Manufacturing method of display panel and substrate for display device

A technology for display devices and display panels, applied in identification devices, lighting devices, semiconductor/solid-state device manufacturing, etc., to prevent water vapor and oxygen, prevent drive circuit degradation, and achieve long life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

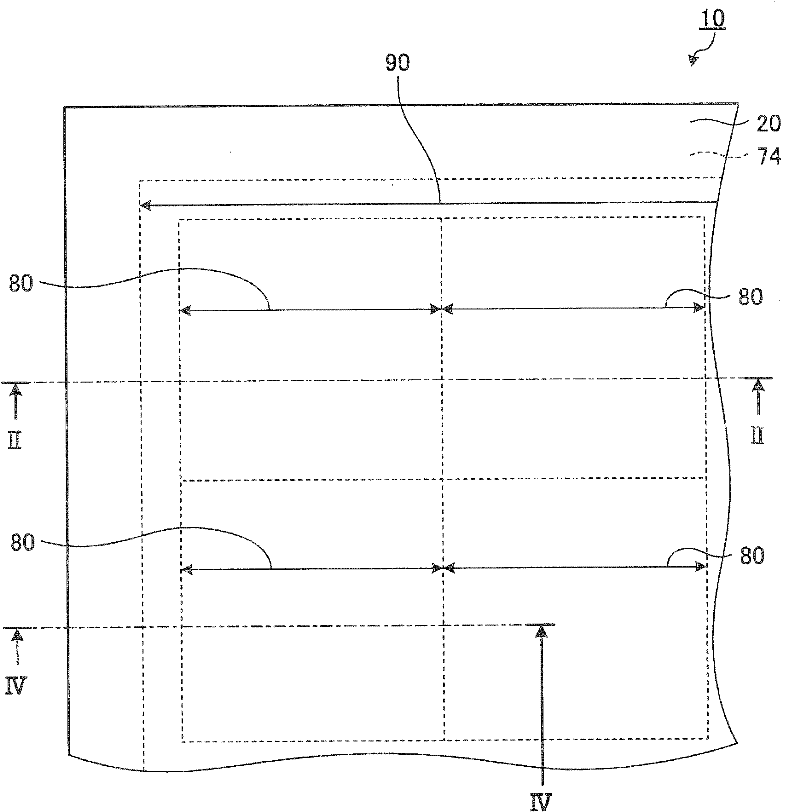

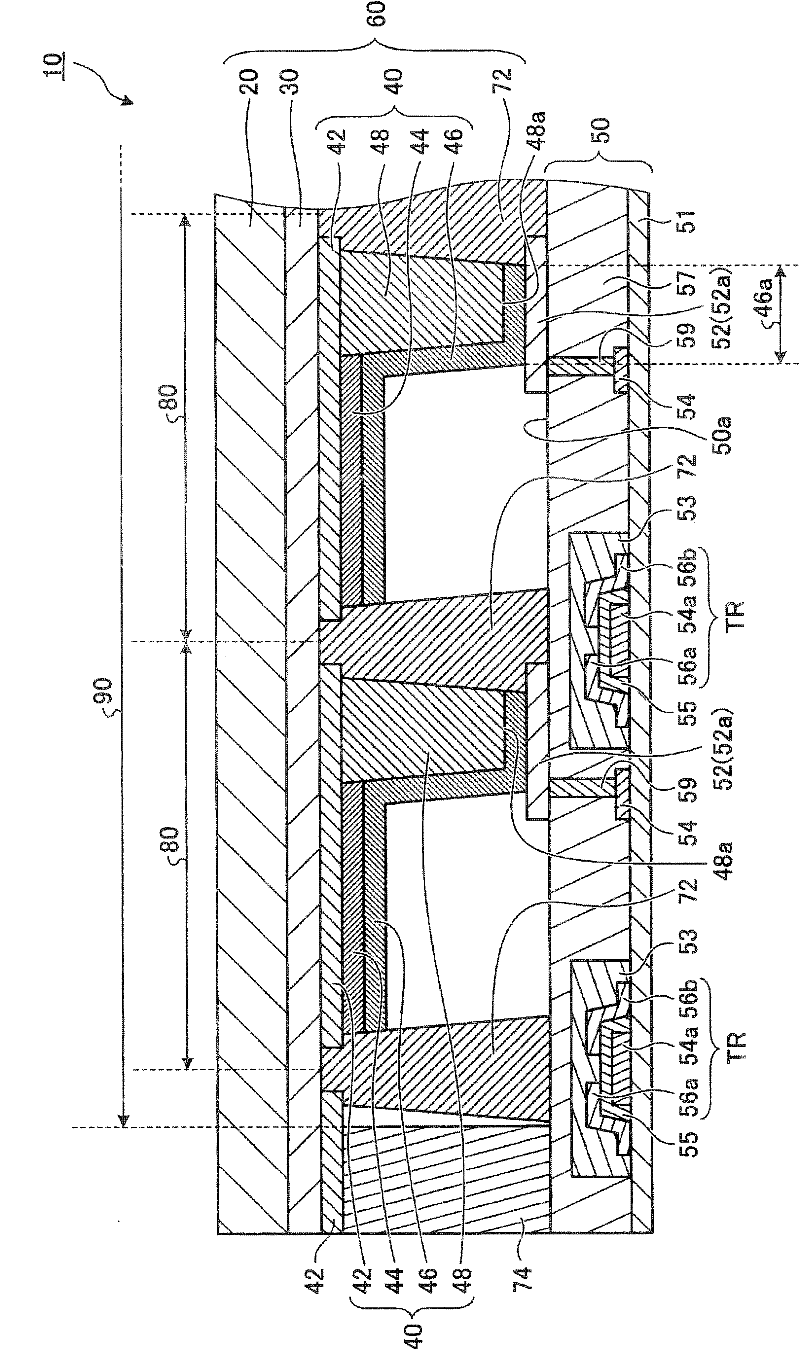

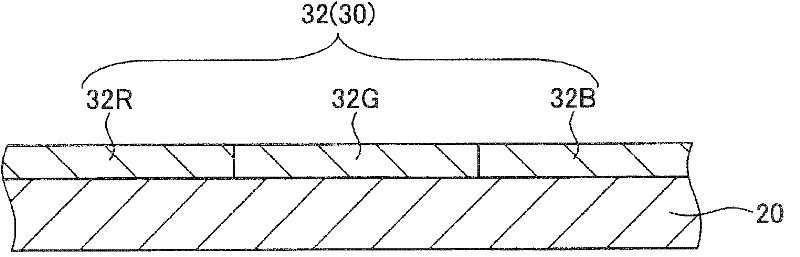

[0034] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, each figure schematically shows the shape, size, and arrangement|positioning of a component only for understanding of invention. The present invention is not limited to the following description, and each component can be appropriately changed within a range not departing from the gist of the present invention. In addition, in each figure used for the following description, the same code|symbol is attached|subjected to the same component, and the overlapping description may be abbreviate|omitted even in a different embodiment. In addition, although there are components such as electrode lead wires in the device on which the organic EL element is mounted, since they are not directly necessary in the description of the present invention, the description may be omitted. The device of the present invention equipped with an organic EL element does not necessarily...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com