Superstructure of engine

An engine and structure technology, applied in the direction of engine starting, engine cooling, engine components, etc., can solve problems such as oil hammer, increase cost, damage connecting rod, etc., and achieve the effect of preventing assembly errors, rapid assembly, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

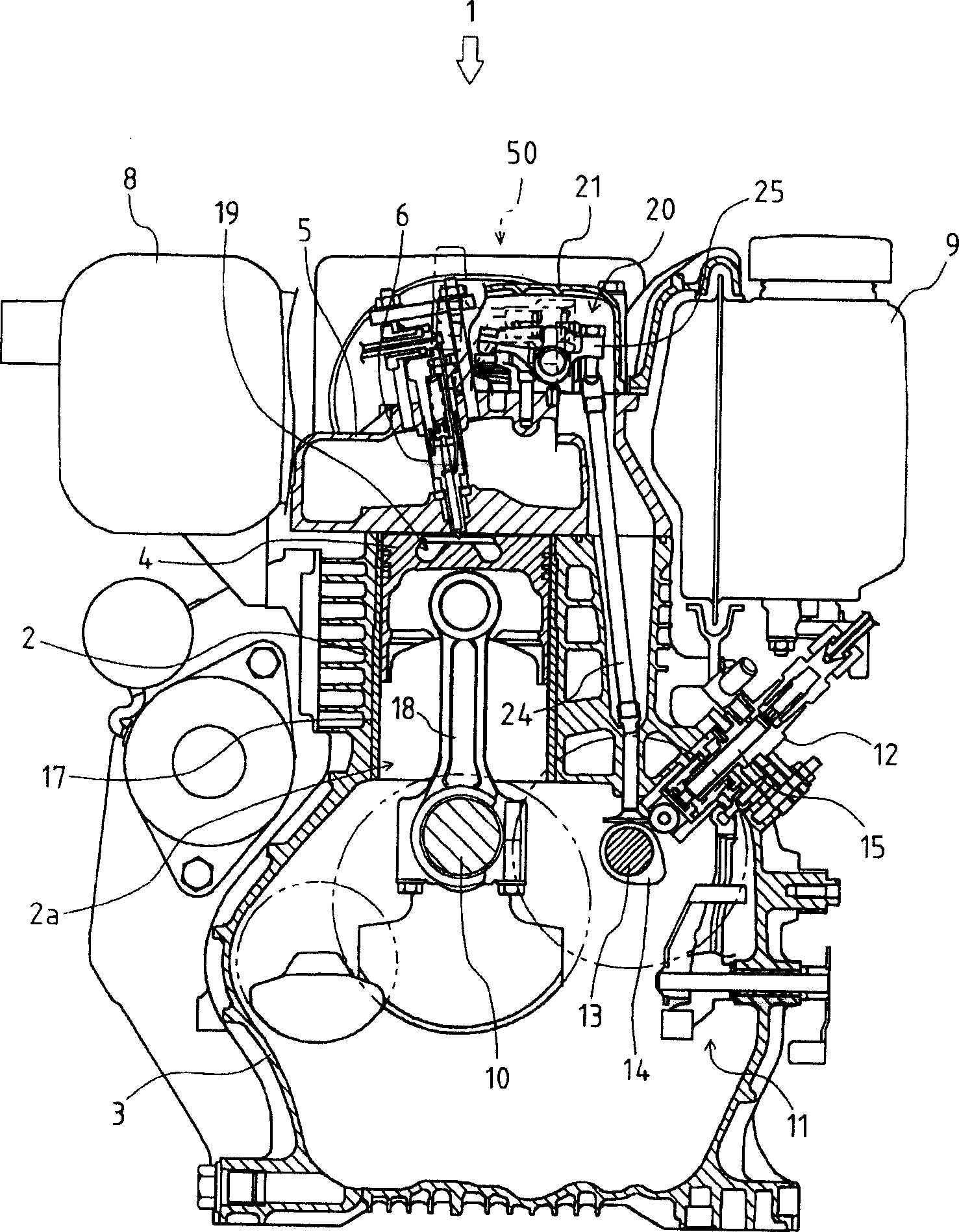

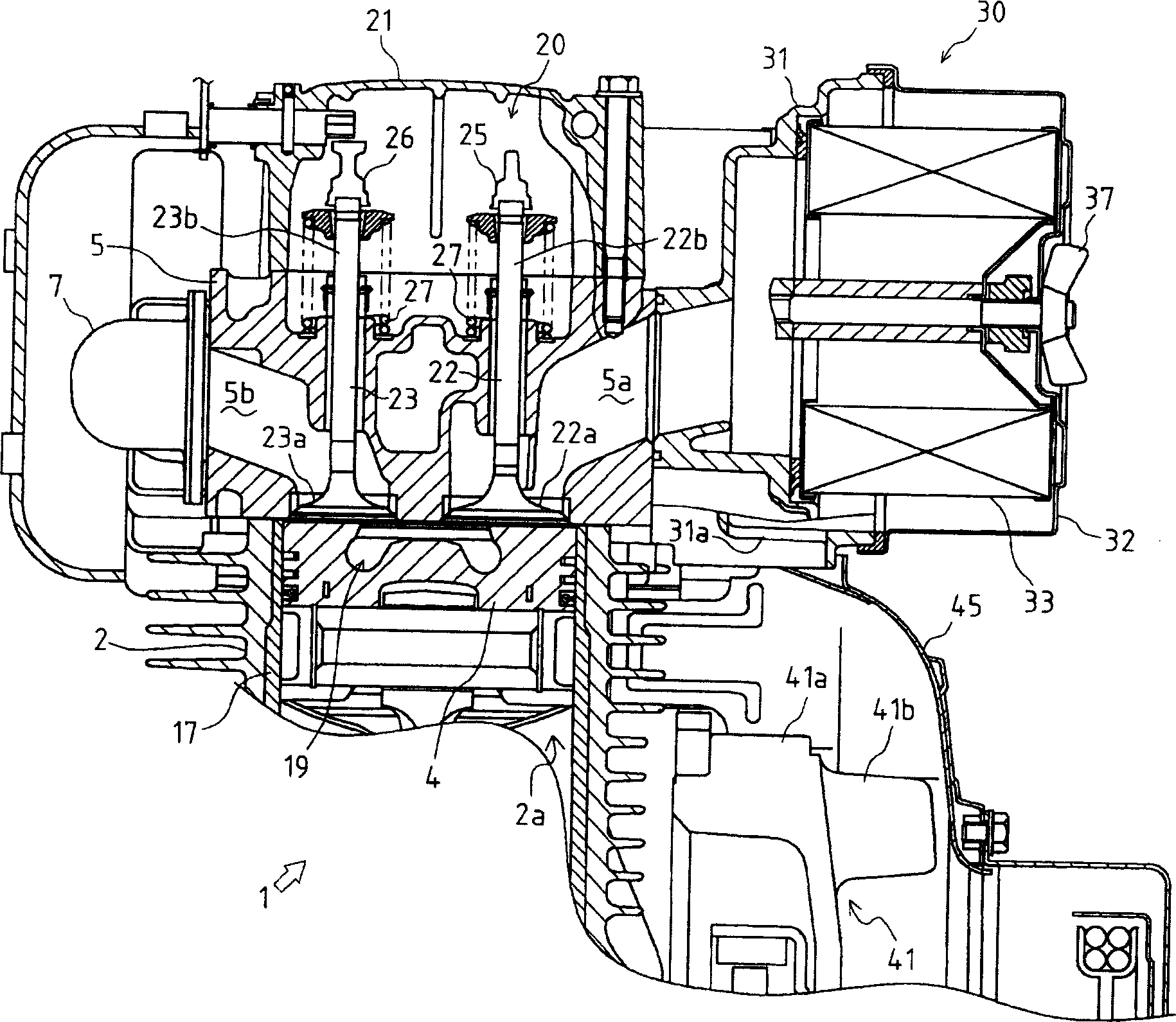

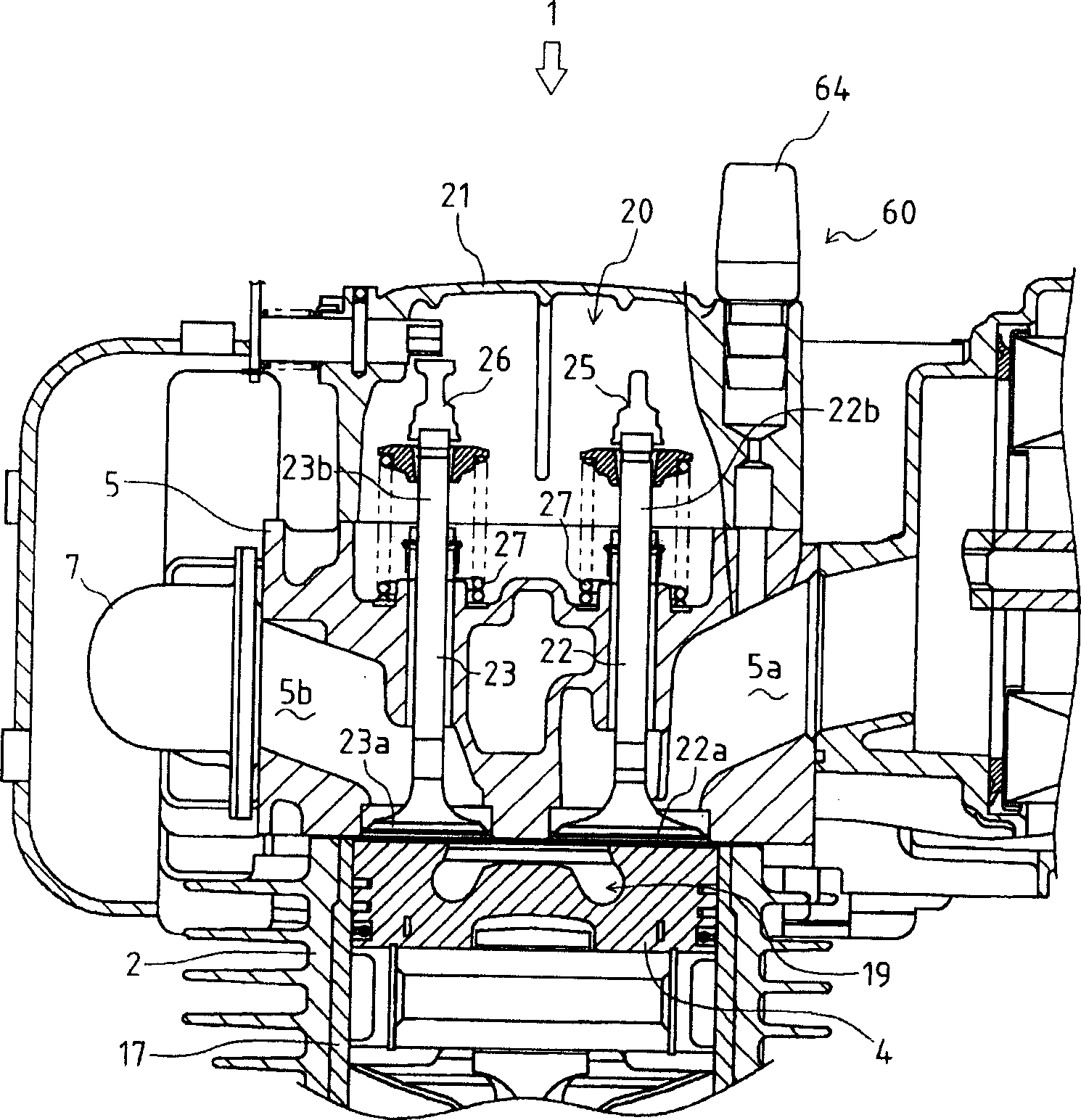

[0046] First, use Figure 1 to Figure 3 The overall structure of the engine 1 of the present invention will be described.

[0047] The engine 1 consists of a cylinder block 2 constituting the upper part of its main body, and a crankcase 3 constituting the lower part of its main body. The cylinder block 2 forms a cylinder 2a in the vertical direction at the center thereof, and accommodates the piston 4 in a cylinder liner 17 inside the cylinder 2a so as to be slidable in the vertical direction. Below the cylinder block 2 , a crankshaft 10 is pivotally supported by the crankcase 3 in the front-rear direction, and the crankshaft 10 and the piston 4 are connected by a connecting rod 18 .

[0048] The upper portion of the aforementioned cylinder block 2 is covered by a cylinder head 5 . In this cylinder head 5, an intake valve 22, an exhaust valve 23, a fuel injection nozzle 6, and the like are disposed. The upper side of the cylinder head 5 is covered by a valve arm case 21 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com