Diamond-coated cutting tool

A cutting tool and diamond technology, applied in the field of diamond-coated cutting tools, can solve the problem of insufficient wear resistance on the surface of diamond film, and achieve the effects of improving chip discharge, seeking long life and excellent wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

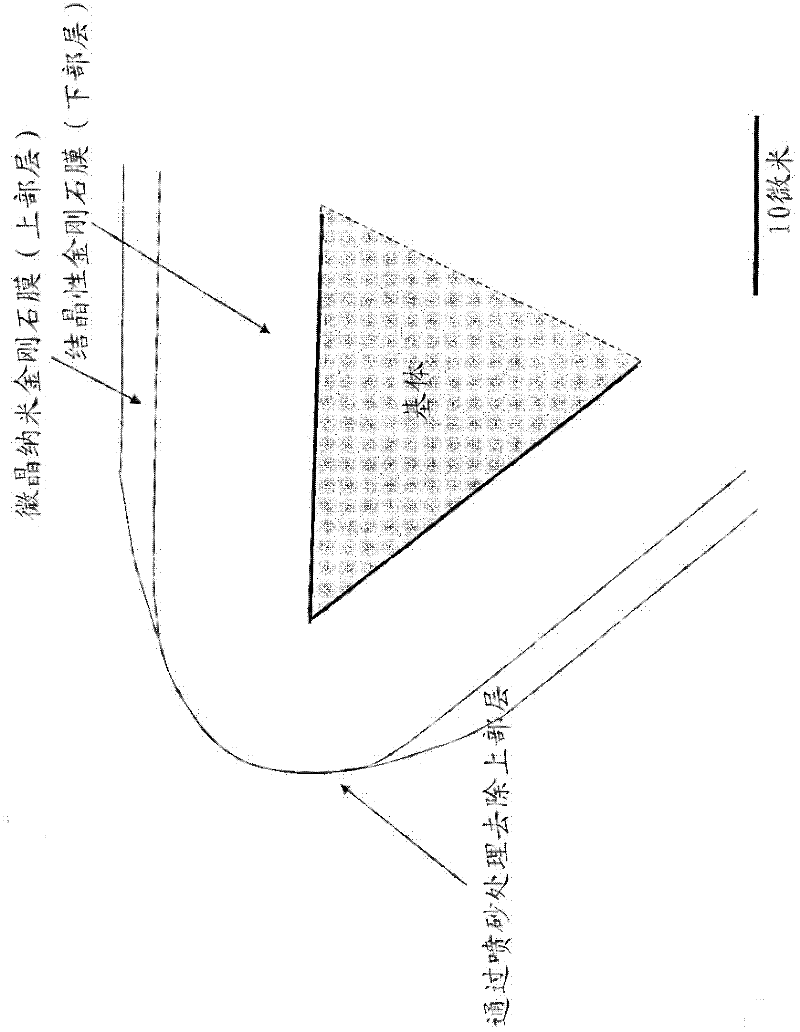

[0052] First, prepare the raw material powders shown in Table 1, which all have a predetermined average particle size in the range of 1 to 3 μm, and prepare mixed powders with the same composition shown in Table 1, wet-mix this with a ball mill for 72 hours, and dry it. , Formed by 100MPa pressure stamping to form round rod compacts with diameters of 10mm and 8mm, and sinter these round rod compacts to manufacture sintered bodies. In addition, use grinding to process the outer diameter of the groove forming part to 8mm and 6mm. At this time, the outer peripheral edge and the edge of the cutting edge are subjected to gas blasting using SiC abrasive grains of #600 and finishing grinding of 30 μm or more using a diamond wheel of #1200 to produce the outer edge. Tool bases 1-5 with a diameter of 8 mm and tool bases 6-10 with an outer diameter of 6 mm.

[0053] (a) Next, on the above-mentioned tool substrates 1 to 10, use a solution of mixing sulfuric acid, hydrogen peroxide and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com