Ultraviolet irradiation apparatus and optical device manufacturing apparatus

A technology of an illumination device and an optical device, which is applied in the direction of optics, optical components, and image reproducers using projection devices, can solve the problems of inability to improve convenience, inability to miniaturize light sources, and poor operability, and achieve Effects of lower power consumption, prevention of thermal deterioration, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0058] Next, a first embodiment of the present invention will be described with reference to the drawings.

[0059] 1. The structure of the projector

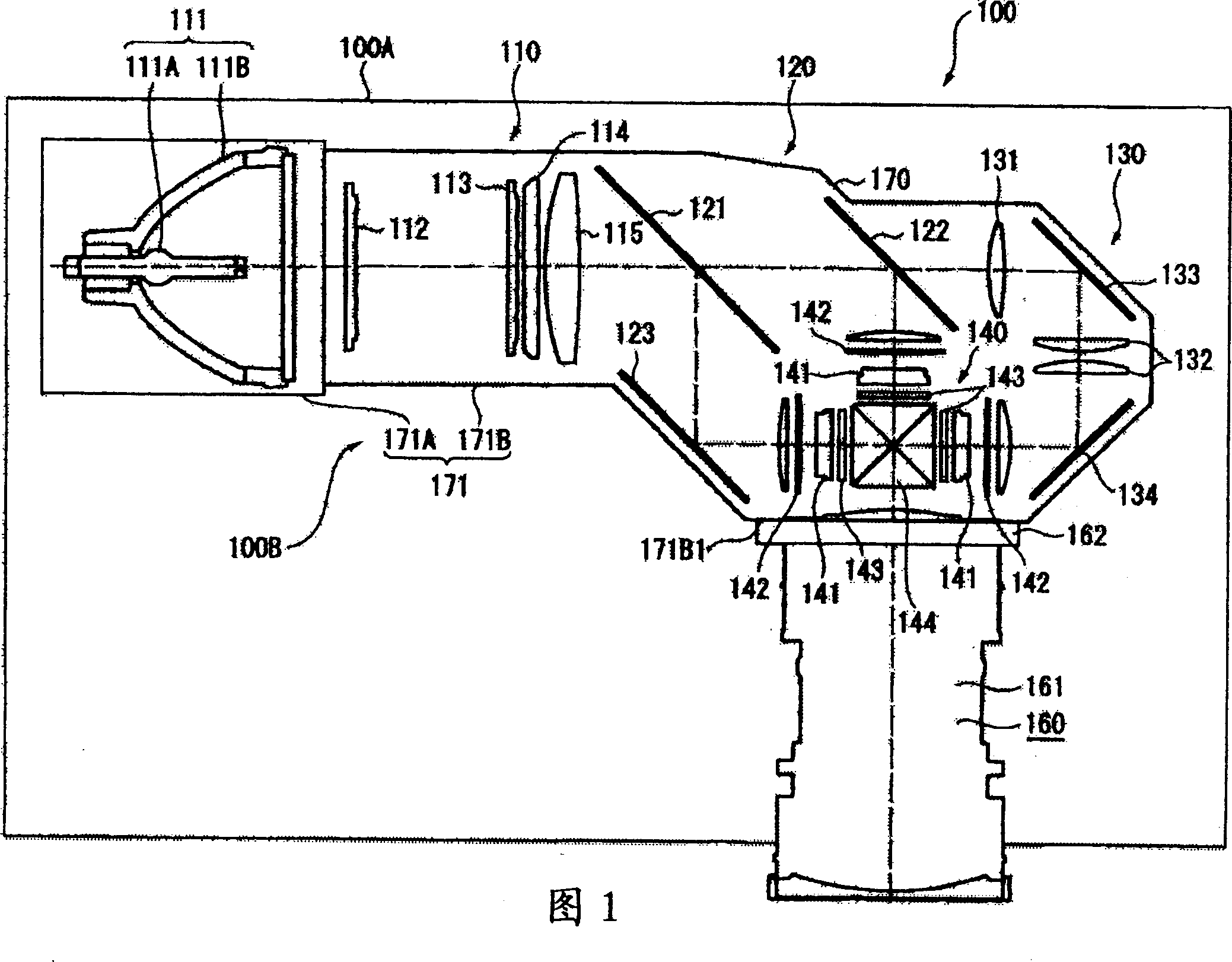

[0060] FIG. 1 schematically shows the configuration of a projector 100 including an optical device to be manufactured in the first embodiment.

[0061] The projector 100 is used to form a color image by modulating light beams emitted from a light source according to image information, and enlarge and project the formed color image onto a screen not shown. As shown in FIG. 1 , this projector 100 includes an exterior housing 100A and an optical unit 100B.

[0062] In addition, although illustration is omitted in FIG. 1 , in the space other than the optical unit 100B inside the exterior housing 100A, a power supply unit for supplying external power to the components of the projector 100 is arranged. ; a cooling assembly, used to cool the inside of the projector 100; and a control substrate, used to control the projector 100 as a...

no. 2 Embodiment approach

[0285] Next, a second embodiment of the present invention will be described. In the following description, the same reference numerals are assigned to the same parts as those already described, and description thereof will be omitted.

[0286] Figure 27 It is a perspective view showing the structure of the second irradiation device 82' in the second embodiment.

[0287] In this embodiment, if Figure 27 As shown, the difference from the above-mentioned first embodiment is that a plurality of irradiation device main bodies are arranged in advance in the plurality of through-holes 822D1 of the support plate 822D of the second irradiation device 82 described in the above-mentioned first embodiment. 821. In addition, according to this configuration, the control of the plurality of irradiation device main bodies 821 by the control unit 93 is also different from the first embodiment described above.

[0288] In the memory 933 of the control unit 93, the following data are inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com