Surge absorber

A technology for surge absorption and components, applied in the field of surge absorbers, can solve the problems of weak coating adhesion and difficulty in fully exerting the characteristics of SnO coating, and achieve the effect of suppressing scattering and shortening life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

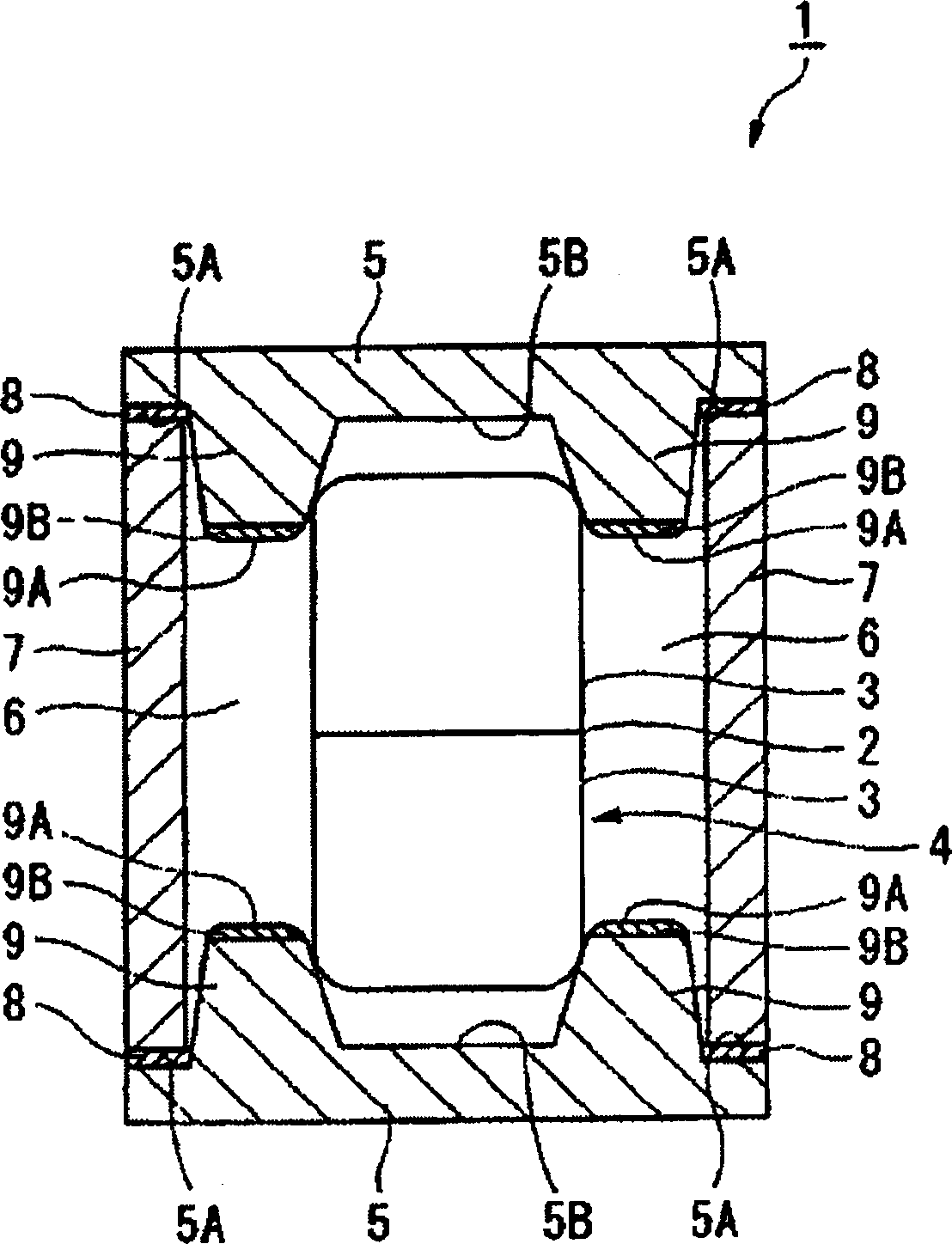

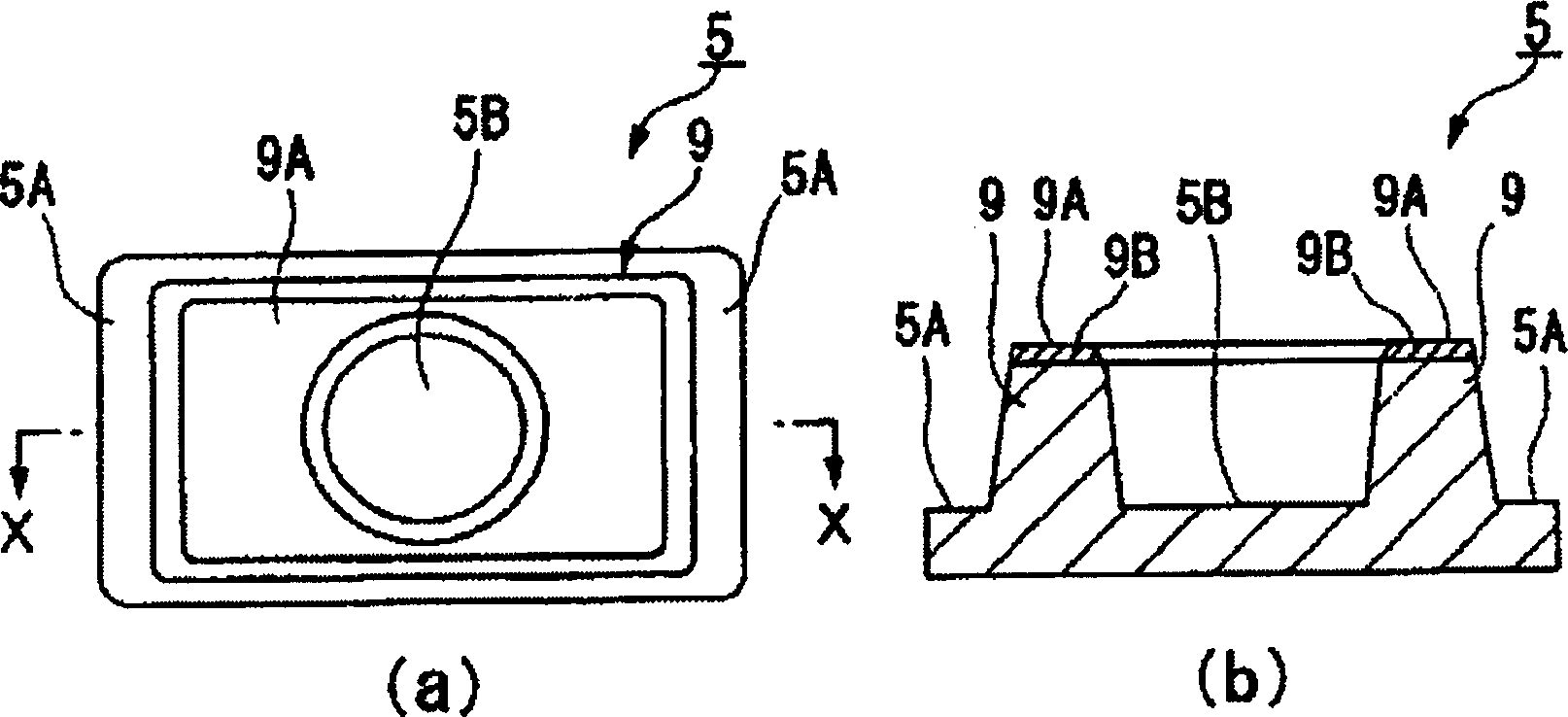

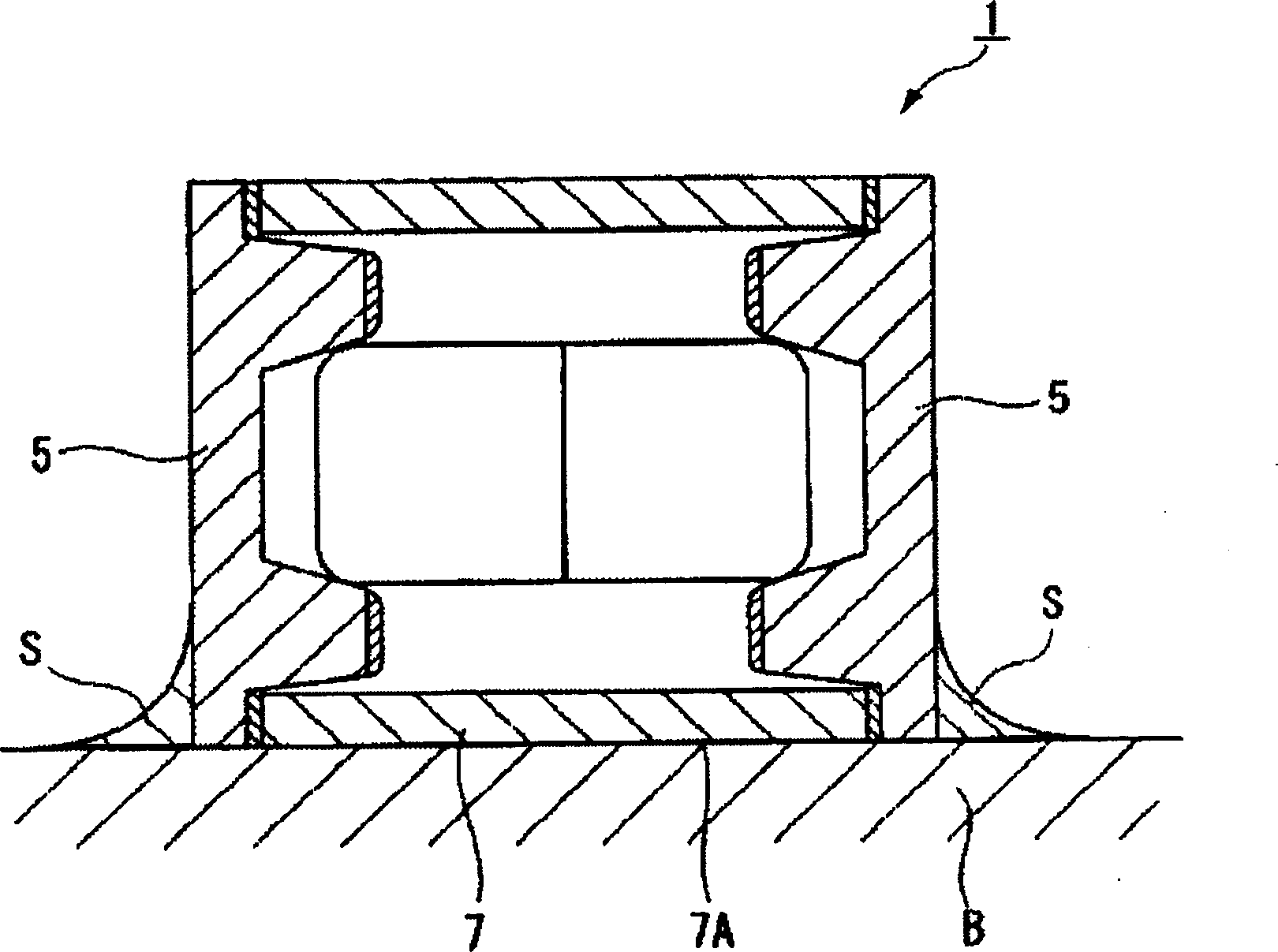

[0101] Second, refer to Figure 9 and Figure 10 , the surge absorber related to the present invention will be described in detail through examples.

[0102] The lifetimes of the surge absorber 20 according to the second embodiment described above and a conventional surge absorber without the oxide film 23B were compared with each other when mounted on a substrate or the like and used.

[0103] Specifically, as an example, the Figure 9 The surge current shown is repeatedly applied to the surge absorber for a given number of times, and the result of measuring the discharge start voltage V in the gap at this time is expressed in Figure 10 Indicated.

[0104] In the conventional surge absorber, if the surge current is repeatedly applied, the metal components of the metal electrodes of the main discharge electrode parts are mostly scattered, and these metal components accumulate in the micro gaps in a short time, so the discharge between the gaps starts. The voltage is reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com