Patents

Literature

32results about How to "Seek long life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

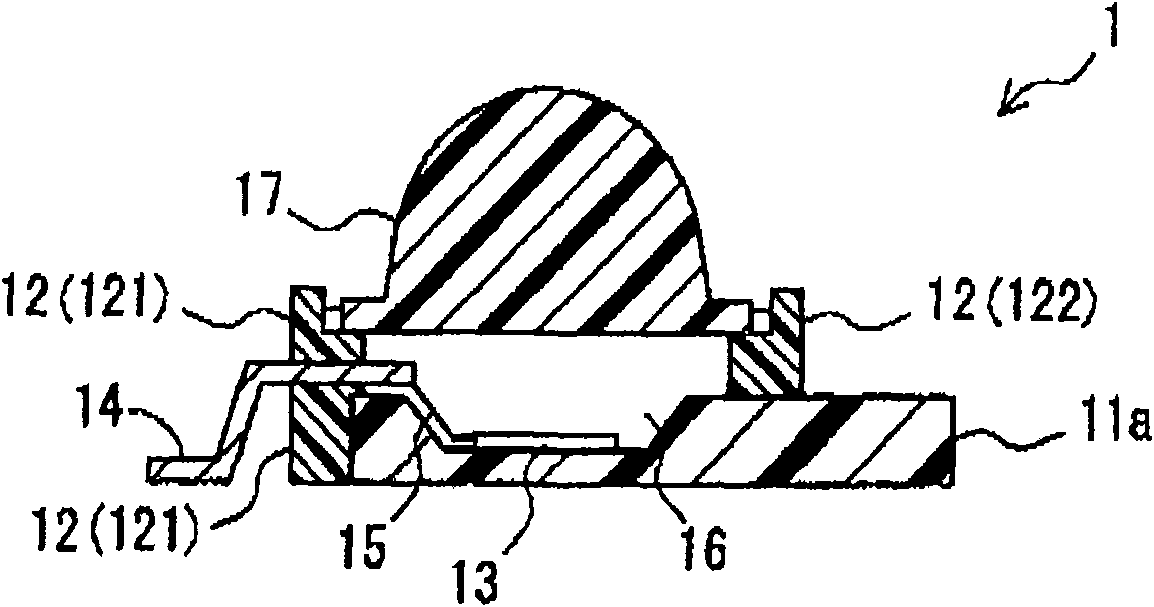

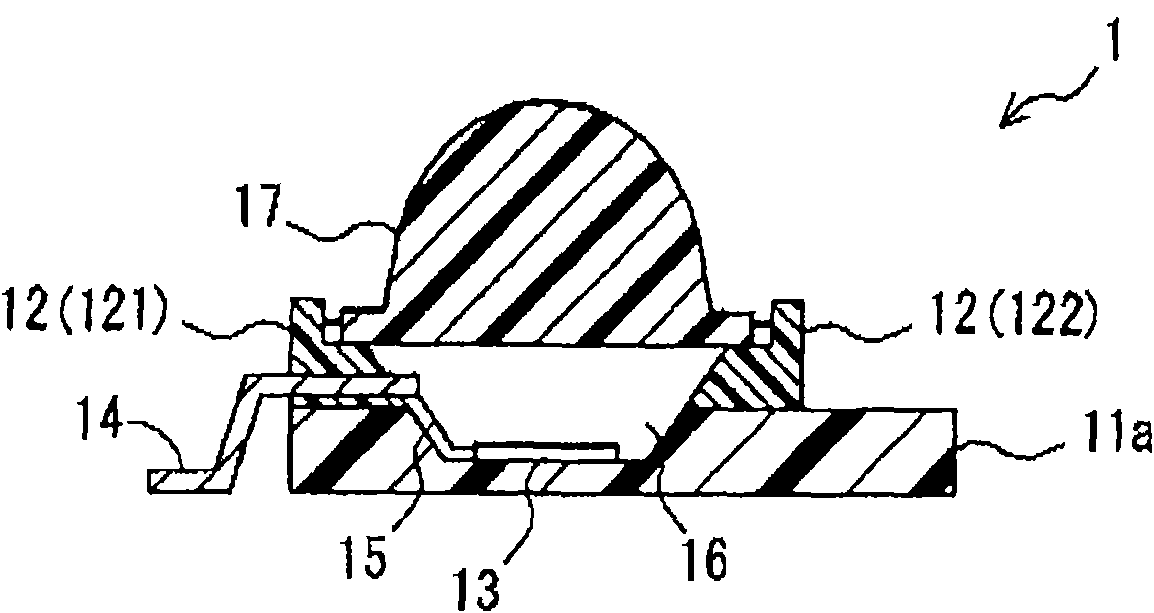

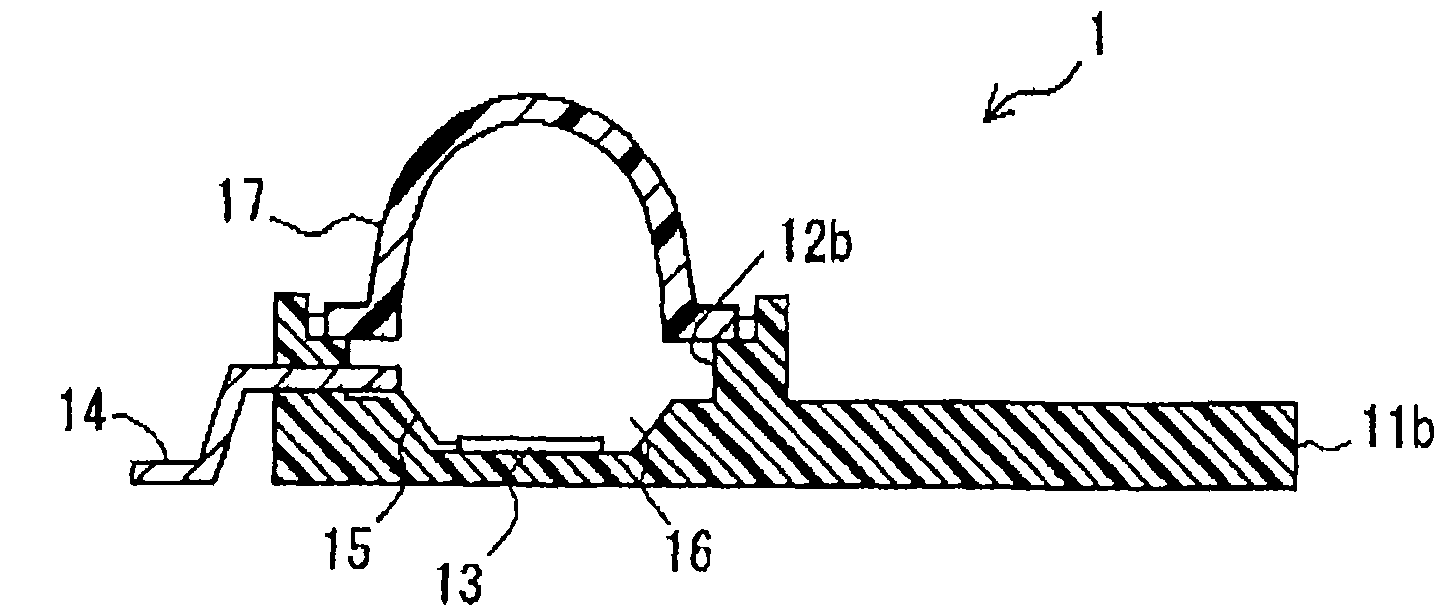

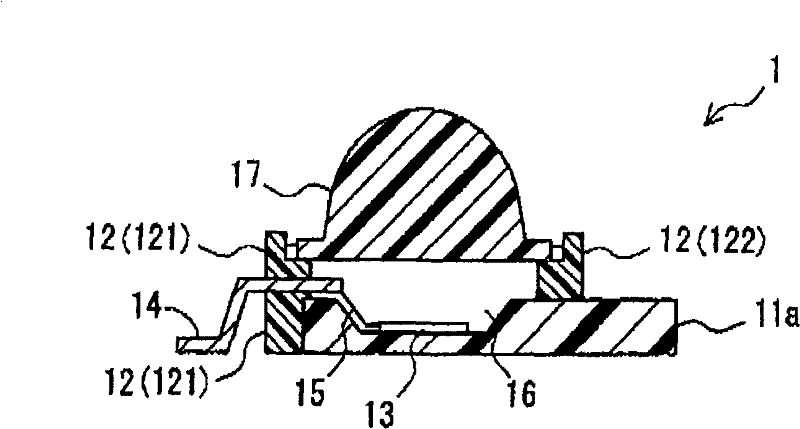

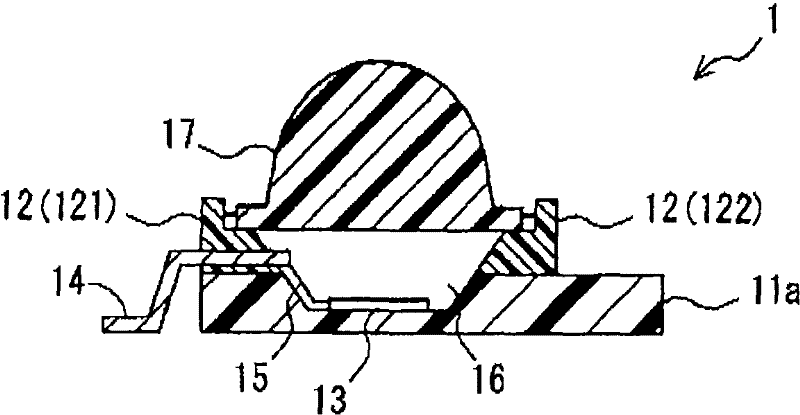

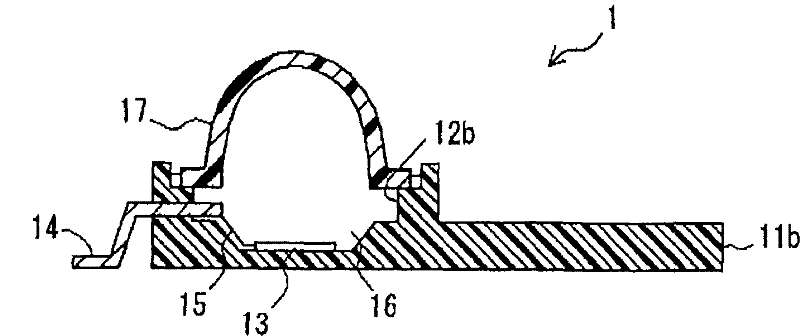

Heat-dissipating resin composition, substrate for LED mounting, reflector, and substrate for LED mounting having reflector portion

InactiveCN101583670AEasy to processImprove impact resistanceSolid-state devicesHeat exchange apparatusHeat deflection temperatureEmissivity

Disclosed is a heat-dissipating resin composition which is used for forming a substrate for LED mounting or a reflector provided on the substrate for LED mounting, and excellent in heat dissipation, electrical insulation, heat resistance and light resistance during the time when an LED element emits light. Also disclosed are a substrate for LED mounting and a reflector respectively containing such a heat-dissipating resin composition. Specifically disclosed is a composition containing a thermoplastic resin such as a modified PBT and a thermally conductive filler such as a flake boron nitride. The composition has a heat distortion temperature of not less than 120 DEG C, a thermal conductivity of not less than 2.0 W / (m K) and a thermal emissivity of not less than 0.7.

Owner:TECHNO POLYMER CO LTD

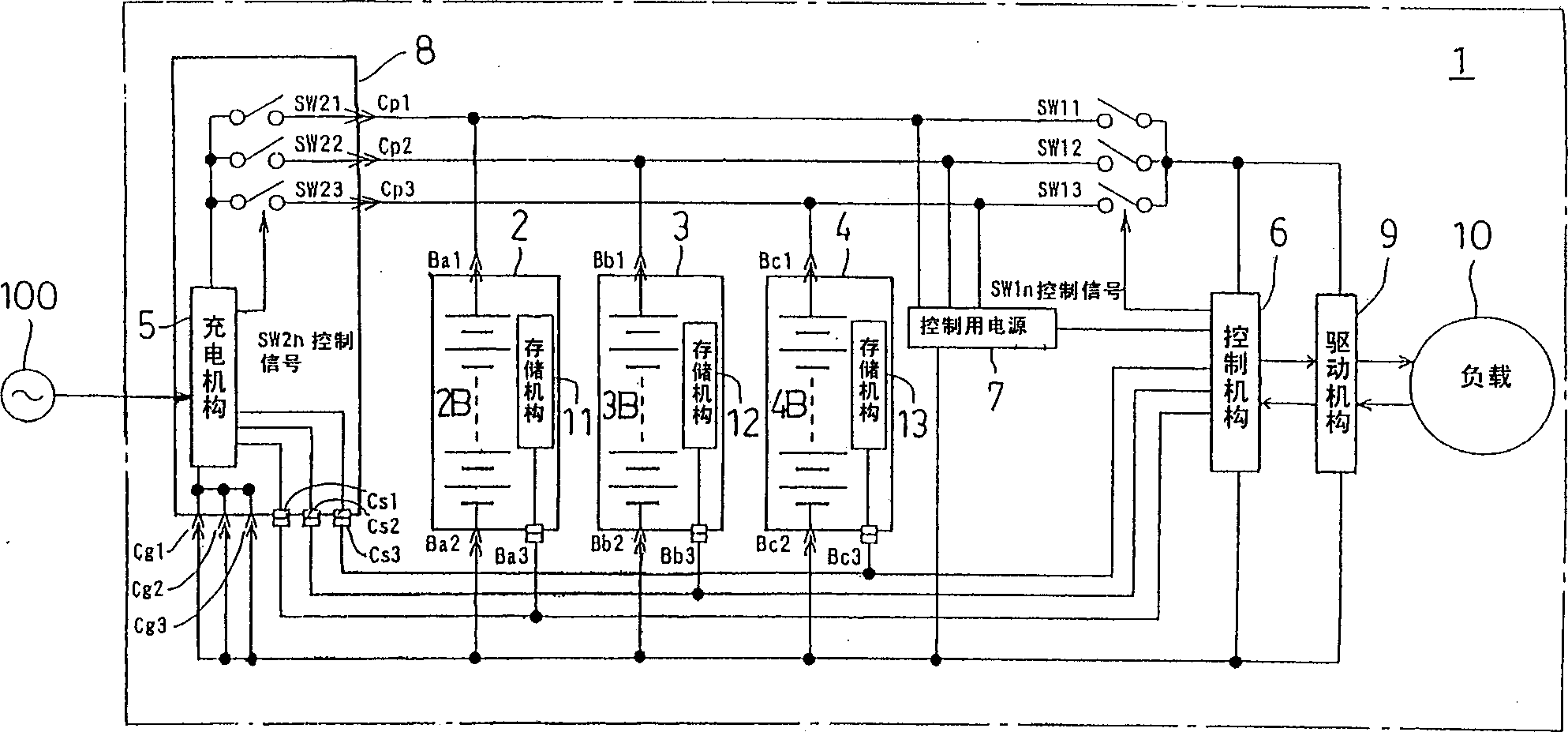

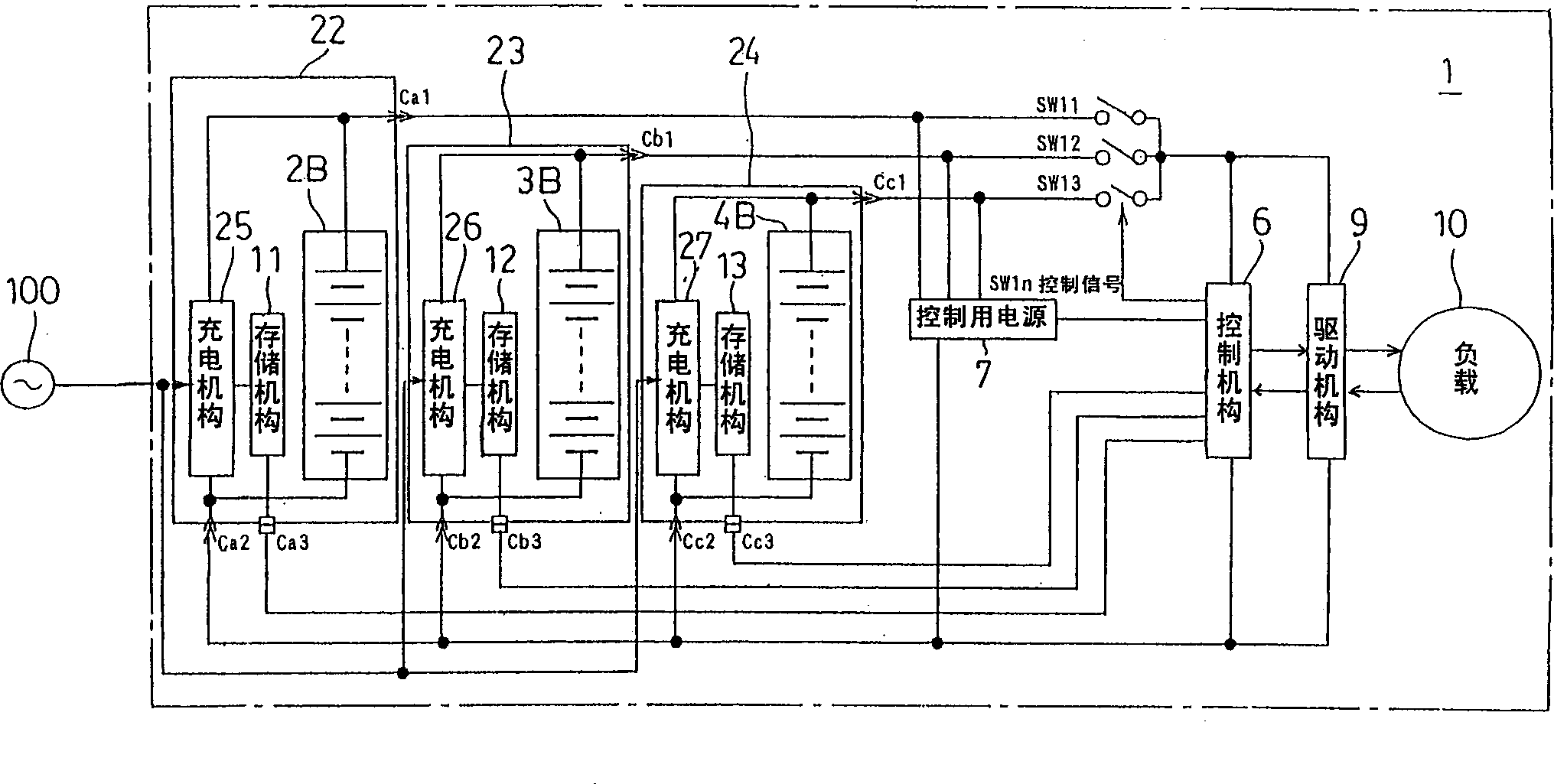

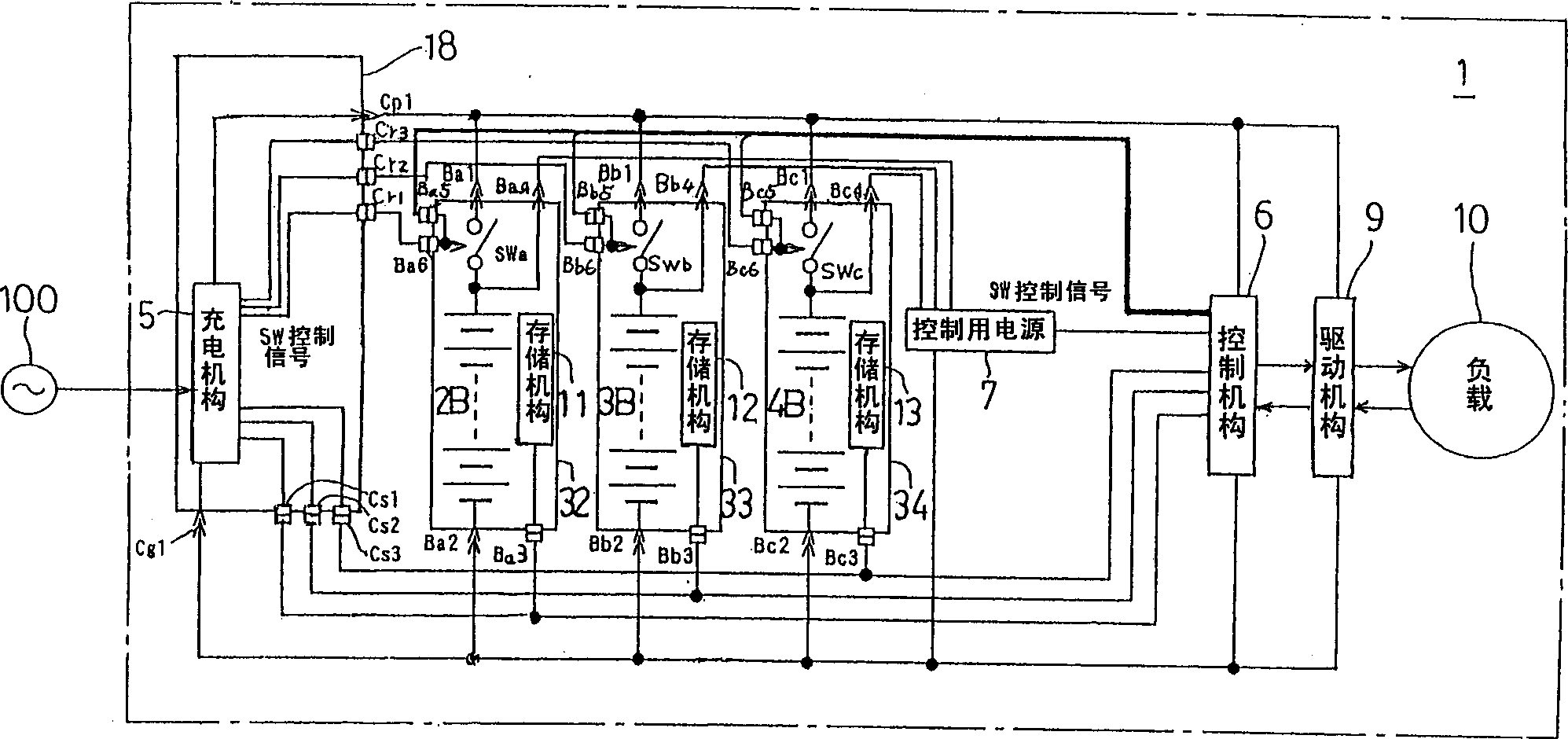

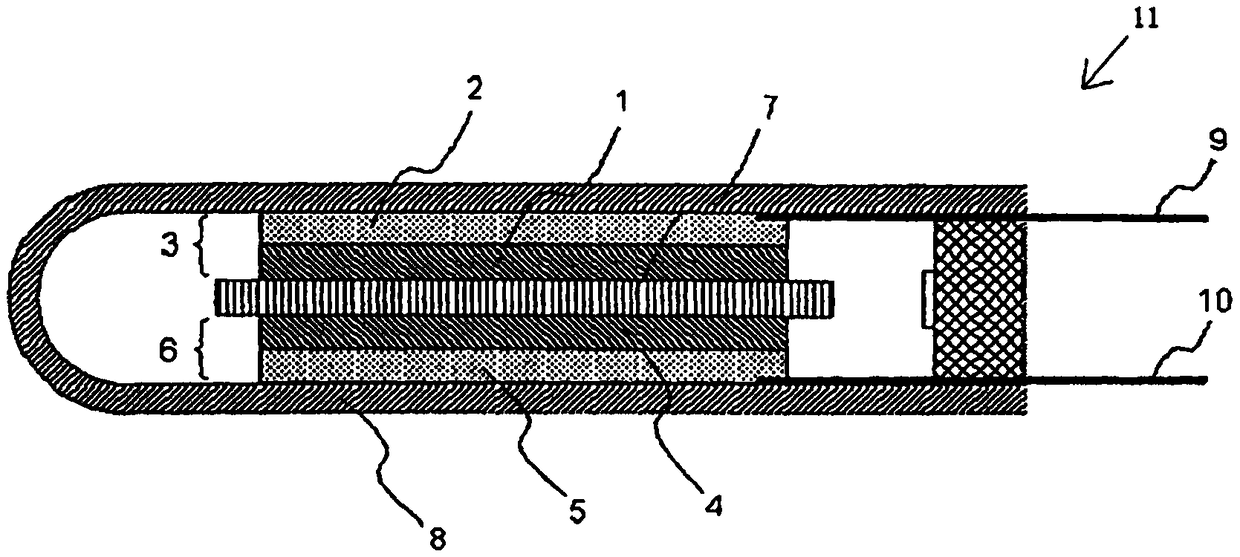

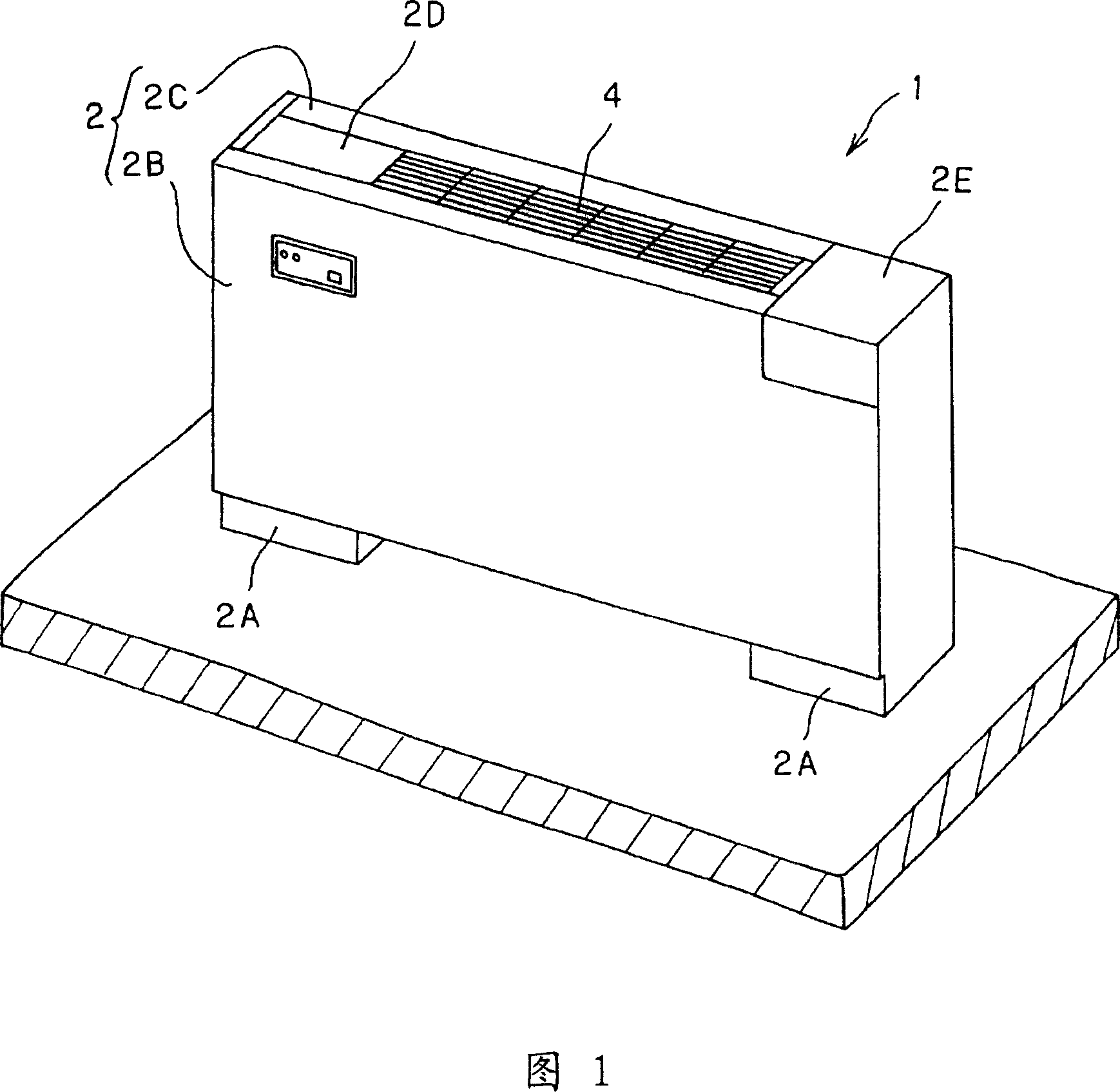

Electric device and apparatus for charging battery unit, and method for charging and discharging

InactiveCN1369127AProper charge and discharge controlAlways master capacityParallel/serial switchingSecondary cells charging/dischargingEngineeringBattery cell

An electric device, comprising a plurality of detachable battery units 2, 3, 4, each comprising a battery pack 2B, 3B, 4B and a storage mechanism 11, 12, 13 for storing information about the charging and discharging status of the battery. A connection mechanism is provided to electrically connect and disconnect the electric device 1 in response to each battery cell being attached and detached. The device includes a driving mechanism 9 for driving a load, a charging mechanism 5 for charging the accumulators 2B, 3B, 4B with reference to information stored in the storage mechanisms 11, 12, 13 of the installed battery units 2, 3, 4, and The control means 6 controls the electric power supplied from each battery unit 2, 3, 4 to the drive means 9 with reference to the above-mentioned information.

Owner:TOKYO R & D LTD

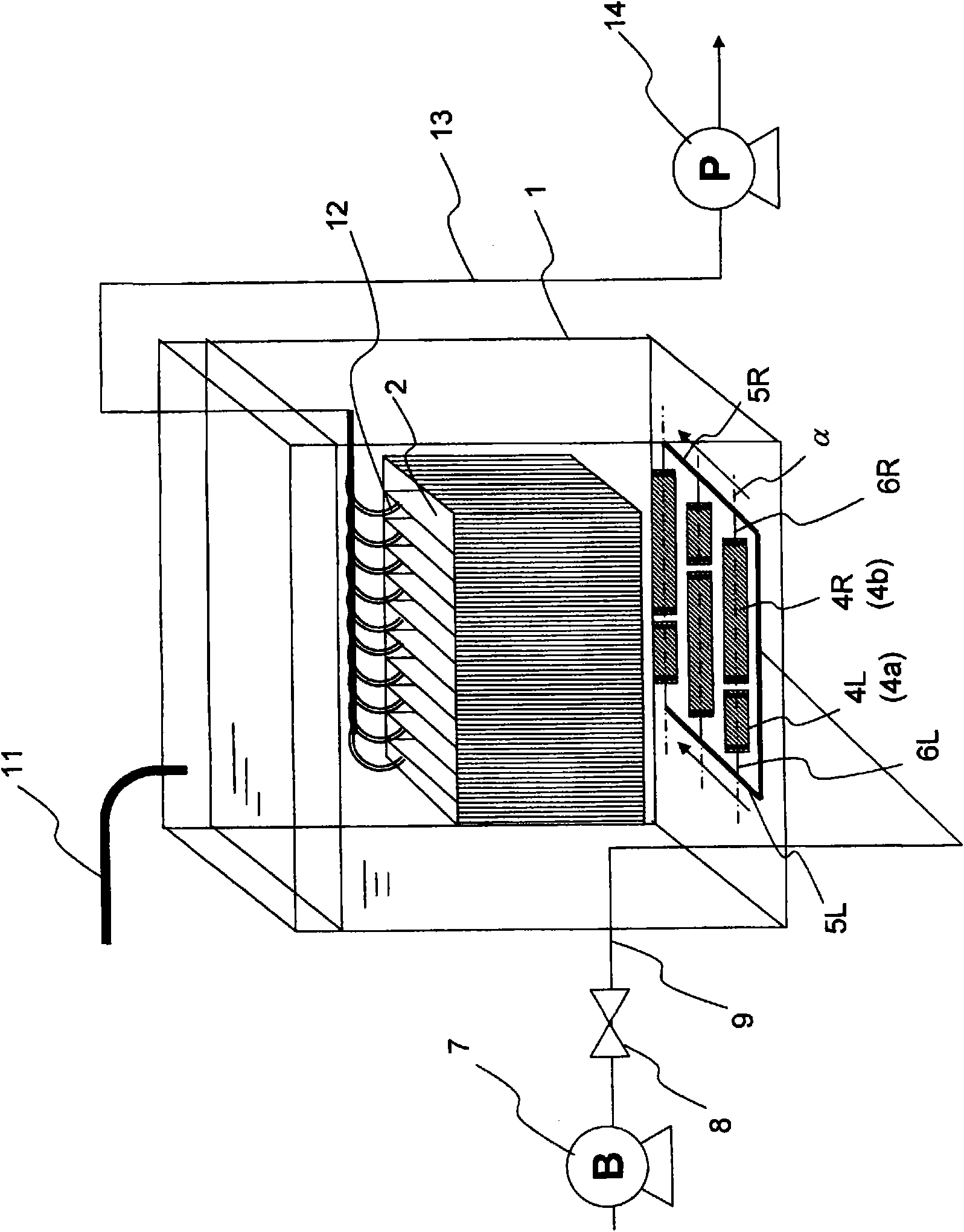

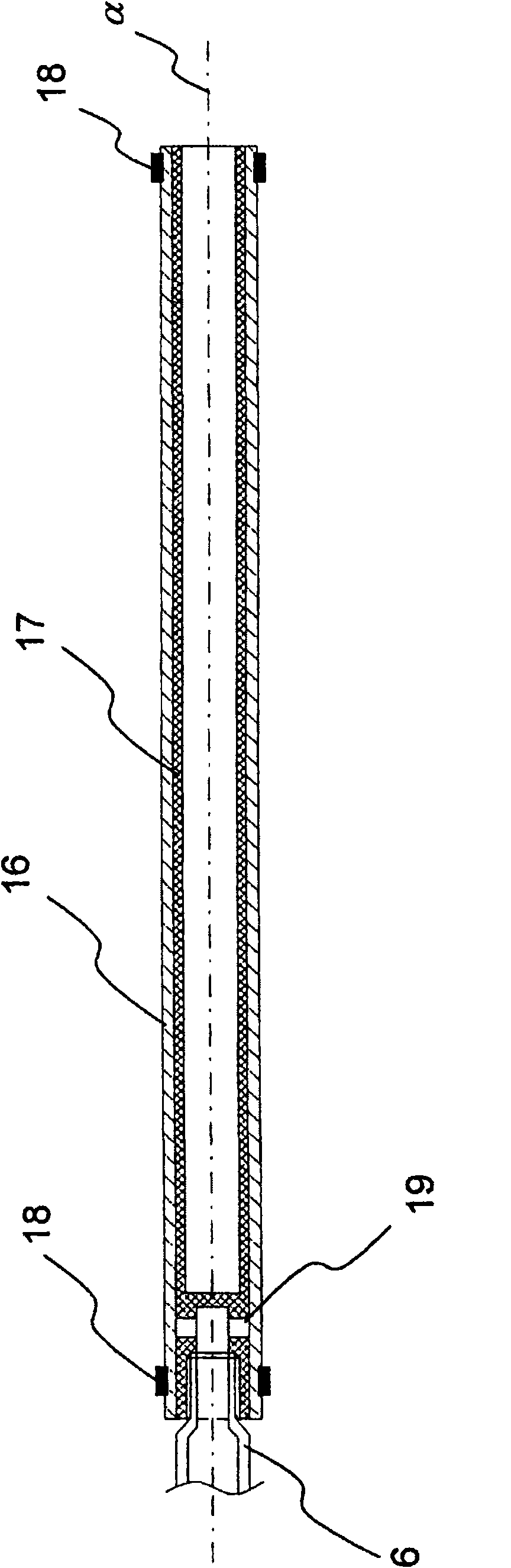

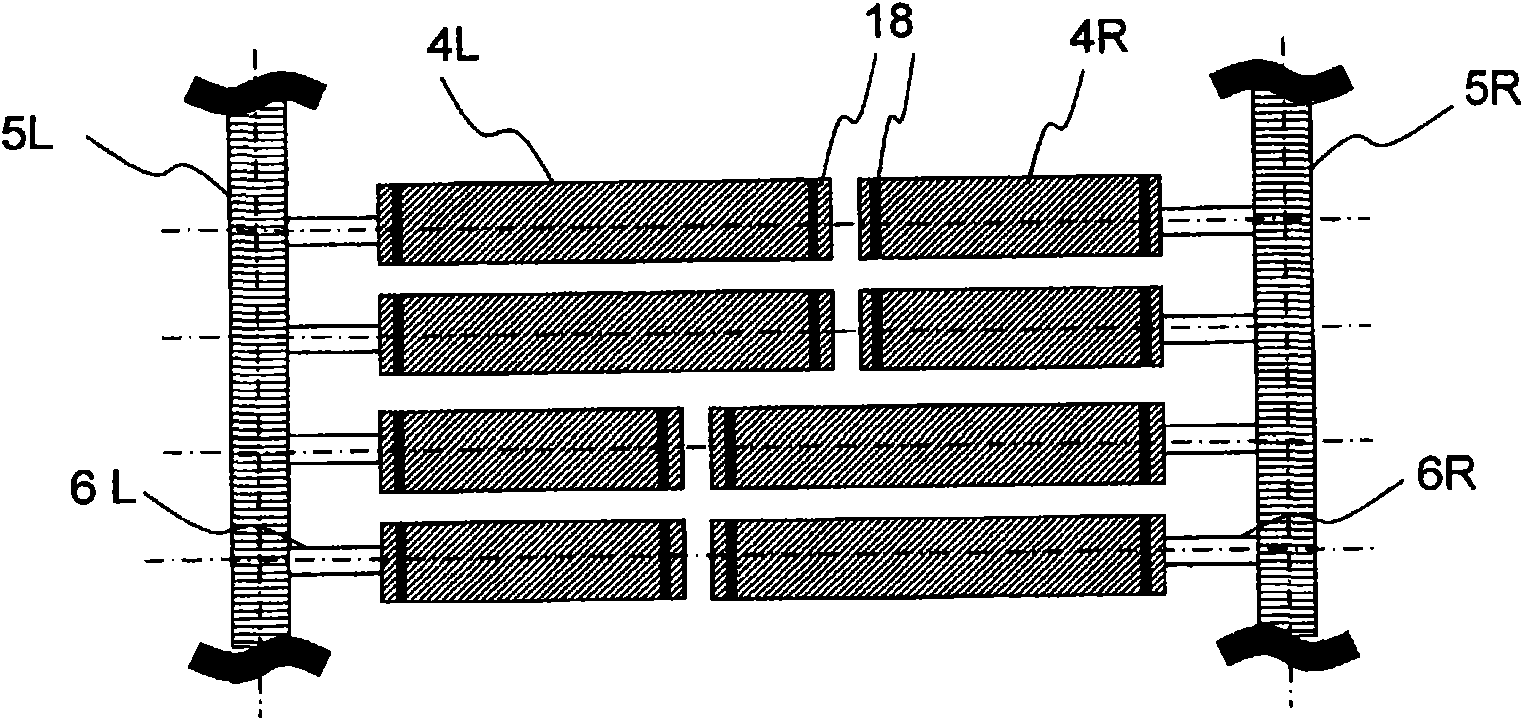

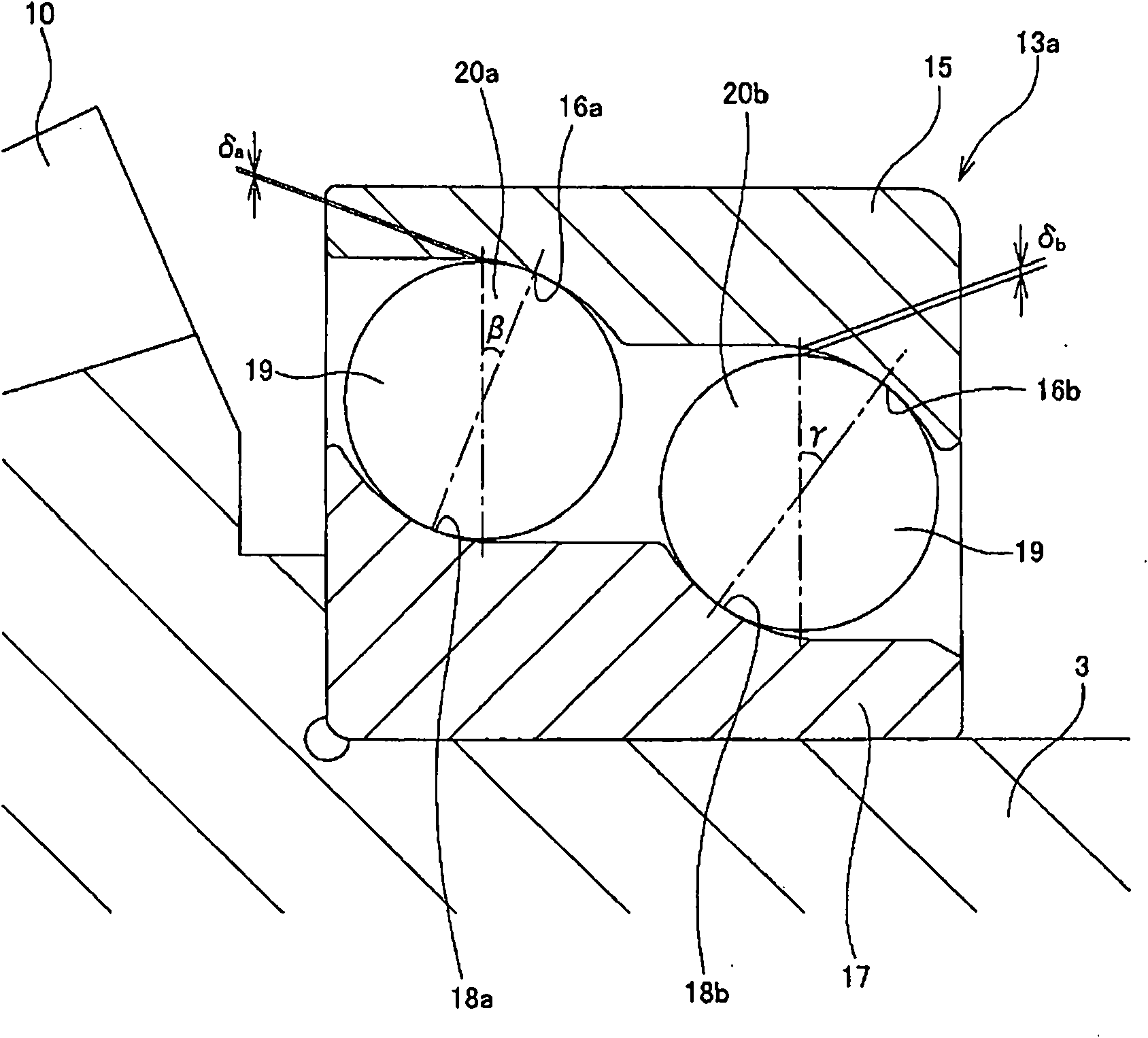

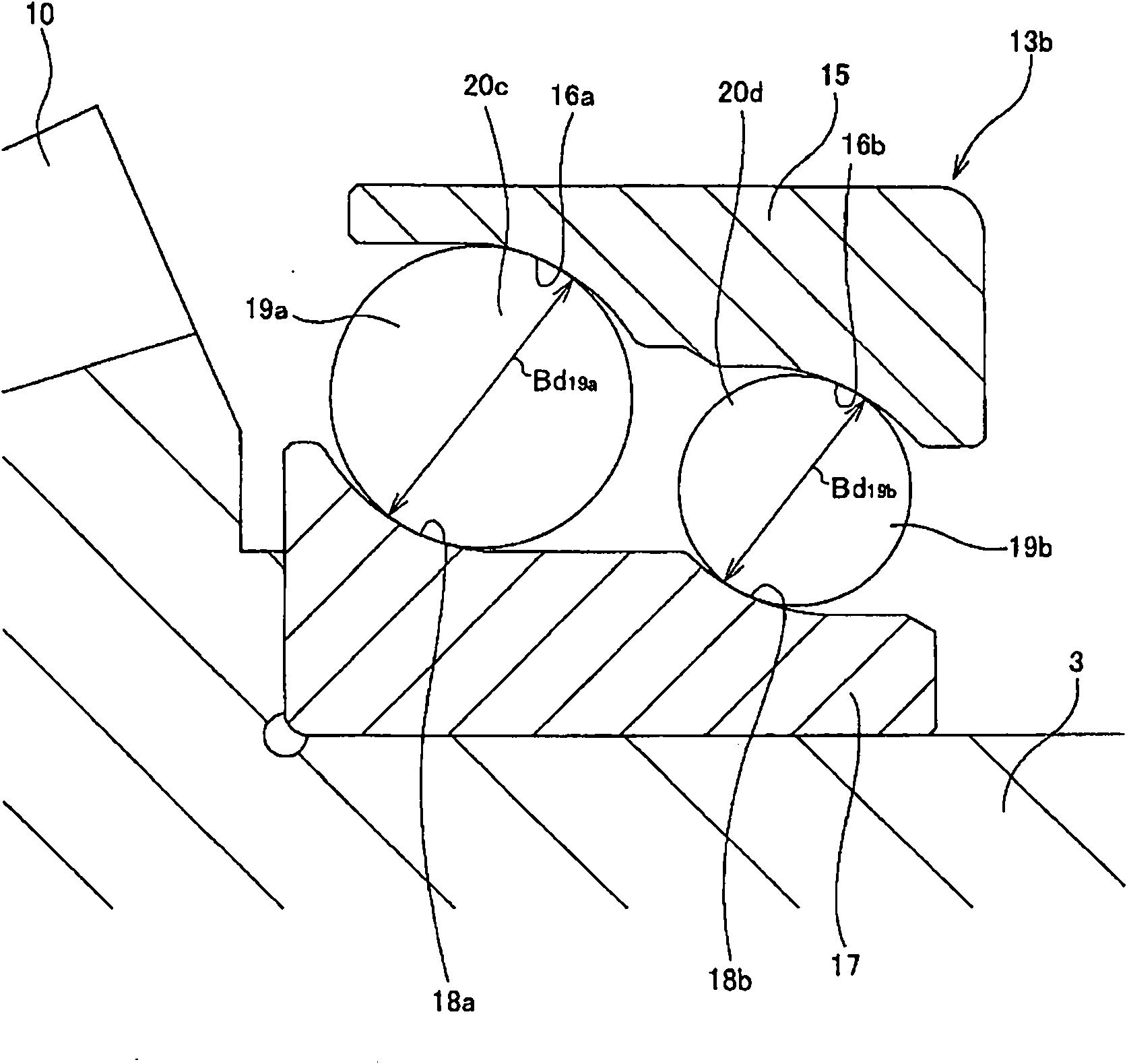

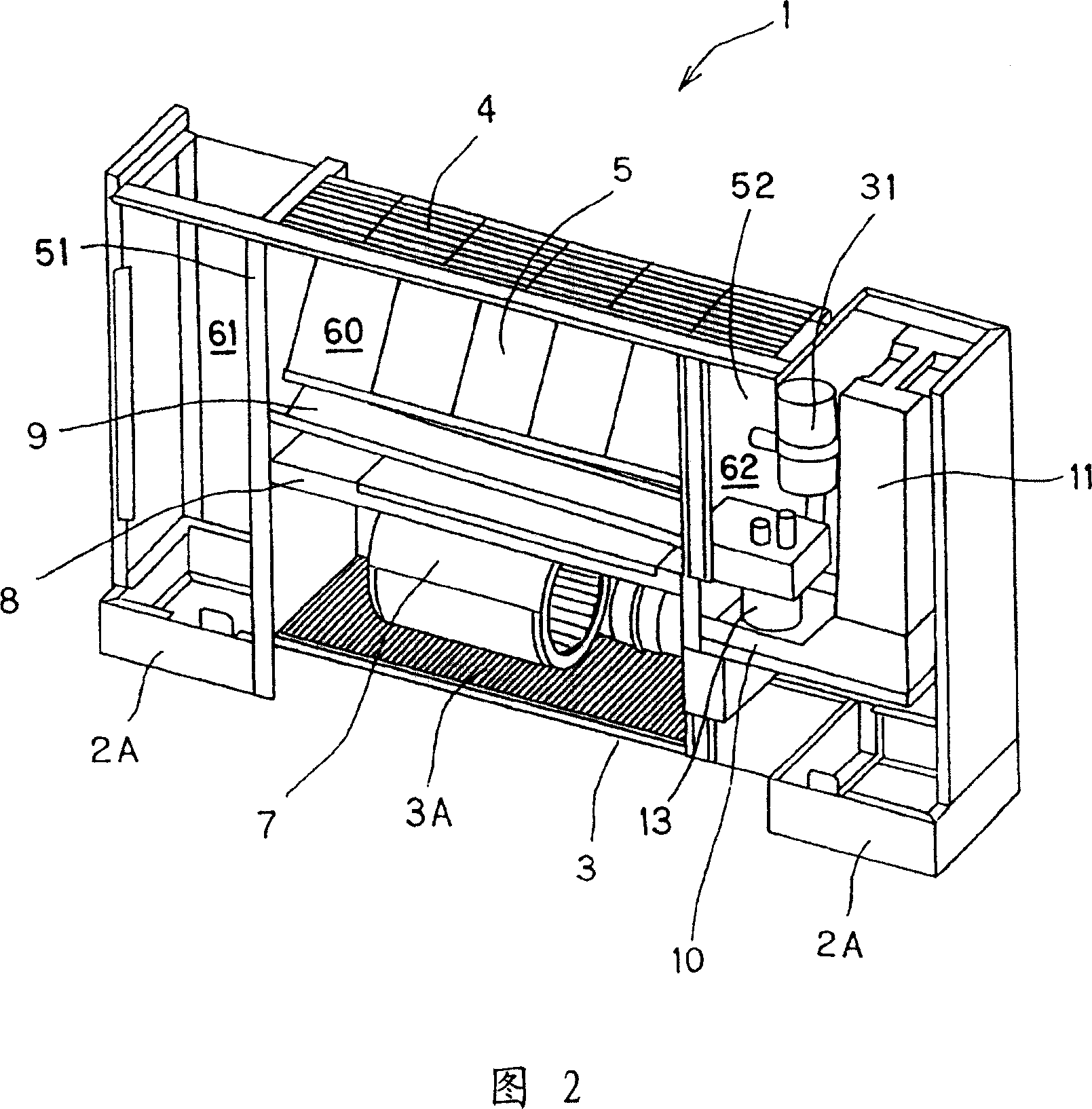

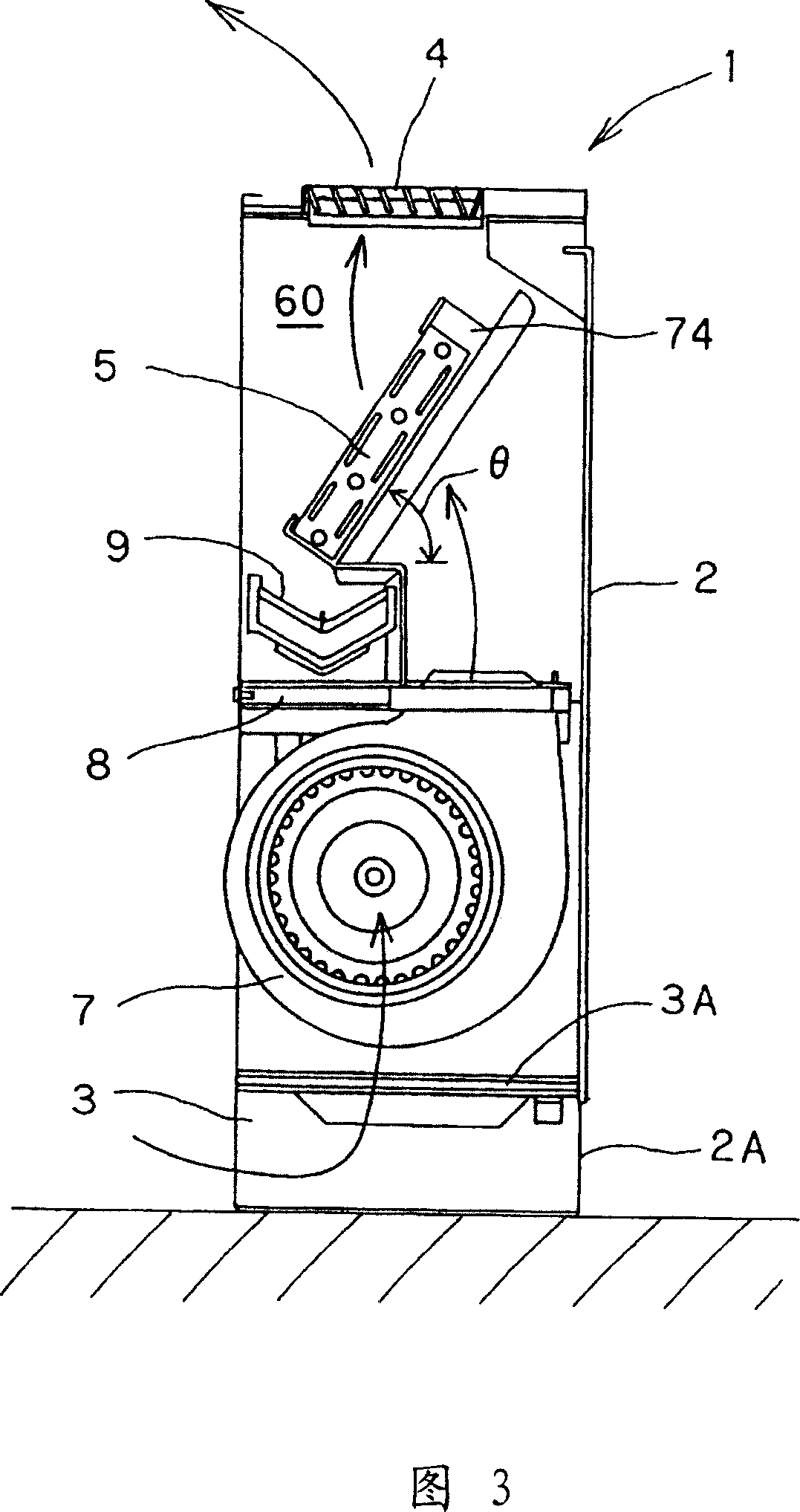

Immersion type membrane separation apparatus and method of operating the same

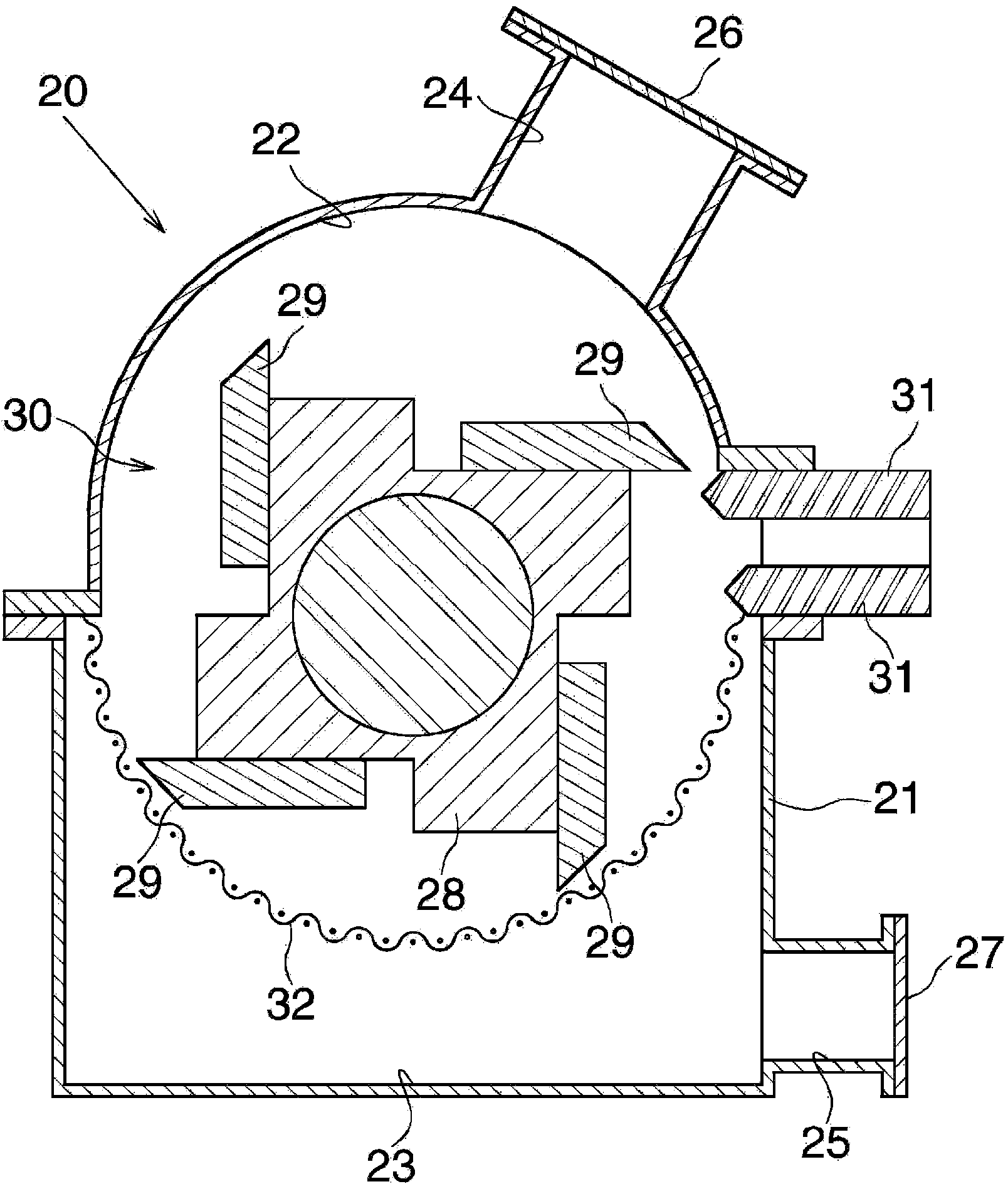

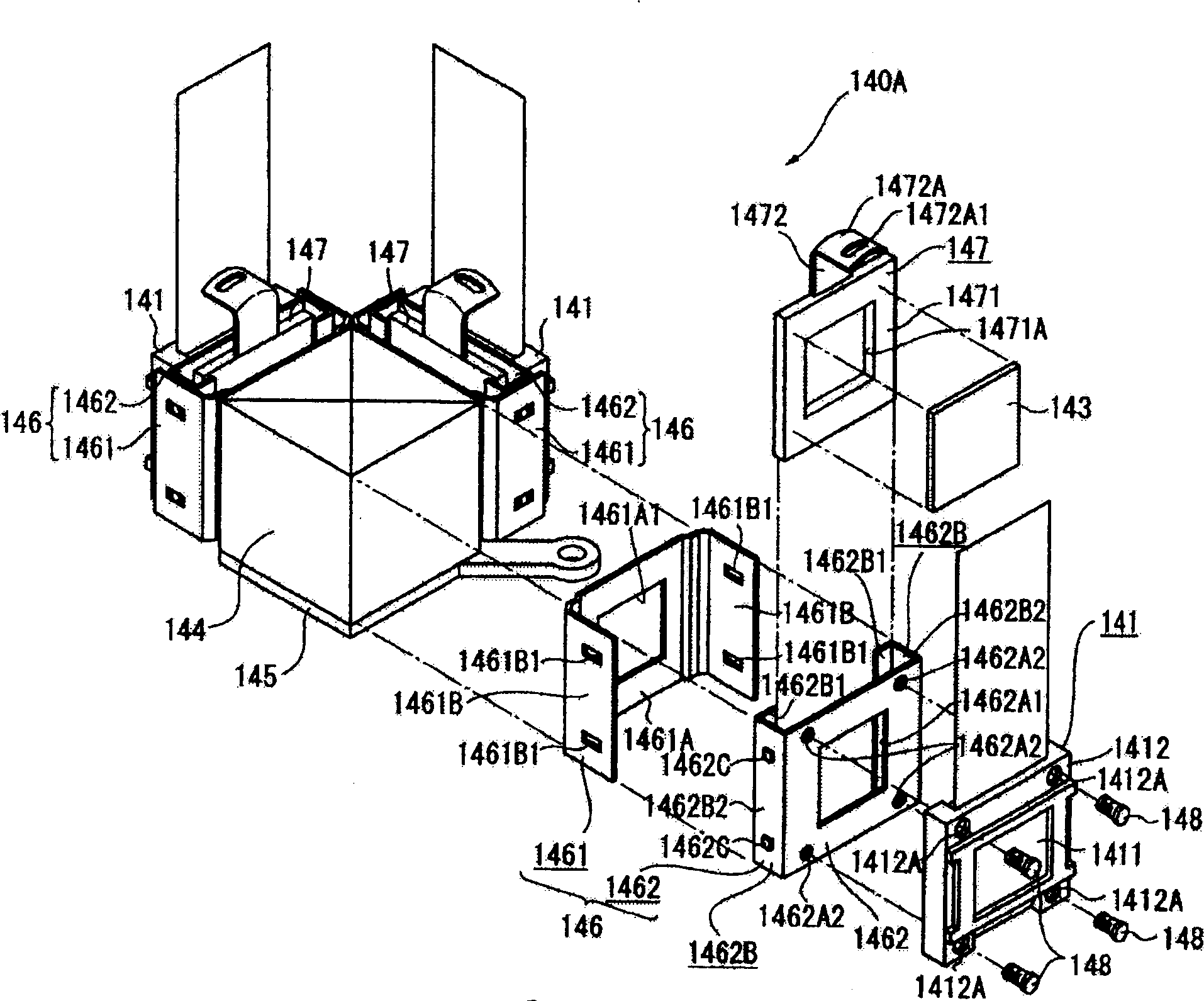

ActiveCN101678282ASeek long lifeWash evenlyMembranesTreatment using aerobic processesMicrobubblesLarge size

The invention provides an immersion type membrane separation apparatus having a microbubble dispersing tube placed vertically beneath a separation membrane module, in which even when the separation membrane module is of large size, there can be attained all-round uniform generation of microbubbles from an area vertically beneath the separation membrane module. The apparatus comprises a separation membrane module (2) having multiple separation membrane elements each using a flat membrane as a separation membrane disposed in parallel so that the membrane surfaces are parallel to each other; multiple microbubble dispersing tubes (4) placed vertically beneath the separation membrane module; and multiple gas supply tubes (5) for supplying a gas to the microbubble dispersing tubes. The multiple gas supply tubes (5) are arranged so as to be opposite to each other across an area vertically beneath the separation membrane module. The multiple microbubble dispersing tubes (4) connected in communicating relationship to the gas supply tubes are arranged so as to extend in a direction crossing a membrane surface of separation membrane element and so as to realize proximity to each other, or superposition on each other, of the distal ends of the opposite microbubble dispersing tubes.

Owner:TORAY IND INC

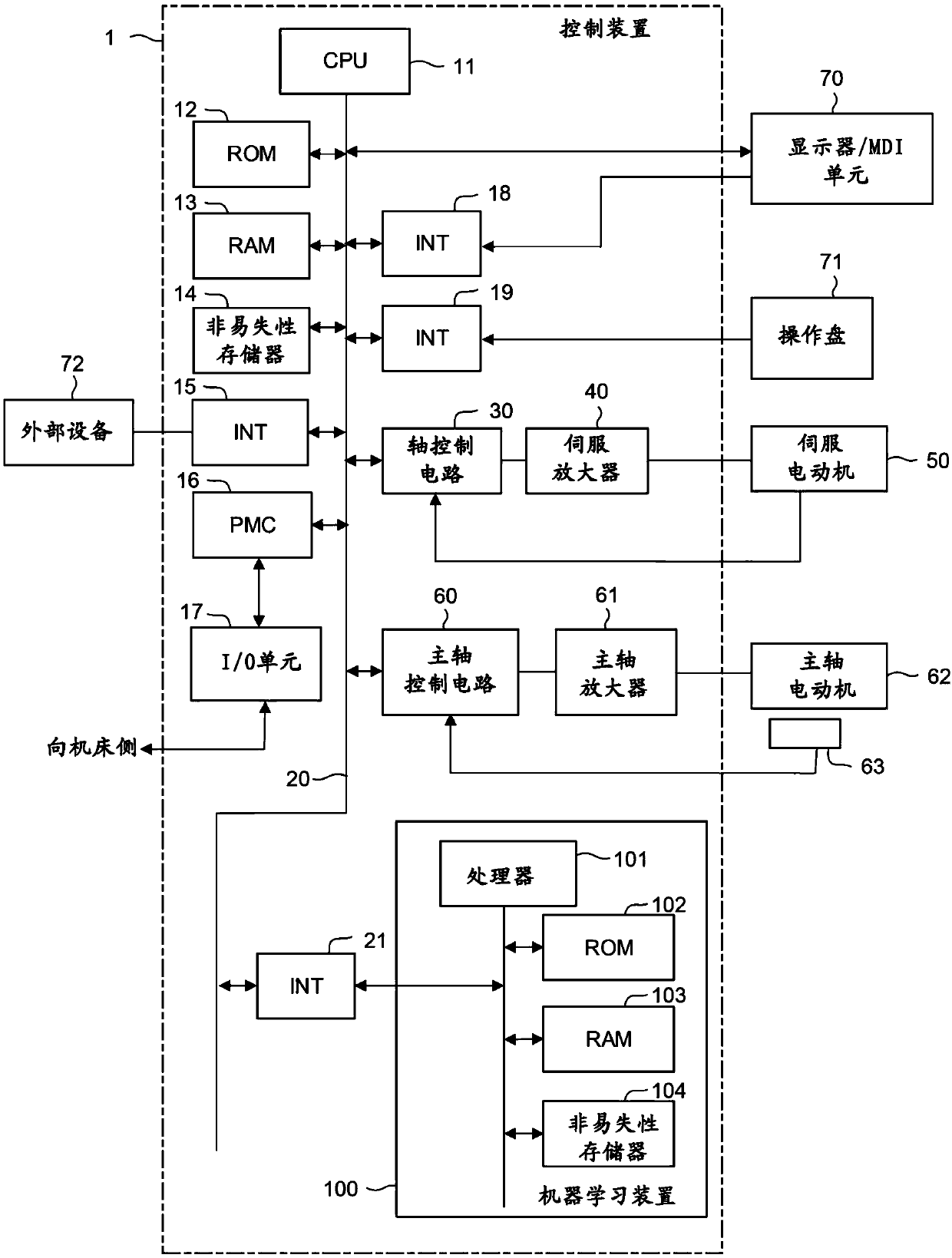

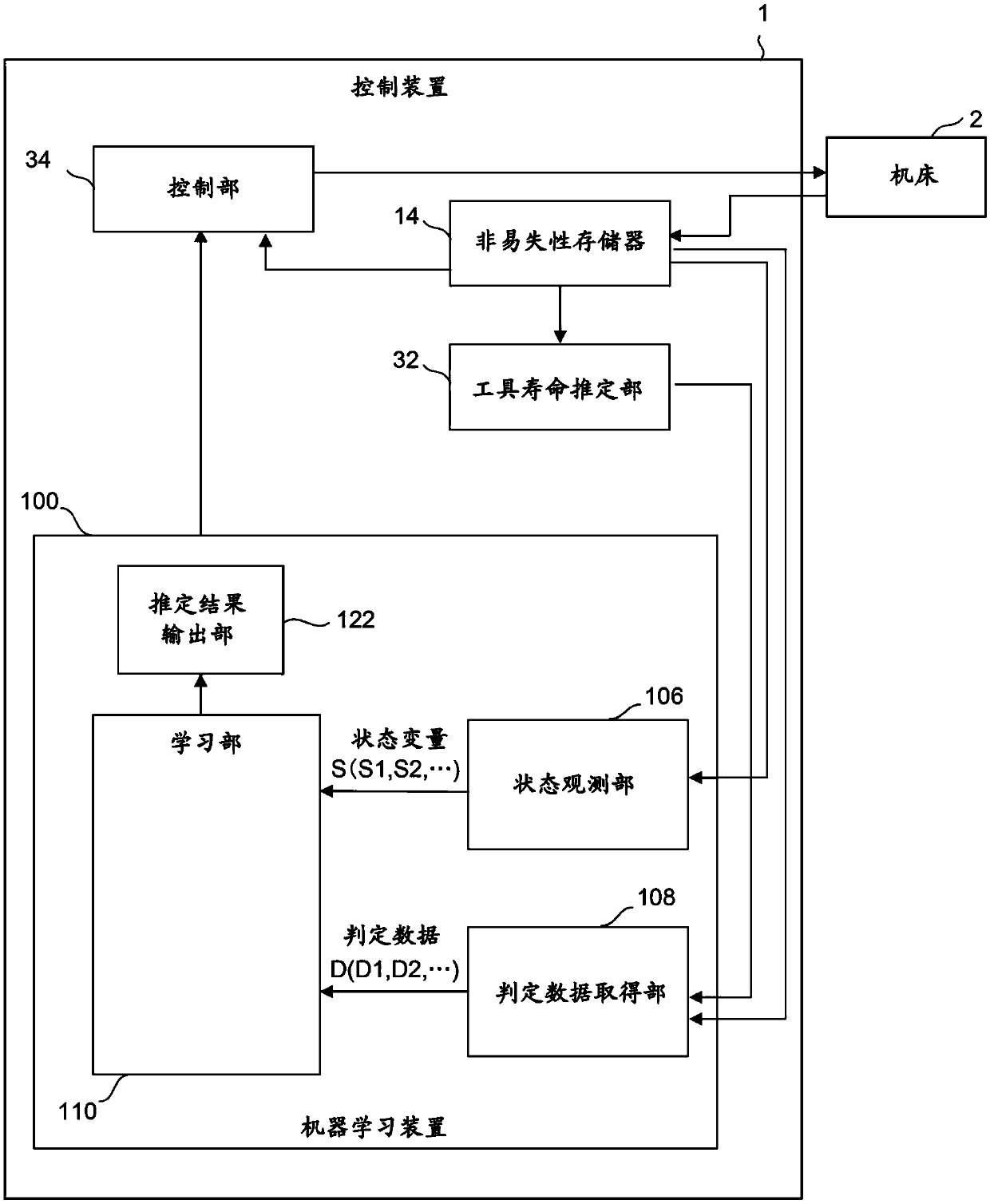

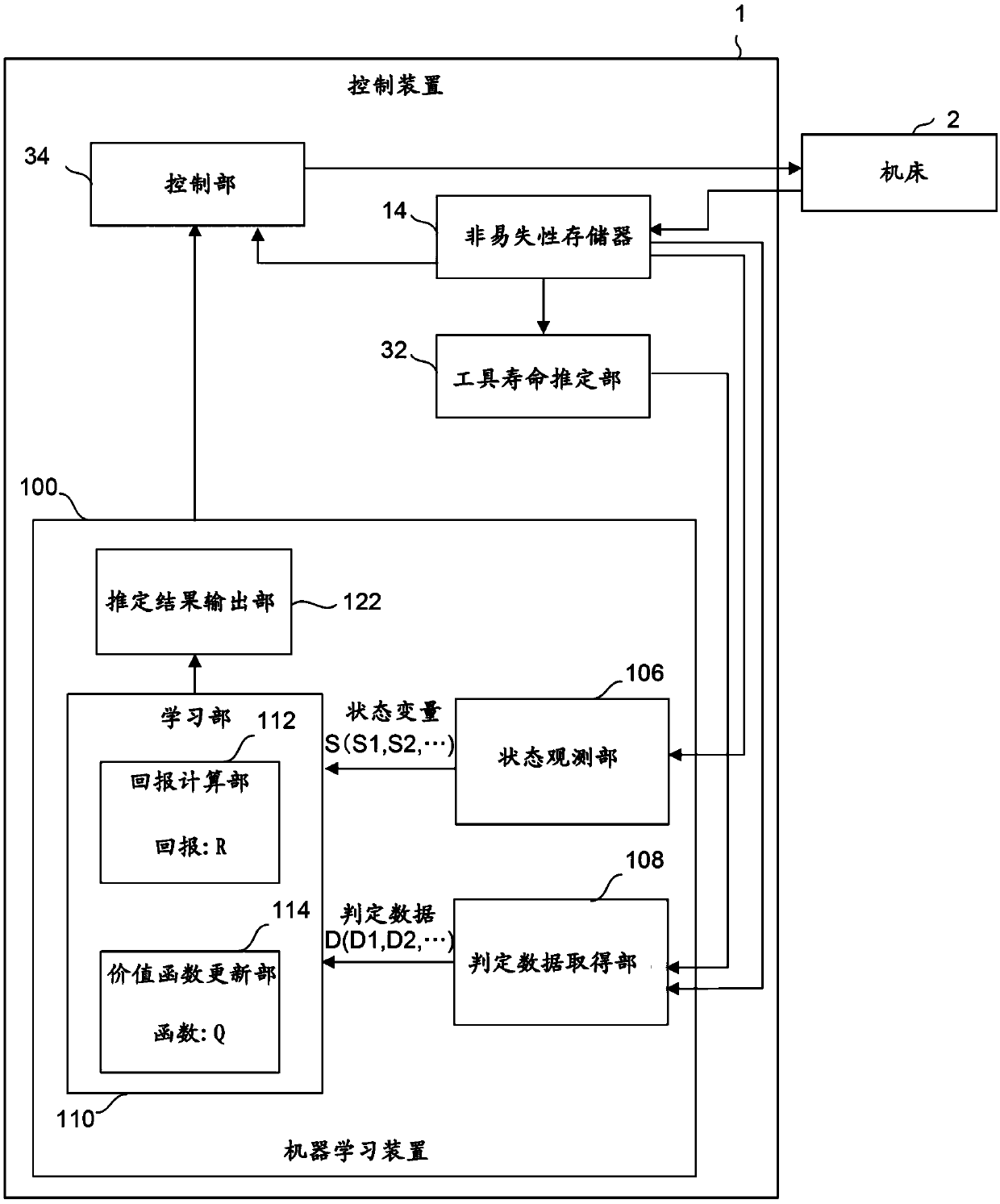

Control device and machine learning device

The present invention provides a control device and a machine learning device, wherein the machine learning device provided in the control device can determine parameters of the PID control, and the parameters of the PID control can extend the life of the tool without increasing the cycle time to a required degree or more. The machine learning includes a state observation unit that observes, as state variables representing a current state of an environment, PID control parameter data indicating the a parameter of the PID control during machining, machining condition data indicating a machiningcondition of the machining, and machining environment data relating to a machining environment of the machining, a determination data acquisition unit that acquires, as determination data, tool lifedetermination data indicating an appropriateness determination result relating to depletion of the life of a tool during the machining, and cycle time determination data indicating an appropriatenessdetermination result relating to the cycle time of the machining, and a learning unit that learns the machining condition and the machining environment of the machining, and the parameter of the PID control in association with each other.

Owner:FANUC LTD

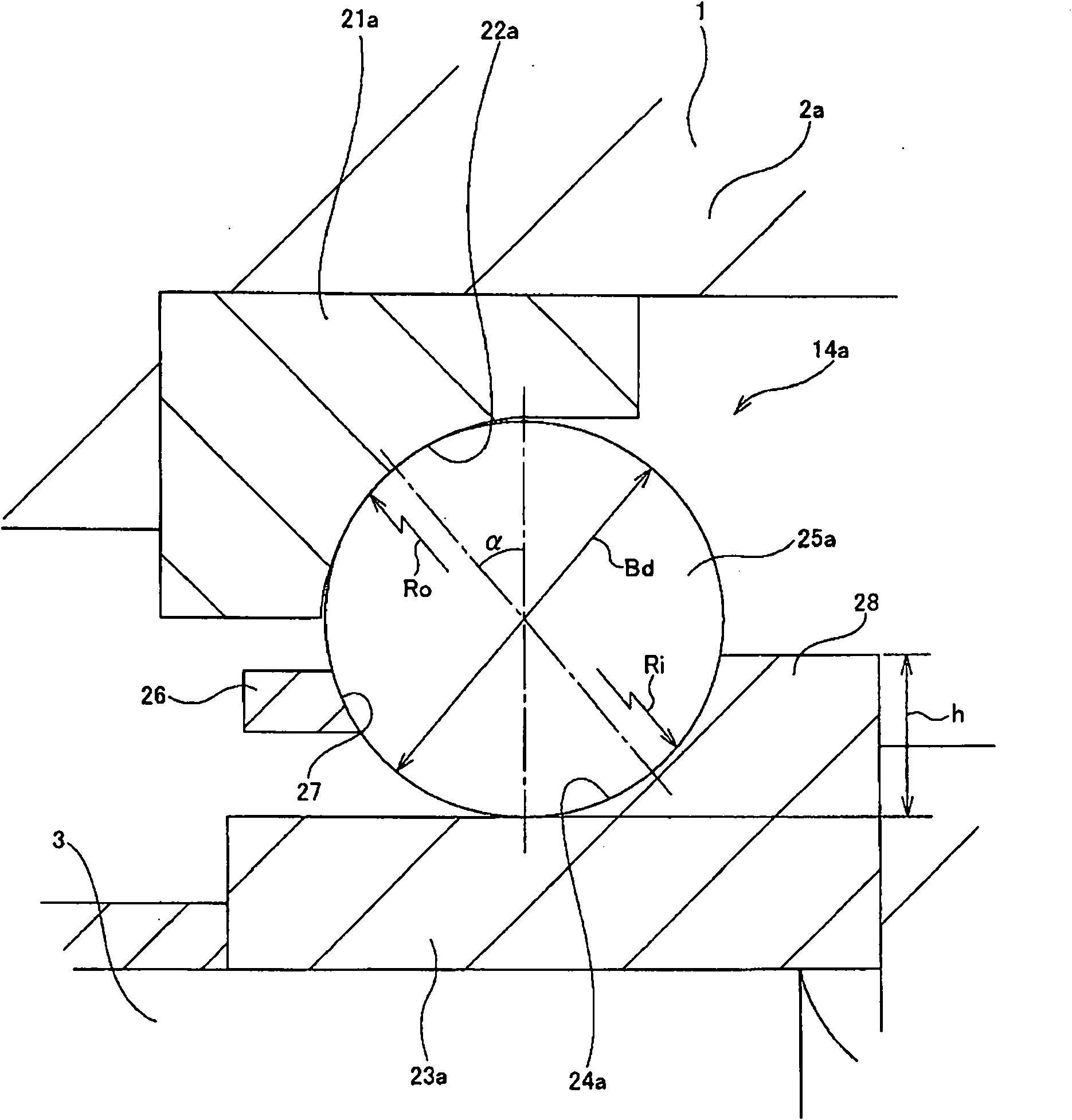

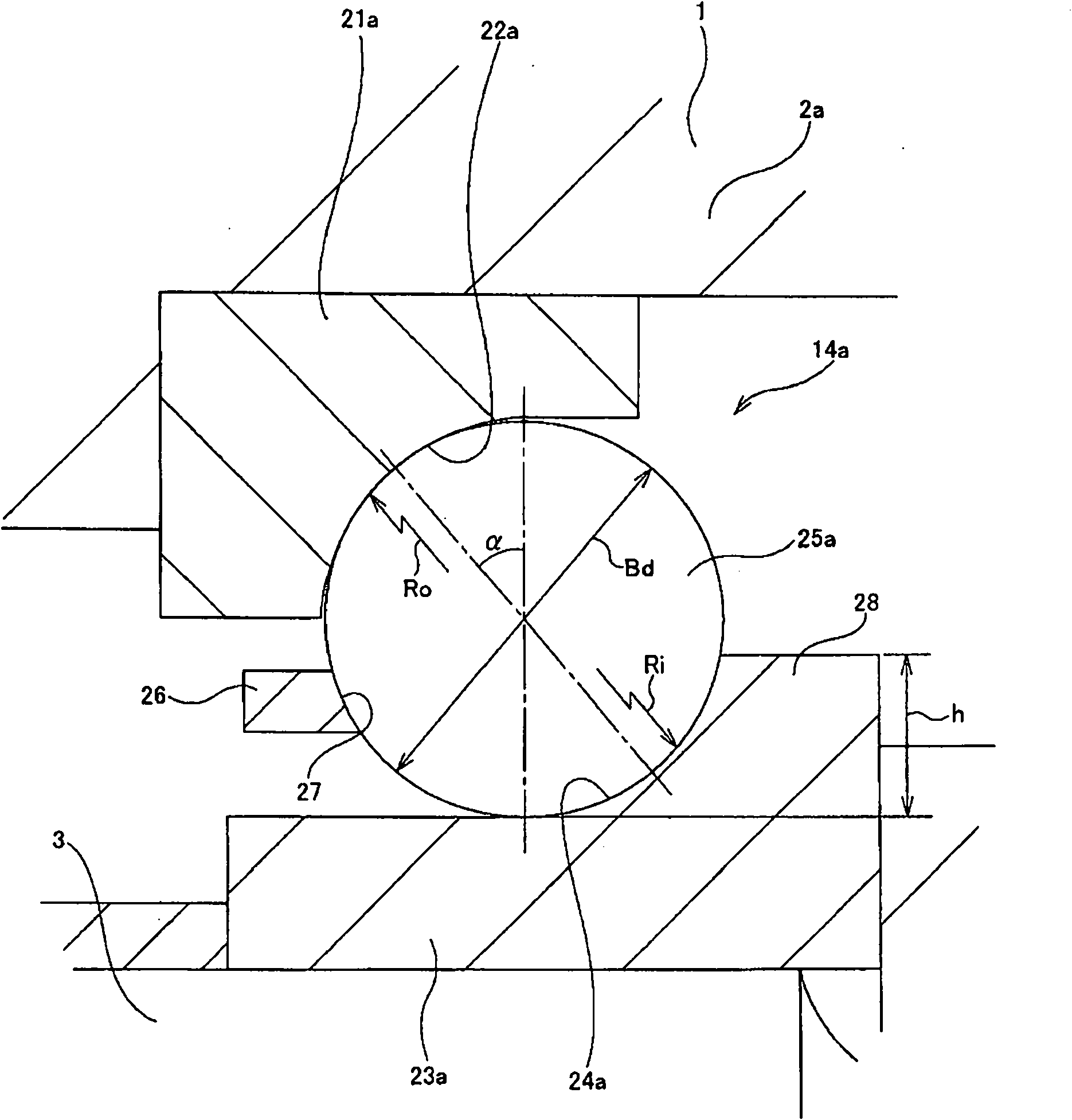

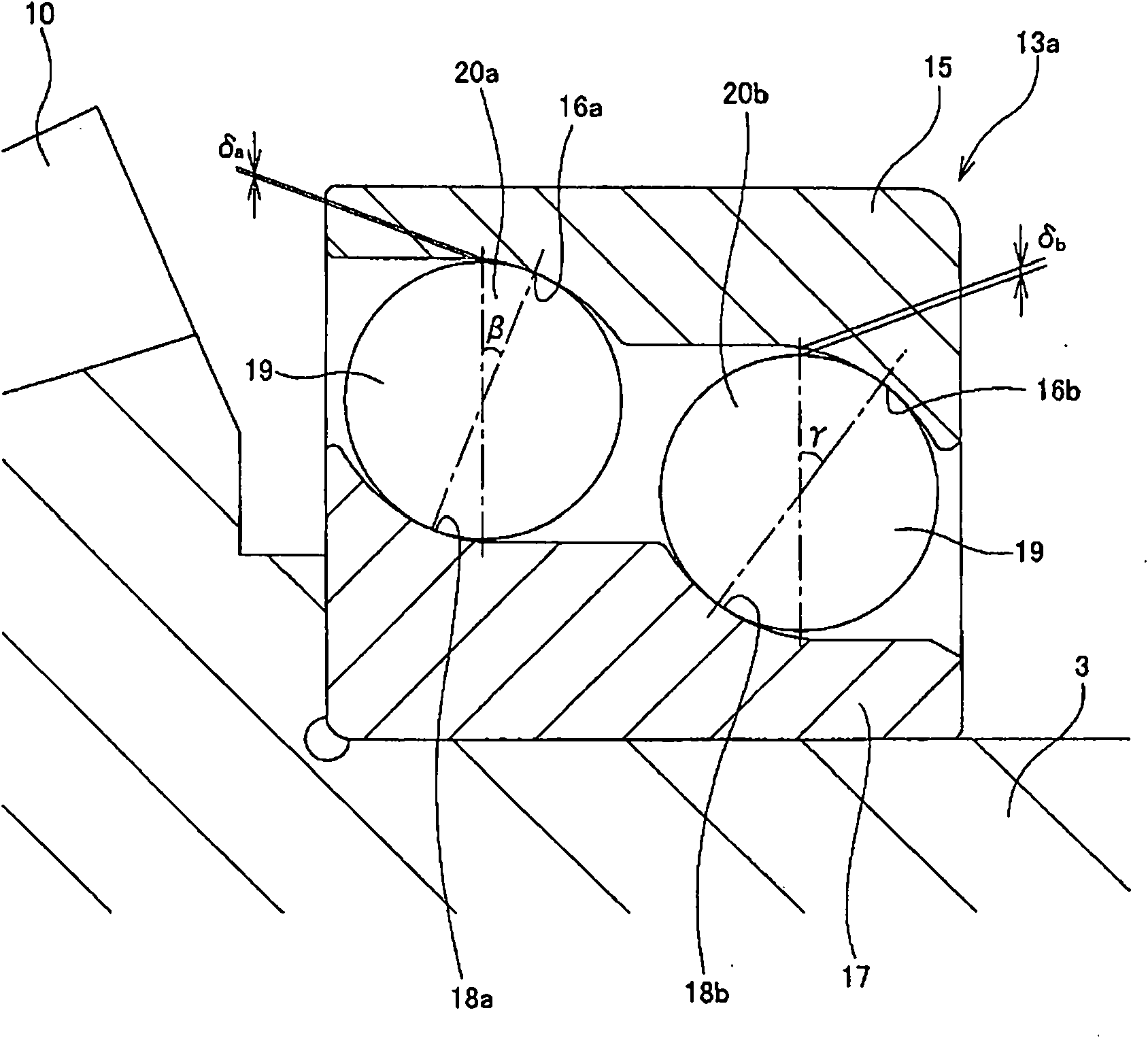

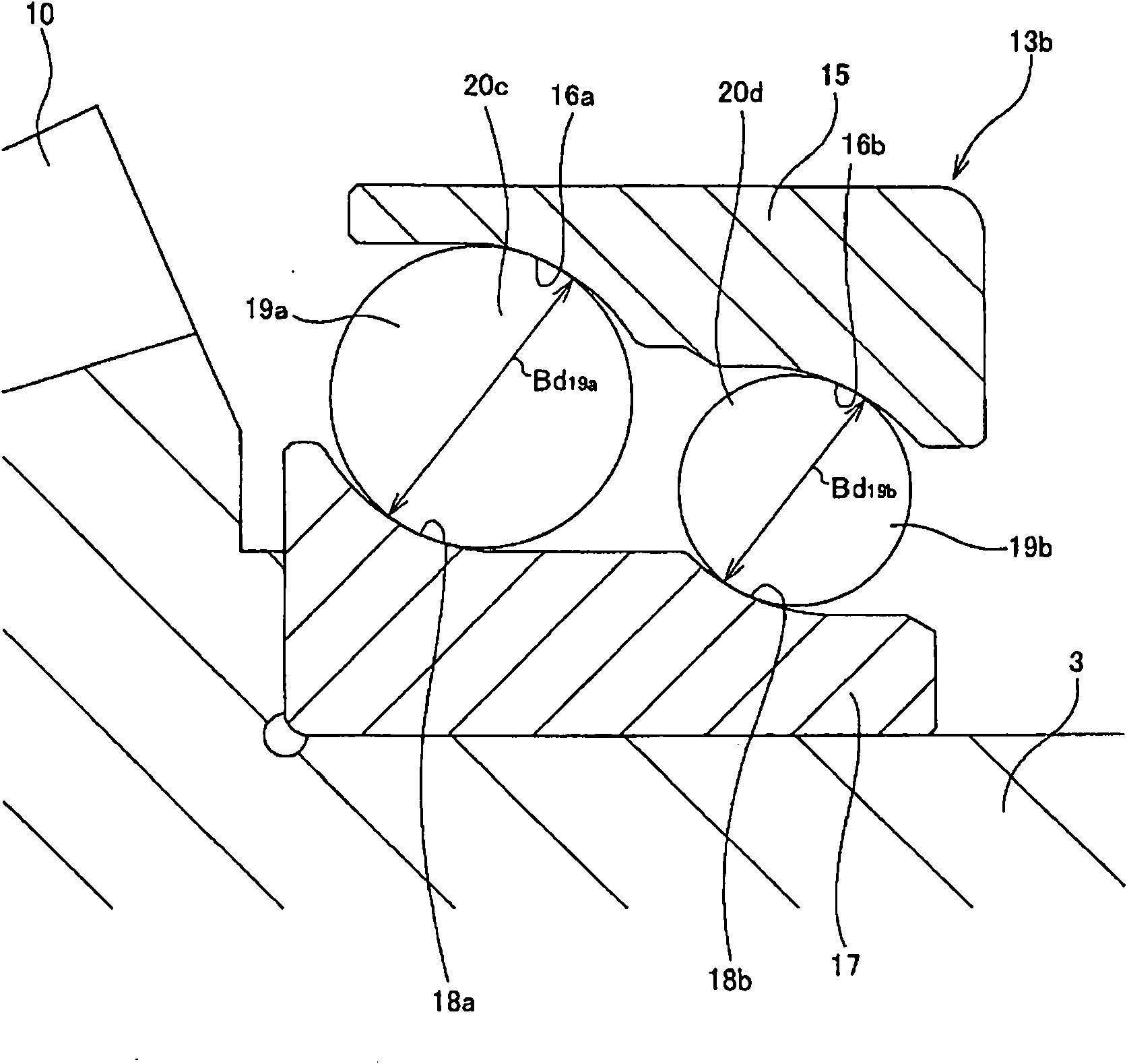

Rotation support device for pinion shaft

InactiveCN102171469AGuaranteed rigidityReduce dynamic torqueBearing assemblyShaftsBall bearingEngineering

Provided is a rotation support device for a pinion shaft, said device having a structure whereby it is possible to ensure that a rolling bearing on the opposite side from a pinion gear has sufficient axial rigidity while reducing the dynamic torque during operation and the starting torque upon operation startup. A single-row angular contact ball bearing (14a) is used as the rolling bearing on the opposite side from the pinion gear. The ratio (Ro / Bd) between the radius of curvature (Ro) of the outer race track (22a) and the diameter (Bd) of each ball (25a) is adjusted to be within the range of 0.52 < Ro / Bd <= 0.56, and the contact angle (alpha) is adjusted to be within the range of 35 DEG to 45 DEG.

Owner:NSK LTD

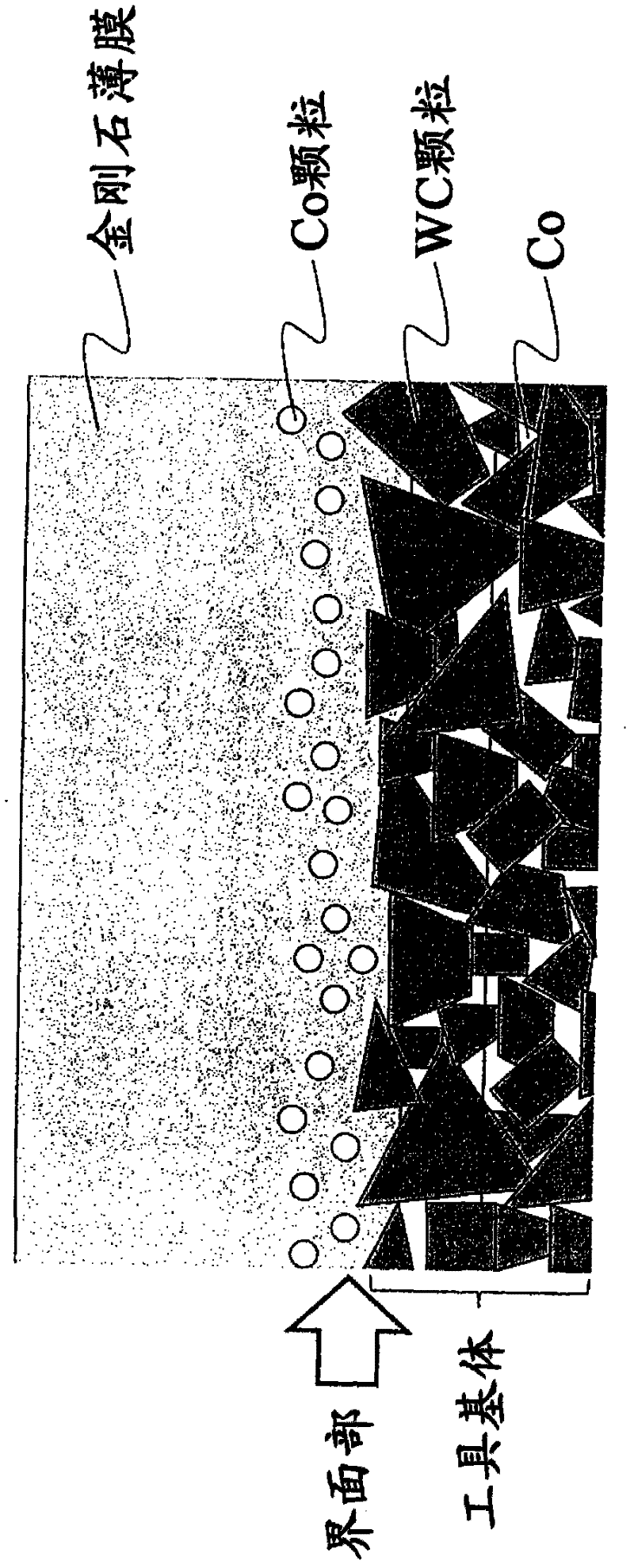

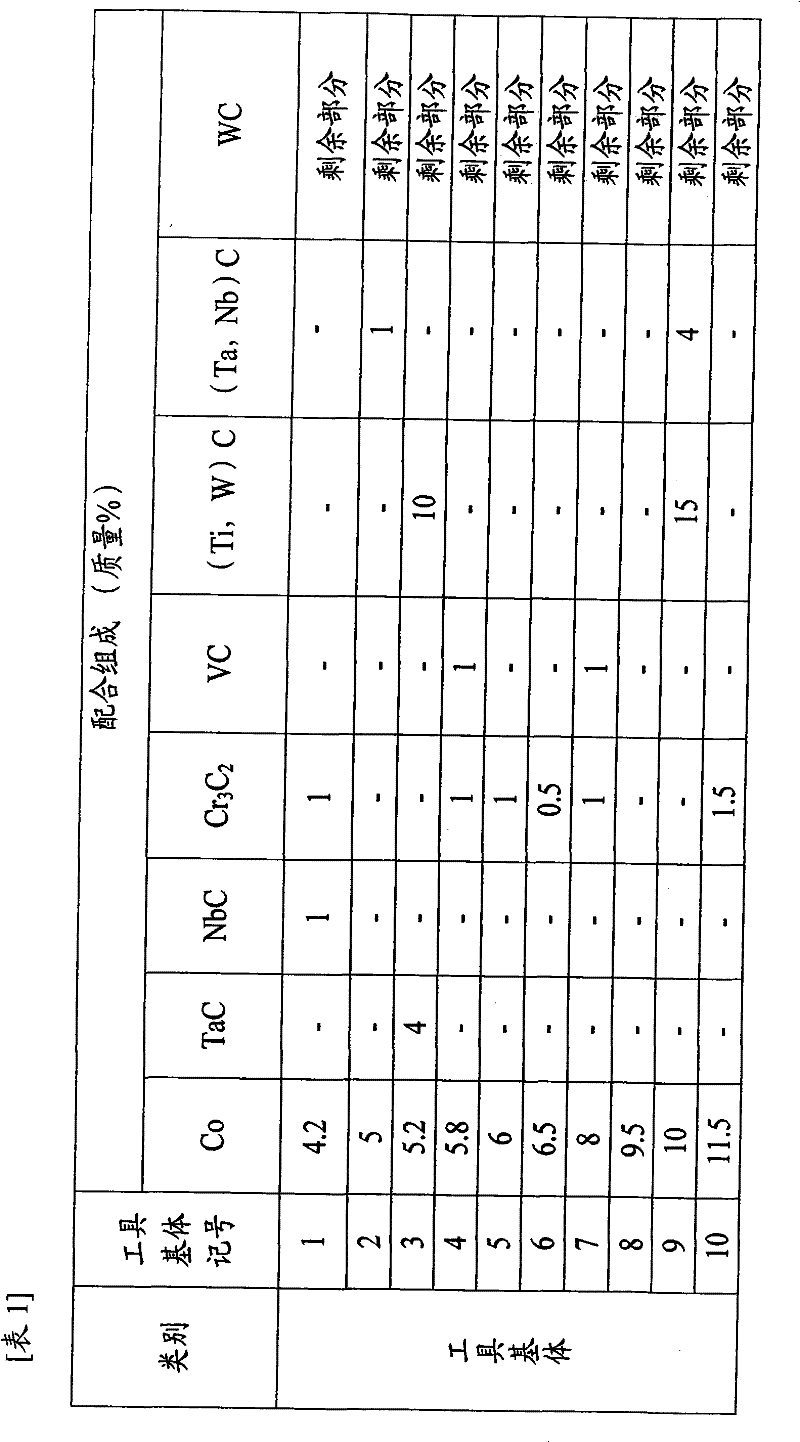

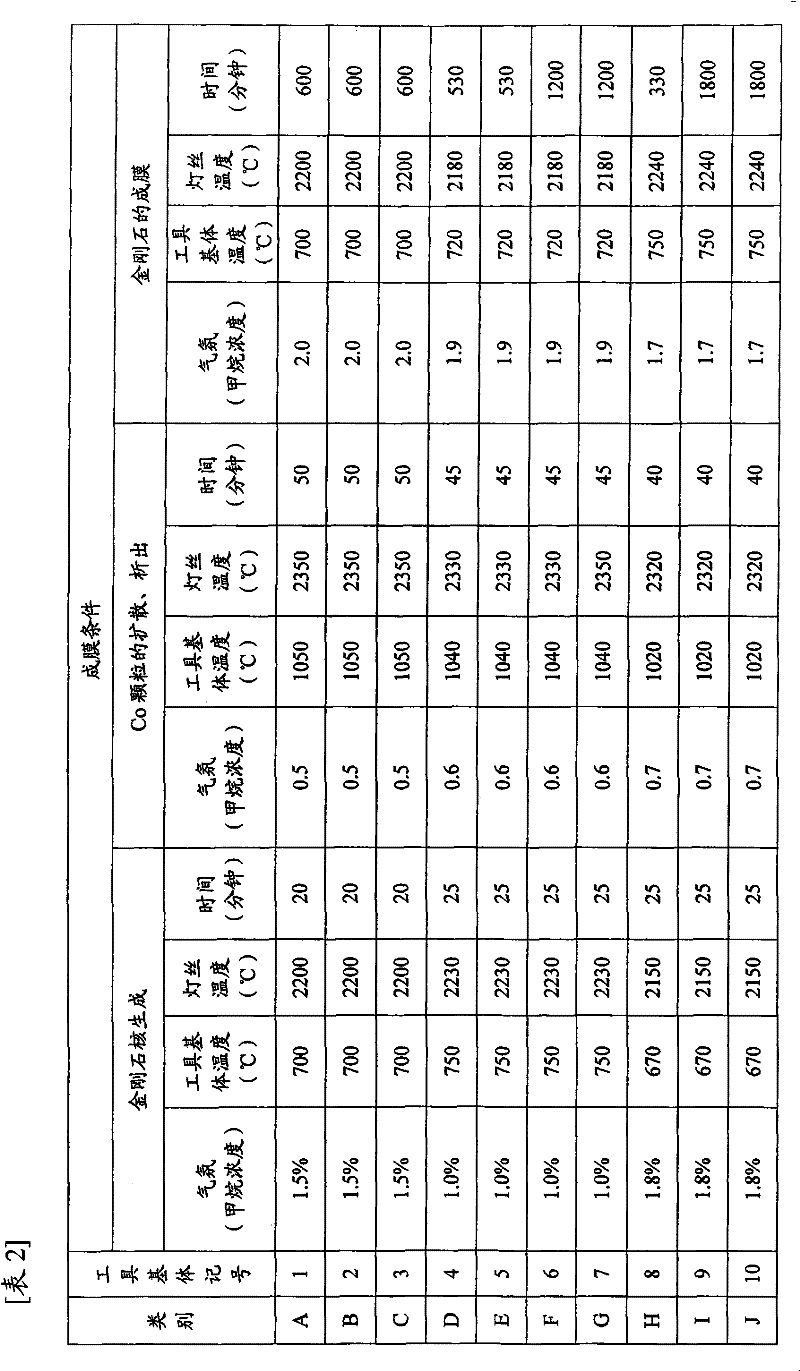

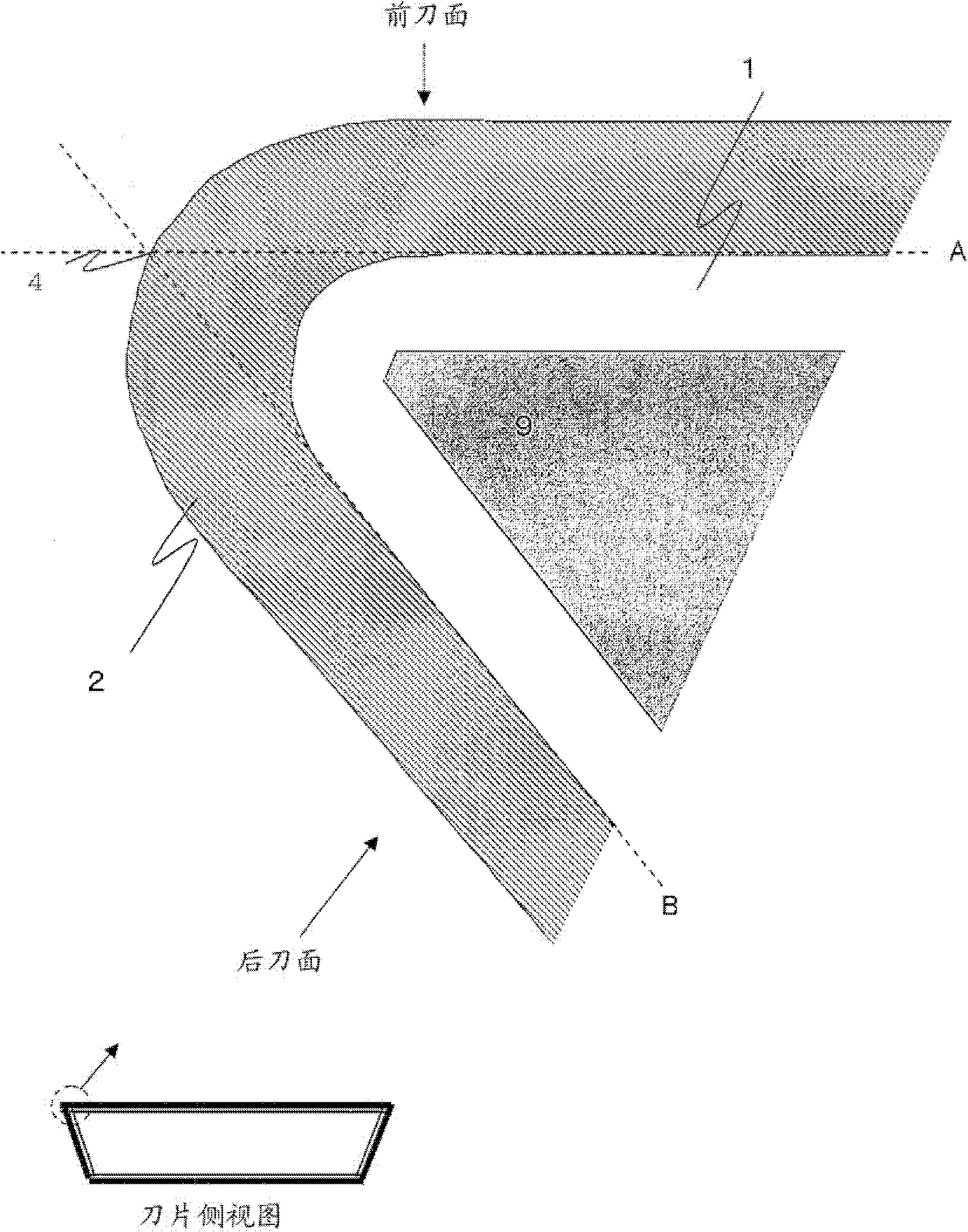

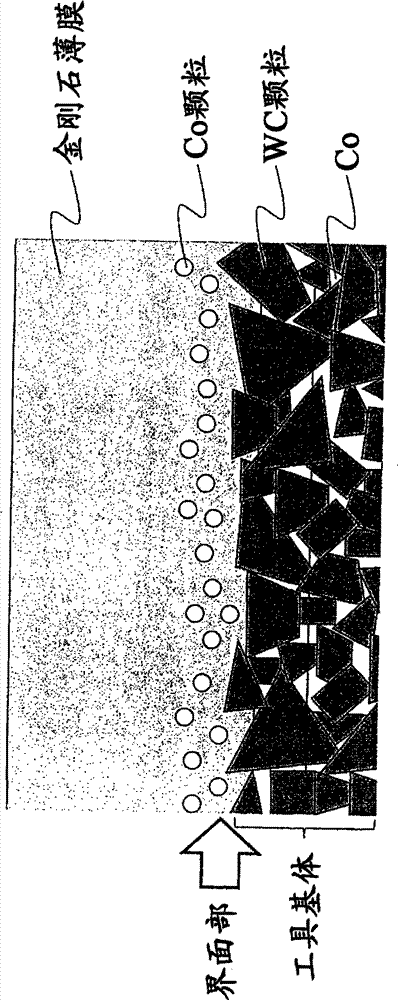

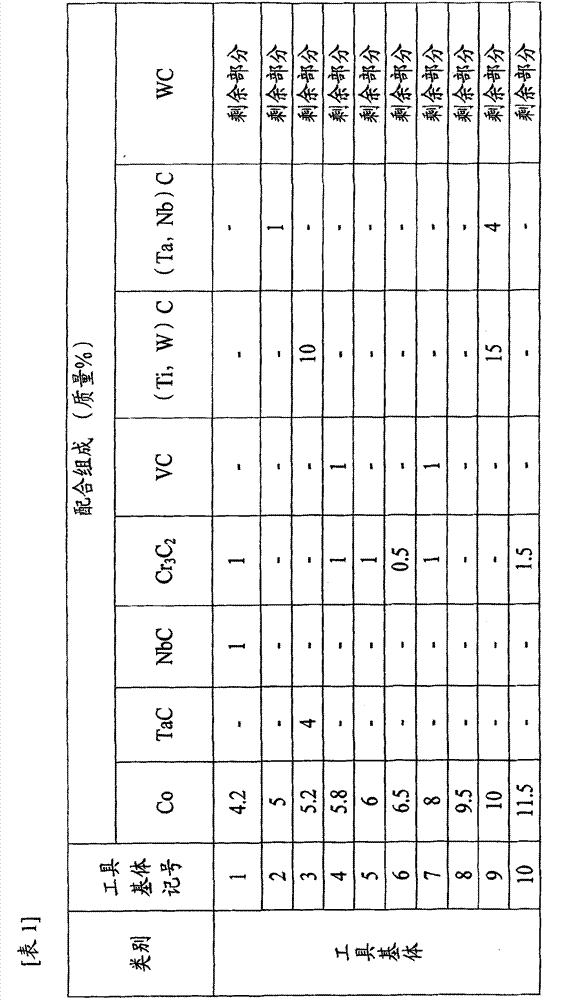

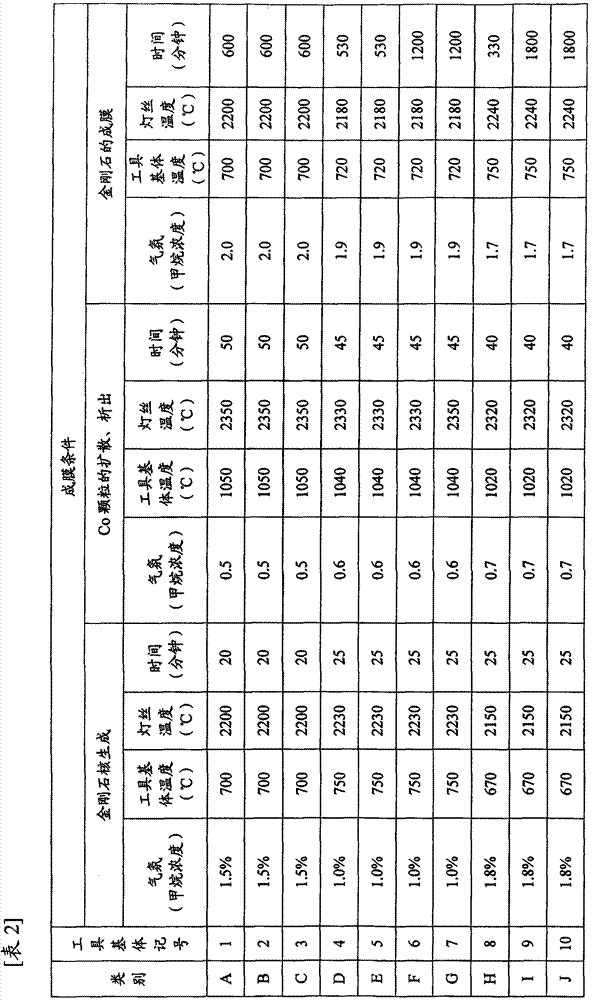

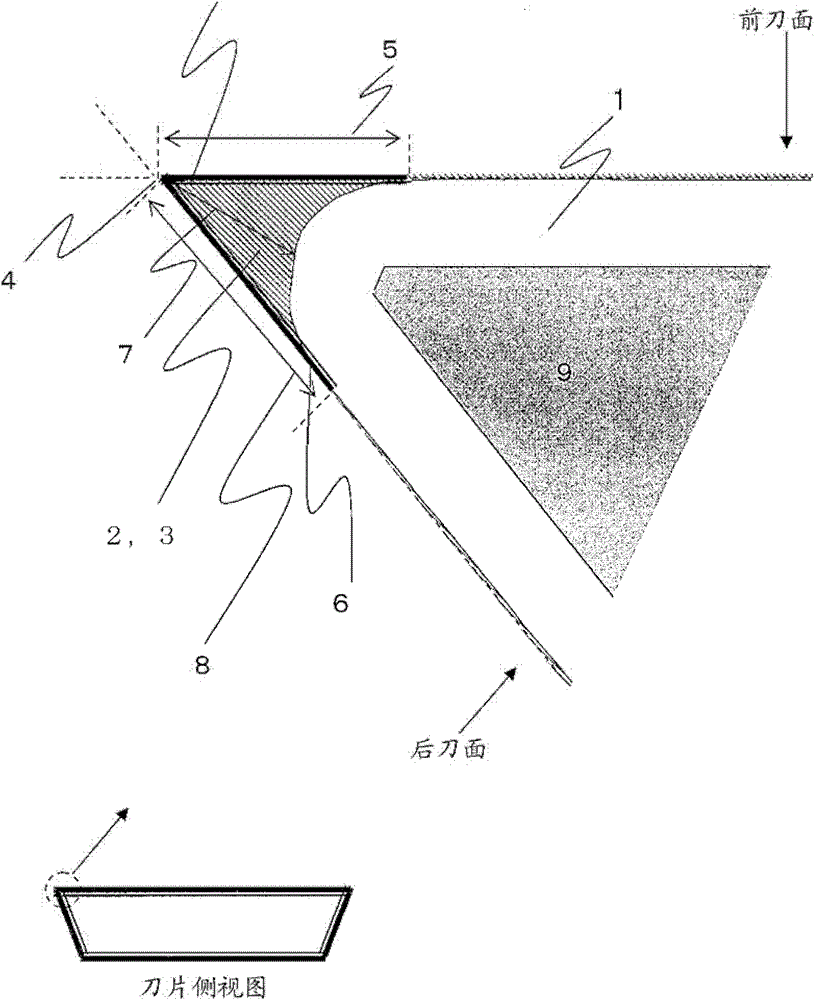

Diamond coating and cutting element

ActiveCN102198523ASeek long lifePrevent peelingTurning toolsChemical vapor deposition coatingCemented carbideTitanium carbonitride

The invention provides a diamond coating and cutting element, which has anexcellent adhesiveness in the cutting process of materials hard to be cut like aluminium alloys or graphites, CFRP materials and performs excellent wear resistance during a long-term use. Diamond films in thickness of 5-30Mum are coated on the surface of the diamond coating and cutting element composed by tungsten carbide-based hard alloys or titanium carbonitride-based cermet. Co particles with average diameter of 5-200nm are precipitated at the diamond film side of interface portion between the element body and the diamond films, and the proportion of Co particles is 0.1-20 atom%.

Owner:MITSUBISHI MATERIALS CORP

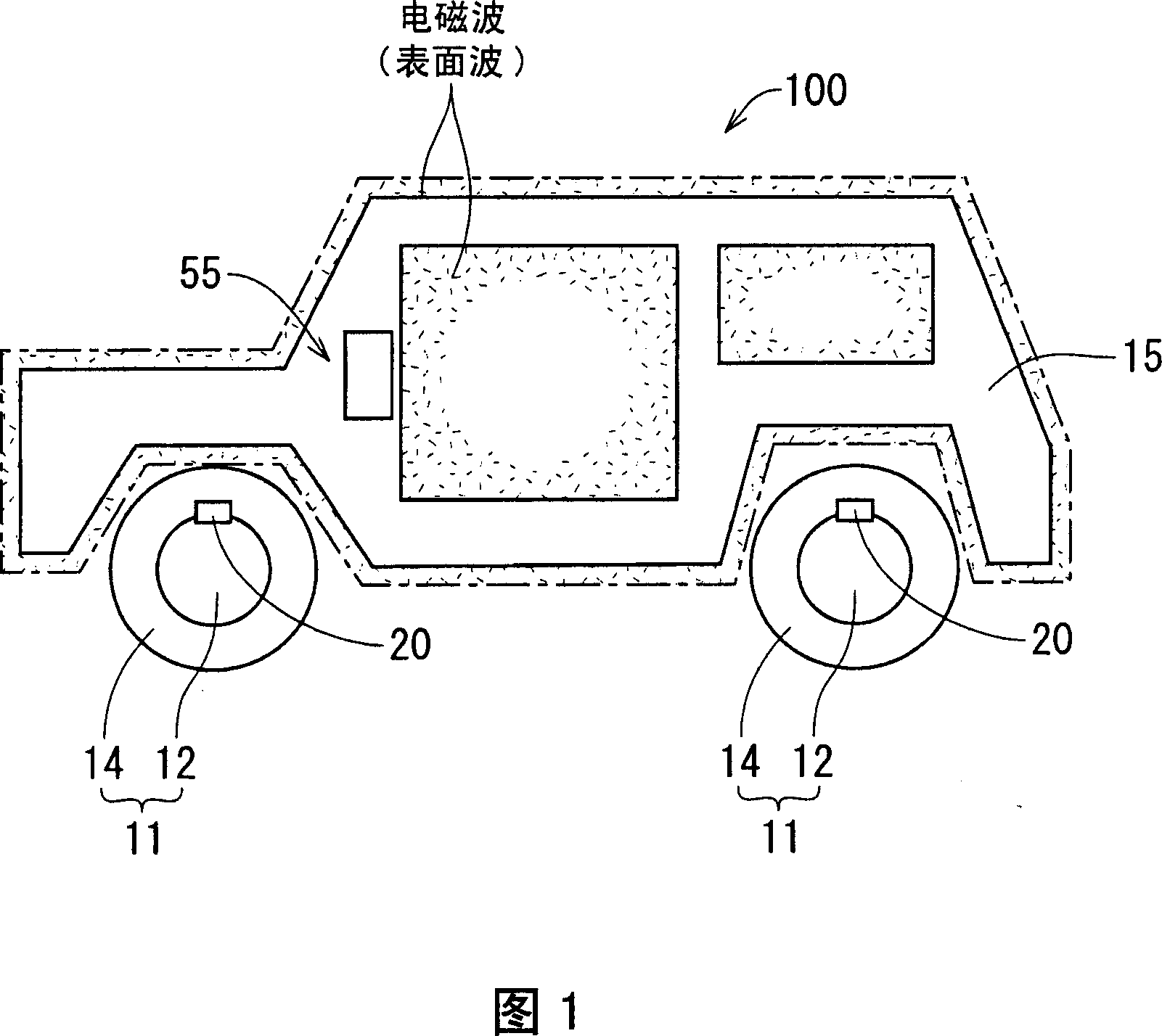

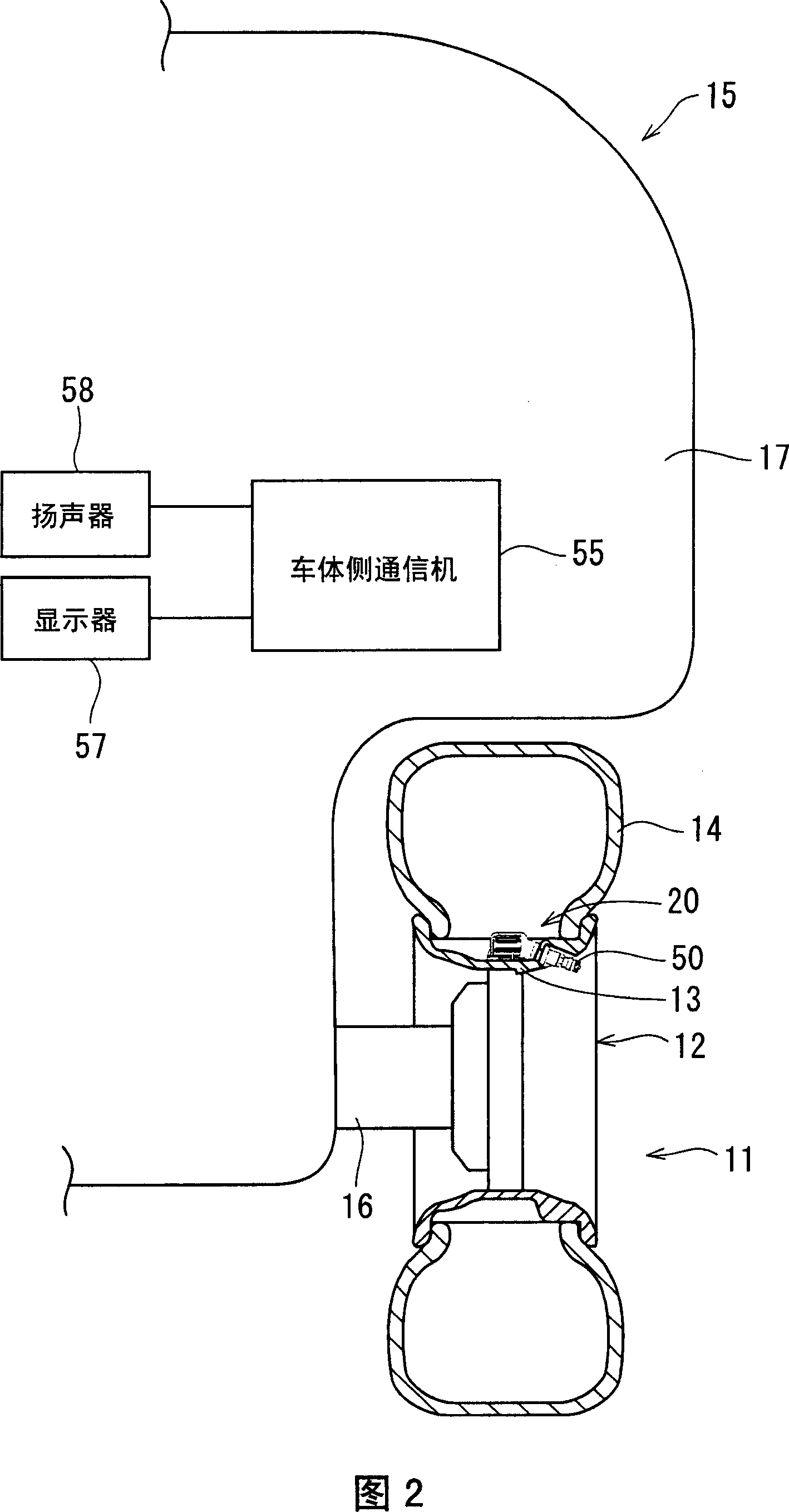

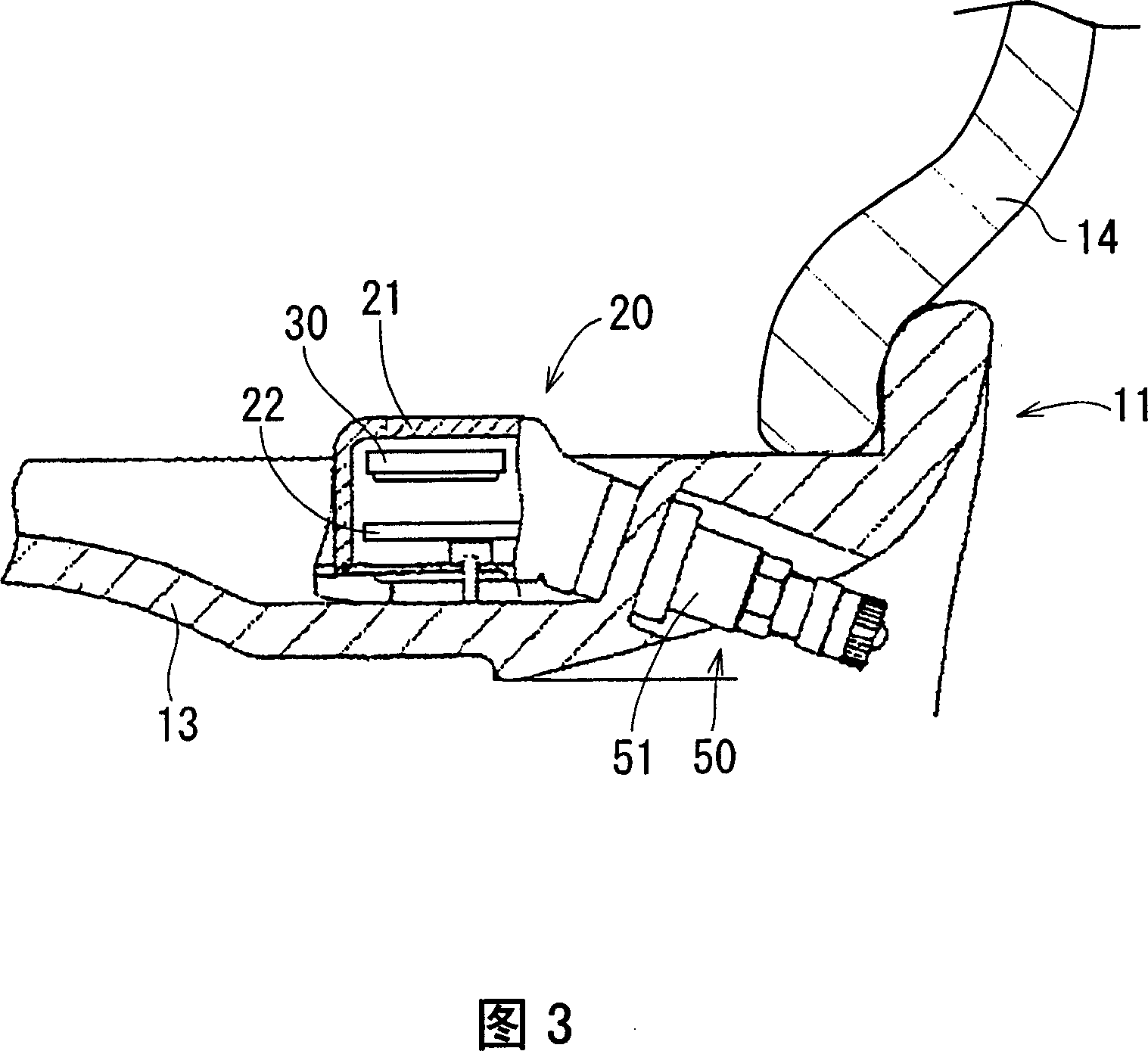

Tire condition monitoring system

InactiveCN1975796AImprove reliabilityPrevent false receptionTransmission systemsTyre measurementsMonitoring systemMicrocell

The object is to provide a tire condition monitoring system in which power consumption upon output of information by the tire side communication device can be reduced as compared with the conventional tire condition monitoring systems. According to the present inventive tire condition monitoring system 10, the tire side communication devices 20 superimpose detection information on the electromagnetic waves, delivering the electromagnetic waves as surface waves of the tire wheel 12 and vehicle body 15. Accordingly the power comsumption in output of information can be reduced as compared with the conventional tire condition monitoring systems. Consequently, the size of the microcell 30 used in the tire side communication device 20 can be downsized and the life of the microcell 30 can be longer. More specifically, the tire condition monitoring system 10 of the embodiment consumes -10 dBm (0.1 mW) at the time of information output although a conventional system consumes 3 dBm (2 mW). Thus, the power consumption in inforrmation output can be reduced to one twentieth of that of the conventional system.

Owner:PACIFIC INDUSTRIAL CO LTD

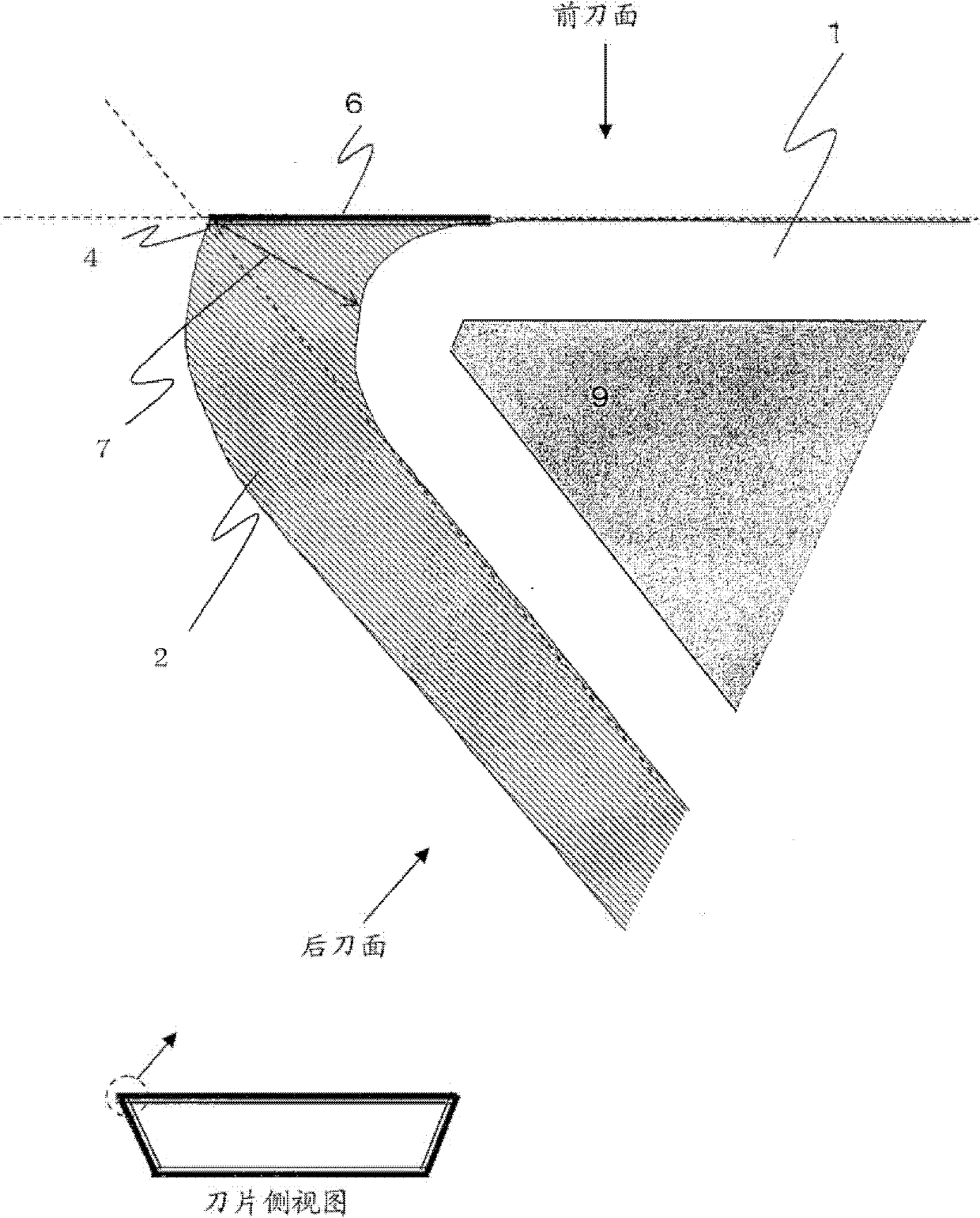

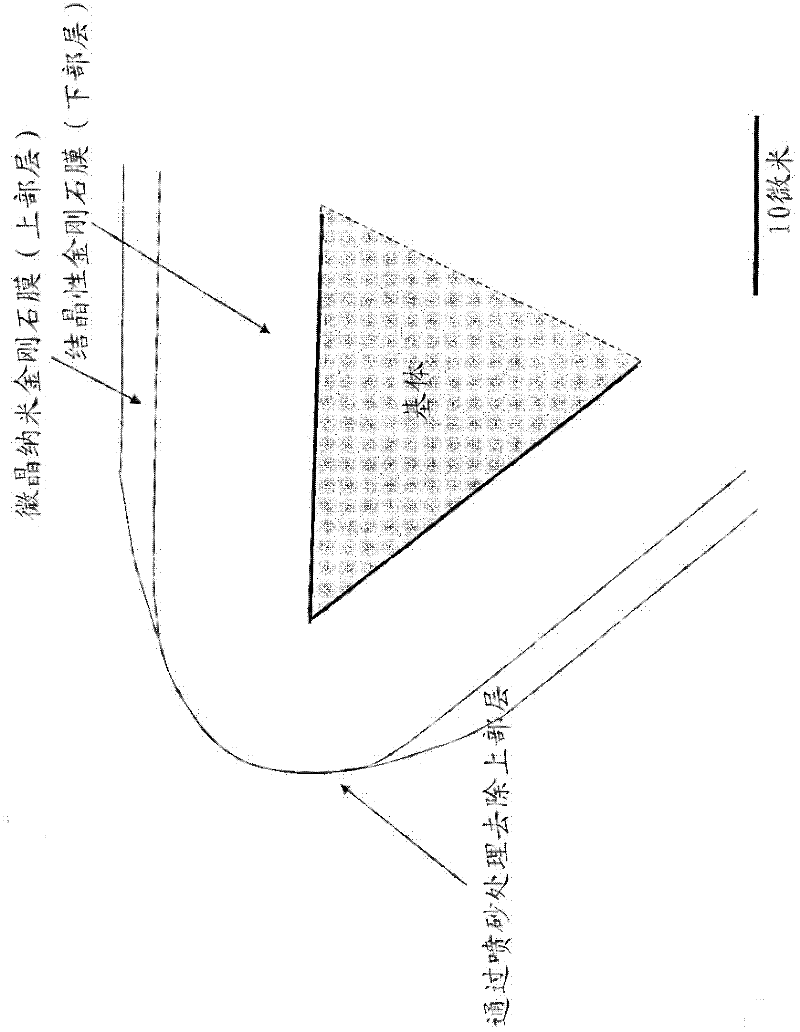

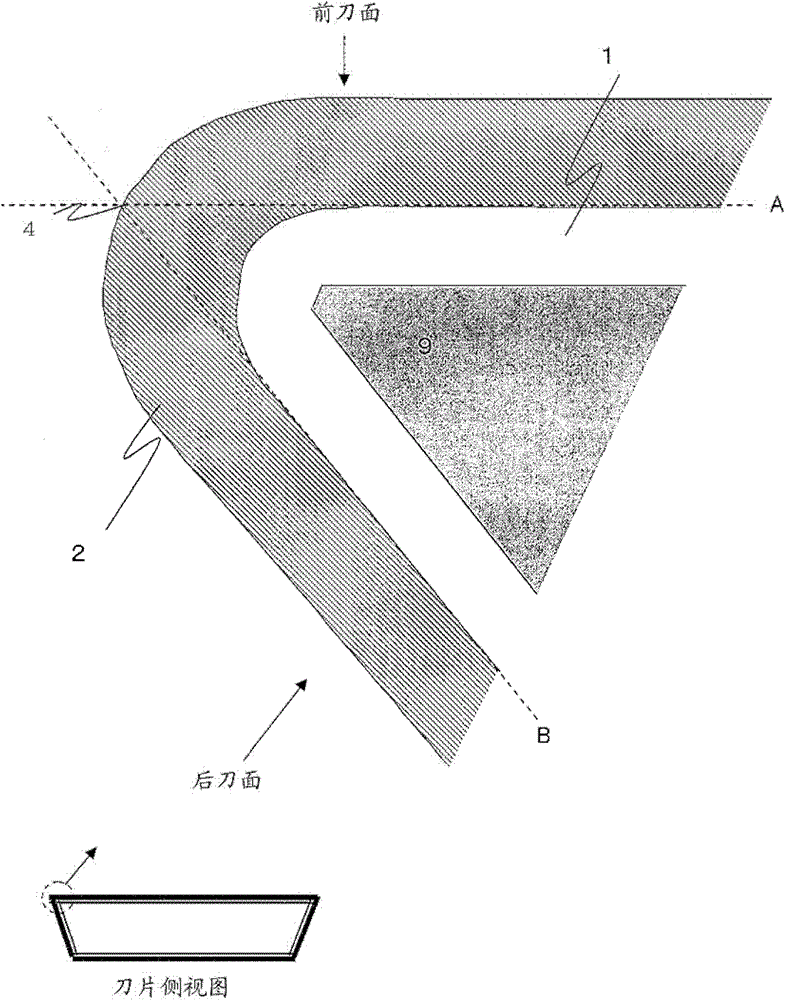

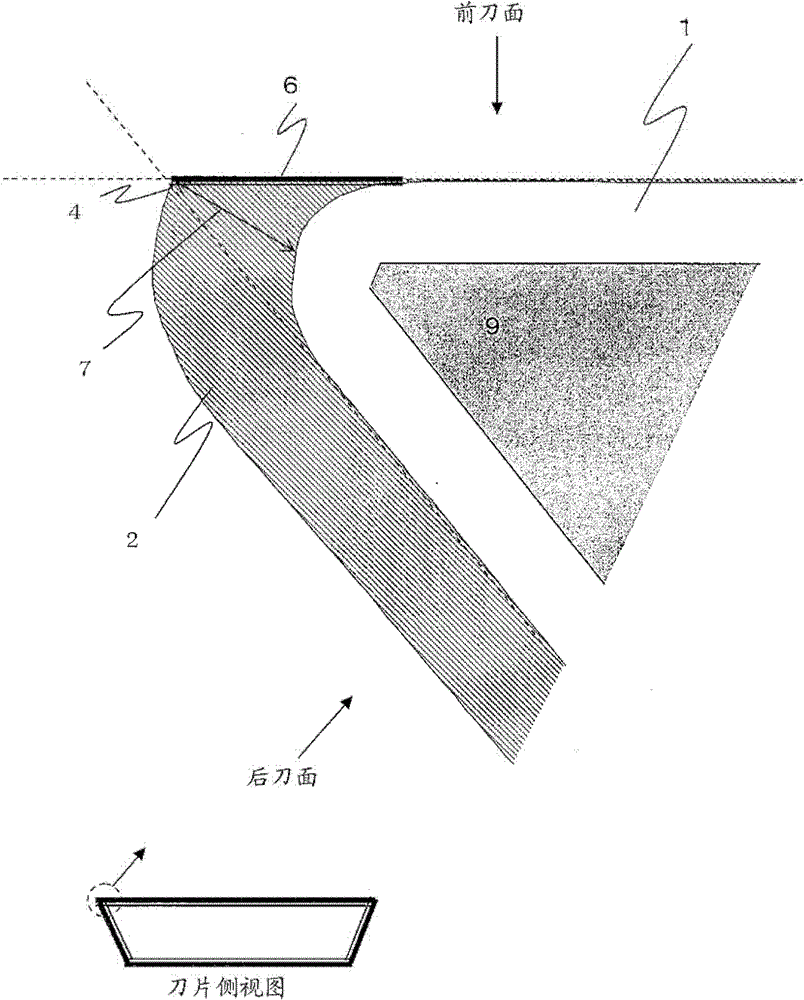

Cutting tool covered with diamond

ActiveCN102626853AImprove the lubrication effectEasy chip removalTransportation and packagingMilling cuttersCarbon filmSurface layer

The invention provides a cutting tool covered with diamond. The tool substrate composed of tungsten carbide cemented carbide or titanium carbonitride base metallic ceramics is covered with a crystal diamond layer. Nanometer diamond film having average grain diameters of 1 to 50 nm and laminated alternatively at a lamination space of 0.2 to 2.0 micrometers and alternating lamination films of crystal diamond film having average grain diameters of 0.1 to 2 micrometers cover the crystal diamond layer. The shortest distance between the front end of a cutting blade to the crystal diamond layer is determined to be 3 to 15 micrometers. And a non-crystal carbon film having surface roughness less than 0.1 micrometer and thickness of 10 to 200 micrometers is formed on the surface layer of a front blade face of the nanometer diamond layer of the cutting blade.

Owner:MITSUBISHI MATERIALS CORP

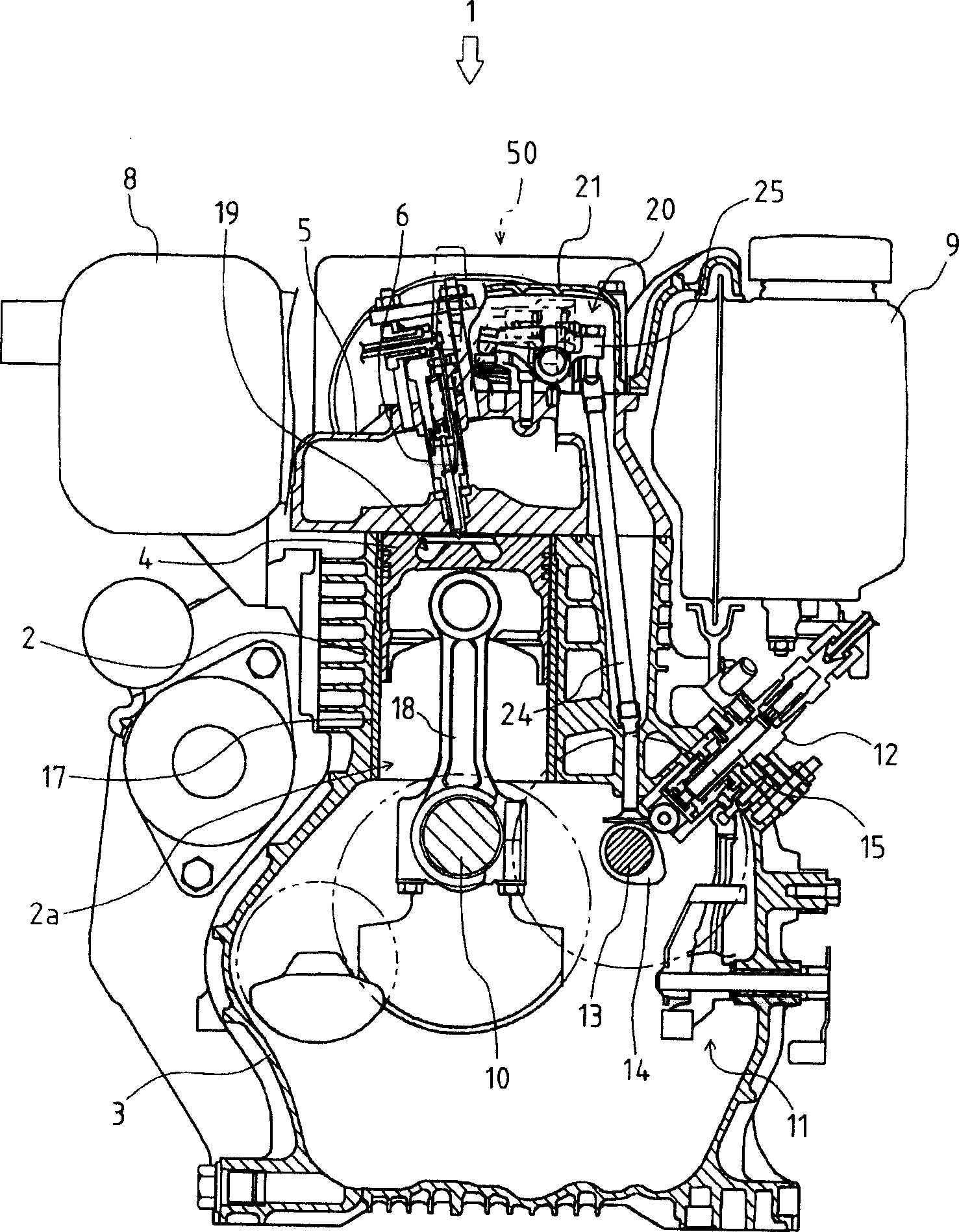

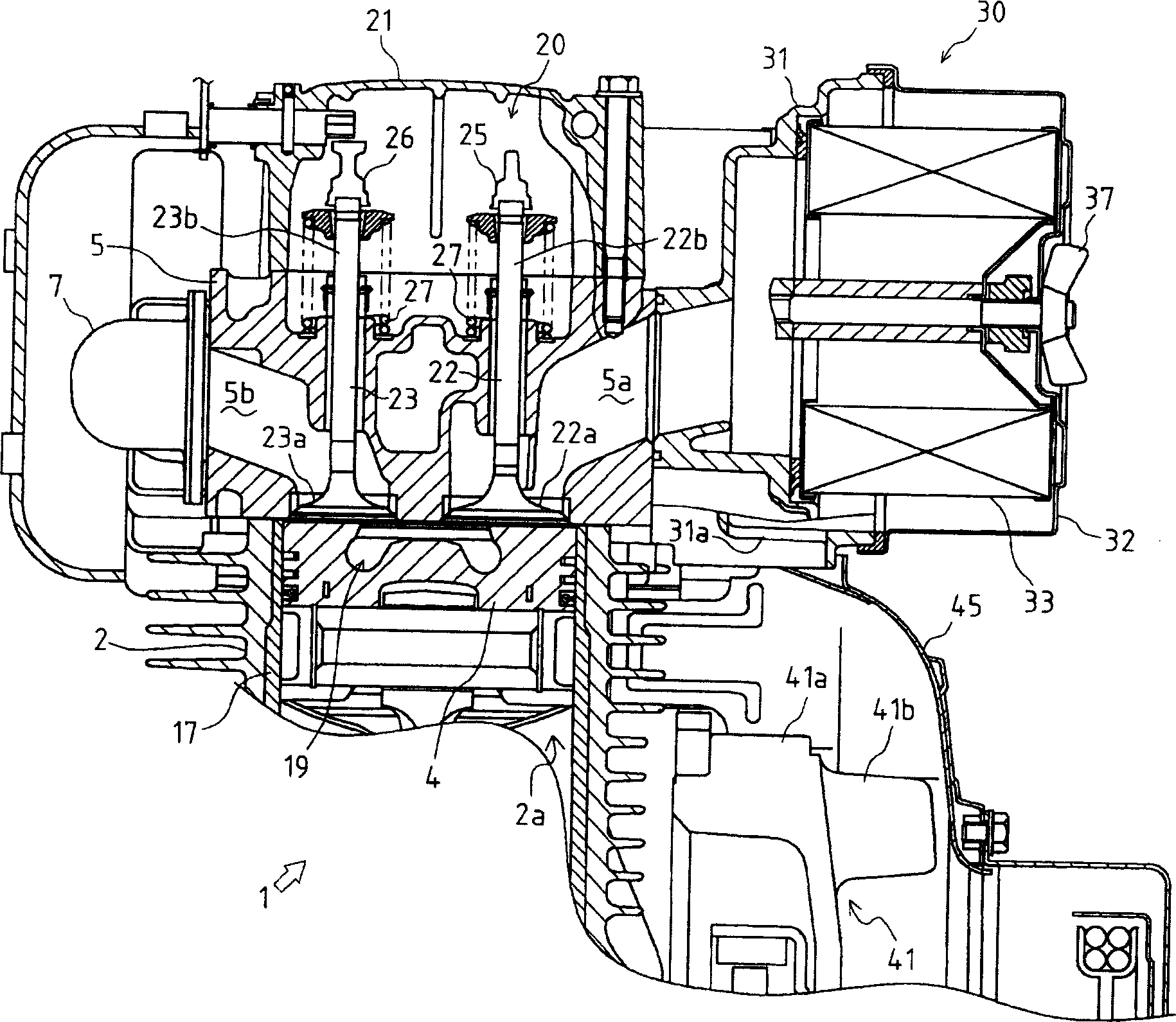

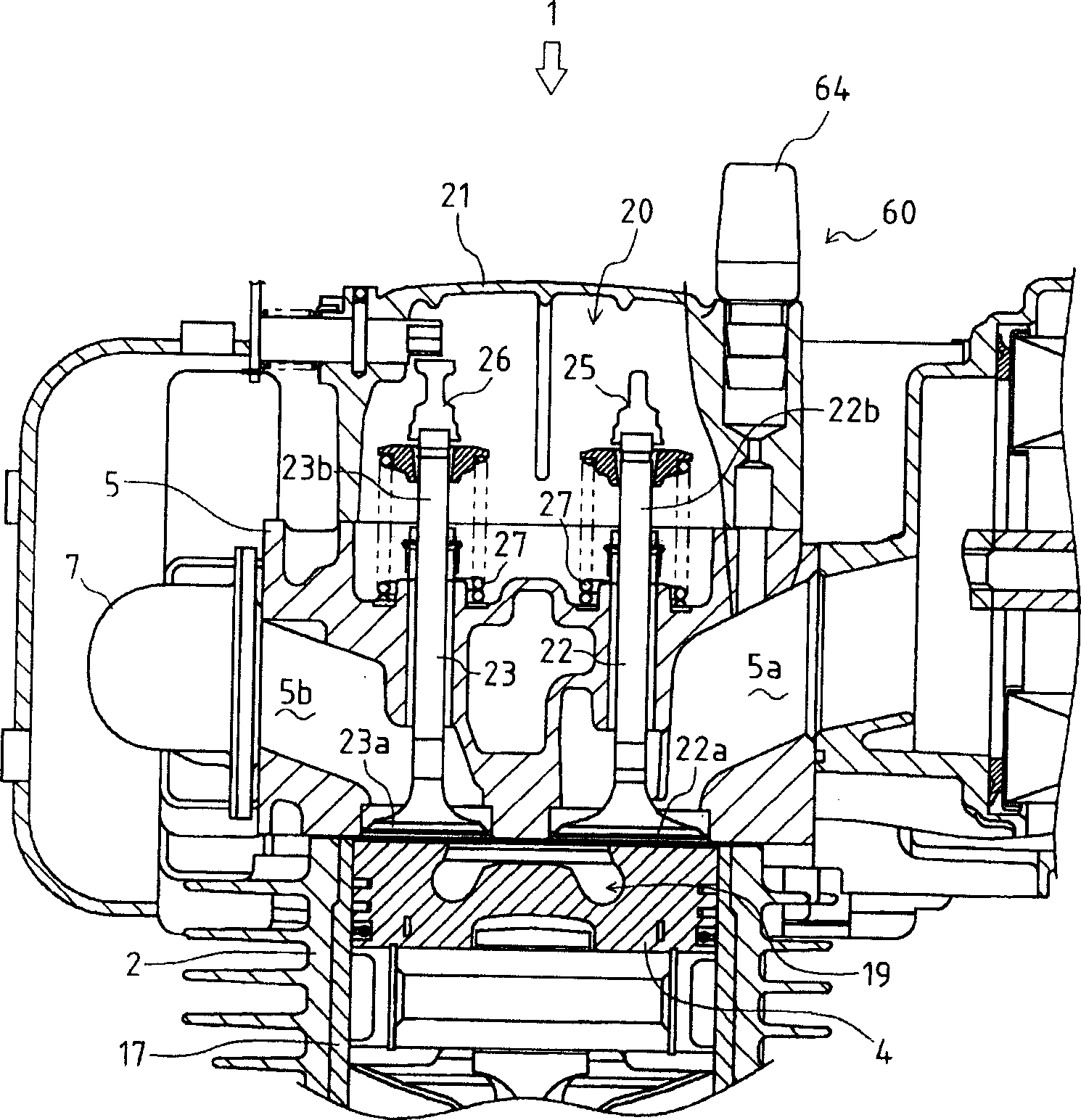

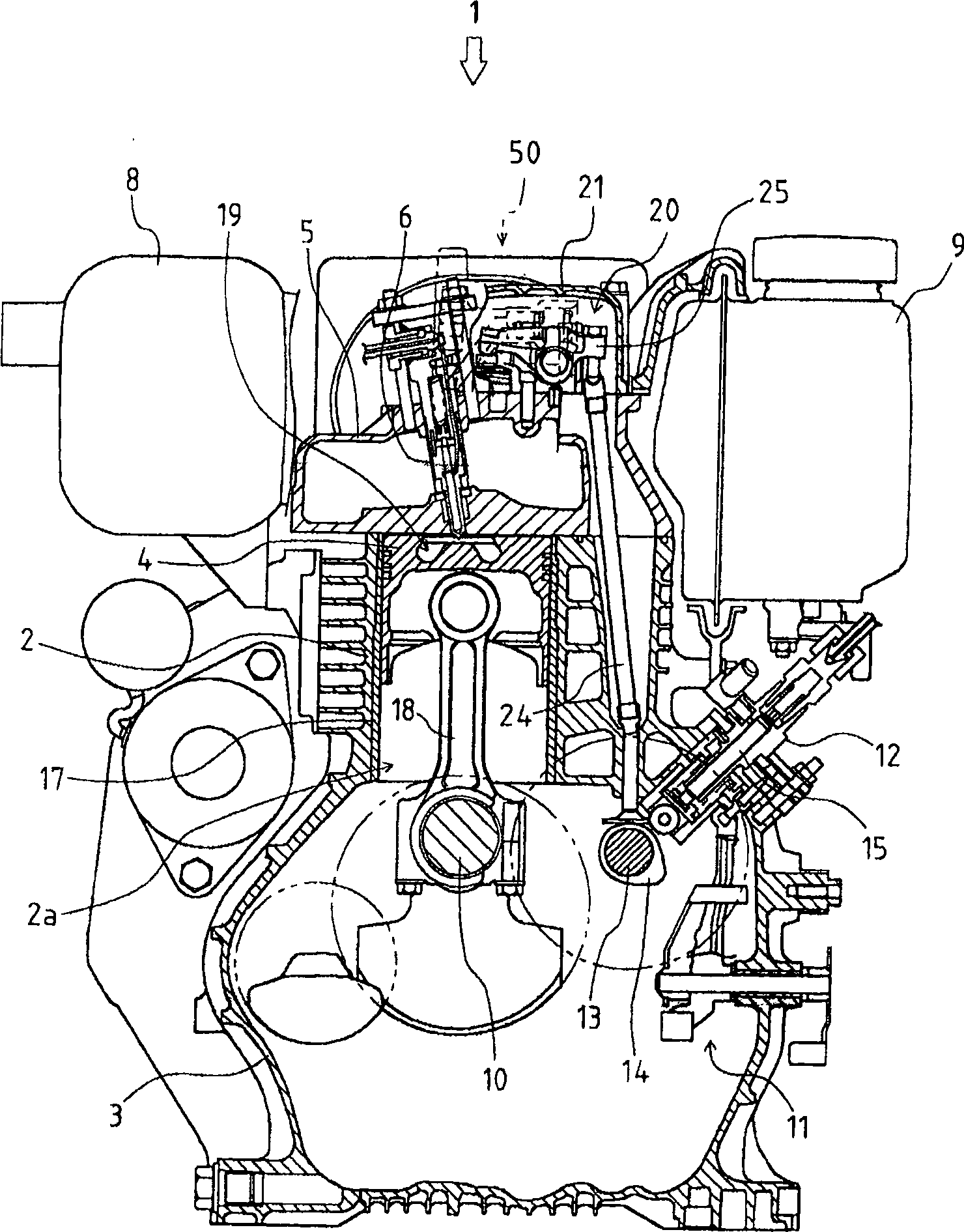

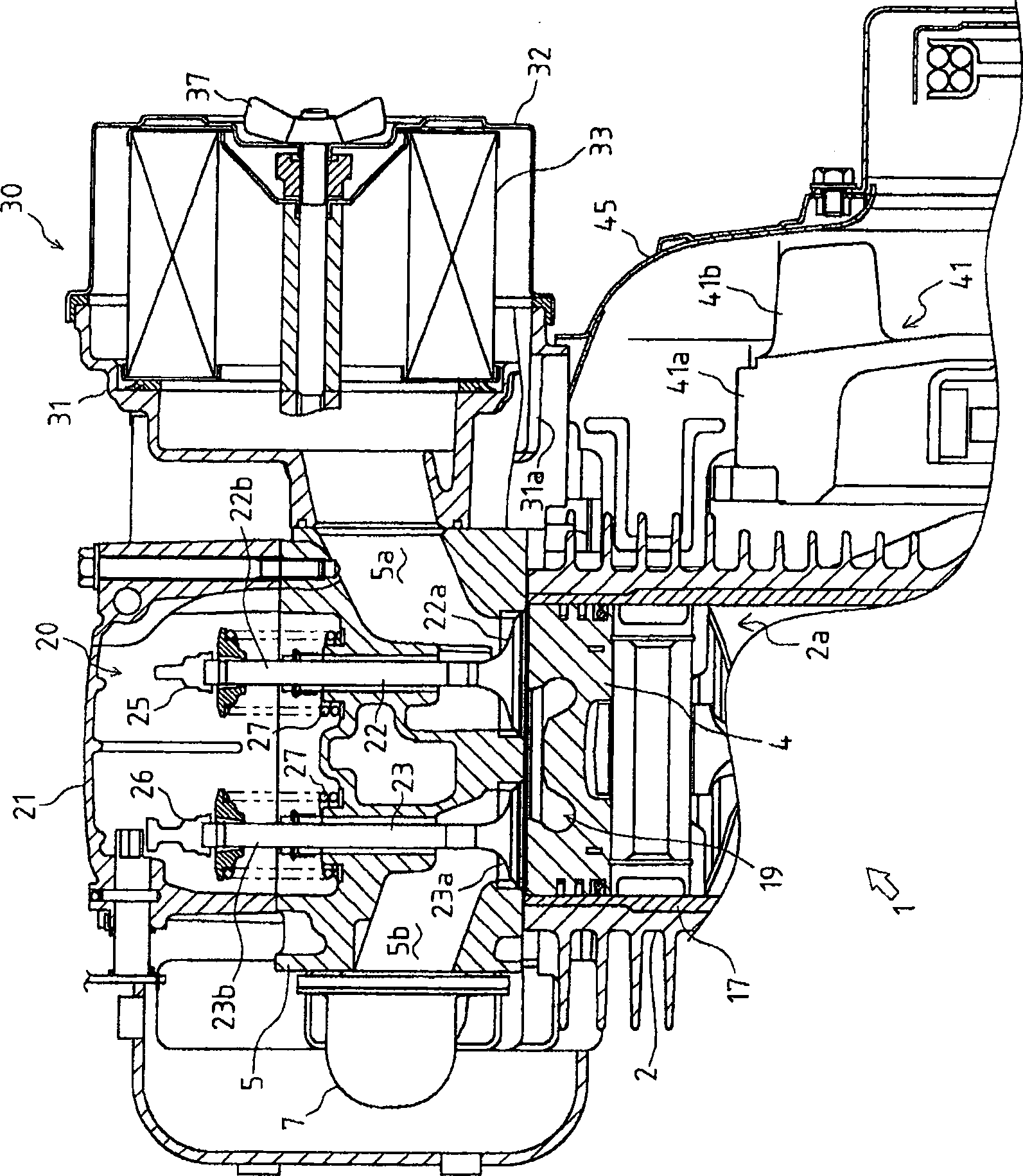

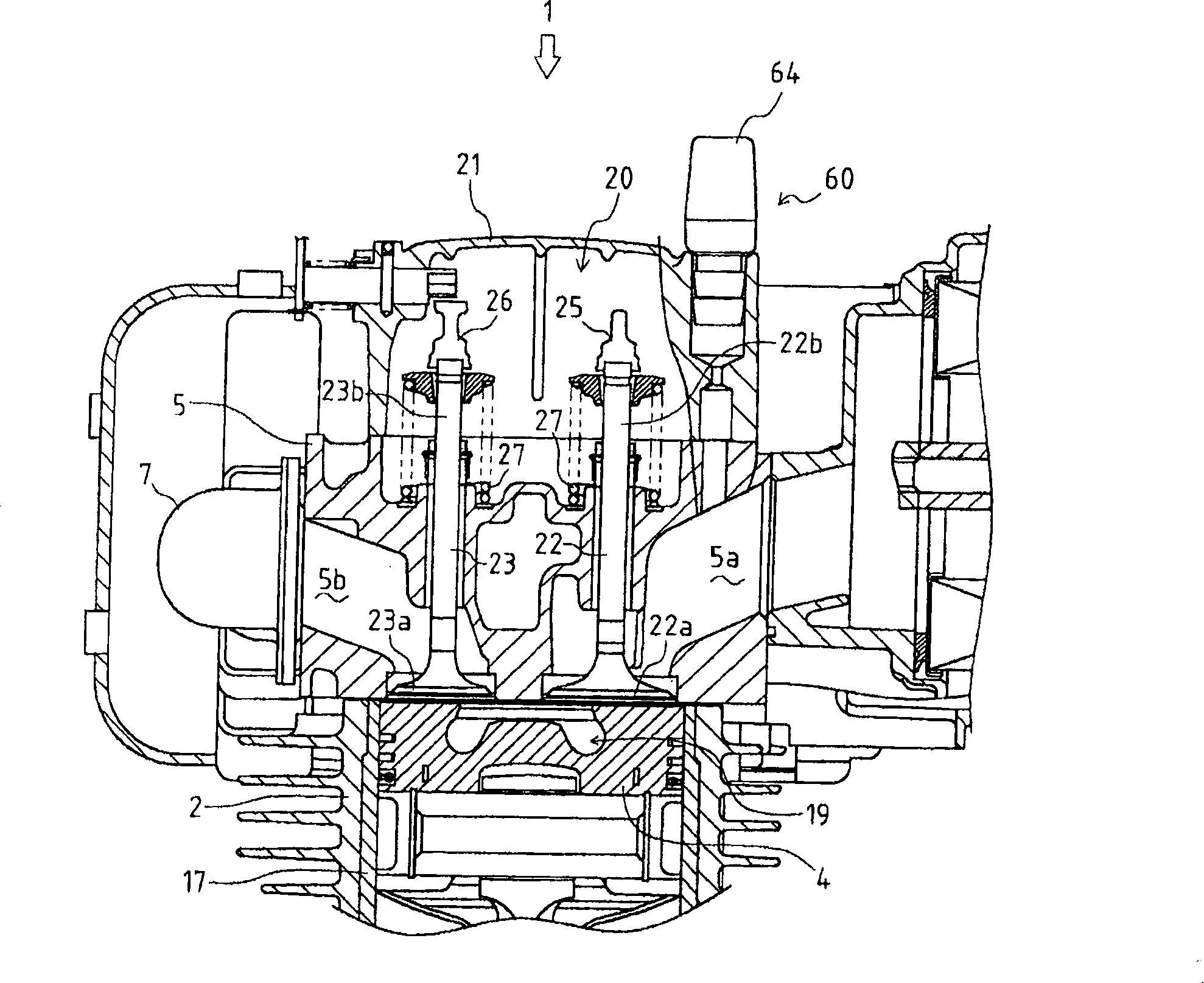

Superstructure of engine

InactiveCN1759235ALow costAvoid assembly errorsInternal combustion piston enginesNon-fuel substance addition to fuelAir cleanersEngineering

With regard to a construction that a fan 41 is provided at one side of an engine 1 and covered by a fan casing 45, and an air cleaner 30 is arranged near the fan casing 45 and at a side of a cylinder head 5 on which an intake port 5a is disposed, a suction port 31a communicated with the inside of the fan casing 45 is provided in a main body 31 of the air cleaner 30. A barrier 46 is provided at a position facing to the suction port 31a in the air cleaner 30. A wall standing toward the fan casing 45 and the cylinder head 5 is formed on the outer surface of the main body 31 of the air cleaner 30. An air intake part is provided on one of side surfaces of a cover body 32 of the air cleaner 30 and the cover body 32 is constructed to be an equilateral polygon. An intake pipe 31k communicating the air cleaner 30 with the intake port 5a of the cylinder head 5 is constructed integrally with a main body 31 of the air cleaner 30.

Owner:YANMAR CO LTD

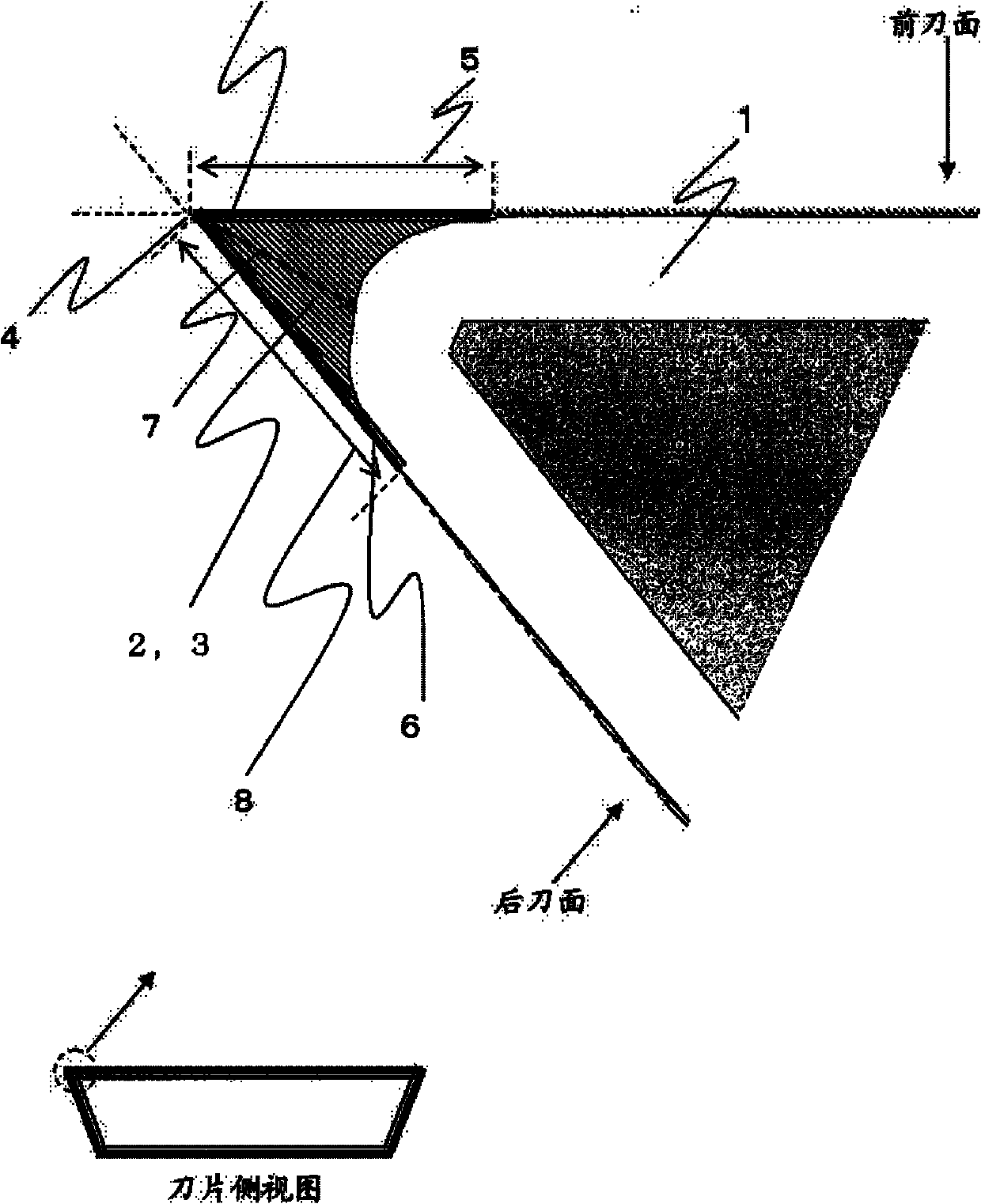

Diamond-coated cutting tool

InactiveCN102554318ASeek long lifeImprove wear resistanceTransportation and packagingMilling cuttersCrystallinityRidge

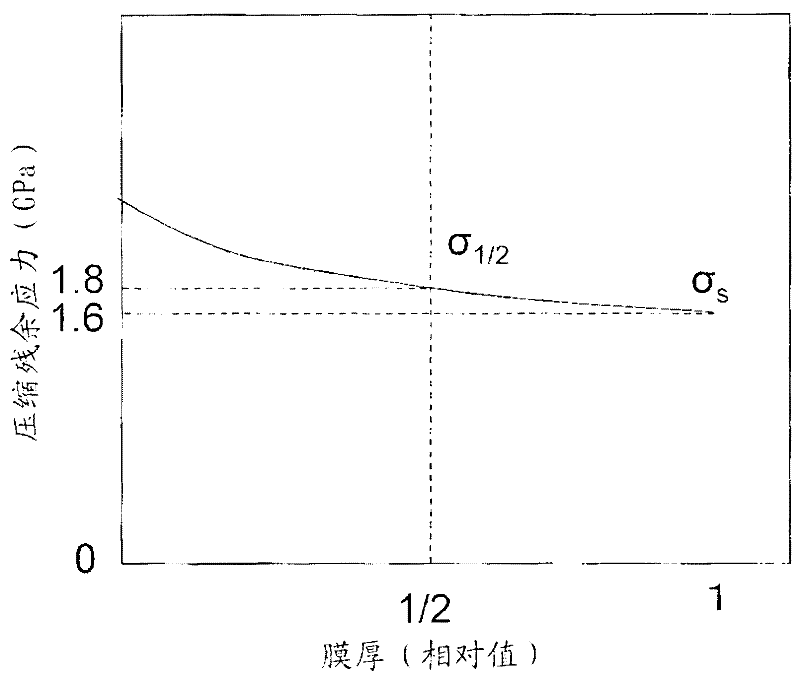

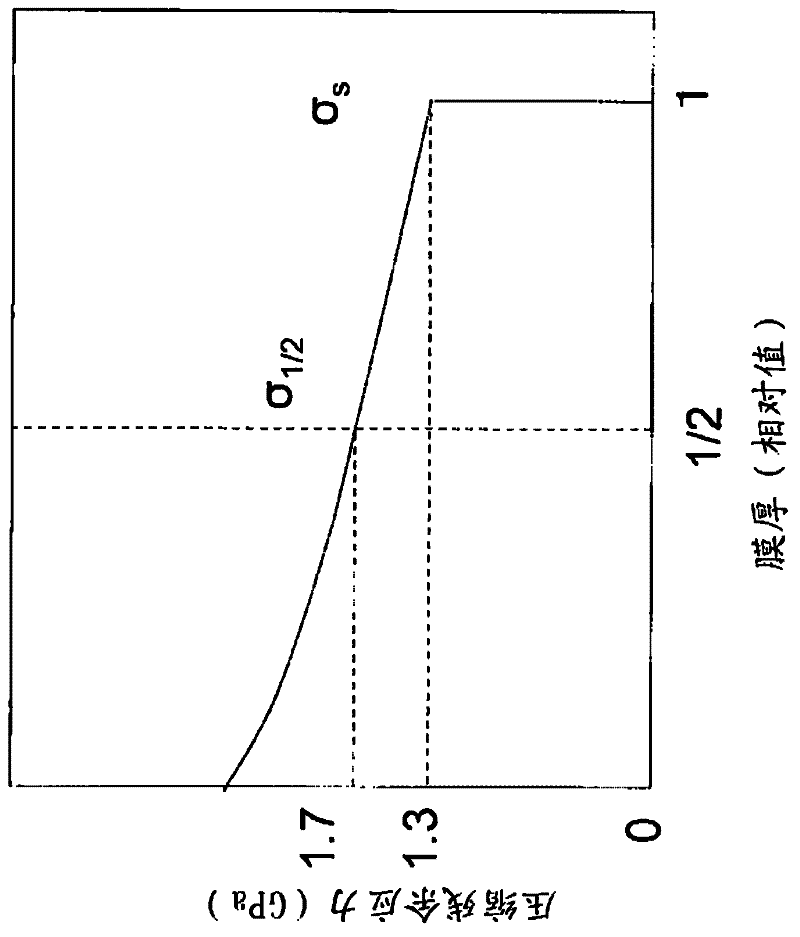

The present invention provides a diamond-coated cutting tool, which has an excellent wear resistance in the drilling machining and end mill machining process of materials hard to be cut like CFRP material, aluminium alloys containing high silicon, and graphites. In the diamond-coated cutting tool, the base body surface of the tool, formed by tungsten carbide-based hard alloy is coated with a crystallinity diamond film as a lower portion layer, and with a crystallite nanometer diamond film as an upper layer. Only the ridge portion of the cutter tip is processed through wet-type sandblasting to enable the lower layer to be exposed, wherein when the compressive residual stress formed on the lower layer of the ridge portion of the cutter tip of the tool is determined, the residual stress value sigma s of the exposed surface of the lower layer is 1.5-3 GPa; and when the residual stress value formed at the 1 / 2 position of the lower layer of the ridge portion of the cutter tip is set as sigma 1 / 2, the value of sigma s / sigma 1 / 2 is 0.8-1.0.

Owner:MITSUBISHI MATERIALS CORP

Copper foil for lithium ion secondary battery negative electrode collector, lithium ion secondary battery negative electrode material, and method for selecting lithium ion secondary battery negative electrode collector

InactiveCN103210533AIncrease energy densityIncrease capacityElectrode manufacturing processesElectrode carriers/collectorsLithiumElectrical battery

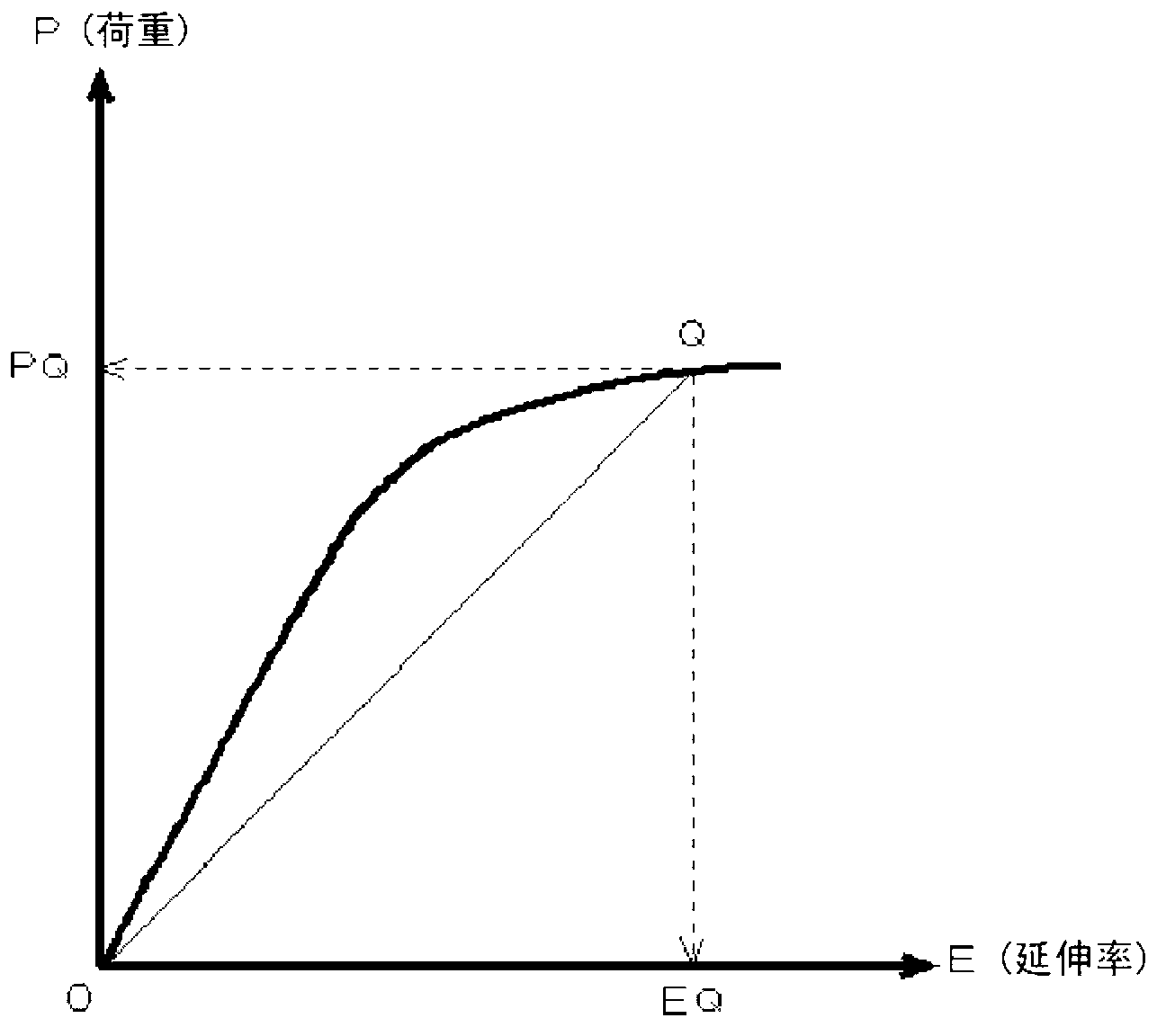

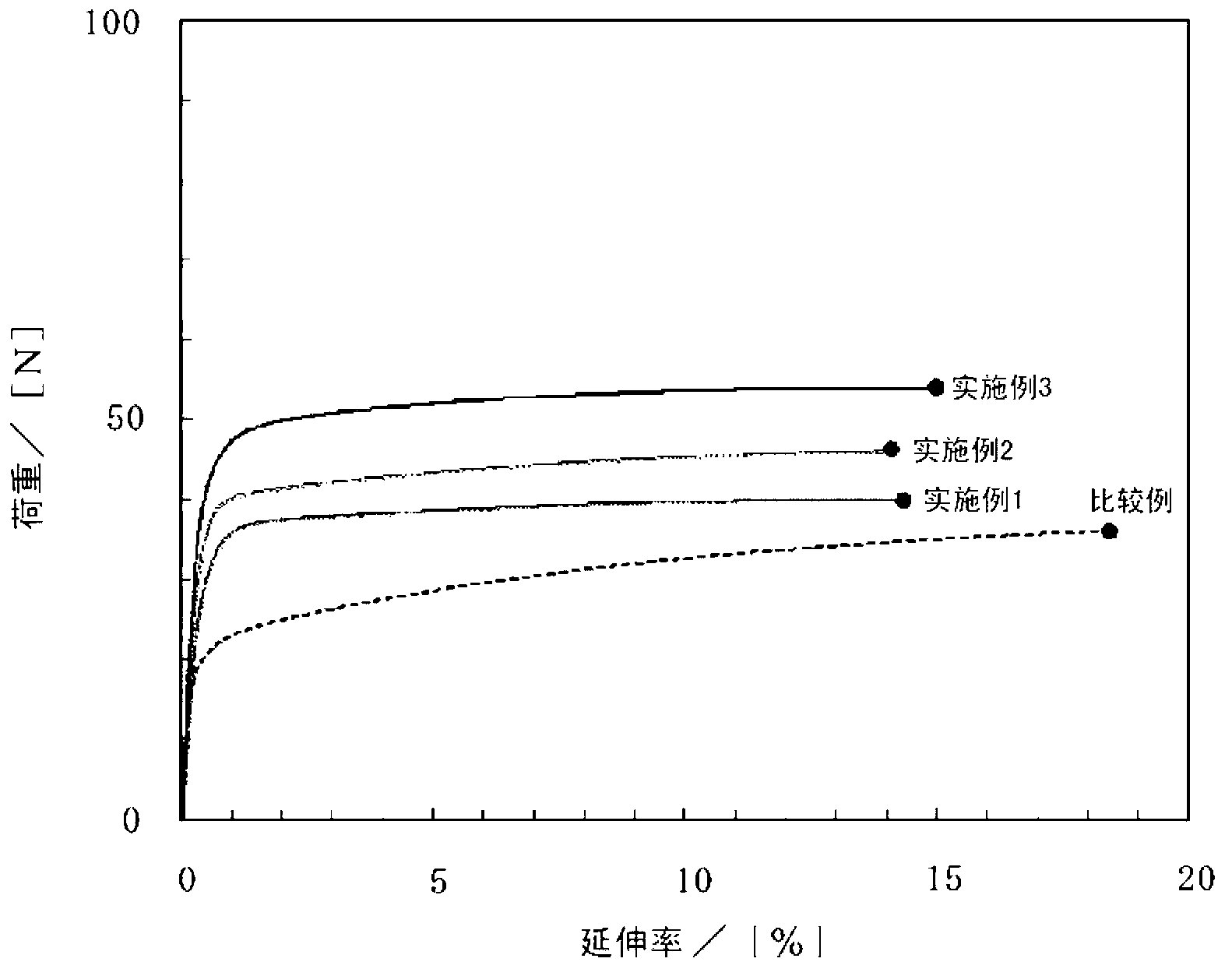

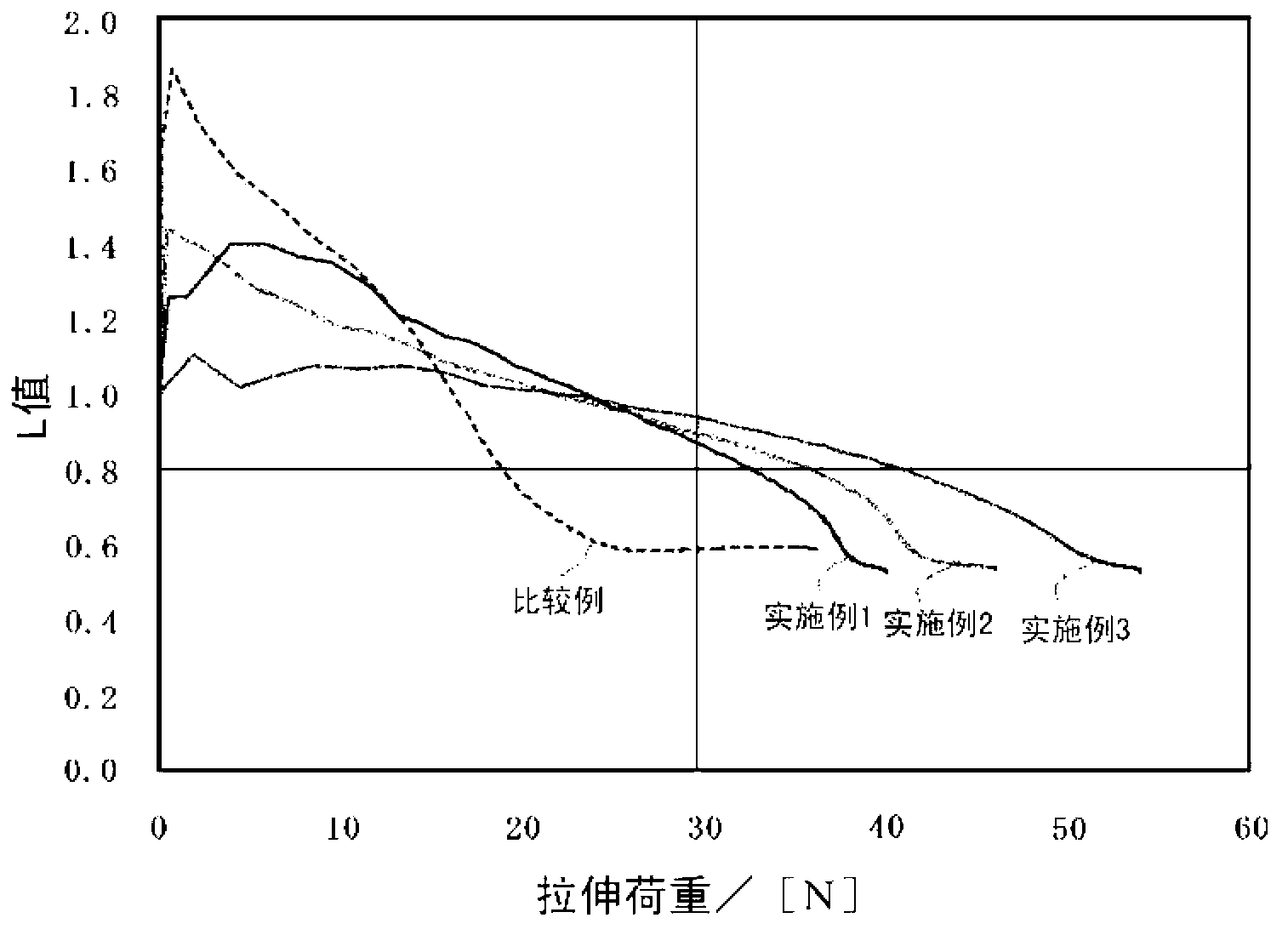

The problem addressed by the present invention is providing a copper foil for a lithium ion secondary battery negative electrode collector that can prevent deformation of the collector even with repetition of a charging and discharging cycle and also providing a lithium ion secondary battery negative electrode material and a method for selecting a lithium ion secondary battery negative electrode collector. To address this problem, the present invention is a copper foil for a lithium ion secondary battery negative electrode collector wherein a copper foil is used. That copper foil is characterized by having a maximum negative load of 30 N or greater in a tension test of a sample in a load-extension curve for tension tests on a 10 mm wide test sample formed from this foil, when O is the origin, EQ the extension, PQ the load, and Q a point on this load-extension curve, with the L value in Equation (1) being in the region of 0.8 or greater. L value = (triangle OQEQ surface area) / (region OQEQ surface area)... (1)

Owner:MITSUI MINING & SMELTING CO LTD

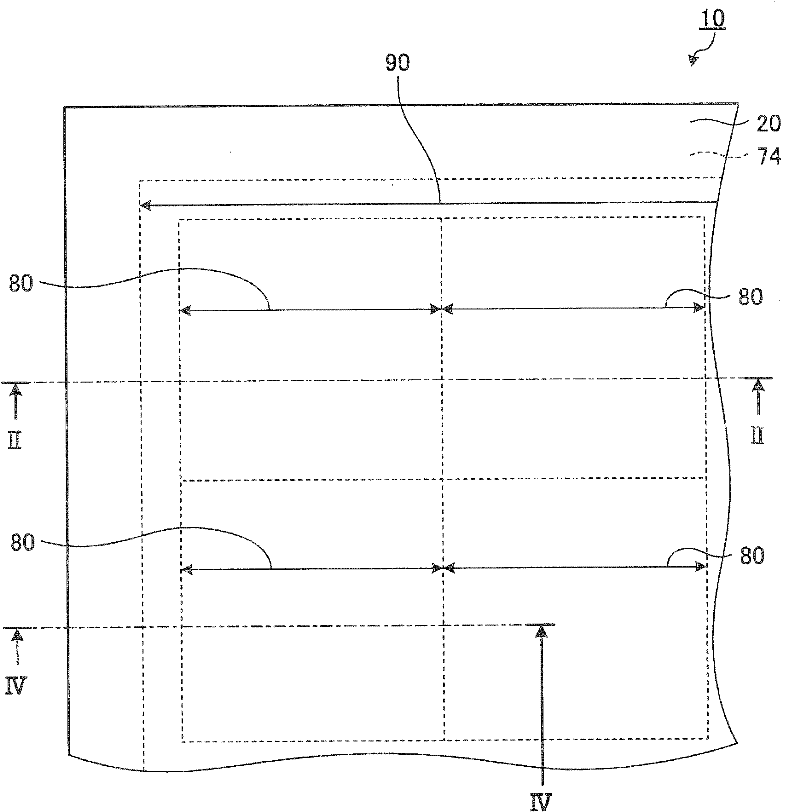

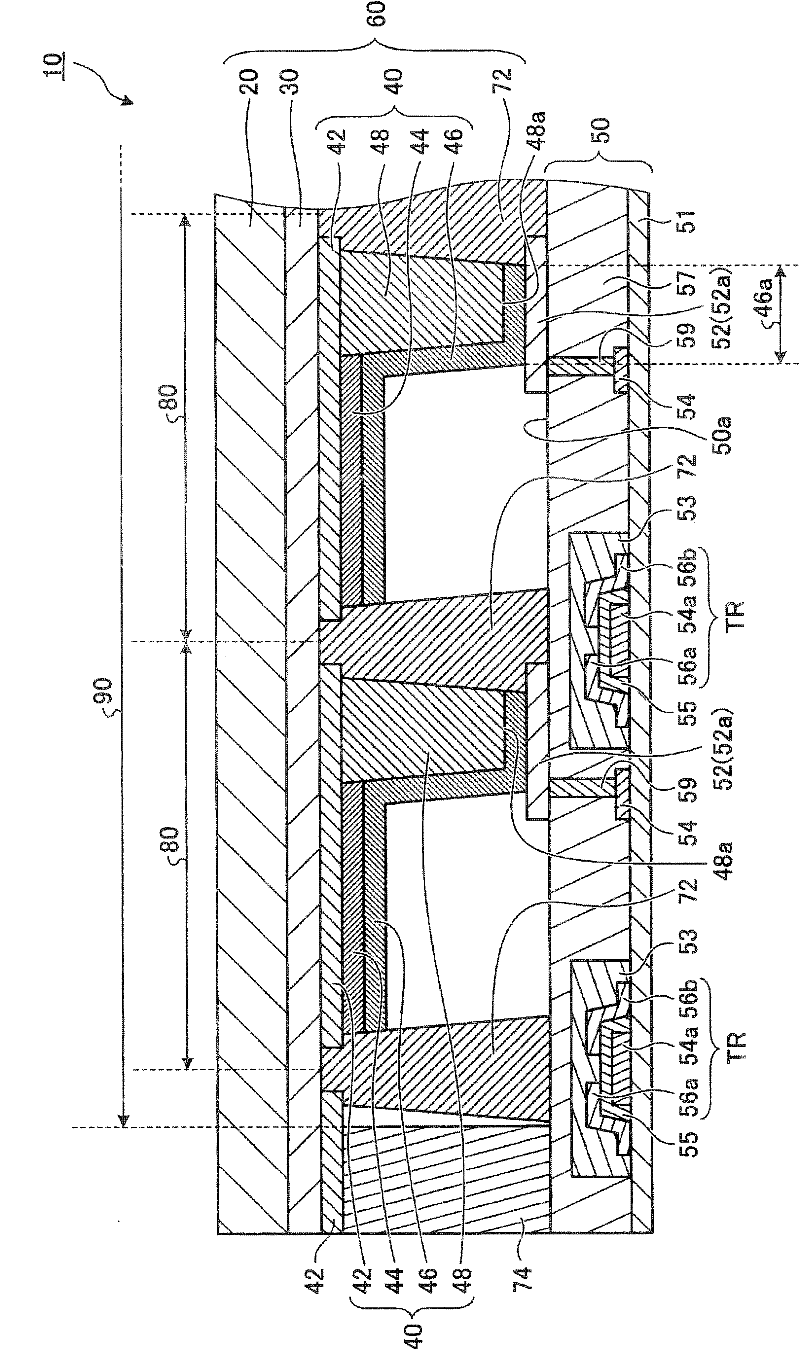

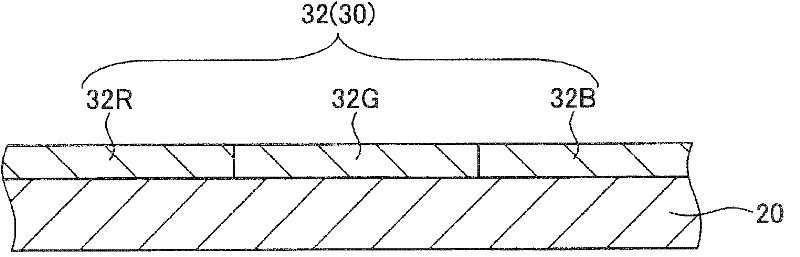

Manufacturing method of display panel and substrate for display device

InactiveCN102293056AInhibit deteriorationSimple processElectroluminescent light sourcesSolid-state devicesColor gelDisplay device

Owner:SUMITOMO CHEM CO LTD

Surge absorber

InactiveCN1823458AGood chemical stabilitySuppression of scatteringOvervoltage arrestors using spark gapsChemical stabilityMaterials science

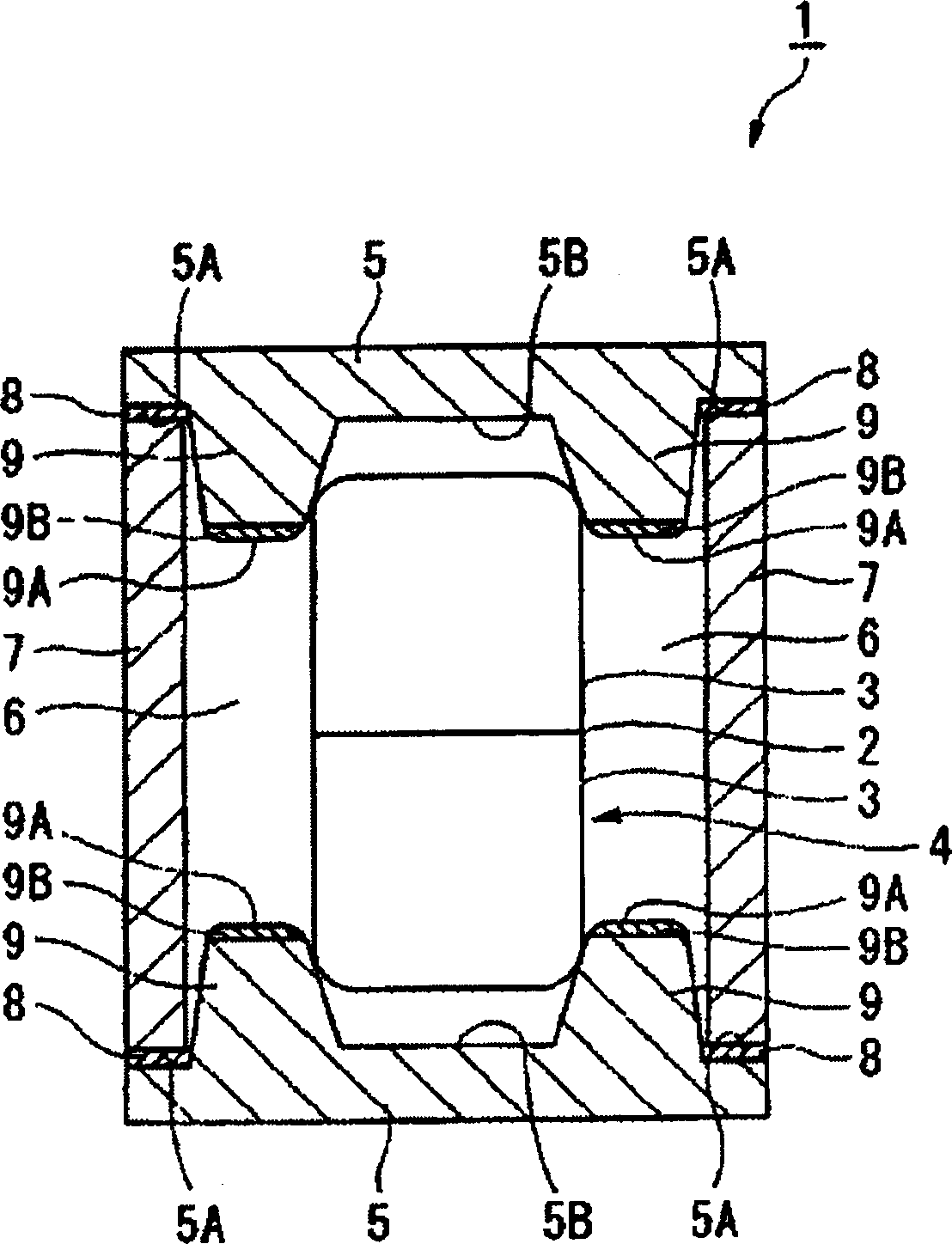

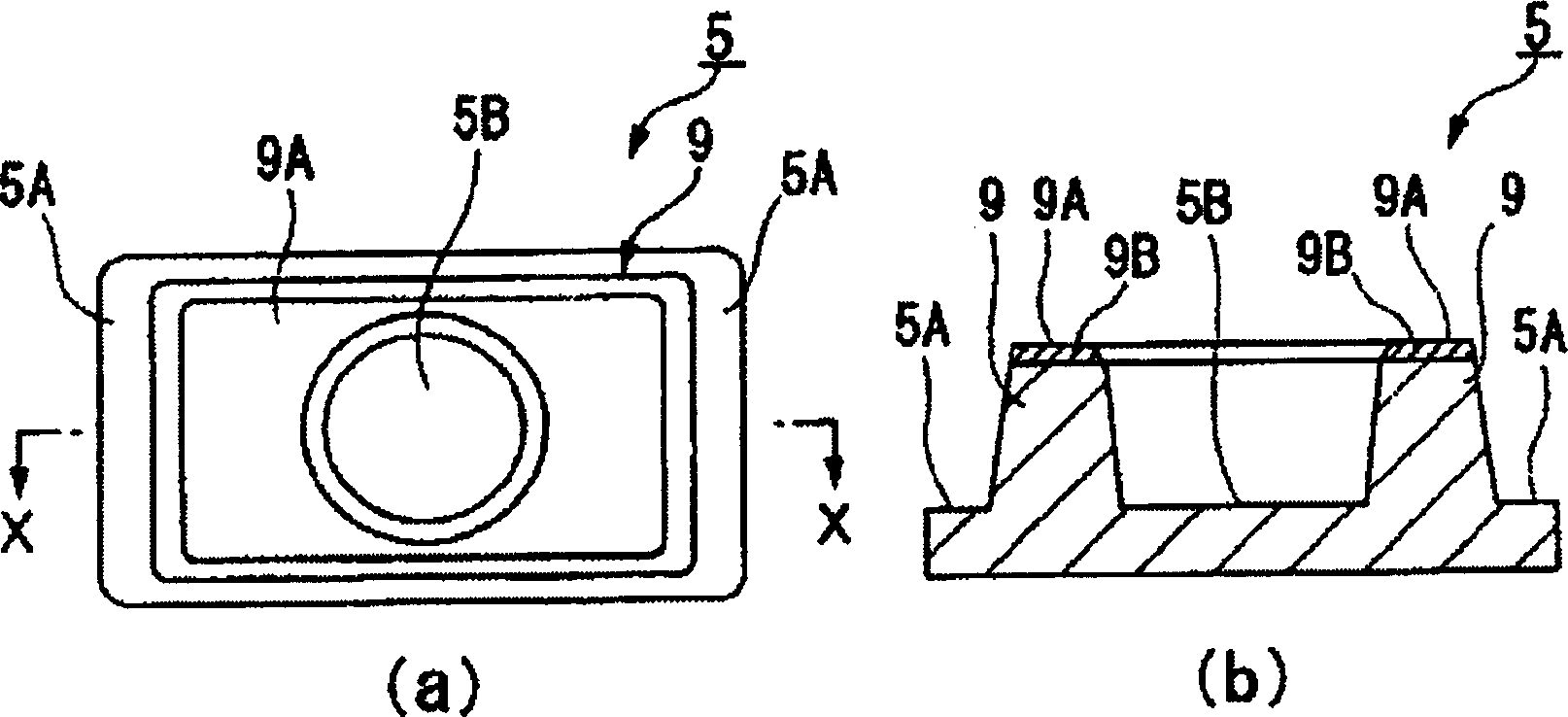

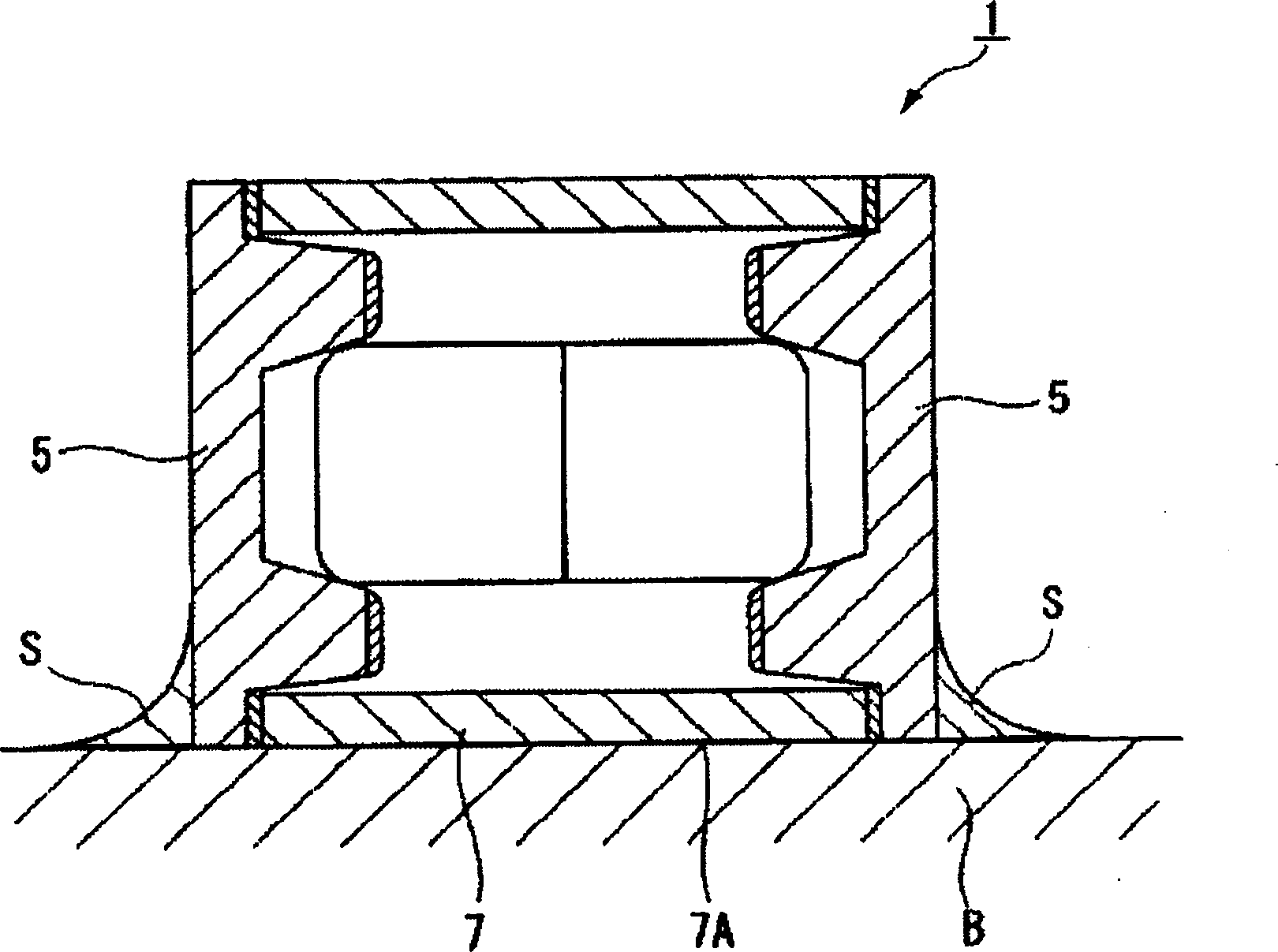

A surge absorber in which an oxide layer excellent in chemical stability in the high temperature range and excellent in adhesion to main discharge electrodes is deposited on the main discharge electrodes. The surge absorber comprises a cylindrical ceramic body (4) on which conductive films (3) separated by a discharge gap (2) are formed, a pair of main discharge electrode members (5) opposedly disposed at both ends of the cylindrical ceramic body (4) and in contact with the conductive films (3), and a tubular ceramic body (7) in which the paired main discharge electrode members (5) are opposed, the cylindrical ceramic body (4) is contained, and a filling gas (6) is sealed. Each of the paired main discharge electrode members (5) has a projecting support (9). The opposed surfaces of the projecting supports (9) serve as main discharge surfaces (9A). Oxide films (9B) are formed on the main discharge surfaces (9A) by oxidation.

Owner:MITSUBISHI MATERIALS CORP

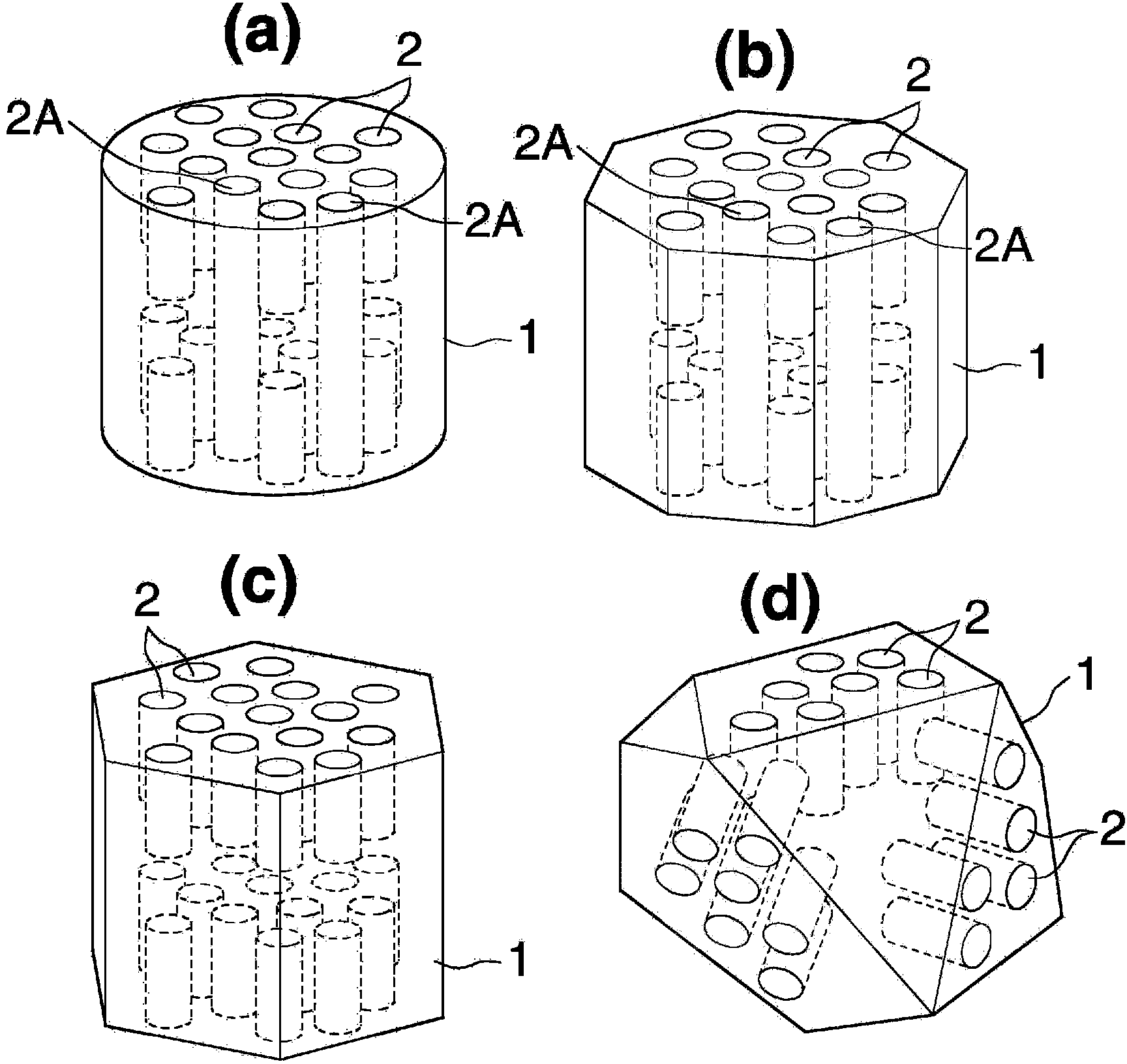

Negative electrode active material for lithium secondary battery and method for manufacturing same

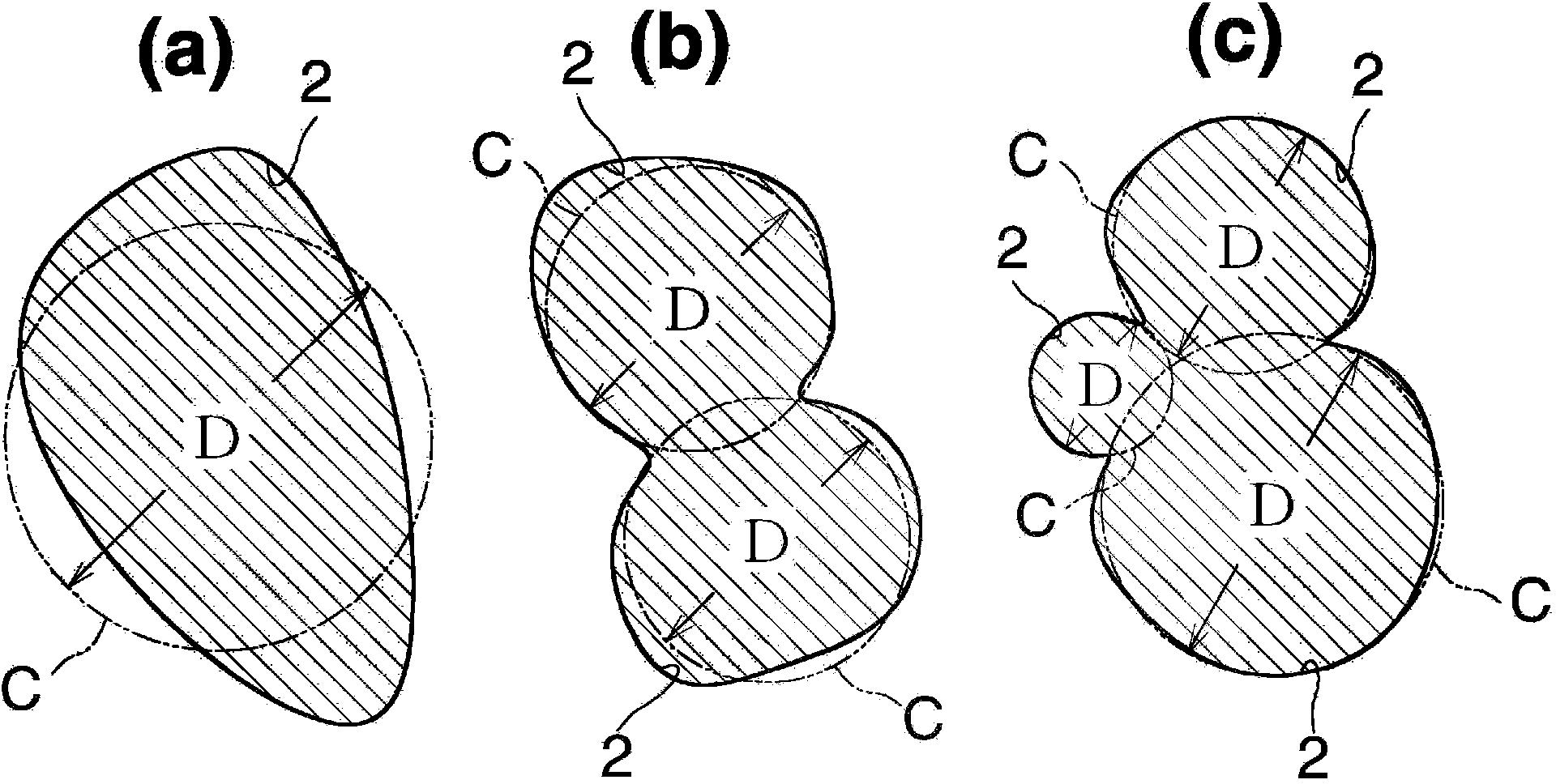

This negative electrode material for a lithium secondary battery is formed from a powder formed by carrying out in order a step for creating an etched foil by etching both surfaces of a foil that has a Fe content of 0.05% by mass or less and Al as a main component and a step for cutting that etched foil. This powder includes particles (1) that have holes (2) that are opened in the surface of the particles and have a hole diameter of 0.5 [mu]m or greater. The total of the opening surface area for all of the holes (2) in the surface of a particle (1) in the particles (1) having the holes (2) is 10% or greater of the surface area of the particle having the holes (2). With the use of this negative electrode material (1) for a lithium secondary battery, increased life for cycle life of the lithium secondary battery can be achieved.

Owner:SHOWA DENKO KK

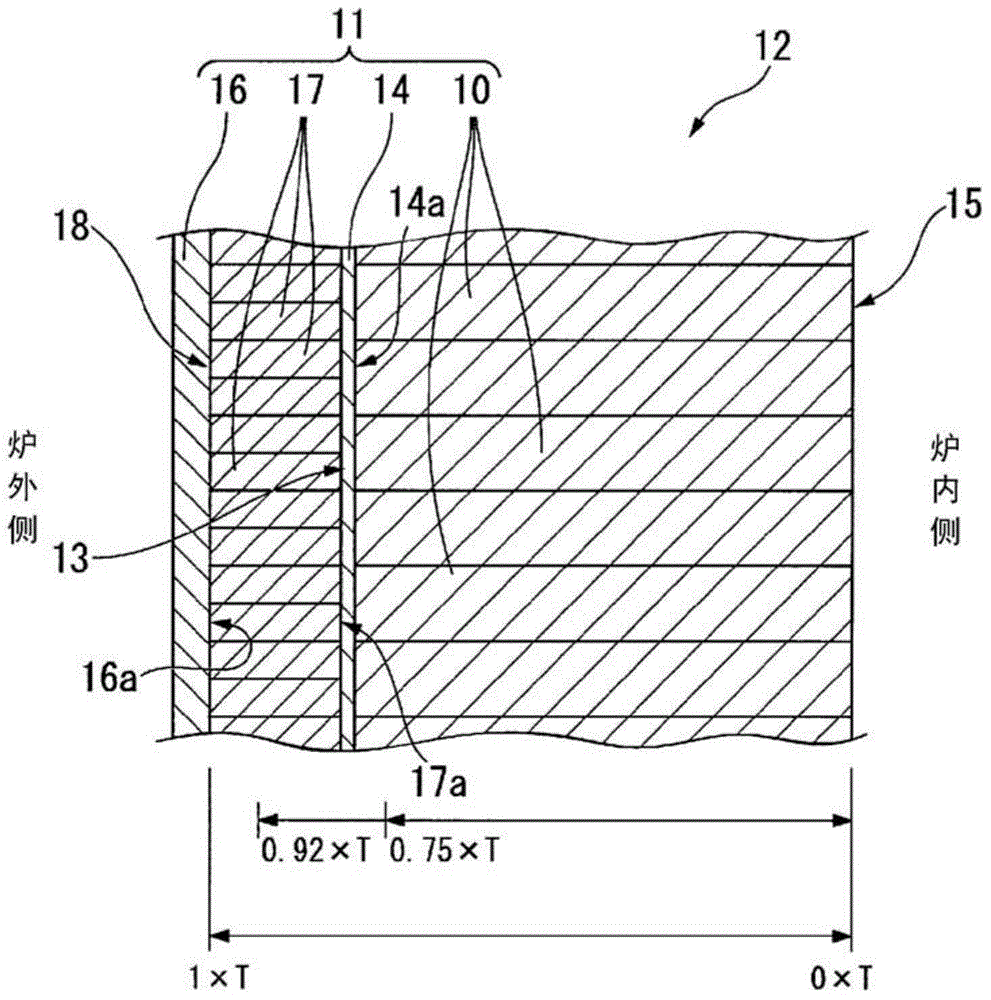

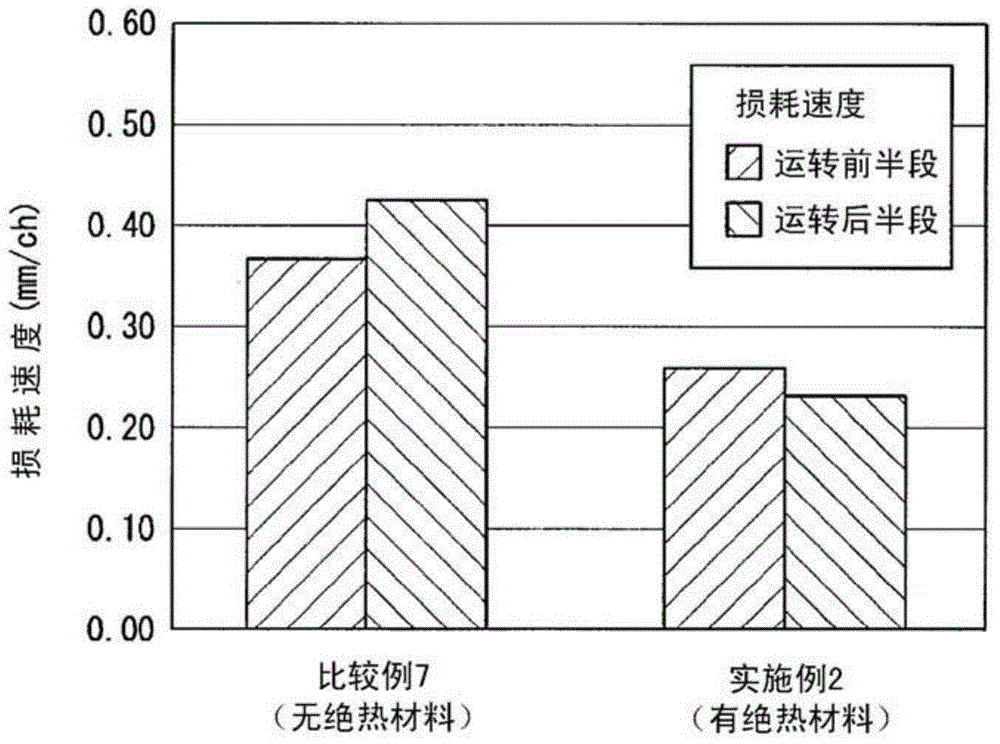

Furnace wall structure of molten metal container and furnace wall construction method of molten metal container

ActiveCN103620332BReduce temperature gradientMinimize thermal expansion differencesManufacturing convertersFurnace liningsRefractoryMolten metal

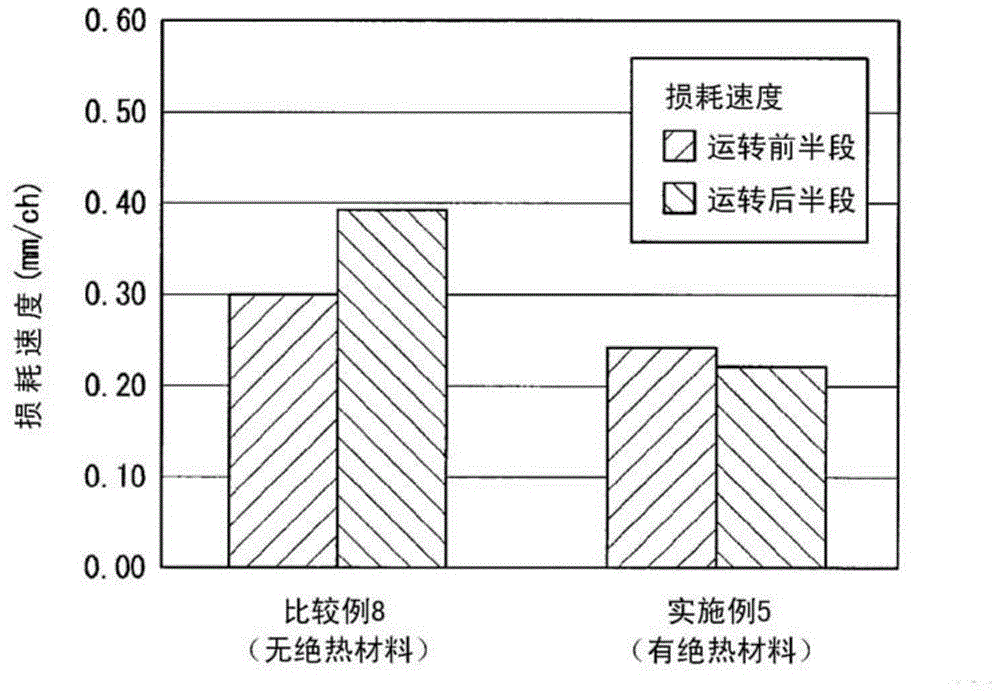

This furnace wall structure of a molten metal container contains a heat insulation material which exhibits a thermal conductivity of 0.01 to 0.15 W / (m·K) in a temperature range of 25 to 300°C and which has a melting point of 1000 to 1400°C and a thickness of 2 to 10mm in a position in the longitudinal section view, said position being within a thicknesswise region of 0.75×T to 0.92×T (mm) from the inside surface of a magnesia / carbon refractory toward a steel shell. T is the thickness of the furnace wall exclusive of the steel shell.

Owner:NIPPON STEEL CORP

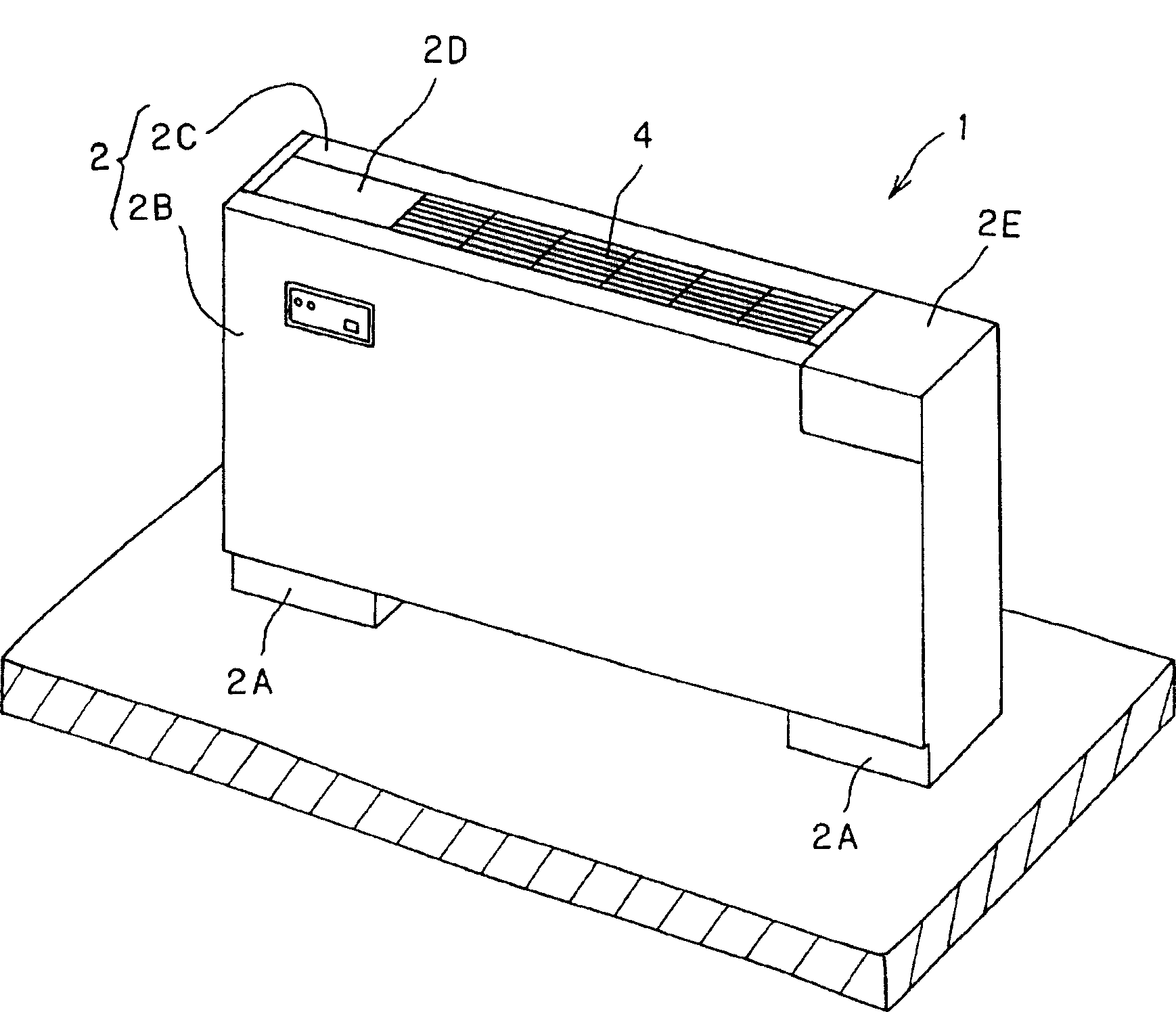

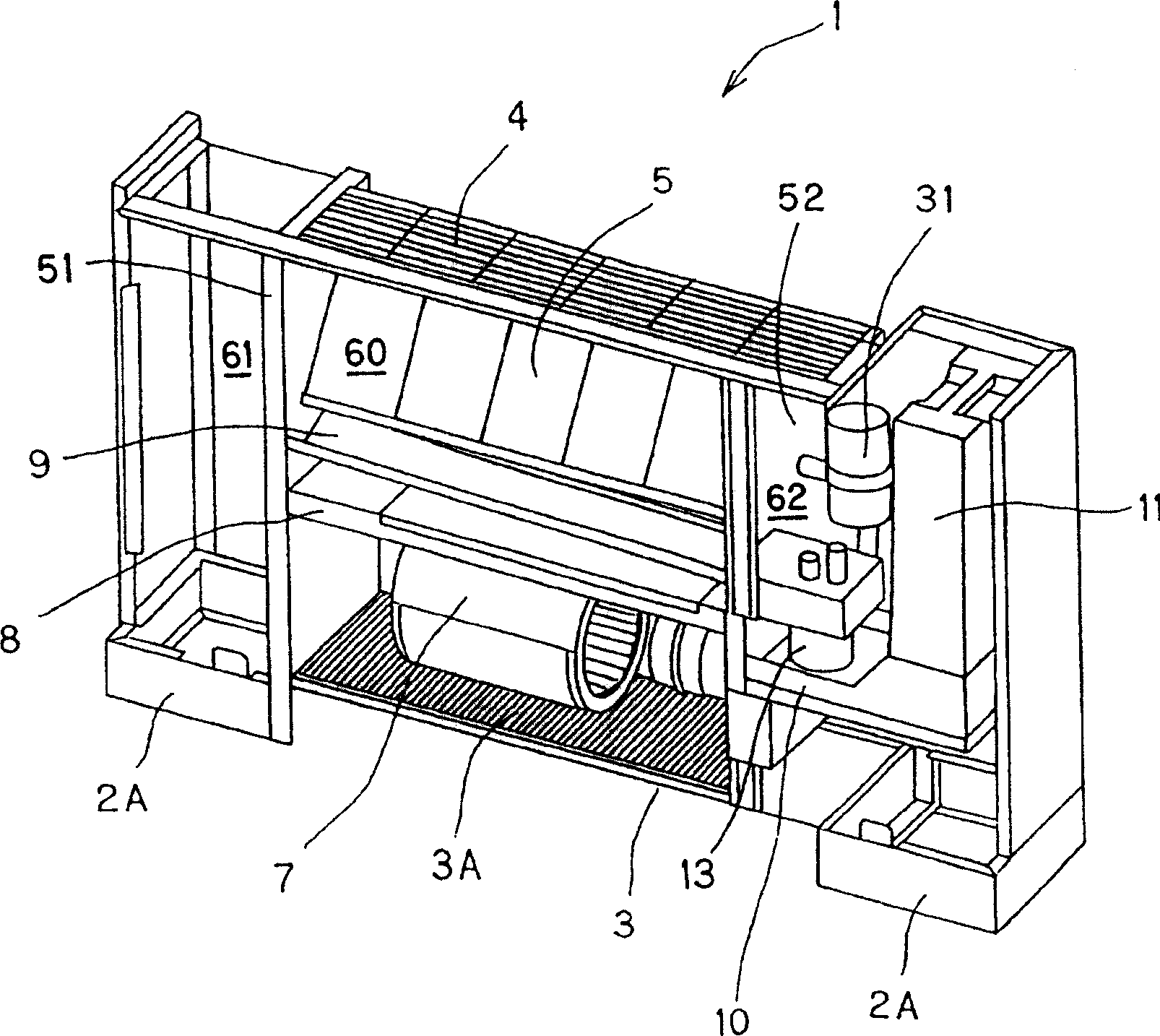

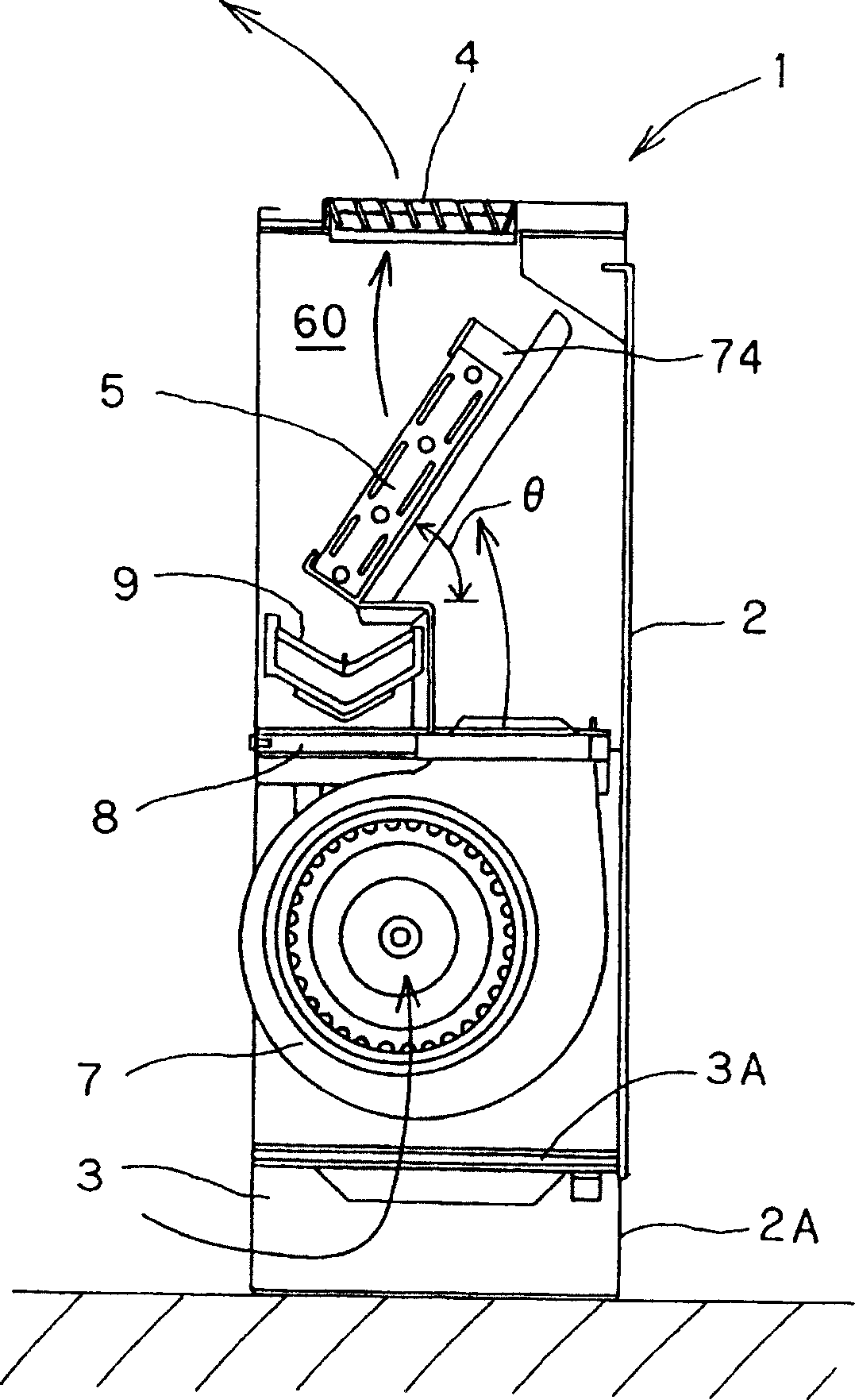

Air filtering apparatus

InactiveCN101024092BGuaranteed water permeabilitySeek long lifeMechanical apparatusLighting and heating apparatusAir filterHardness

The invention relates to an air sterilizing device preventing the decline of the sterilizing efficiency by securing the water-permeability of a flow-dividing sheet if the hardness component of electrolytic water precipitates as scale. The air sterilizing device comprises a gas-liquid contact member 5 disposed in a housing, an electrolytic water supply pipe 17 for dropping electrolytic water into the gas-liquid contact member, and a blowing fan 13 for blowing air to the gas-liquid contact member into which electrolytic water infiltrates. A first flow-dividing sheet 76 with water retention characteristics for dividing the flow of electrolytic water dropped from the electrolytic water supply pipe into the whole area of the gas-liquid contact member 15 is disposed above the gas-liquid contactmember. The first flow-dividing sheet has troughs 76D at which the scale S accumulates if the hardness component in the electrolytic water precipitates as the scale S.

Owner:SANYO ELECTRIC CO LTD

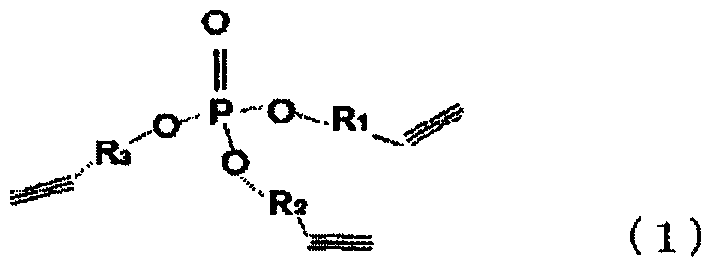

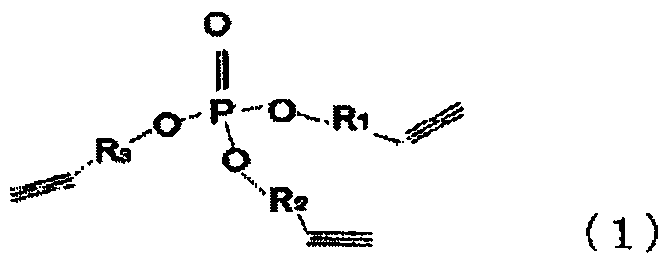

Lithium secondary battery and electrolyte solution for lithium secondary battery

ActiveCN105409047BSeek long lifeExcellent cycle characteristicsCell electrodesLi-accumulatorsPhosphoric Acid EstersEngineering

The present invention provides: a lithium secondary battery which is suppressed in deterioration of a negative electrode active material due to charging and discharging and has excellent cycle characteristics, while having a long service life especially for use in a high-temperature environment; and an electrolyte solution which is used in this lithium secondary battery. A lithium secondary battery according to the present invention contains an electrolyte solution, in which a positive electrode and a negative electrode that absorb and desorb lithium during charging and discharging are immersed, and has a negative electrode that contains a silicon-based negative electrode active material. The electrolyte solution contains an unsaturated phosphoric acid ester that is represented by formula (1) (wherein each of R1-R3 independently represents a direct bond or an alkylene group having 1-5 carbon atoms).

Owner:ADEKA CORP

Diamond coating and cutting element

ActiveCN102198523BSeek long lifePrevent peelingTurning toolsChemical vapor deposition coatingTitanium carbonitrideGraphite

The invention provides a diamond coating and cutting element, which has anexcellent adhesiveness in the cutting process of materials hard to be cut like aluminium alloys or graphites, CFRP materials and performs excellent wear resistance during a long-term use. Diamond films in thickness of 5-30Mum are coated on the surface of the diamond coating and cutting element composed by tungsten carbide-based hard alloys or titanium carbonitride-based cermet. Co particles with average diameter of 5-200nm are precipitated at the diamond film side of interface portion between the element body and the diamond films, and the proportion of Co particles is 0.1-20 atom%.

Owner:MITSUBISHI MATERIALS CORP

Diamond Coated Cutting Tools

ActiveCN102626853BSharp cutting edgeSharp lubricityTransportation and packagingMilling cuttersCarbon filmShortest distance

The invention provides a cutting tool covered with diamond. The tool substrate composed of tungsten carbide cemented carbide or titanium carbonitride base metallic ceramics is covered with a crystal diamond layer. Nanometer diamond film having average grain diameters of 1 to 50 nm and laminated alternatively at a lamination space of 0.2 to 2.0 micrometers and alternating lamination films of crystal diamond film having average grain diameters of 0.1 to 2 micrometers cover the crystal diamond layer. The shortest distance between the front end of a cutting blade to the crystal diamond layer is determined to be 3 to 15 micrometers. And a non-crystal carbon film having surface roughness less than 0.1 micrometer and thickness of 10 to 200 micrometers is formed on the surface layer of a front blade face of the nanometer diamond layer of the cutting blade.

Owner:MITSUBISHI MATERIALS CORP

Superstructure of engine

InactiveCN100513765CInhibition biasSeek long lifeInternal combustion piston enginesNon-fuel substance addition to fuelBreatherEngineering

PROBLEM TO BE SOLVED: To provide an engine upper structure capable of preventing exhaust emission, oil hammer or the like by devising a shape of a baffle plate provided on a vent hole (an inlet) of a breather provided on an upper part of a valve arm chamber of an engine, and a shape of an engine starting aid filling passage of, and disposing the breather and the engine starting aid filling passage in a compact and collective manner. SOLUTION: A slit 34 with a lower portion thereof opened is formed in a baffle plate 33 formed around a vent hole 36 of a breather 30, a throttle 45 is formed in a filling passage 42 of an engine starting aid, and the breather 30 and the filling passage 42 are integrated with a valve arm case 21.

Owner:YANMAR CO LTD

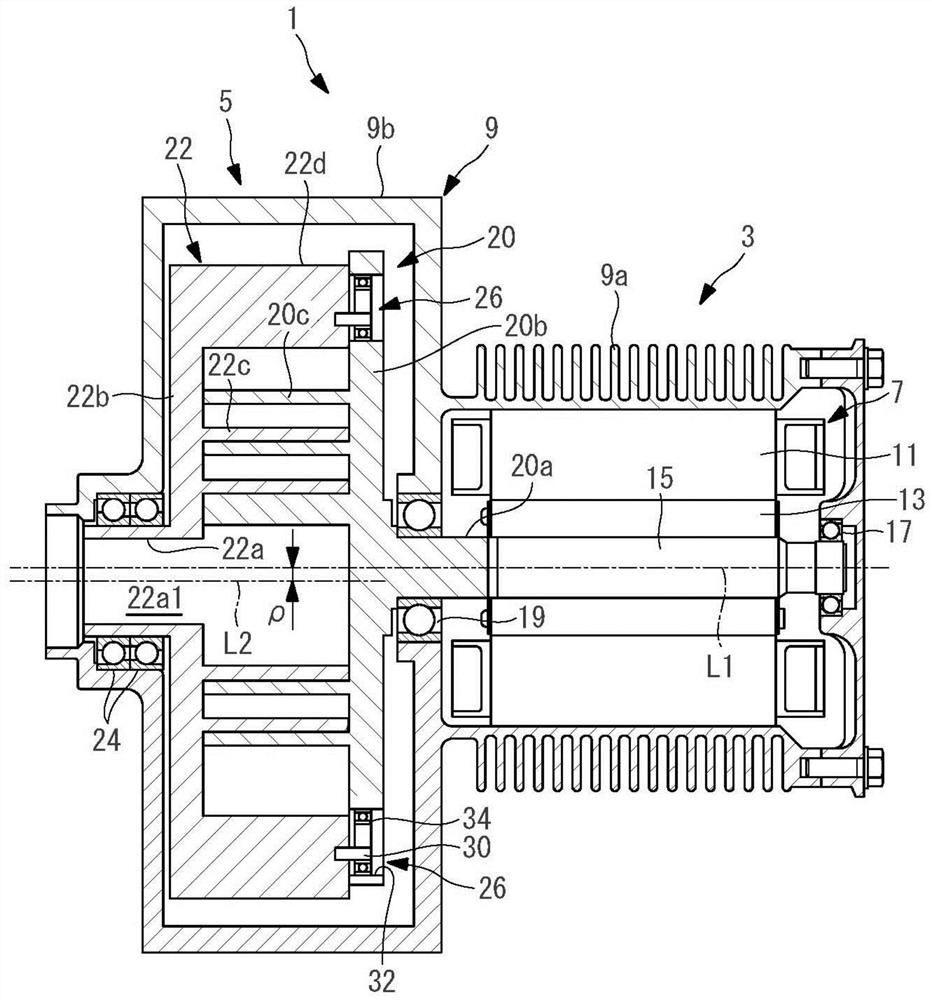

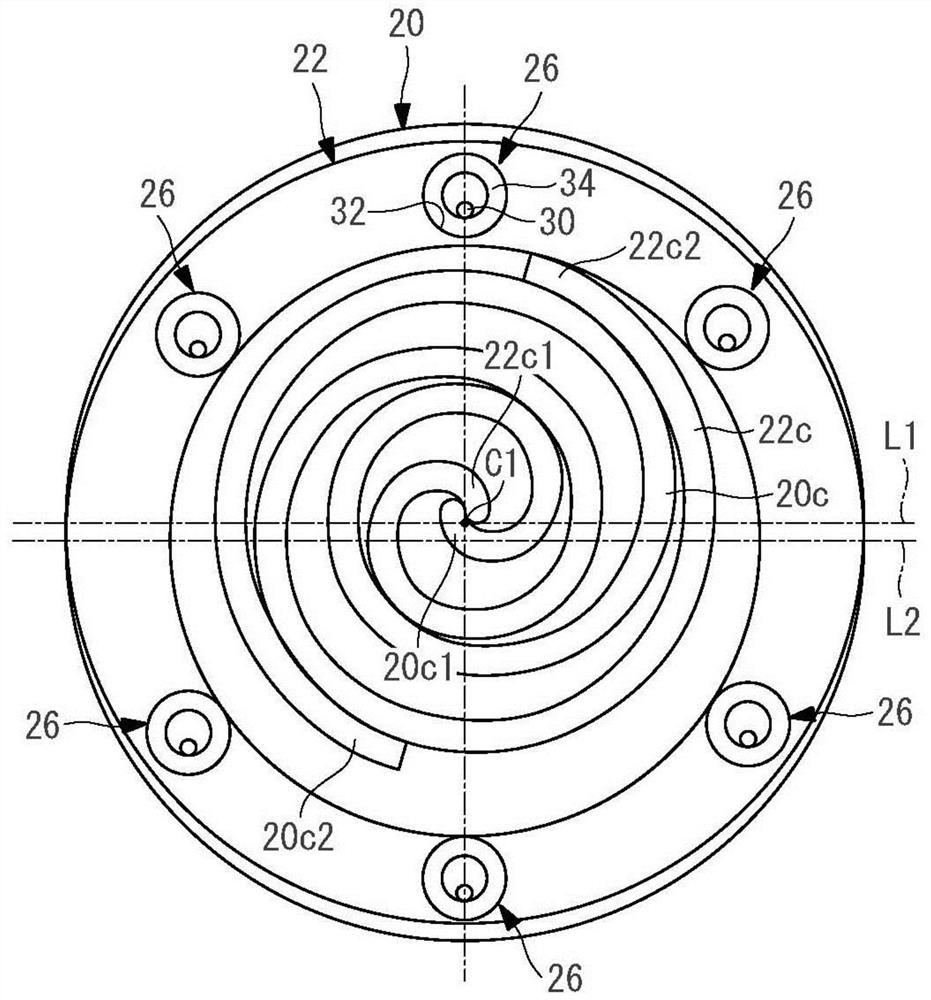

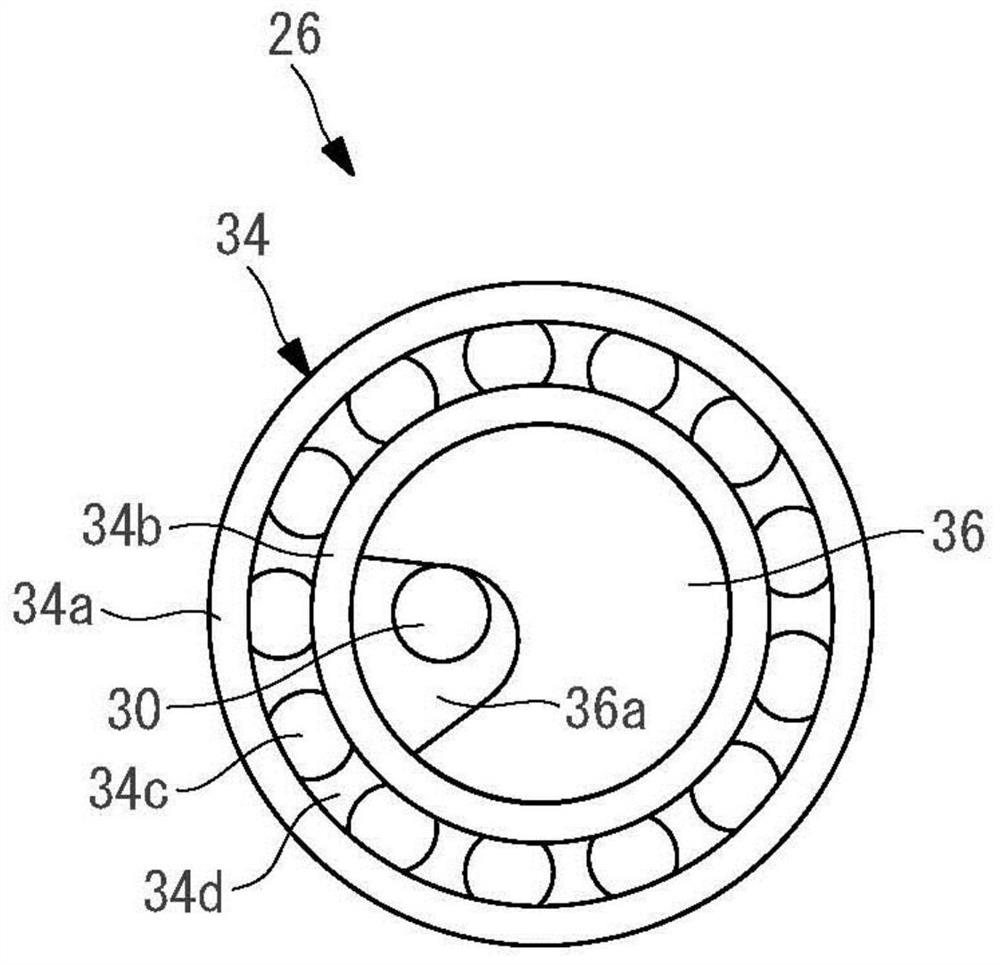

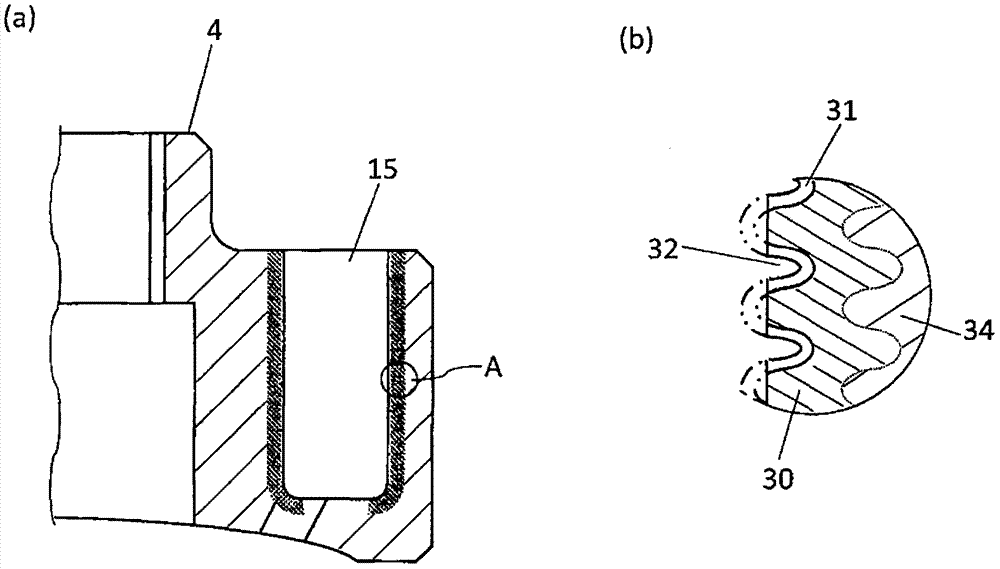

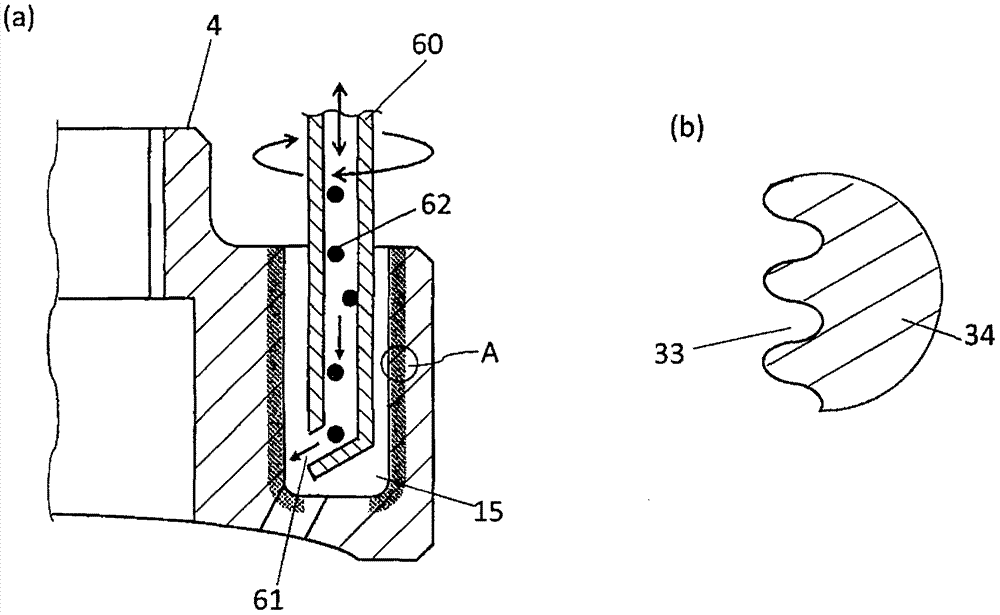

Scroll compressor

InactiveCN110139988BReduce loadReduce wearRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

A pin ring mechanism (26) is provided for supporting the driving scroll member and the driven scroll member so that the driving scroll member and the driven scroll member orbit and orbit relative to each other. The pin-ring mechanism (26) includes: a pin member (30); an inner ring (34b) in contact with the pin member (30), a plurality of balls (34c) rolling relative to the inner ring (34b), and a retainer (34d) a ring member (34); and a bush arranged on the inner periphery of the inner ring (34b) and rotated together with the inner ring (34b) by receiving the component force in the circumferential direction of the inner ring (34b) from the pin member (30) (36).

Owner:MITSUBISHI HEAVY IND LTD

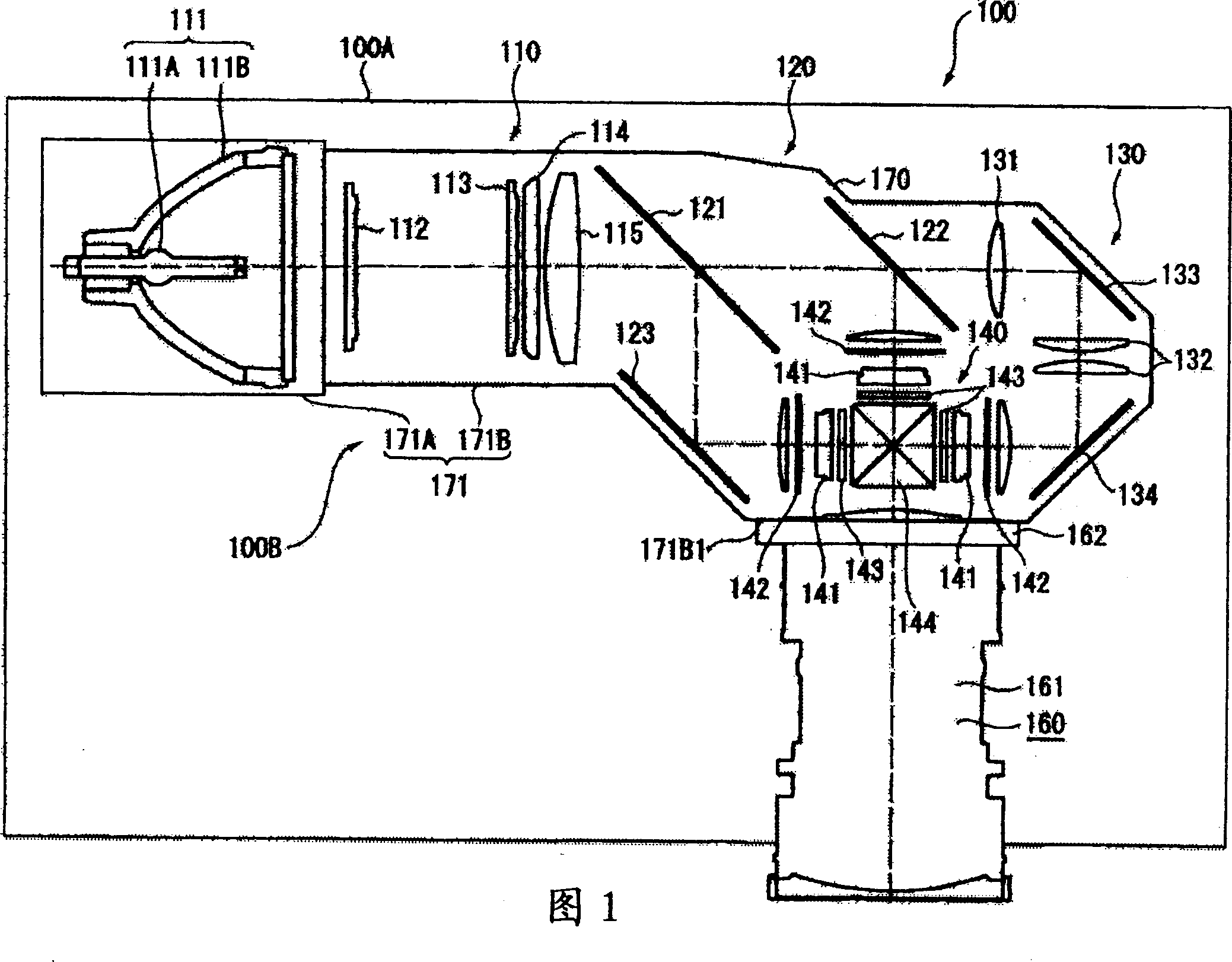

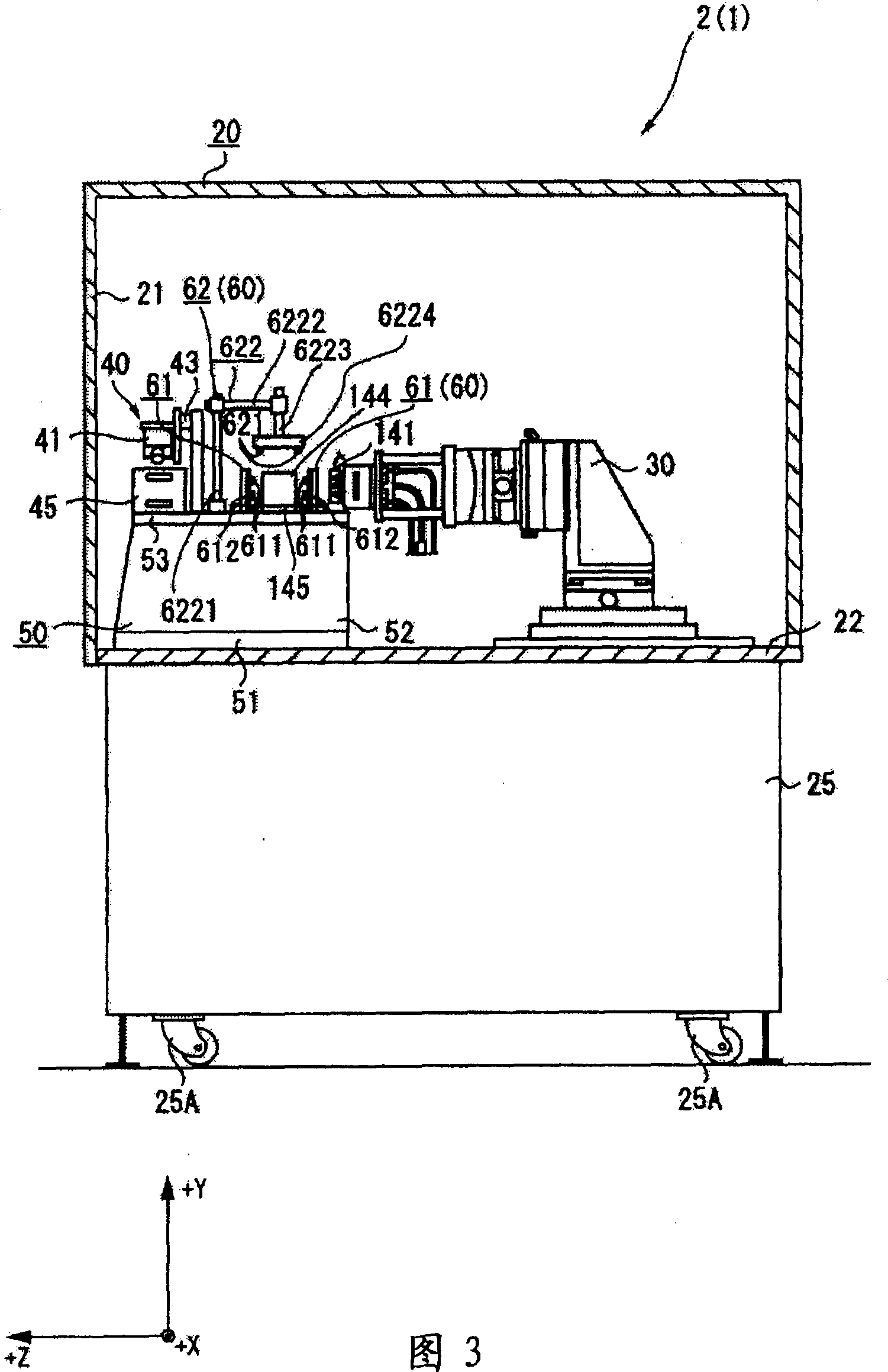

Ultraviolet irradiation apparatus and optical device manufacturing apparatus

InactiveCN1818740AReduce power consumptionPrevent thermal deteriorationPicture reproducers using projection devicesOptical elementsLight beamUltraviolet

To provide an ultraviolet ray irradiation device which is miniaturized and improved in convenience. The fixed device (3) functioning as the ultraviolet ray irradiation device is equipped with: an irradiation device main body (811) having a self light emitting element for emitting luminous flux in an ultraviolet region, a light condensing element for condensing the luminous flux and disposed on the luminous flux emitting side of the self light emitting element, and a fixed member made of metal which connects the self light emitting element to the light condensing element and is connected to the self light emitting element so that heat can be transmitted; and a moving mechanism (812) supporting the irradiation device main body (811) and moving the irradiation device main body in a direction where it approaches to or separates from an object to be irradiated.

Owner:SEIKO EPSON CORP

Heat-dissipating resin composition, substrate for LED mounting, reflector, and substrate for LED mounting having reflector portion

InactiveCN101583670BImprove cooling effectImprove insulation performanceSolid-state devicesHeat exchange apparatusHeat deflection temperatureEmissivity

The purpose of the invention is to provide a heat-dissipating resin composition which is used for forming a substrate for LED mounting or a reflector provided on the substrate for LED mounting, and excellent in heat dissipation, electrical insulation, heat resistance and light resistance during the time when an LED element emits light. Also disclosed are a substrate for LED mounting and a reflector respectively containing such a heat-dissipating resin composition. Specifically disclosed is a composition containing a thermoplastic resin such as a modified PBT and a thermally conductive filler such as a flake boron nitride. The composition has a heat distortion temperature of not less than 120 DEG C, a thermal conductivity of not less than 2.0 W / (m K) and a thermal emissivity of not less than 0.7.

Owner:TECHNO POLYMER CO LTD

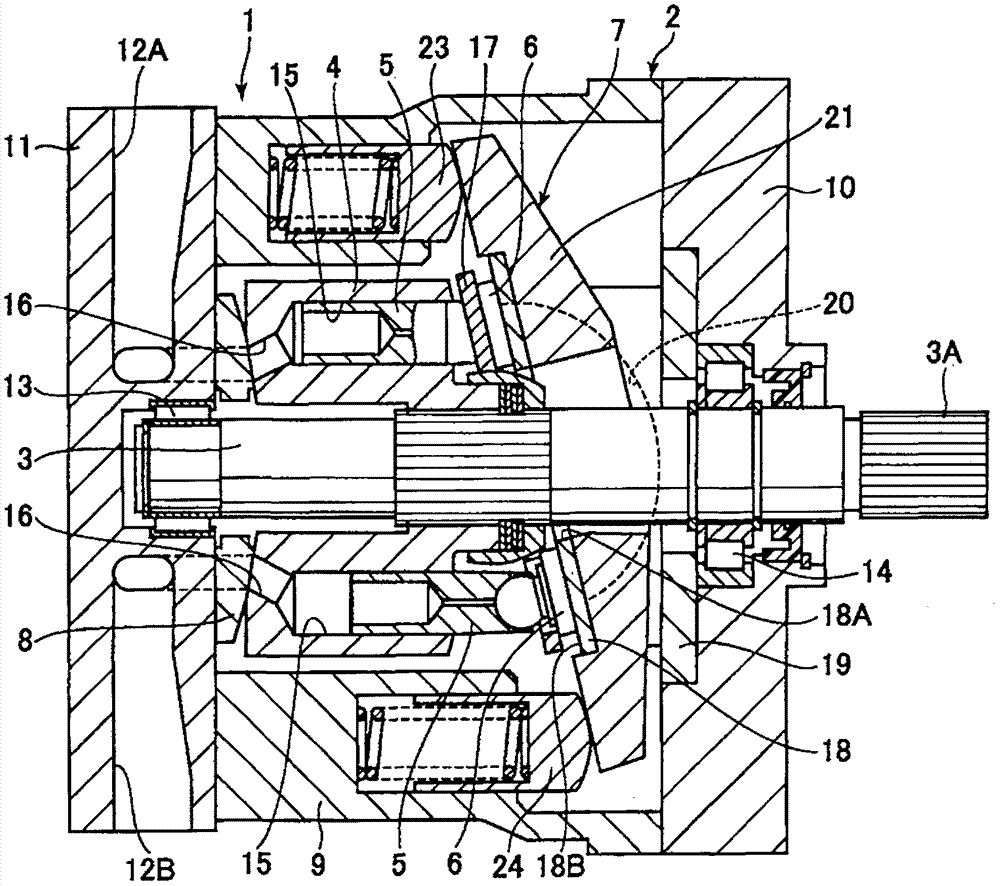

Hydraulic rotary machine and method for manufacturing hydraulic rotary machine

InactiveCN103306929BSeek long lifeImprove wear resistancePositive displacement pump componentsReciprocating piston enginesNitrogenEngineering

The invention provides a hydraulic rotating machine capable of improving the wearing performance and the lubricity of the sliding surface of the cylinder and the piston and a manufacturing method thereof. The hydraulic rotating machine(1) comprises a housing (2), a rotating shaft (3), a cylinder body (4), a piston (5), a slipper shoe (6), an inclined plate (7), and a valve plate (8). A cylinder hole (15) passes through the cylinder body (4), and a nitrogen diffusion layer (30) and a nitrogen compound layer (31), which are disposed in the cylinder hole (15) in the cylinder body (4), and are respectively the surface side of the sliding surface of the piston (5). The nitrogen diffusion layer (30) is disposed on a parent metal (34) side made of iron materials of the cylinder body (4), and the nitrogen compound layer (31) is disposed on the nitrogen diffusion layer (30). The parts of the surface sides of the nitrogen compound layer (31) and the nitrogen diffusion layer (30) can be removed to form the nitrogen diffusion layer (30), which can be exposed by removing the nitrogen compound layer (31), and the concave nitrogen compound layer (32), which is provided with the nitrogen compound layer in the concave part, can be provided.

Owner:NIHON KENKI CO LTD

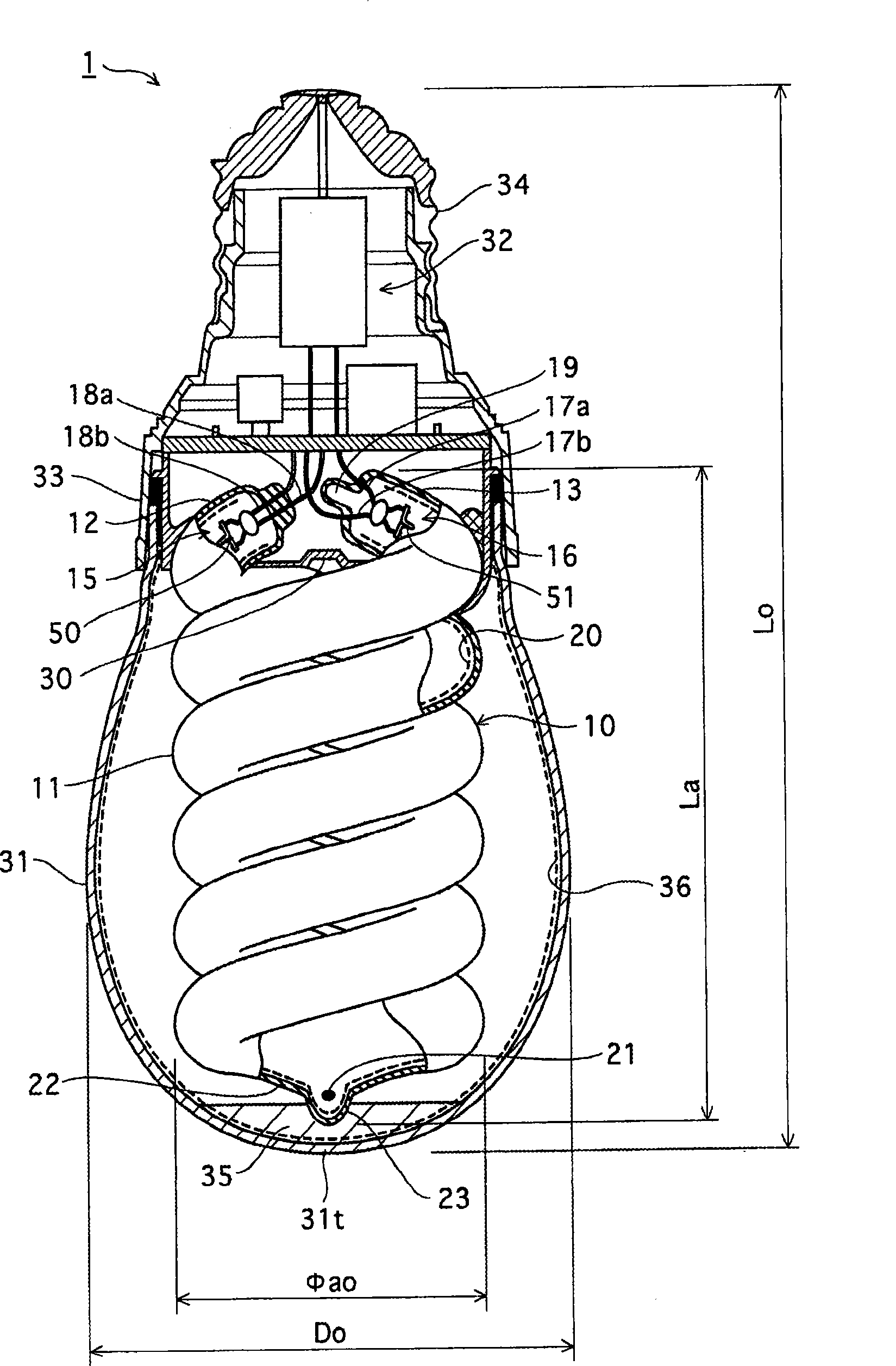

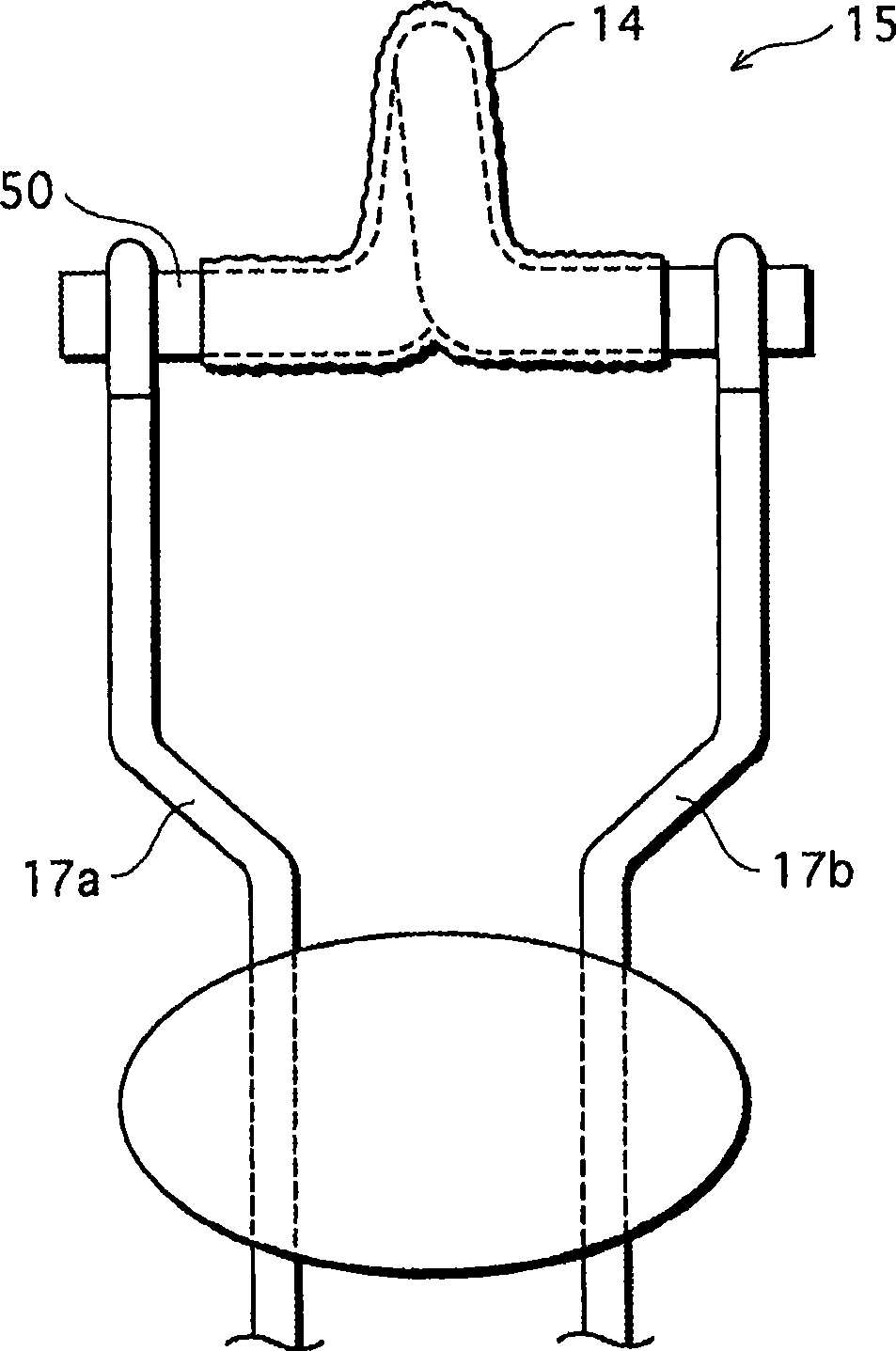

Electrode for discharge lamp and discharge lamp

InactiveCN101467229ASeek long lifeShape stableGas discharge lampsNon-linear opticsGas-discharge lampEngineering

An electrode for a discharge lamp includes a quadruple coil (50) made by winding a filament (41) to form a single coil (44), secondarily winding the single coil (44) to form a double coil (46), tertiarily winding the double coil (46) to form a triple coil (48), and quarternarily winding the triple coil (48). An electron emitting substance is filled in at least the tertiarily wound hollow portion (47') of the quadruple coil (50). Thereby, electrodes (15, 16) for the discharge lamp having a small size and a large capacity for filling the electronic emitting substance can be obtained.

Owner:PANASONIC CORP

Rotation support device for pinion shaft

InactiveCN102171469BGuaranteed rigidityReduce dynamic torqueBearing assemblyShaftsBall bearingRolling-element bearing

Construction of a rotation support device for a pinion shaft is achieved that, together with being able to sufficiently maintain axial rigidity of a rolling bearing on the side opposite from the pinion gear side, it is able to sufficiently reduce the dynamic torque during operation and the starting torque at the start of operation. Together with using a single-row angular contact ball bearing 14a as the rolling bearing on the side opposite from the pinion gear side, the ratio of the radius of curvature Ro of the outer raceway 22a and the diameter Bd of the balls 25a (Ro / Bd) is regulated within the range 0.52 < Ro / Bd ‰¤ 0.56, and the contact angle ± is regulated within the range of 35° to 40°.

Owner:NSK LTD

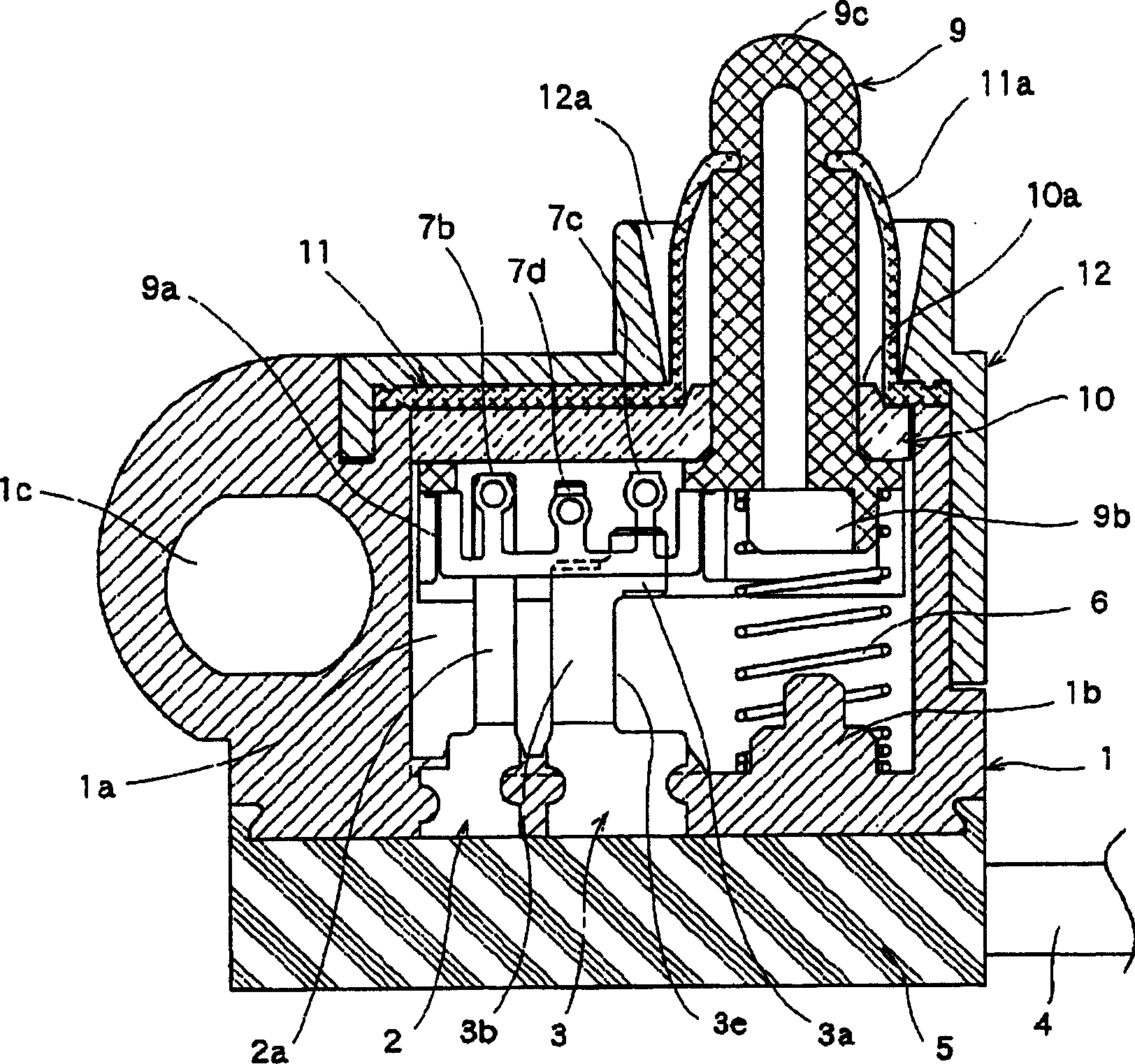

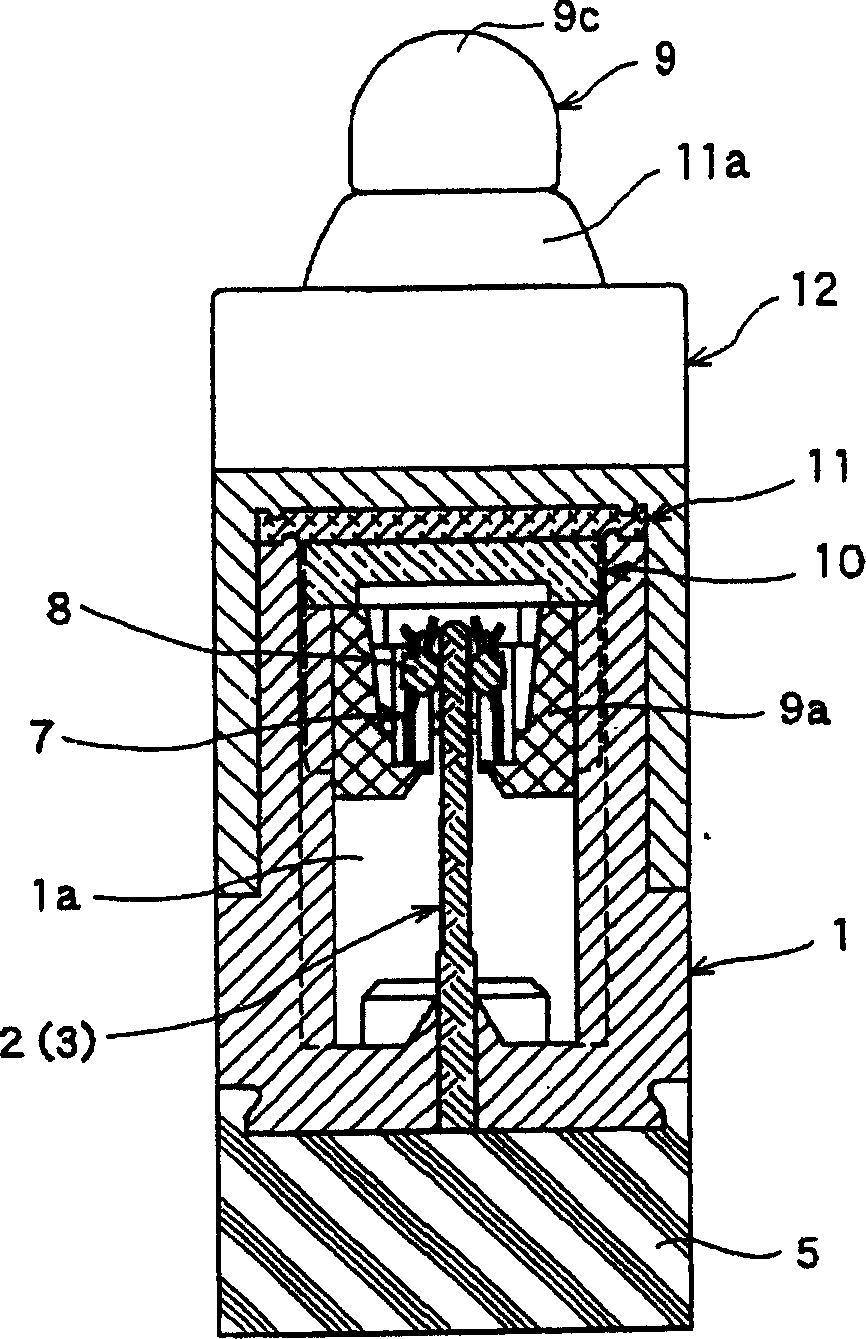

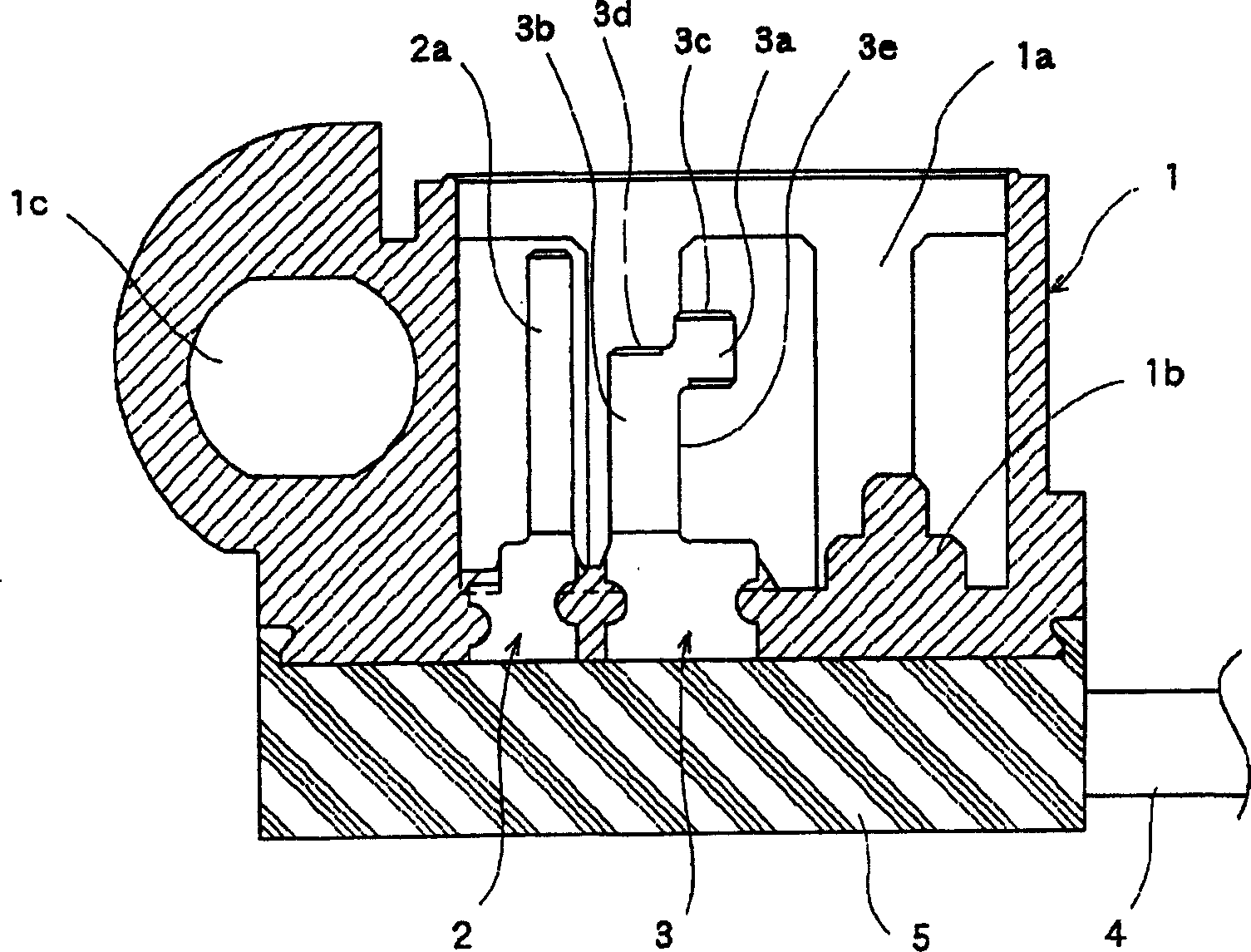

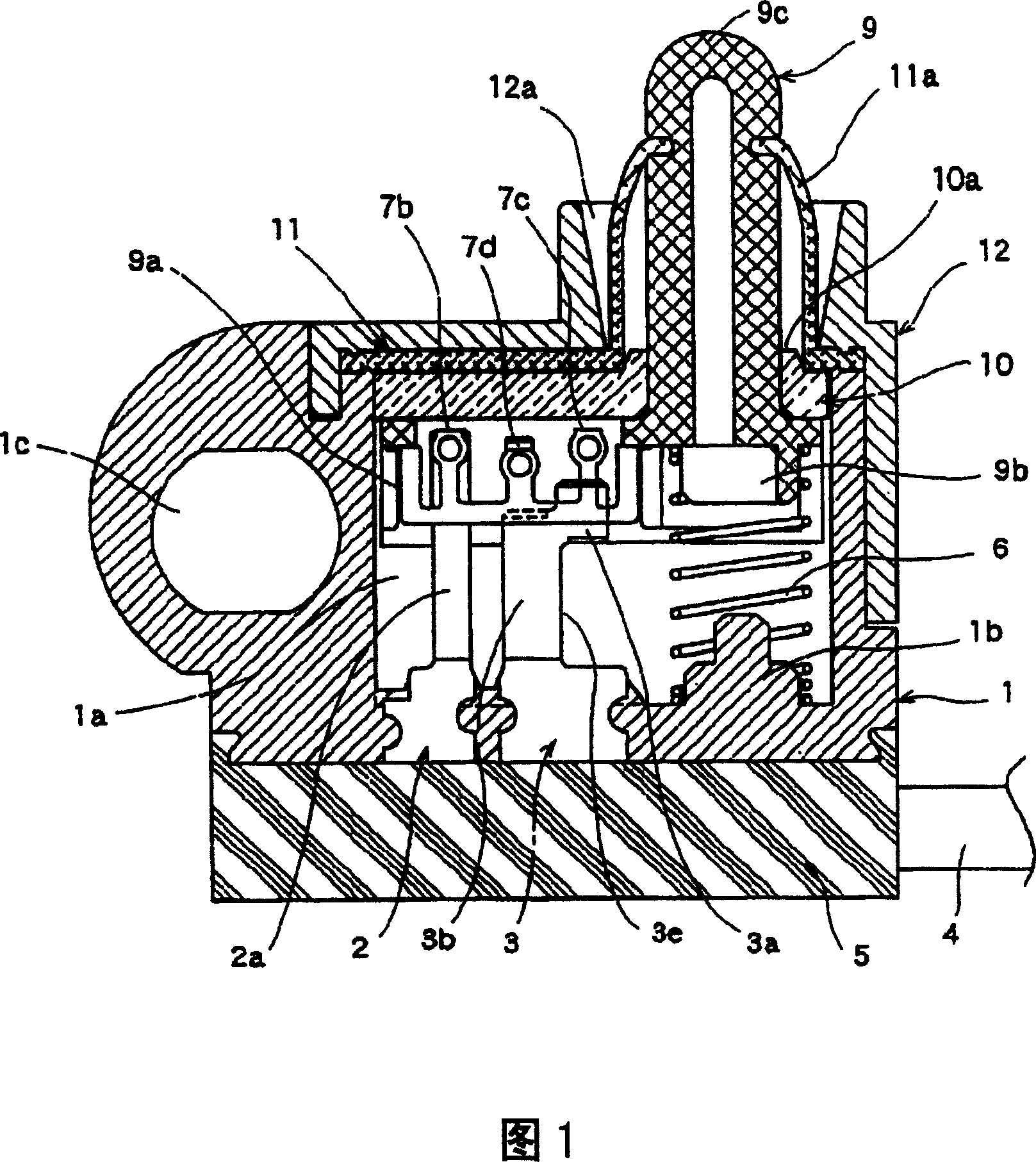

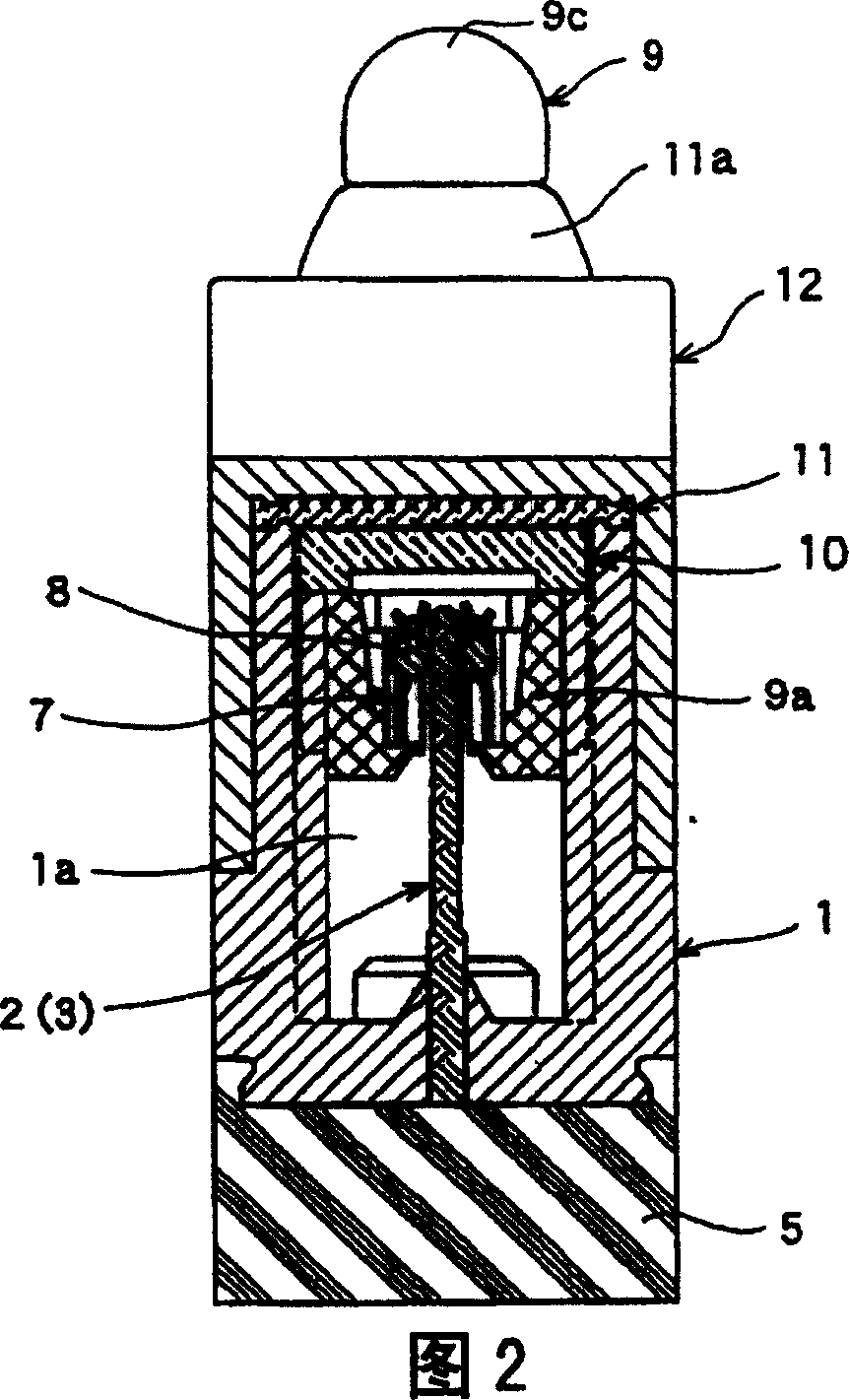

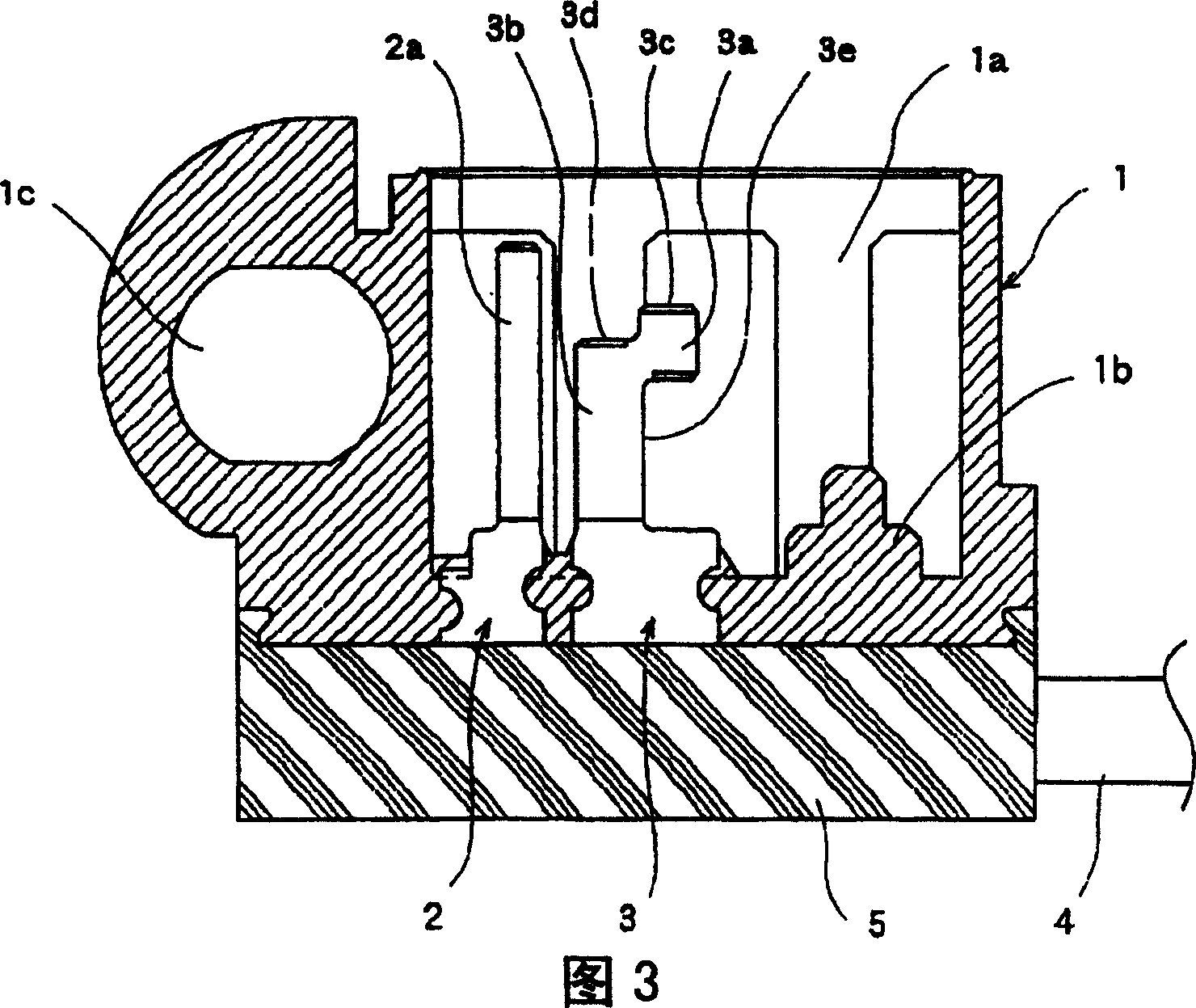

Switch device

A switchgear that can cope with both high-load areas and micro-areas, is less prone to arc consumption at high loads, and can obtain stable contact. Formed on the movable contact (7) is a first contact portion (7b) in sliding contact with the common fixed contact (2), and a second and third contact portion (7c, 7d) in sliding contact with the individual fixed contact (3), On the single fixed contact (3) along the direction perpendicular to the lifting direction of the drive member (9), form the first contact portion (3c) for arc consumption that first contacts the second contact portion (7c), and then contacts with the second contact portion (7c). The 2nd contact part (3d) that the 3rd contact part (7d) contacts, the bottom side of the 2nd contact part (3d) is used as the sliding contact surface with the 3rd contact part (7d), at the same time the first contact part (3c ) is formed on the track of sliding contact with the second contact part (7c) on the lower surface side of the second contact part (7c).

Owner:ALPS ALPINE CO LTD

Switch device

The invention provides a switch device capable of corresponding to a high load area and a minute area, resistant against the consumption due to the arc at a high load, capable of obtaining stable contact. A first contact part 7b contacting a common fixed contact 2, and second and third contact parts 7c, 7d contacting an individual fixed contact 3 are formed at a movable contact 7, and a first contact part 3c for arc consumption contacting the second contact part 7c along the direction perpendicular to the elevation direction of a driving member 9 earlier, and a second contact part 3d contacting the third contact part 7d later are formed on the individual fixed contact 3. The lower surface side of the second contact part 3d is applied as a contact surface contacting the third contact part 7d, and a non-conductive part separating from the second contact part 7c is formed on a contacting trace of the second contacting part 7c.

Owner:ALPS ALPINE CO LTD

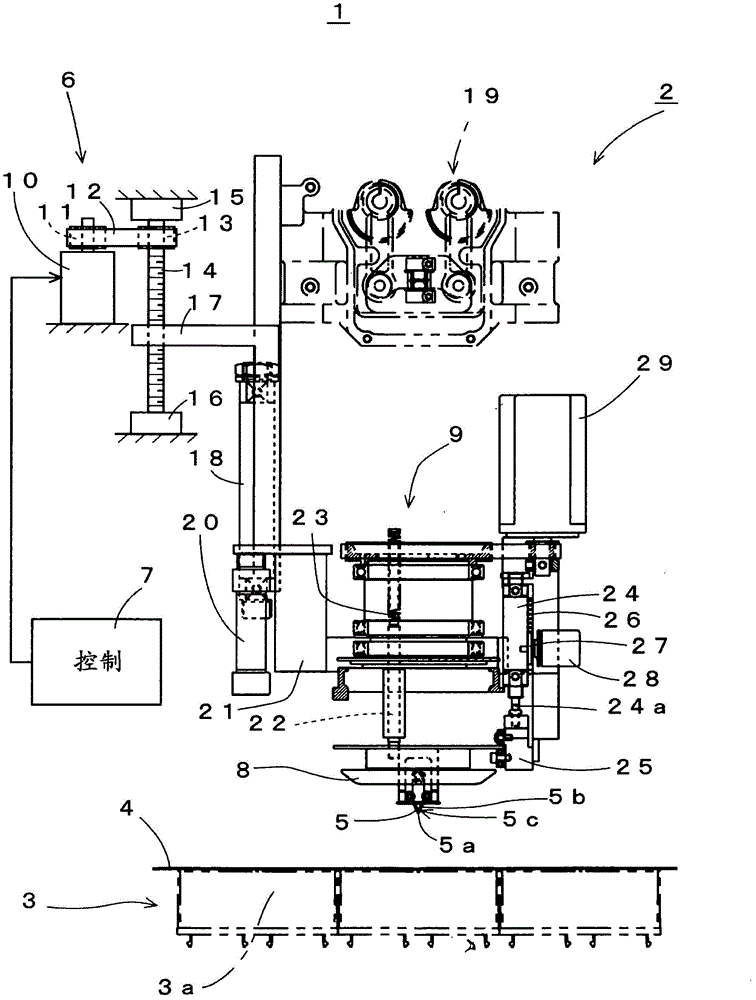

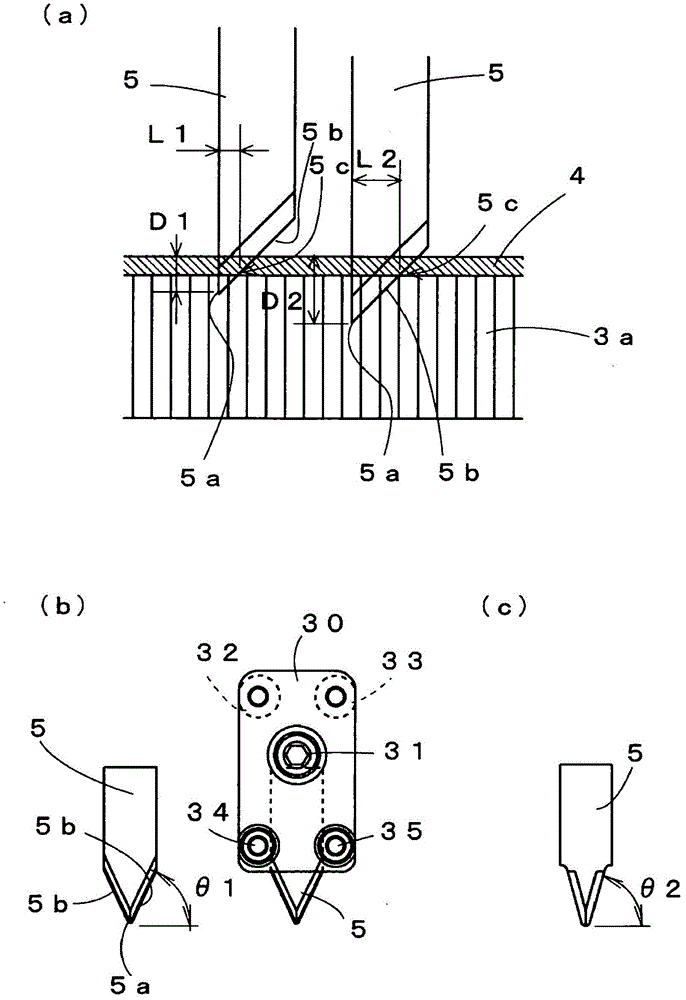

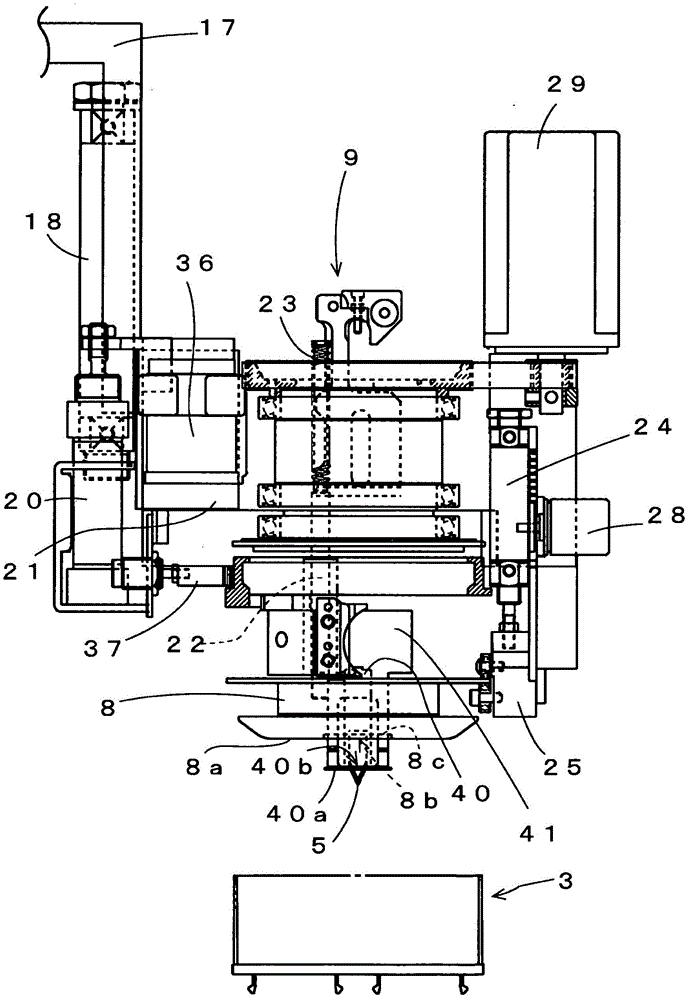

Cutting machine

ActiveCN103085102BSeek long lifeReduce replacement workMetal working apparatusOblique cuttingEngineering

The invention provides a cutting machine which may prolongs service life of a cutting knife in a simple structure and can reduce replacing work of the cutting knife. Cutting a sheet-like article is performed in an action position (5c) that becomes a part of a knife edge (5b) in a state of stabbing an oblique cutting knife (5) to the sheet-like article from above. A cutting knife elevation mechanism (6) is provided for elevating and moving the oblique cutting knife. Even if service life of the action position (5c) reaches the service life of the knife edge (5b), the action position can be switched to other action positions (5c) for continuous cutting. Since the knife edge (5b) is oblique, a distance between a reference position of a cutting head (2) and the action position (5c) varies according to the height of the action position (5c) relative to a knife tip (5a). Concerning the variation, control of the cutting head (2) is performed by modifying cutting data by the control portion (7), and thus cutting with no error can be performed.

Owner:SHIMA SEIKI MFG LTD

Air filtering apparatus

InactiveCN101024092AGuaranteed water permeabilitySeek long lifeMechanical apparatusLighting and heating apparatusAir filterHardness

In an air filtering apparatus including a gas-liquid contact member (5) disposed in a housing (2), an electrolytic water supply pipe (17) for dropping electrolytic water to the gas-liquid contact member and an air blowing fan (7) for blowing air to the gas-liquid contact member to which the electrolytic water infiltrates and blowing out the air to a room, a first sheet member (76) having water retentivity for distributing the electrolytic water dropped from the electrolytic water supply pipe to the gas-liquid contact member is disposed above the gas-liquid contact member, and the first sheet member is equipped with recess portions (76D) at which scale accumulates when hardness components in the electrolytic water precipitate as the scale, or cut-out portions (92) through which the electrolytic water is positively discharged when hardness components in the electrolytic water precipitate as scale and accumulates on the first sheet member.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com