Heat-dissipating resin composition, substrate for LED mounting, reflector, and substrate for LED mounting having reflector portion

A technology of resin composition and thermoplastic resin, which is applied in heat exchange equipment, electric solid-state devices, semiconductor devices, etc., can solve the problems of LED components such as short life, brightness reduction, and temperature rise, and achieve excellent mechanical strength and reflection characteristics Excellent, temperature rise suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0119] The following examples are given to illustrate the present invention in more detail. The present invention is not limited to the examples, as long as it does not exceed the gist of the present invention. In addition, in the following, parts and % are based on mass unless otherwise specified.

[0120] 1. Production and evaluation of heat-dissipating resin composition Raw material components of compositions used in the following examples and comparative examples are shown. 1-1. Thermoplastic resin (1) A1: Copolymerized polybutylene terephthalate (modified PBT endowed with flexibility; dimethyl terephthalate, 1,4-butylene glycol, and polytetramethylene Copolymer of methyl glycol) "NOVADURAN 5505S" (trade name) manufactured by Mitsubishi Engineering-Plastics was used. The glass transition temperature is 27°C. (2) A2: "NOVADURAN 5007" (trade name) manufactured by Mitsubishi Engineering-Plastics Corporation was used for the homopolymerization type polybutylene terephthalate....

Embodiment 25

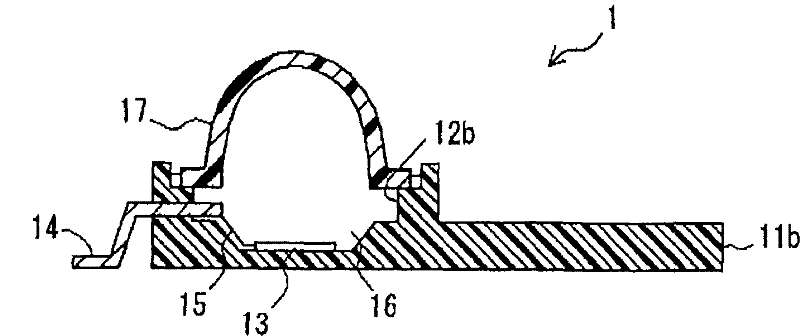

[0142] Example 25 The pellets formed of the heat-dissipating resin composition of Example 1 were melted at 260° C., and the melt was injected into a mold (mold temperature: 50 to 80° C.) formed with Shaped through-holes are used to insert electrodes connected to LED elements on the expanded inner wall, and the mold has a rectangular cavity space such as a circular recess formed from the central part to the end side, thereby obtaining image 3 The shown LED mounting substrate 11b (about 10 mm in length, about 4 mm in width, and about 2 mm in maximum height of the reflector portion) has a reflector portion.

Embodiment 26

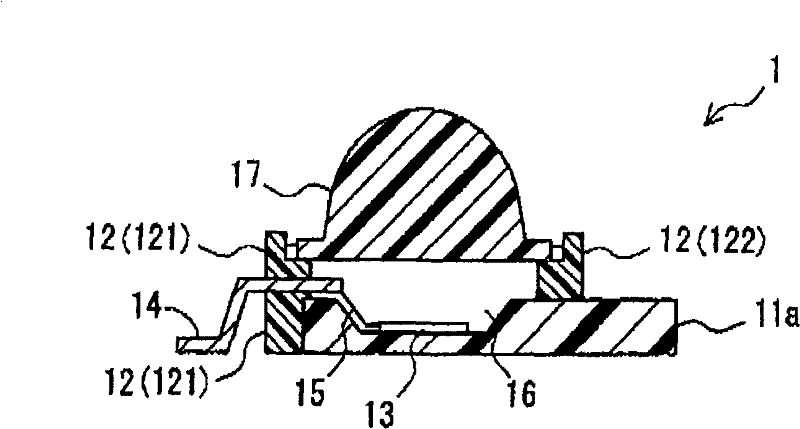

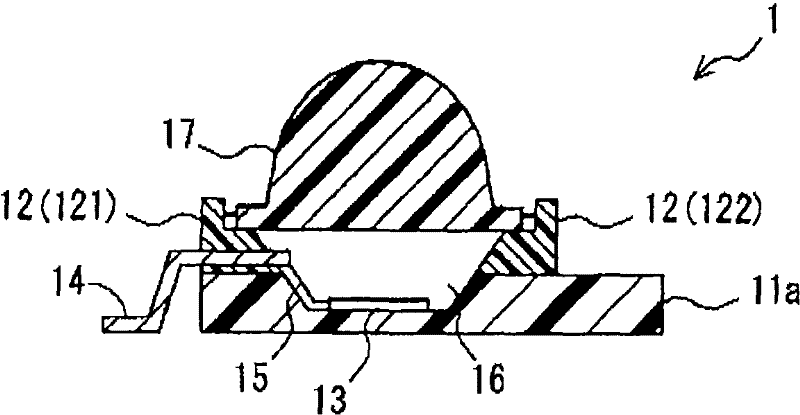

[0143] In Example 26, instead of the heat-dissipating resin composition of Example 1, the heat-dissipating resin composition of Example 18 was used, except that it was performed in the same manner as in Example 24 to obtain figure 2 The LED mounting substrate 11a is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| bending strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com