Quick Release Toilet Mechanism

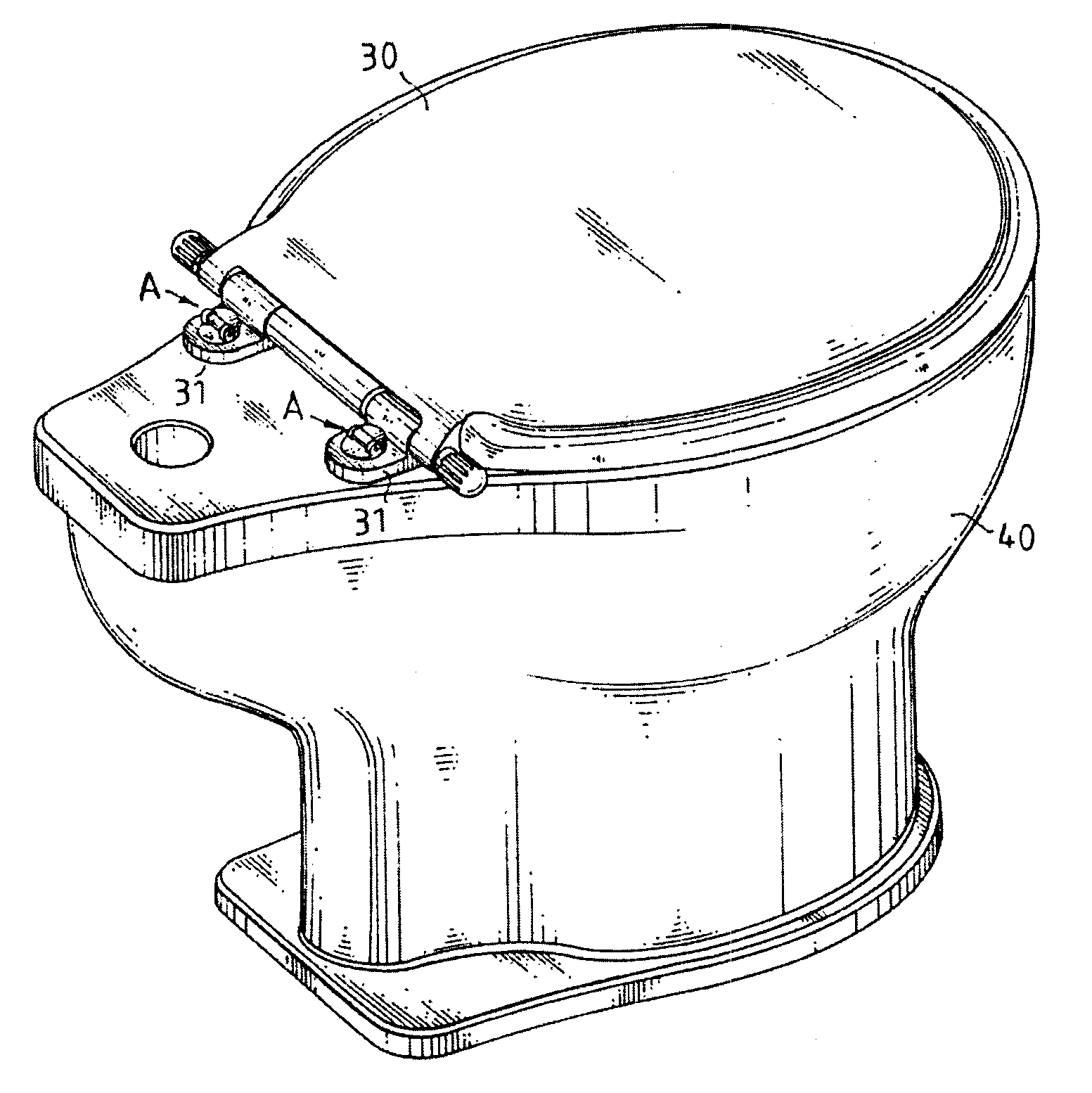

a toilet seat and quick release technology, applied in the field of quick release toilet seat bolt assembly, can solve the problems of affecting the cleaning or repair of the seat, the difficulty of using tools, and the inconvenience of consumers in removing or disassembling the seat, so as to prevent the seat from rotating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

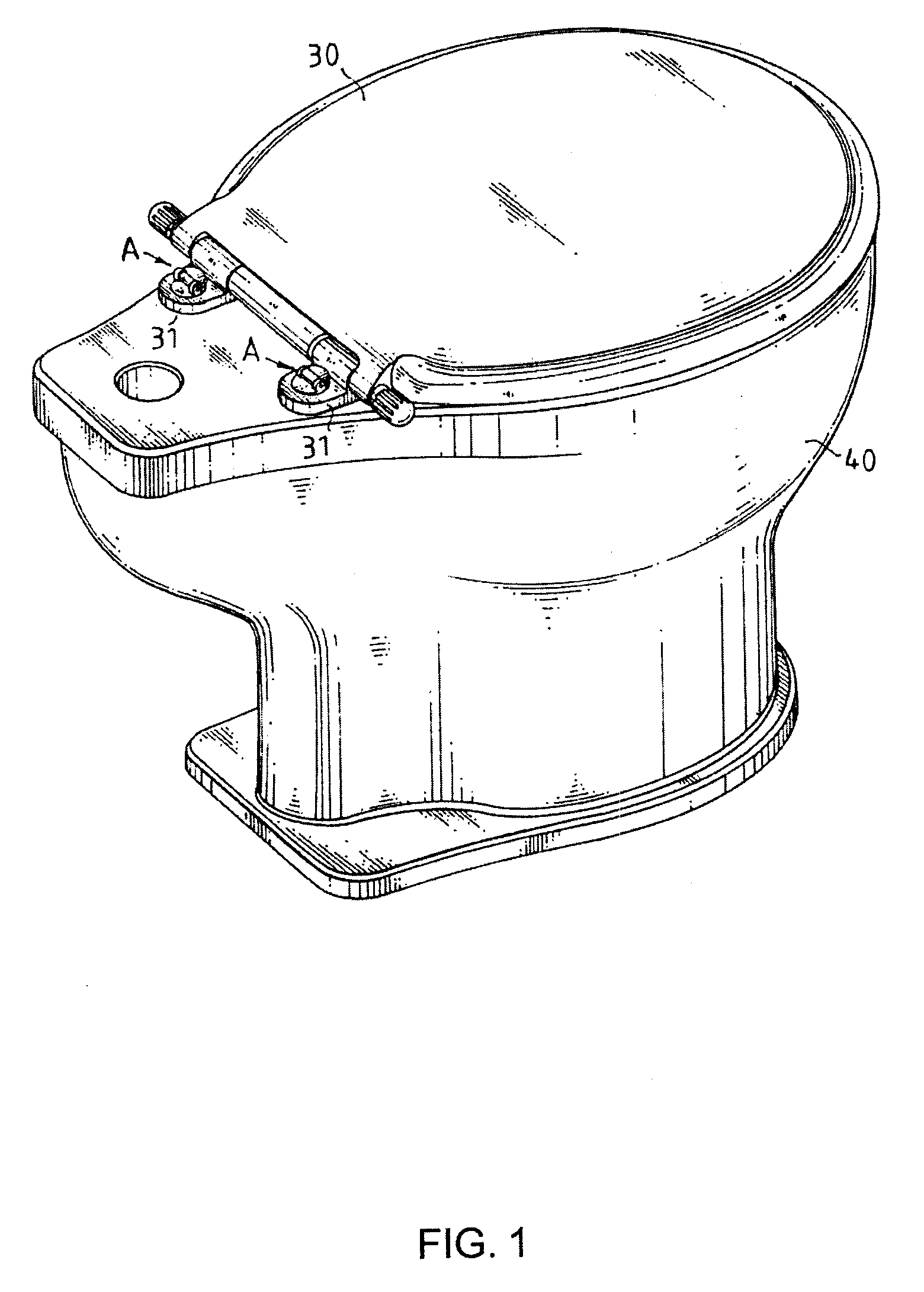

first embodiment

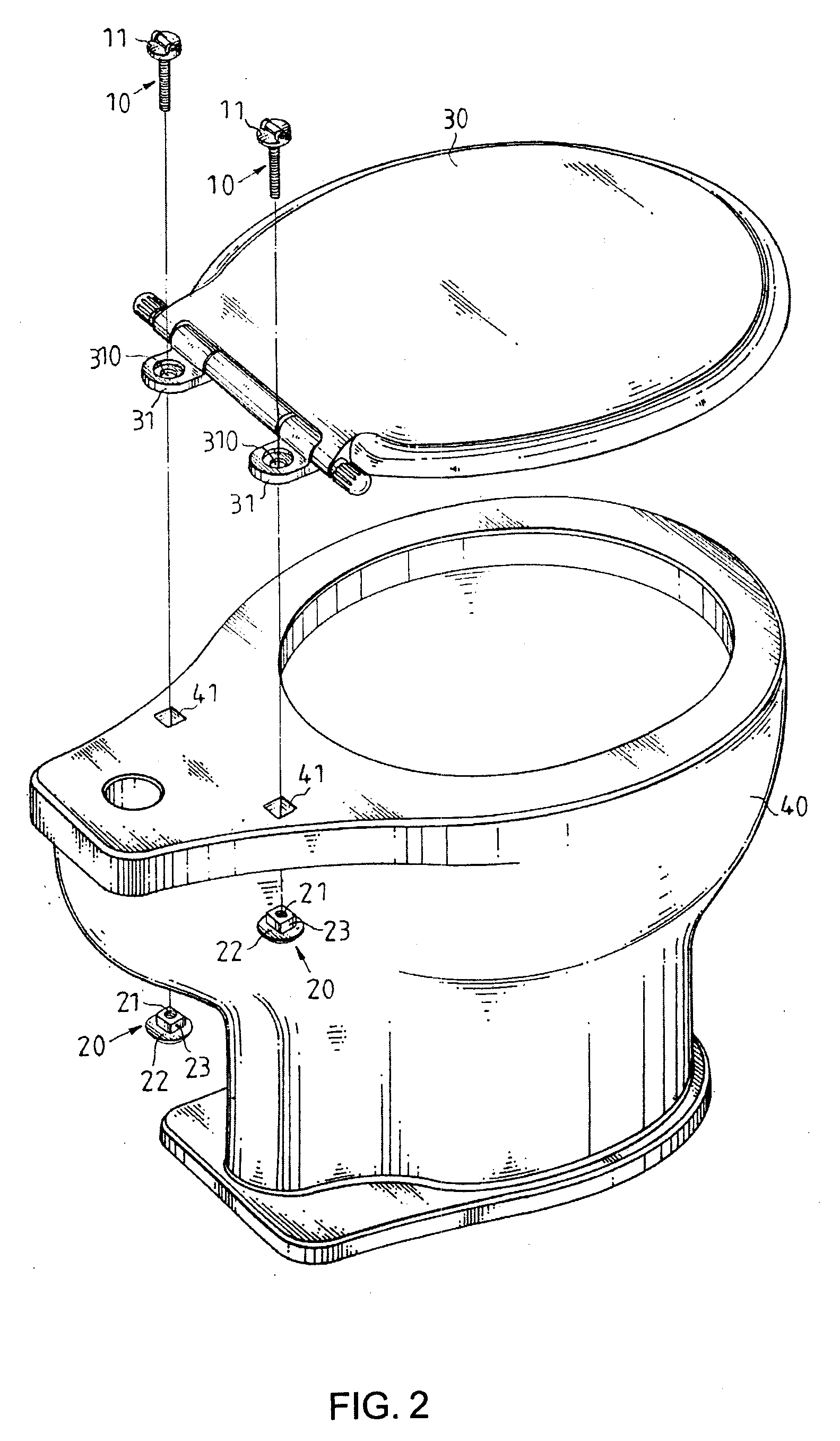

[0028]As further illustrated in FIG. 3, bolt 10 passes through hole 310 in fastening hinge 31. Fastening hinge 31 is coaxially aligned with lock hole 41 in the toilet base 40. As shown in both FIGS. 2 and 3, in a first embodiment lock hole 41 is square shaped to accommodate nut 20. Nut 20 has domed head 22 with a square protruding neck 23 and a threaded hole 21. Nut 20 also has a flat side with a larger diameter presses up against the outside of lock holes 41 when the bolt 10 and nut 20 are assembled. In the present embodiment, the protruding neck 23 and lock hole 41 are square in shape so that rotation of nut 20 in lock hole 41 is restricted. Though protruding neck 23 of nut 20 functions to restrict rotation in square lock hole 41, its shape is not limited to a square only. Triangles, polygons, ovals and various irregular geometric shapes can all serve the same function.

[0029]Accordingly, to install toilet seat 30, bolt 10 passes through hole 310 in fastening hinge 31 to engage thr...

second embodiment

[0030]FIGS. 7˜9 show the present invention. In the second embodiment, bolt assembly A′ is comprised of a bar handle 113, bolt 10a, washer 114, and nut 20. Bar handle 113 has an eccentric pivotally connecting end 1130 with a spanning section 11a and a hole therein as shown in FIG. 8. Bar handle 113 can be fastened to bolt 10a by mounting connecting end 1130 onto the head of bolt 10a with a pin or dowel as shown. Bolt 10a is passed through washer 114, hole 310 of fastening hinge 31, and lock hole 41 to engage nut 20. As shown in FIG. 9, bar handle 114 can be turned to tighten bolt 10a so as to clamp fastening hinge 31 to toilet base 40.

third embodiment

[0031]the invention is shown in FIG. 10, wherein fastening hinge 31a has hole 310 with split channel 311. Split channel 311 allows bolt 10a to be accommodated such that toilet seat assembly 10 can be installed or removed without disassembling bolt assembly A′.

[0032]The fourth and fifth embodiments of the present invention are shown in FIG. 11 and FIG. 12, respectively. In both embodiments, lock hole 41a on the toilet base is round. Fastening hinge 31b has a connecting insert 312 for insertion into lock hole 41a. Connecting insert 312, which protrudes from the bottom of fastening hinge 31b, has clamp hole 313 that extends through connecting insert 312 to form split opening 3120 with two flat sides as shown in FIG. 11. Insert connecting end 312 is inserted into lock hole 41a to engage with nut 20a. Correspondingly, nut 20a has neck 23a with two flat sides 230. When nut 20a is inserted into clamp hole 313, the flat sides 230 on neck 23a mate with the flat sides in split opening 3120, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com