Electrode for discharge lamp and discharge lamp

A discharge lamp and electrode technology is applied in the fields of electrodes for discharge lamps, electrodes for discharge lamps and discharge lamps, and can solve the problems that electron-emitting substances cannot be kept stable, electrodes cannot be installed in luminous tubes, and electron-emitting substances cannot be filled, and the like. The coil size is not easy to increase, the filling capacity is ensured, and the function is enhanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Next, an electrode for a discharge lamp and a discharge lamp according to an embodiment of the present invention will be described with reference to the drawings.

[0045] 1st embodiment

[0046] Use the following Figure 1~6 The electrode for a discharge lamp and the discharge lamp according to the first embodiment will be described.

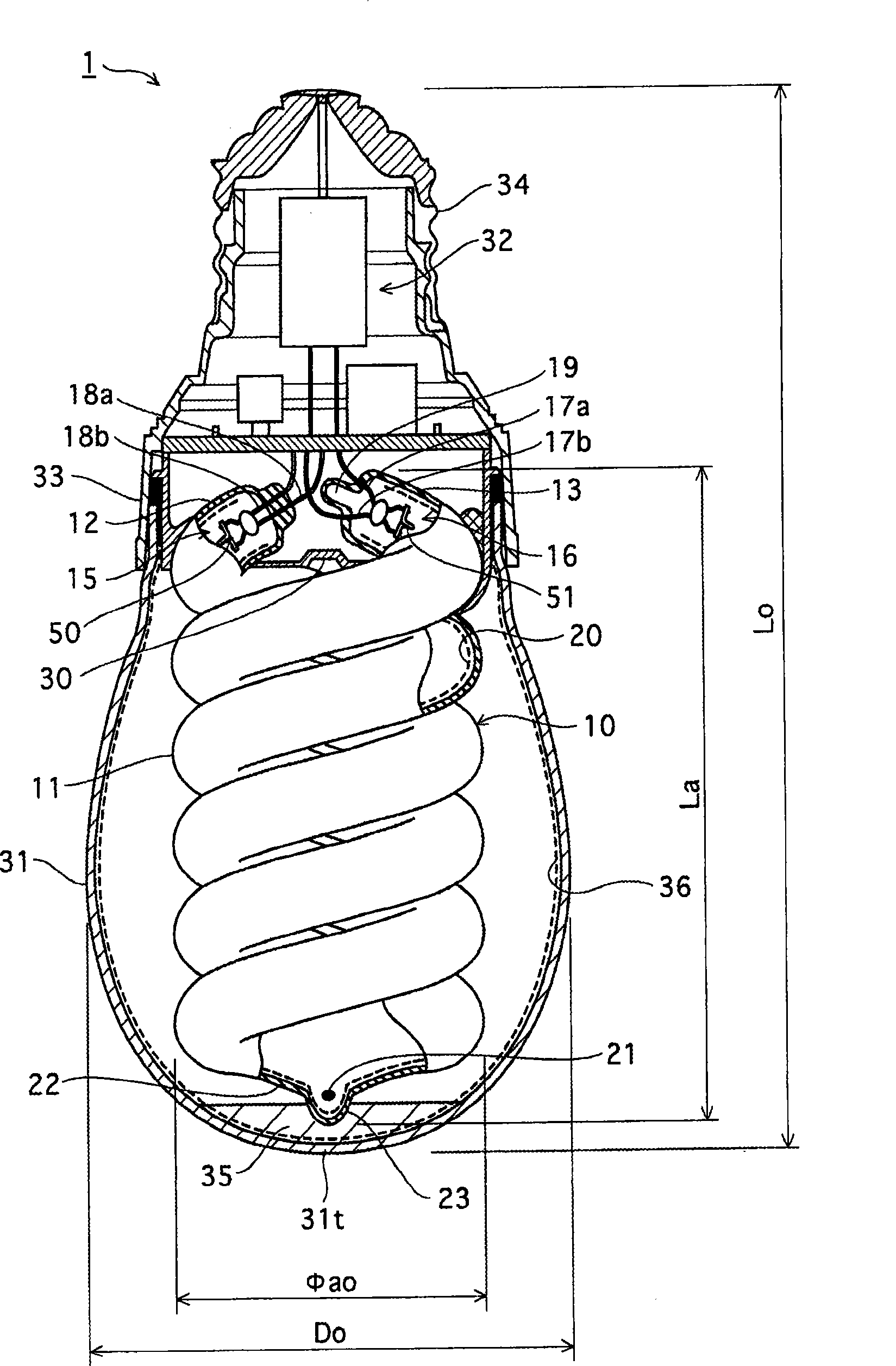

[0047] figure 1 It is a sectional view showing the discharge lamp of the first embodiment. The discharge lamp (hereinafter referred to as lamp) of the first embodiment is a bulb-shaped fluorescent lamp (12W) for replacing a general bulb (60W), and its basic structure is based on that of an existing lamp.

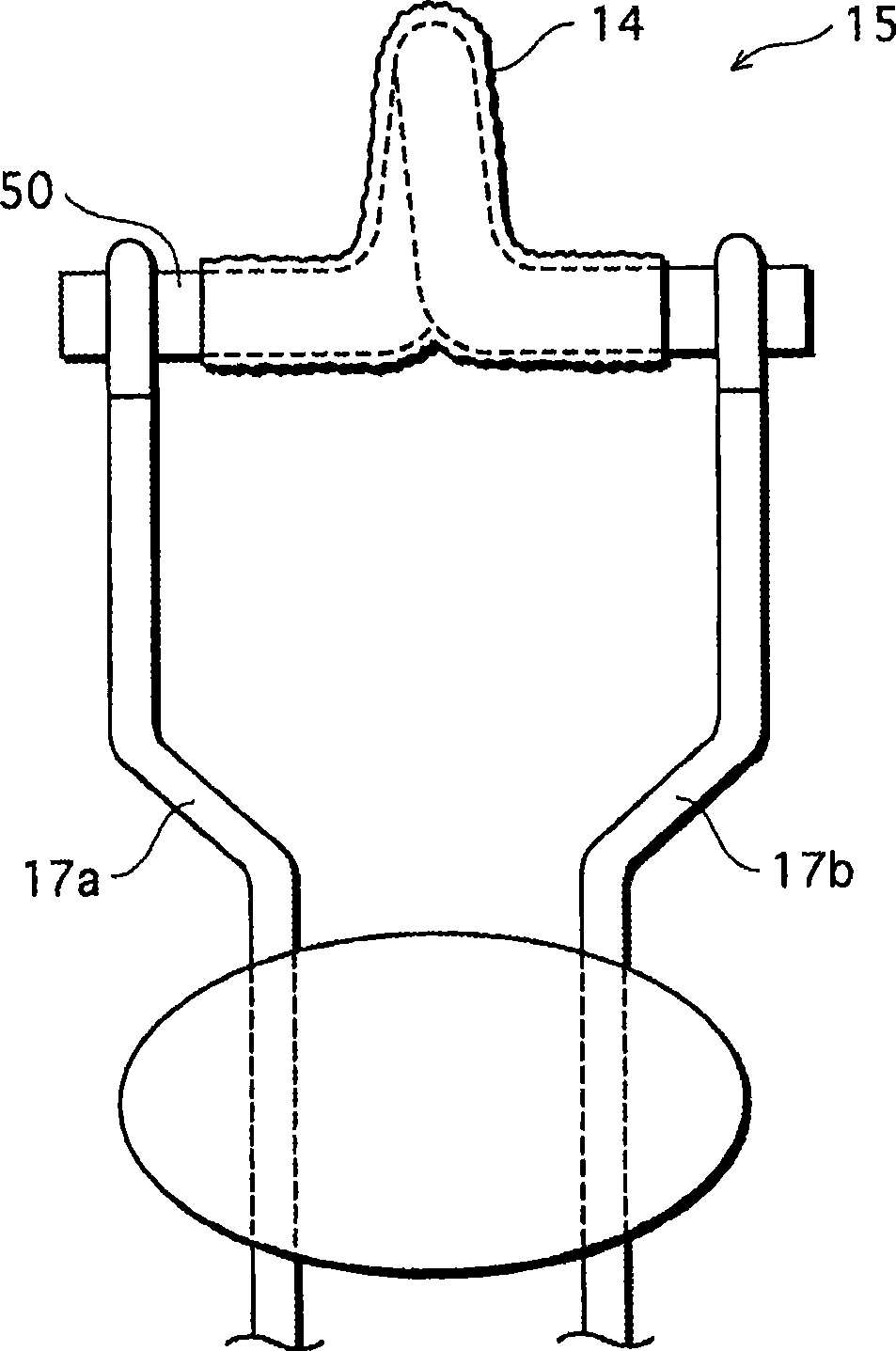

[0048] Such as figure 1 As shown, the lamp 1 includes an arc tube 10, a supporting resin member 30 supporting the arc tube 10, an eggplant-shaped glass outer tube bulb 31 including the arc tube 10, and a lamp integrally assembled on the supporting resin member 30. An electronic stabilizer 32 of a so-called series inverter type f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com