Rotation support device for pinion shaft

A pinion shaft and rotary support technology, applied in gear transmission, bearing assembly, bearings for rotary motion, etc., can solve problems such as saving fuel consumption and increase in automobiles that are difficult to deal with, ensuring the rigidity of bearings and preventing axial displacement. Excessive amount, the effect of ensuring axial rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

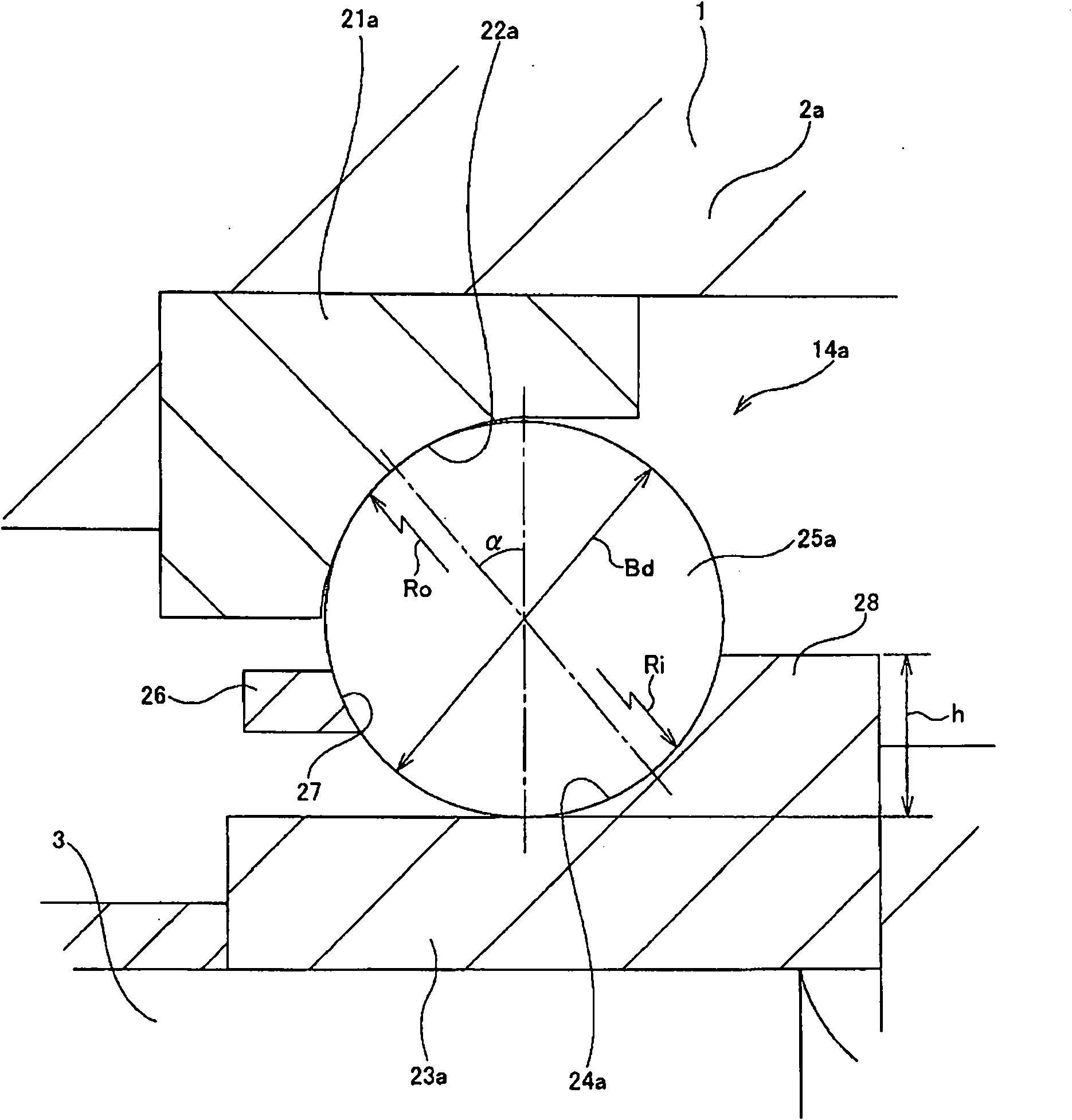

[0076] Next, refer to Figure 4-8 Experiments conducted to confirm the effects of the present invention will be described. First, an experiment conducted to obtain the relationship between the outer ring groove R ratio (Ro / Bd) and the dynamic torque will be described. In the experiment, 8 samples (contact angles are all 40°) with different values of the outer ring groove R ratio in the range of 0.51 to 0.58 were used. 73mm 2 / s) Mineral oil, each sample was run under forced lubrication conditions. In addition, an axial load (2770N) was applied to each sample, and the rotational speed of the inner ring was 3000min. -1 . Figure 4 shows the results of the experiments performed in this way. by the Figure 4 From the experimental results shown, it is clear that the dynamic torque is sufficiently reduced when the outer ring groove R ratio is set to a value larger than 0.52.

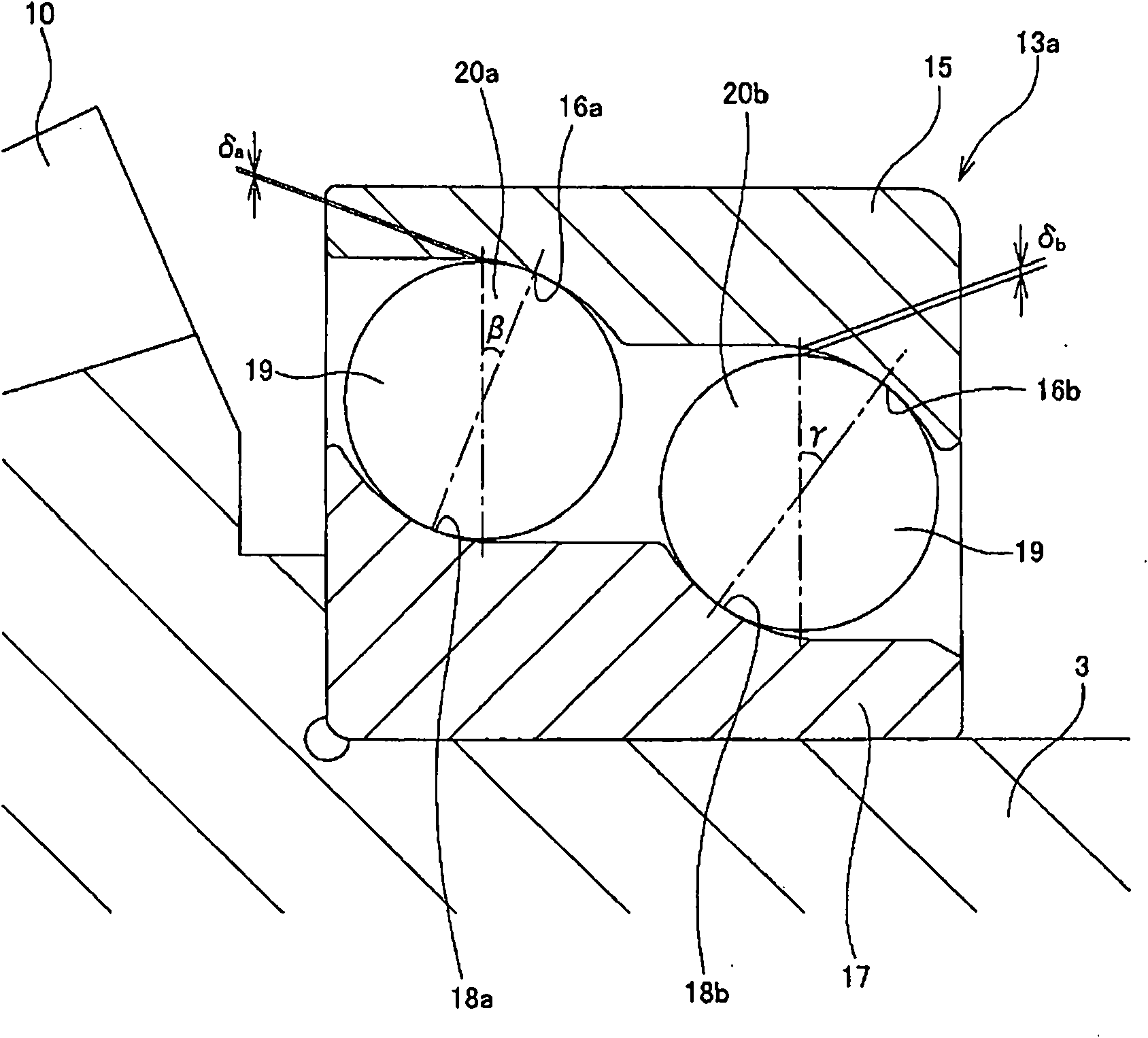

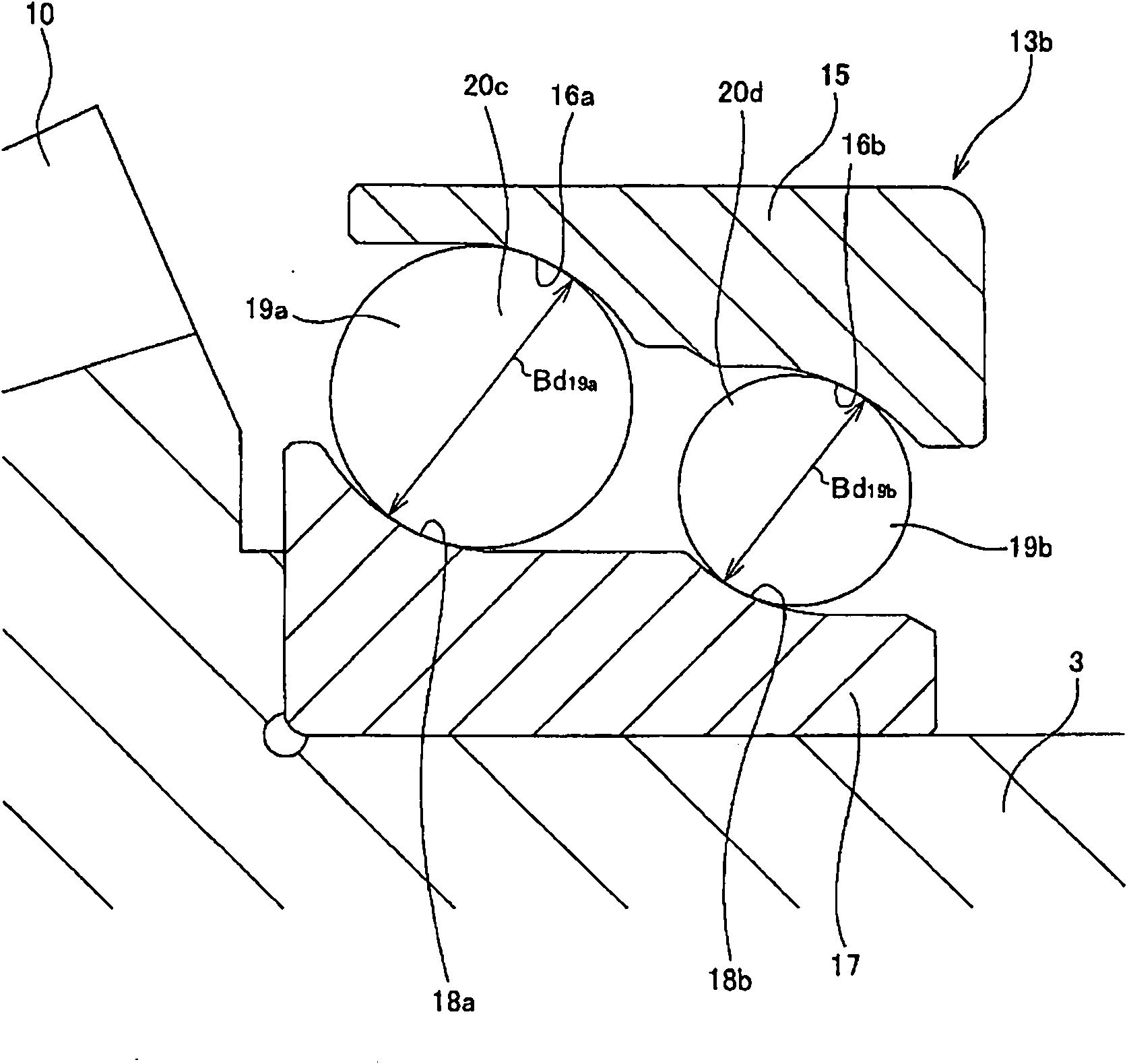

[0077] Next, an experiment performed to obtain the relationship between the outer ring groove R ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com