Immersion type membrane separation apparatus and method of operating the same

A technology for membrane separation and membrane separation, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membranes, etc. It can solve the problems of low sweeping effect of the membrane surface, large reduction of separation membrane filtration function, insufficient cleaning of the membrane surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

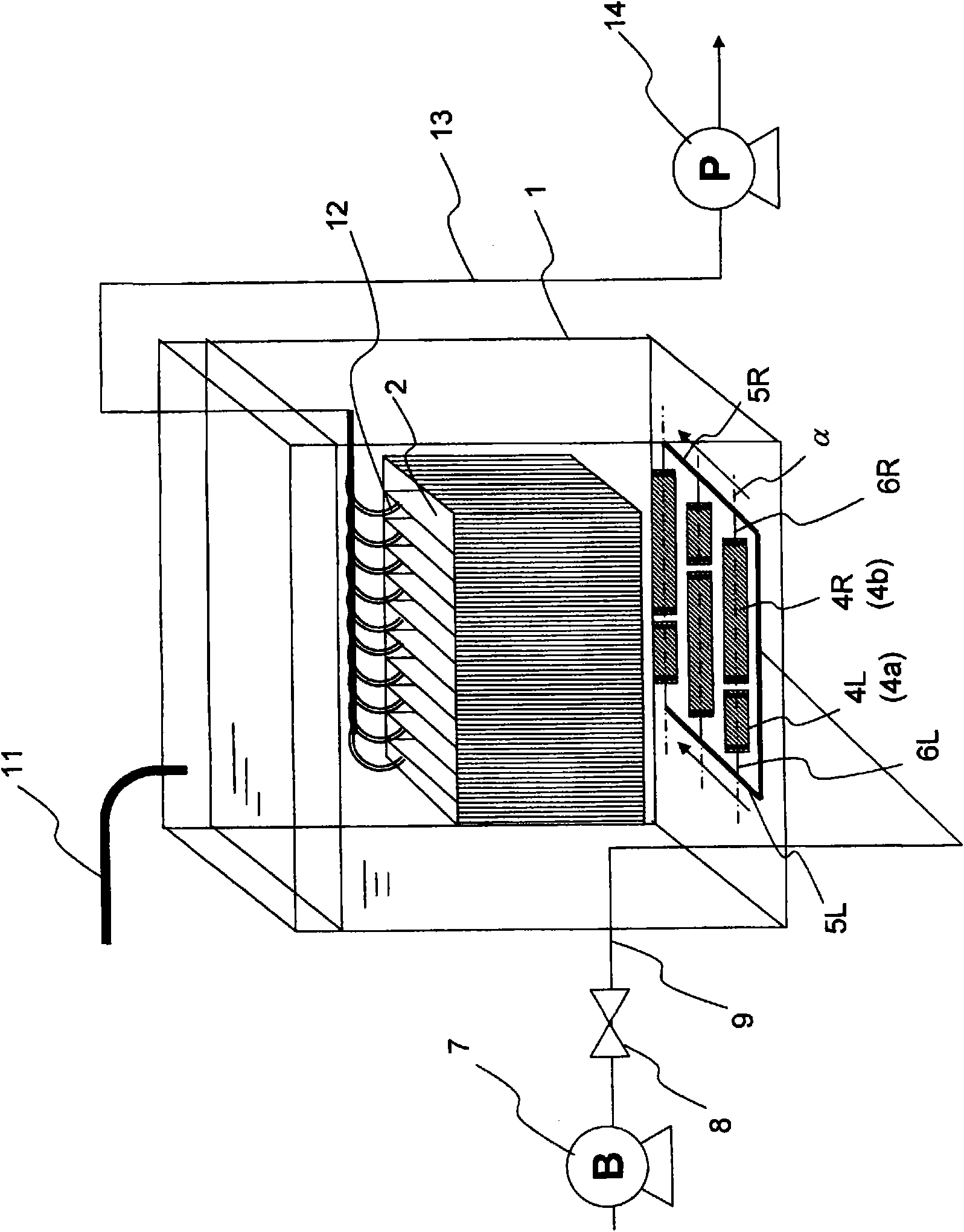

[0122] A specific example of the membrane separation device of the present invention is shown in FIG. 6 . Figure 6(a)(b)(c) are the front view, side view, and A-A sectional view of the membrane separation device, respectively. In this figure, the gas supply pipe and its upstream side are omitted.

[0123] In this device, 100 separation membrane elements arranged in parallel are arranged in the separation membrane module 2 . Vertically below the separation membrane module 2, there are provided a microbubble diffusion pipe extending horizontally from a branch pipe portion 6R of a gas supply pipe (not shown) on the right side, and a gas supply pipe (not shown) on the left side. ) The branch pipe part 6L is a microbubble diffuser pipe extending in the horizontal direction. The central axes α in the longitudinal direction of these microbubble diffuser tubes are arranged in four rows on substantially the same horizontal plane so that the tips of the microbubble diffuser tubes faci...

Embodiment 2

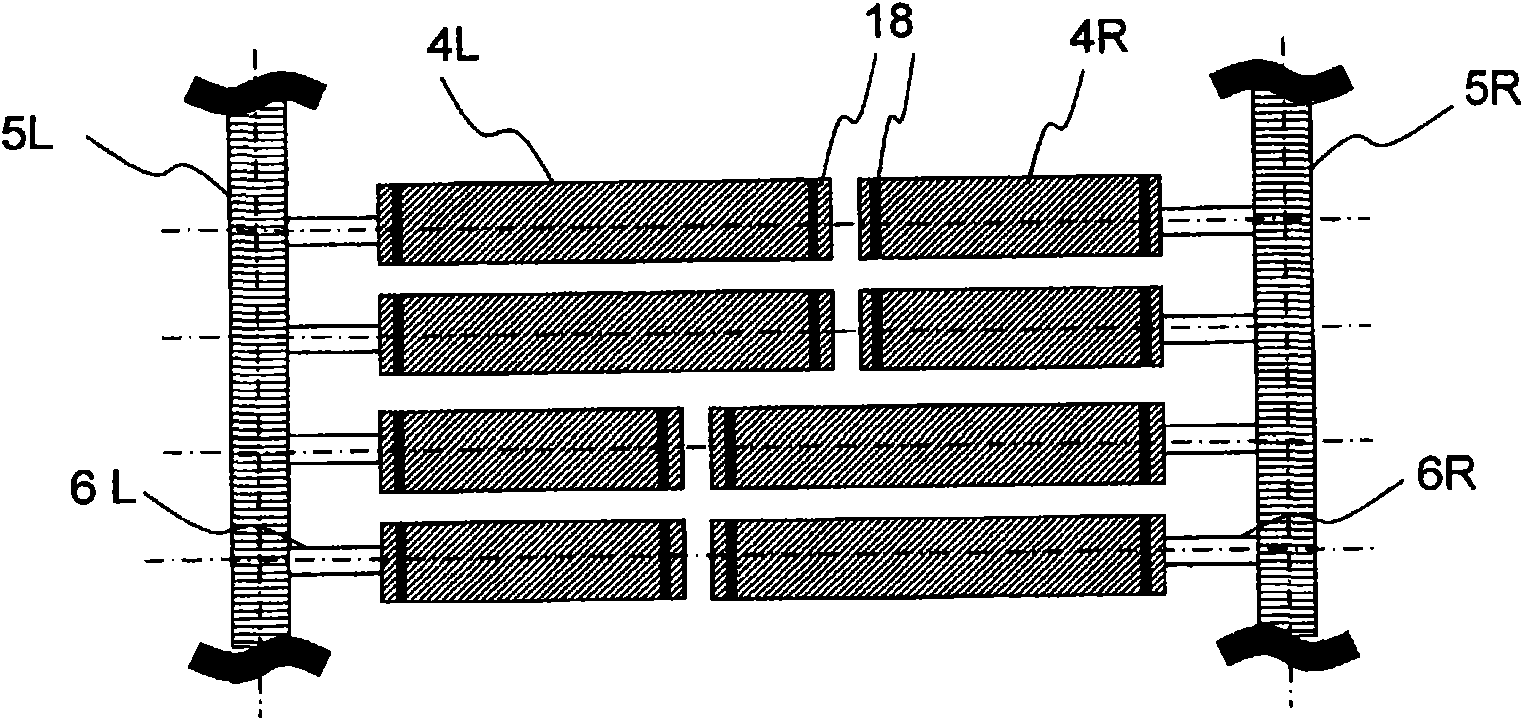

[0125] Another specific embodiment of the membrane separation device of the present invention is shown in FIG. 7, and FIG. 7(a), (b) and (c) are the front view, side view, and A-A sectional view of the membrane separation device, respectively. In this figure, the gas supply pipe and its upstream side are omitted.

[0126] The structure of the separation membrane module 2 in this device is the same as that of the first embodiment, and the structure of the diffuser pipes arranged below the separation membrane module 2 is different from that of the first embodiment. Vertically below the separation membrane module 2, there are provided a microbubble diffusion pipe extending horizontally from a branch pipe portion 6R of a gas supply pipe (not shown) on the right side, and a gas supply pipe (not shown) on the left side. ) The branch pipe part 6L is a microbubble diffuser pipe extending in the horizontal direction. As these micro-bubble diffuser tubes, all use long micro-bubble diff...

Embodiment 3

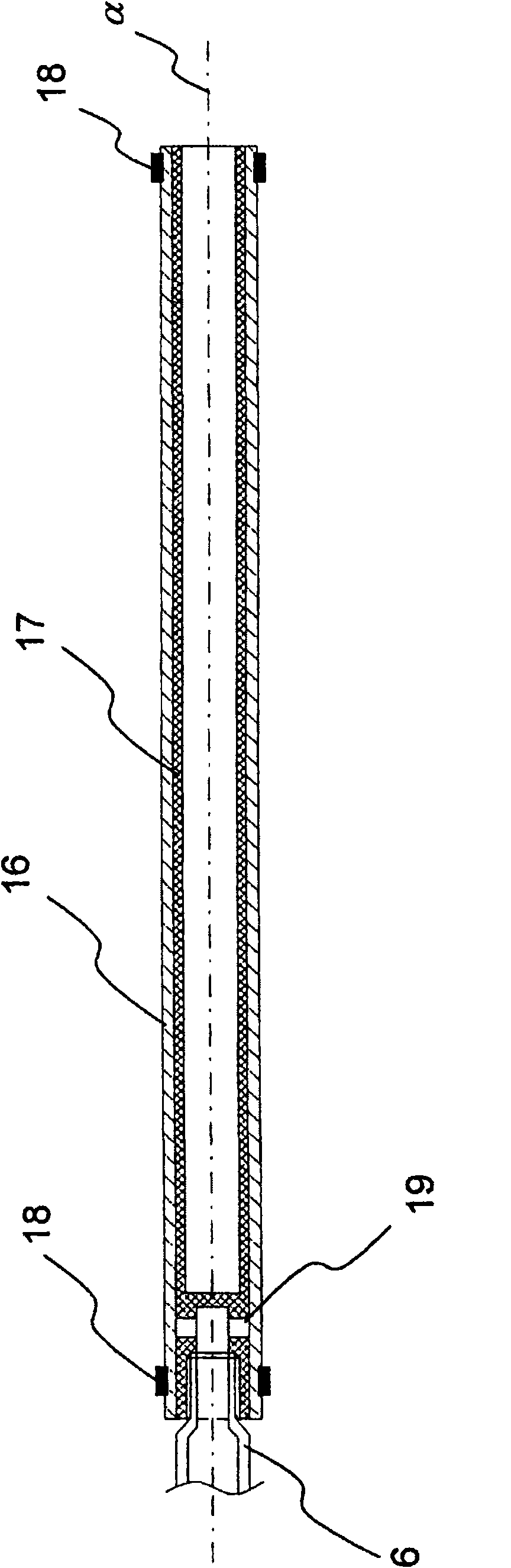

[0128] Separation membranes (flat membranes) were installed on the front and back of an ABS support plate (height 1000mm x width 500mm x thickness 6mm) as a substitute for the flow path material, and a membrane element was produced (separation membrane area: 0.9 m 2 ). Here, a flat membrane made of polyvinylidene fluoride having a surface average pore diameter of 0.08 μm and a surface roughness (RMS) of 0.062 μm was used as the separation membrane.

[0129] Next, the inside size (approximate size) was 1000 mm in height x 515 mm in width x 1400 mm in depth, and the box body which opened up and down was manufactured. A frame is connected under the box, and a micro-bubble diffuser tube is fixed at a predetermined position in the space inside the frame. The distance from the lower end of the component to the micro-bubble diffuser tube in the vertical direction is 220mm. At this time, on the side surface parallel to the arrangement direction of the membrane elements, the area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com