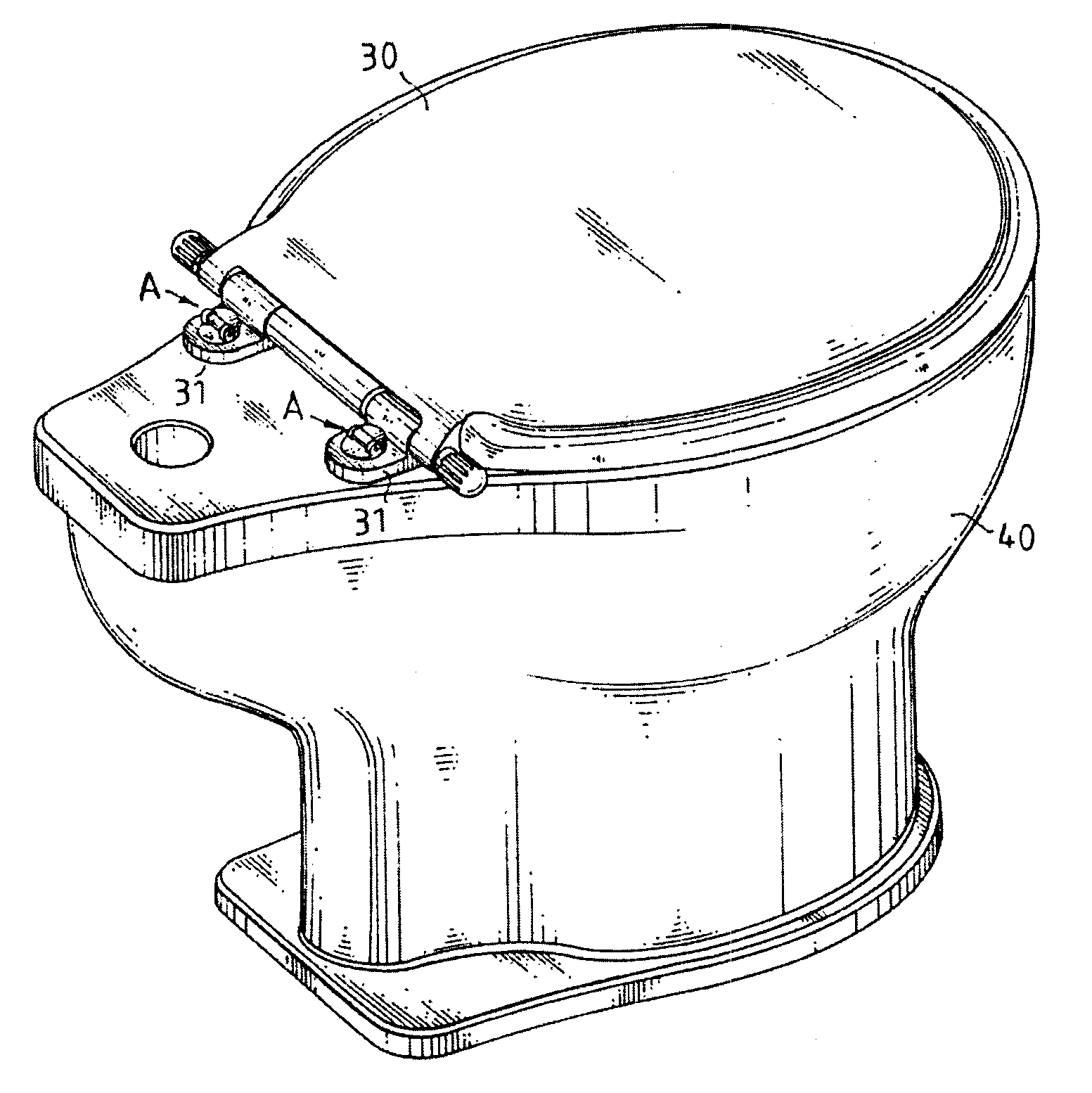

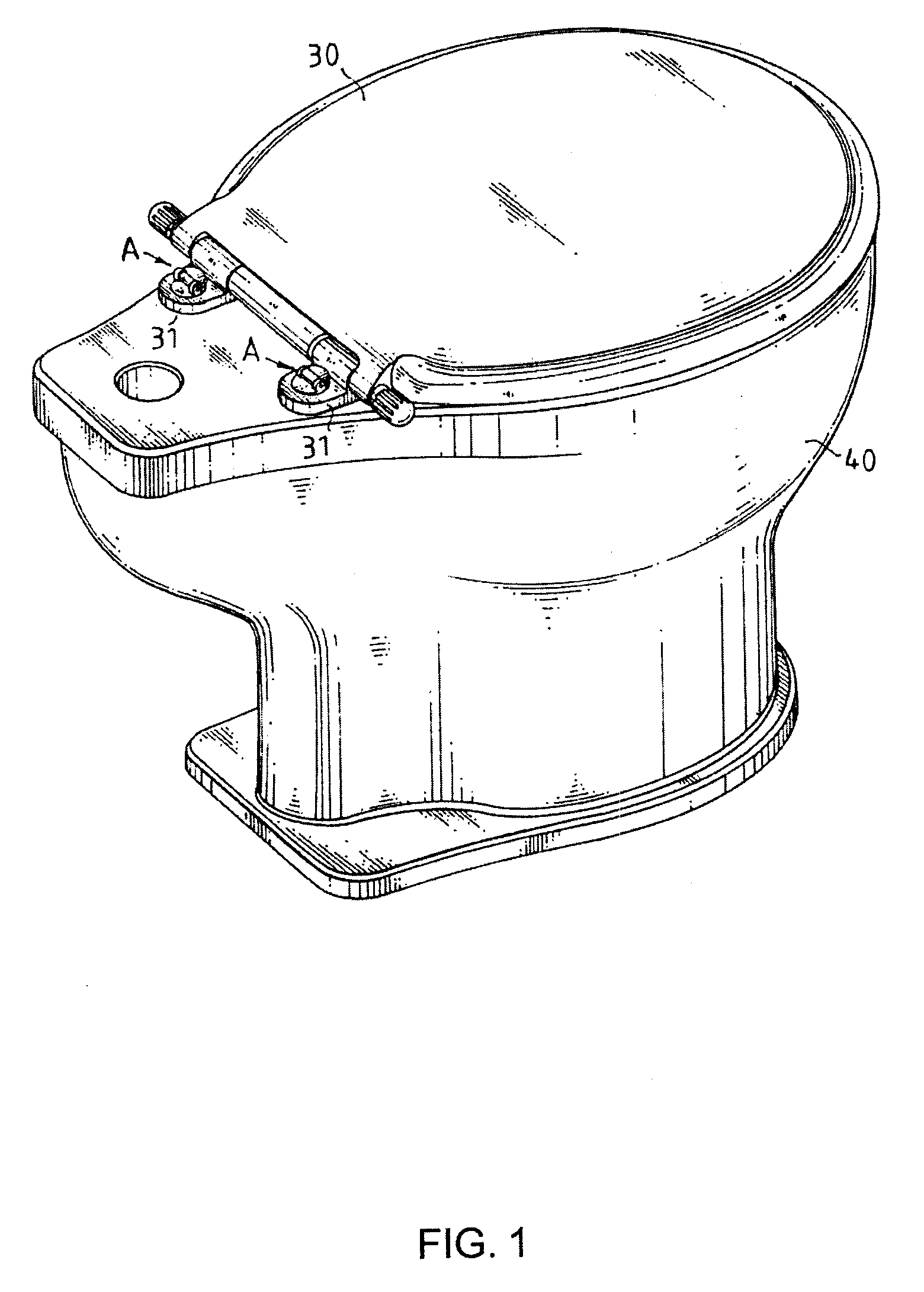

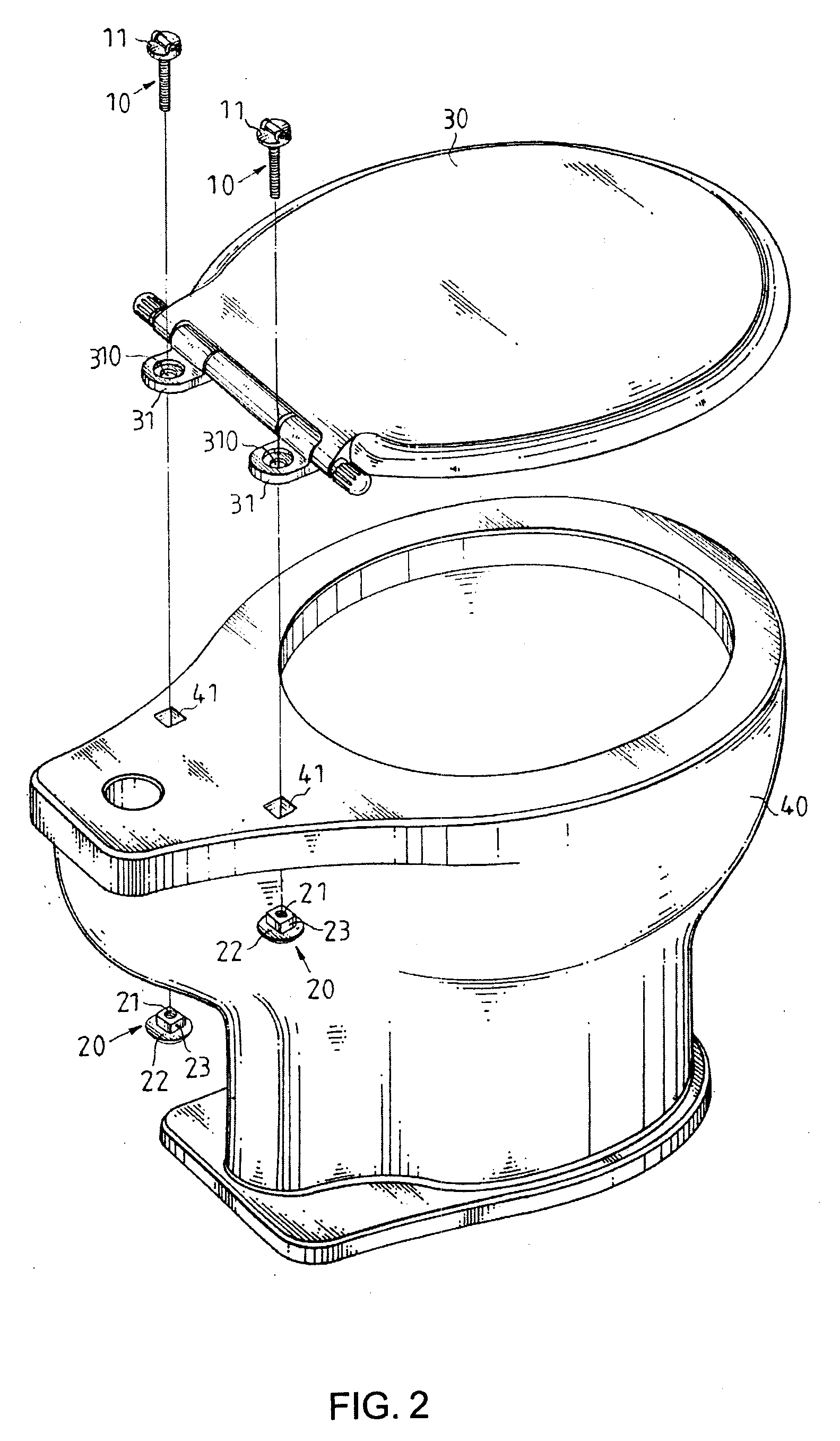

Quick Release Toilet Mechanism

InactiveUS20080172780A1Easy to disassembleSimple and quick assemblyBathroom coversMechanical engineeringToilet

The invention relates to a removable bolt assembly for fastening a toilet seat to a commode using a knob or bar handle. The knob or bar handle, pivotally mounted to the bolt, can be used to twist or clamp the bolt into engagement with a nut that is inserted through a hole in the toilet. The hole in the toilet can be circular or noncircular. Where the hole is noncircular, the nut has a corresponding noncircular geometric neck so as to prevent it from rotating in the hole. Where the hole is circular, a fastening hinge having a connecting insert can be used to prevent rotation of the nut when it is engaged with the connecting insert. In this way the bolt is directly interlocked with the nut without the use of any tool, thereby making it easy to lock and fasten the seat to the commode.

Owner:FUSION EXPERTS

Container for dispensing separate products

InactiveUS7793799B2Easy to manufactureSimple and quick assemblyLarge containersCosmetic containersEngineeringMechanical engineering

Owner:REGGIANI

Recreational structure using a sleeve-joint coupling

A recreational structure, such as a trampoline frame, can be quickly and reliably assembled using a sleeve-joint coupling having a “T” configuration. A first arm member and an aperture that is formed in the sleeve-joint coupling are disposed in an opposite relationship. A second arm member and a third arm member are disposed in an opposite relationship with each other. The first arm member receives one end of a vertical frame member of the recreational structure, while the aperture receives one end of a vertical pole member of, for example, a safety enclosure. The second and third arm members each receive one end of a horizontal frame member of the recreational structure. A tension member applies a force between a vertical frame member and a corresponding vertical pole member that compresses the vertical frame member toward the corresponding vertical pole member.

Owner:CA06

Nozzle for use in connection with dosing of a material from a container, method and use thereof

InactiveUS7931175B2Low production costEasy to useLiquid surface applicatorsLiquid flow controllersSpray nozzleAerospace engineering

A nozzle (1) is disclosed for use in connection with the providing of a fluid material from a container, where the nozzle comprises a first nozzle base part (2), a nozzle tip part and a link (4) connecting the nozzle parts (2, 3). The link (4) has a first pivotal state and a second locked state when the link is under pressure by the material flow The link (4) has a first surface (8) and second surface (10), the surfaces being pivotally connected to each other, and where said surfaces (8, 10) are angled in relation to the longitudinal center axis of the nozzle. The invention also relates to a use of the nozzle (1).

Owner:CLAUS LEONHARDT JENSEN & FINN HOLME HJORT

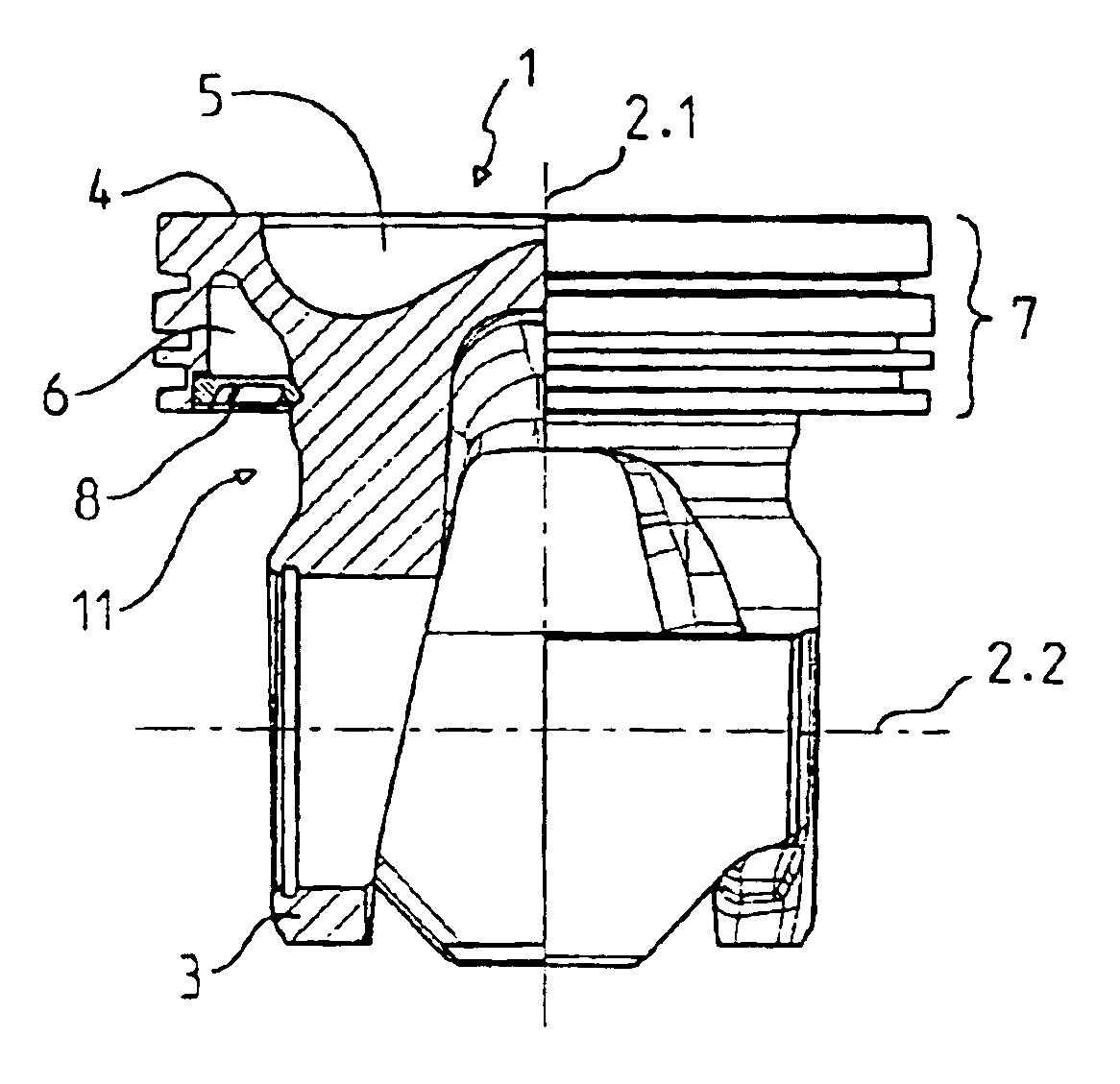

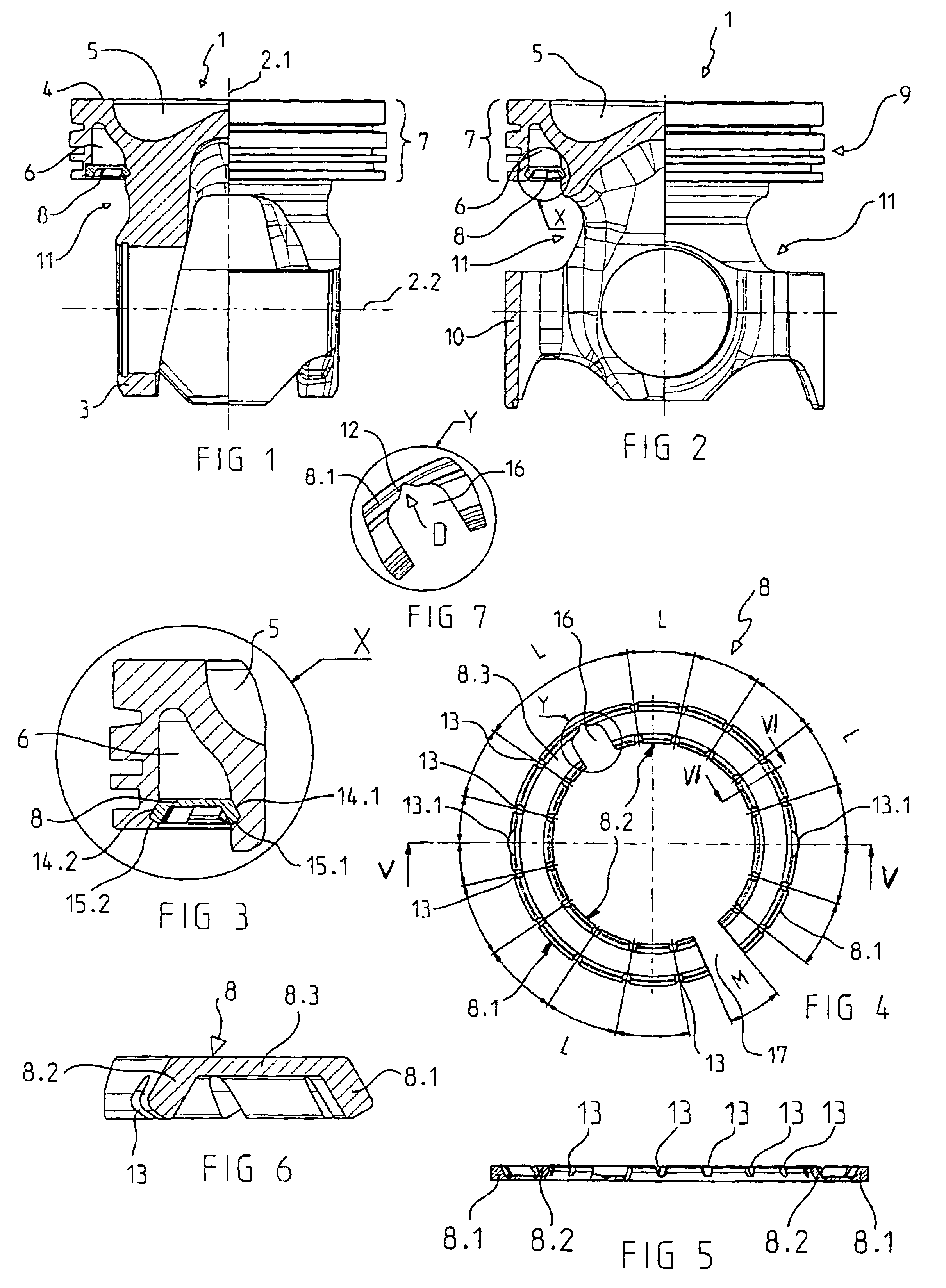

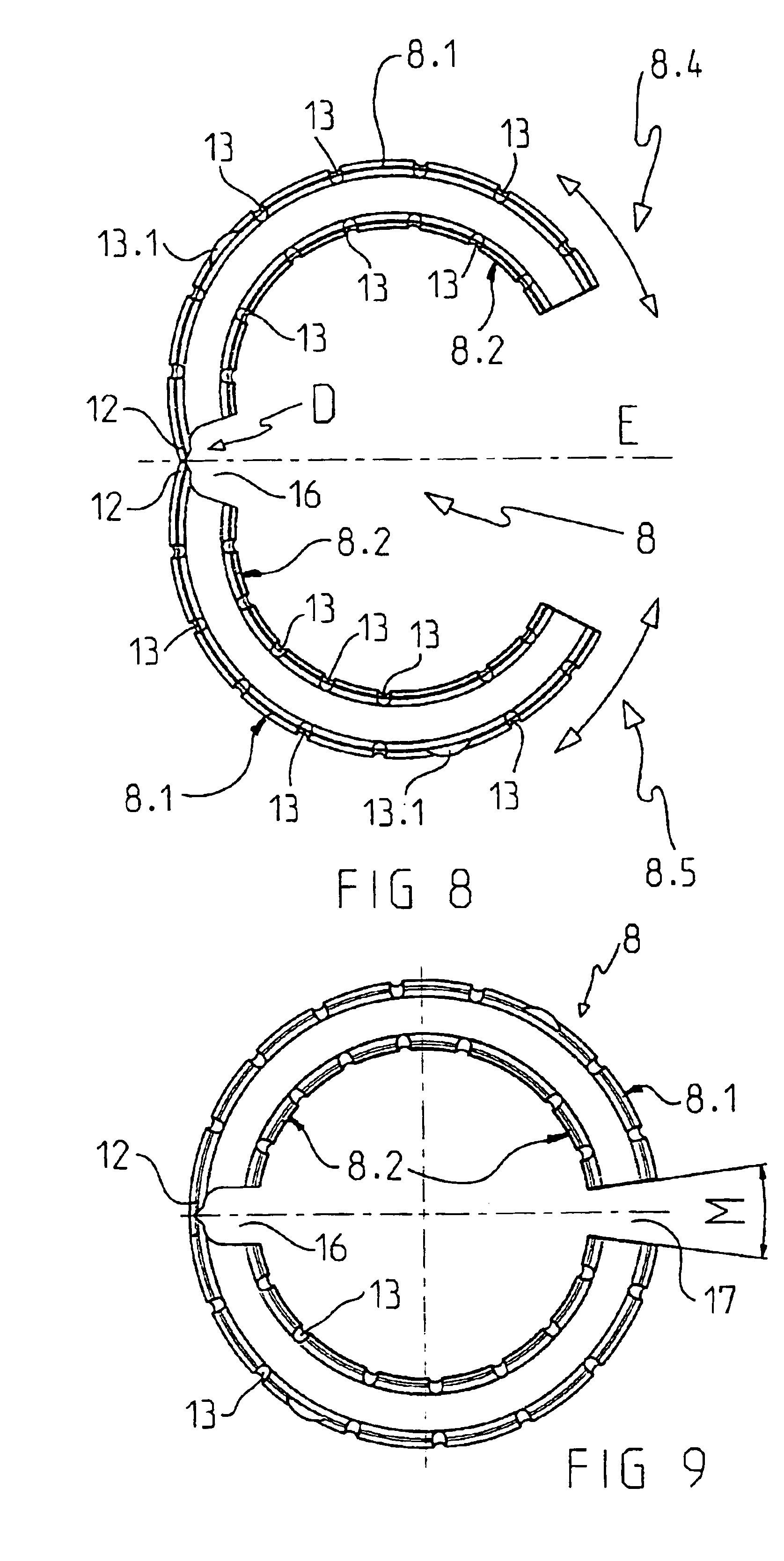

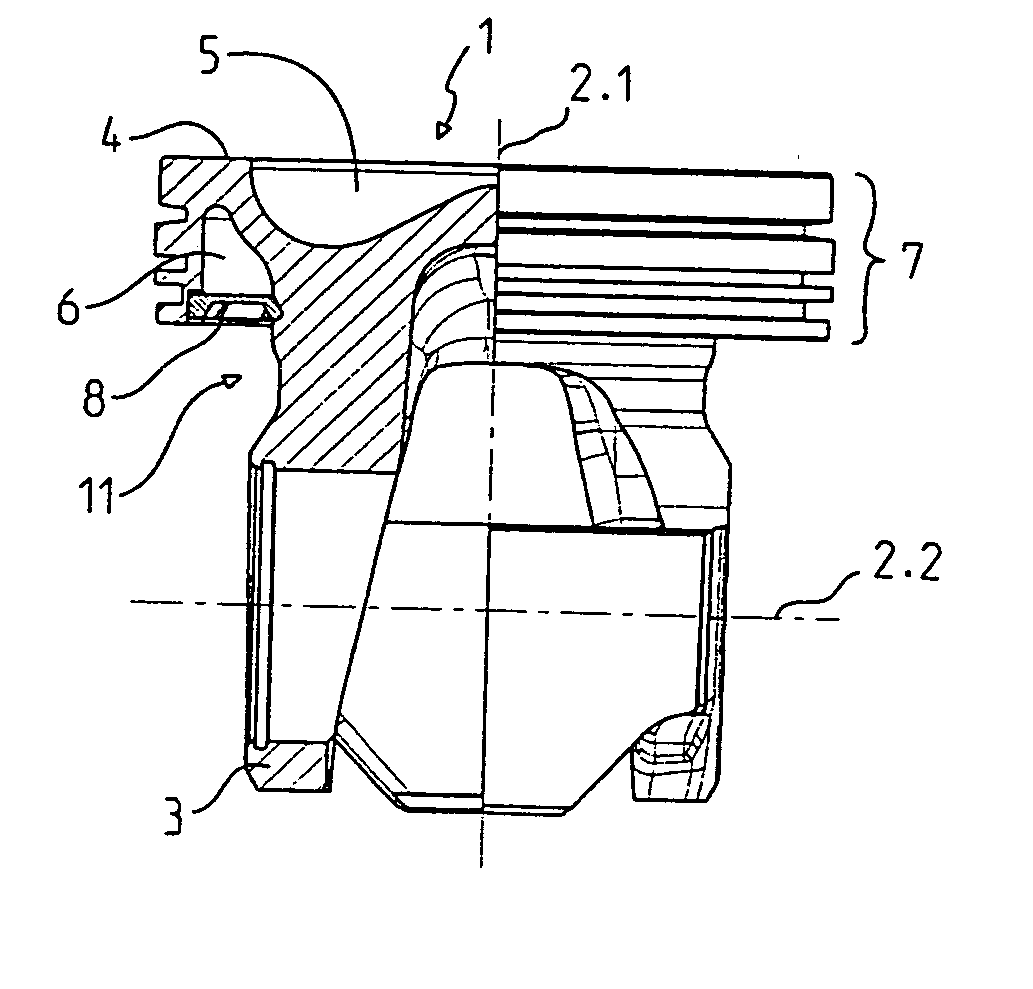

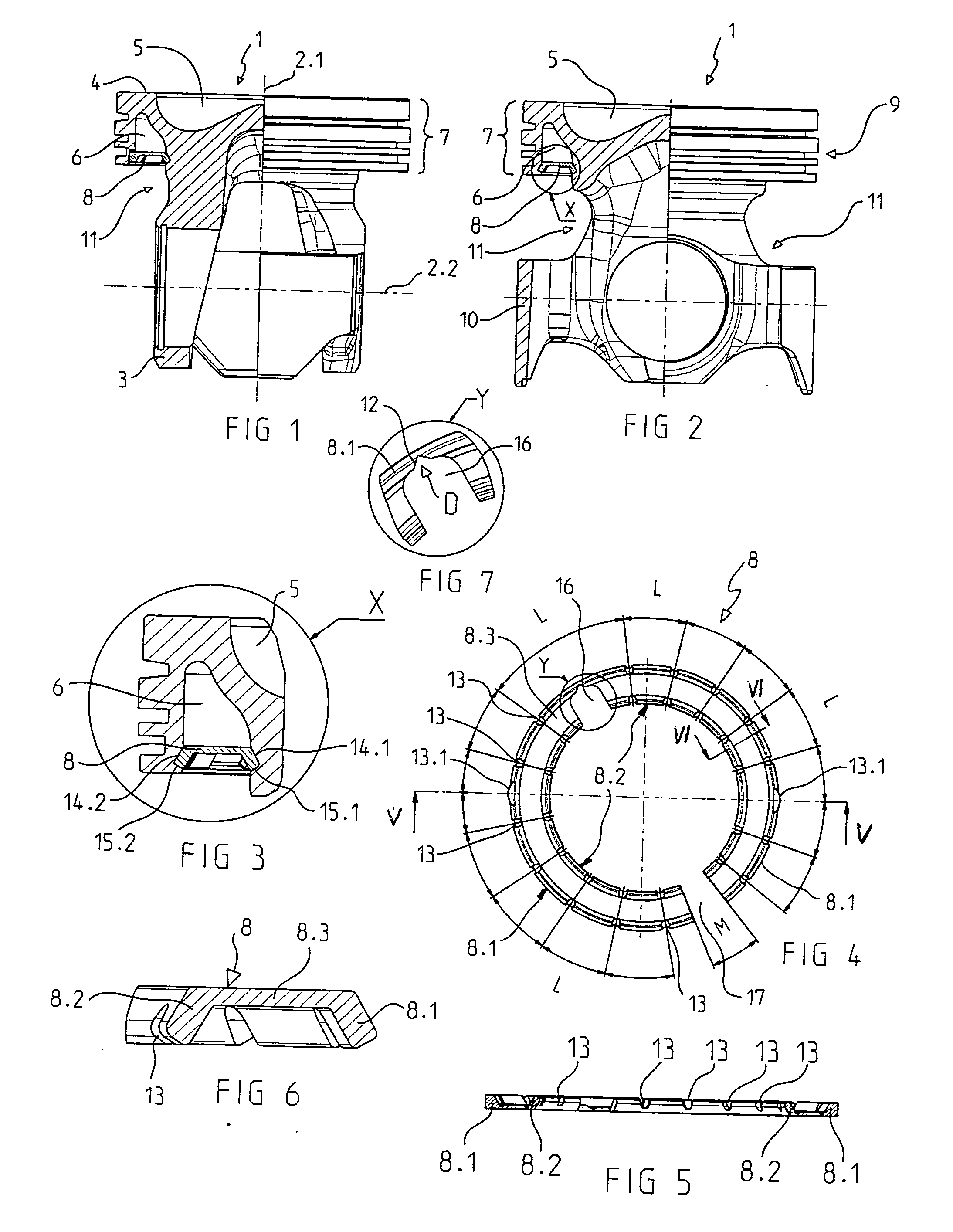

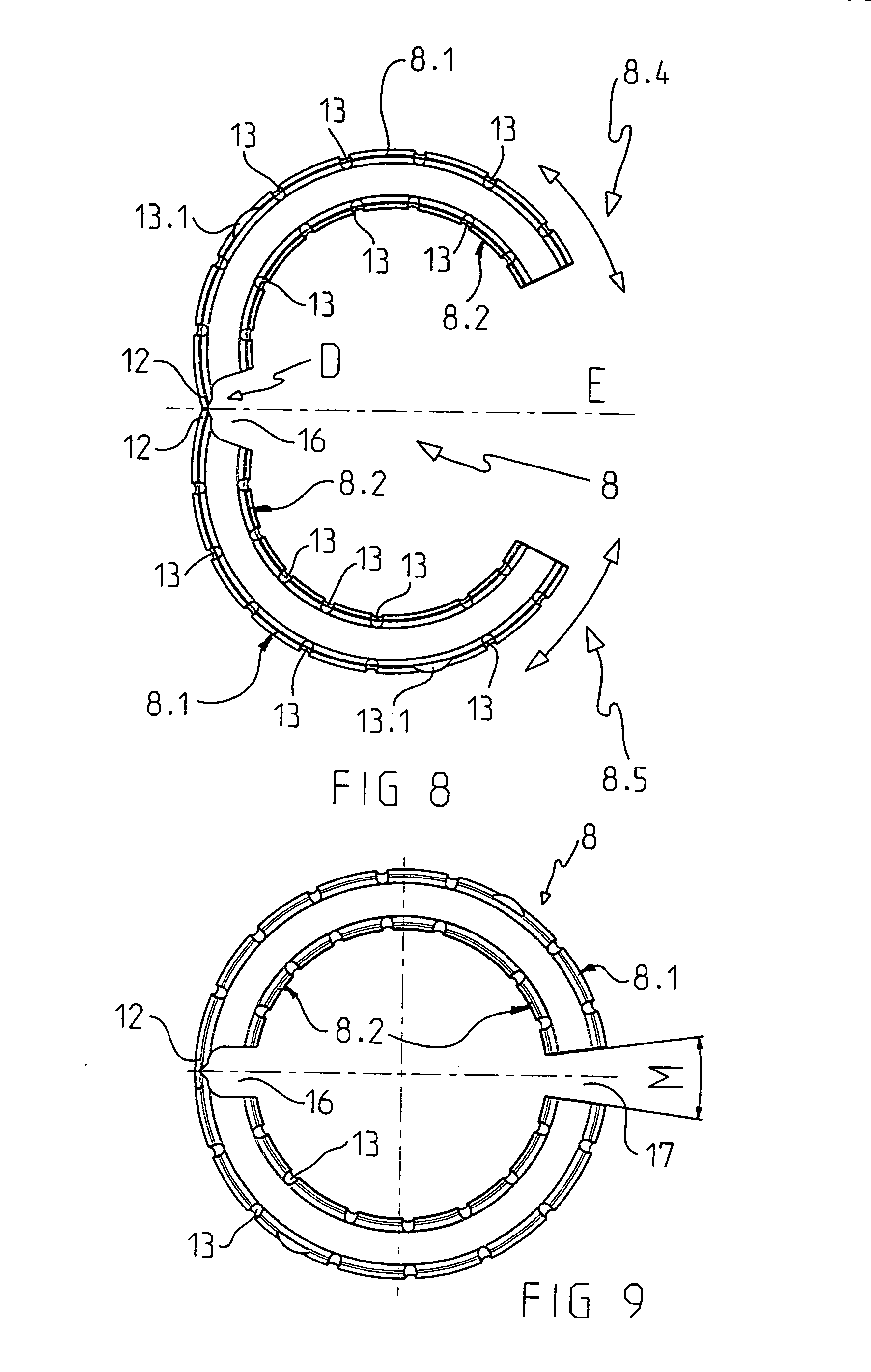

Cooling channel cover for a one-piece piston of an internal combustion engine

InactiveUS6920860B2Quick installationReduce weightValve arrangementsAir coolingPiston ringInternal combustion engine

A cooling channel cover for a one-piece piston of an internal combustion engine, the piston having a closed cooling channel that runs around inside the piston crown, at the level of the piston ring band, and a ring-shaped recess provided between the piston ring band and the piston shaft. The piston shaft is connected with the piston hubs suspended on the piston crown. In such a piston, an easy to assemble cooling channel cover is achieved by a one-piece plastic / spring steel ring that is U-shaped in cross-section, having a ring bottom and an outer shank around the circumference, molded onto the ring bottom and angled off radially to the outside, and an inner shank around the circumference, angled off radially to the inside. The plastic ring has a first radial division having a mouth width and a second radial division, opposite the first division, which does not separate the radially angled outer shank that runs around the circumference, to form a film hinge for radial deflection of a ring shank formed by the film hinge.

Owner:MAHLE GMBH

Cooling channel cover for a one-piece piston of an internal combustion engine

InactiveUS20050072386A1Quick installationReduce weightValve arrangementsAir coolingPiston ringInternal combustion engine

A cooling channel cover for a one-piece piston of an internal combustion engine, the piston having a closed cooling channel that runs around inside the piston crown, at the level of the piston ring band, and a ring-shaped recess provided between the piston ring band and the piston shaft. The piston shaft is connected with the piston hubs suspended on the piston crown. In such a piston, an easy to assemble cooling channel cover is achieved by a one-piece plastic ring that is U-shaped in cross-section, having a ring bottom and an outer shank around the circumference, molded onto the ring bottom and angled off radially to the outside, and an inner shank around the circumference, angled off radially to the inside. The plastic ring has a first radial division having a mouth width and a second radial division, opposite the first division, which does not separate the radially angled outer shank that runs around the circumference, to form a film hinge for radial deflection of a ring shank formed by the film hinge.

Owner:MAHLE GMBH

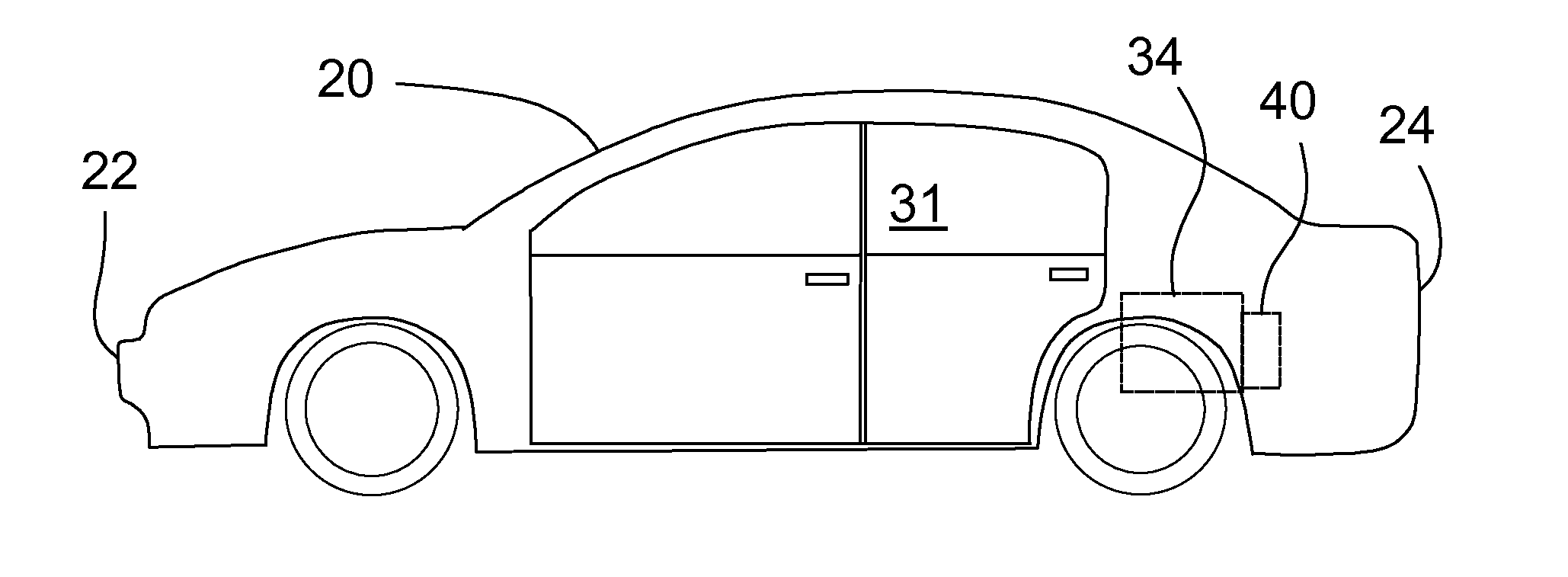

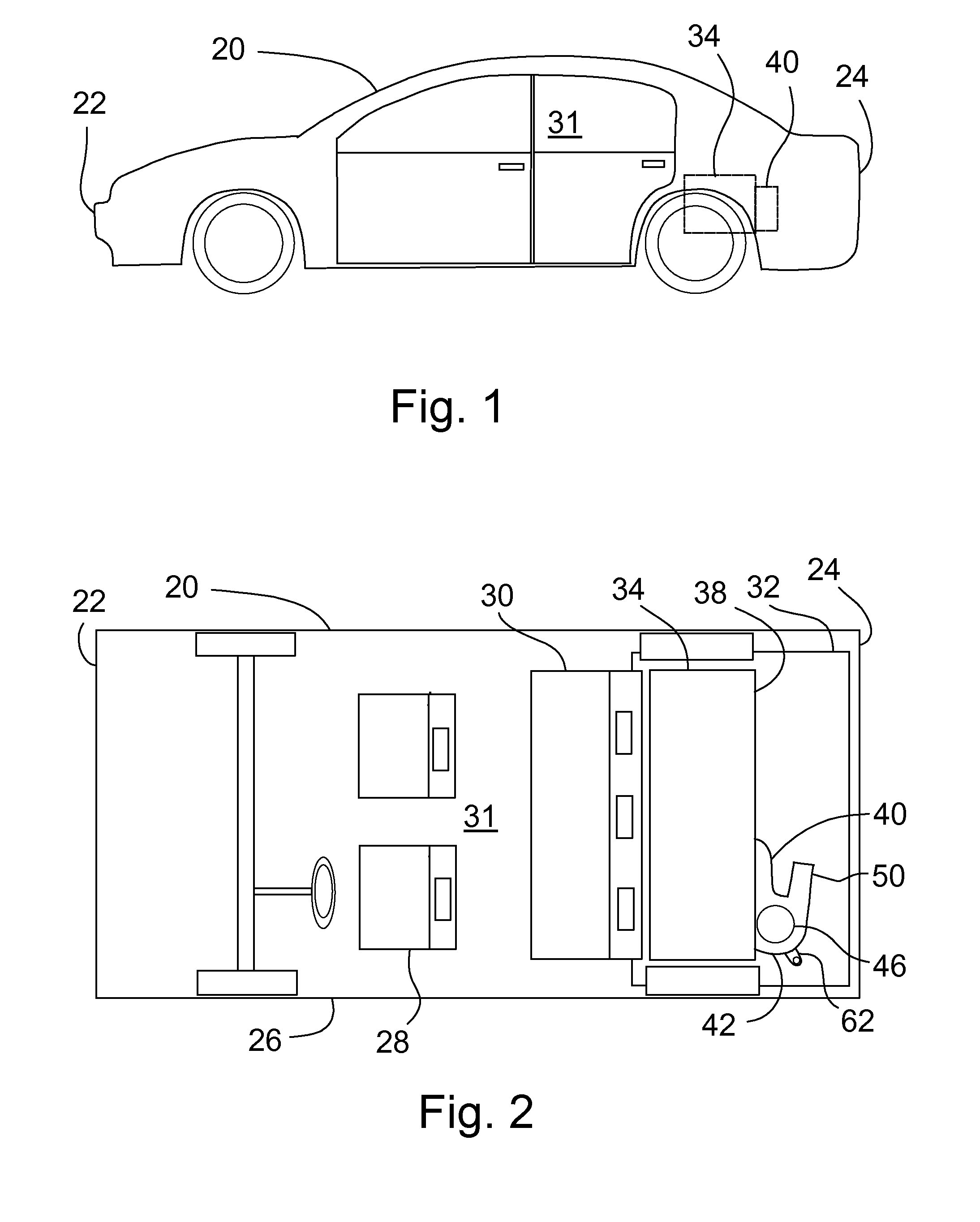

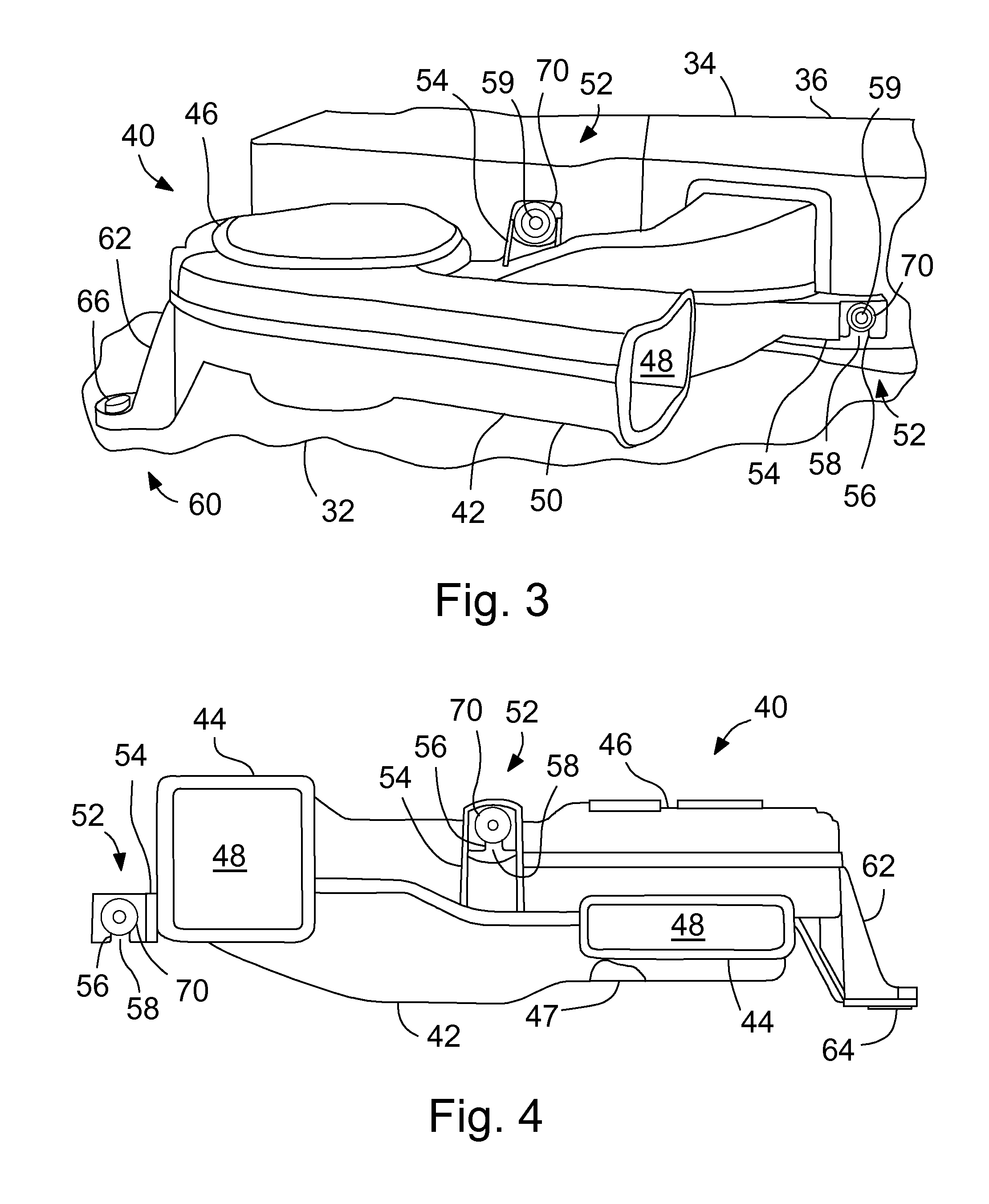

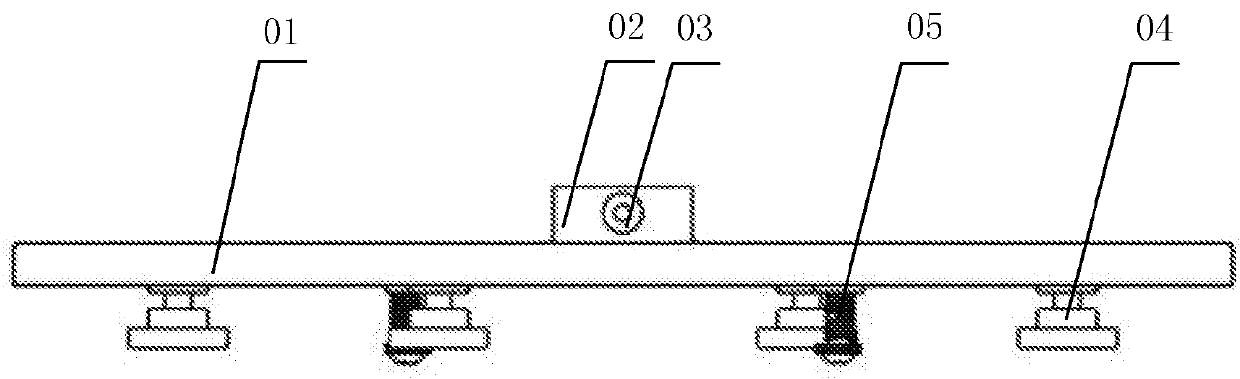

Battery cooling fan mounting

InactiveUS20150037629A1Risk minimizationSimple and quick assemblySecondary cellsPropulsion by batteries/cellsBattery packFlange

A vehicle having: vehicle structure including a pair of opposed sides and a rear, with a floor extending horizontally between the sides and rear; a battery-pack mounted above the floor; a fan assembly having a housing with a motor mounted therein directly behind the battery-pack, with the housing including a pair of flanges having U-slots with slot openings facing downward; and fasteners extending horizontally through the U-slots and secured to the battery-pack.

Owner:FORD GLOBAL TECH LLC

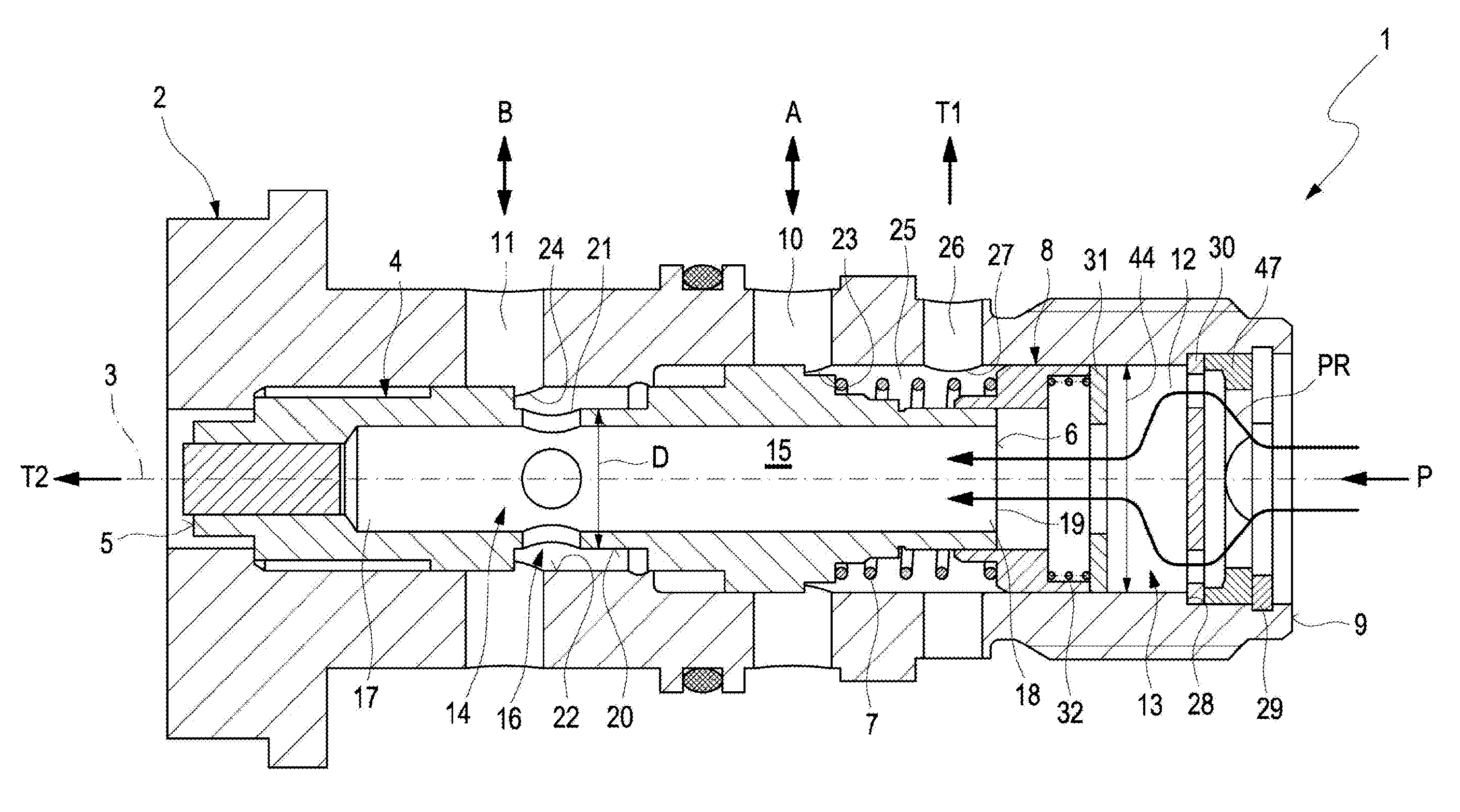

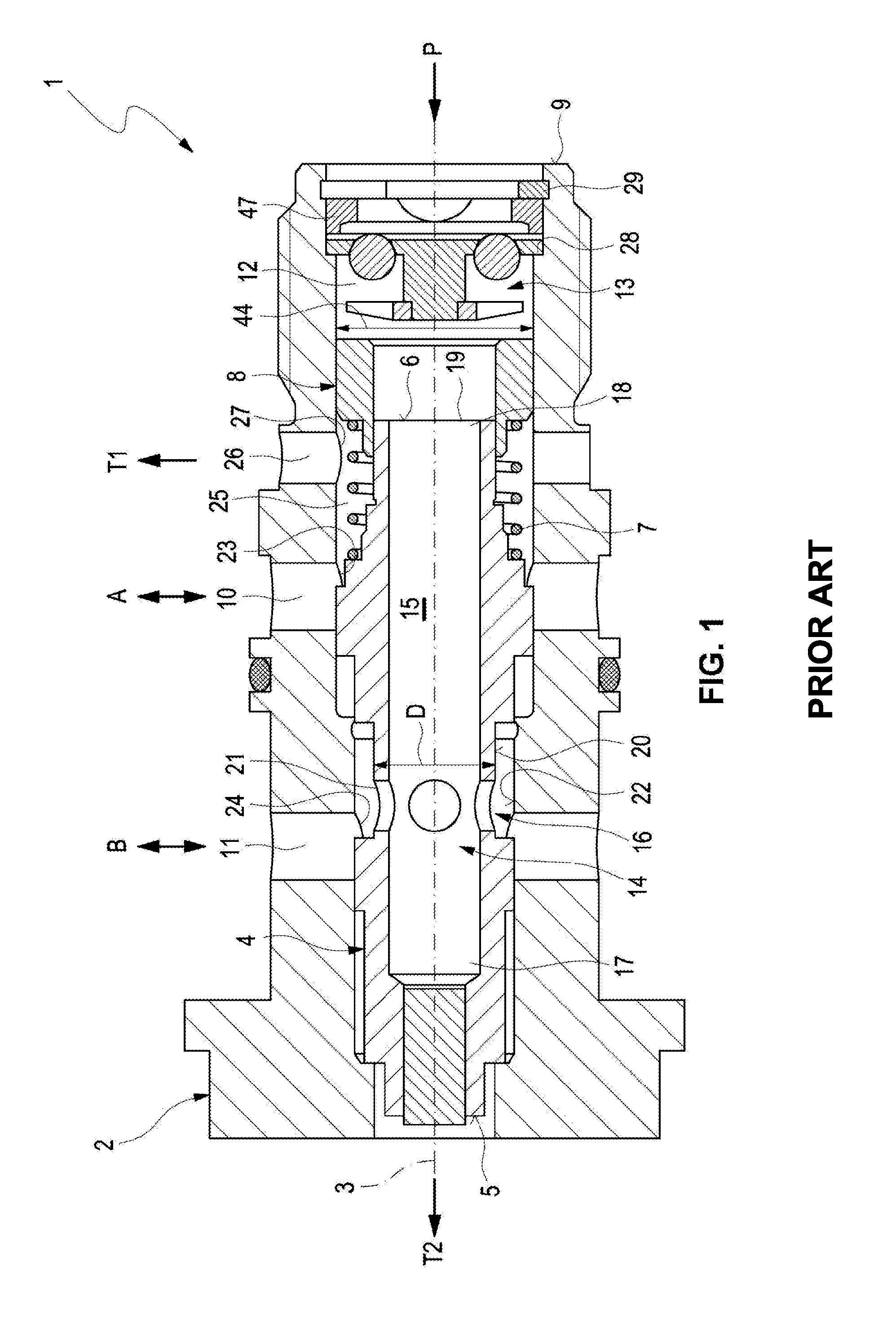

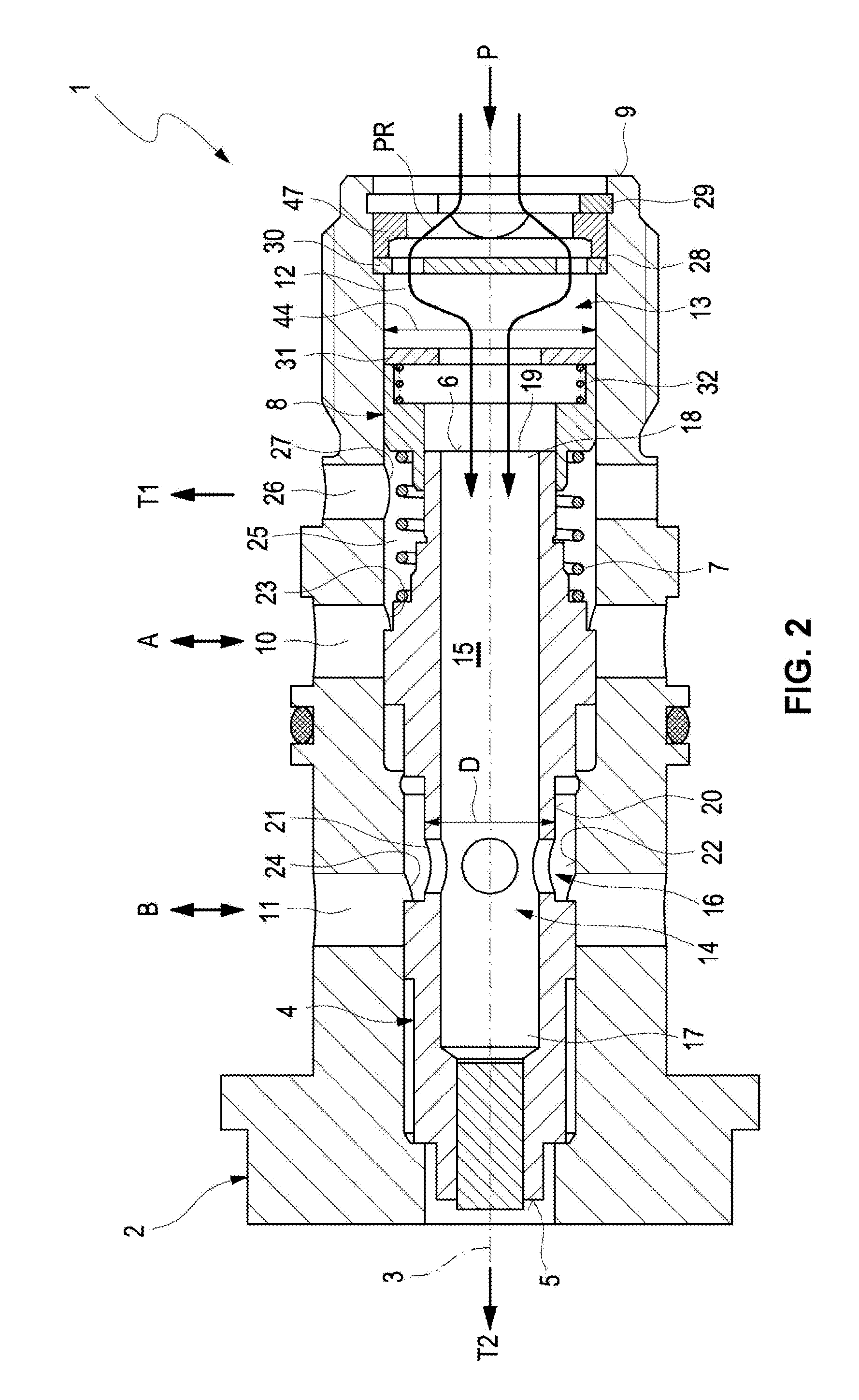

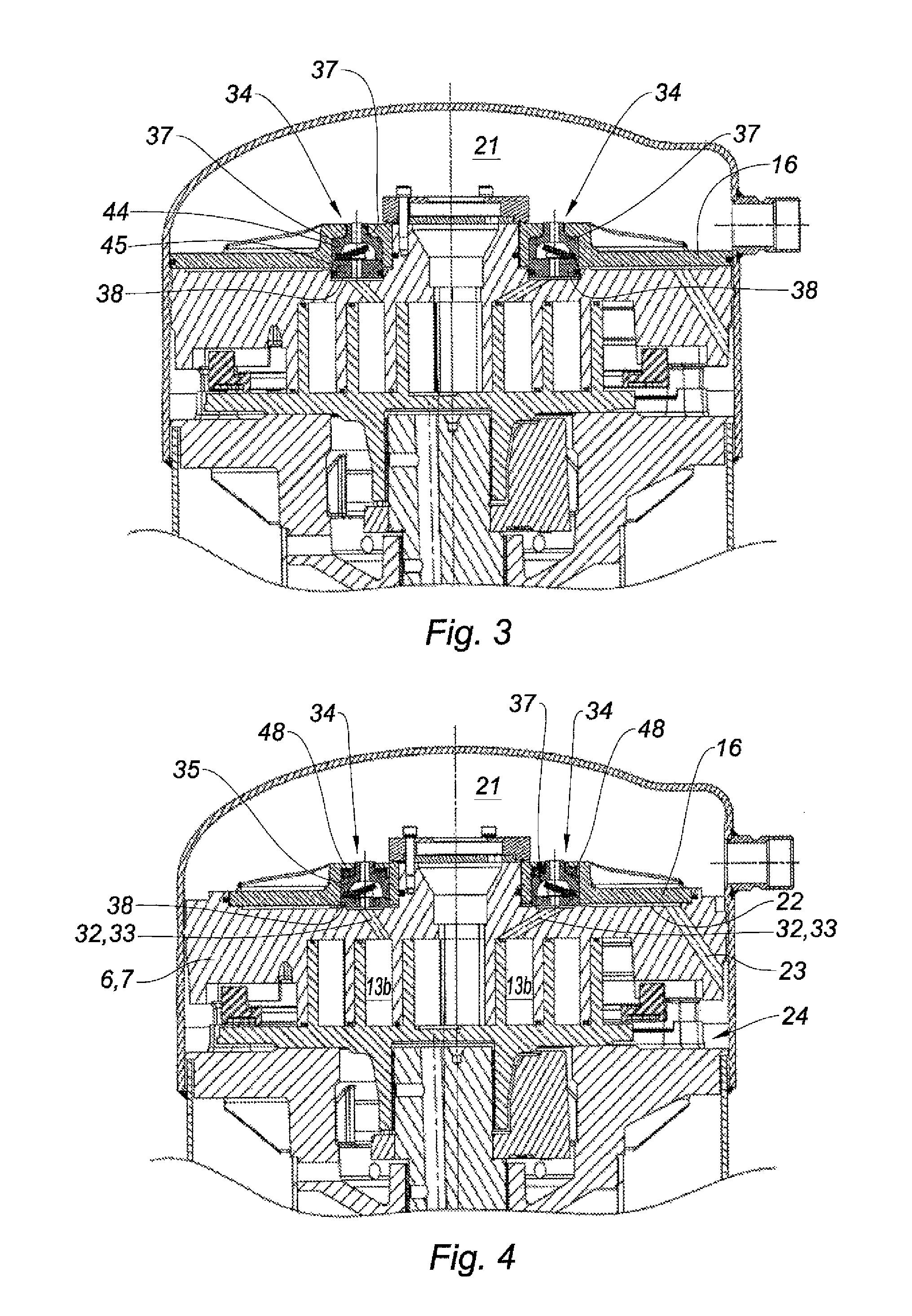

Hydraulic valve for cam phaser

A hydraulic valve for a cam phaser including a valve housing with a longitudinal axis and a valve piston that is axially moveable along the longitudinal axis, wherein the valve piston opens and closes a first operating connection of the valve housing and a second operating connection of the valve housing, wherein the first operating connection and the second operating connection are axially offset from one another; and a supply connection of the valve housing which is used for supplying the hydraulic valve with a hydraulic fluid fed by a feed device, wherein the hydraulic valve is configured to be flowed through by the hydraulic fluid on different paths controlled by a flow permeable channel system of the valve piston, and wherein a check valve opening and closing an inflow channel is arranged in the hydraulic valve in the inflow channel of the valve housing.

Owner:HILITE GERMANY

Recreational structure using a coupling member

A recreational structure, such as a trampoline frame, can be quickly and reliably assembled using a coupling member generally having a “T” configuration. A first arm member and a second arm member are disposed in an opposite relationship with each other. The first and second arm members each receive one end of a horizontal frame member of the recreational structure. The third arm member includes flange members that receive one end of a vertical frame member of the recreational structure and one end of a vertical pole member of, for example, a safety enclosure.

Owner:CA06

Data centre

ActiveUS9347233B2Reduce construction costsSimple and quick assemblyServersEnergy saving control techniquesData centerEngineering

A data center comprises a plurality of sections (15a-15h) assembled together to define a unitary structure (10) such that there exists at least one personnel area that spans at least two sections; wherein the sections comprise a first section with which there is associated a first service—carrying chassis (40, 50, 60, 70) and a second section with which there is associated a second service—carrying chassis 40, 50, 60, 70), each of the first and second service—carrying chassis comprising a frame (41, 51, 61, 71) onto which is mounted components of at least two different services (42-44, 46); the first and second chassis are connected to each other by means of a junction (47) between the first and second chassis; and the first and second sections each include a ceiling (22) and the first service carrying chassis is mounted on the ceiling of the first section and the second service carrying chassis is mounted on the ceiling of the second section.

Owner:BRIPCO

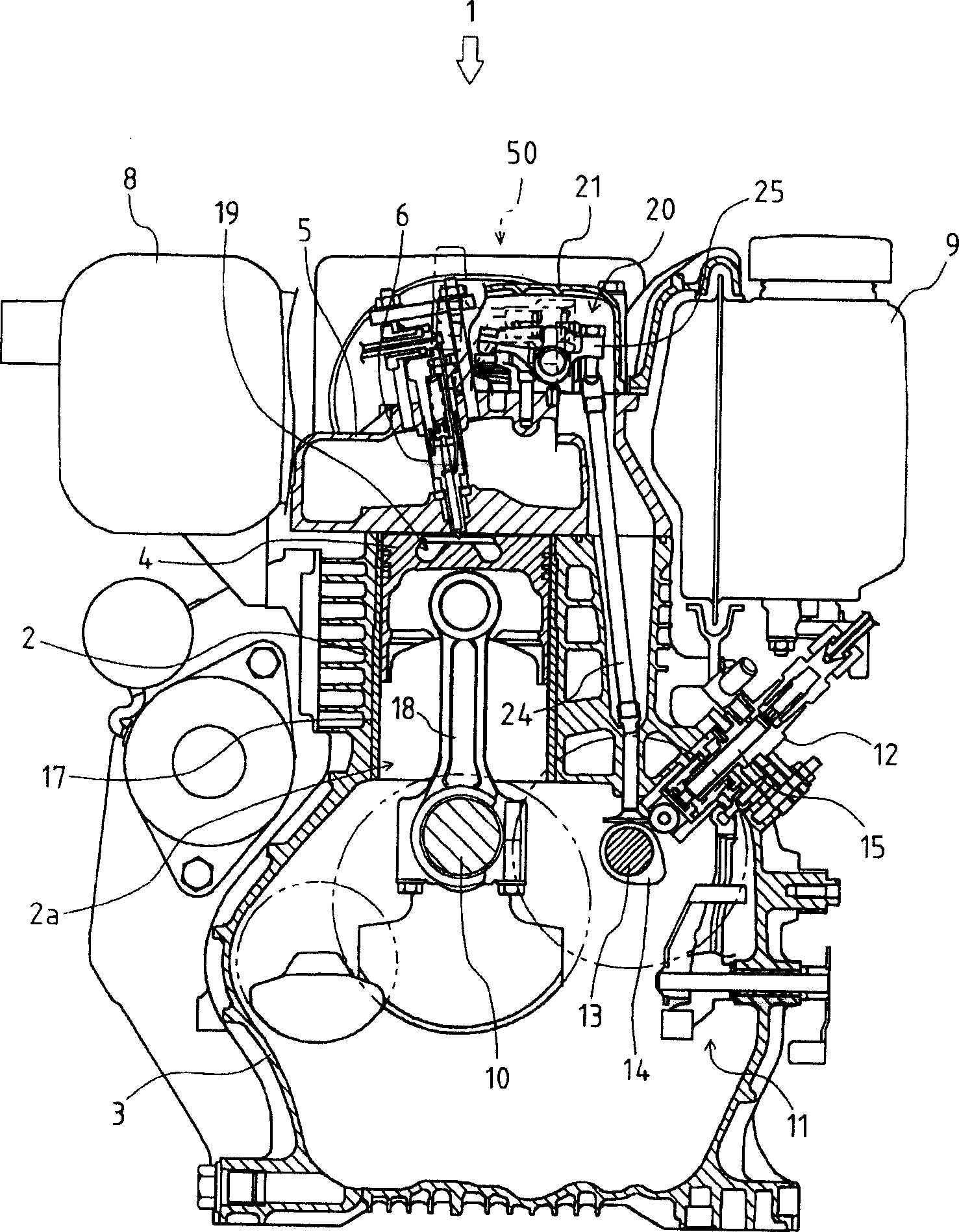

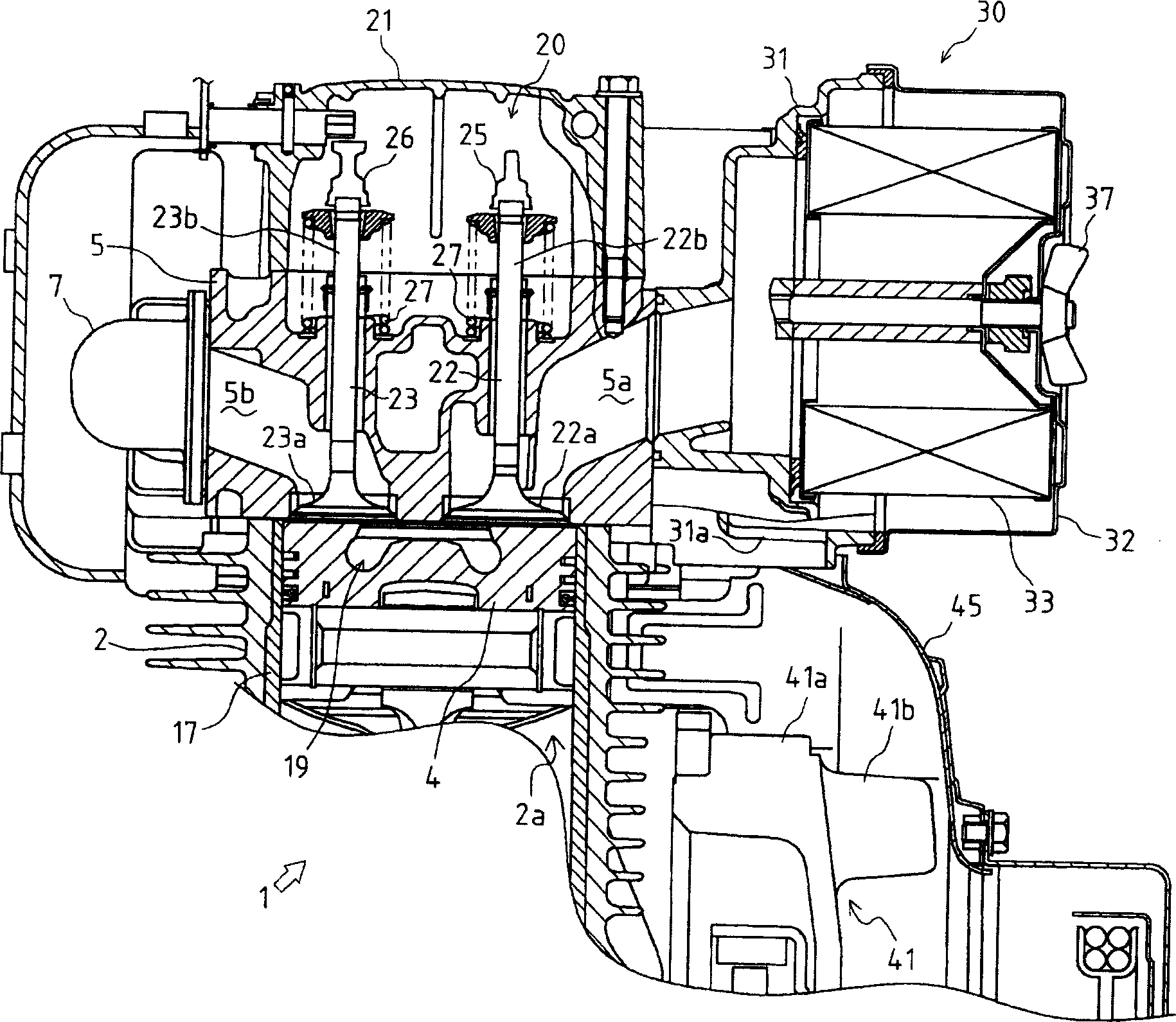

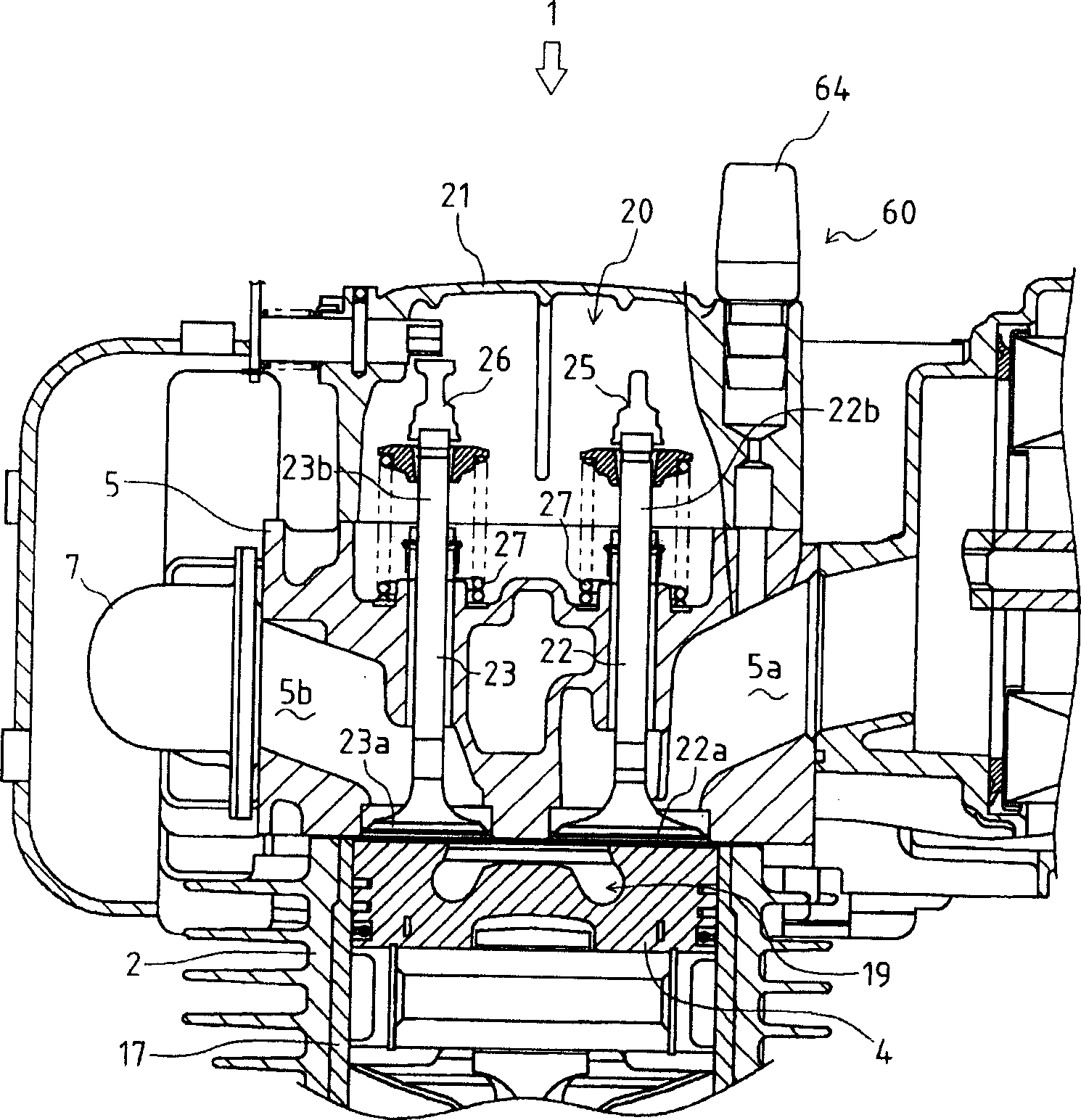

Superstructure of engine

InactiveCN1759235ALow costAvoid assembly errorsInternal combustion piston enginesNon-fuel substance addition to fuelAir cleanersEngineering

With regard to a construction that a fan 41 is provided at one side of an engine 1 and covered by a fan casing 45, and an air cleaner 30 is arranged near the fan casing 45 and at a side of a cylinder head 5 on which an intake port 5a is disposed, a suction port 31a communicated with the inside of the fan casing 45 is provided in a main body 31 of the air cleaner 30. A barrier 46 is provided at a position facing to the suction port 31a in the air cleaner 30. A wall standing toward the fan casing 45 and the cylinder head 5 is formed on the outer surface of the main body 31 of the air cleaner 30. An air intake part is provided on one of side surfaces of a cover body 32 of the air cleaner 30 and the cover body 32 is constructed to be an equilateral polygon. An intake pipe 31k communicating the air cleaner 30 with the intake port 5a of the cylinder head 5 is constructed integrally with a main body 31 of the air cleaner 30.

Owner:YANMAR CO LTD

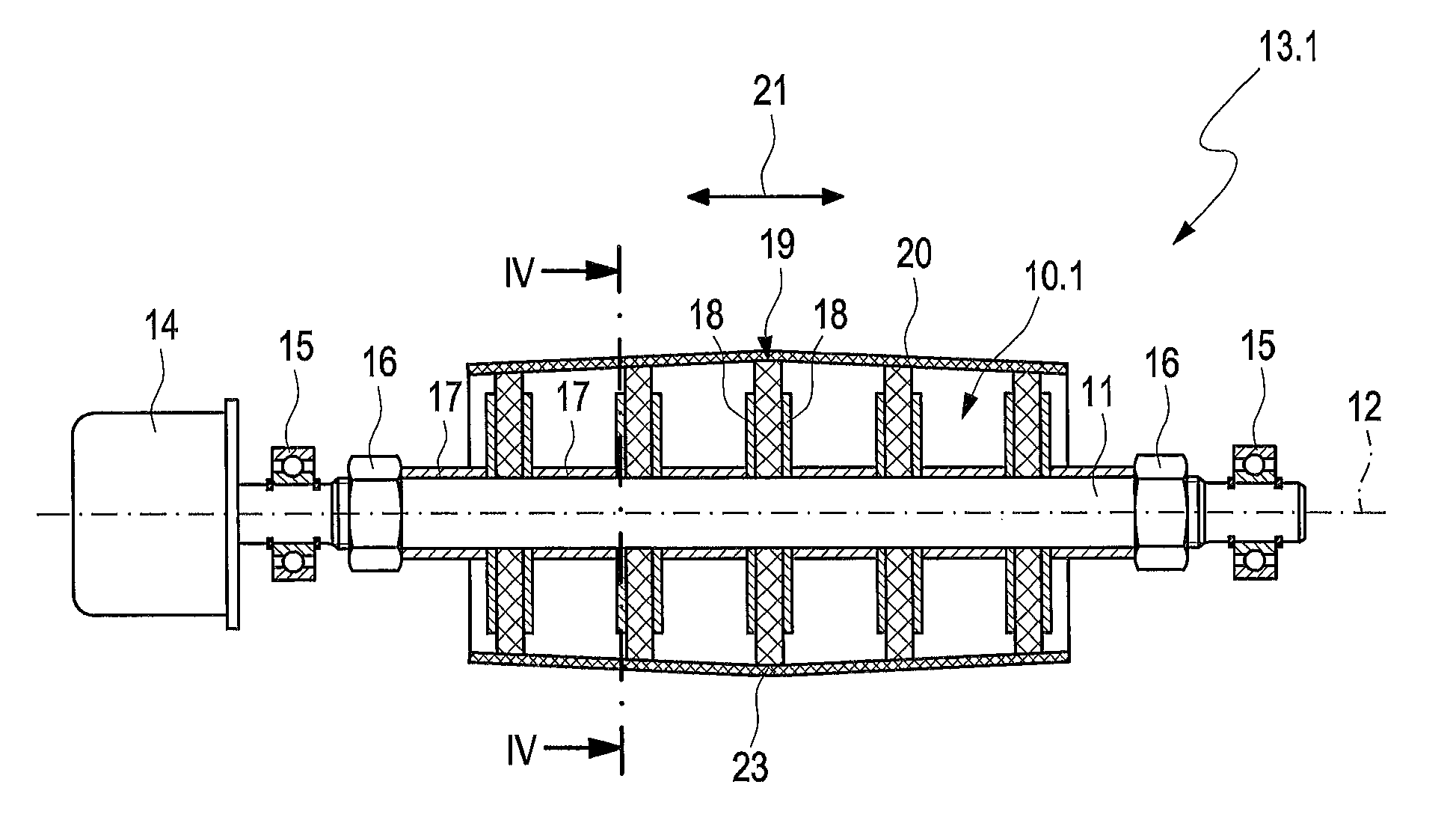

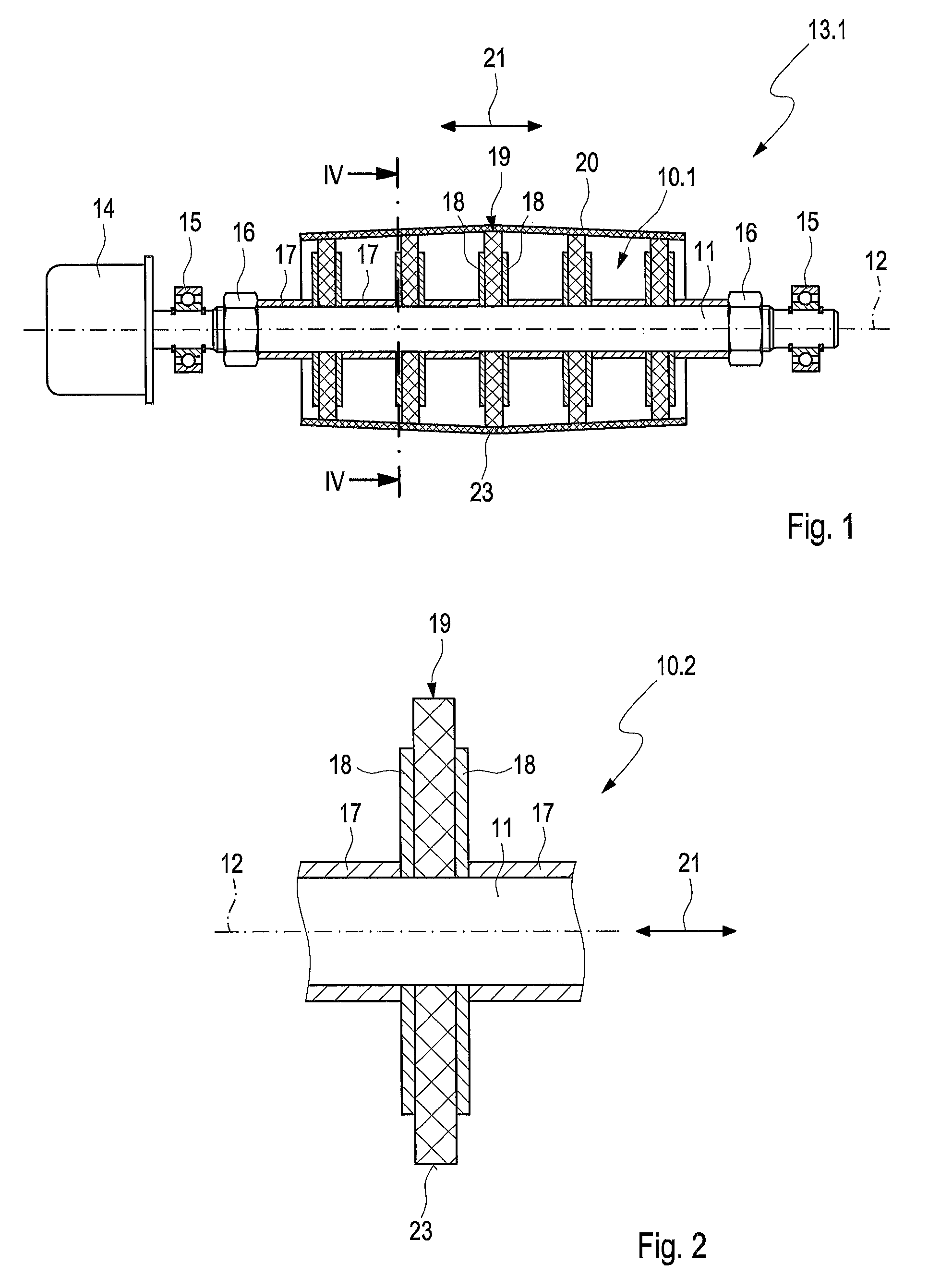

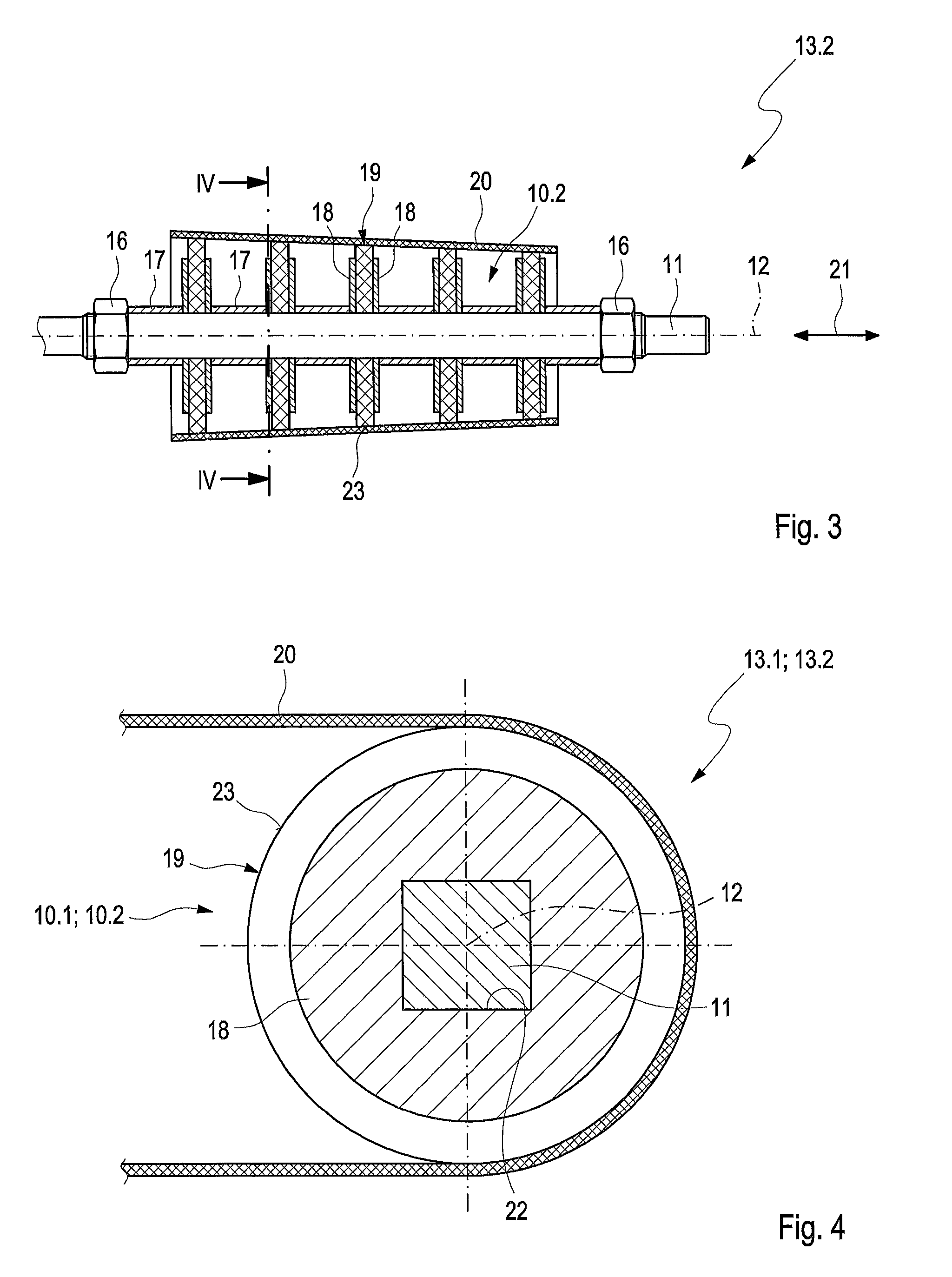

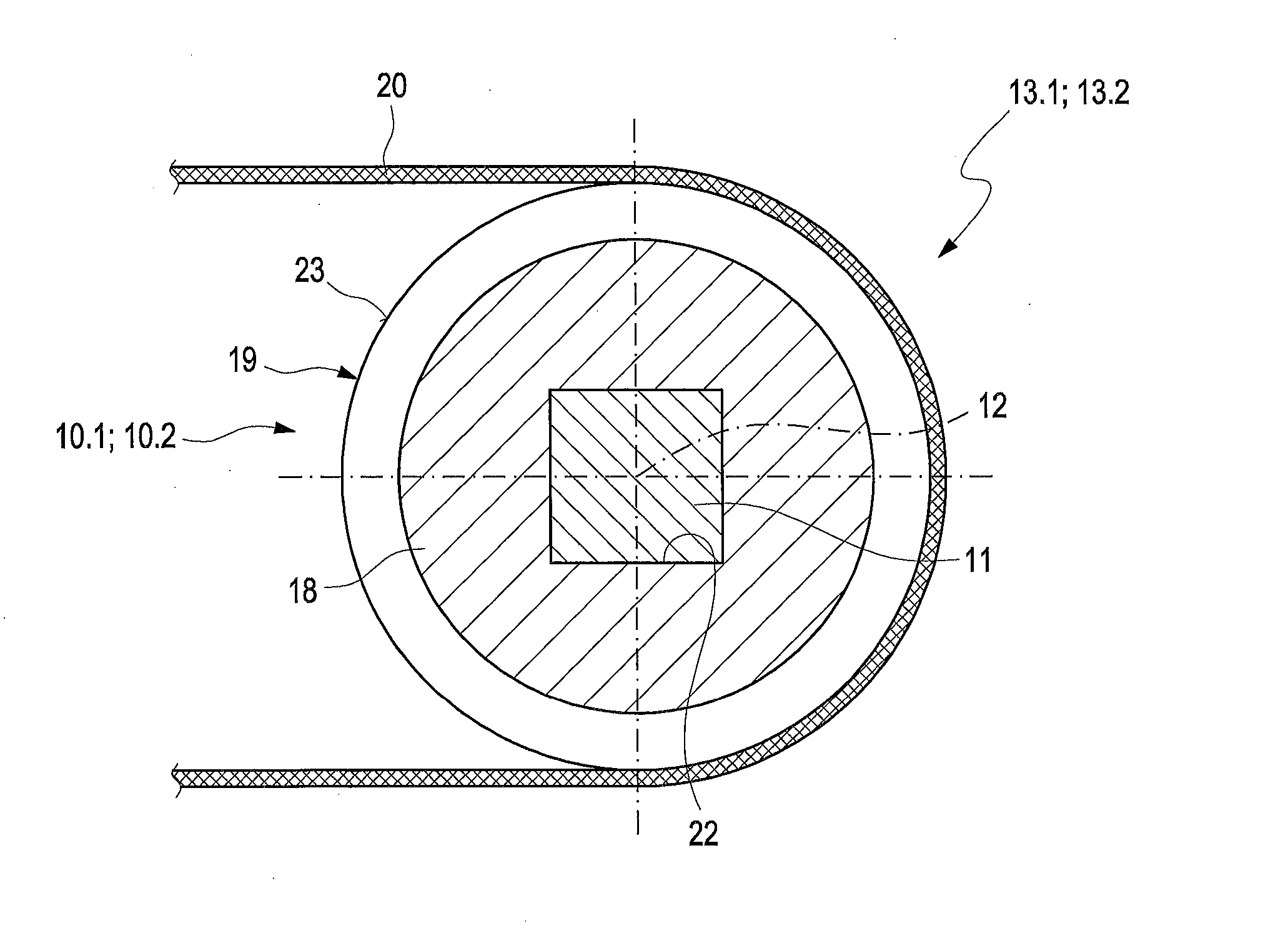

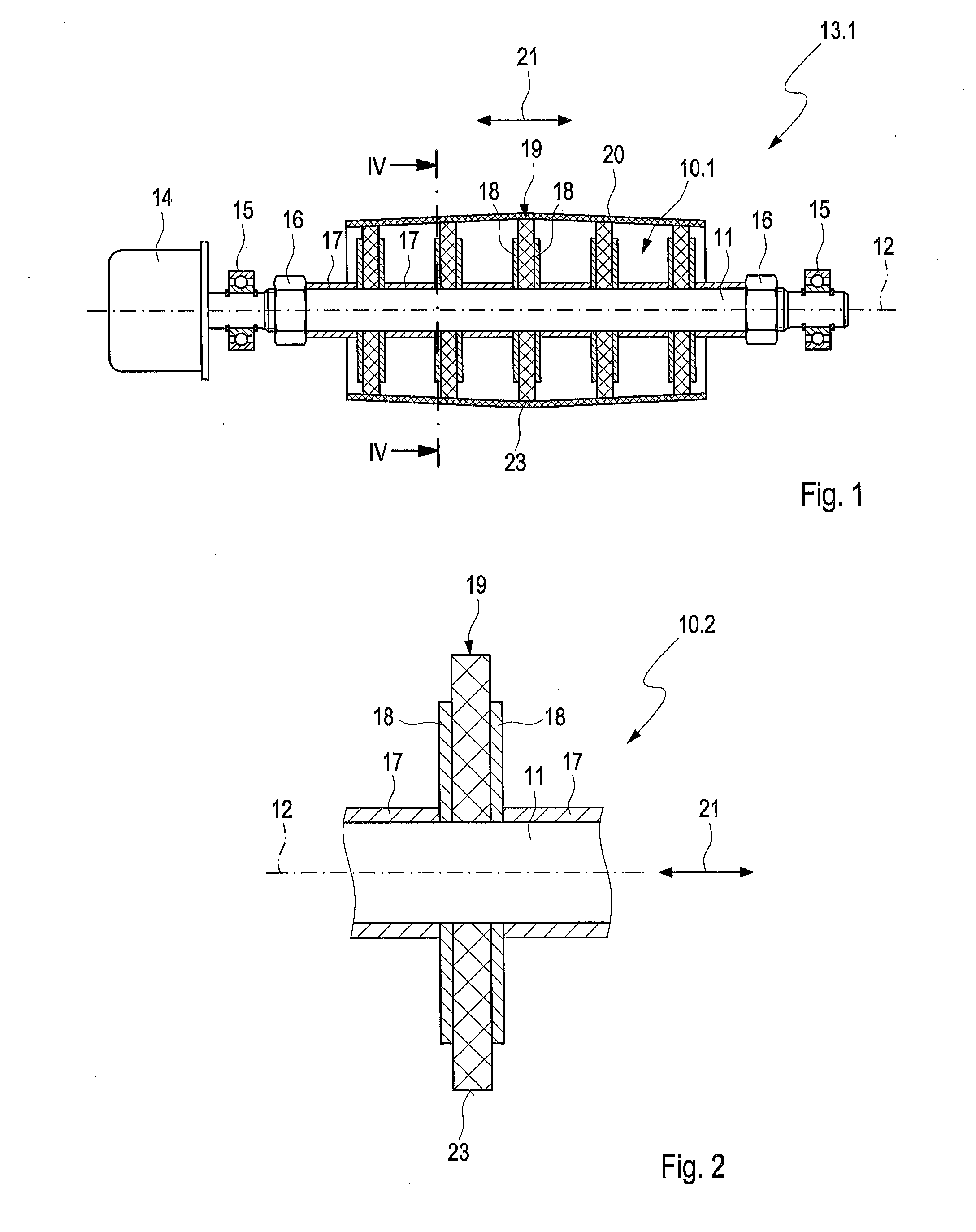

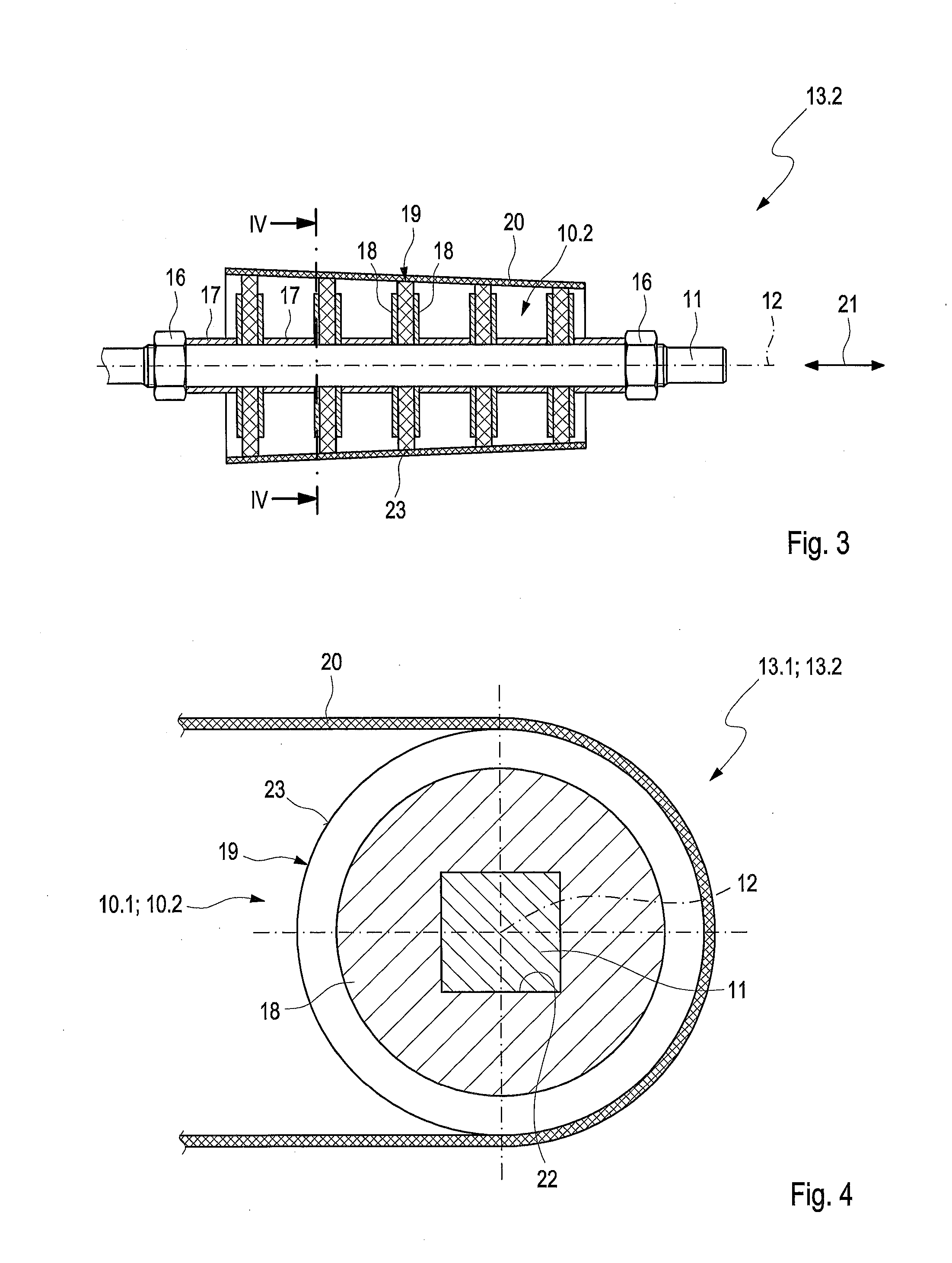

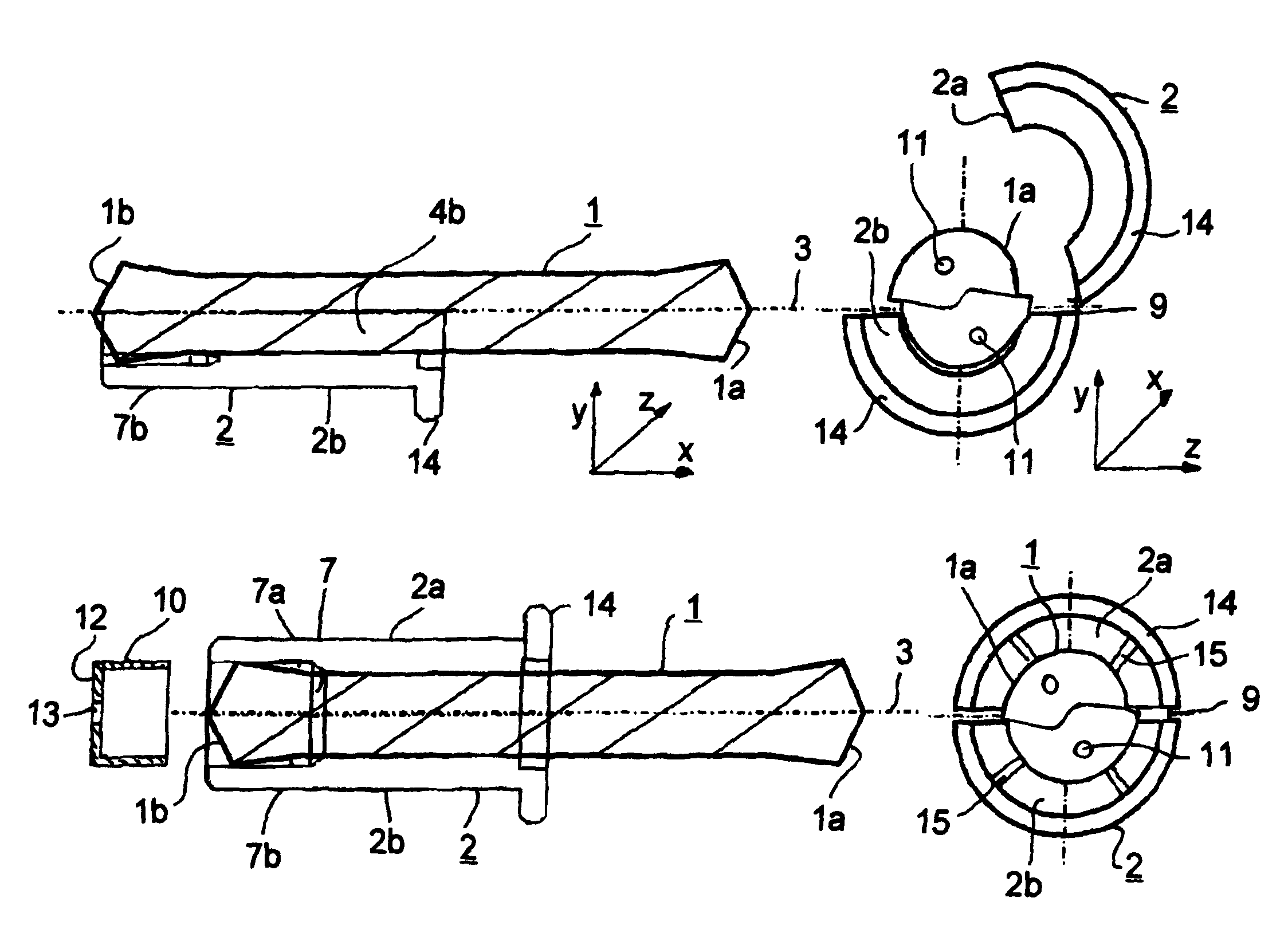

Belt band conveyor

InactiveUS9440796B2Simple and quick assemblyImproved optimal transferConveyorsRollersRotational axisEngineering

A belt band conveyor has an endless conveyor belt band guided over deflection and / or drive friction rollers, for deflecting and / or driving the conveyor belt band. Each roller includes an axially-extending shaft. At least three roller segments are releasably mounted on the shaft, axially apart from one another, so as to rotate about a rotational axis extending axially in the longitudinal direction, Each roller segment has an inside circumference contour and a friction surface on its radial outside circumference engaging on the lower belt with friction fit. The inside circumference contour of each roller segment and the outside circumference contour of the shaft are structured so that each roller segment is connected with the shaft with shape fit to prevent twisting about the rotational axis. When the shaft turns about the rotational axis, in a rotational direction, the roller segments also turn about the rotational axis, in this rotational direction.

Owner:AXMANN FOERDERSYST

Belt band conveyor

InactiveUS20160176645A1Improved optimal transferAvoid disadvantagesRollersRotational axisEngineering

A belt band conveyor has an endless conveyor belt band guided over deflection and / or drive friction rollers, for deflecting and / or driving the conveyor belt band. Each roller includes an axially-extending shaft. At least three roller segments are releasably mounted on the shaft, axially apart from one another, so as to rotate about a rotational axis extending axially in the longitudinal direction, Each roller segment has an inside circumference contour and a friction surface on its radial outside circumference engaging on the lower belt with friction fit. The inside circumference contour of each roller segment and the outside circumference contour of the shaft are structured so that each roller segment is connected with the shaft with shape fit to prevent twisting about the rotational axis. When the shaft turns about the rotational axis, in a rotational direction, the roller segments also turn about the rotational axis, in this rotational direction.

Owner:AXMANN FOERDERSYST

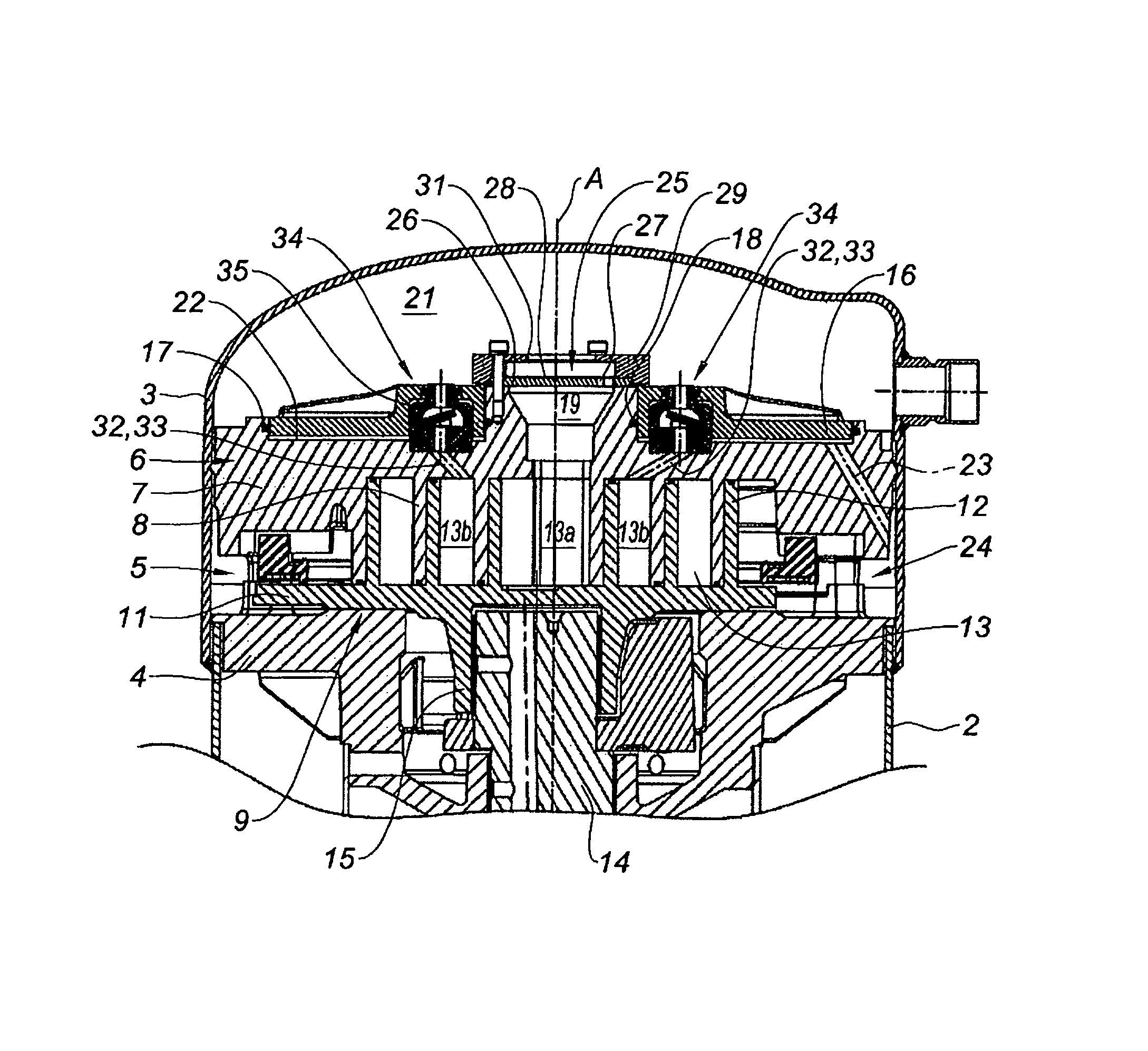

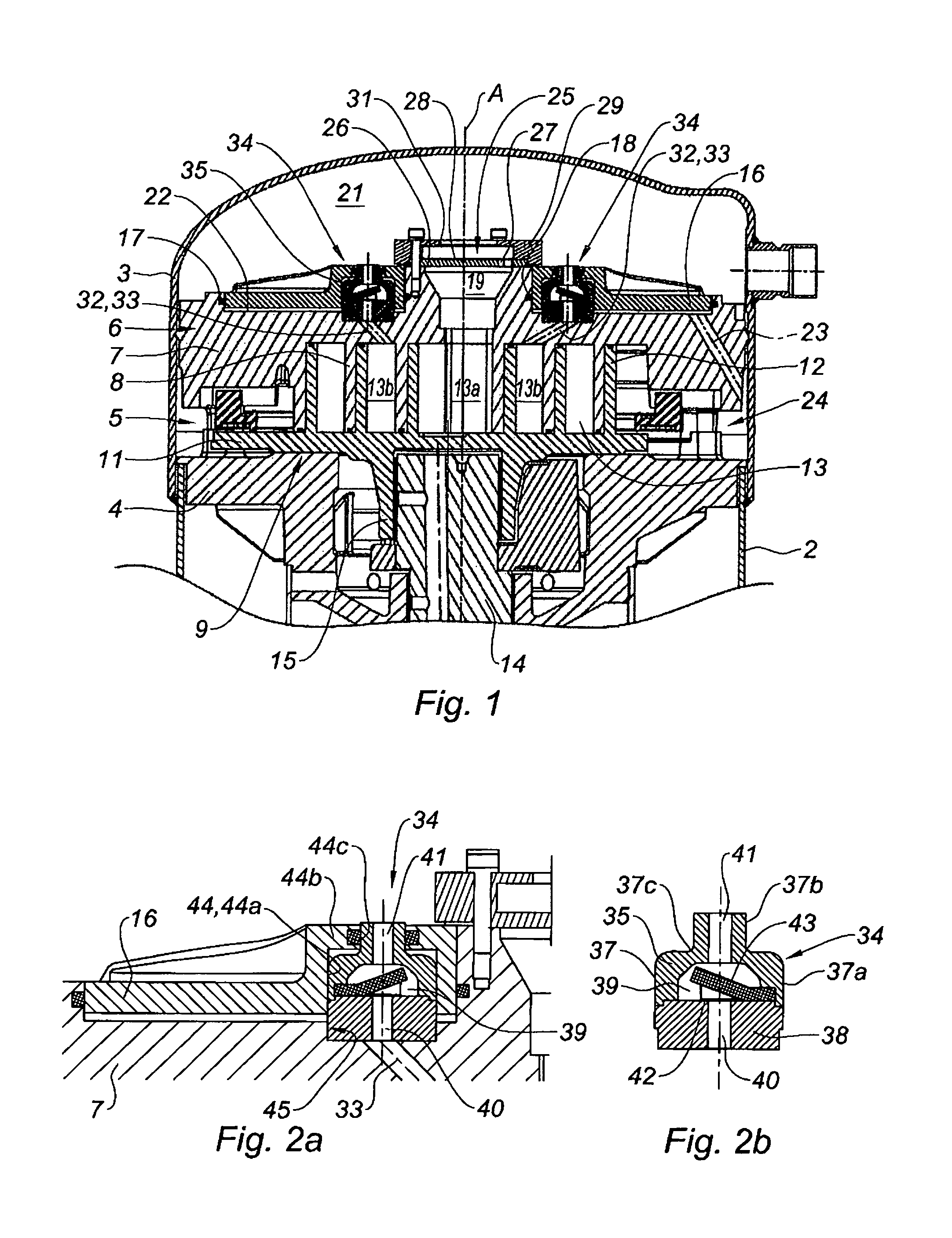

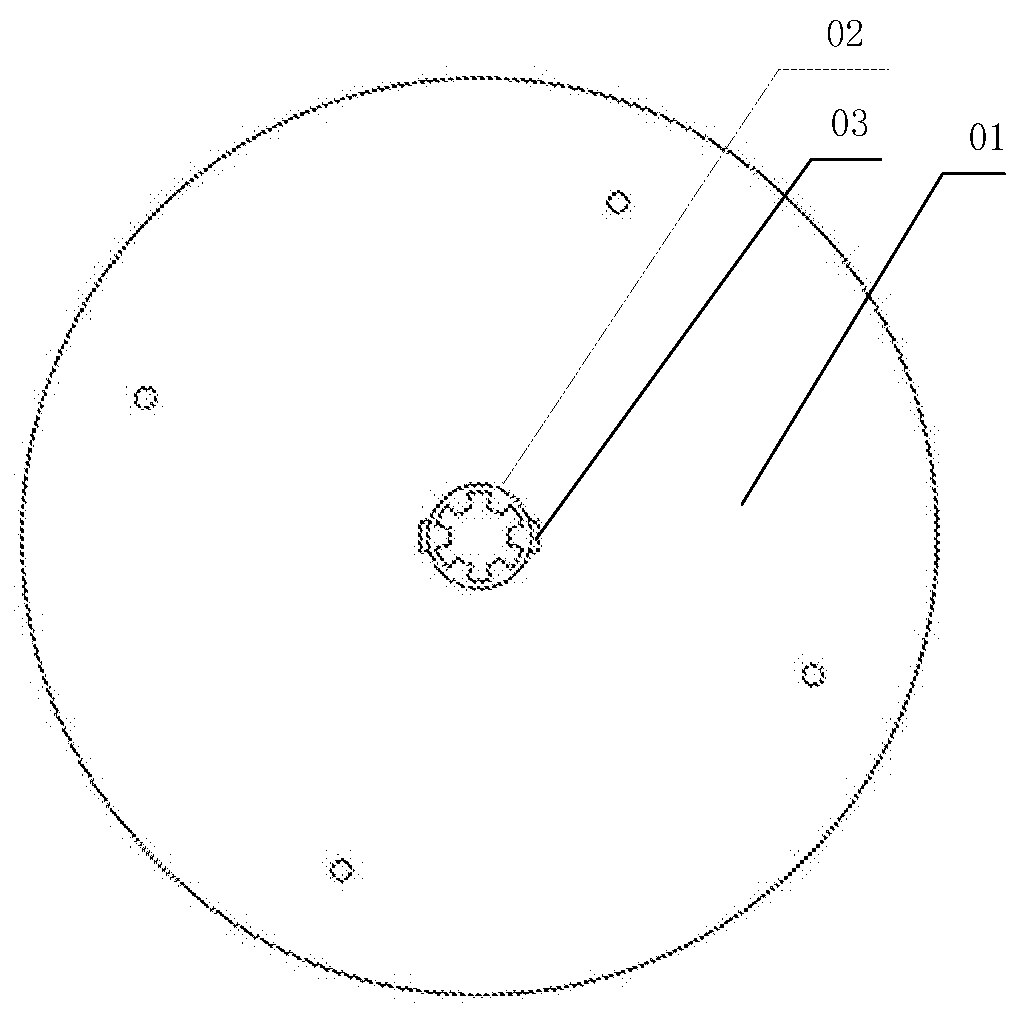

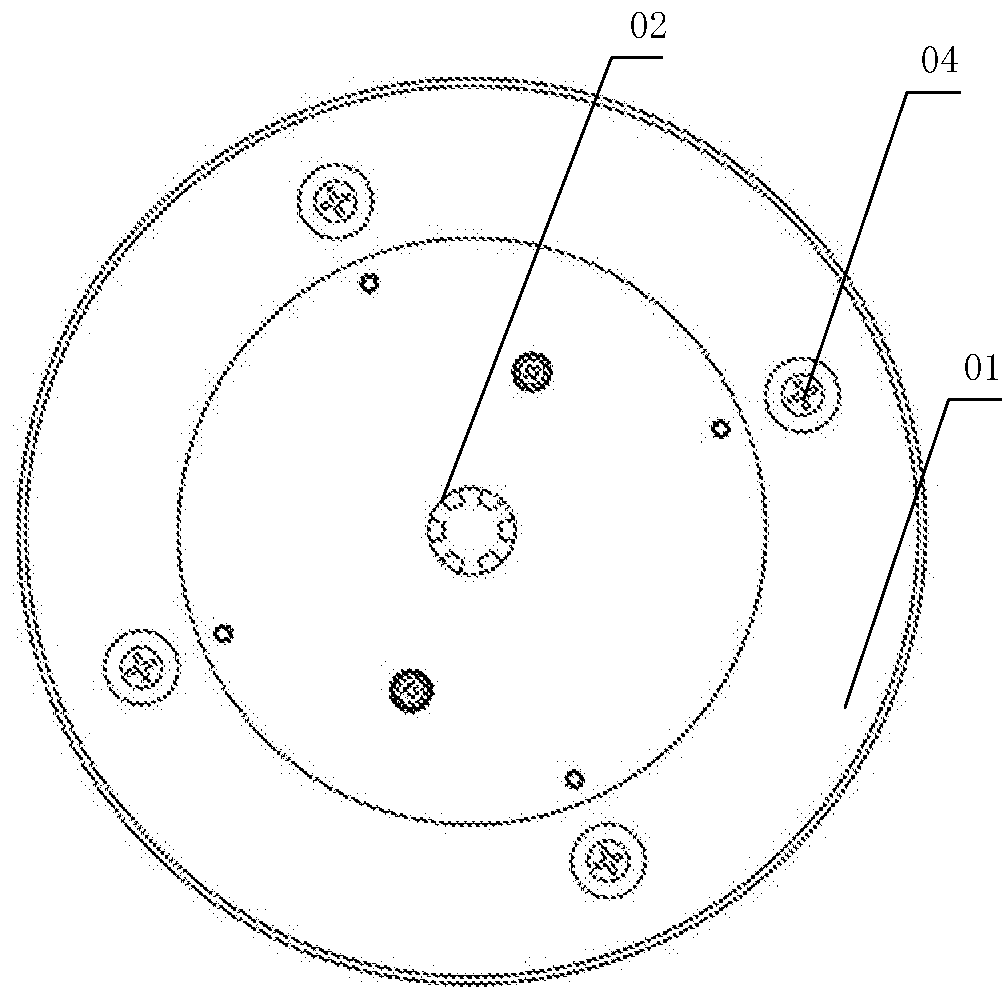

Scroll refrigeration compressor with anti-return device

InactiveUS9017050B2Simple and cost-effective structureImprove compressor performanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeRefrigeration compressorEngineering

The scroll refrigeration compressor includes a stationary volute and a moving volute provided with spiral wraps defining variable-volume compression chambers, a separating member sealably mounted on a plate of the stationary volute so as to allow a relative movement between the separating member and the stationary volute, a delivery chamber at least partially defined by the separating member and the sealed casing. The compressor further includes a bypass passage arranged to communicate the delivery chamber with an intermediate compression chamber, and a anti-return device comprising a closing member movable between closing and opening positions for closing and opening the bypass passage, and an enclosure, positioned between the separating member and the plate of the stationary volute, including a first portion sealably mounted in a housing defined by the separating member and oriented substantially parallel to the longitudinal axis of the compressor.

Owner:DANFOSS COMML COMPRESSORS

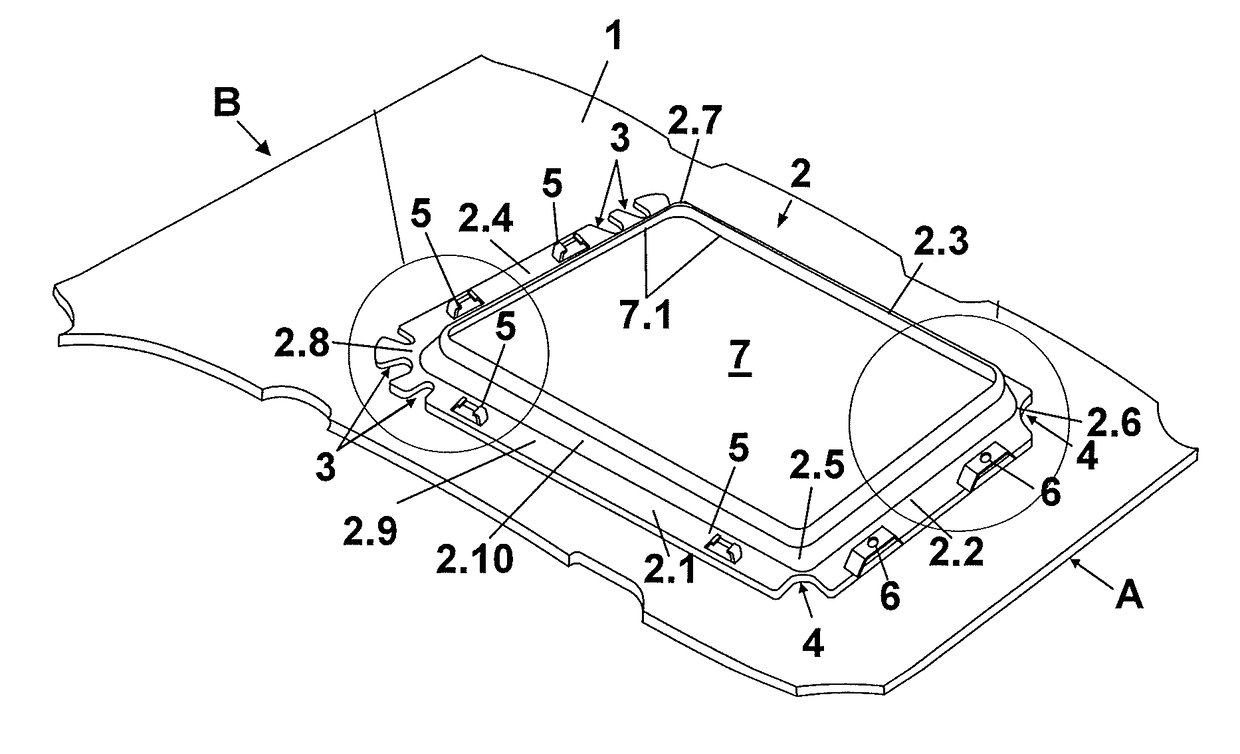

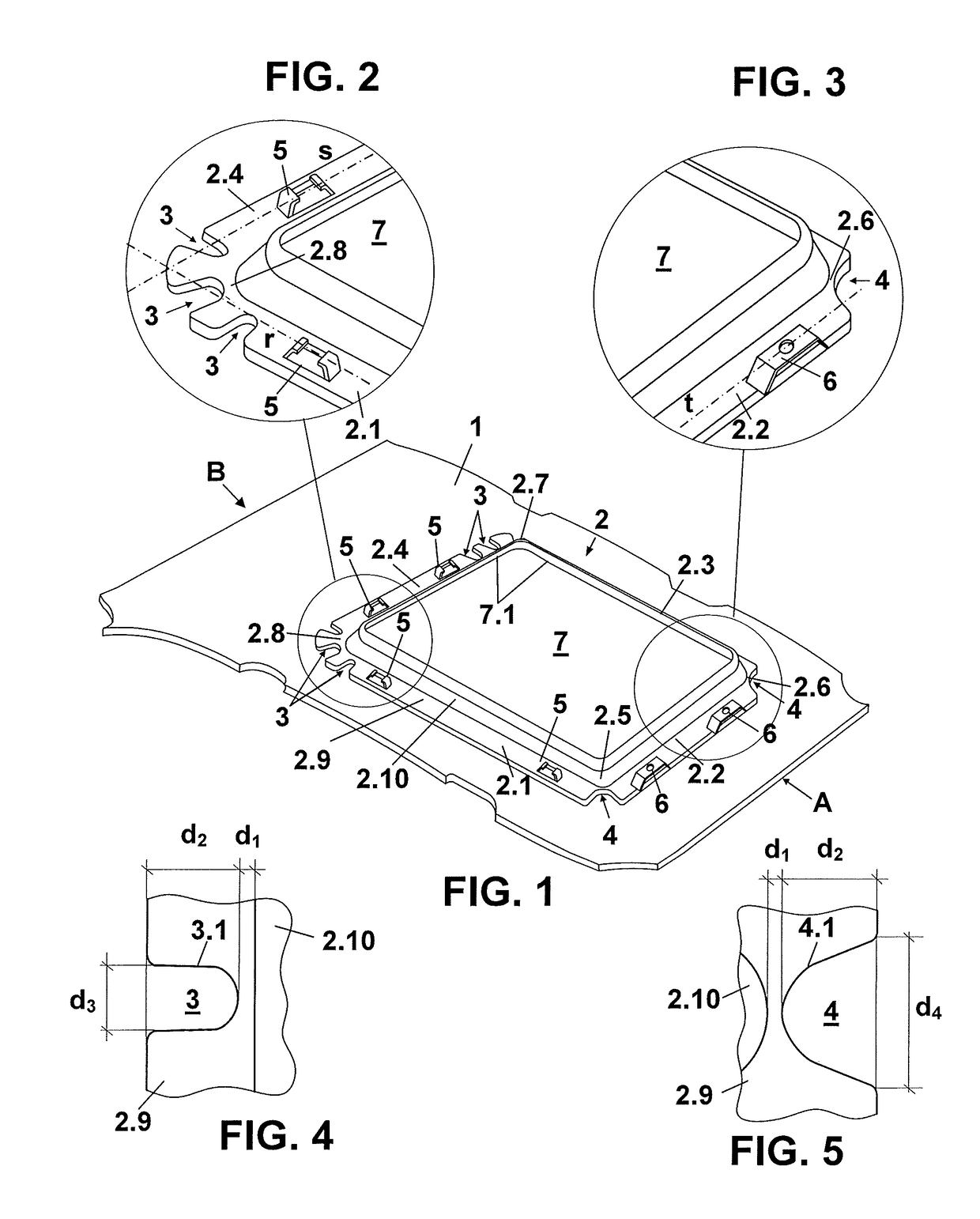

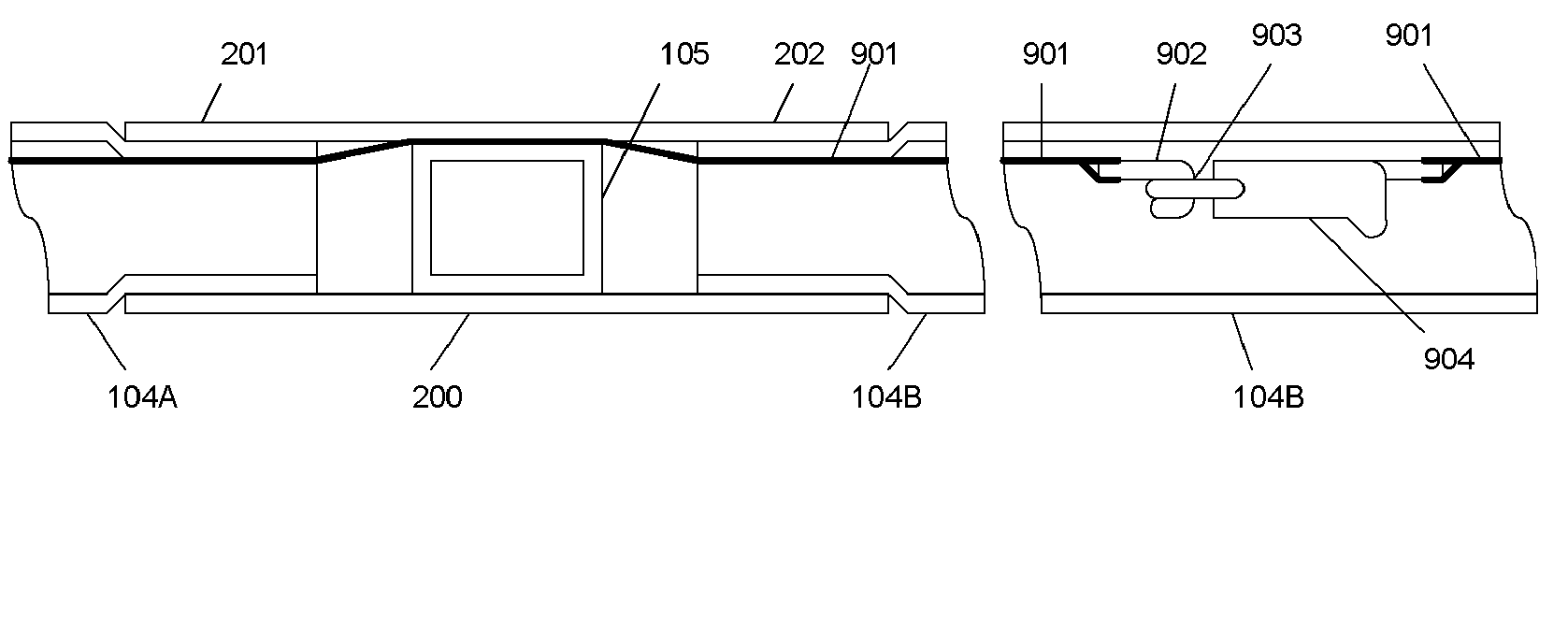

Headliner for vehicle roof with transparent portion

ActiveUS20180079373A1Relieve stressPreventing concentration of tensionSuperstructure subunitsStructural engineeringMechanical engineering

Owner:GRP ANTOLIN ING SA

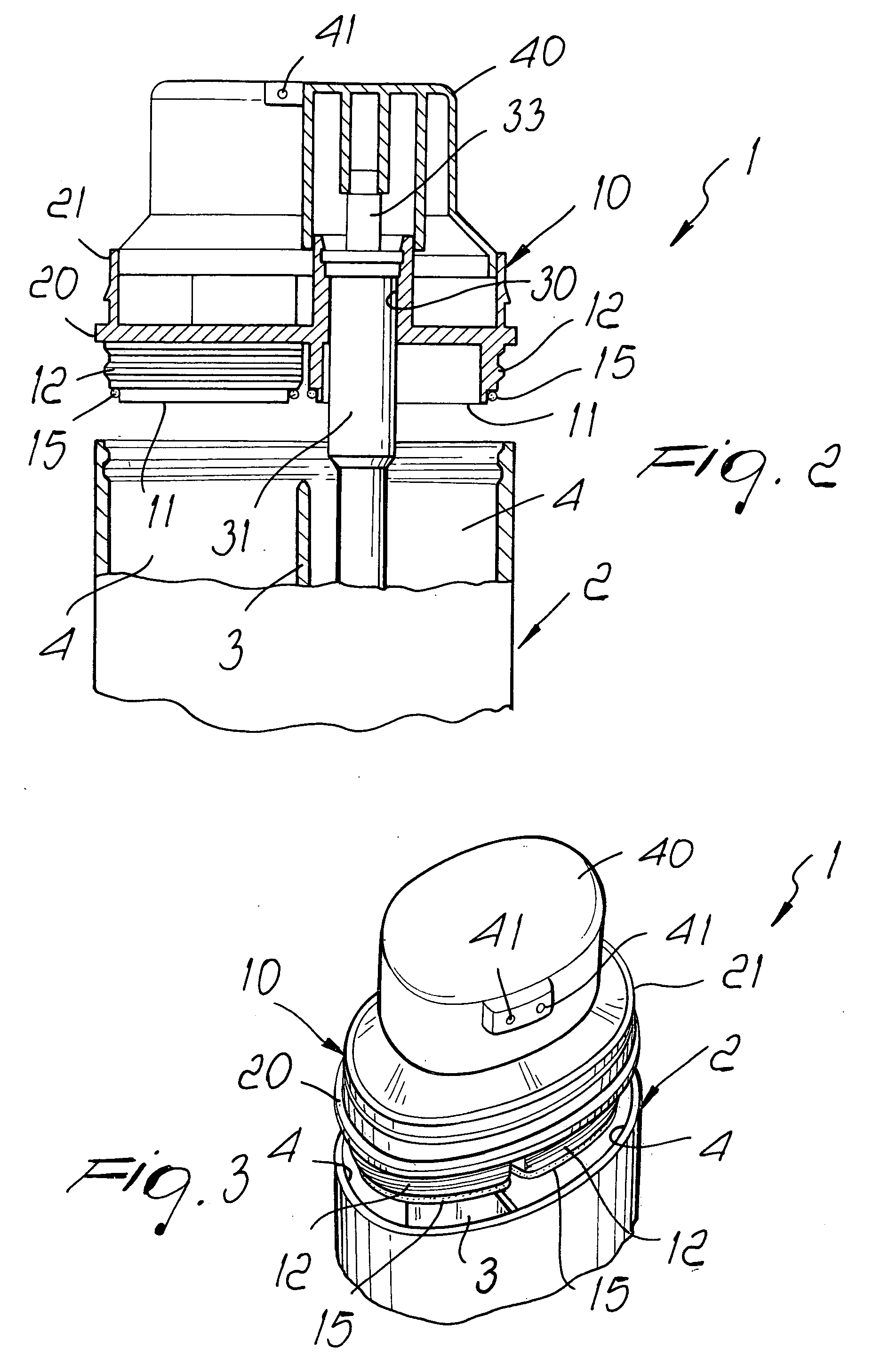

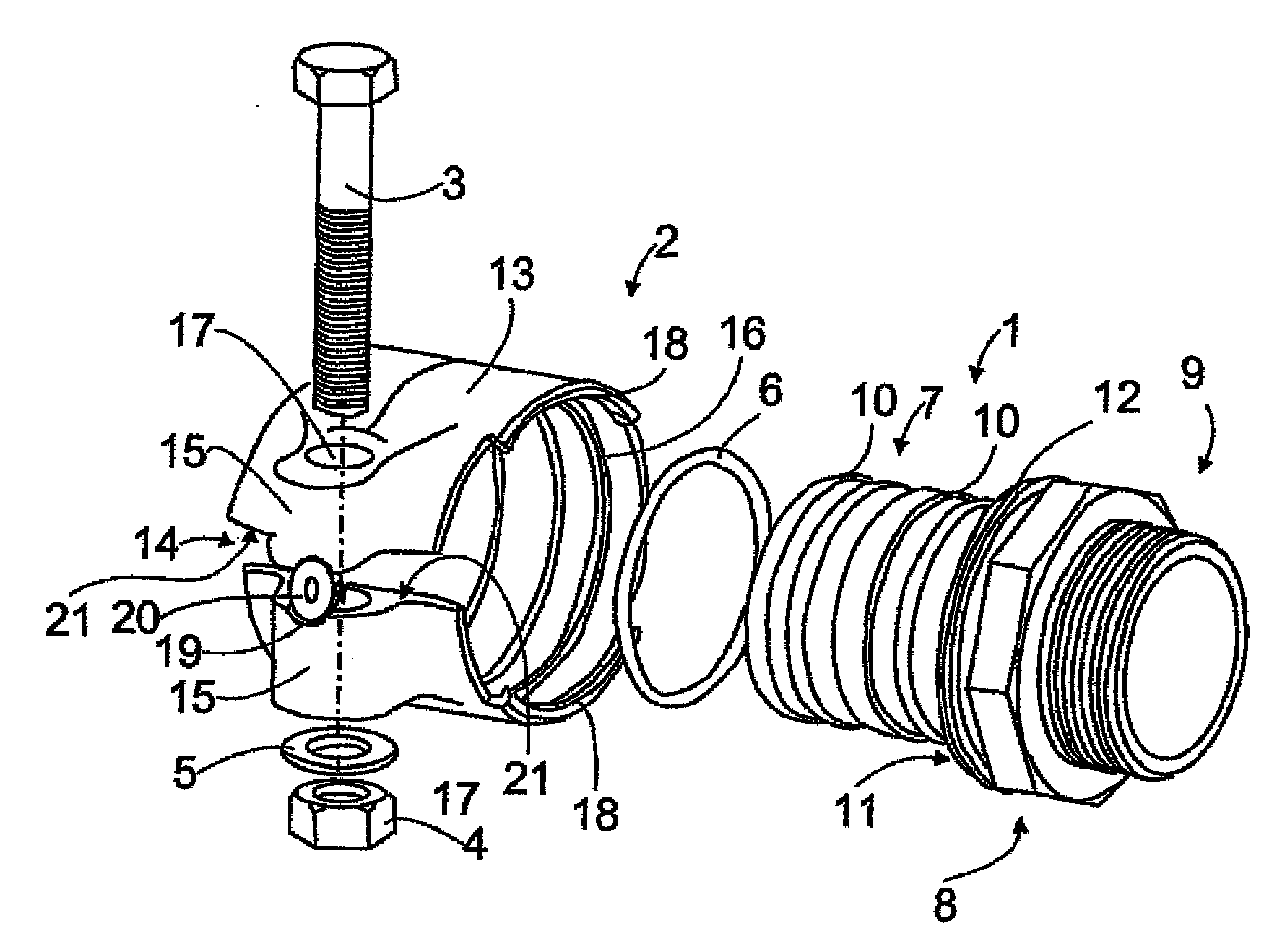

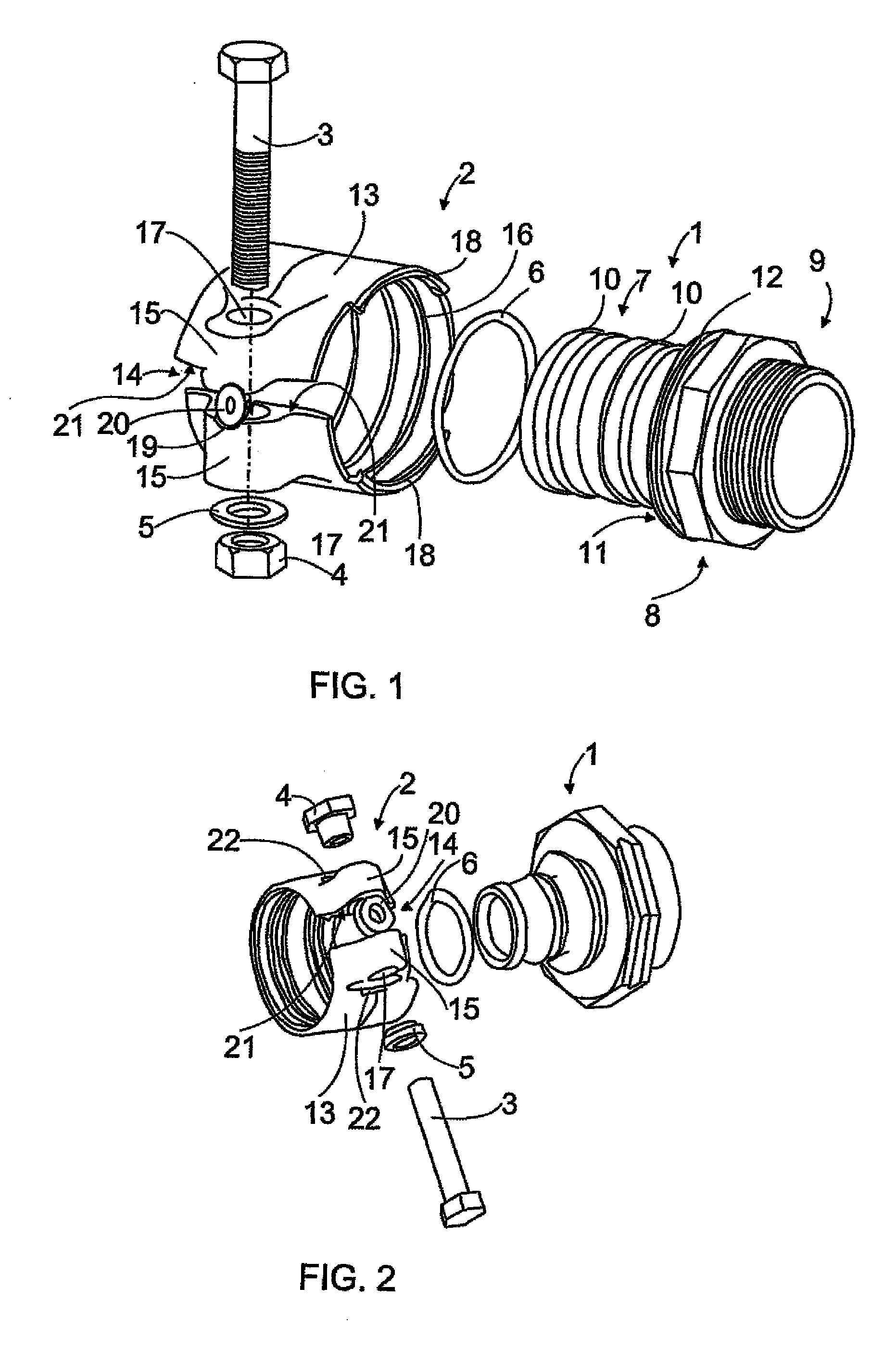

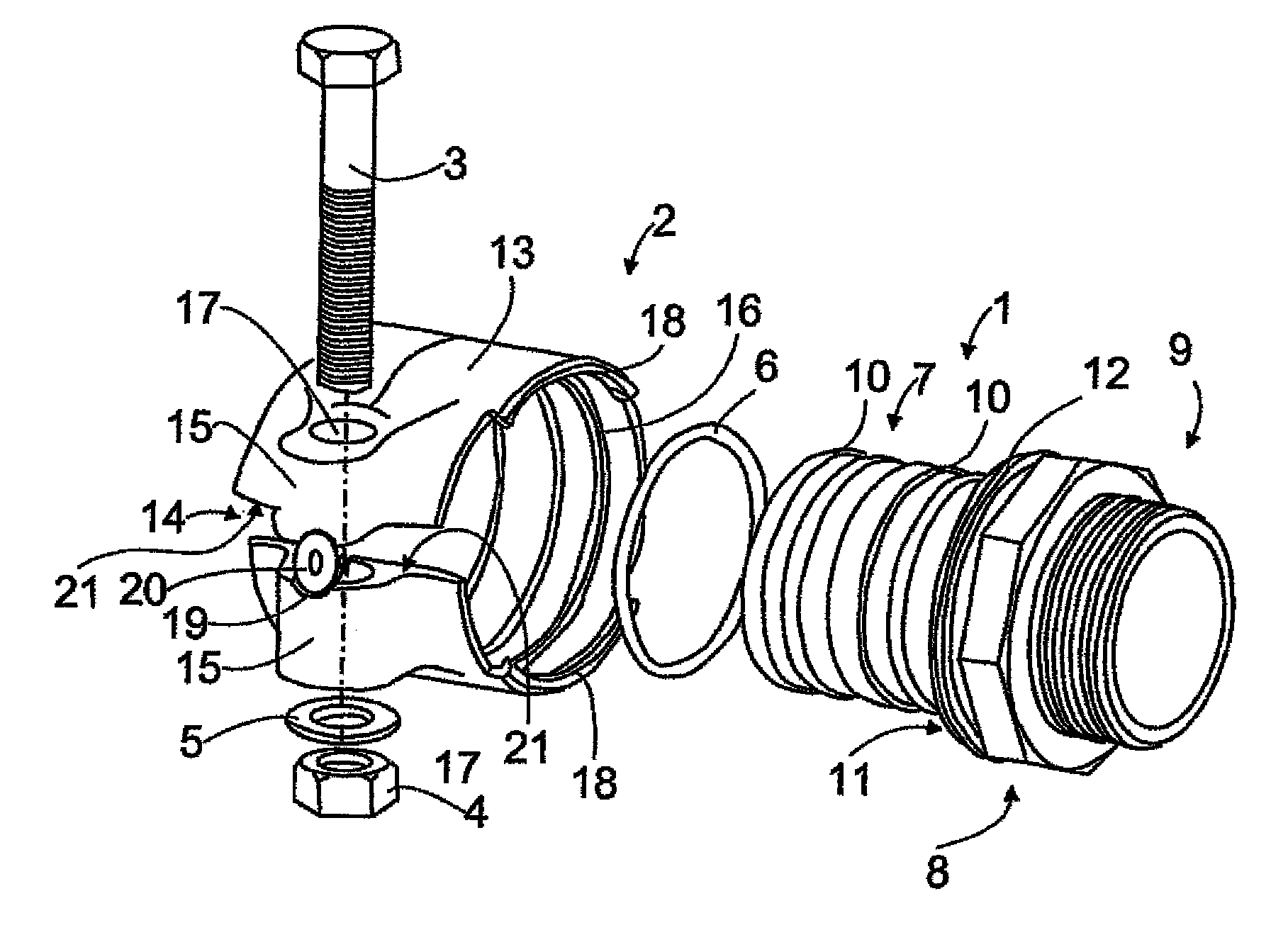

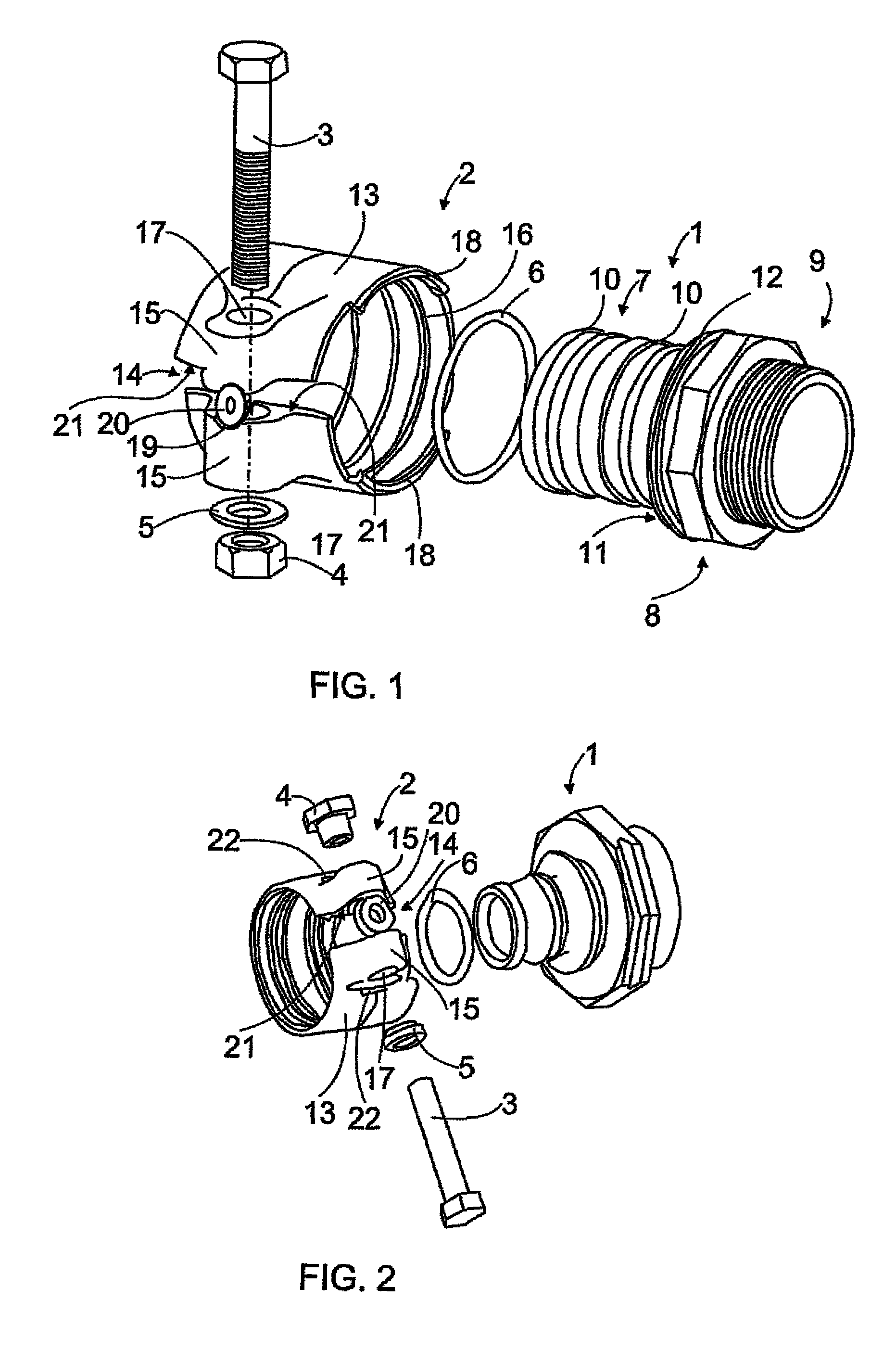

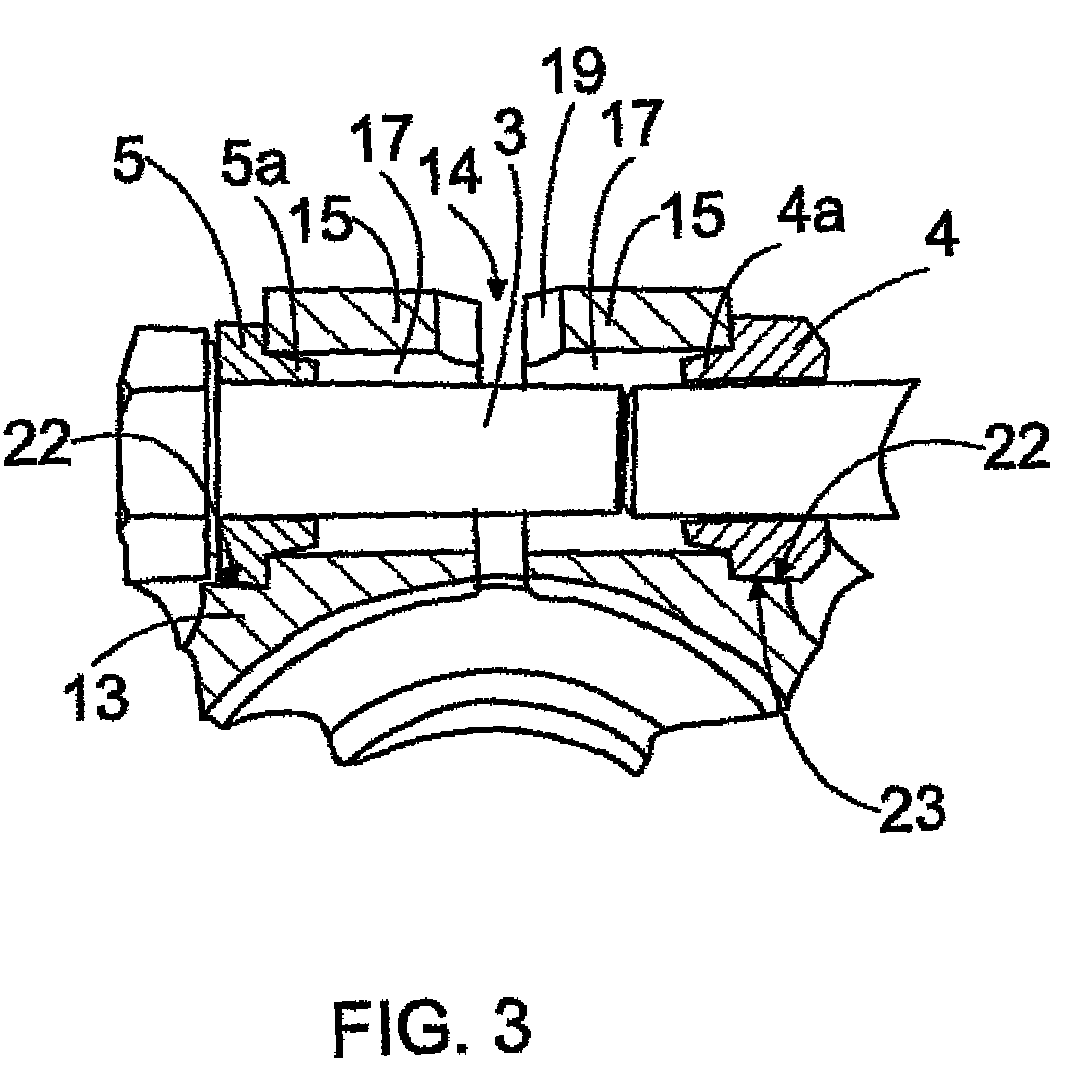

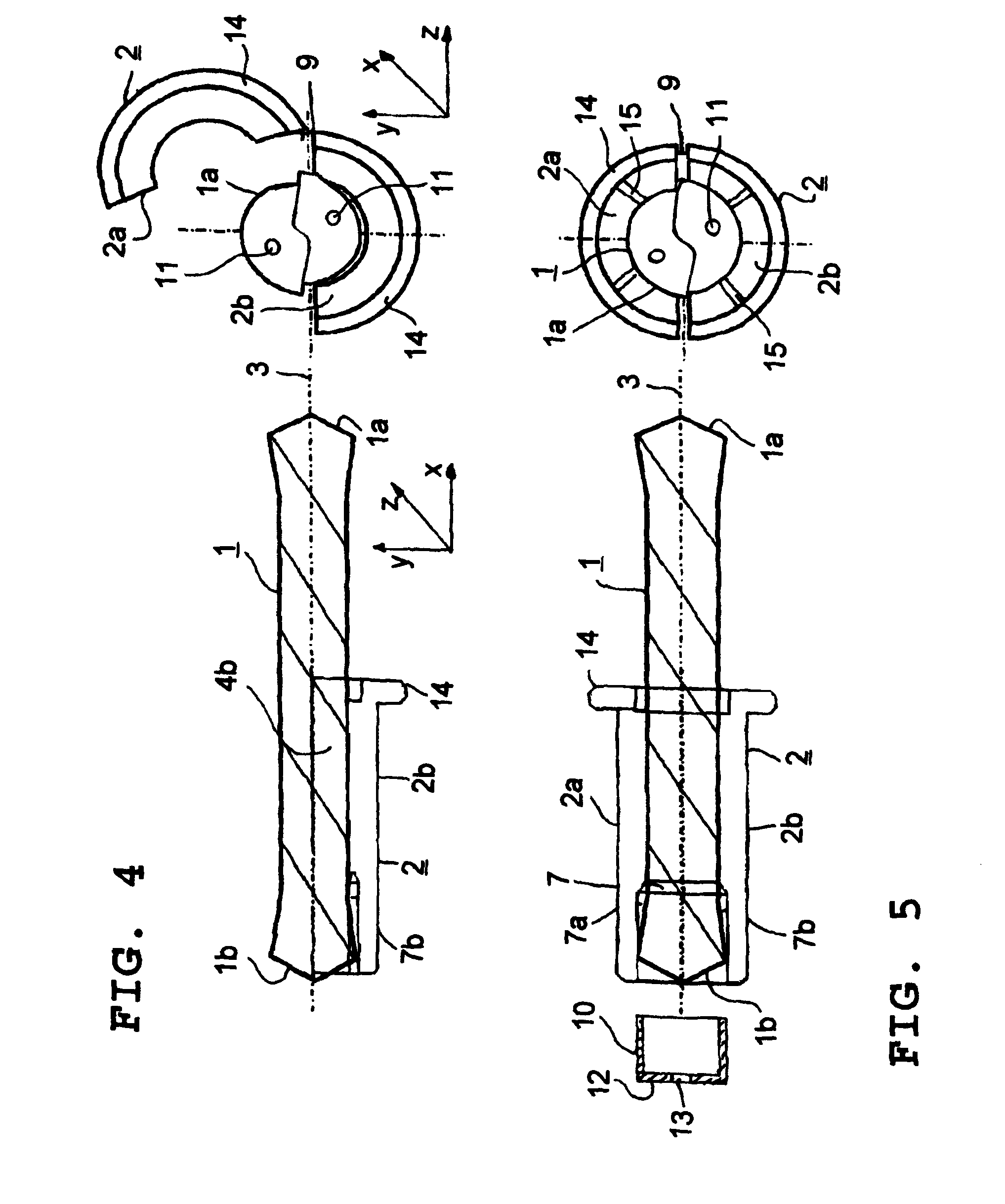

Pipe Coupling

ActiveUS20080290653A1Enhanced couplingLarge inner diameterSnap fastenersPipe elementsEngineeringAbutment

The pipe coupling for connection to a pipe end of a pipe made of polymer material comprises an inner sleeve (1) which is intended for insertion into the pipe end and for abutment with the inner surface of said pipe end, an outer sleeve which is intended for abutment with the outer surface of said pipe end and which includes a slot-like opening (14), and means for adjusting said opening (14). The coupling further comprises a pre-widening means positioned between the edges (21) of the slot-like opening (14). The pre-widening means makes the slot-like opening (14) larger such that the inner diameter of the outer sleeve (2) is larger than the outer diameter of the pipe.

Owner:UPONOR INNOVATION AB

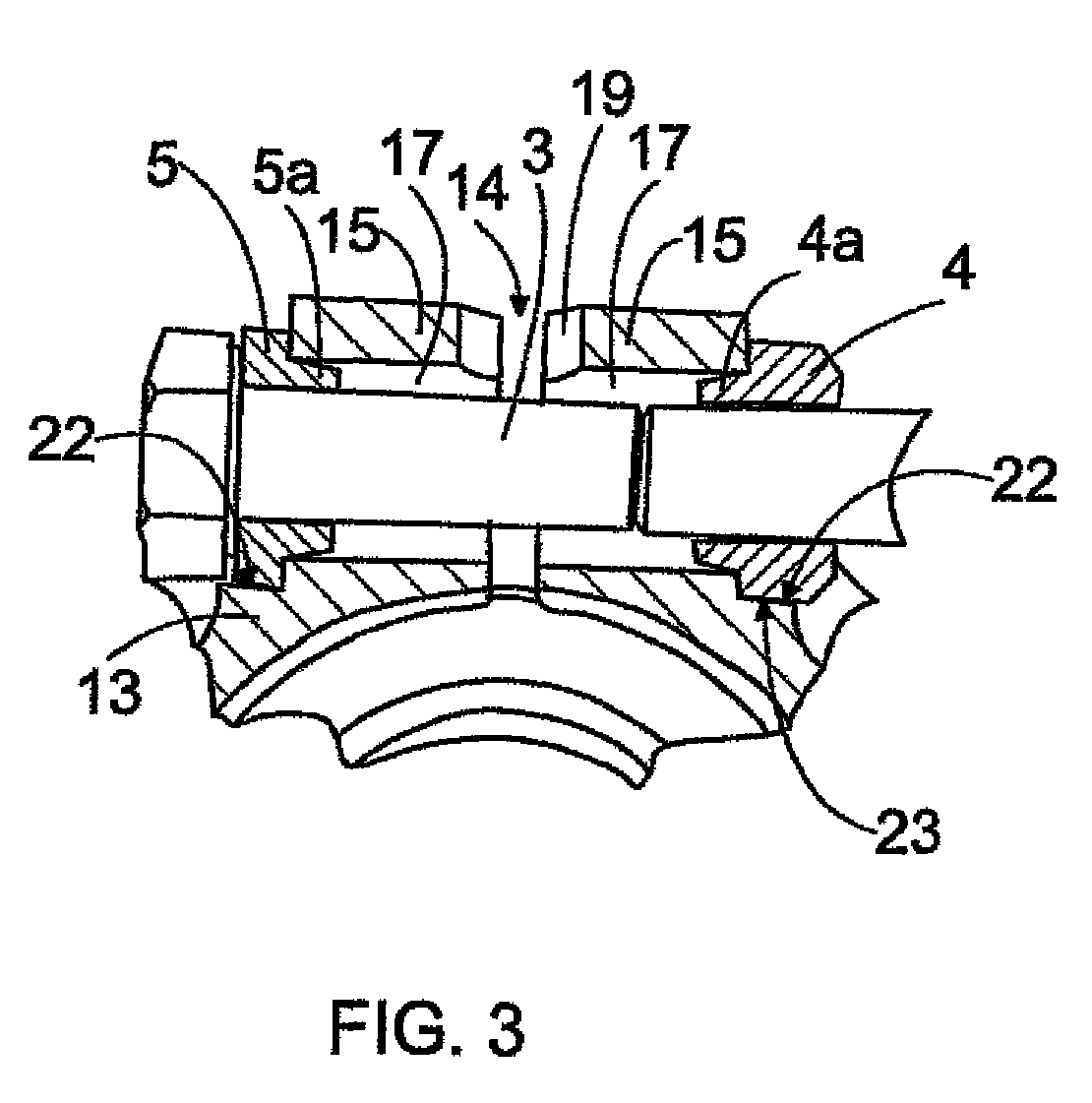

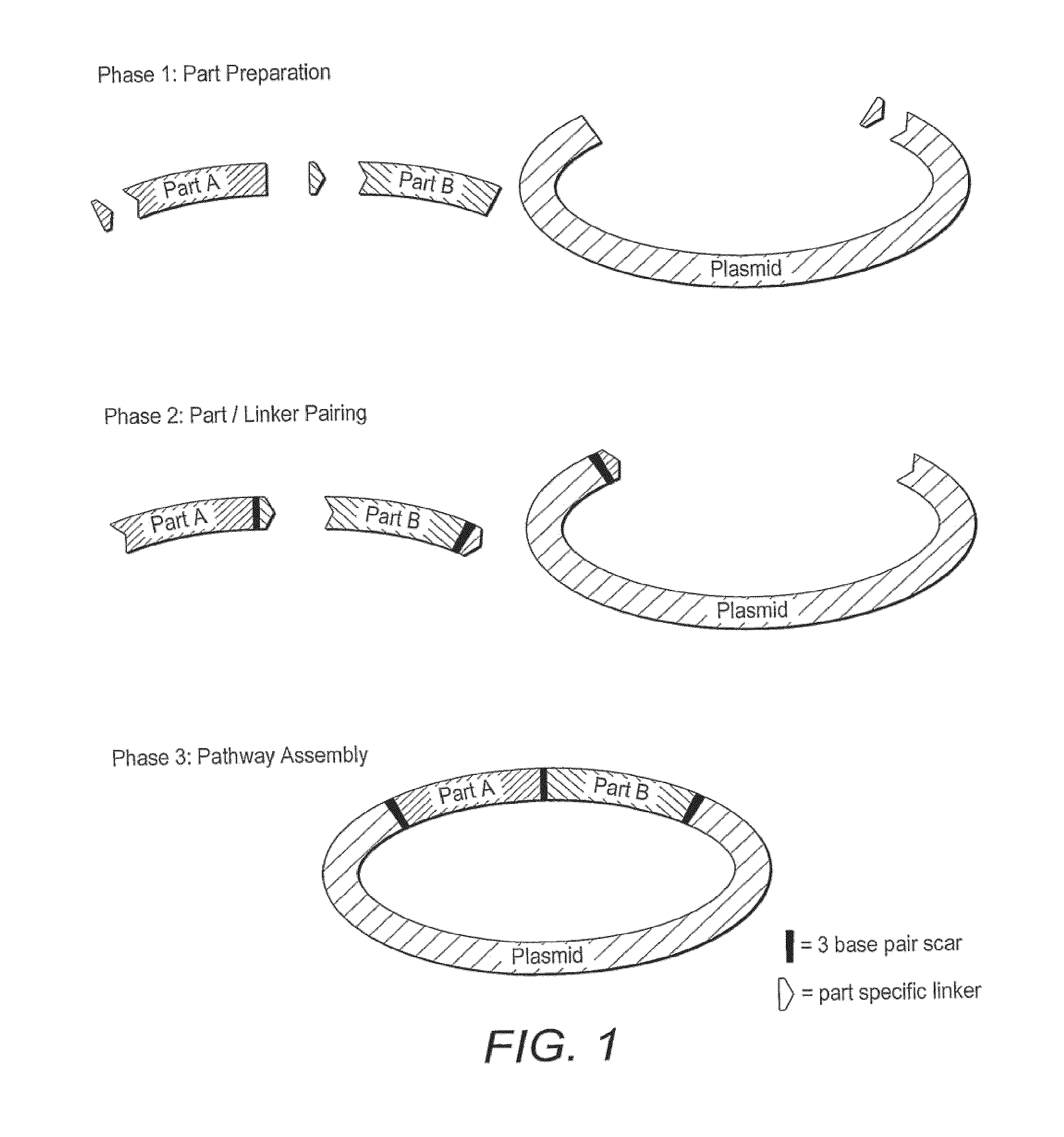

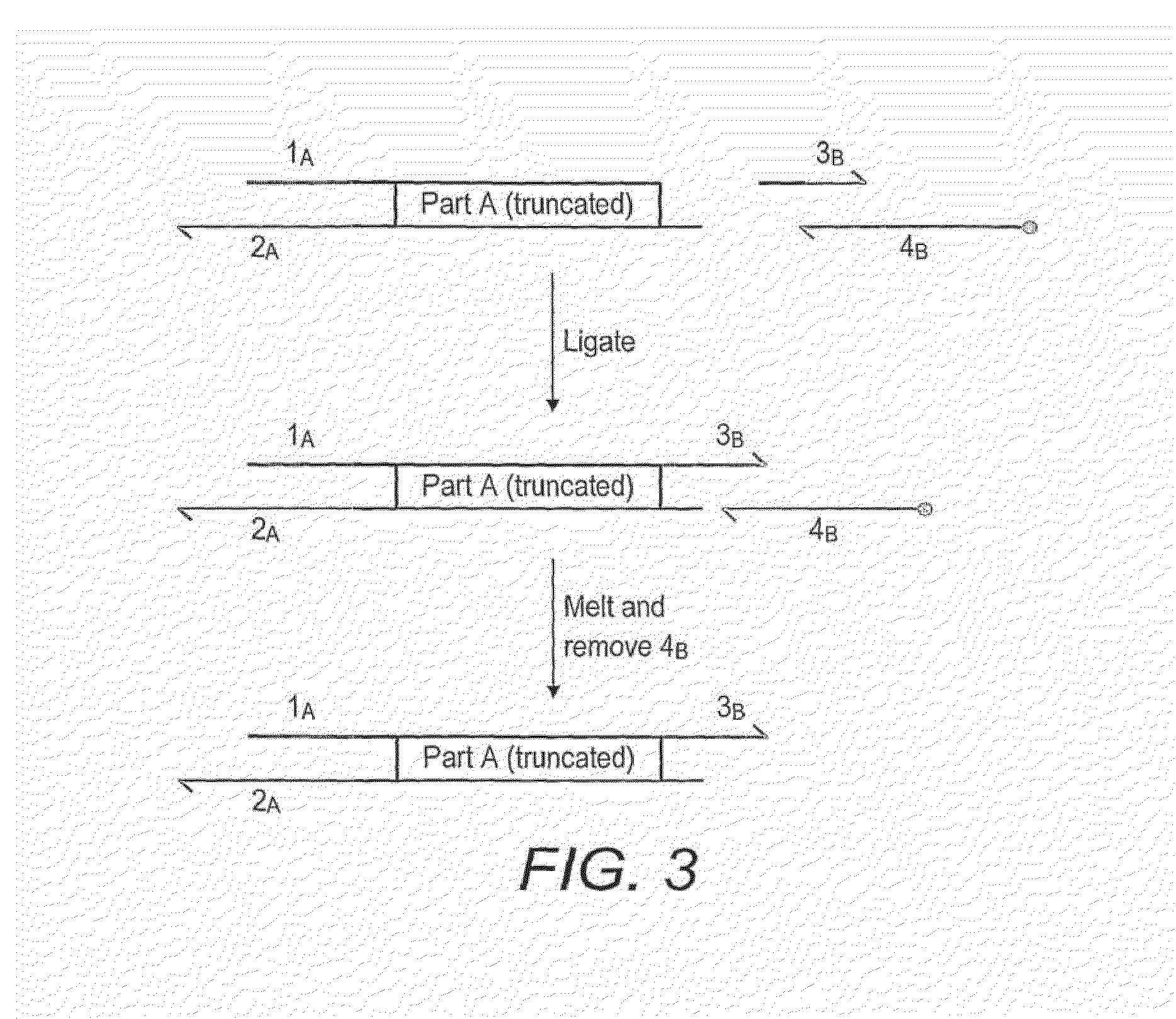

Method for assembly of polynucleic acid sequences

InactiveUS8999679B2Quicker and convenient to useSimple and quick assemblyTransferasesFermentationNucleic acid sequencingOligonucleotide Linker

The present invention provides a method for the assembly of a polynucleic acid sequence from a plurality of nucleic acid sequences in which the polynucleic acid sequence is of a formula Nn+1, in which N represents a nucleic acid sequence and where n is 1 or greater than 1 and each N may be the same or a different nucleic acid sequence, in which the method comprises: (i) providing a first nucleic acid sequence N1 which has an oligonucleotide linker sequence L13 at the 3′-end of the nucleic acid sequence; (ii) providing a second nucleic acid sequence N2 which optionally has an oligonucleotide linker sequence L23′ at the 3′-end of the nucleic acid sequence and which has an oligonucleotide linker sequence L25′ at the 5′-end of the nucleic acid sequence, wherein the 5′-end linker sequence L25′ of nucleic acid sequence N2 is complementary to the 3′-end linker sequence L13′ of nucleic acid sequence N1; (iii) optionally providing one or more additional nucleic acid sequences N, wherein nucleic acid sequence N2 has an oligonucleotide linker sequence L23′ at the 3′-end of the nucleic acid sequence, and wherein said one or more additional nucleic acid sequences N comprises a terminal additional nucleic acid sequence NZ, and wherein each additional nucleic acid sequence N has an oligonucleotide linker sequence at its 3′-end, wherein said terminal additional nucleic acid sequence NZ optionally lacks an oligonucleotide linker sequence at its 3′-end and wherein each additional nucleic acid sequence N has an oligonucleotide linker sequence at its 5′-end, wherein for the first additional nucleic acid sequence N3 the 5′-end linker sequence L35′ is complementary to the 3′-end linker sequence L23′ of nucleic acid sequence N2 and for each second and subsequent additional nucleic acid sequence N the 5′-end linker sequence is complementary to the 3′-end linker sequence of the respective preceding additional nucleic acid sequence; and (iv) ligating said nucleic acid sequences to form said polynucleic acid sequence.

Owner:ITI SCOTLAND

Pipe coupling

A pipe coupling for connection to a pipe end of pipe made of polymer material includes an inner sleeve which is intended for insertion into the pipe end and for abutment with the inner surface of the pipe end, and an outer sleeve which is intended for abutment with the outer surface of the pipe end and which includes a slot-like opening. The pipe coupling also includes a device for adjusting the opening, and a pre-widening device positioned between the edges of the slot-like opening. The pre-widening device makes the slot-like opening larger such that the inner diameter of the outer sleeve is larger than the outer diameter of the pipe.

Owner:UPONOR INNOVATION AB

Combination of the chucking device and a drill and a chucking device for a drill with cutting tips on both ends

InactiveUS8672332B2Clamped easily and safelySimple and quick assemblySleeve/socket jointsTransportation and packagingTrademarkEngineering

Owner:KENNAMETAL INC

Recreational structure using a sleeve-joint coupling

InactiveUS7927254B2Simple and quick assemblyStable structureSpring boardsTrampolinesCouplingEngineering

A recreational structure, such as a trampoline frame, can be quickly and reliably assembled using a sleeve-joint coupling having a “T” configuration. A first arm member and an aperture that is formed in the sleeve-joint coupling are disposed in an opposite relationship. A second arm member and a third arm member are disposed in an opposite relationship with each other. The first arm member receives one end of a vertical frame member of the recreational structure, while the aperture receives one end of a vertical pole member of, for example, a safety enclosure. The second and third arm members each receive one end of a horizontal frame member of the recreational structure. The vertical pole member extends through the sleeve-joint coupling into an inner portion of the vertical frame member received by the first arm of the sleeve-joint coupling.

Owner:CA06

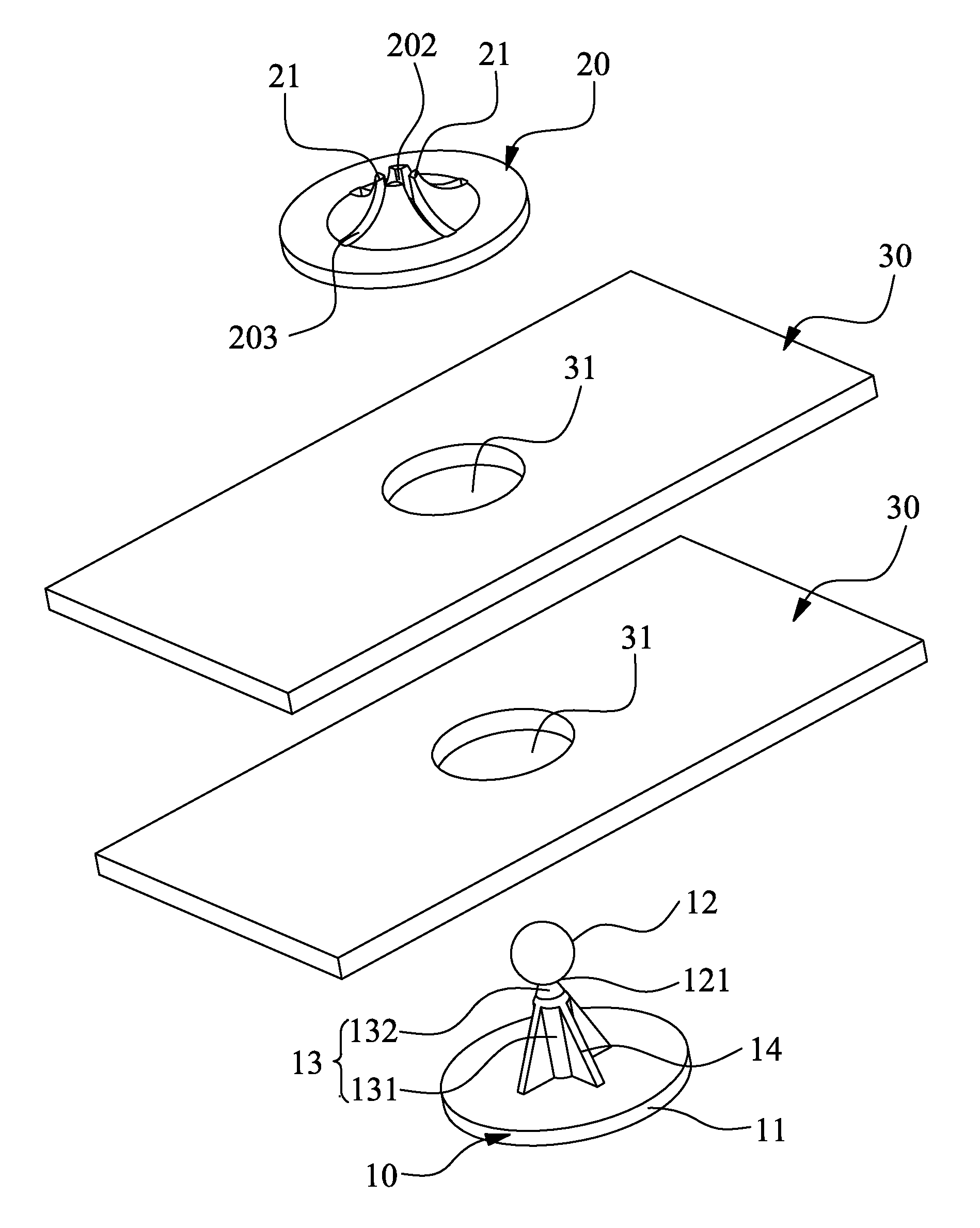

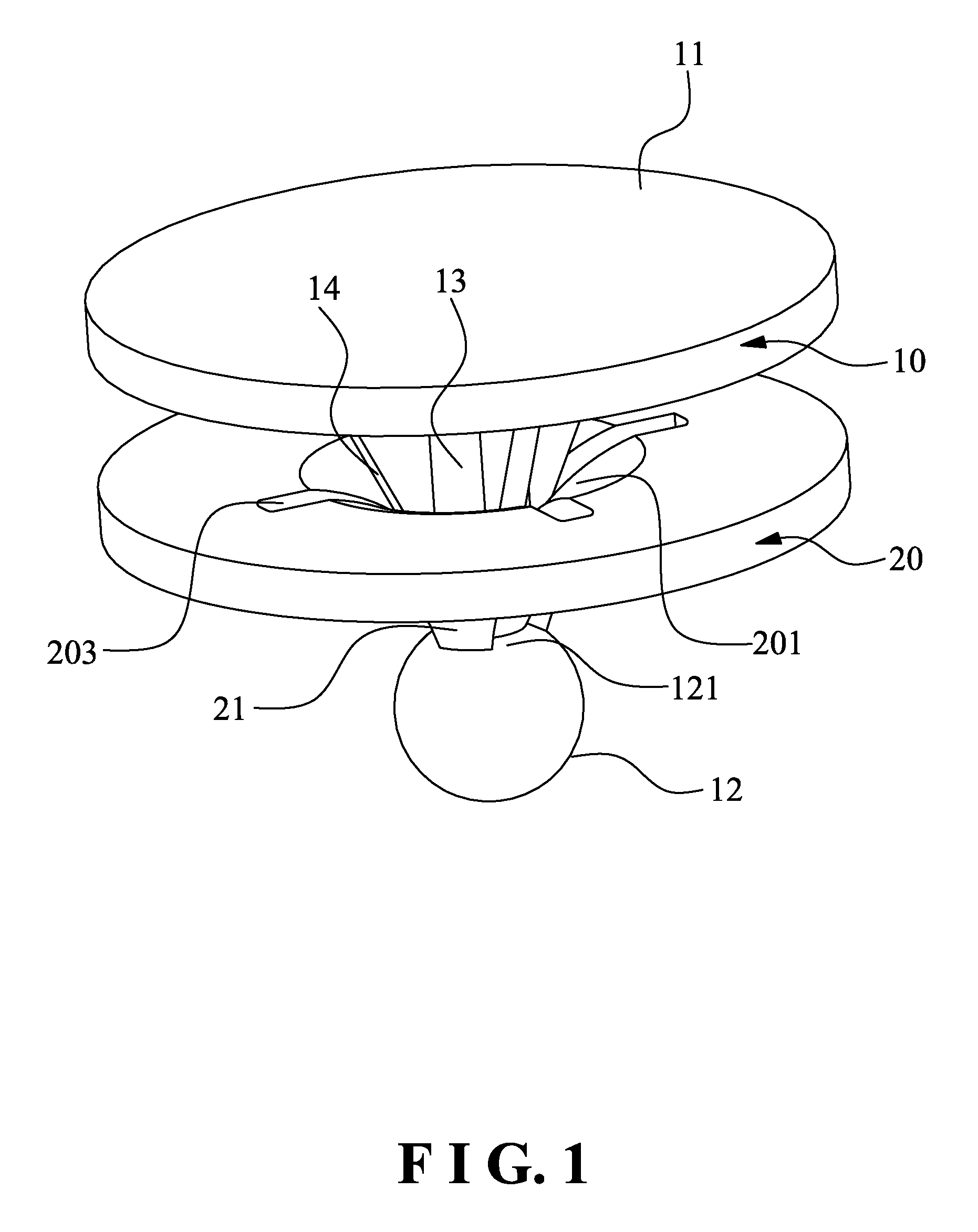

LED module and LED lamp

ActiveUS20180094776A1Conveniently installedReduce lossesCeilingsLighting support devicesComputer moduleLED lamp

An LED module includes a module board. A boss coaxial with a central axis of the module board is provided on one side surface of the module board, and the boss is provided, in a direction of the central axis of the module board, with a through hole through which a central rod of an LED lamp passes, a side wall of the boss is provided with a fastener hole to allow a fastener to be inserted into the fastener hole to abut against an outer wall of the central rod of the LED lamp; and multiple screws are fixedly mounted on the other side surface of the module board and configured to be detachably connected to drip holes in a surface of the LED lamp respectively. An LED lamp including the LED module is provided, which has a reduced cost.

Owner:SHIA PING YEUNG DENNIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com