Patents

Literature

73results about How to "Improve compressor performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

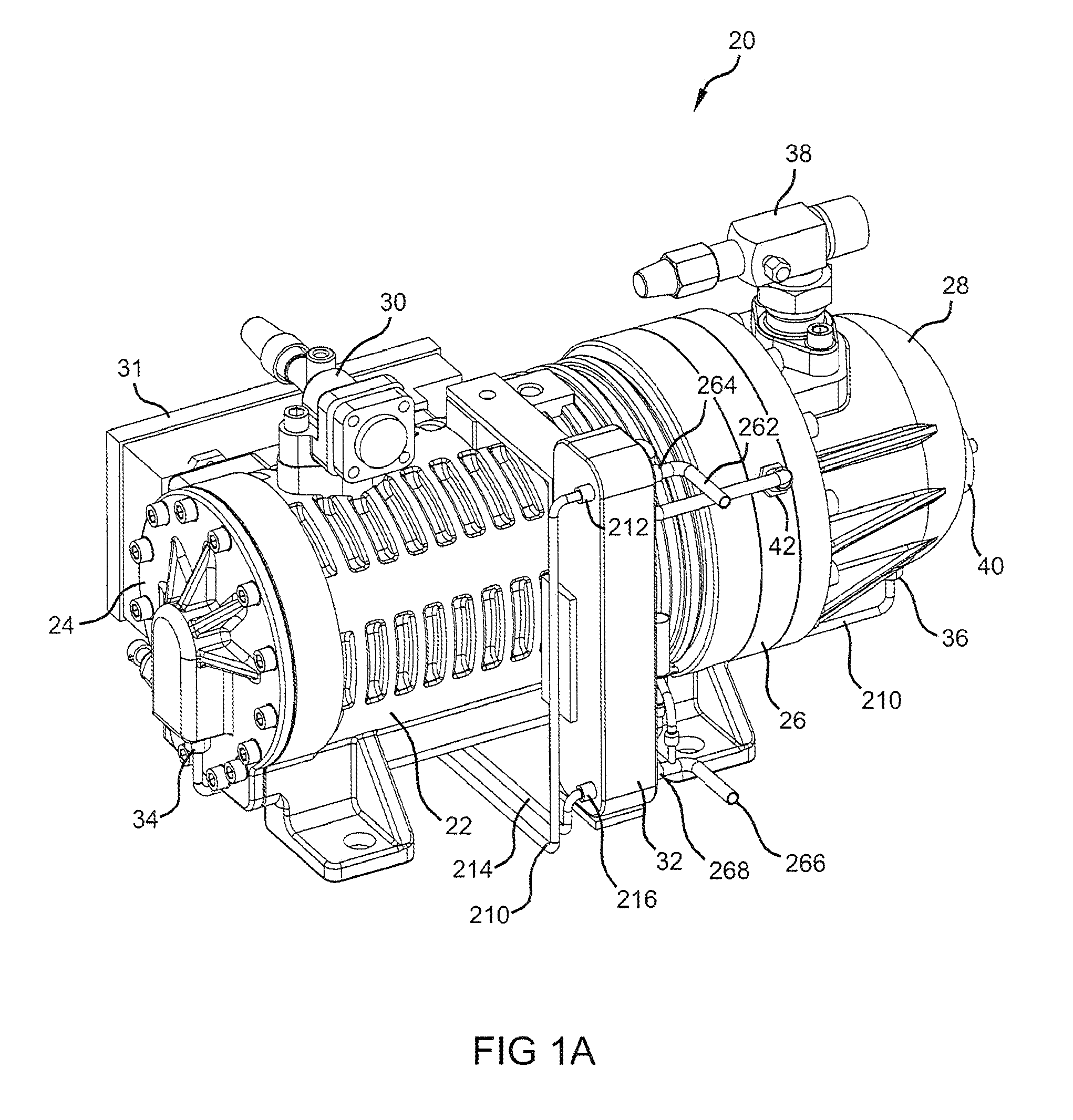

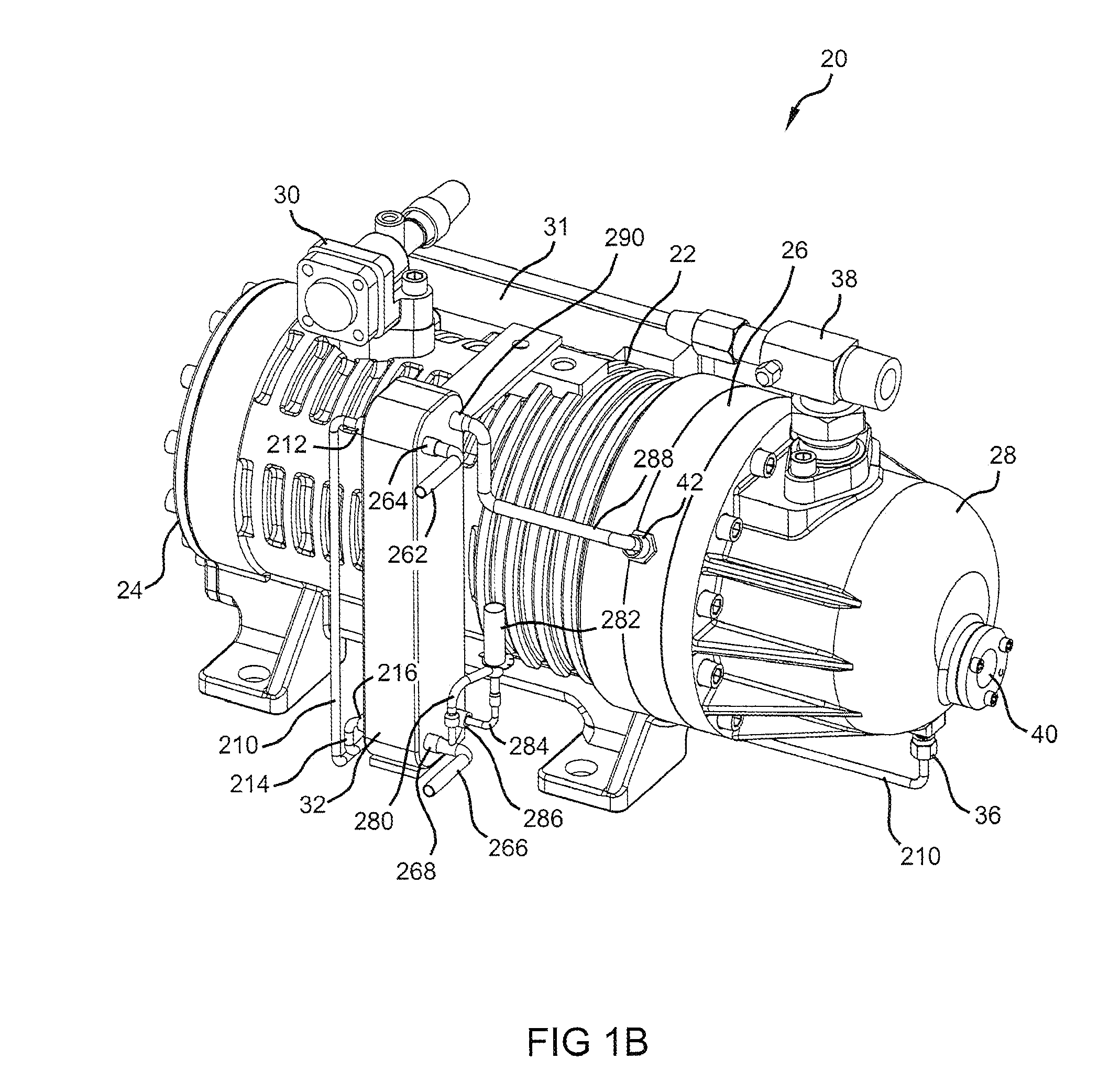

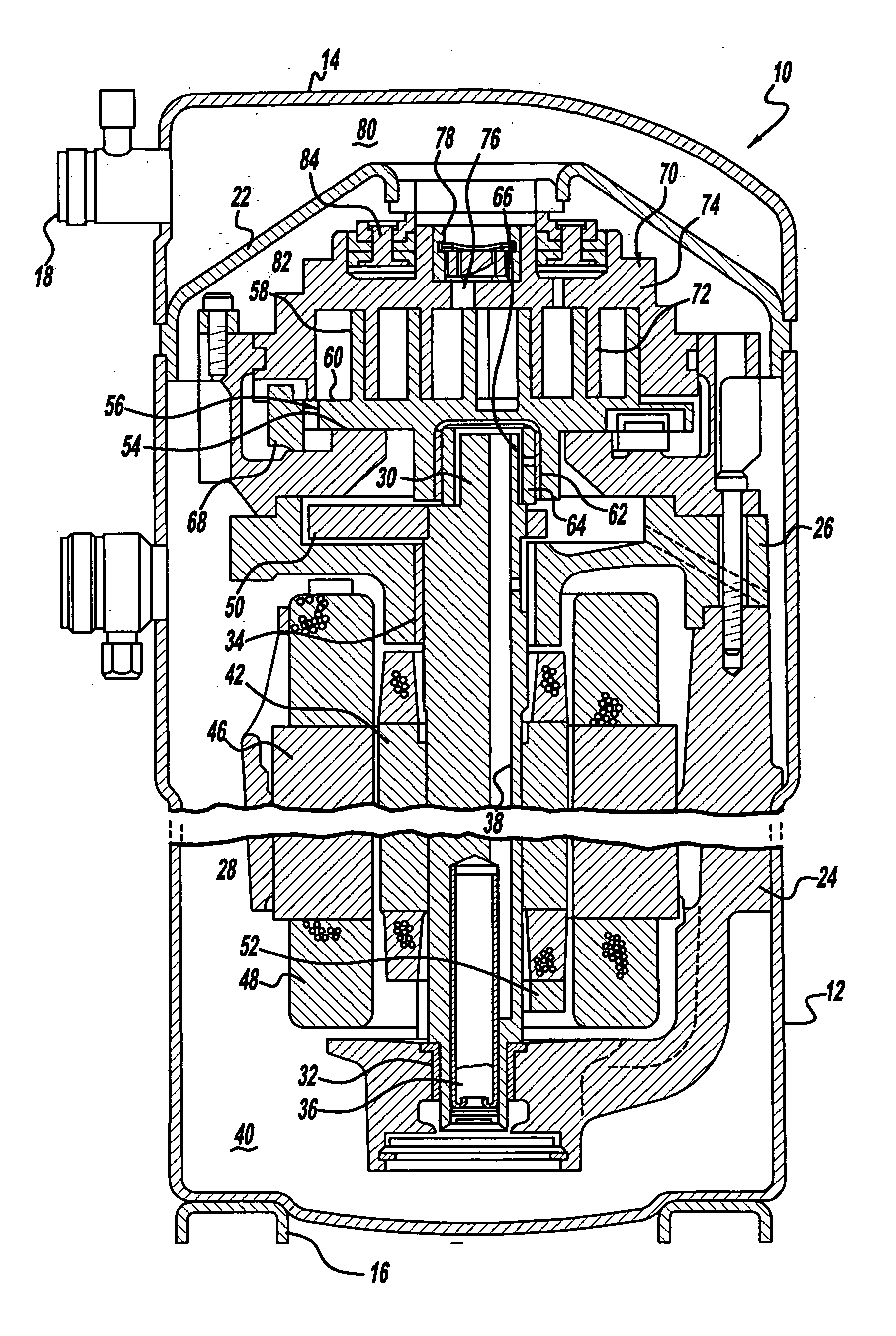

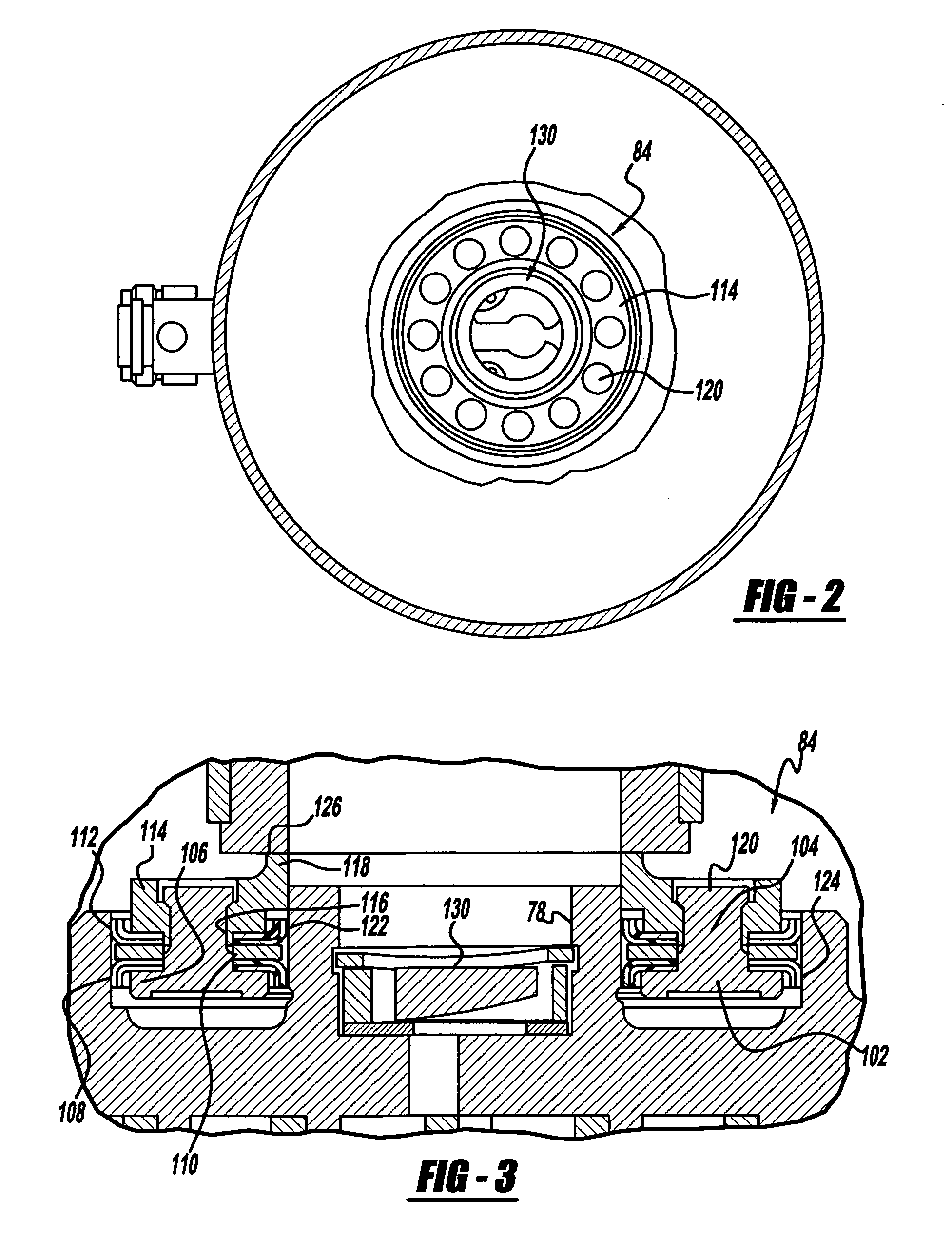

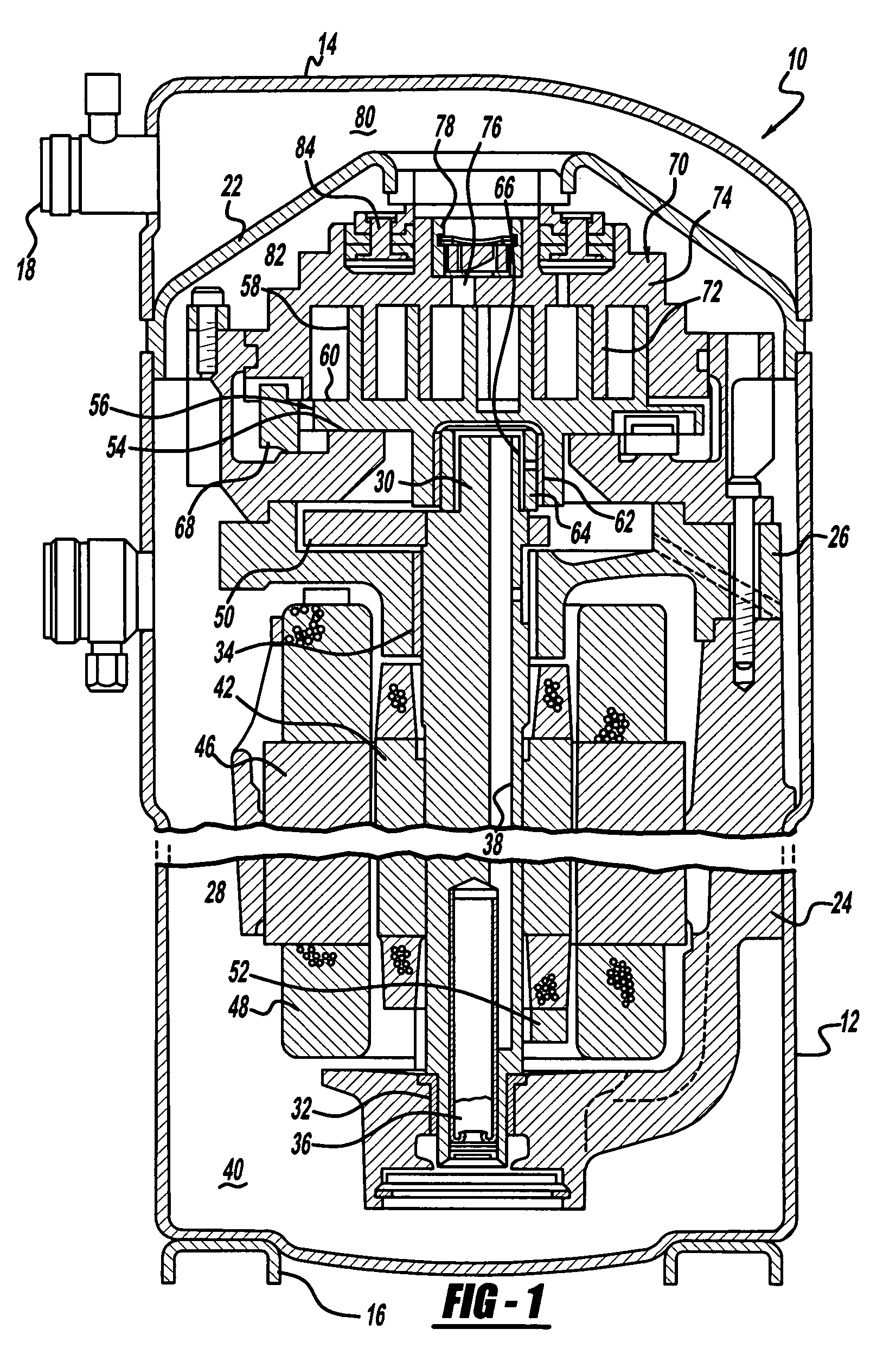

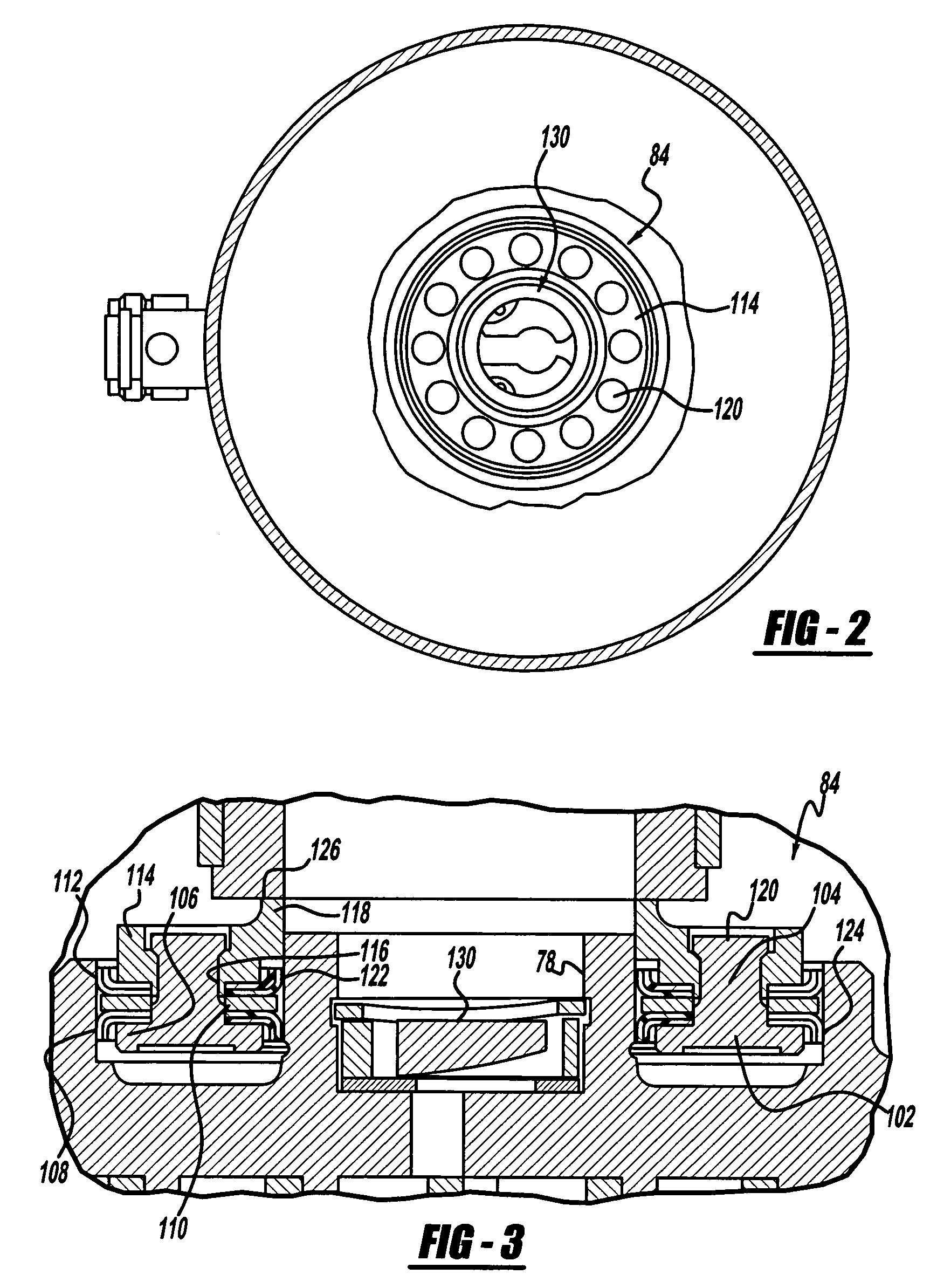

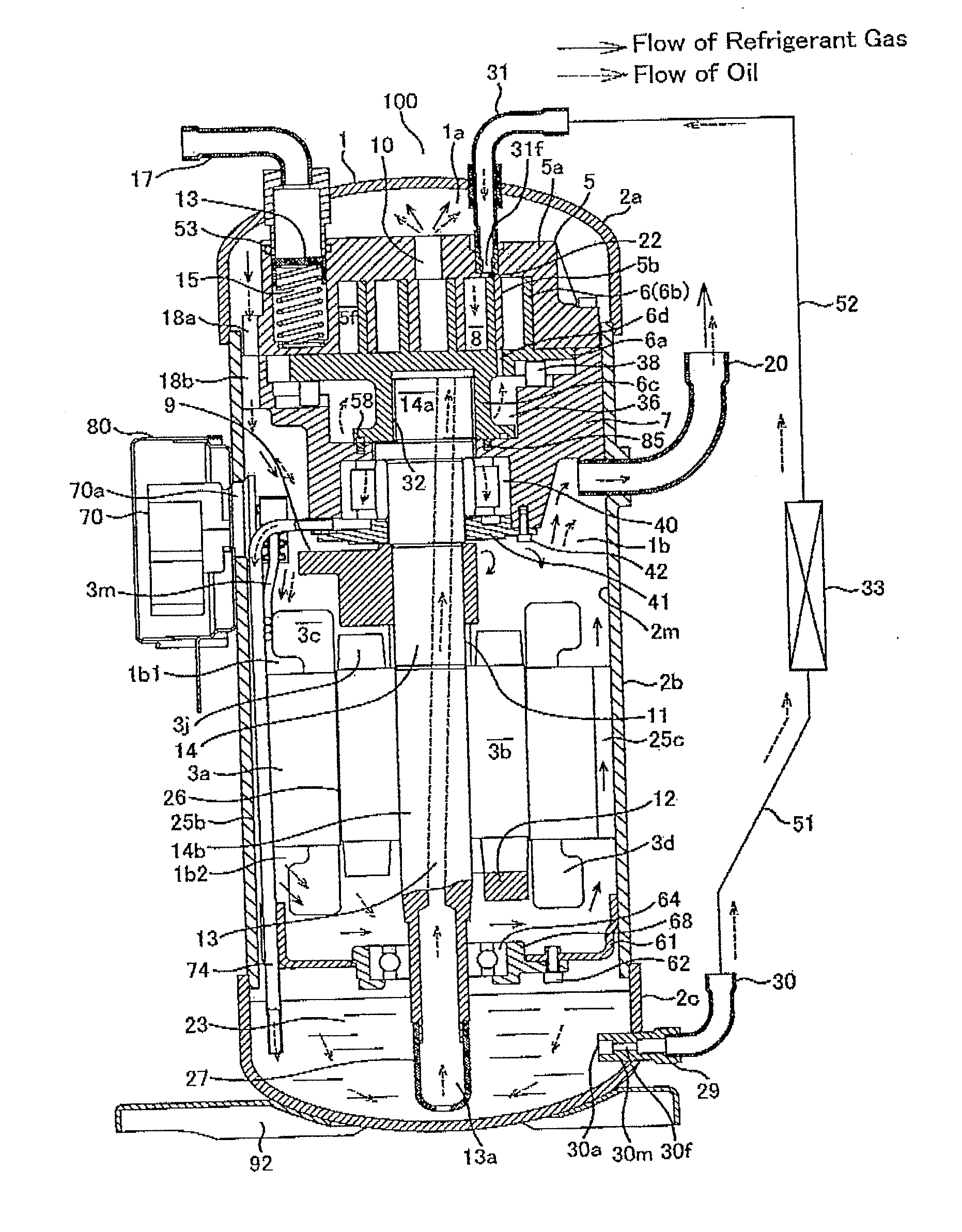

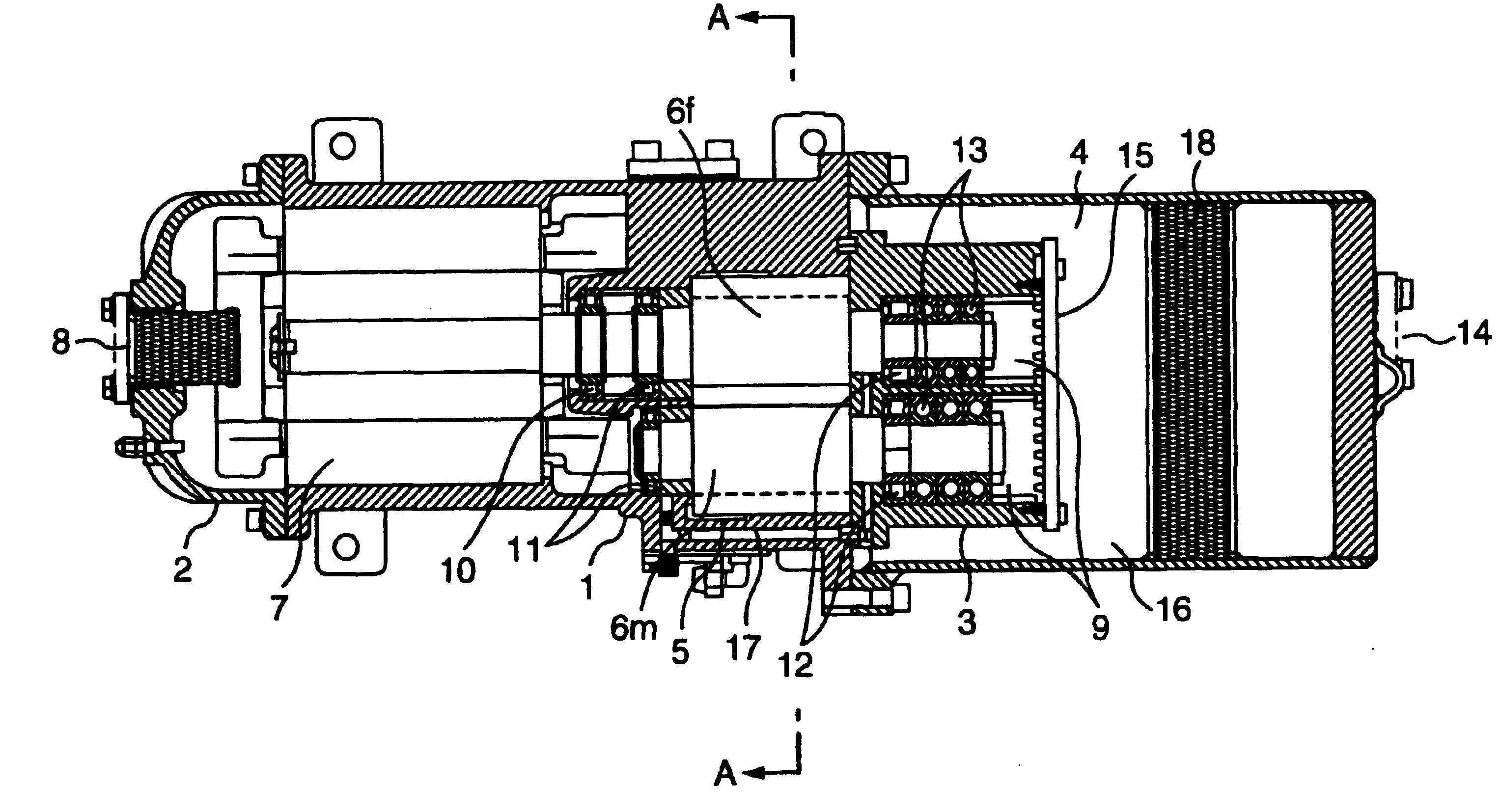

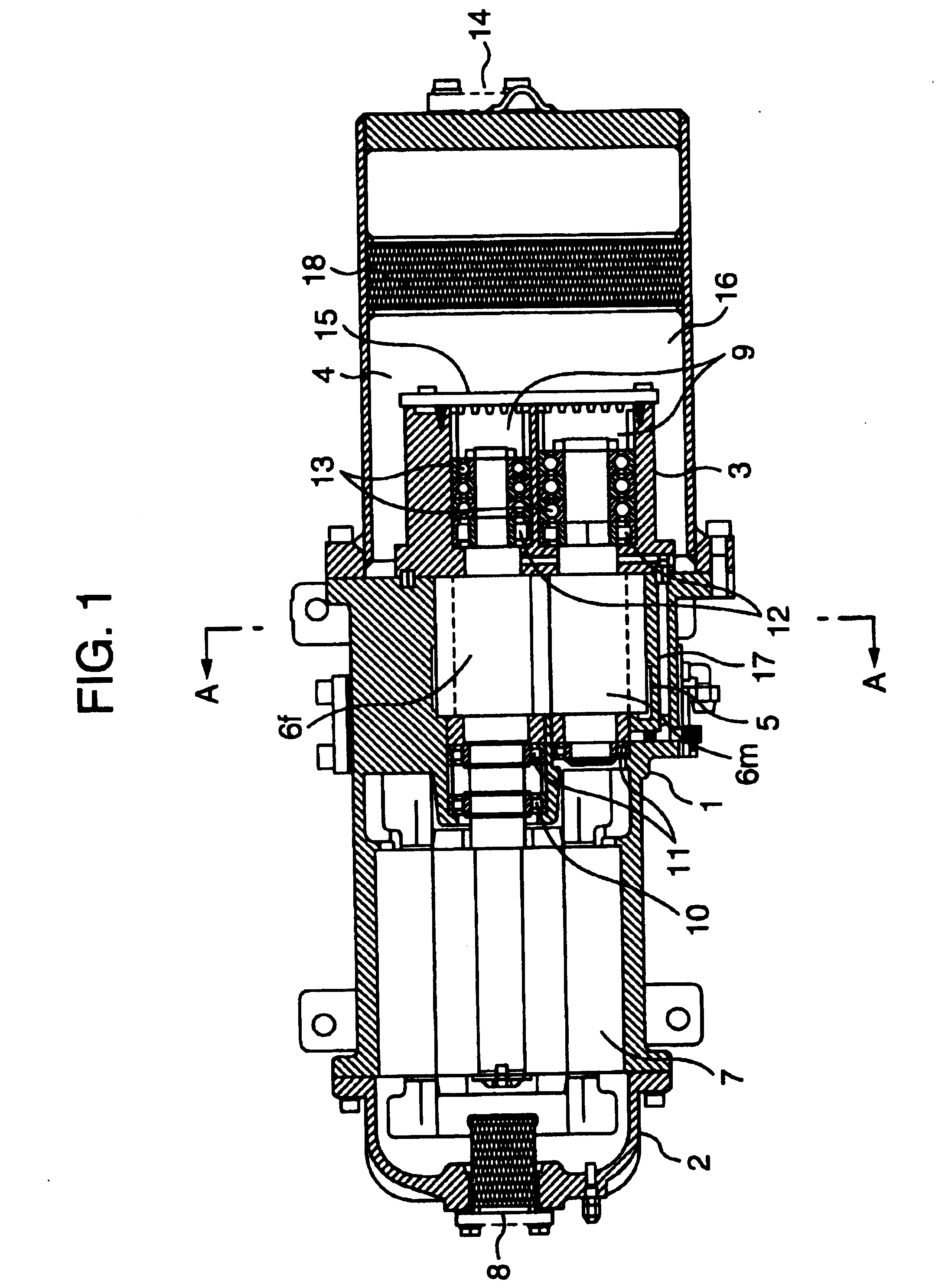

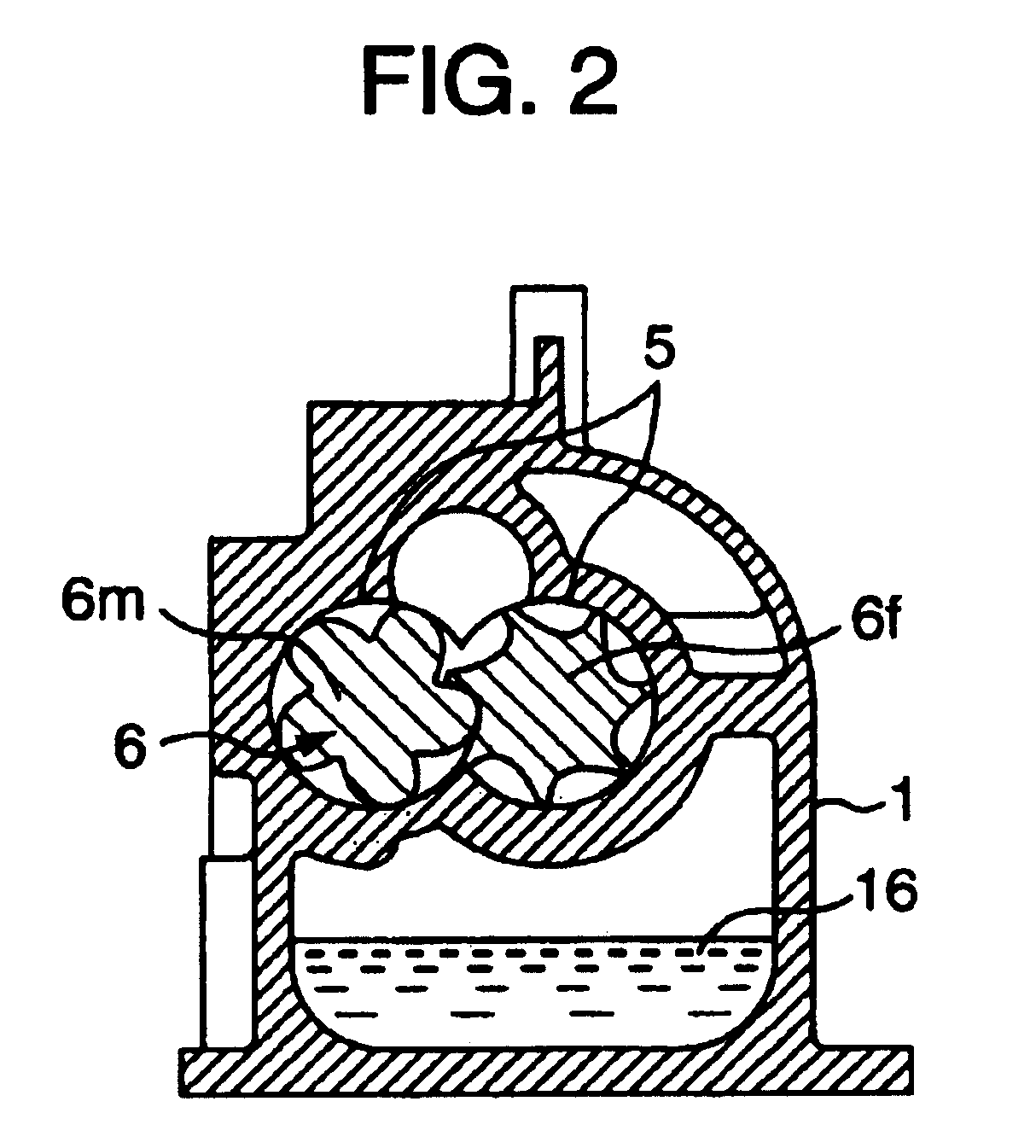

Compressor and oil-cooling system

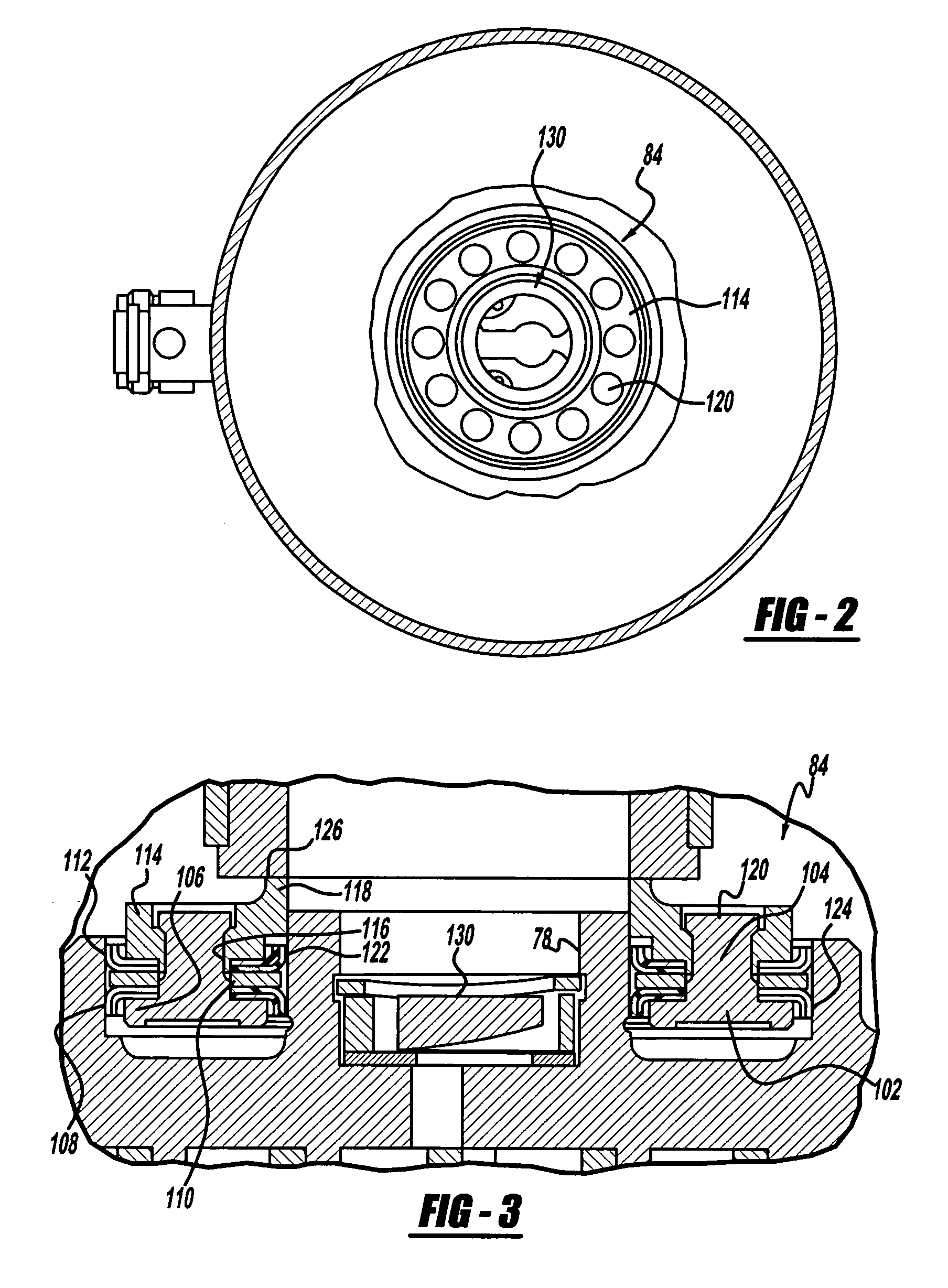

ActiveUS20100307173A1Reduce suction superheatImproving compressor volumetric efficiencyCompressorRotary/oscillating piston combinations for elastic fluidsWorking fluidEngineering

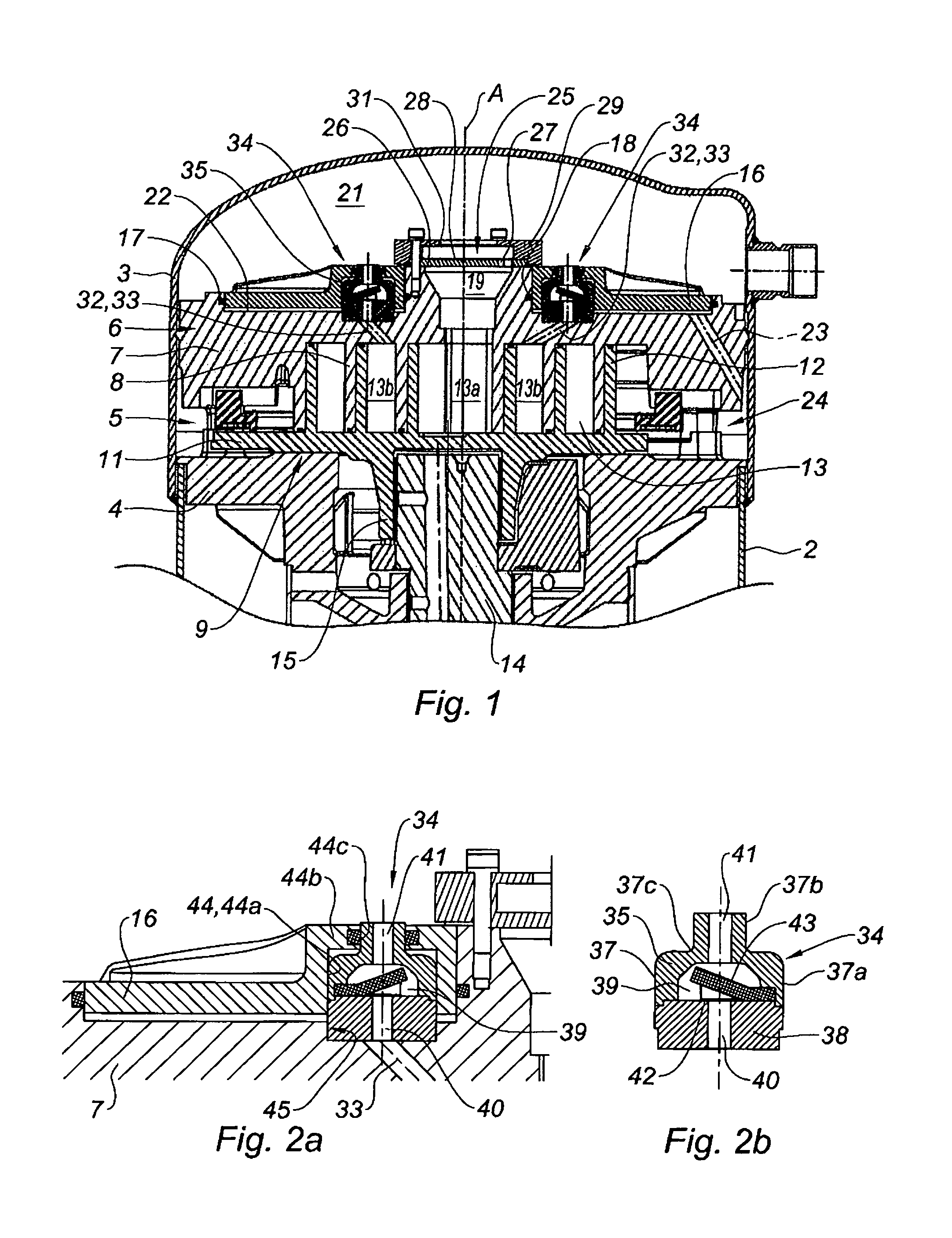

An external heat exchanger is used to transfer heat from a compressor lubricant to an expanded working fluid, thereby cooling the lubricant. The heat exchanger may also be used to sub-cool condensed working fluid with the same flow of expanded working fluid. A horizontal scroll-type compressor includes an intermediate lubricant sump between a main bearing support and a scroll member. A counterweight on the crankshaft can travel through the lubricant in the intermediate sump to splash the lubricant around. A horizontal scroll-type compressor can include multiple machined surfaces that are utilized to precisely center and align components of the compressor.

Owner:COPELAND LP

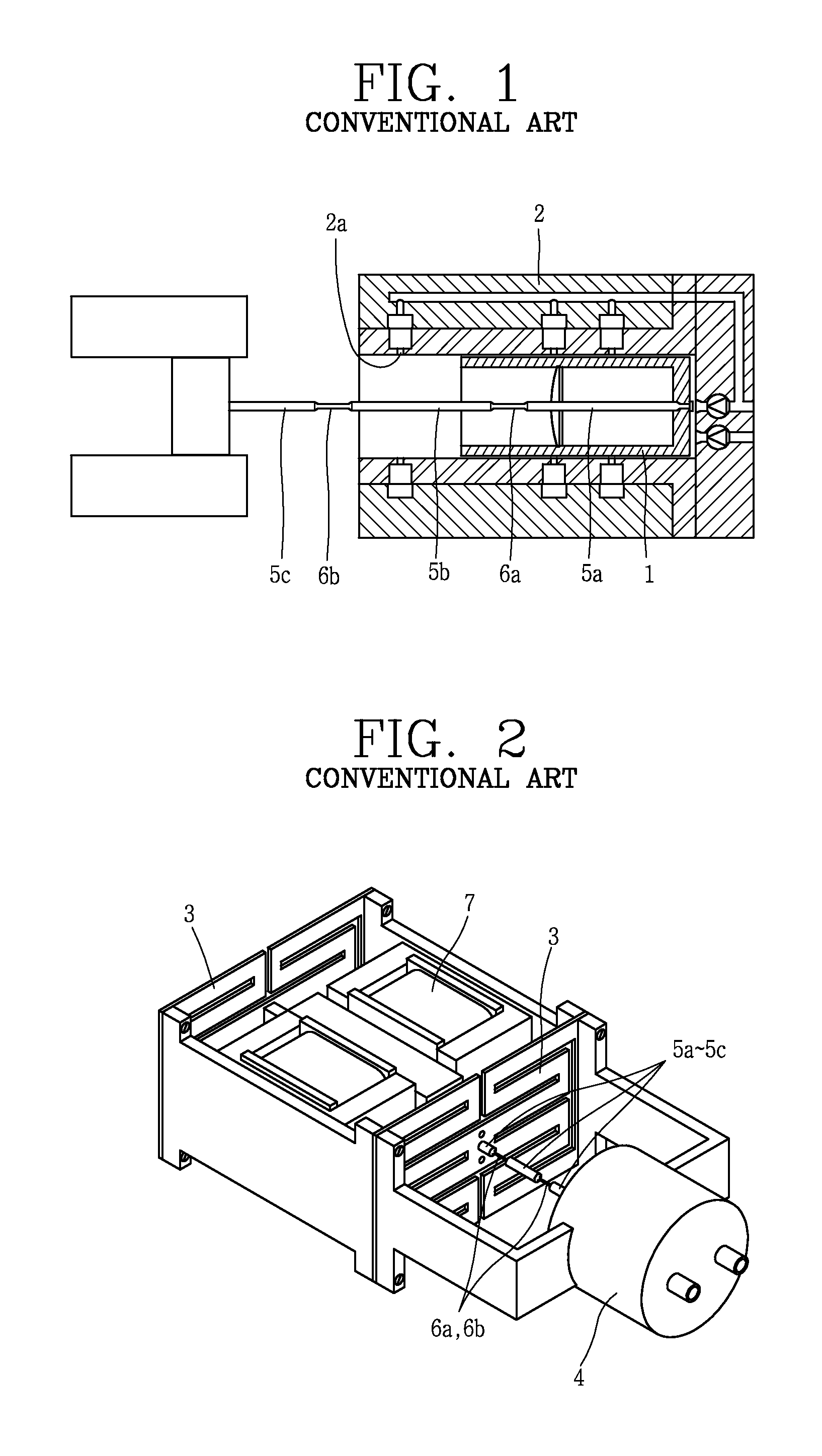

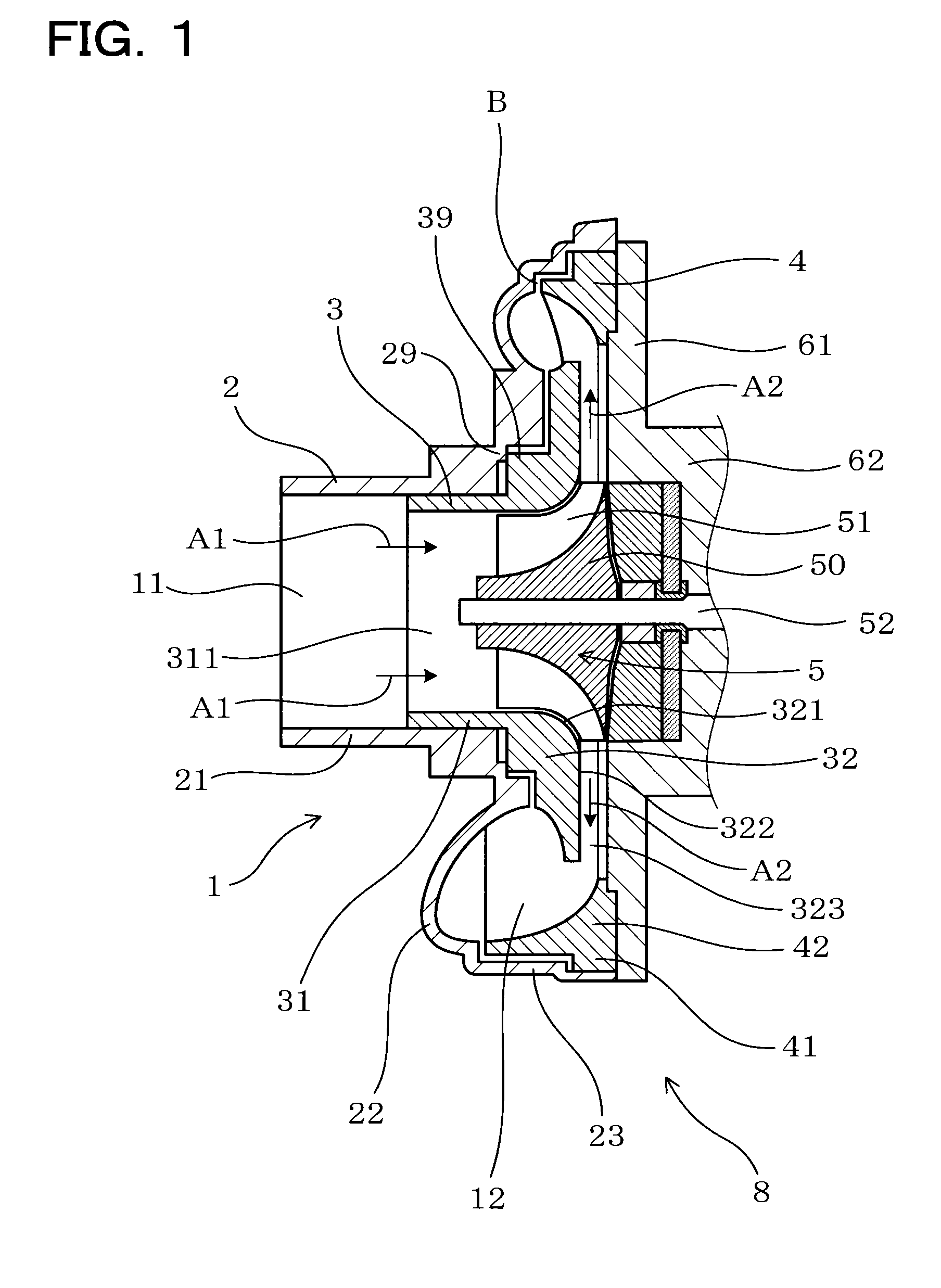

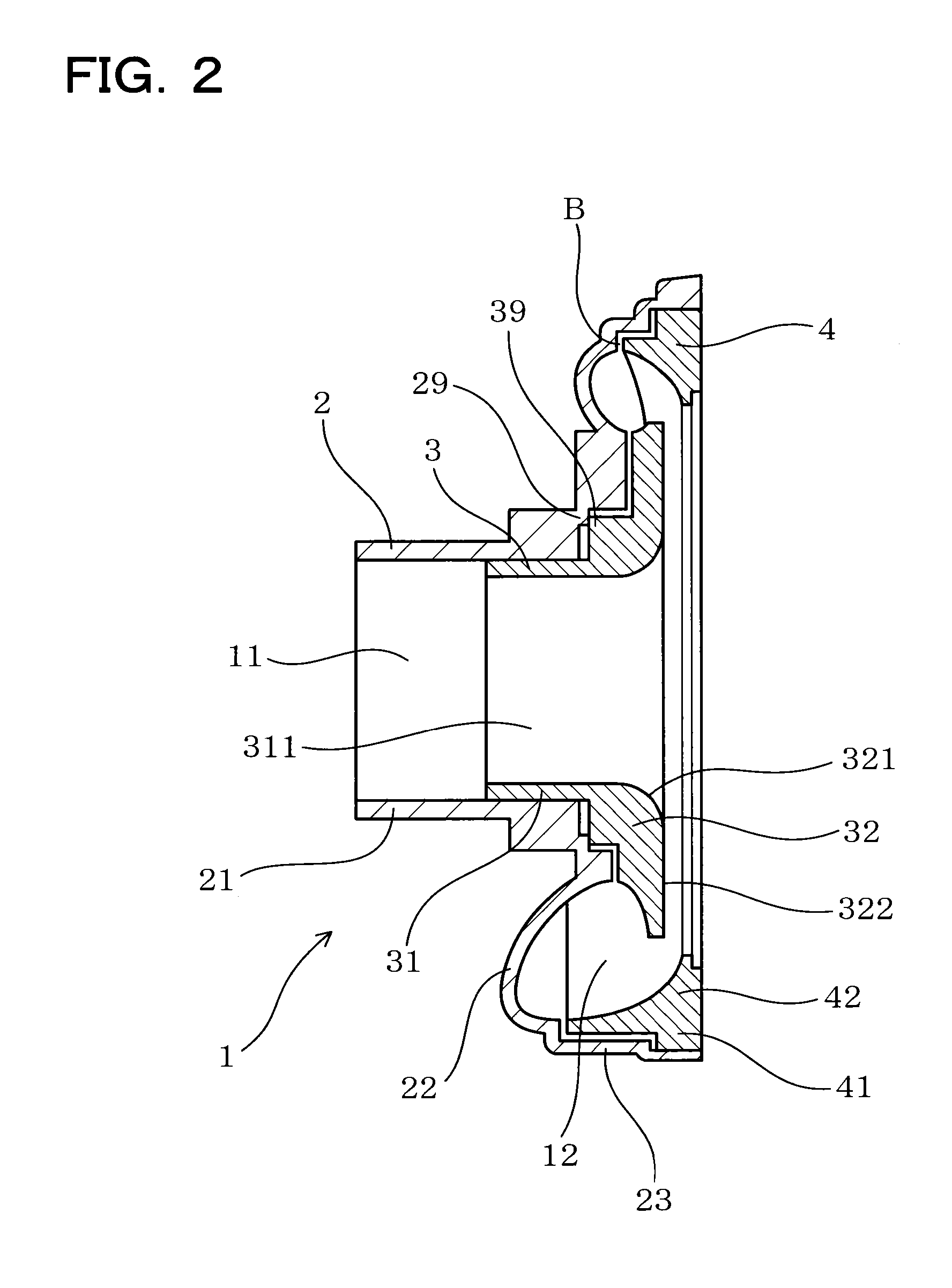

Reciprocating compressor

InactiveUS20130058816A1Well formedImprove compressor performancePositive displacement pump componentsPiston pumpsRefrigerantMechanical engineering

A reciprocating compressor comprises a cylinder having a cylinder side gas flow path for guiding refrigerant discharged to the discharge space to an inner circumferential surface of the cylinder and a piston having a piston side gas flow path communicating with the cylinder side gas flow path to distribute and supply the refrigerant guided through the cylinder side gas flow path between the cylinder and the piston. Also, an outlet of the gas flow path is formed in the piston and an inlet of the gas flow path is formed in the cylinder.

Owner:LG ELECTRONICS INC

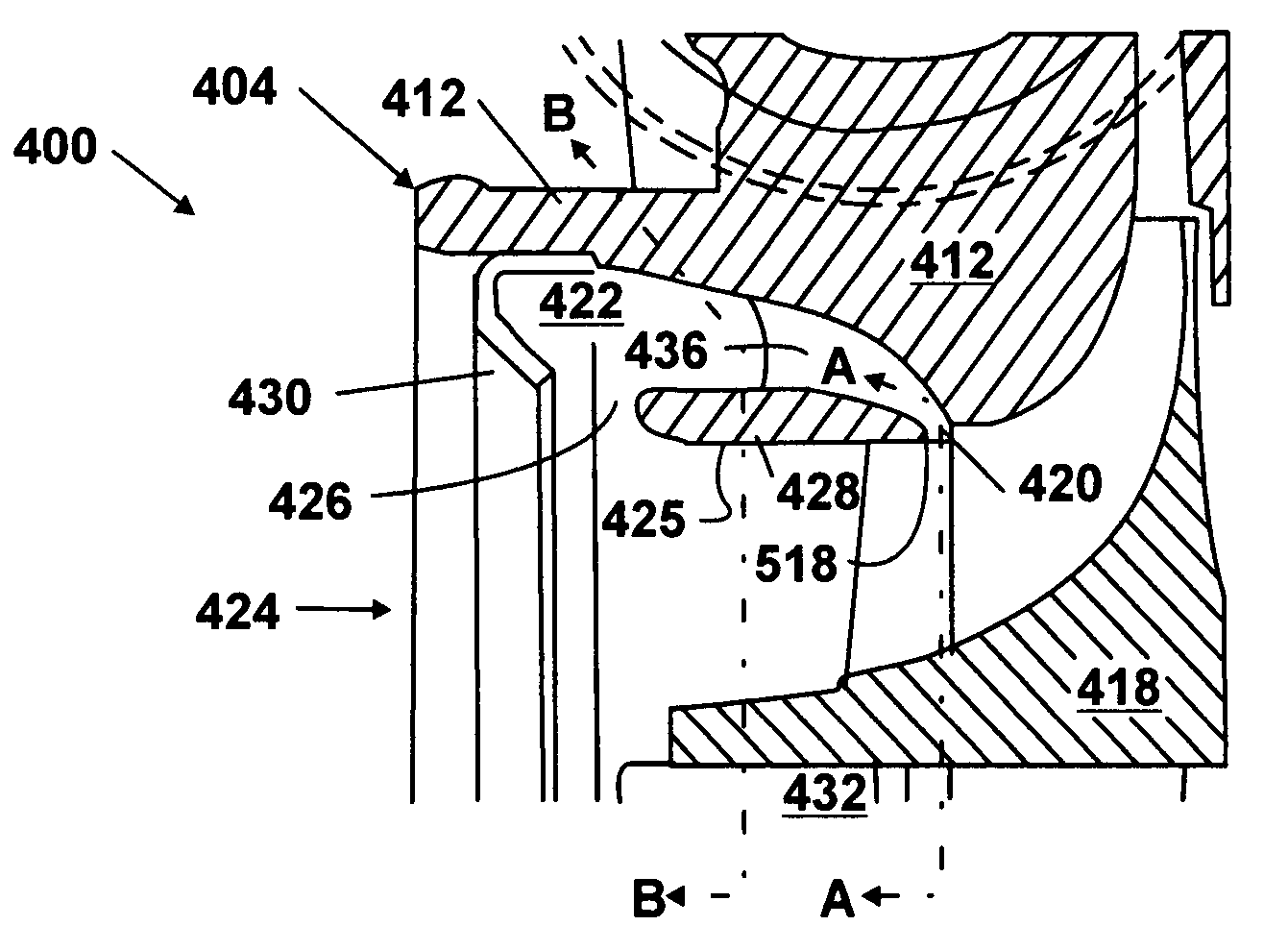

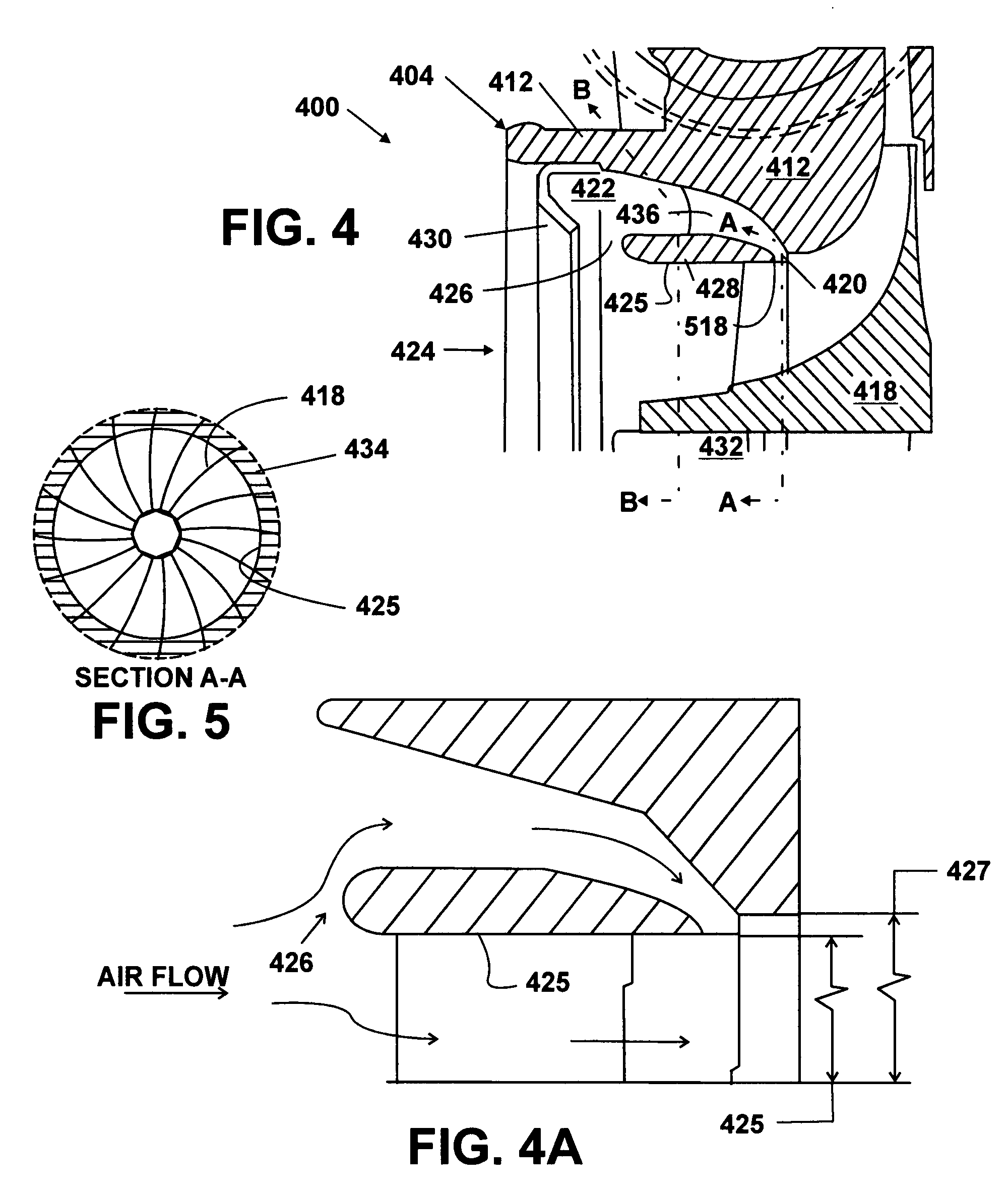

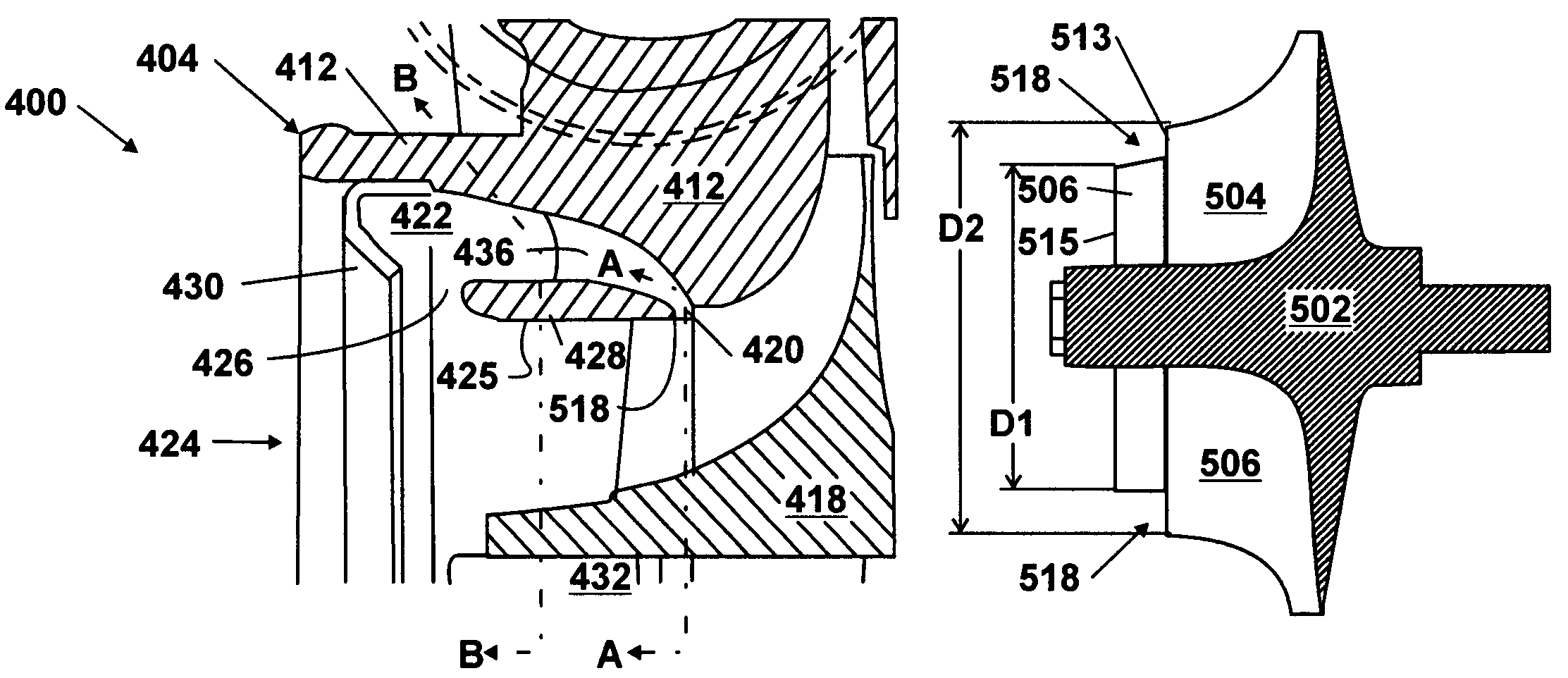

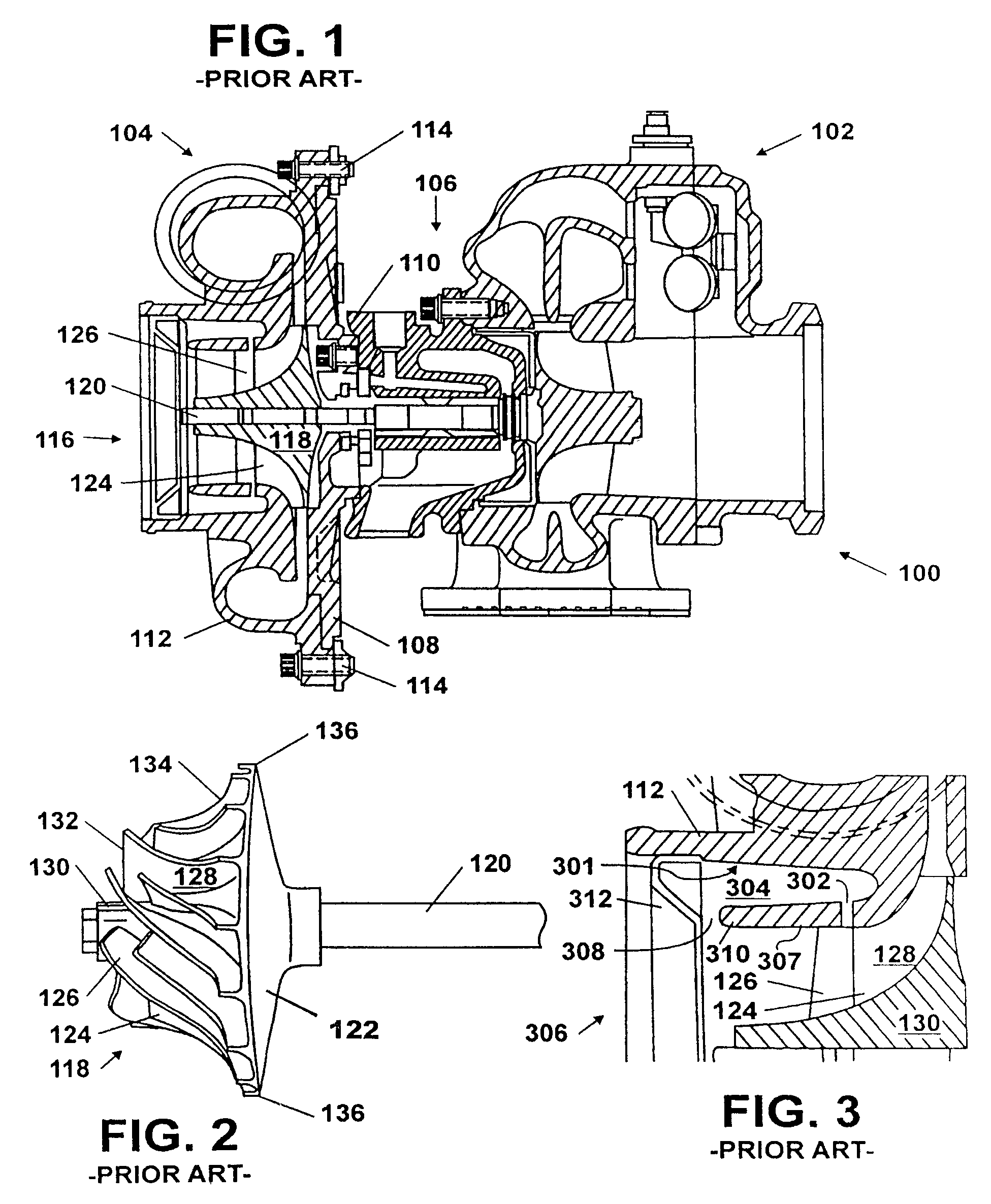

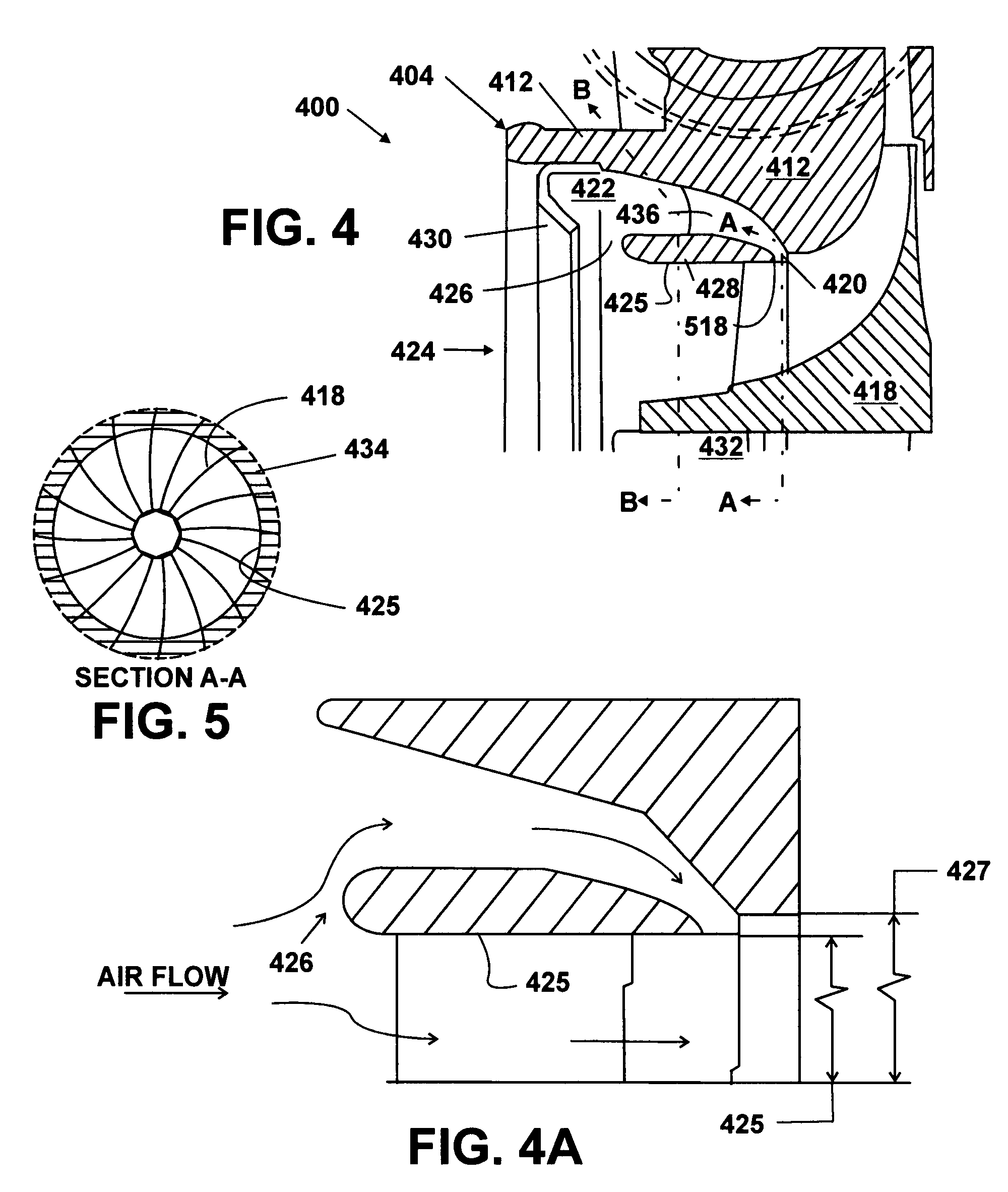

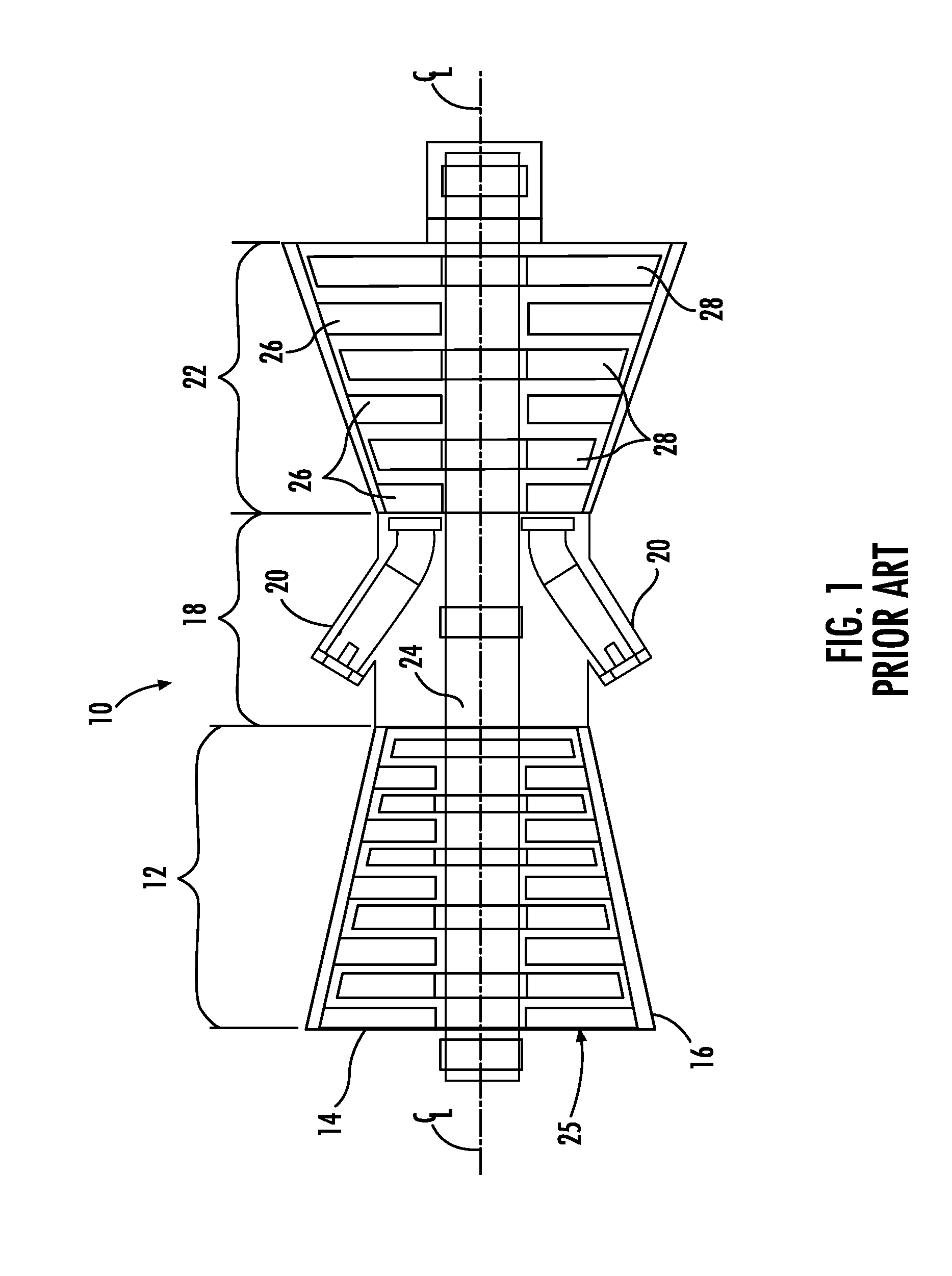

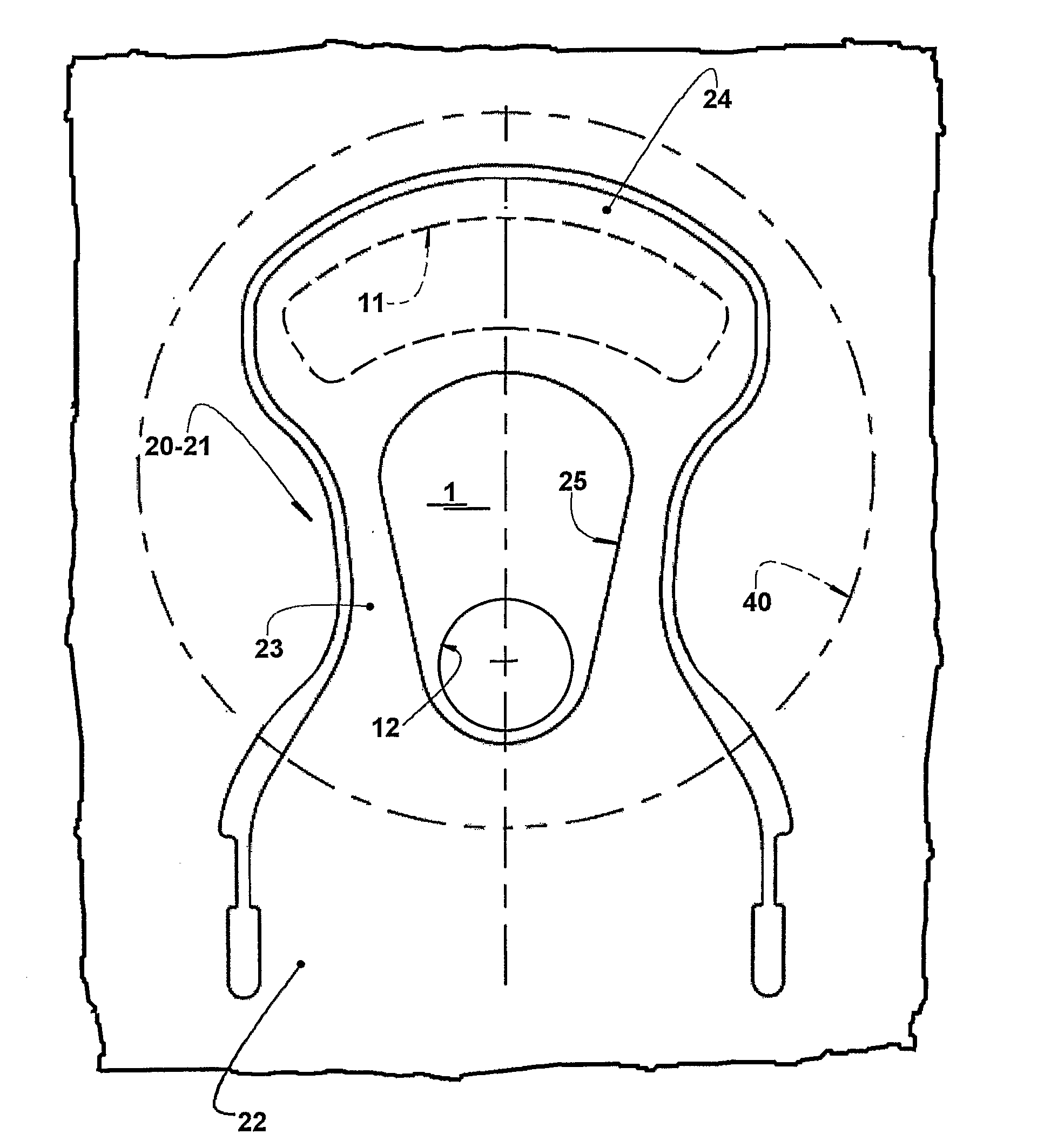

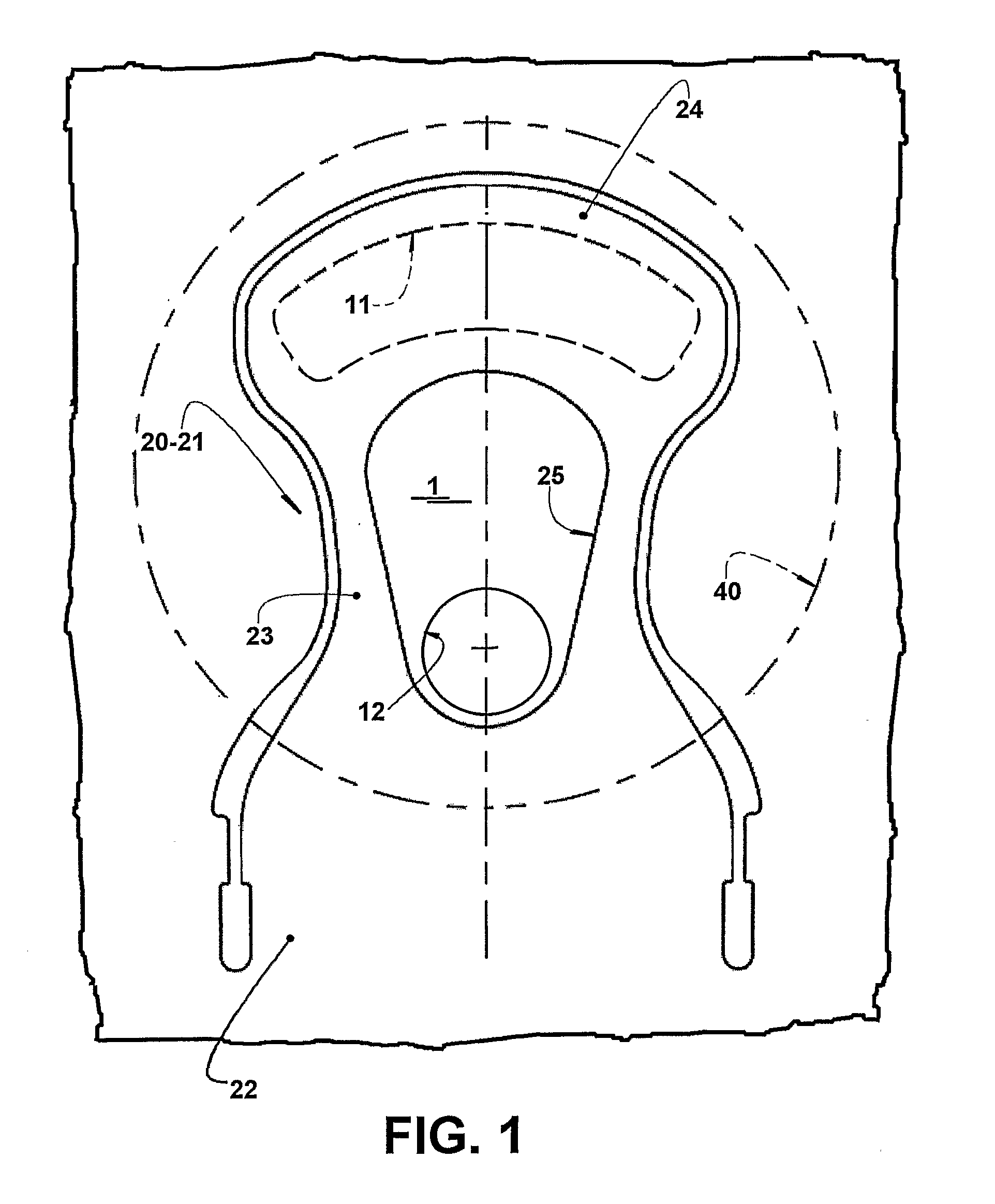

Engine intake air compressor having multiple inlets and method

ActiveUS20070269308A1Increase the areaIncrease capacityEngine manufacturePump componentsImpellerEngineering

A compressor assembly (404) includes a compressor housing (412) having a main inlet bore (424) and a secondary inlet passage (422) that has an increasing flow cross-sectional area. The secondary inlet passage (422) is positioned in the compressor housing (412) and around the main inlet bore (424). A secondary inlet slot (426) and an outlet slot (420) fluidly connect the secondary inlet passage (422) with the main inlet bore (424). A compressor wheel (418) is in the compressor housing (412) and has a stepped portion (518) formed by at least one plurality of vanes (506). The stepped portion (518) is located adjacent to the outlet slot (420) of the housing (412).

Owner:INT ENGINE INTPROP CO LLC

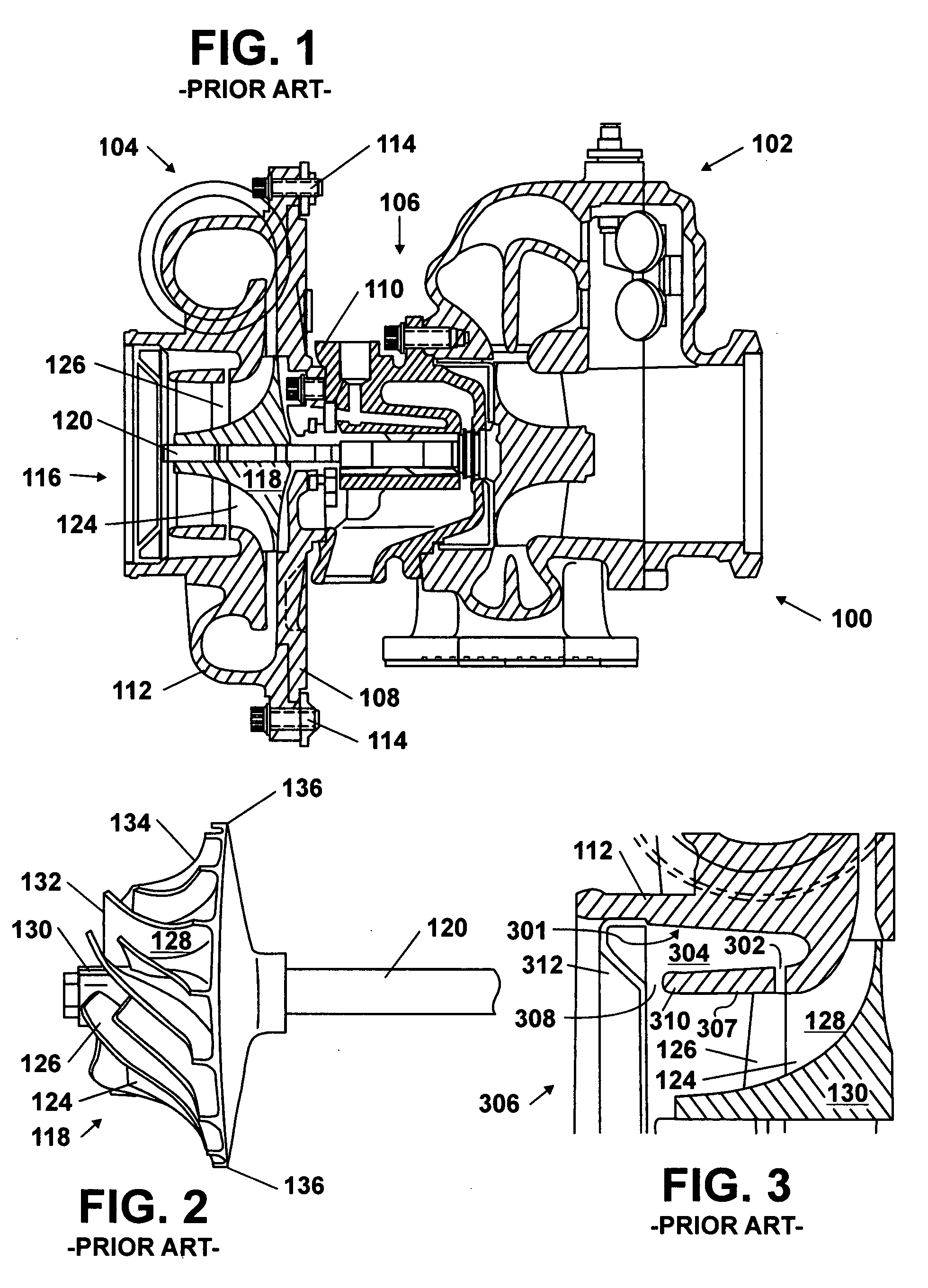

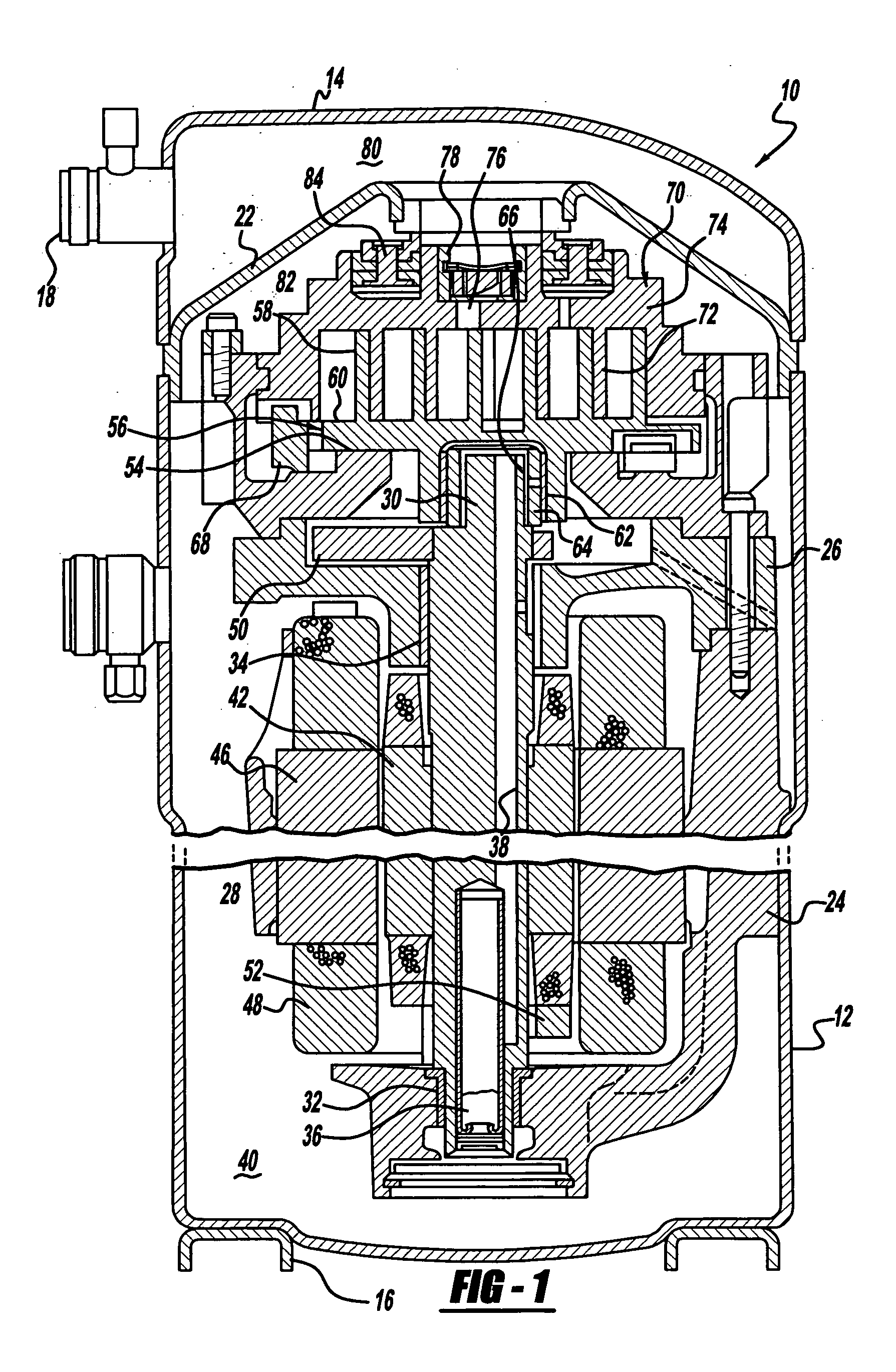

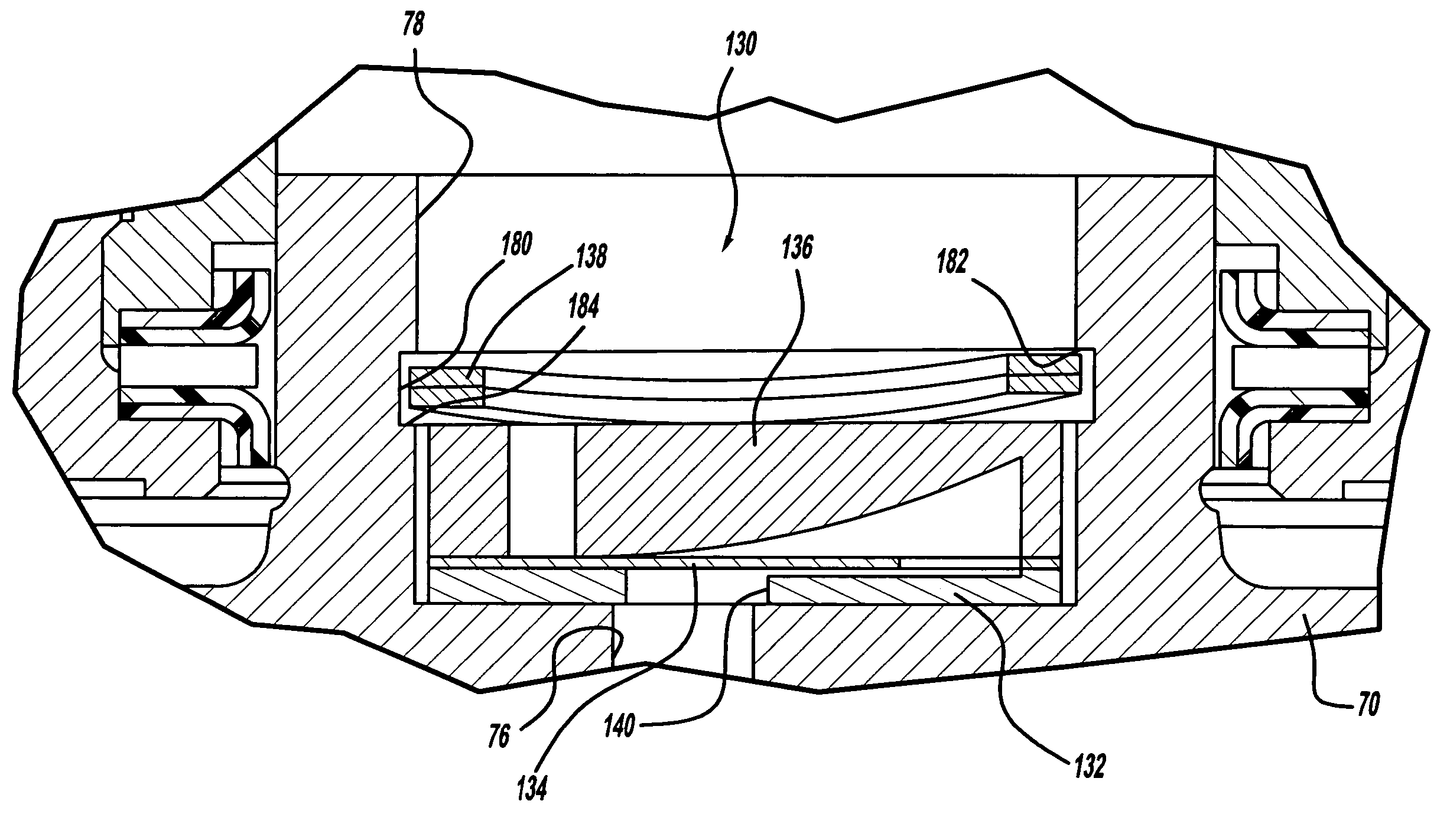

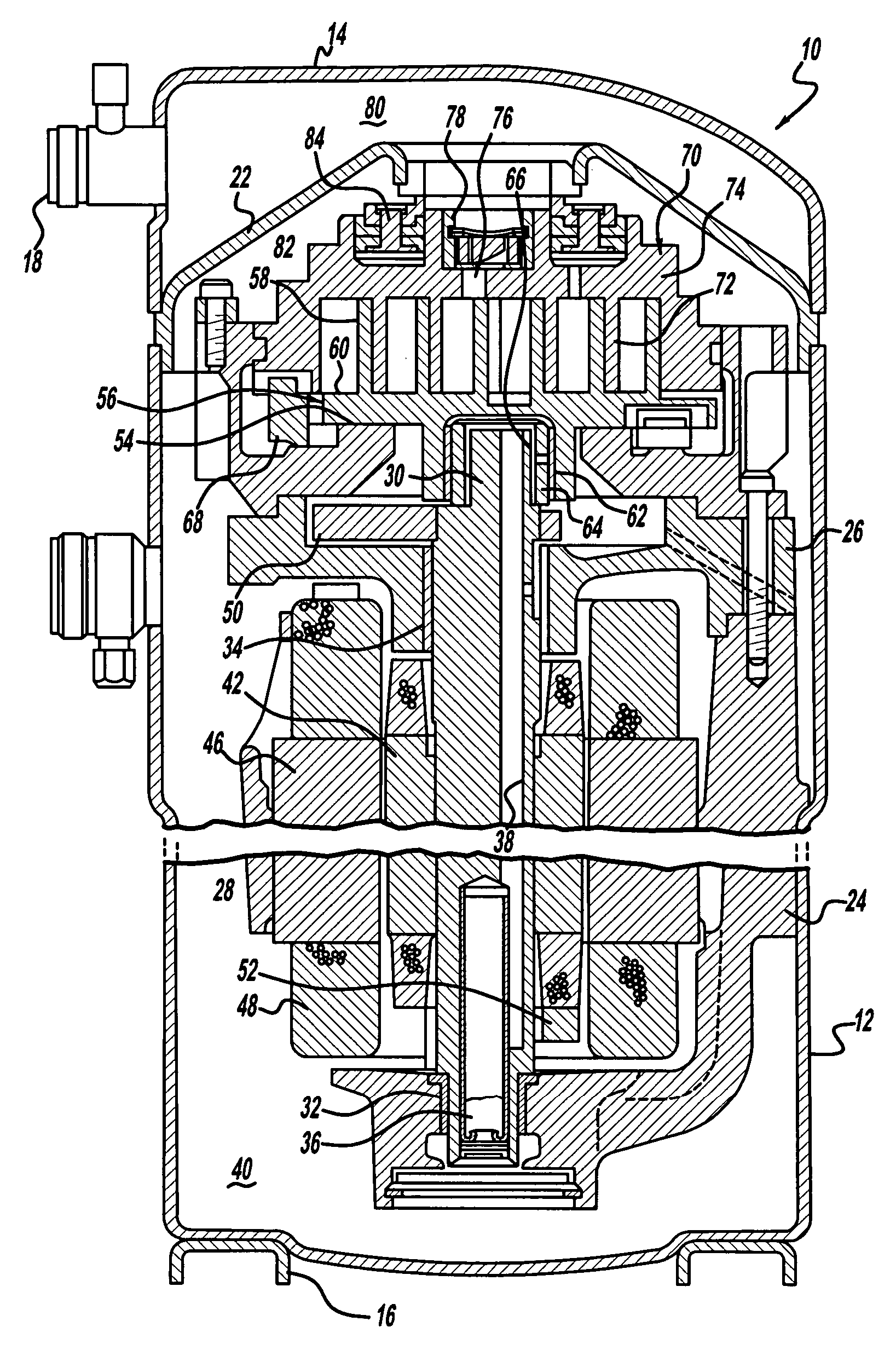

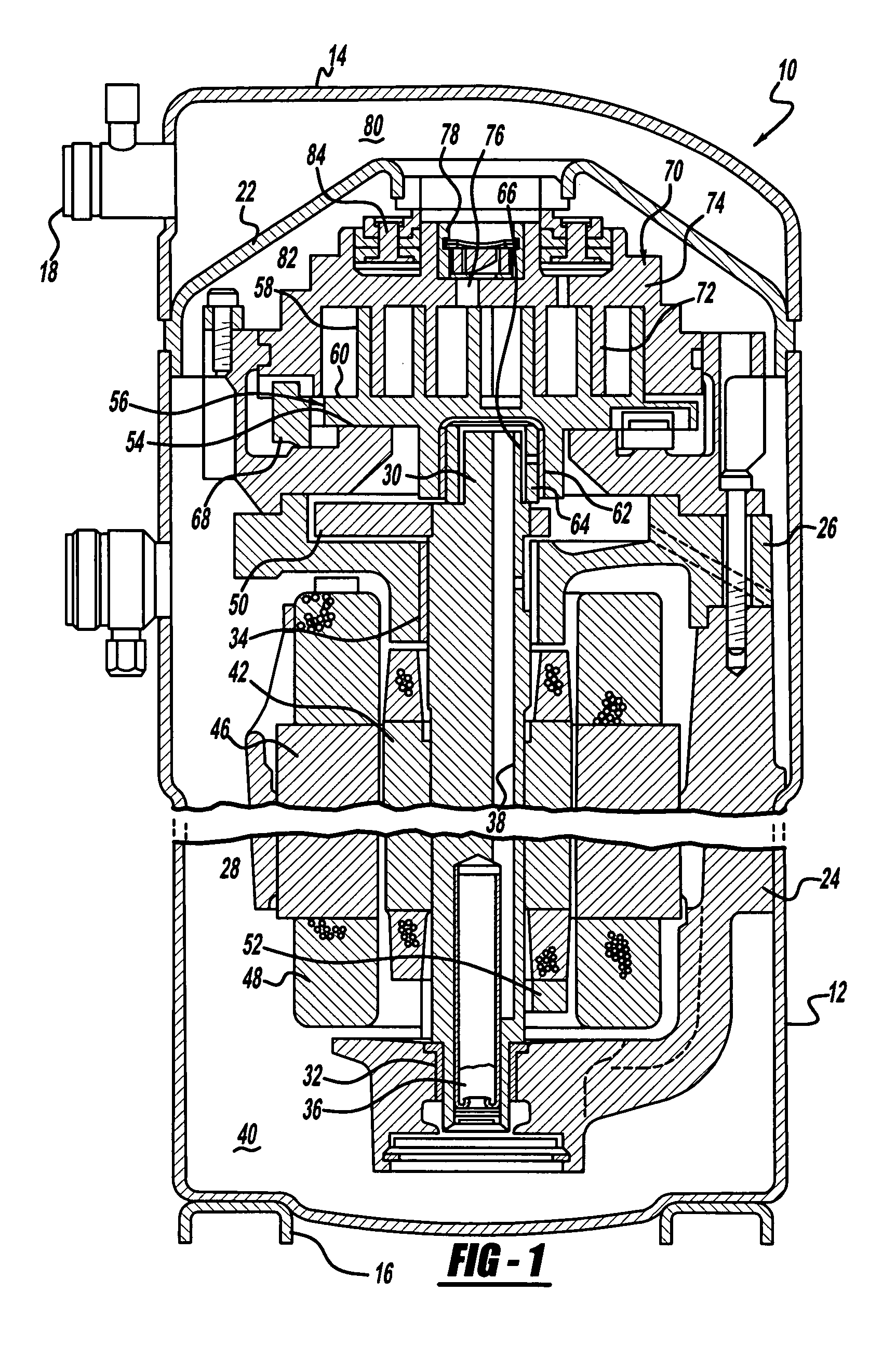

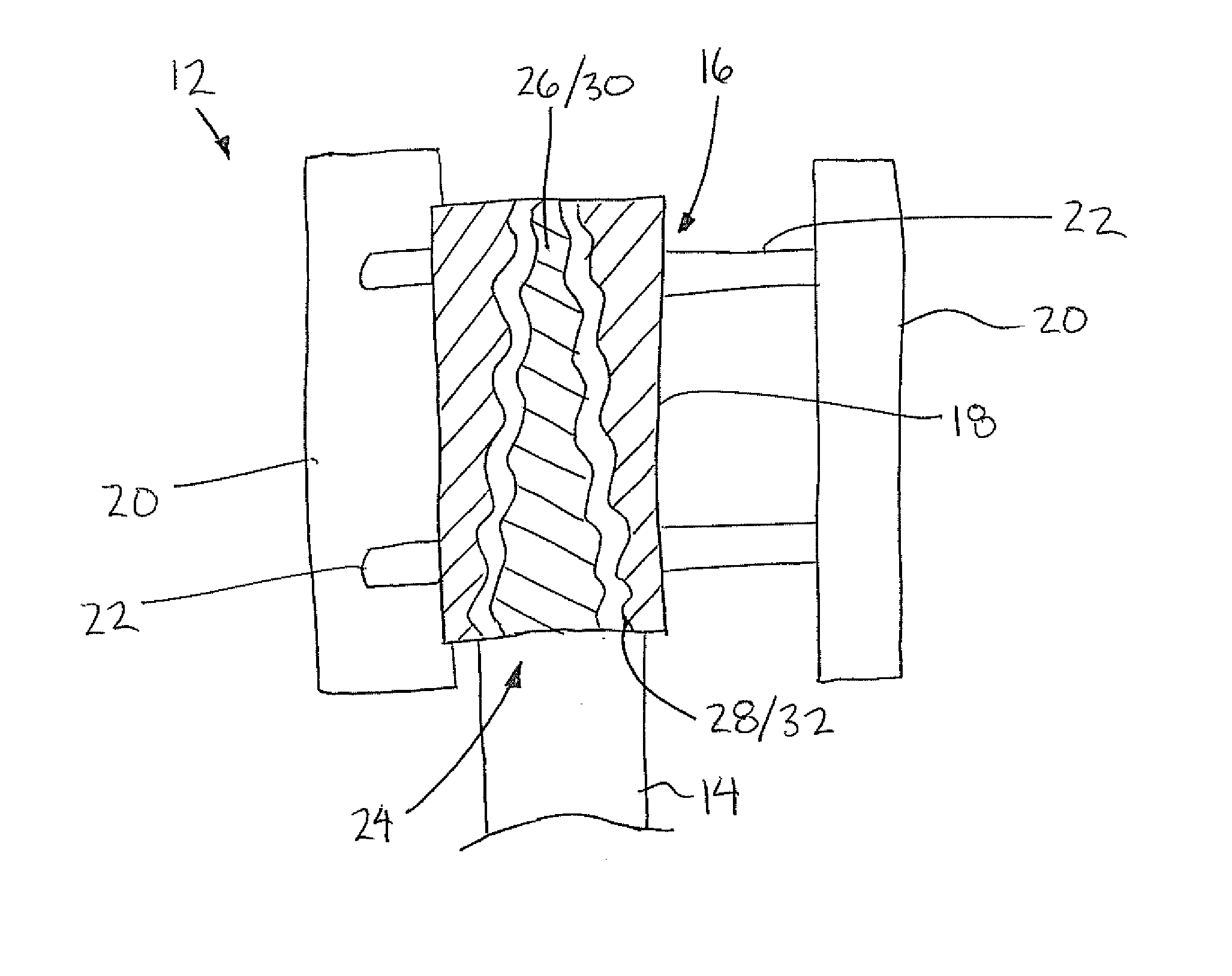

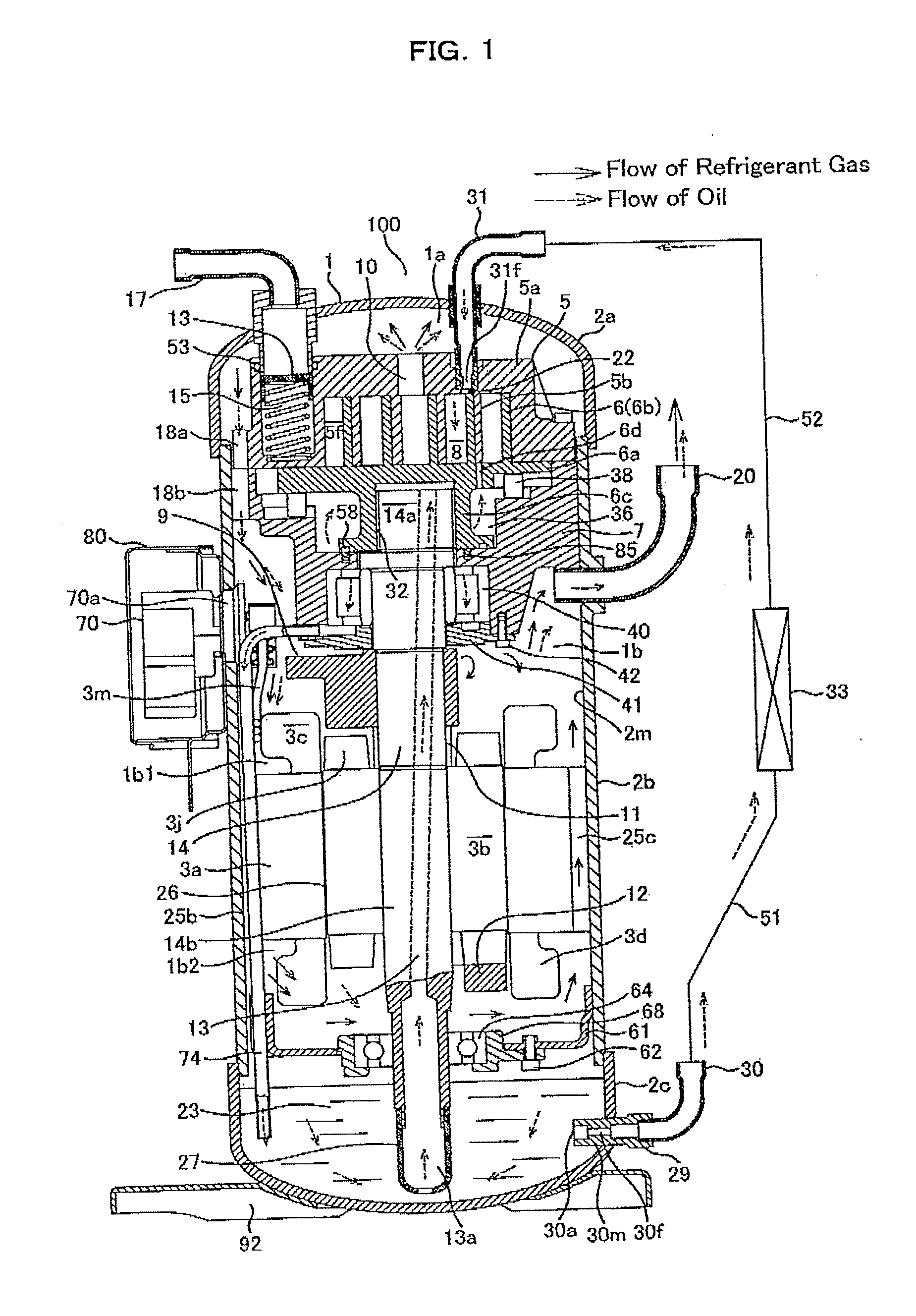

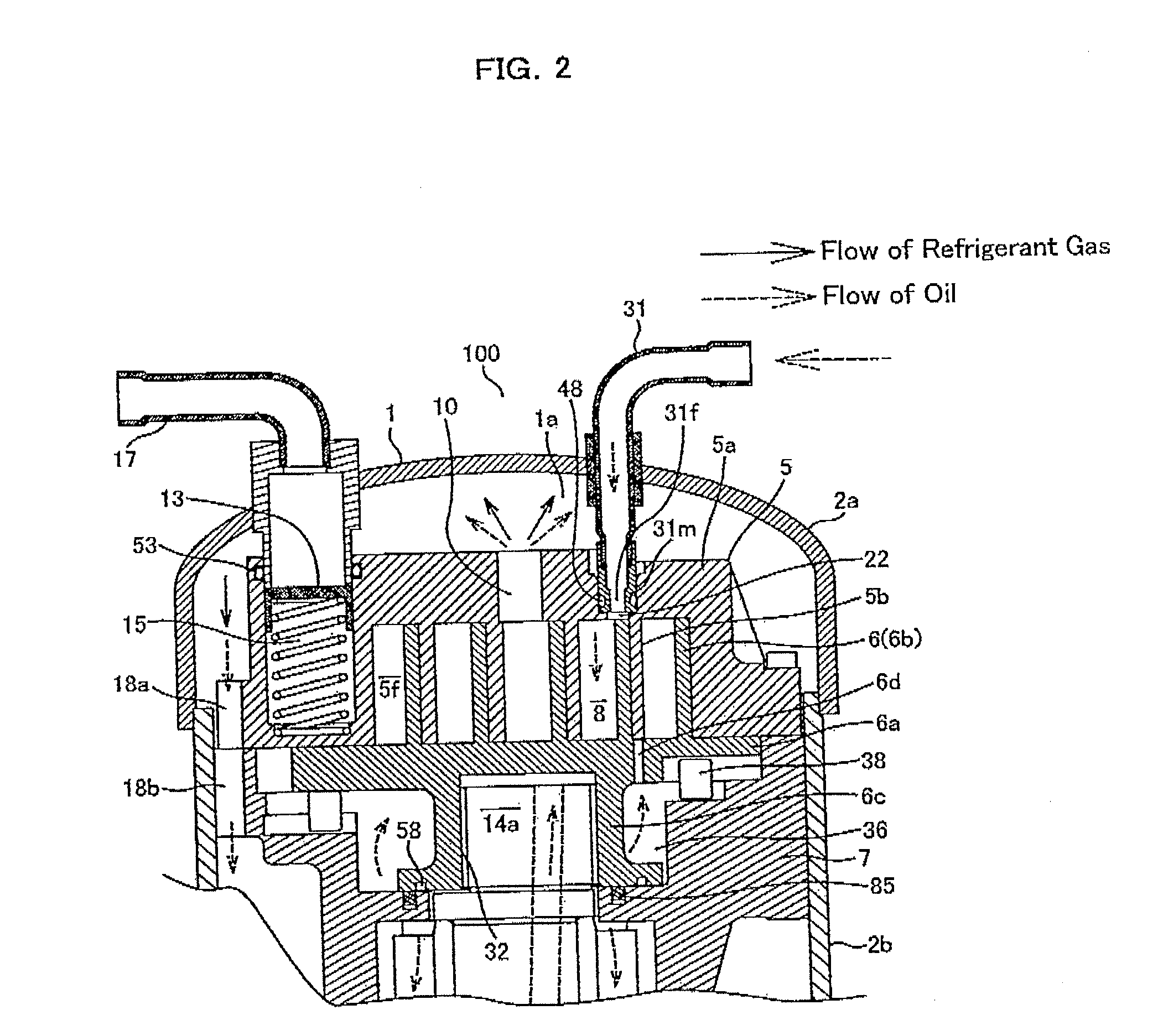

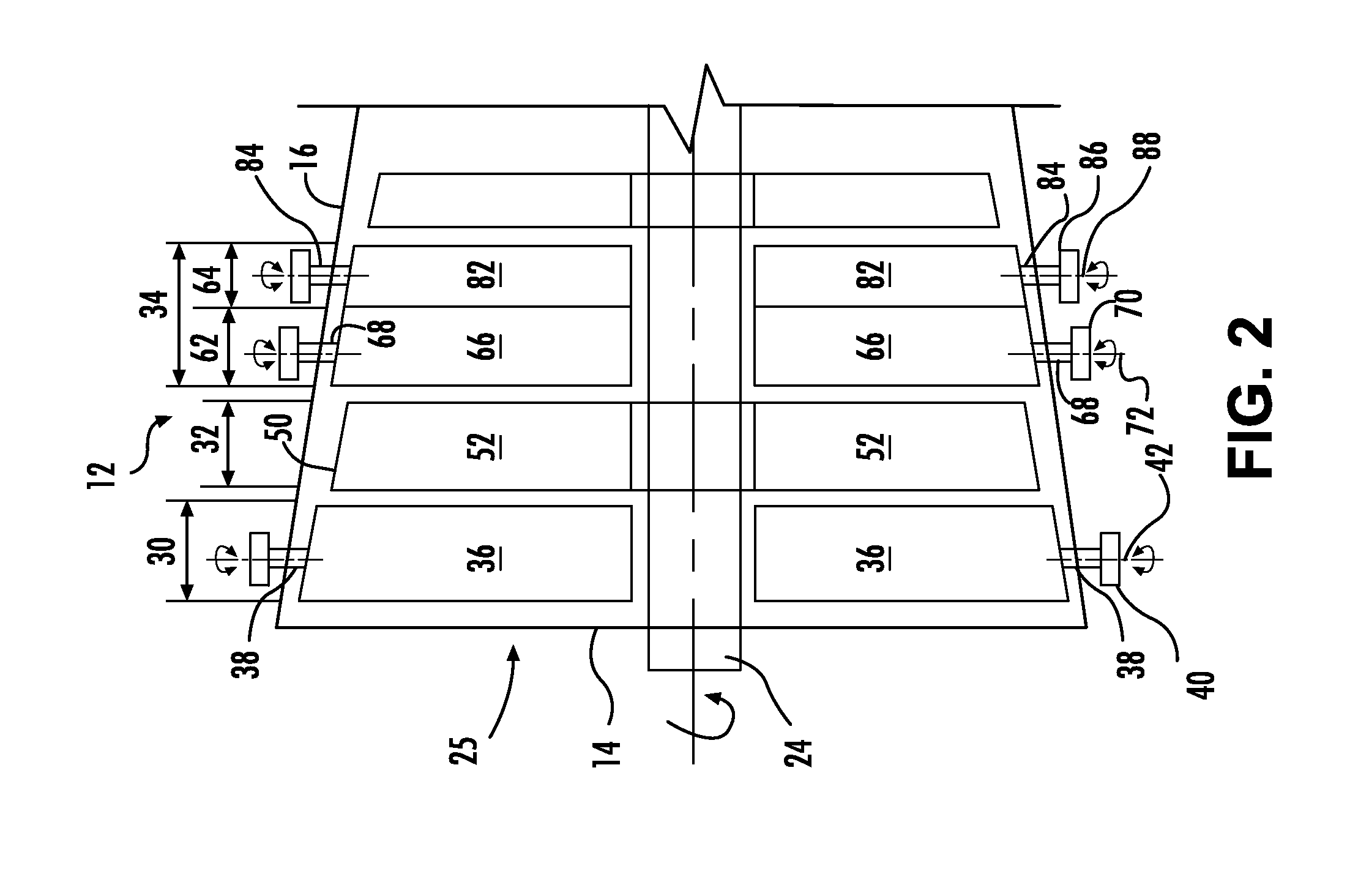

Scroll machine

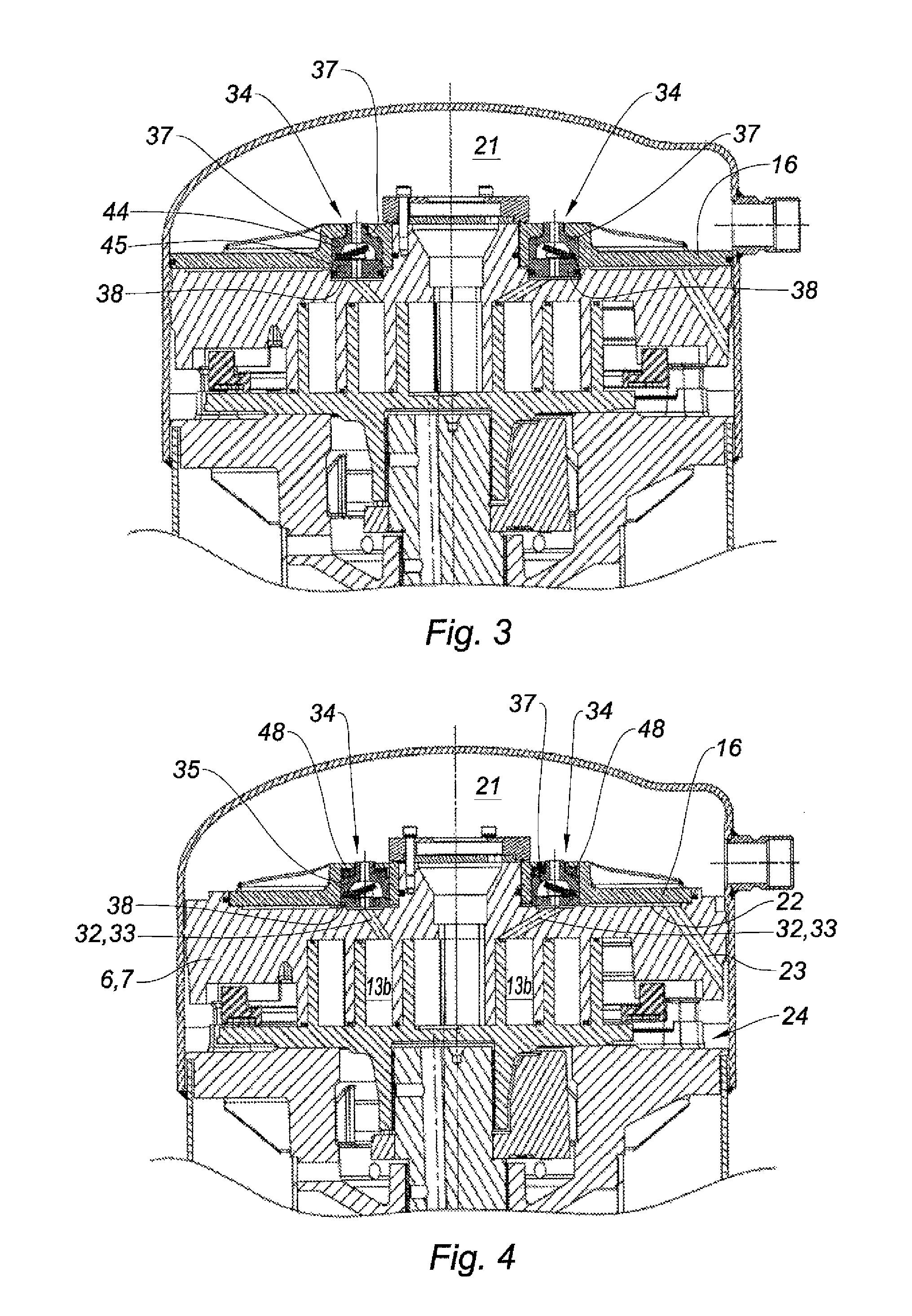

InactiveUS20070110604A1Performance maximizationImprove compressor performanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringDischarge pressure

A scroll machine includes a shell defining a discharge chamber, a first scroll member having a first spiral wrap projecting outwardly from a first end cap, a second scroll member having a second spiral wrap projecting outwardly from a second end cap intermeshed with the first spiral wrap, and a drive member causing the scroll members to orbit relative to one another. The spiral wraps create pockets of progressively changing volume between a suction pressure zone and a discharge pressure zone with the discharge pressure zone being in communication with the discharge chamber. A discharge valve assembly is disposed between the discharge pressure zone and the discharge chamber and is movable relative to the first scroll member. The discharge valve assembly includes a valve plate movable between a first open state and a closed state.

Owner:PEYTON JESSE

Scroll machine

ActiveUS7160088B2Performance maximizationImprove compressor performanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigerant

A compressor includes a normally open discharge valve assembly for controlling compressed refrigerant flow from the discharge chamber through the compression members. This controlling of flow results in an increased performance for the compressor by reducing recompression volume and the elimination of reverse rotation at shut down. The discharge valve assembly includes a valve seat, a valve plate and a valve stop secured within a recess formed within the compressor with a wave ring retainer. The valve stop and the valve seat include a contoured surface that is engaged by the valve plate when it opens and closes. The contoured surface controls the movement of the valve plate.

Owner:EMERSON CLIMATE TECH INC

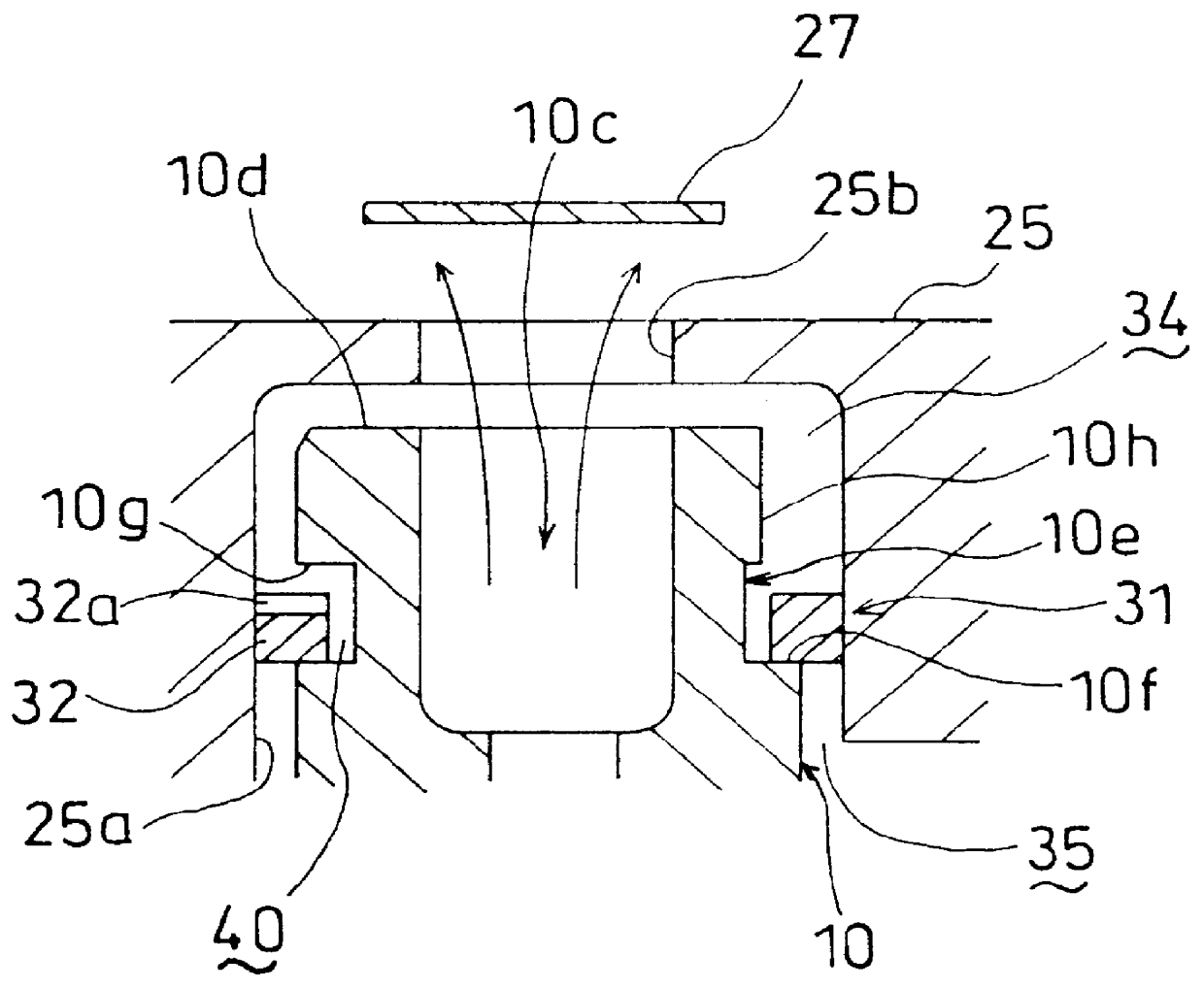

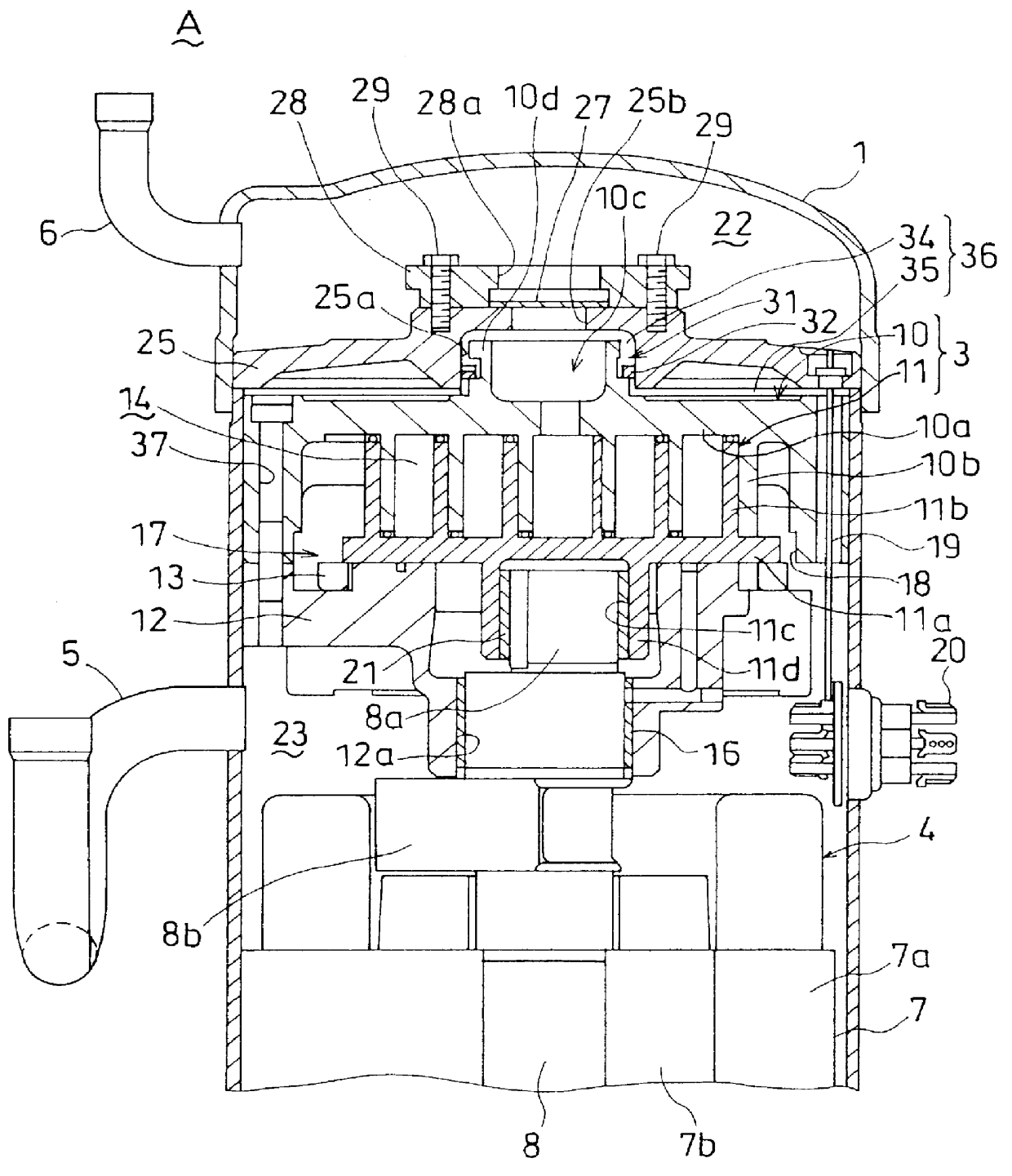

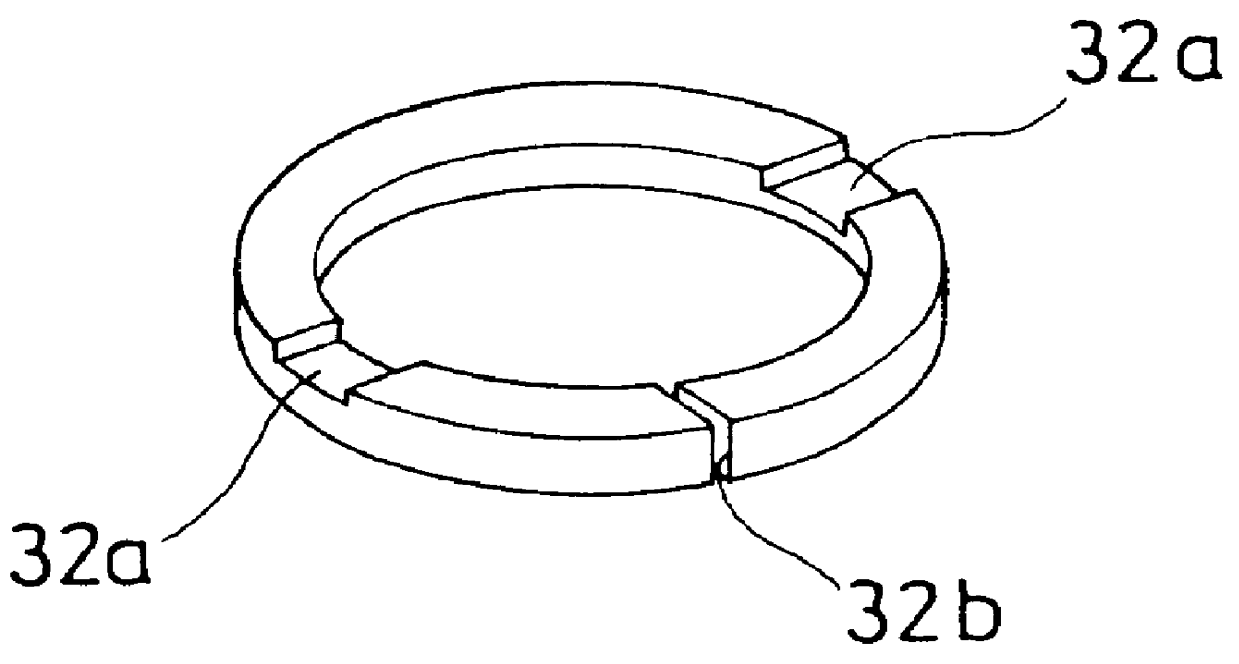

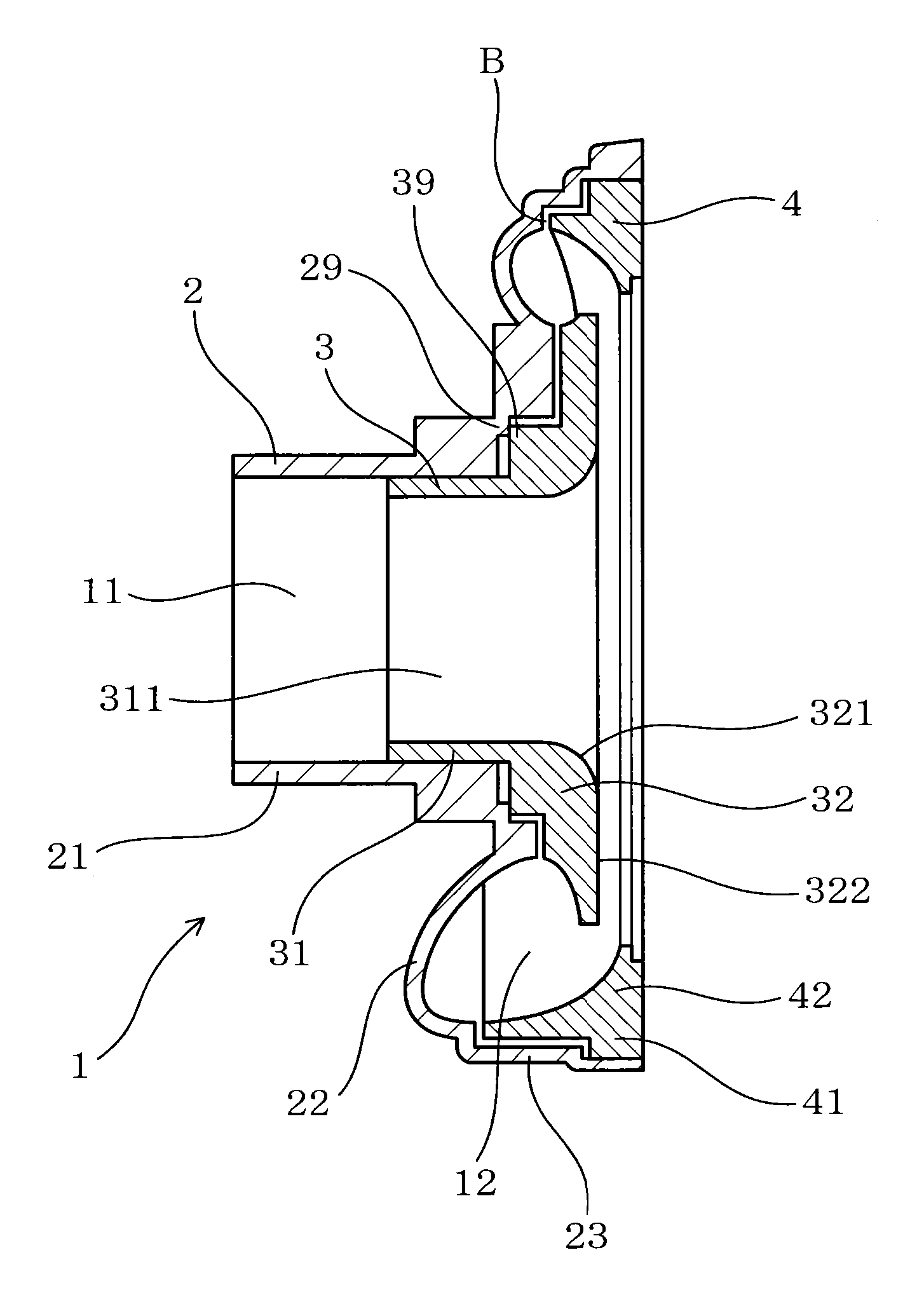

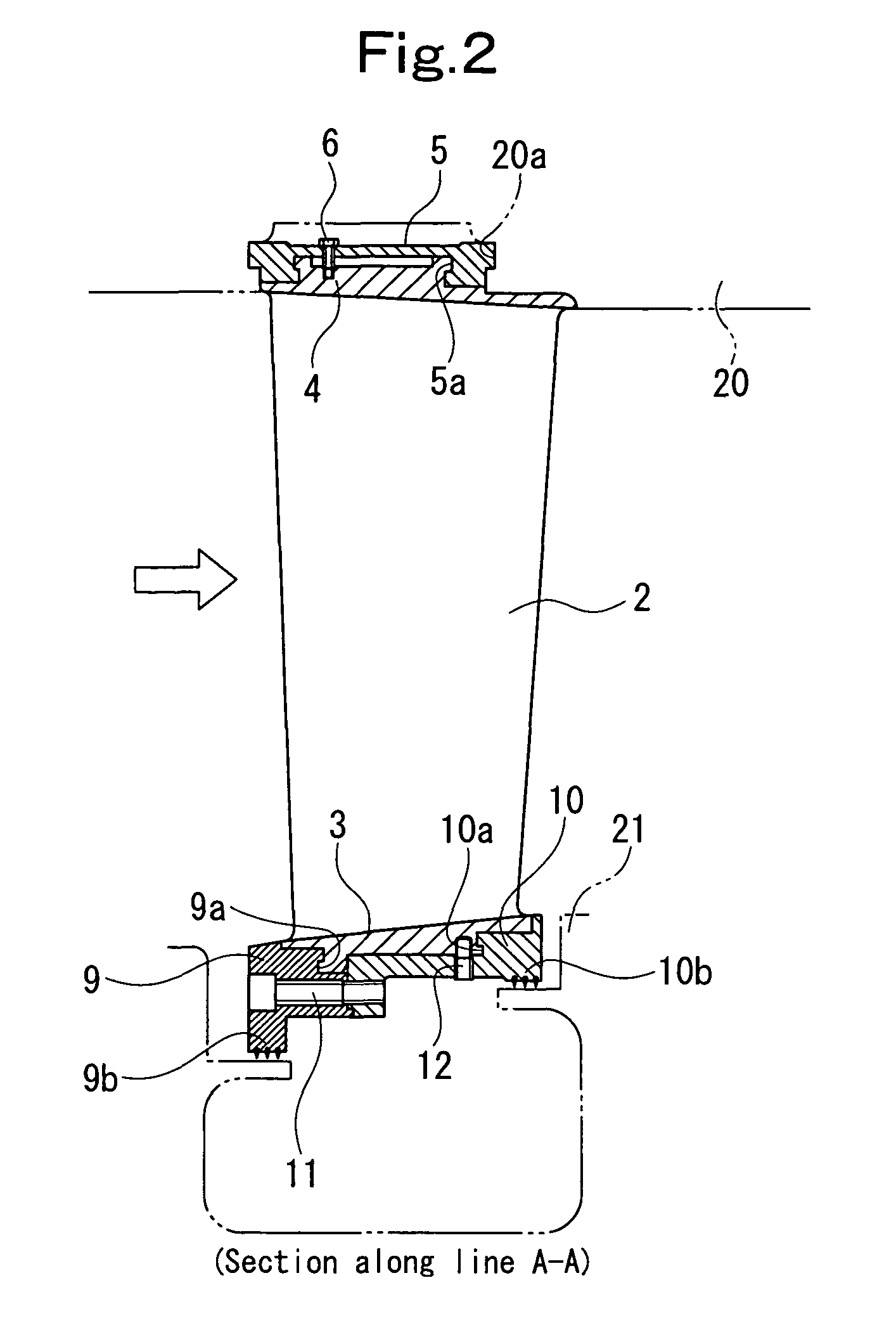

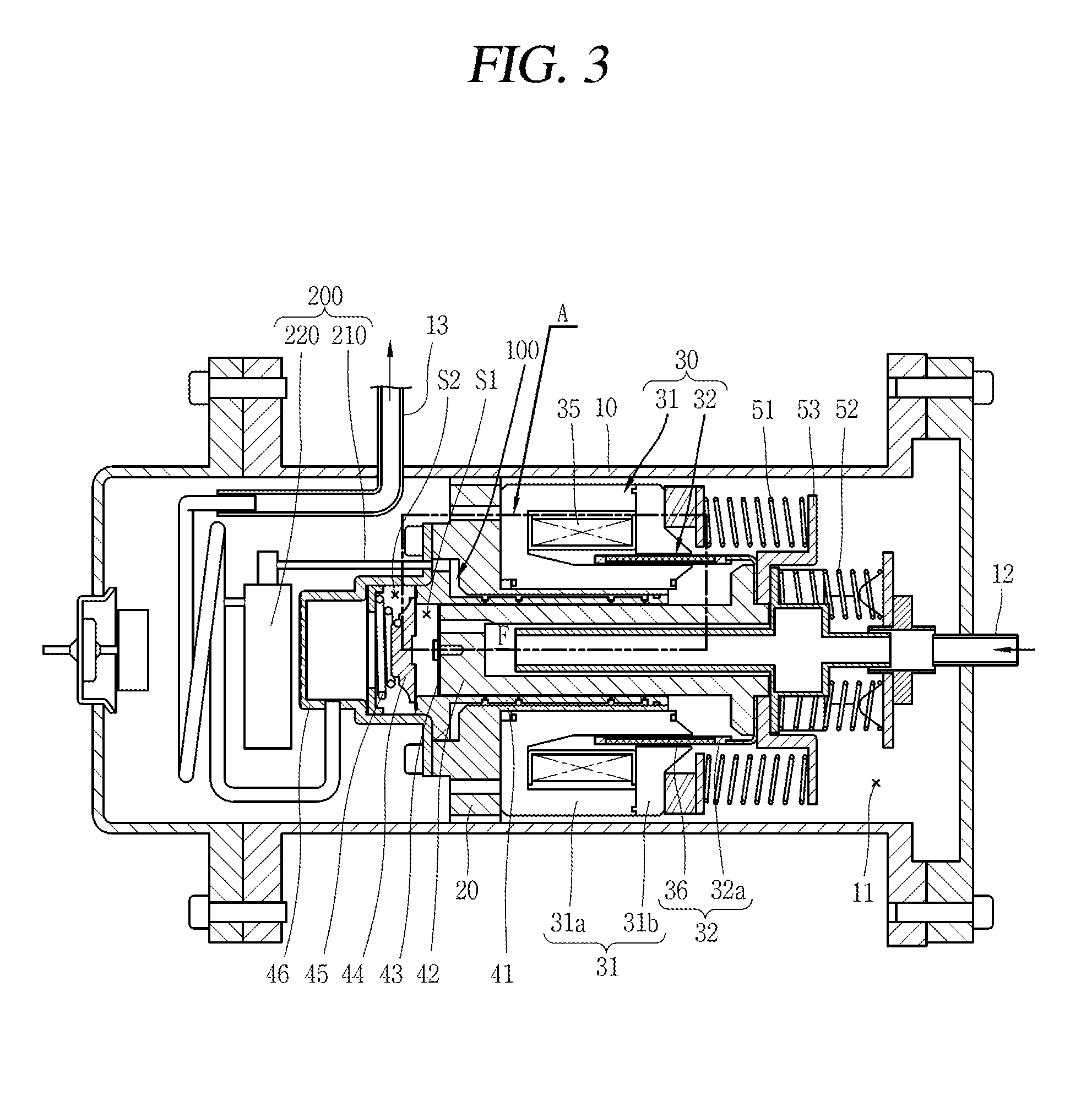

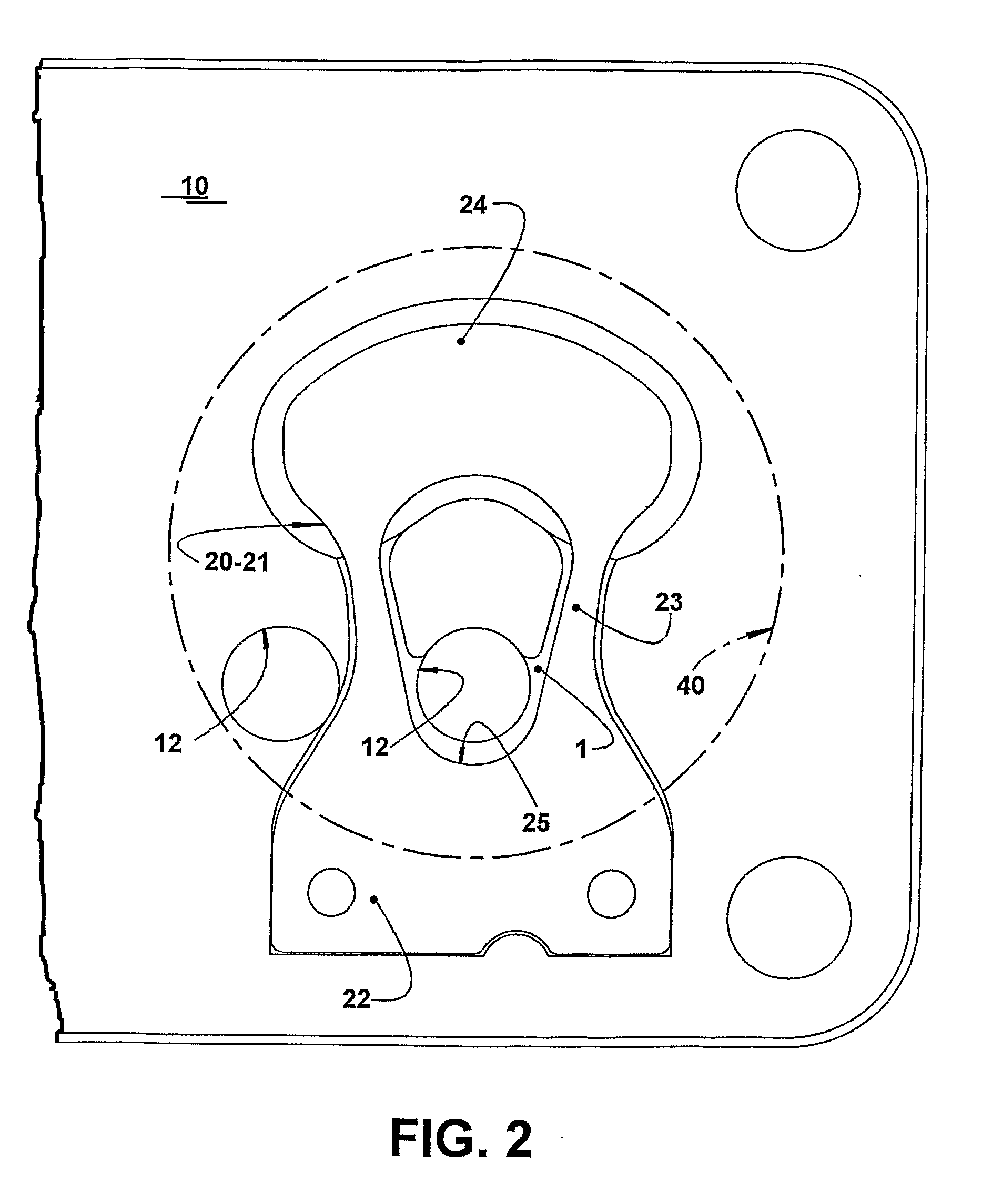

Reverse rotation protection for a scroll compressor using a valve means

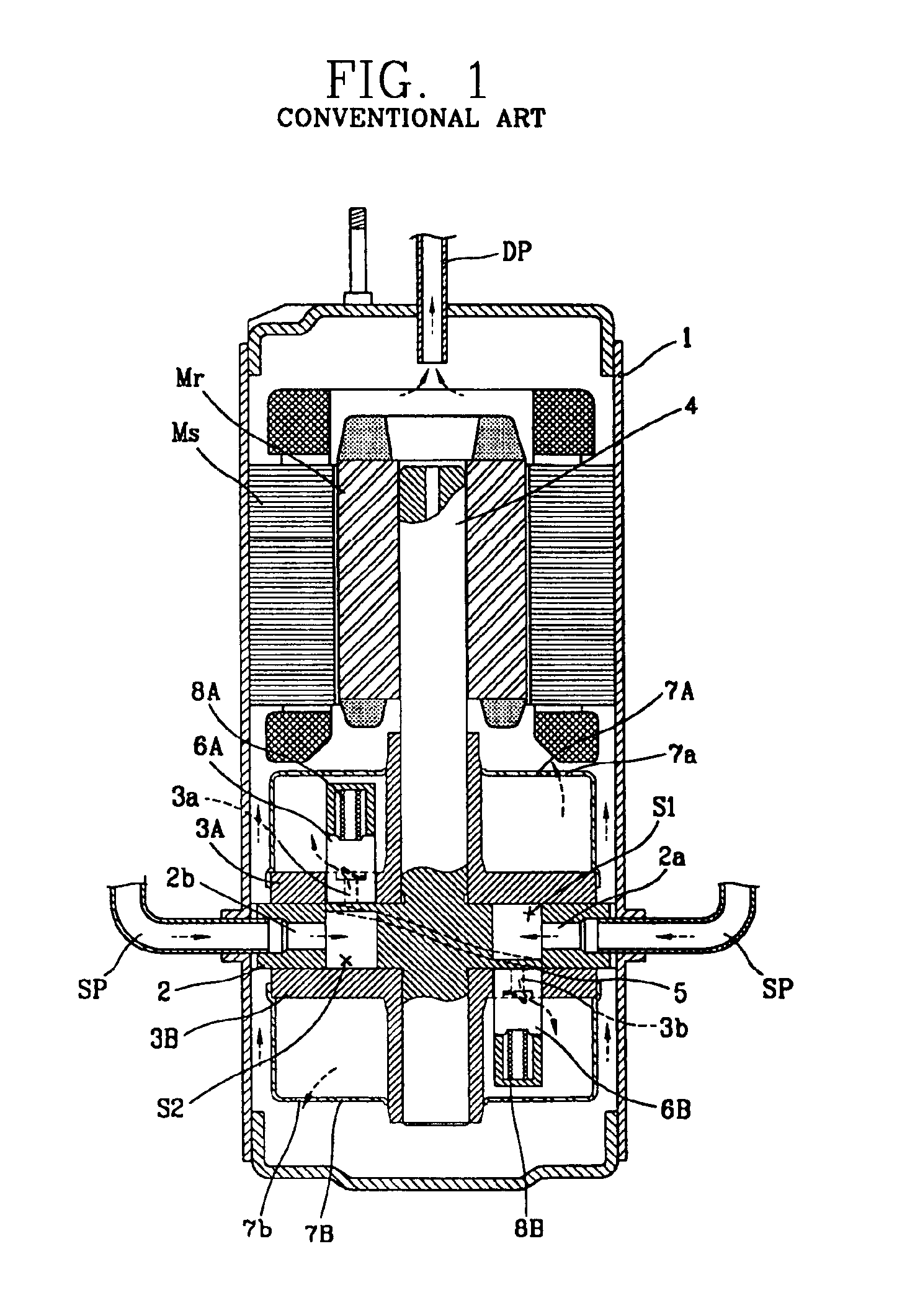

InactiveUS6095764AReduction of overall compressor costAvoid deformationSealing arrangement for pumpsCheck valvesEngineeringCheck valve

PCT No. PCT / JP97 / 01799 Sec. 371 Date Jan. 28, 1998 Sec. 102(e) Date Jan. 28, 1998 PCT Filed May 27, 1997 PCT Pub. No. WO97 / 45642 PCT Pub. Date Dec. 4, 1997A scroll compressor (A) includes a barrier wall (25) which divides the internal cavity of a casing (1) into a discharge chamber (22) and a suction chamber (23) and has a discharge opening (25b) for providing the communication of the compartments (22) and (23), a check valve (27) operable to prevent a flow of gas from the discharge chamber (22) into the suction chamber (23), and a scroll compression mechanism (3) which is provided in the suction chamber (23), which a space (36) left between the mechanism (3) and the barrier wall (25), for discharging compressed gas into the space (36). In addition, a valve (31) is provided in the space (36) which has a seal member (32) operable to interrupt the communication of an inner compartment (34) with an outer compartment (35) of the space (36) during the correct operation period while on the other hand providing the communication during the reverse operation period. Without suffering a drop in performance during the correct operation period, frictional heat occurring at the forward end surfaces of involute bodies (10b) and (11b) of fixed and moving scrolls (10) and (11) is positively removed to outside the scroll compression mechanism (3), thereby preventing these end surfaces from undergoing seizing.

Owner:DAIKIN IND LTD

Scroll machine

ActiveUS20050069444A1Maximizing of performance of compressorIncrease discharge pressureRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringCompression member

A compressor includes a normally open discharge valve assembly for controlling compressed refrigerant flow from the discharge chamber through the compression members. This controlling of flow results in an increased performance for the compressor by reducing recompression volume and the elimination of reverse rotation at shut down. The discharge valve assembly includes a valve seat, a valve plate and a valve stop secured within a recess formed within the compressor with a wave ring retainer. The valve stop and the valve seat include a contoured surface that is engaged by the valve plate when it opens and closes. The contoured surface controls the movement of the valve plate.

Owner:EMERSON CLIMATE TECH INC

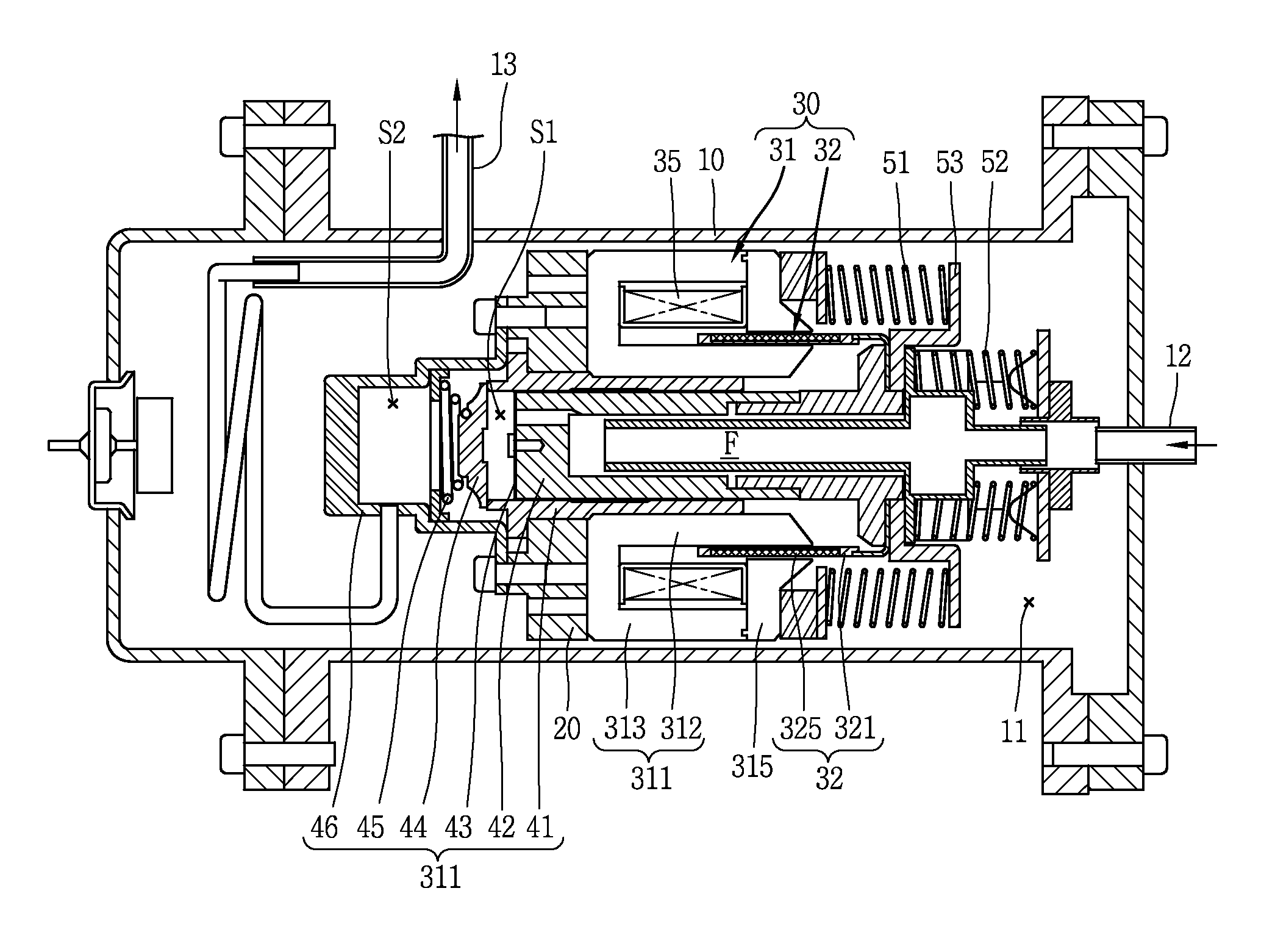

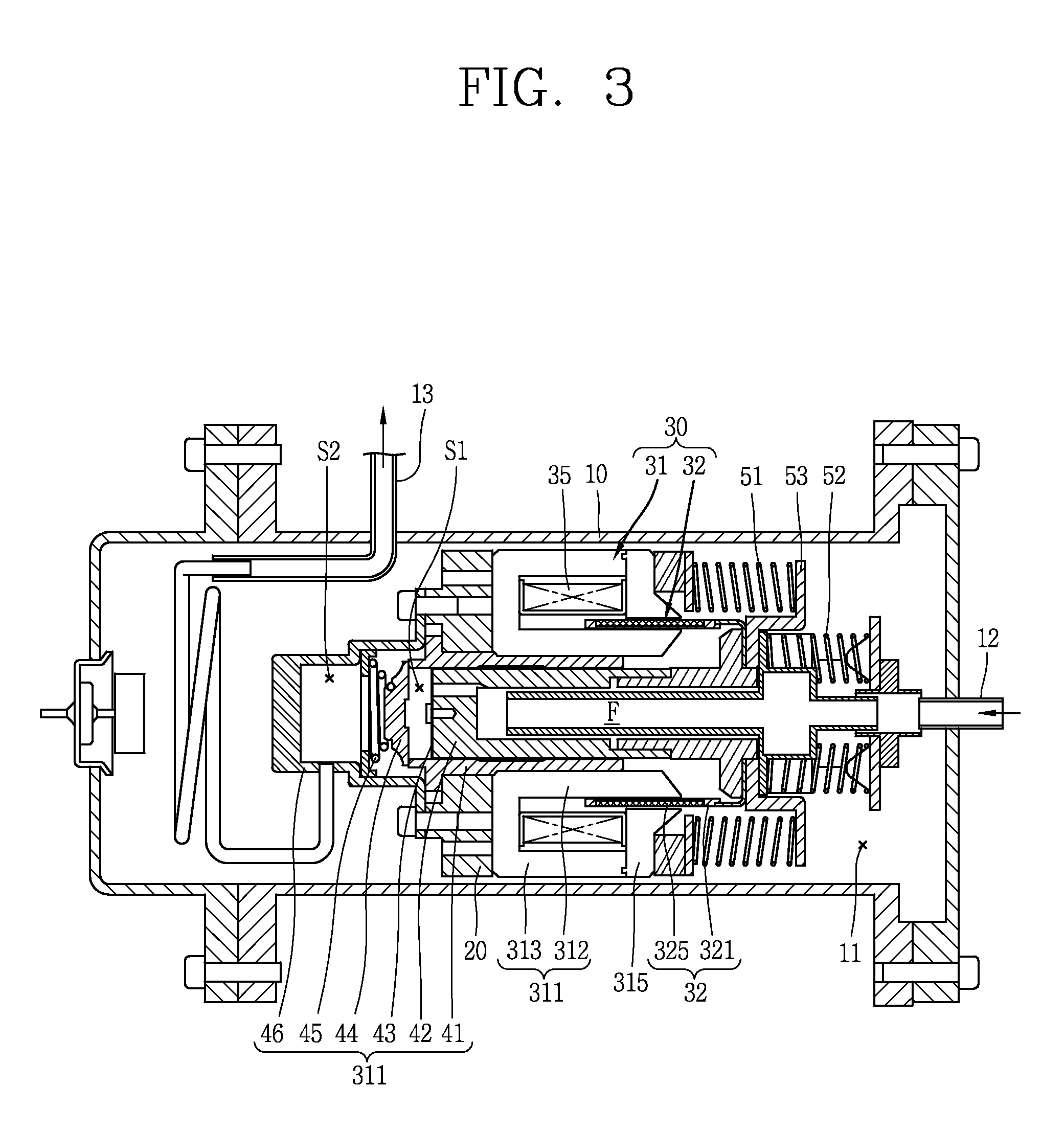

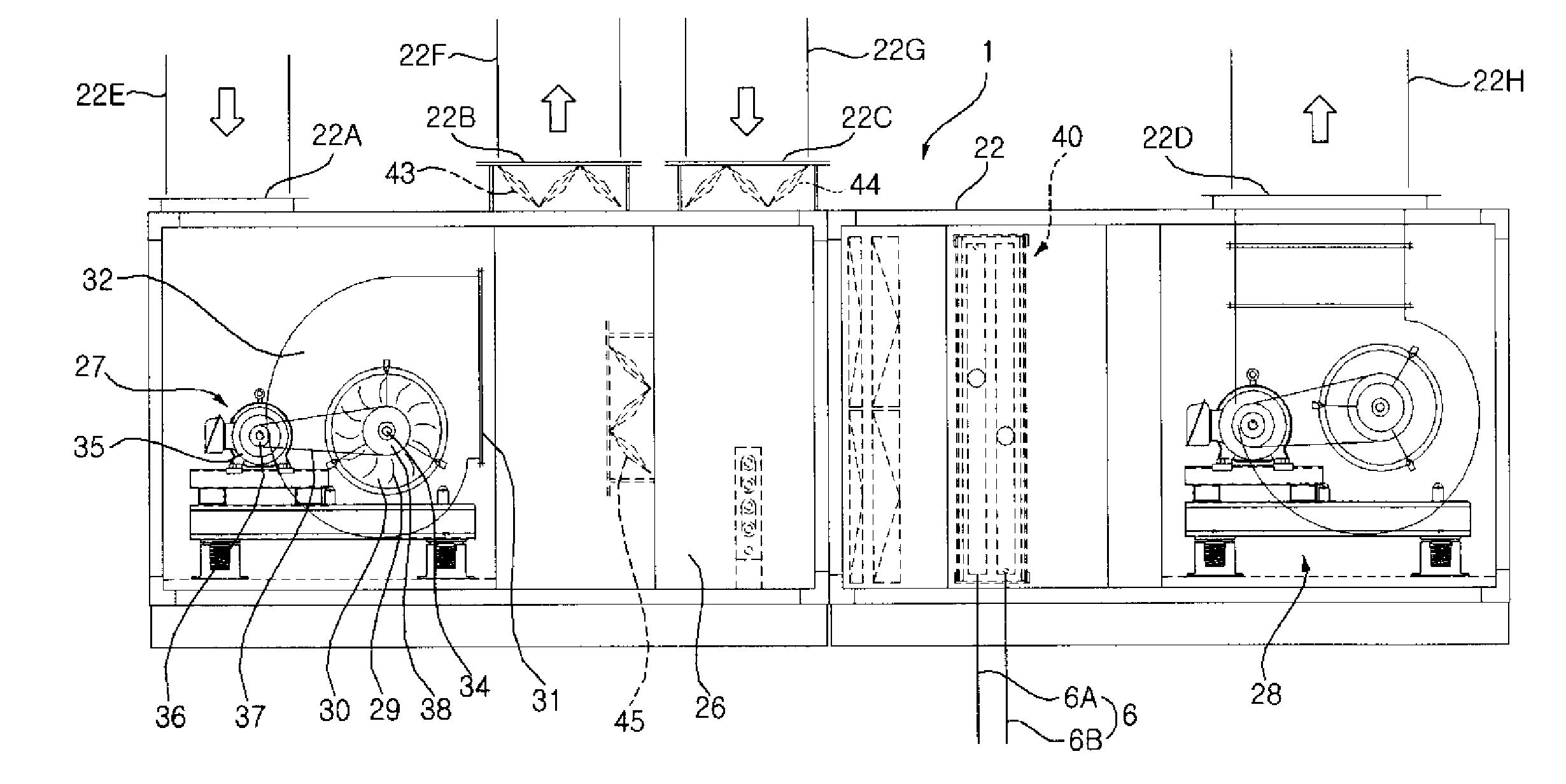

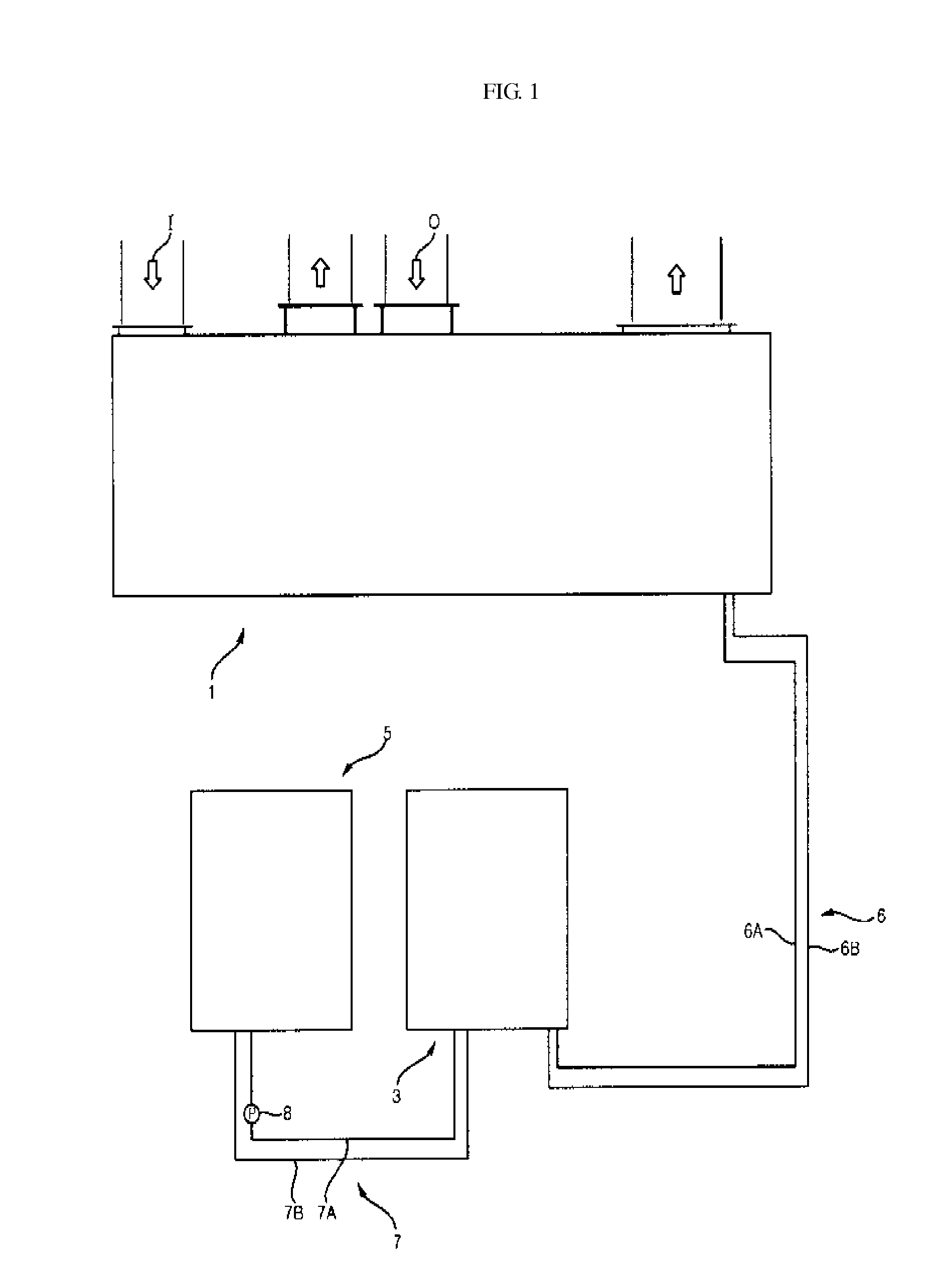

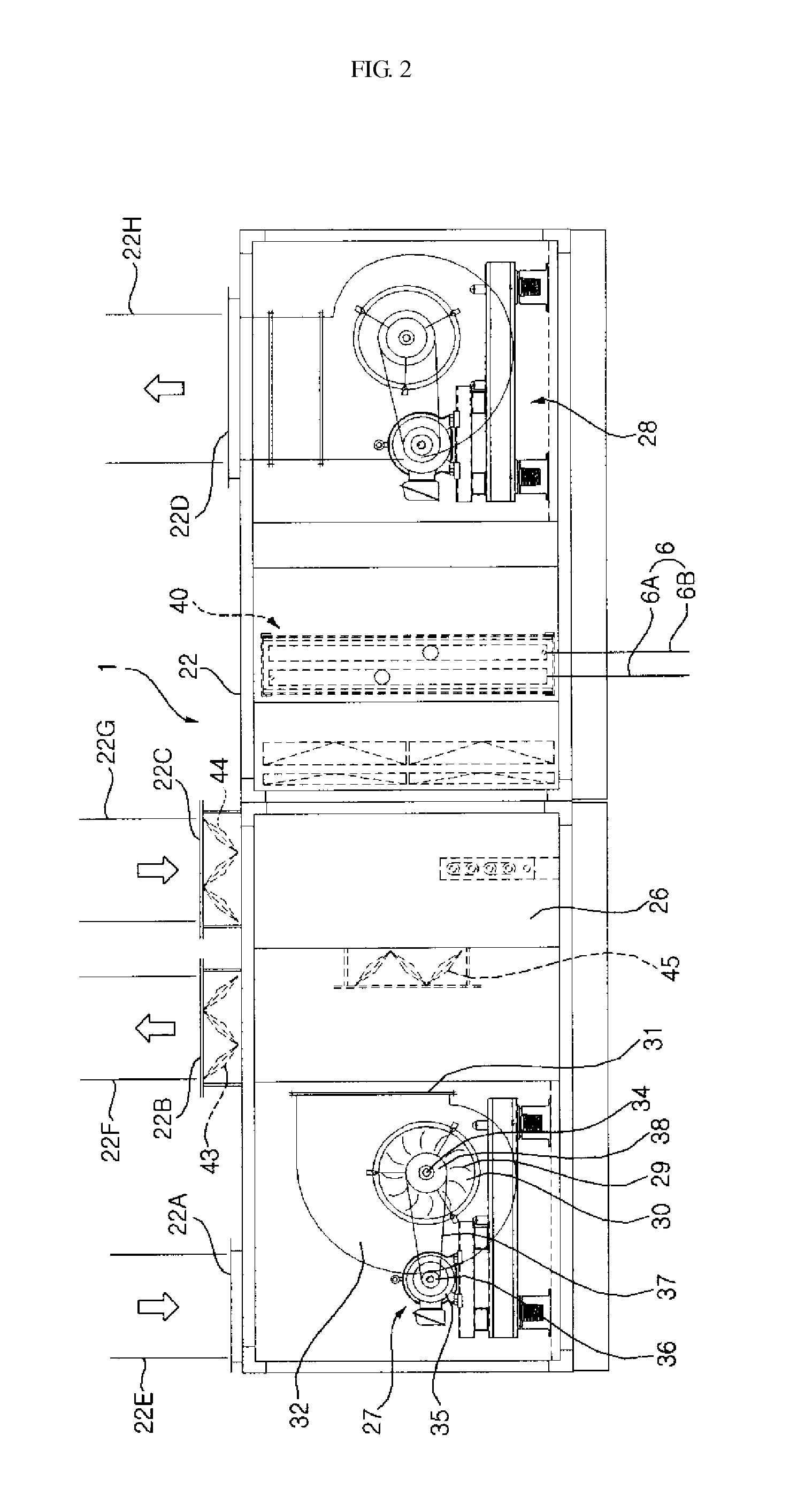

Variable Displacement Compressor

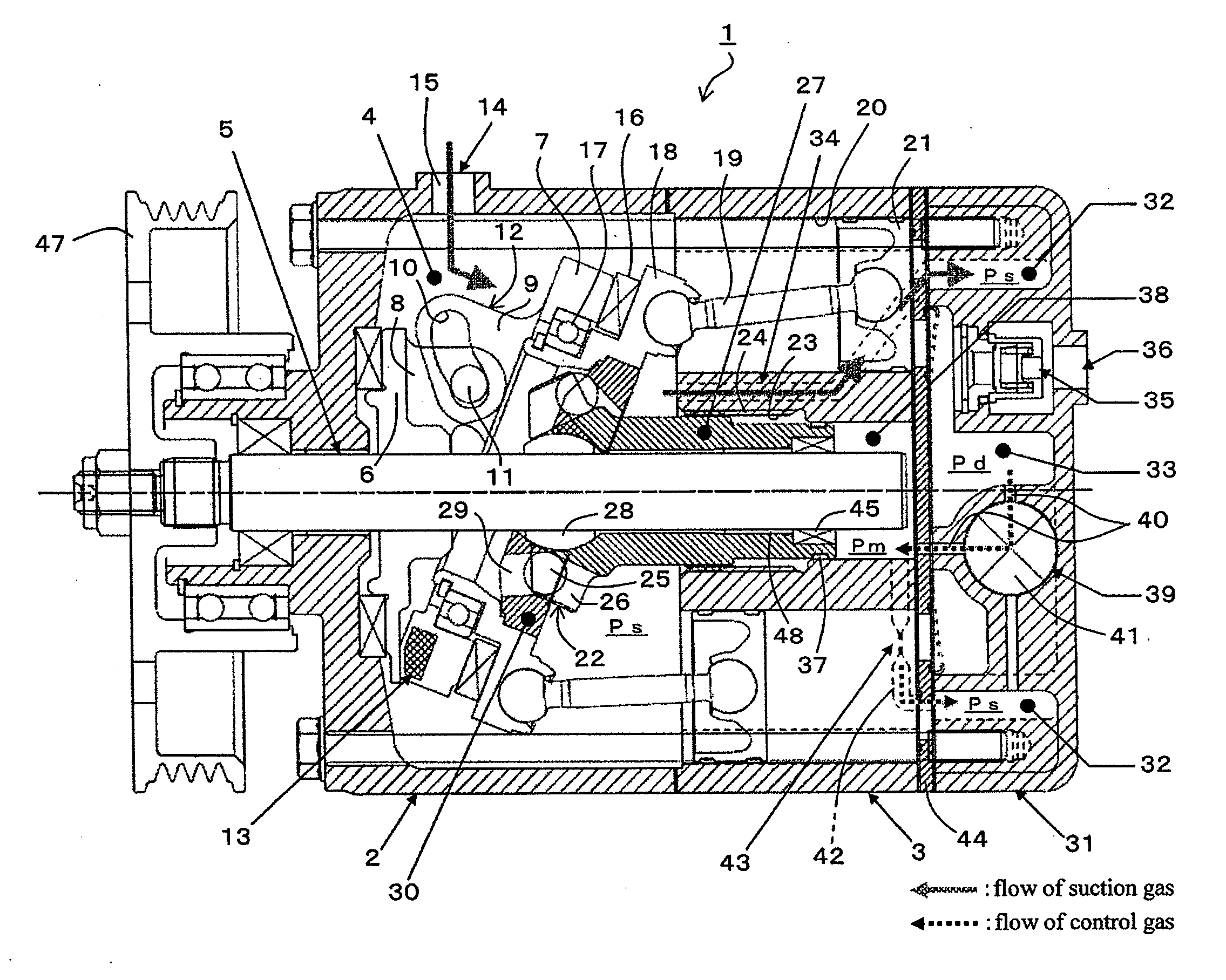

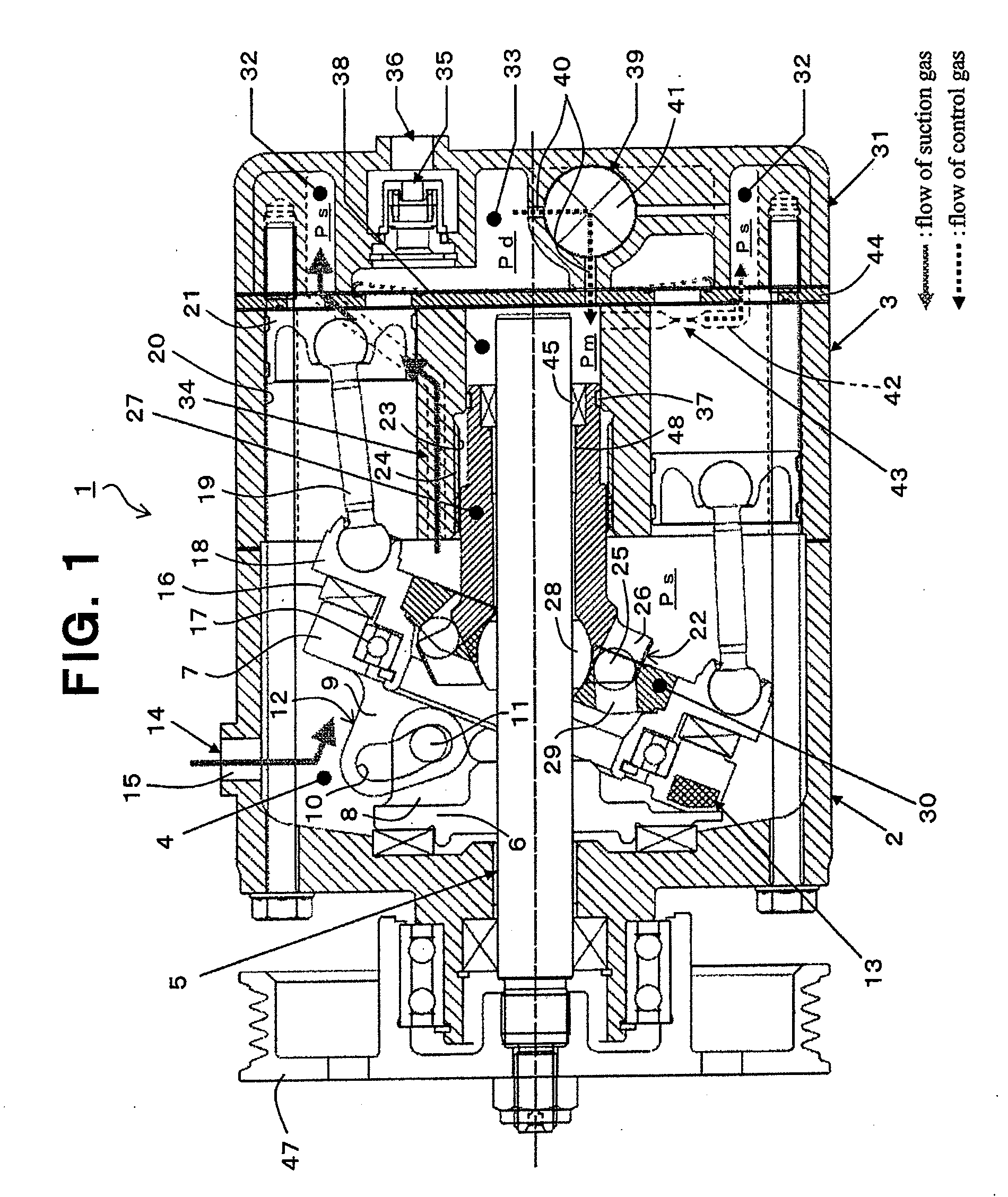

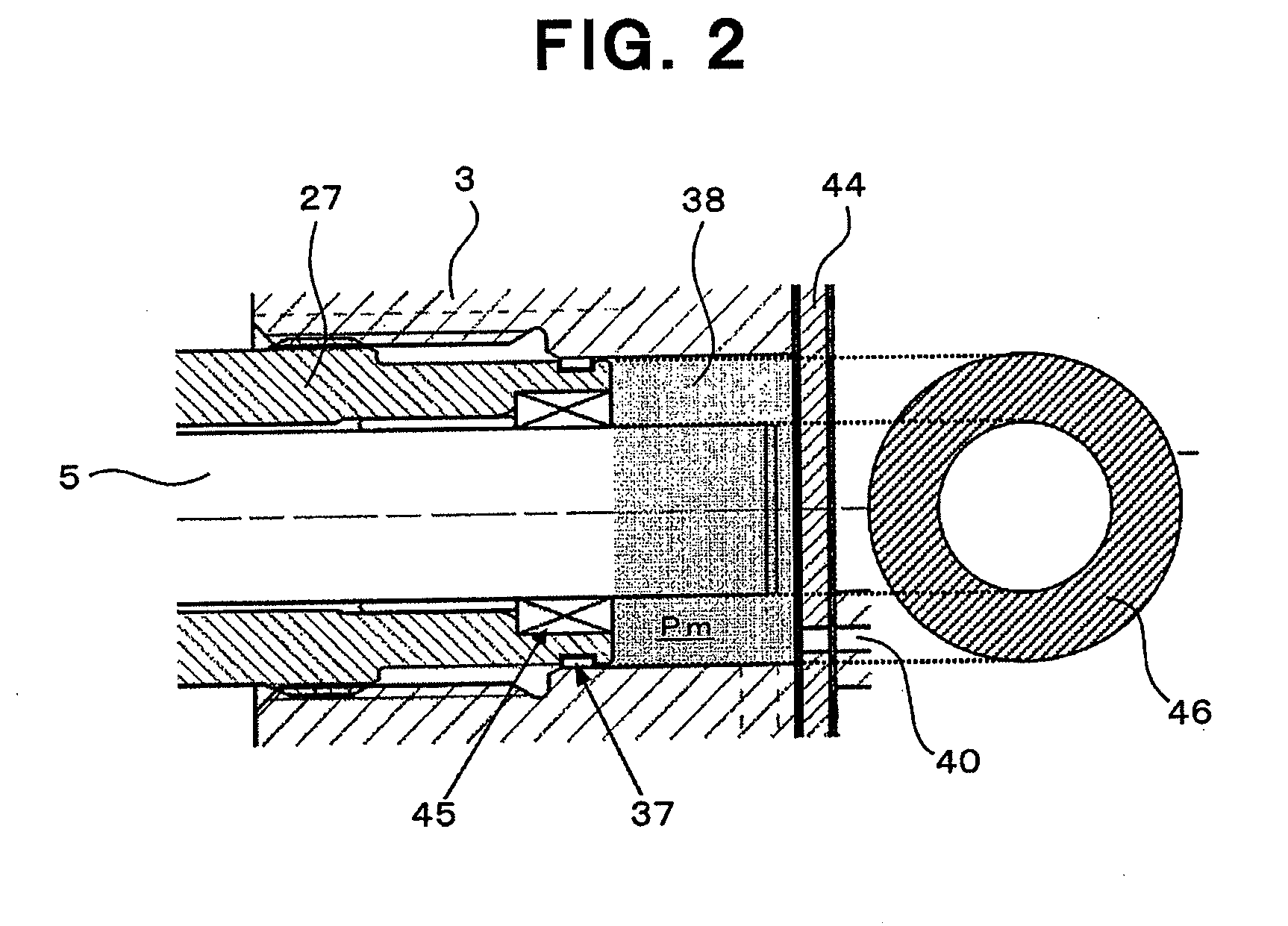

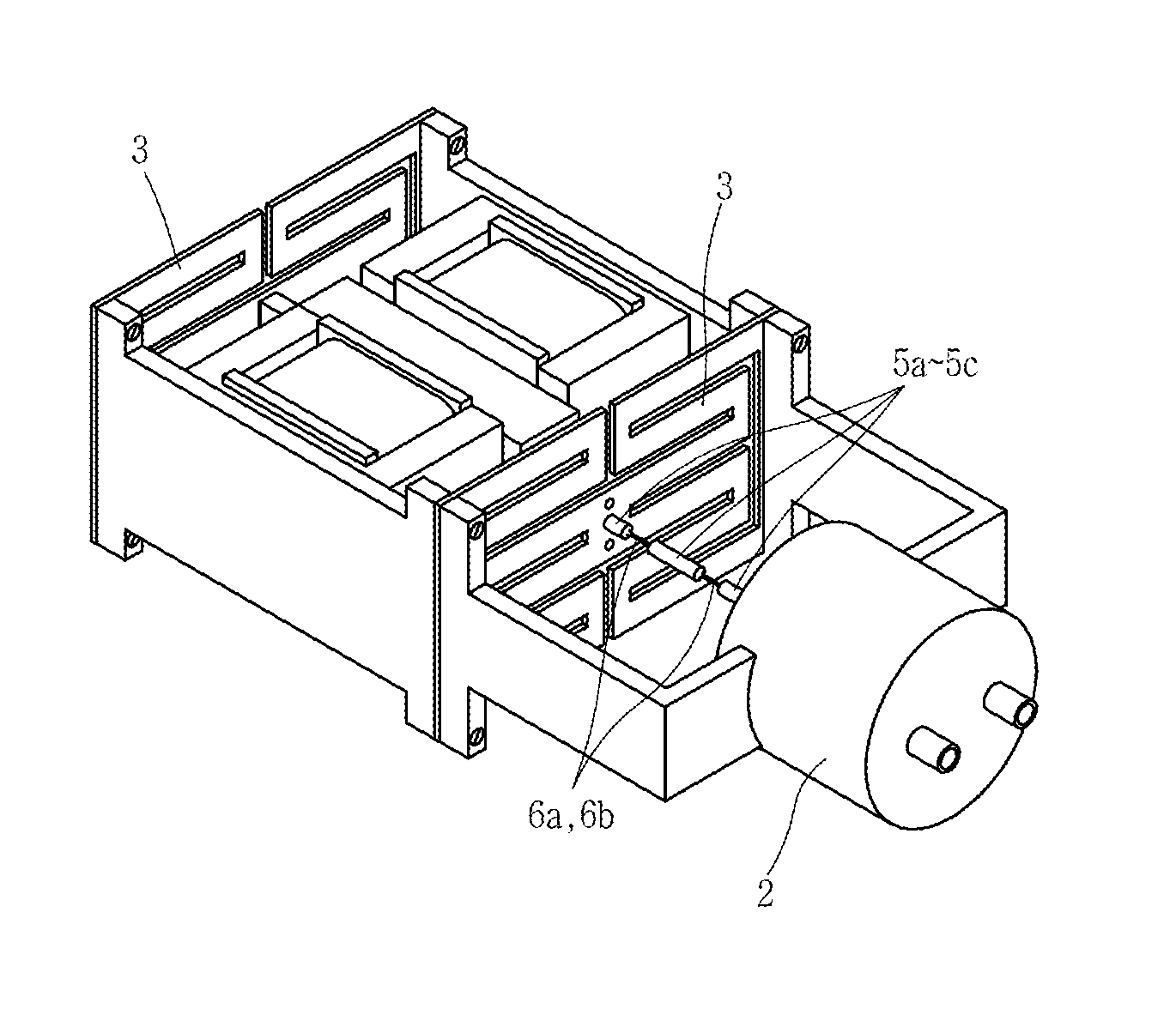

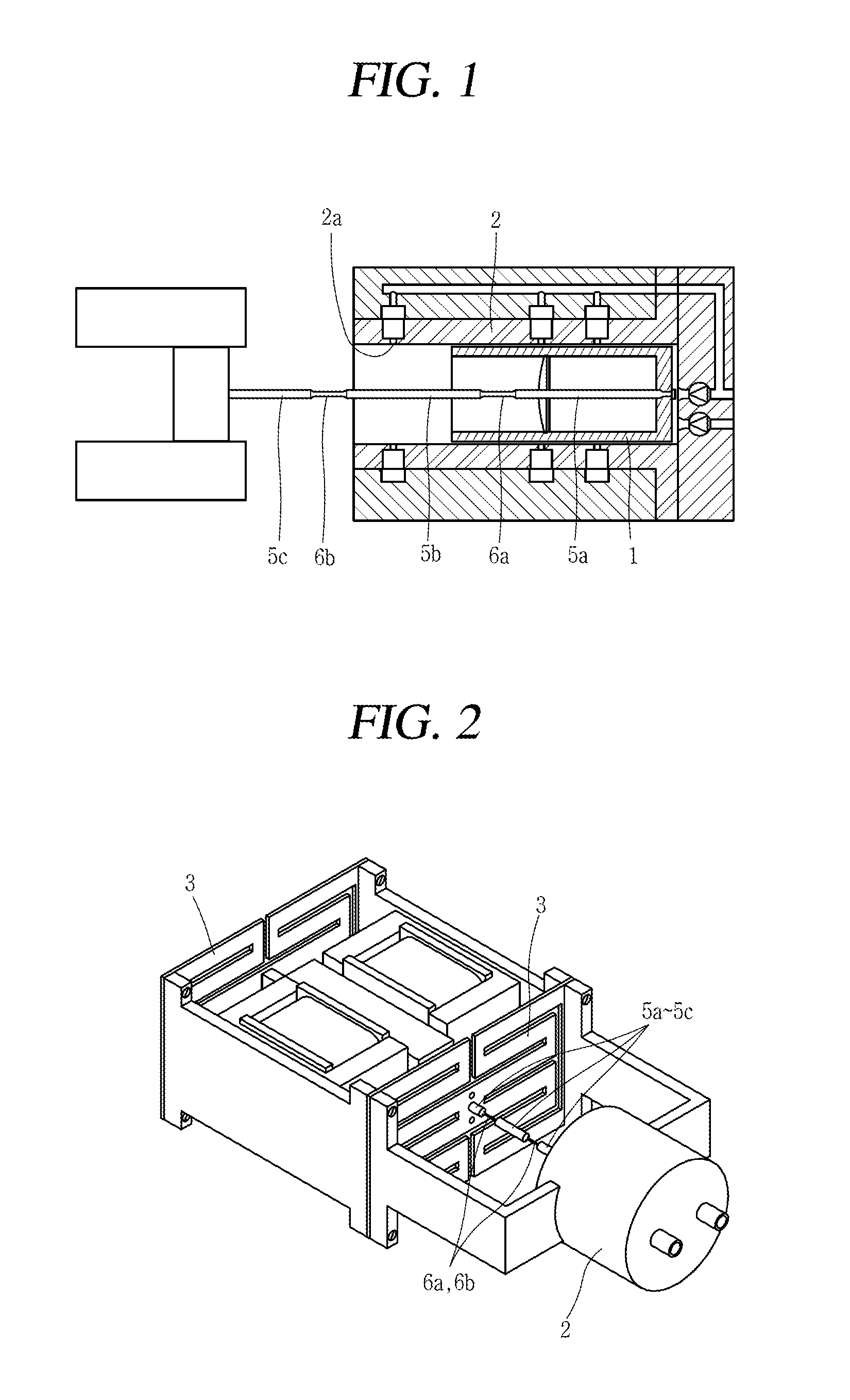

InactiveUS20120073430A1Improve compressor performanceImprove performanceMulti-stage pumpsReciprocating piston enginesReciprocating motionCylinder head

Disclosed is a variable displacement compressor having improved compressor performance such as reduced pulsation and improved durability and resistance to pressure and allowing smooth and high-precision control of a swash plate tilt angle at a target tilt angle by using an axial movement member. The variable displacement compressor is provided with a cylinder head in which a suction chamber and a discharge chamber are formed, a cylinder block having a cylinder bore into which a piston is inserted at a condition capable of being reciprocated, a crank chamber formed by the cylinder block and a front housing, a swash plate which is disposed in the crank chamber and which is rotated with a main shaft and is supported so that the tilt angle thereof can be changed relative to the main shaft, and a movement conversion mechanism for converting the rotational movement of the swash plate to the reciprocating movement of the piston, wherein: a suction path for intake of a suction gas into the compressor is formed so as to open into the crank chamber; a communication path for communicating the crank chamber and the suction chamber is provided in the cylinder block; around the main shaft, an axial movement member is provided that can move in a direction along the axis of the main shaft in an essentially one to one correspondence with the tilt angle of the swash plate; the axial movement member is disposed such that one end is applied with the pressure in the crank chamber, and the other end is applied with an intermediate pressure between the pressure in the discharge chamber and the pressure in the suction chamber; and an intermediate pressure control mechanism which can control the intermediate pressure is also provided.

Owner:SANDEN CORP

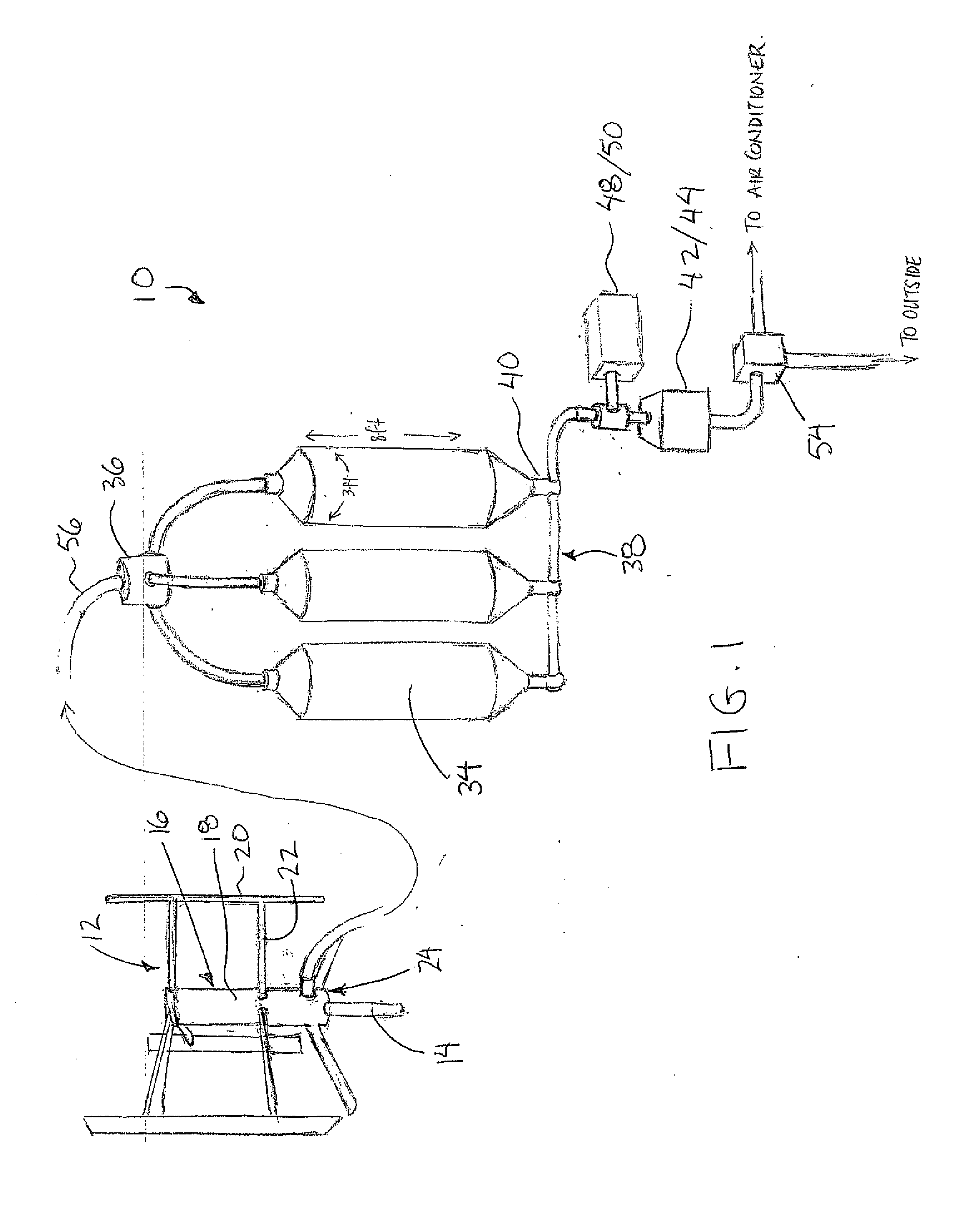

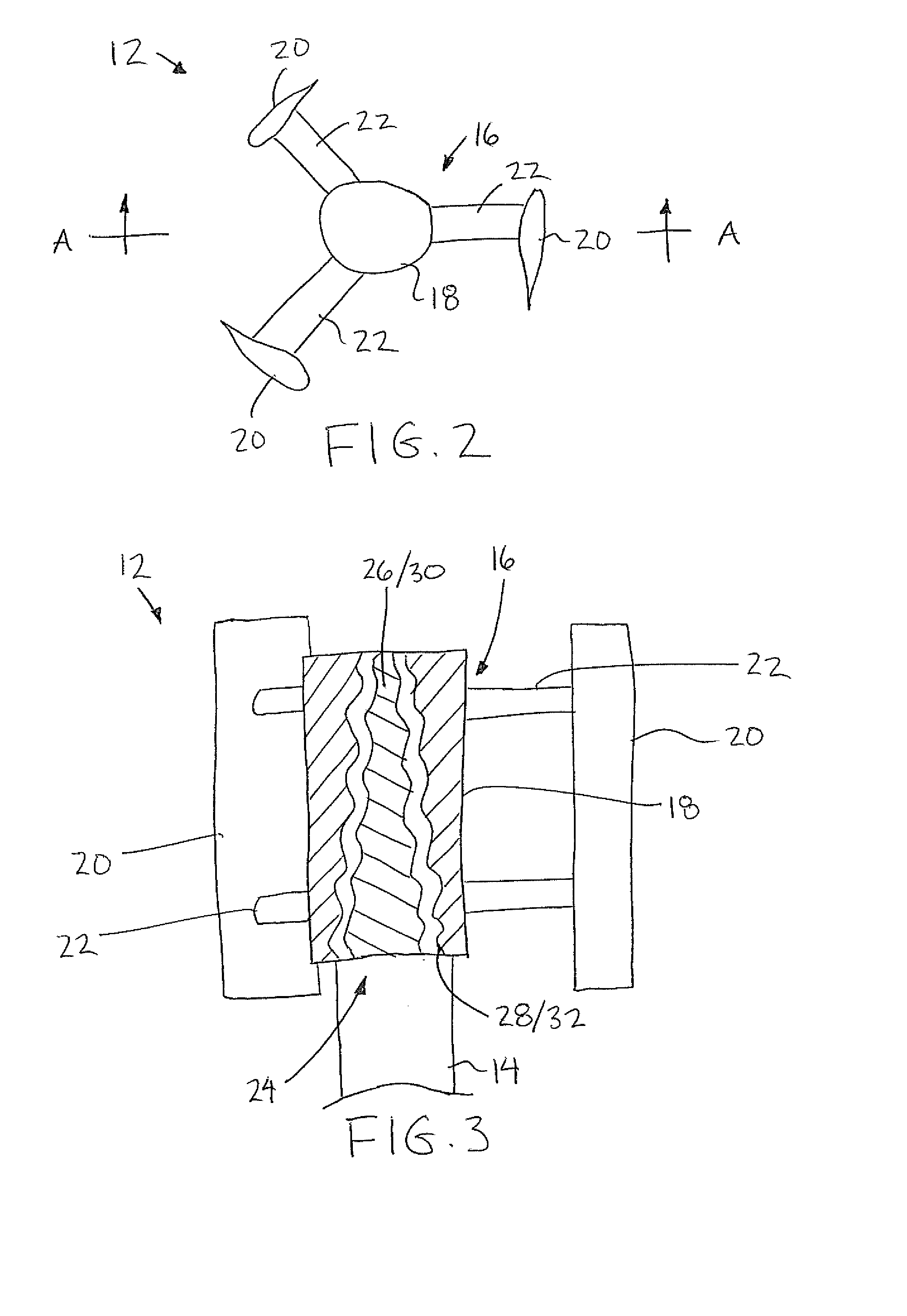

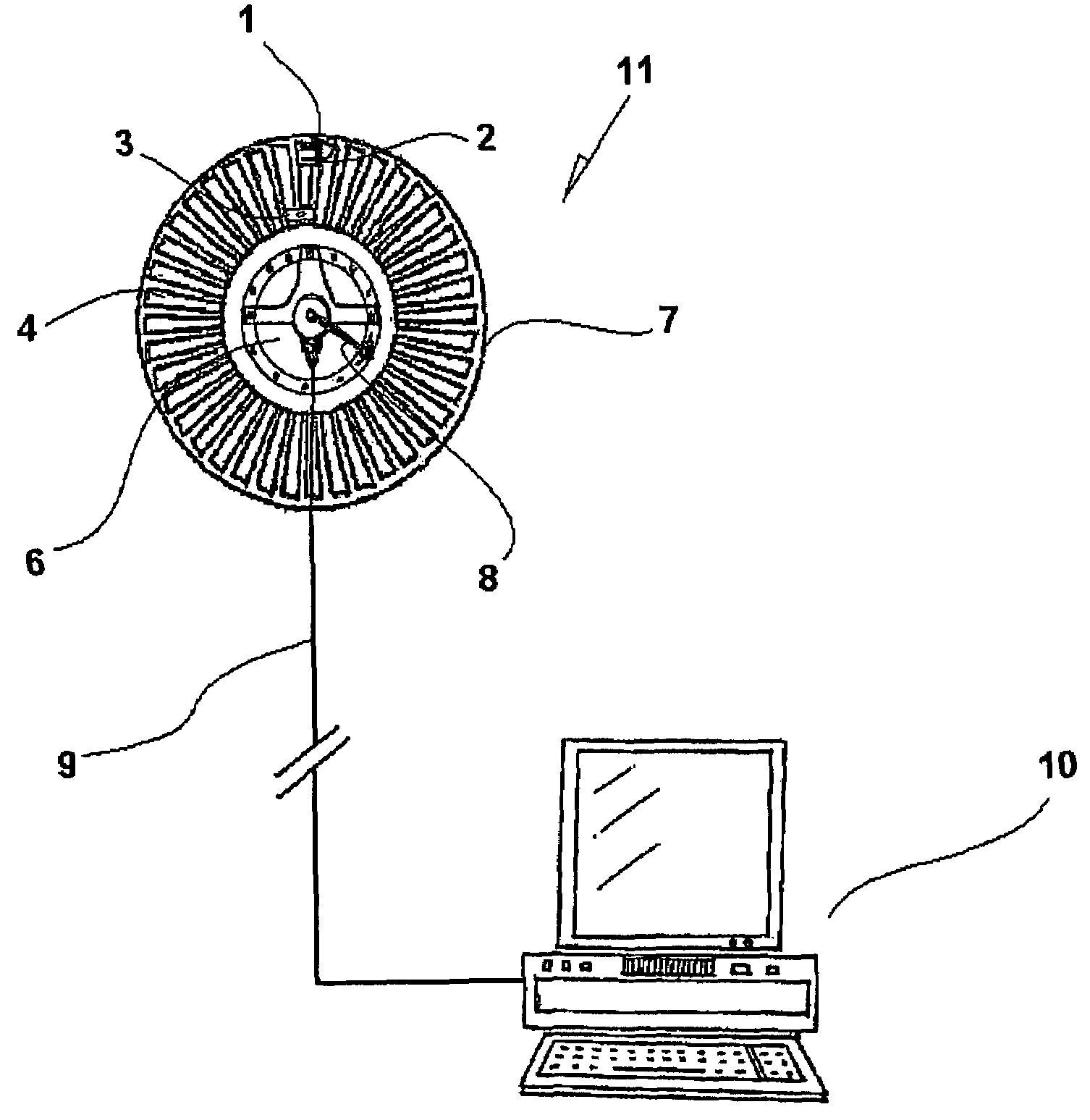

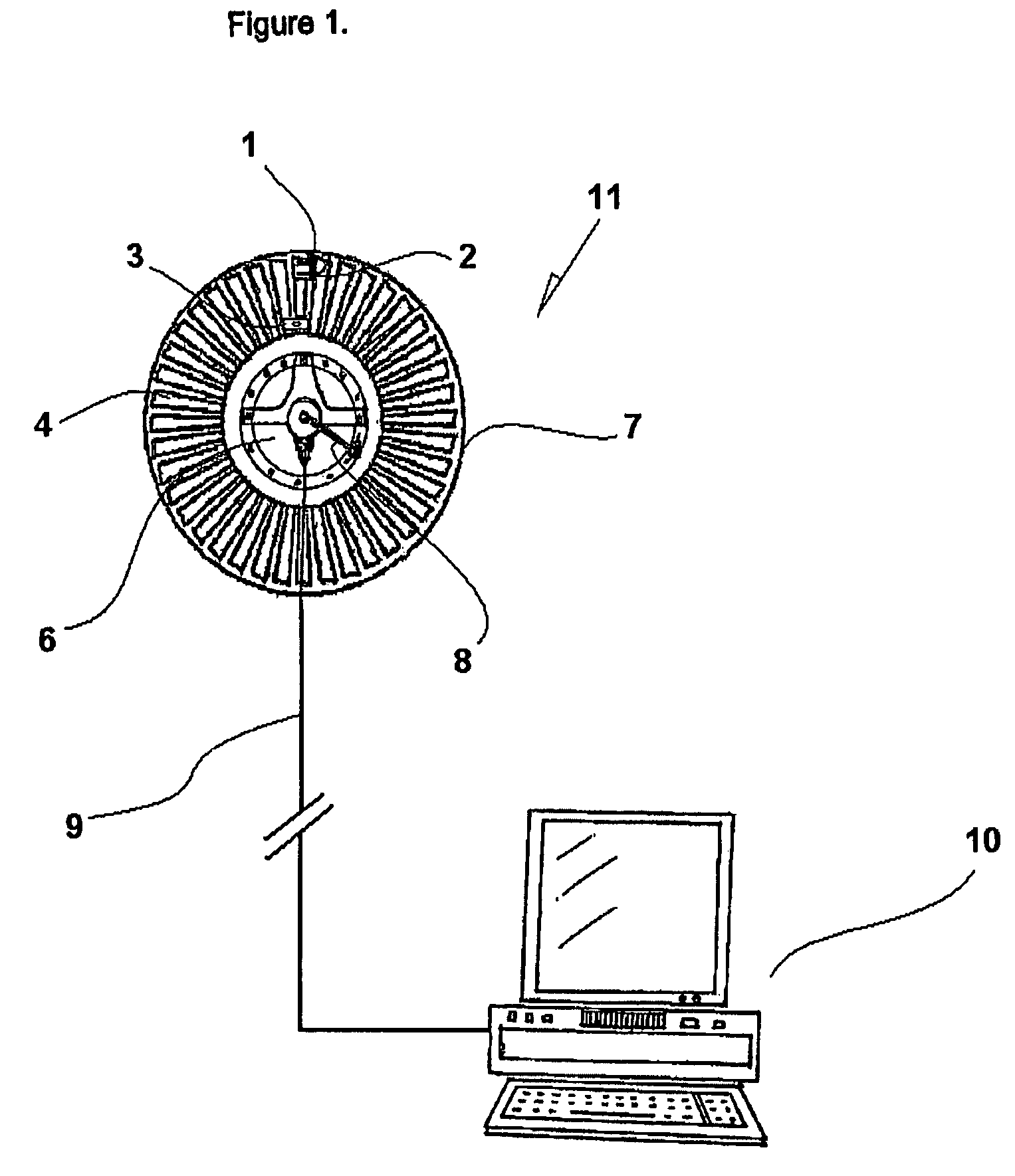

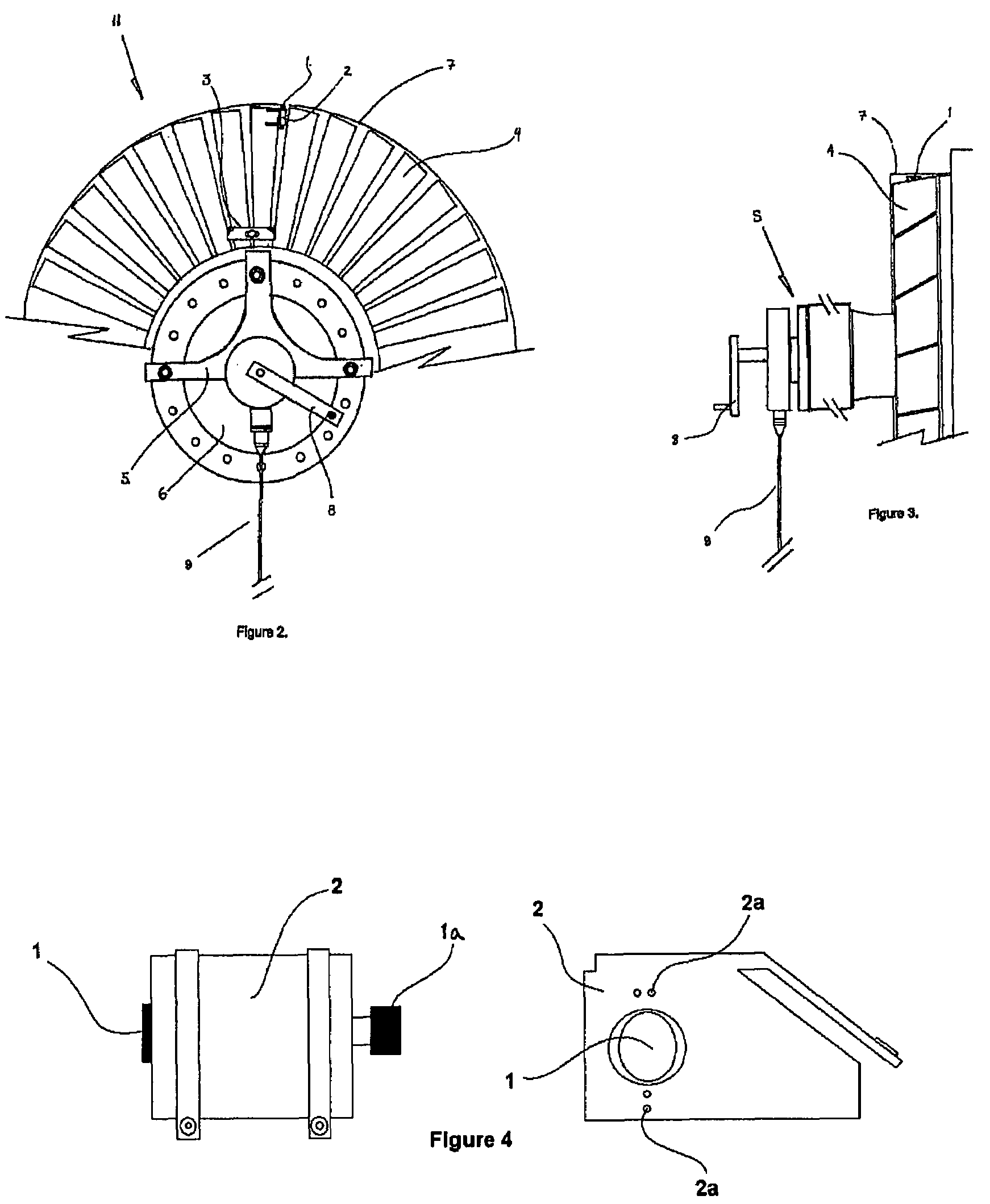

Wind Energy Generating and Storing System

InactiveUS20120038170A1Run fastEfficiency lossesWind motor with solar radiationWind motor controlElectricityTransmission loss

A wind energy system includes a vertical-axis turbine and a compressor driven by the turbine. The turbine includes blades supported on a central rotor by respective support arms having an airfoil shape so as to generate a load on the rotor in an axial direction so as to affect the performance of the compressor. The compressor rotor and the turbine rotor can be integrally coupled with one another for rotation together about a common vertical axis to minimize drive transmission losses. A primary and a secondary compressed air driven generators generate respective primary and secondary electricity from a common source of compressed air. The primary generator is controlled by an electrical controller which is powered by the secondary electricity.

Owner:STUART ALEX J +1

Compressor housing for supercharger and method for manufacturing the same

ActiveUS20130039750A1Improve productivityEasy to shapeEngine manufacturePump componentsImpellerEngineering

A compressor housing is provided with a scroll piece that includes a cylindrical intake port forming section that forms an intake port, a scroll wall surface forming section that forms an air-intake side wall surface of a discharge scroll chamber, and a scroll outer circumferential section that covers an outer circumferential side of the discharge scroll chamber; a shroud piece that includes a cylindrical shroud press fitted section press fitted into the intake port forming section, and a shroud wall surface forming section that forms an inner circumferential side wall surface of the discharge scroll chamber and also forms a shroud surface that opposes an impeller and a diffuser surface; and an outer circumferential annular piece that includes an outer circumferential annular press fitted section that is press fitted inside the scroll outer circumferential section, and an outer circumferential annular wall surface forming section that forms an outer circumferential side wall surface of the discharge scroll chamber.

Owner:OTICS CORP +1

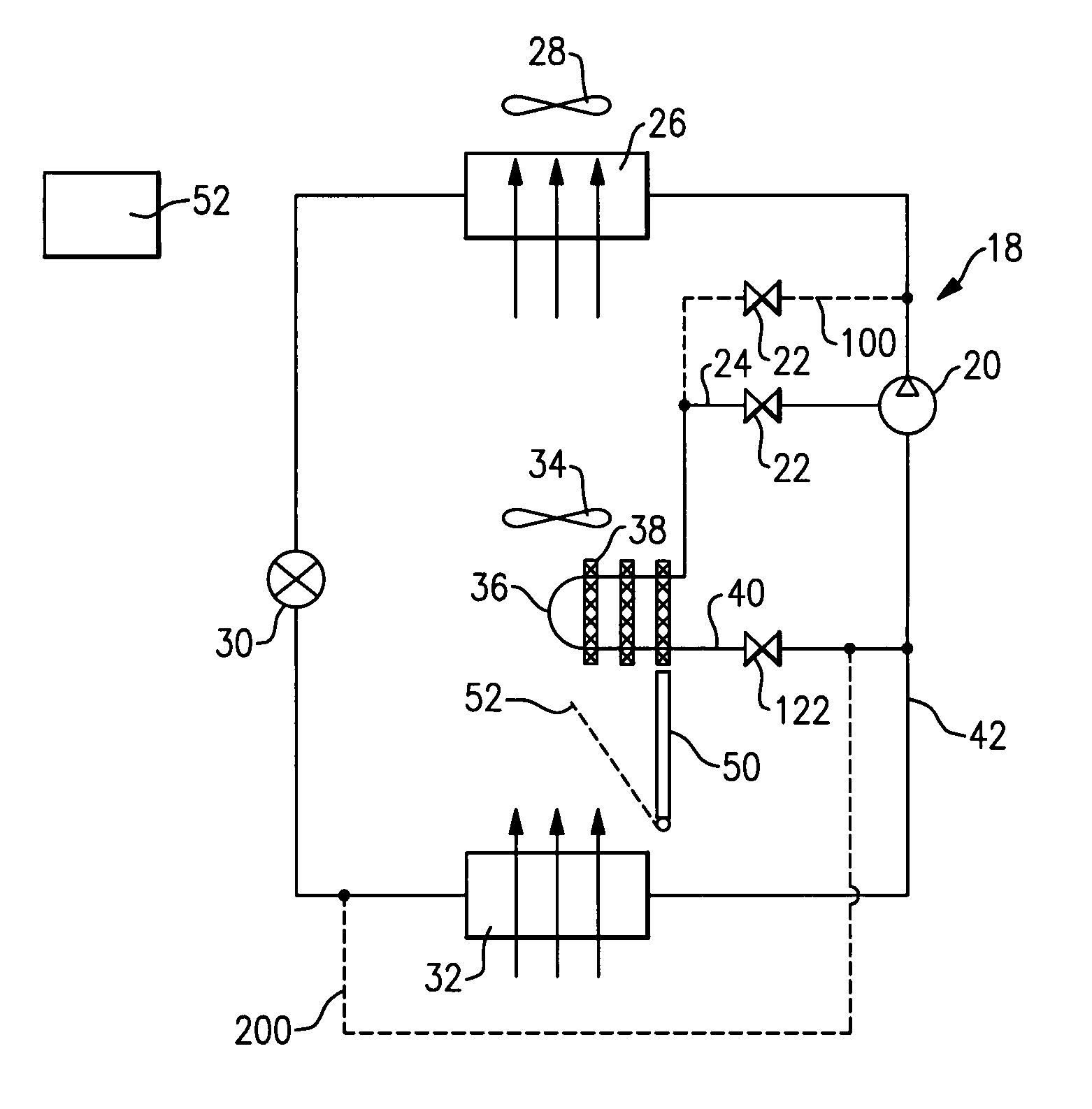

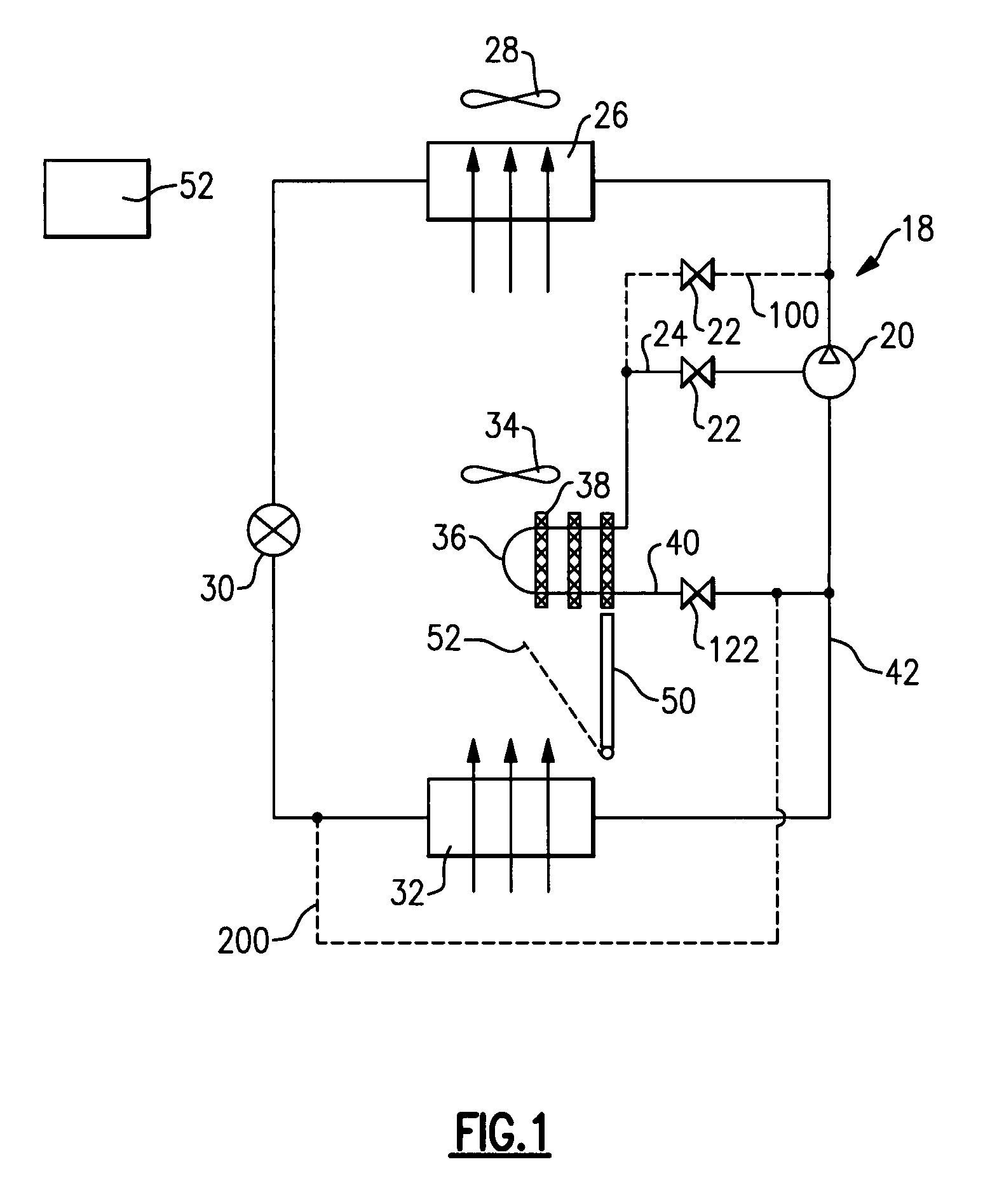

Utilization of bypass refrigerant to provide reheat and dehumidification function in refrigerant system

InactiveUS7257957B2Potential reliability problems associated with the compressor overheating are avoidedImprove compressor performanceFluid circulation arrangementRefrigeration safety arrangementEngineeringRefrigerant

A refrigerant system is provided with an unloader bypass line to selectively unload the compressor and deliver refrigerant from a partially (or fully) compressed location back to a suction port of the compressor. A section of this unloader bypass line is placed in the path of air having passed over an evaporator and towards an environment to be conditioned. This section of the unloader bypass line would contain refrigerant that is at a higher temperature than the refrigerant, which had been delivered into the evaporator by the main circuit. In this manner, this bypass line section will provide the function of reheating the air above the temperature to which it had been cooled in the evaporator to achieve a desired humidity level. Thus, the reheat function is obtained without requiring a dedicated reheat loop, associated components and additional structure. Also, through the refrigerant temperature reduction, compressor reliability and performance are improved. Furthermore, the flow control device may be of an adjustable type (e.g. modulating or pulsating) to achieve variable sensible heat ratios and to cover a wide range of potential applications. Lastly, the bypass line may have extended heat transfer elements allowing heat transfer enhancement between the air and refrigerant.

Owner:CARRIER CORP

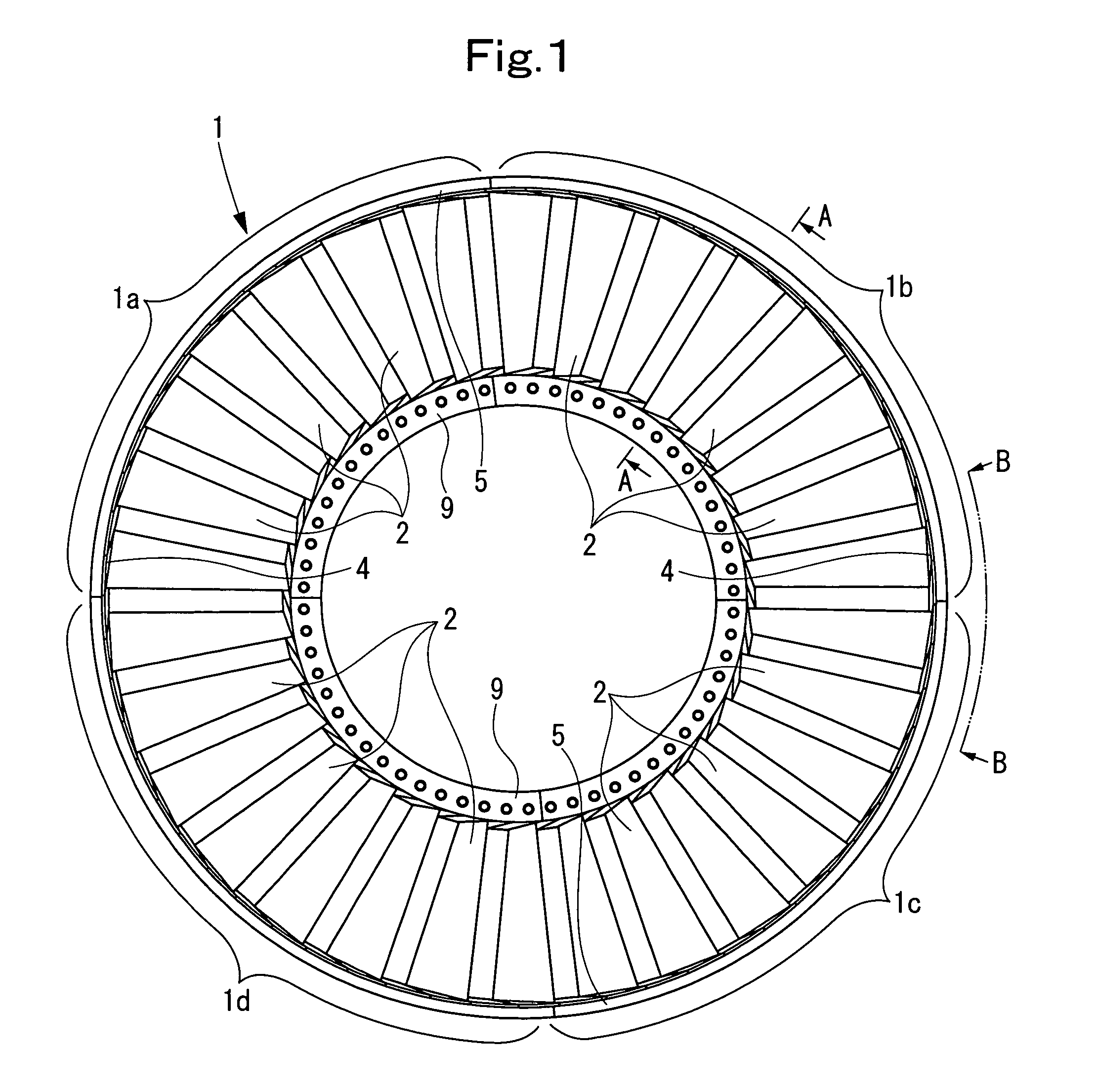

Stationary blade ring of axial compressor

ActiveUS8206094B2Rule out the possibilityImprove reliabilityPump componentsEngine fuctionsAxial compressorMechanical engineering

Owner:MITSUBISHI POWER LTD

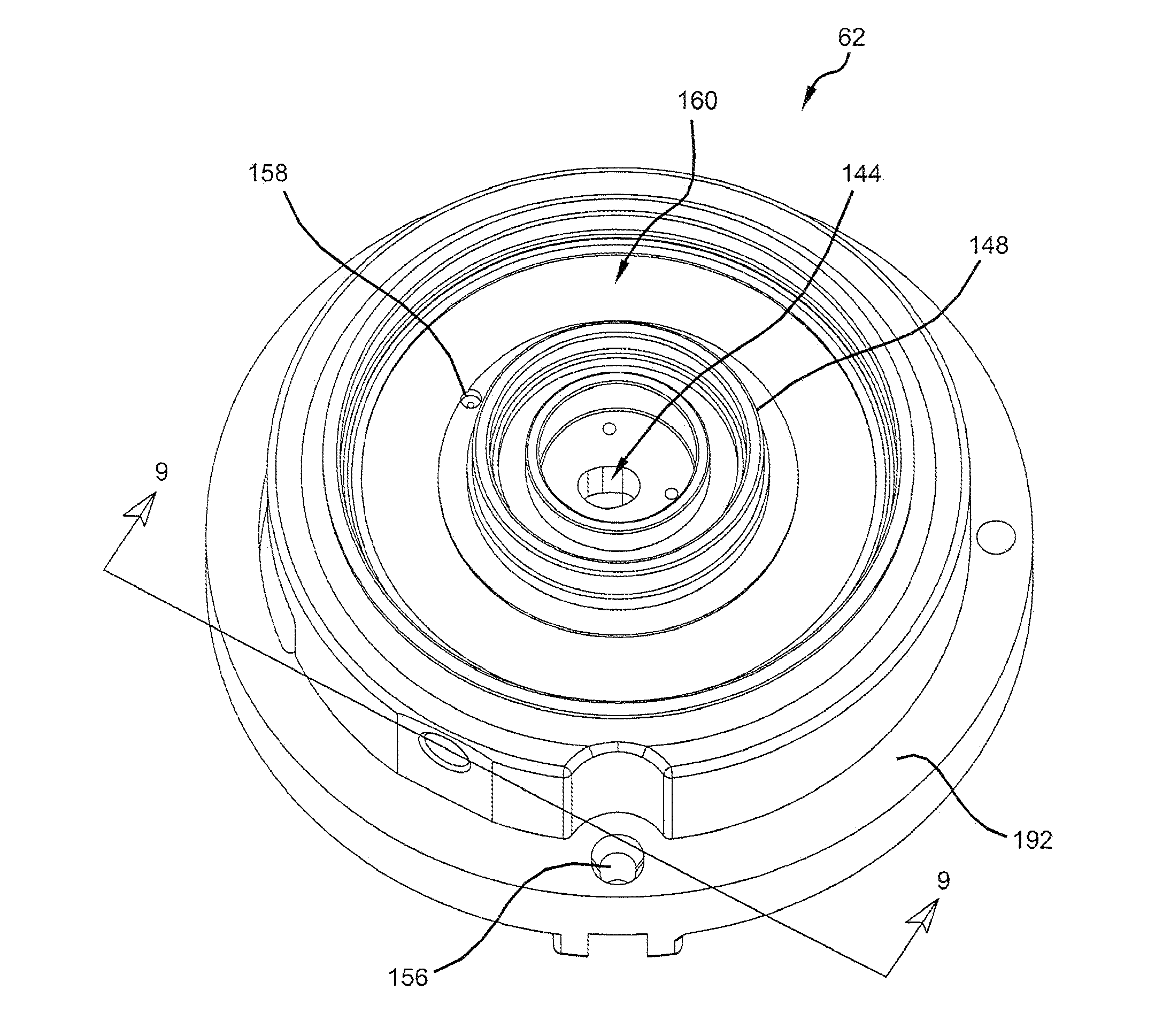

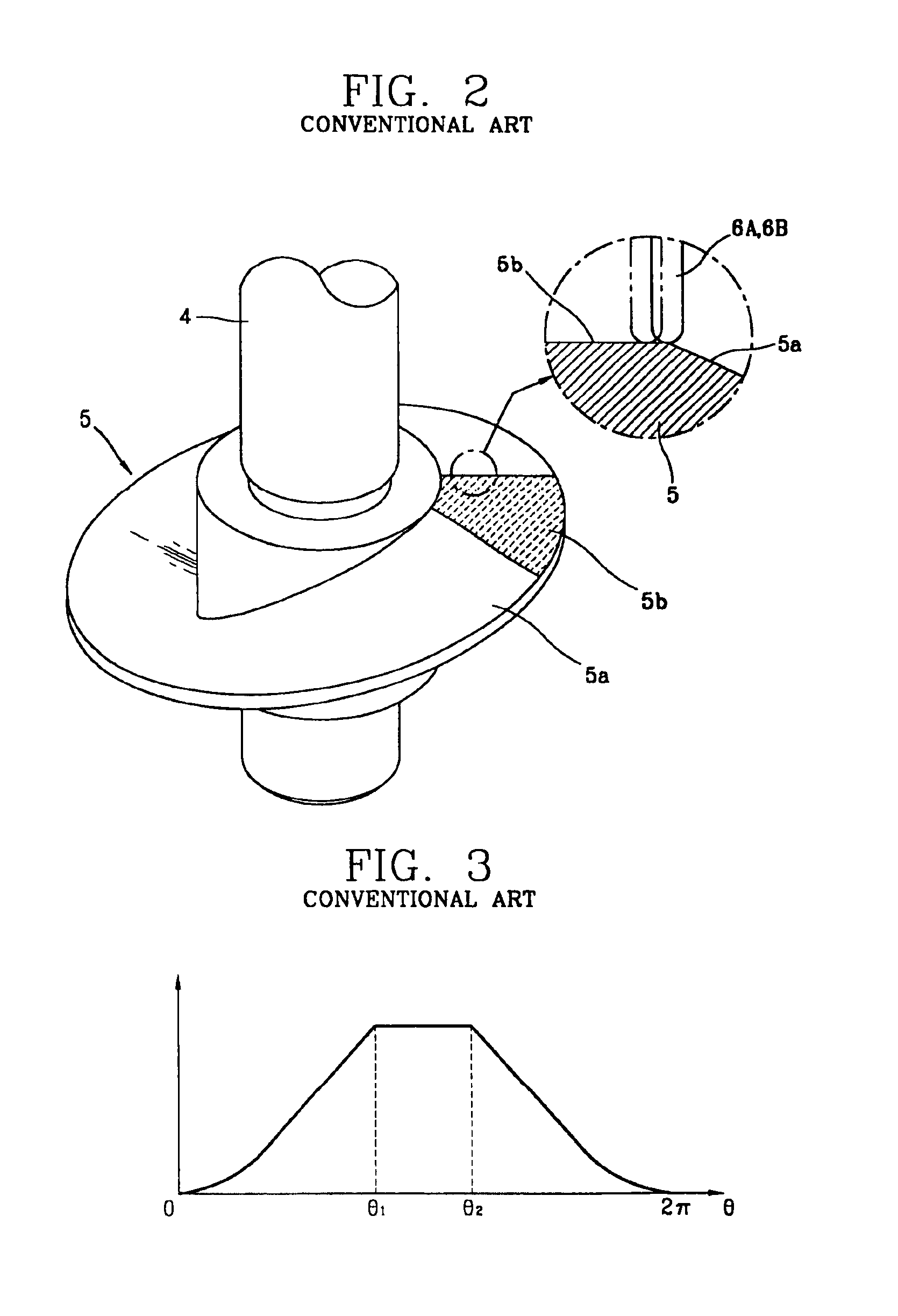

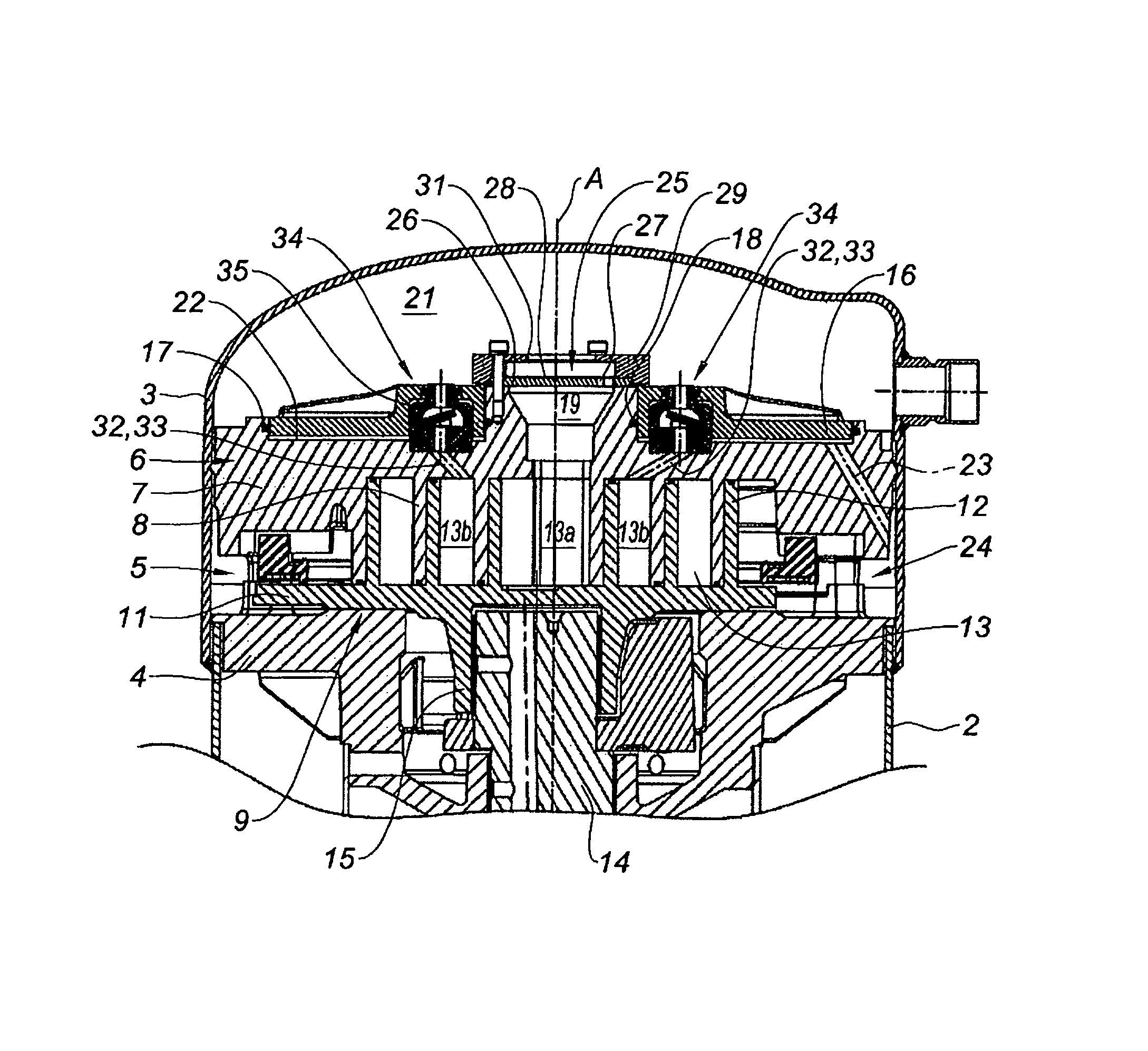

Sealed Scroll Compressor for Helium

InactiveUS20120294748A1Improve compressor performanceImprove performanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeInjection portEngineering

A sealed scroll compressor for helium having a stationary scroll, an orbiting scroll, and an oil-injection mechanism. The oil-injection mechanism has an oil-injection pipe arranged to pass through a sealed container and connected to an oil-injection port, and the opening of the oil-injection port is arranged at a bottom surface of a groove between ridges formed with the scroll wrap of the stationary scroll in such a manner that a first range of the orbital angle of the orbiting scroll is approximately identical to a second range of the orbital angle of the orbiting scroll, where the oil-injection port is connected to the outer compression chamber while the orbital angle of the orbiting scroll is in the first range, and is connected to the inner compression chamber while the orbital angle of the orbiting scroll is in the second range.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Rotor blade system for rotor and rotor case inspection

ActiveUS7579844B2Improve compressor performanceMinimized tip clearanceSpectral/fourier analysisPropellersEngineeringMechanical engineering

Owner:STANDARD AERO SAN ANTONIO

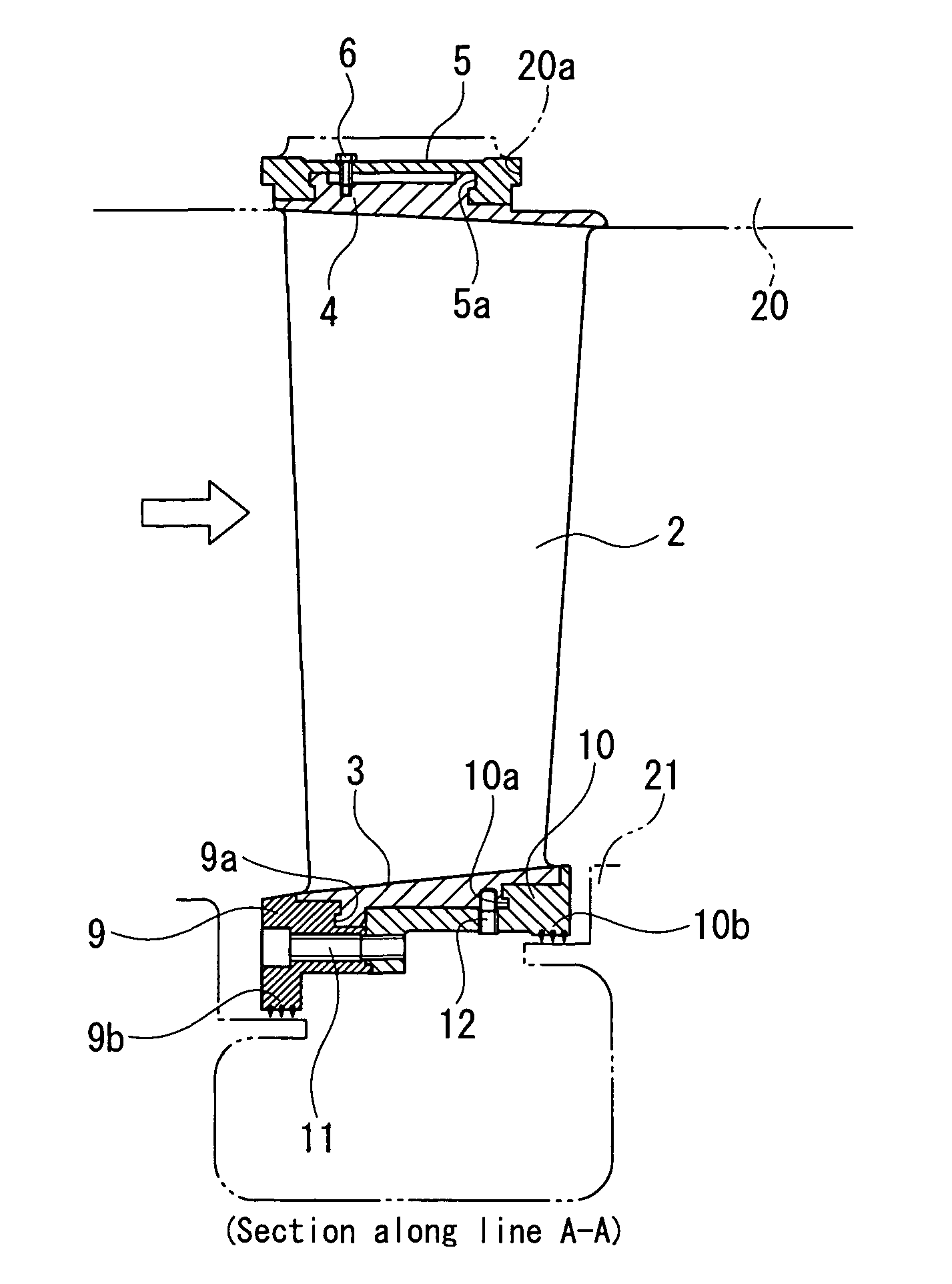

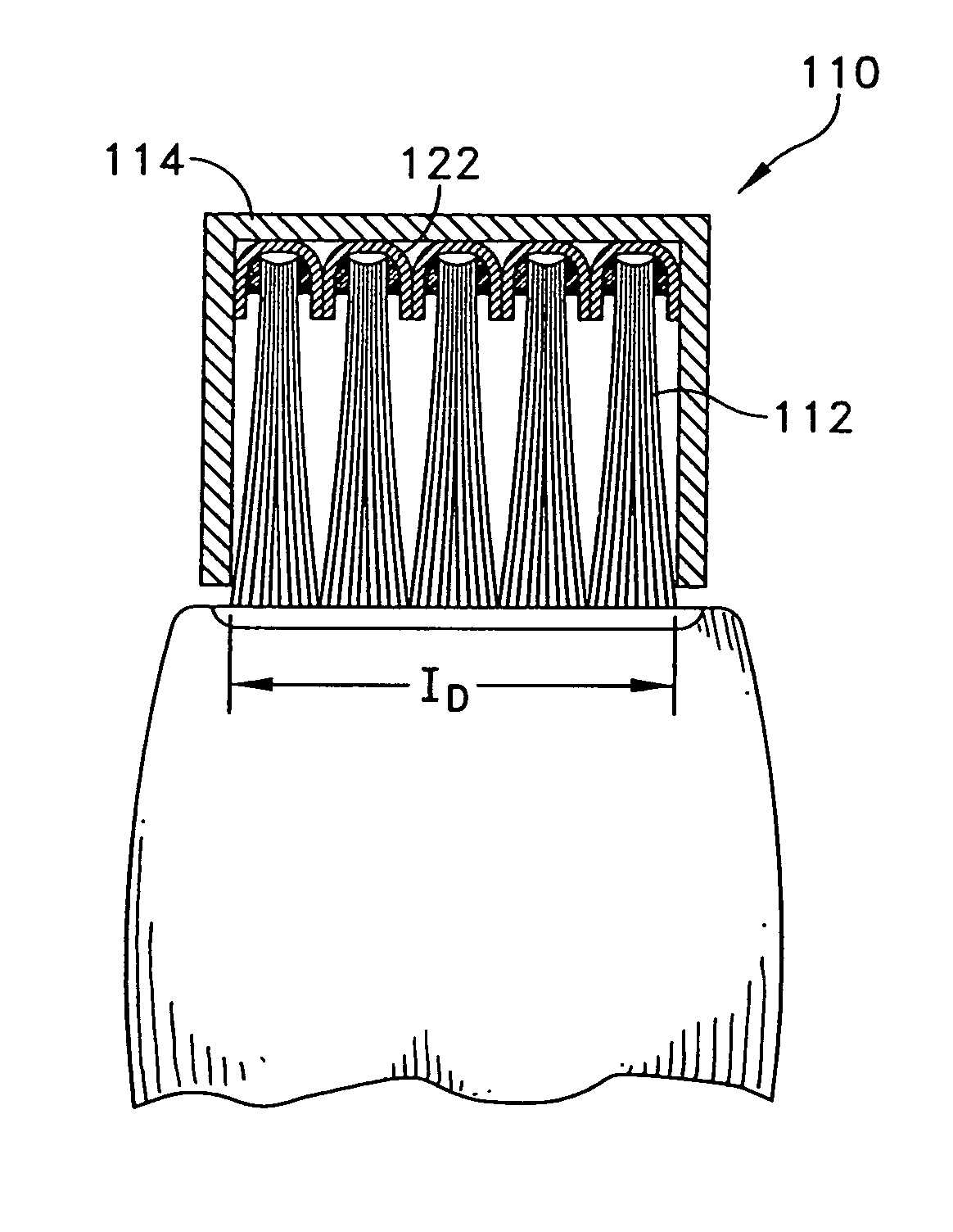

Compliant brush shroud assembly for gas turbine engine compressors

A brush shroud assembly for reducing the tip clearance between a rotating blade and an engine casing is disclosed. The assembly includes a plurality of bristle packs supported within a housing such that the bristle distribution at the inner diameter of the bristle packs is substantially continuous. The continuous surface is created by mounting the bristles packs within a housing such that the packs are flared, i.e. width at the outer diameter of the bristle pack is smaller than that at the inner diameter. Various embodiments are disclosed for mounting the flared bristle packs to form a substantially continuous inner diameter. The bristle strips may be mounted in one or more annular rings, may be secured within one or more channels in the housing, the bristle packs may be formed into a tufted ring, or any of these may be utilized in combination with a backplate supporting an abradable seal, i.e. a hybrid design.

Owner:ADVANCED COMPONENTS & MATERIALS

Engine intake air compressor having multiple inlets and method

ActiveUS7575411B2Increase the areaIncrease capacityEngine manufacturePump componentsImpellerEngineering

A compressor assembly (404) includes a compressor housing (412) having a main inlet bore (424) and a secondary inlet passage (422) that has an increasing flow cross-sectional area. The secondary inlet passage (422) is positioned in the compressor housing (412) and around the main inlet bore (424). A secondary inlet slot (426) and an outlet slot (420) fluidly connect the secondary inlet passage (422) with the main inlet bore (424). A compressor wheel (418) is in the compressor housing (412) and has a stepped portion (518) formed by at least one plurality of vanes (506). The stepped portion (518) is located adjacent to the outlet slot (420) of the housing (412).

Owner:INT ENGINE INTPROP CO LLC

Compressor with Z-plate

InactiveUS6893242B2Avoid scratchesImprove compressor performanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMechanical engineering

A compressor is provided which minimizes impact noise and abrasion between a Z-plate of the compressor and vanes formed in the compressor. Ends of the vanes formed in the compressor contact sides of the Z-plate, and the motion and surface configuration of the Z-plate cause the vanes to move reciprocally and to section compression spaces within the compressor into a suction area and a compression area. Due to the curvature of the surfaces of the Z-plate, the vanes remain in constant contact with the surface of the Z-plate, which allows for smooth transition phases and a subsequent reduction in impact noise and abrasion between the vanes and the Z-plate.

Owner:LG ELECTRONICS INC

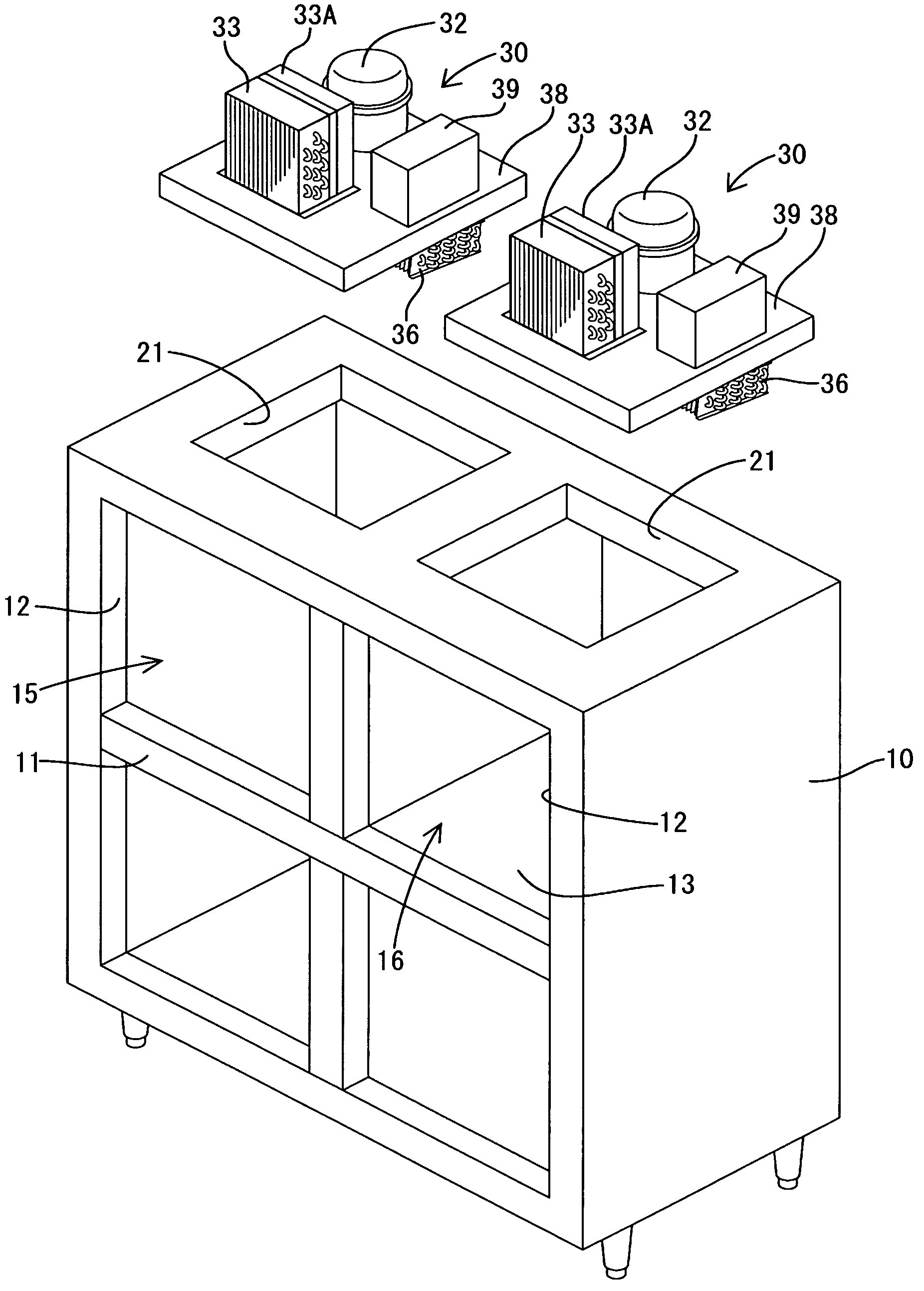

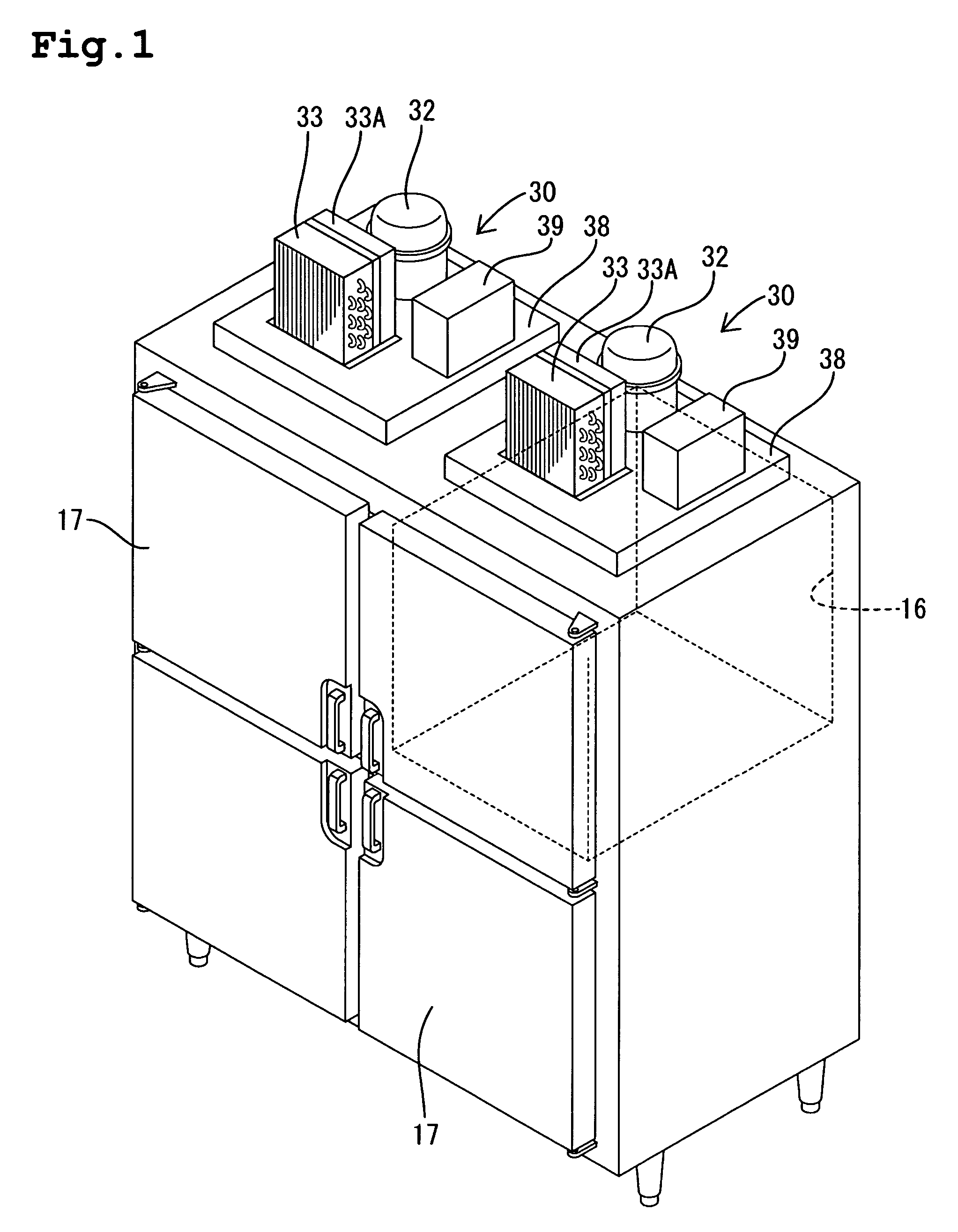

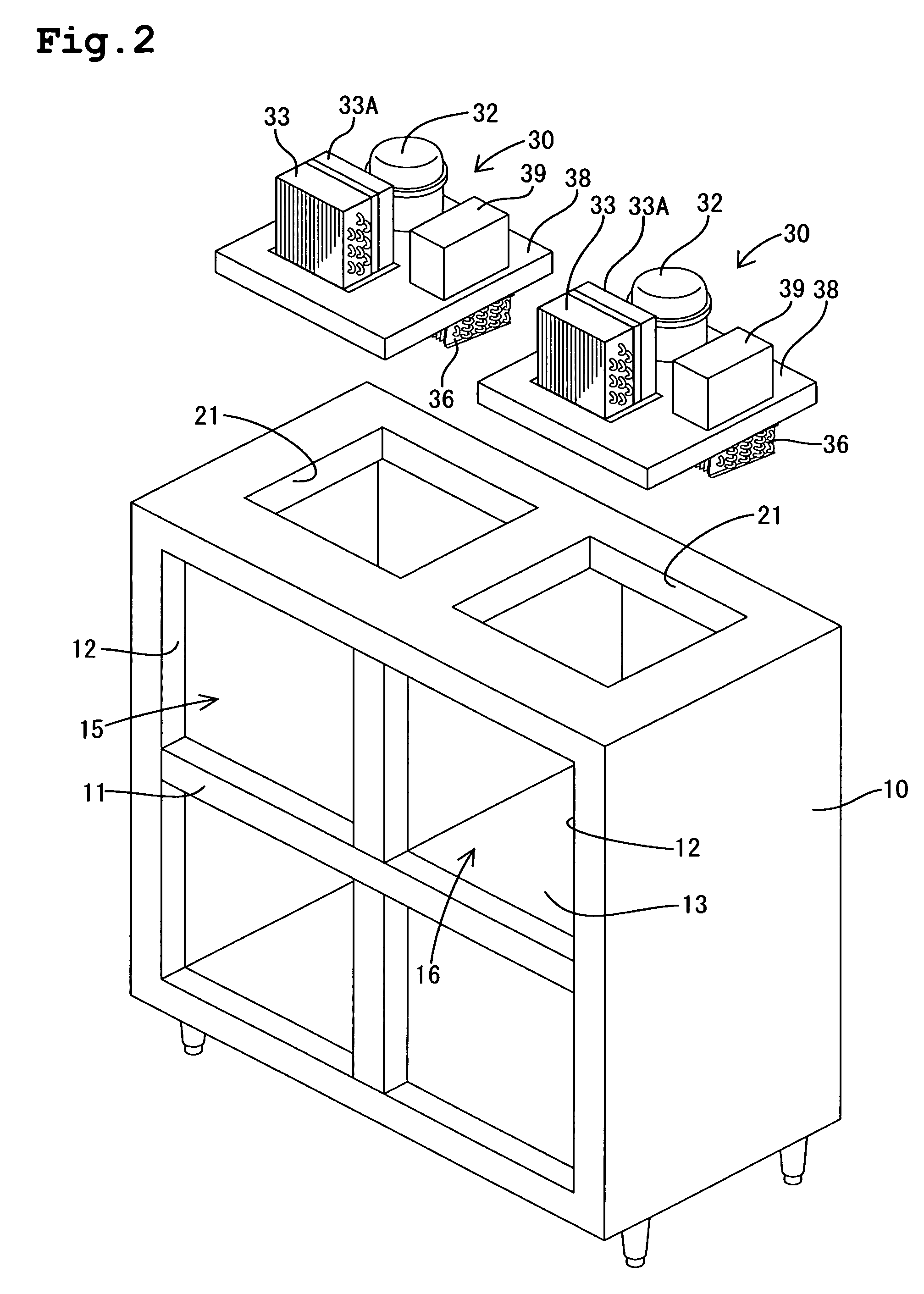

Refrigerating storage cabinet

InactiveUS7730732B2Operation of compressor can be stoppedReduced operating requirementsTemperature control without auxillary powerTemperature control with auxillary non-electric powerControl theoryInternal temperature

A storing section stores data of a pull down cooling characteristic indicative of a time-varying mode of reduction in a target temperature drop. For example, when this is a linear function line, a target internal temperature drop degree takes a constant value, irrespective of an operating time. An actual temperature drop degree is computed on the basis of the detected internal temperature. The computed value is compared with a target value read from the storing section. When the computed value is less than the target value, a rotational speed of an inverter compressor is increased via an inverter circuit. When the computed value is larger than the target value, the rotational speed of the compressor is decreased. The speed increases and decreases are repeated so that pull down cooling is performed along the linear line.

Owner:HOSHIZAKI ELECTRIC CO LTD

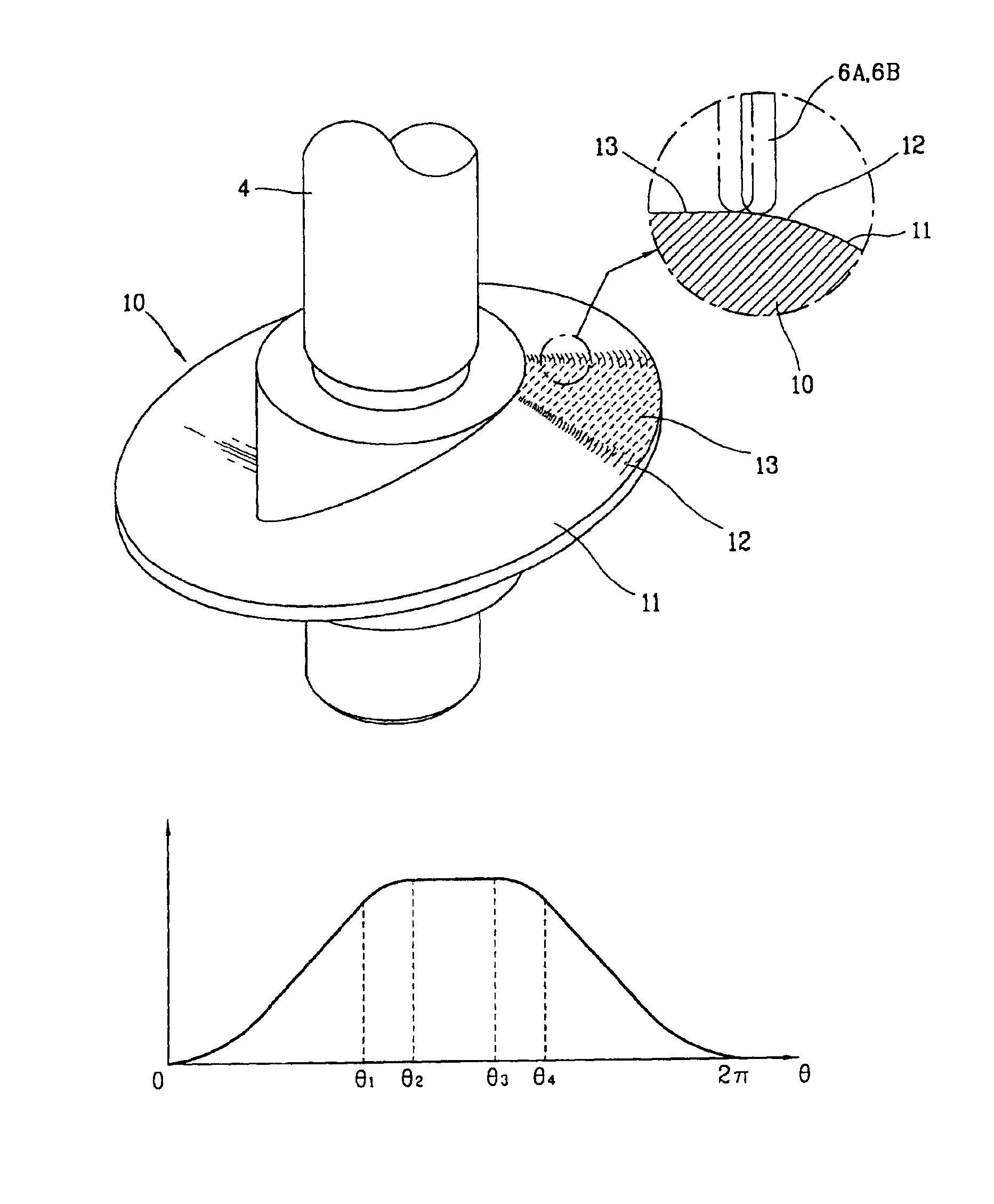

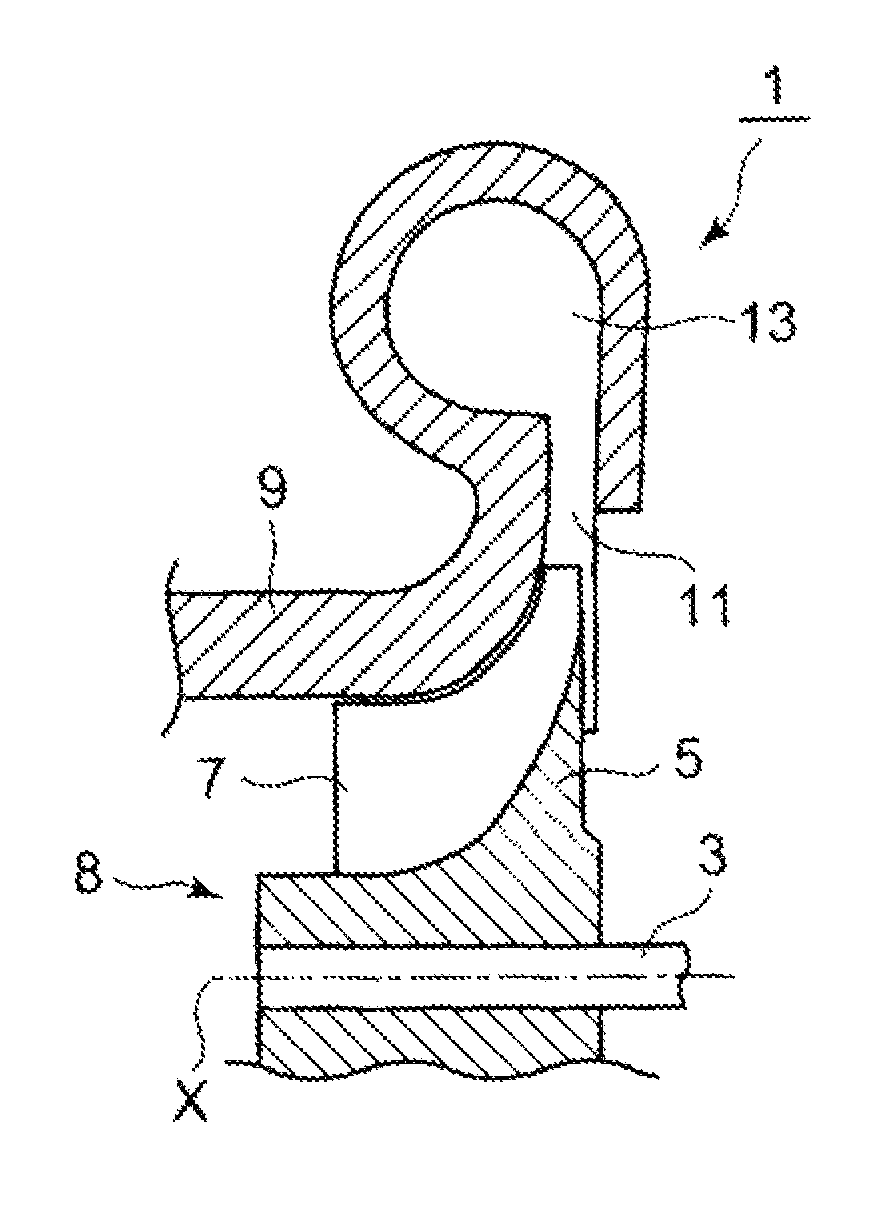

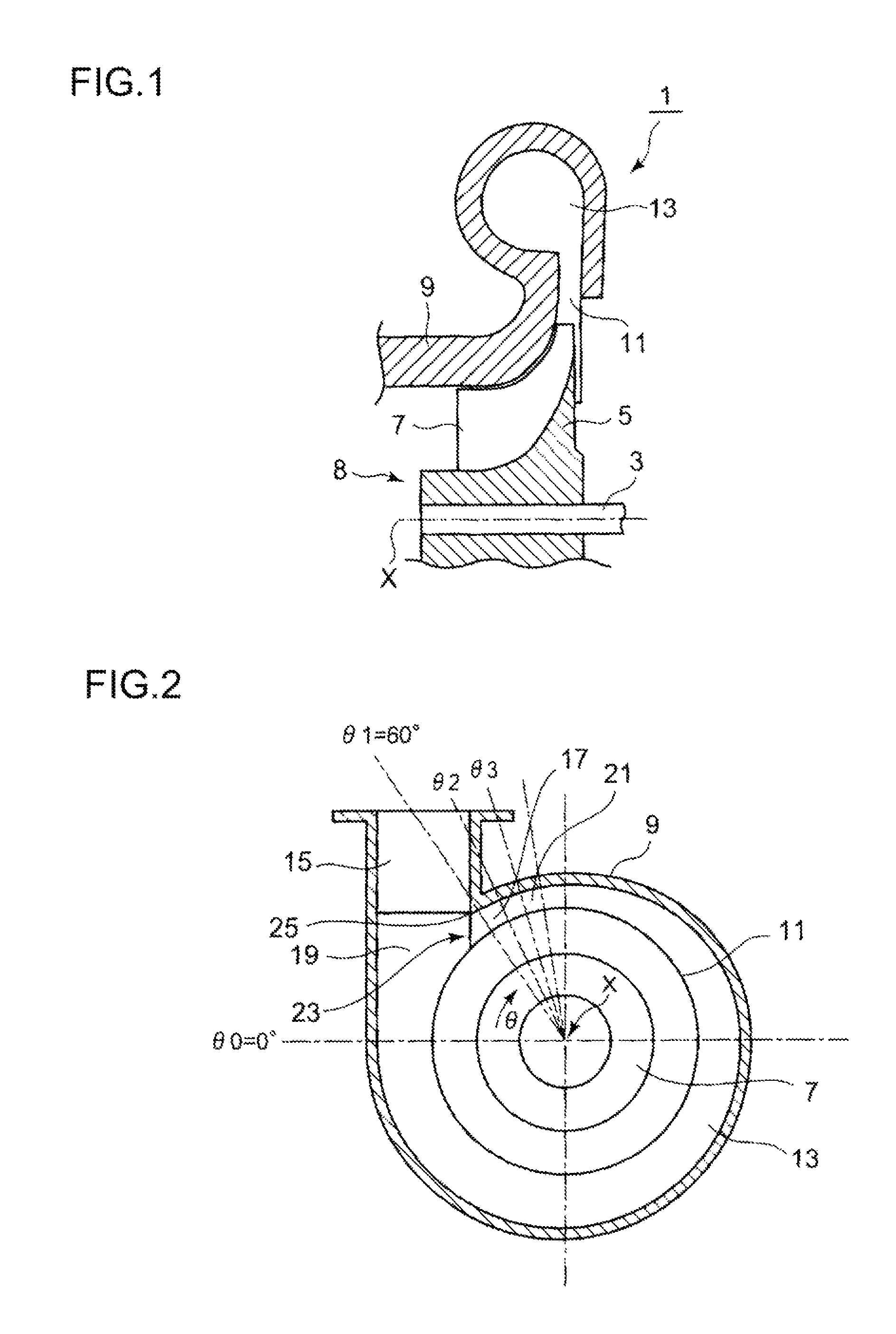

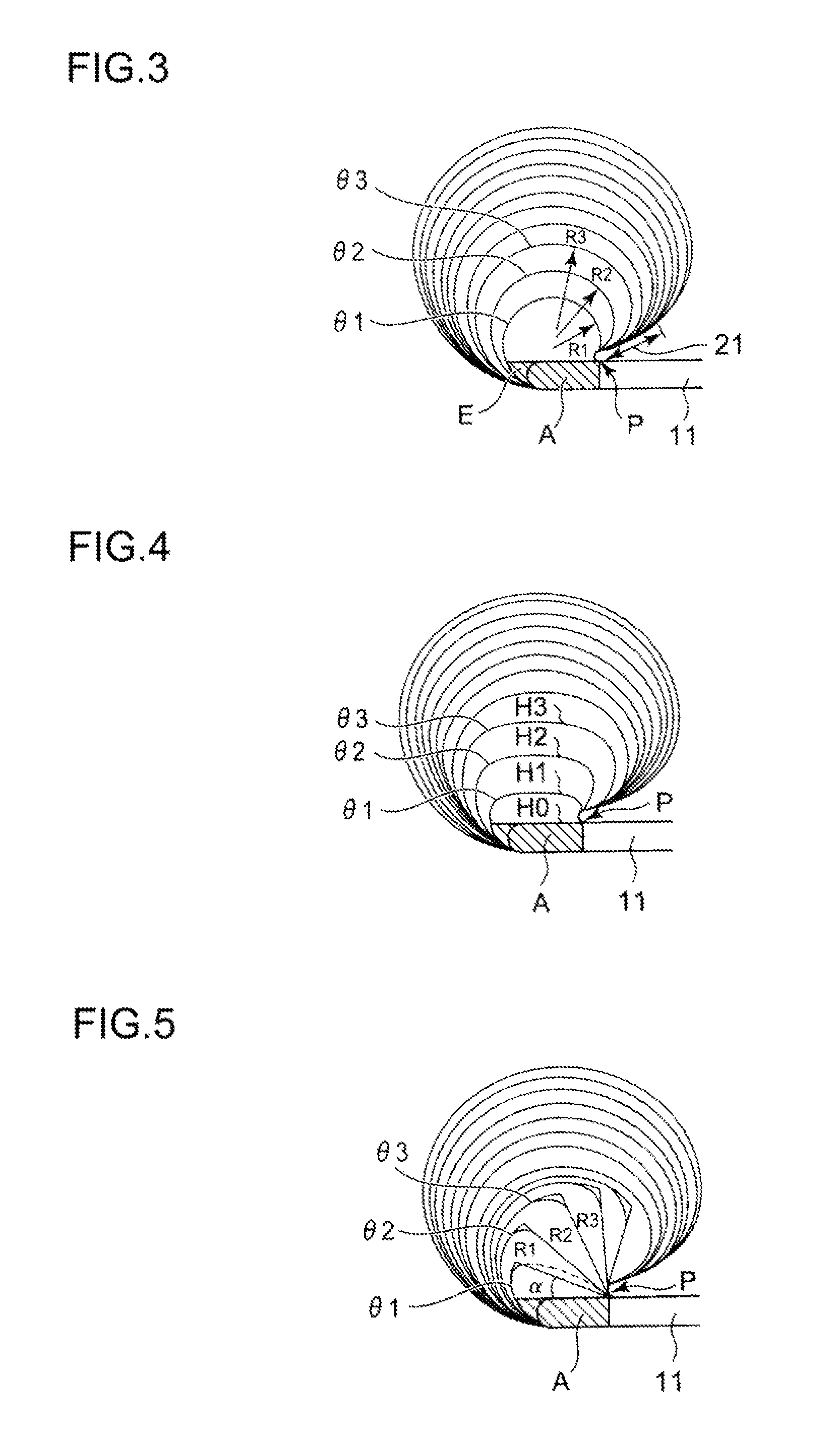

Scroll structure of centrifugal compressor

ActiveUS9541094B2Easy to shapeMinimize flowEngine manufacturePump componentsMechanical engineeringCentrifugal compressor

A scroll structure of a centrifugal compressor 1 having a spirally formed scroll passage 13. The scroll passage 13 includes: a flat connecting portion A at a flow passage joint 23 where a scroll start and a scroll end of the scroll passage 13 meet, this flat connecting portion having a flat cross-sectional shape with a same height as that of an outlet passage of a diffuser; and a transition part 21 where the flat cross-sectional shape of the flat connecting portion A gradually changes back to a circular cross-sectional shape along a circumferential direction.

Owner:MITSUBISHI HEAVY IND LTD

Reciprocating compressor and method for driving same

ActiveUS20150226191A1Great suctionReduce volumeFluid parameterPositive displacement pump componentsFriction lossEngineering

The present disclosure relates to reciprocating compressor. The present invention can prevent friction loss or abrasion between a cylinder and a piston, which is caused when a hydraulic bearing is blocked with a foreign substance, by preventing the foreign substance mixed in refrigerant gas from flowing into the hydraulic bearing, and can improve compressor performance by preventing a specific volume in a compression space from increasing when high-temperature refrigerant gas discharged in the compression space is cooled, such that vibration noise of the compressor can be reduced since a gas guiding part offsets vibration and the noise generated when a refrigerant is discharged in the compression space. Furthermore, the number of vibrations of a mover is increased and a driving operation for removing foreign substances is carried out to increase the number of vibrations of a cylinder such that any foreign substance stuck in a gas hole can be cleaned, thereby increasing performance and reliability of the compressor.

Owner:LG ELECTRONICS INC

Screw compressor and method of manufacturing rotor for the same

InactiveUS6884049B2Improve compressor performanceReduce leakageOscillating piston enginesEngine of counter-engagement typeQuenchingHeat treated

A screw compressor of which a female rotor is driven by a motor, and of which a male rotor is driven by the female rotor. The male or female rotor is composed of a member which is made of cast iron and is subjected to surface hardening treatment or heat treatment including quenching. The surface hardening treatment may include sulphonitriding or nitiriding treatment. In the case of subjecting the cast iron to the heat treatment, austemper treatment is applied.

Owner:JOHNSON CONTROLS HITACHI AIR CONDITIONING TECHNOLOGY (HONG KONG) LIMITED

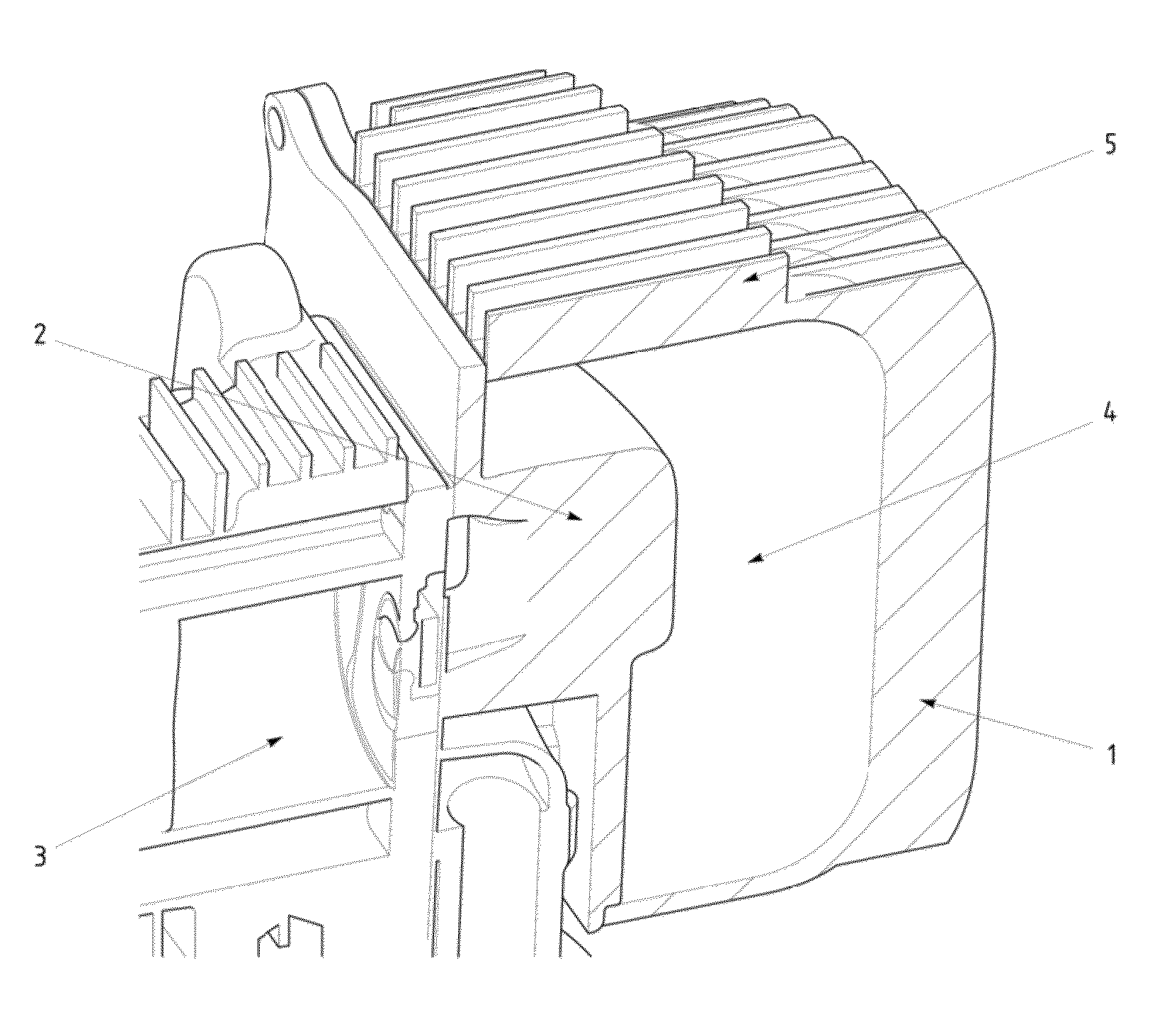

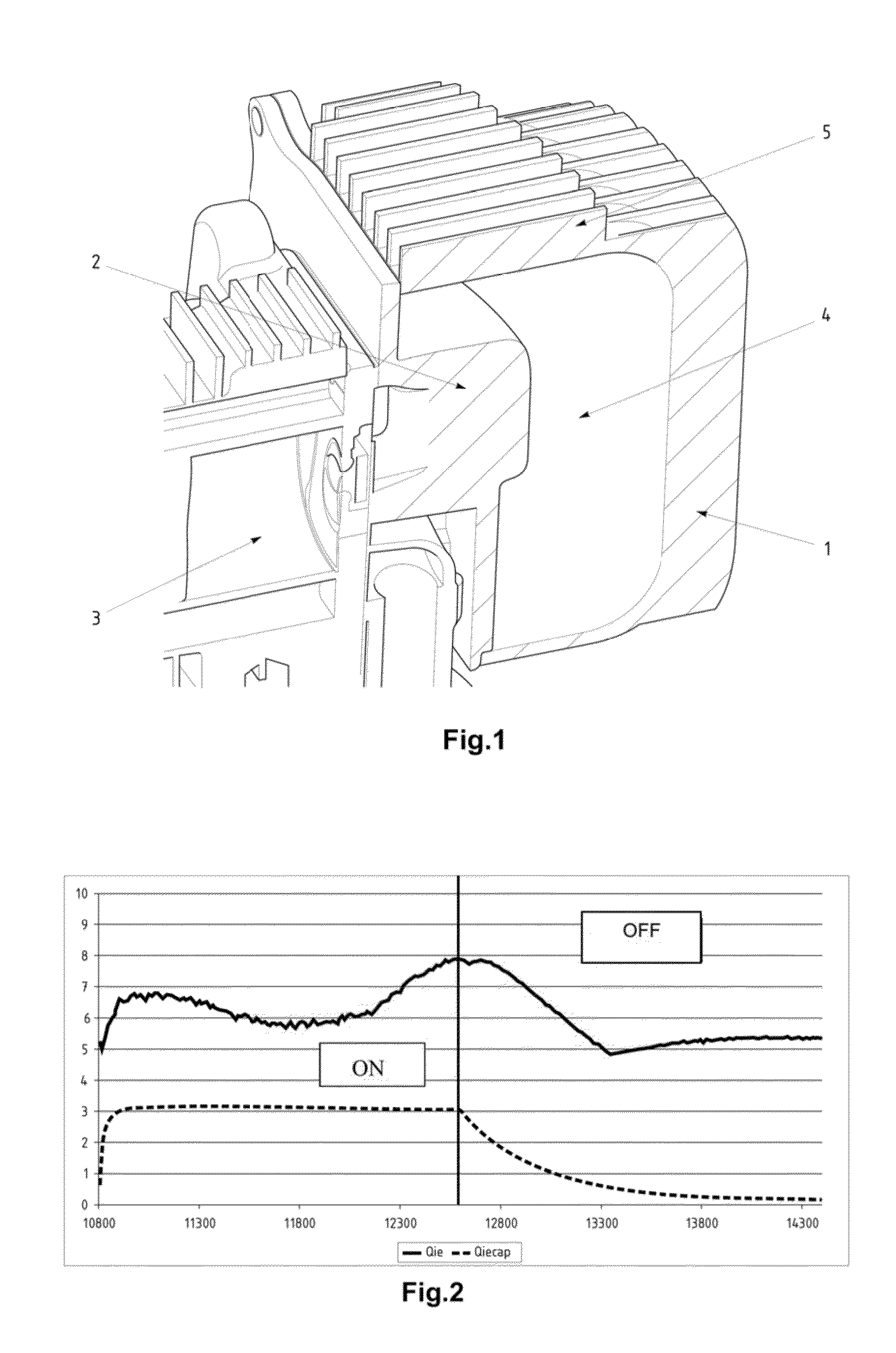

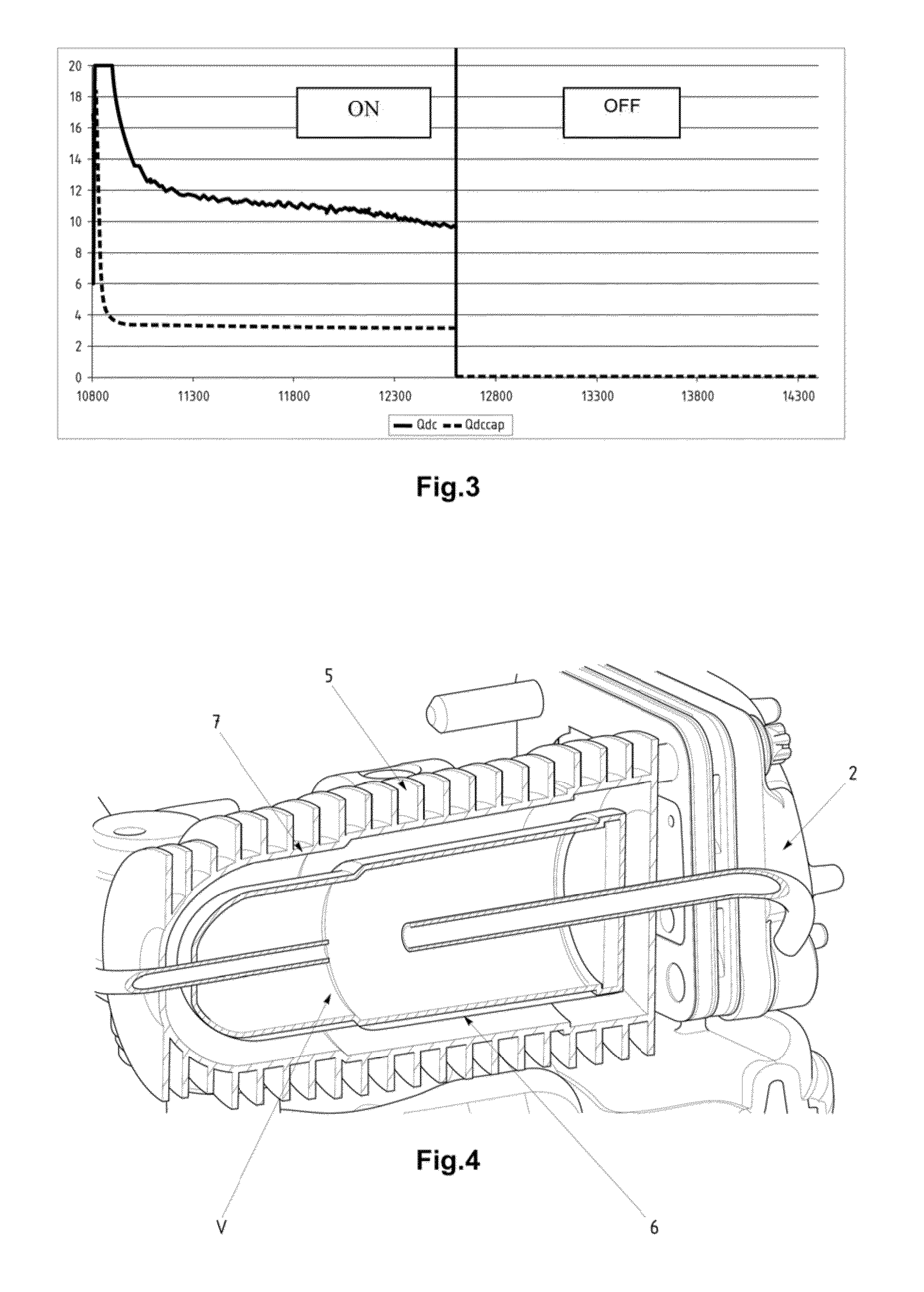

Refrigeration compressor

InactiveUS20130045119A1Improve compressor performanceInternal temperature reliably and efficientlyPositive displacement pump componentsEngine componentsRefrigeration compressorEngineering

The present invention relates to a thermally efficient refrigeration compressor, comprising a housing which surrounds the component parts of the compressor and a heat accumulating material occupying a volume internal (4, 7, 15, 18, 23, 27) or adjacent (9, 11, 30, 32, 37) to the compressor housing. Accordingly, the present invention takes advantage of the thermodynamics existing between the compressor and the refrigeration system, achieving a reduction of the internal temperatures reliably and efficiently and consequently improving the performance of the compressor.

Owner:WHIRPOOL SA

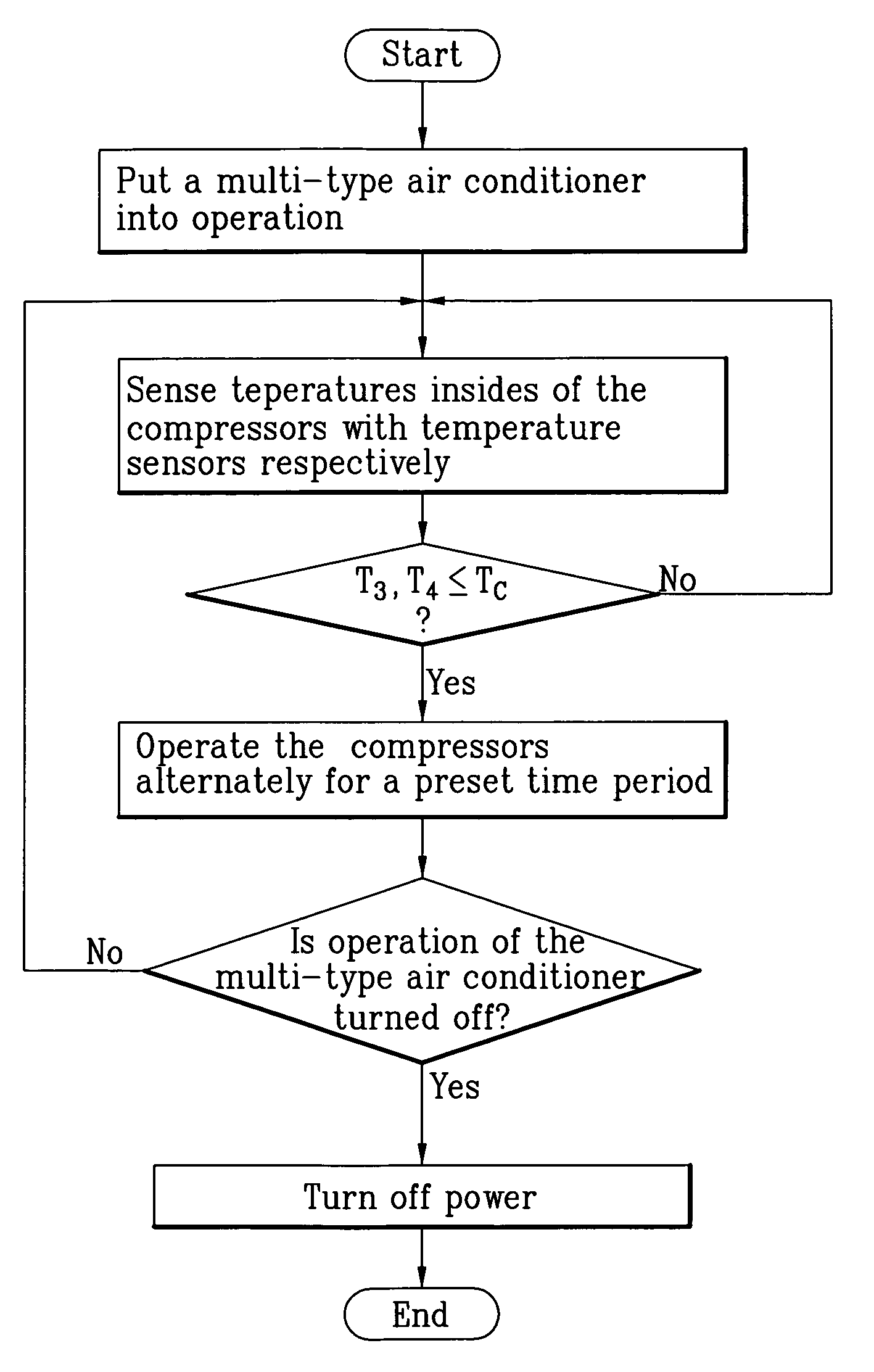

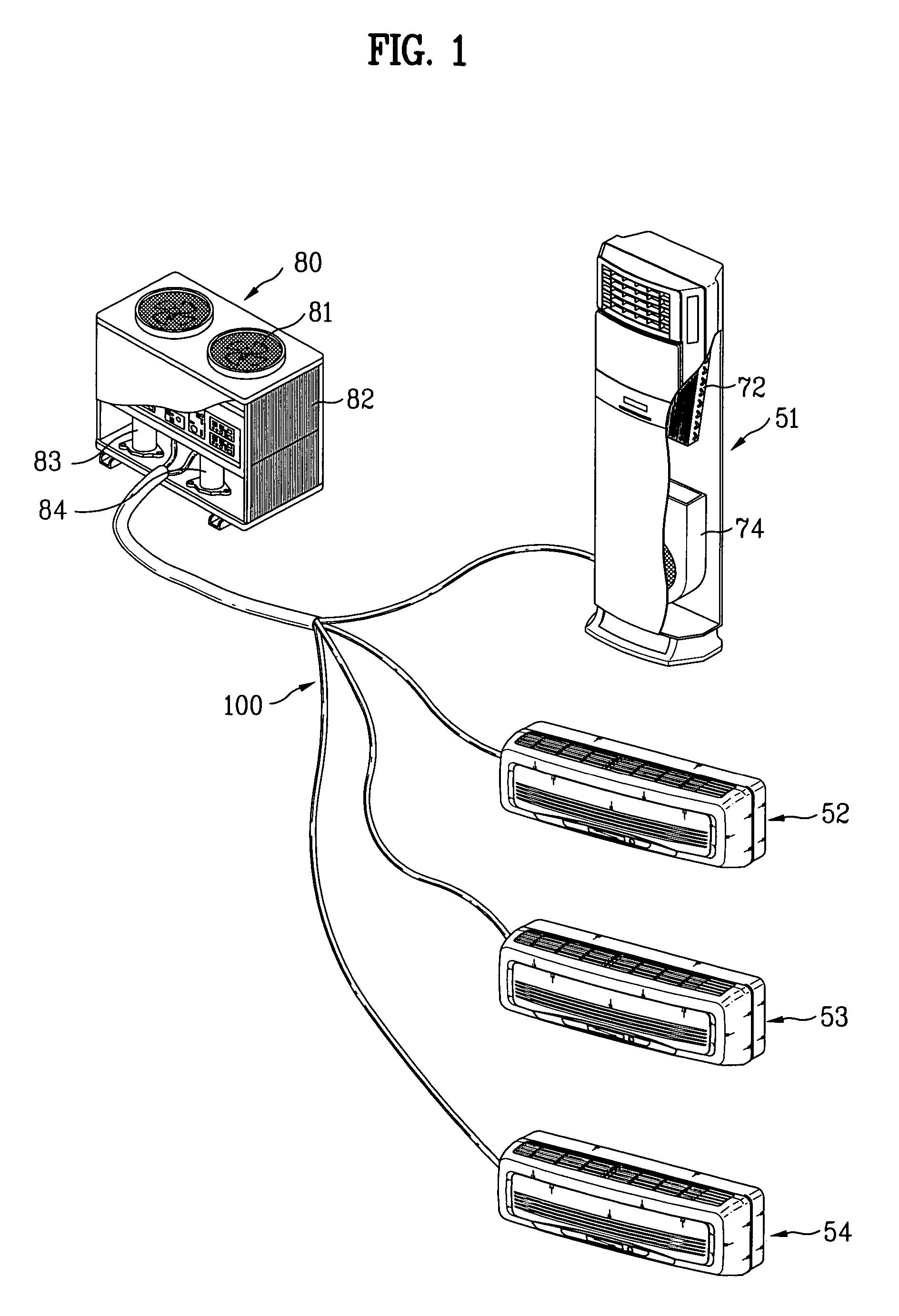

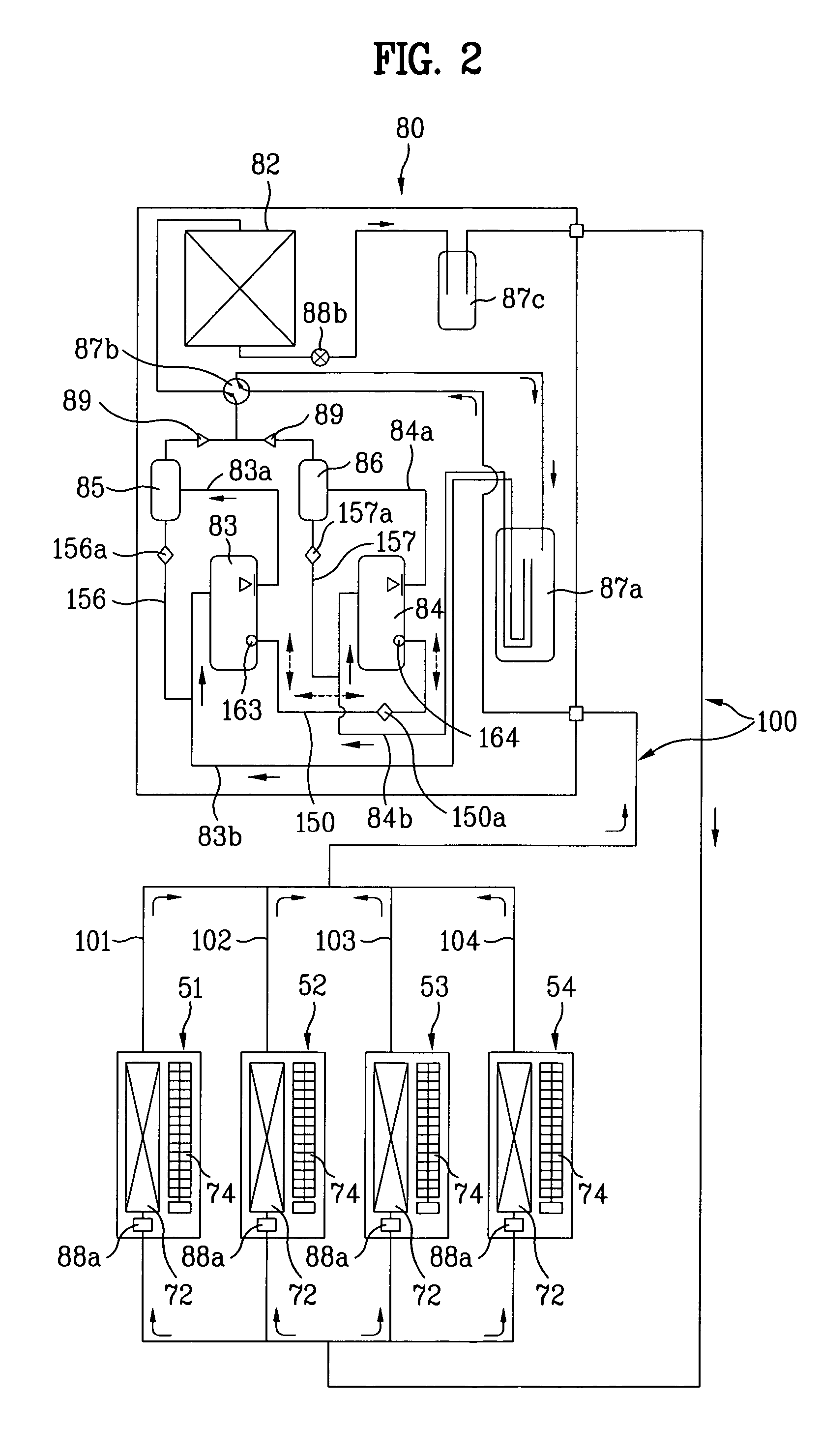

Multi-type air conditioner and method for controlling the same

InactiveUS7721559B2Improve compressor performanceGood air effectCompressorCompression machines with non-reversible cycleEngineeringTemperature sense

Multi-type air conditioner including a plurality of compressors, a plurality of temperature sensors mounted in the plurality of compressors for sensing temperatures in the compressors respectively, and an equalizing pipe in communication with the plurality of compressors, for uniform distribution of oil among the plurality of compressors according to the temperatures sensed at the plurality of temperature sensors respectively, thereby distributing oil among the compressors uniformly at an exact time point at which the oil is distributed among the compressors non-uniformly, not only to permit improvement of the performance of the compressors, but also to permit improvement performance of the air conditioner having the compressors.

Owner:LG ELECTRONICS INC

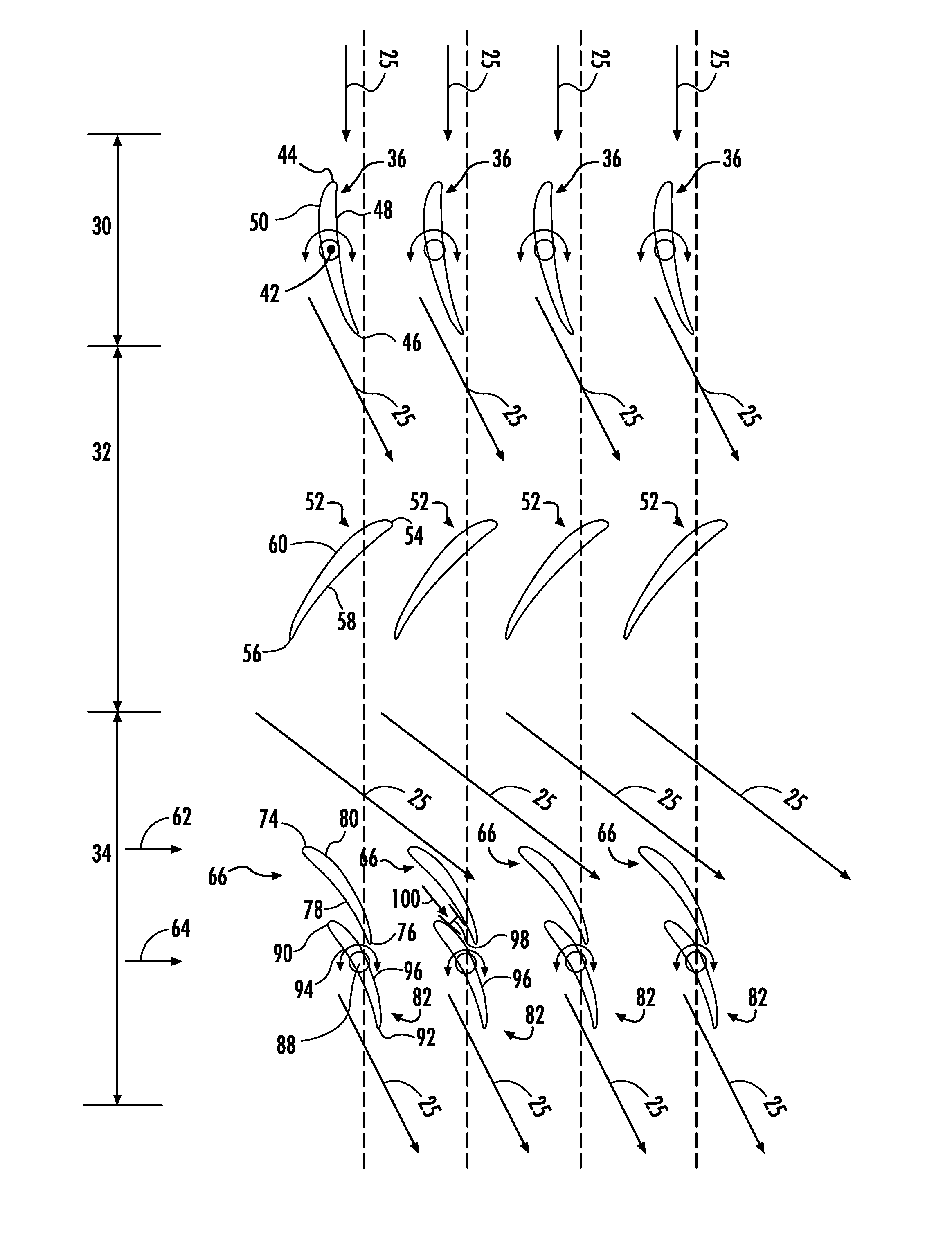

System and method for improving gas turbine performance at part-load operation

InactiveUS20140130513A1Improve compressor performanceSupersonic fluid pumpsWind motor controlLeading edgeTrailing edge

A compressor section of a gas turbine generally includes a stage of inlet guide vanes positioned adjacent to an inlet of the compressor section and a stage of rotor blades disposed downstream from the inlet guide vanes. A stage of stator vanes is positioned downstream from the stage of rotor blades. The stage of stator blades includes a row of leading guide vanes having a trailing edge. A row of trailing guide vanes coupled to an actuator is disposed between two corresponding adjacent leading guide vanes. Each of the trailing guide vanes includes a trailing edge. The leading edge of each trailing guide vane is disposed upstream of the trailing edge of a corresponding leading guide vane when the trailing guide vane is in an open position and downstream from the trailing edge of the corresponding leading guide vane when the trailing guide vane is in a closed position.

Owner:GENERAL ELECTRIC CO

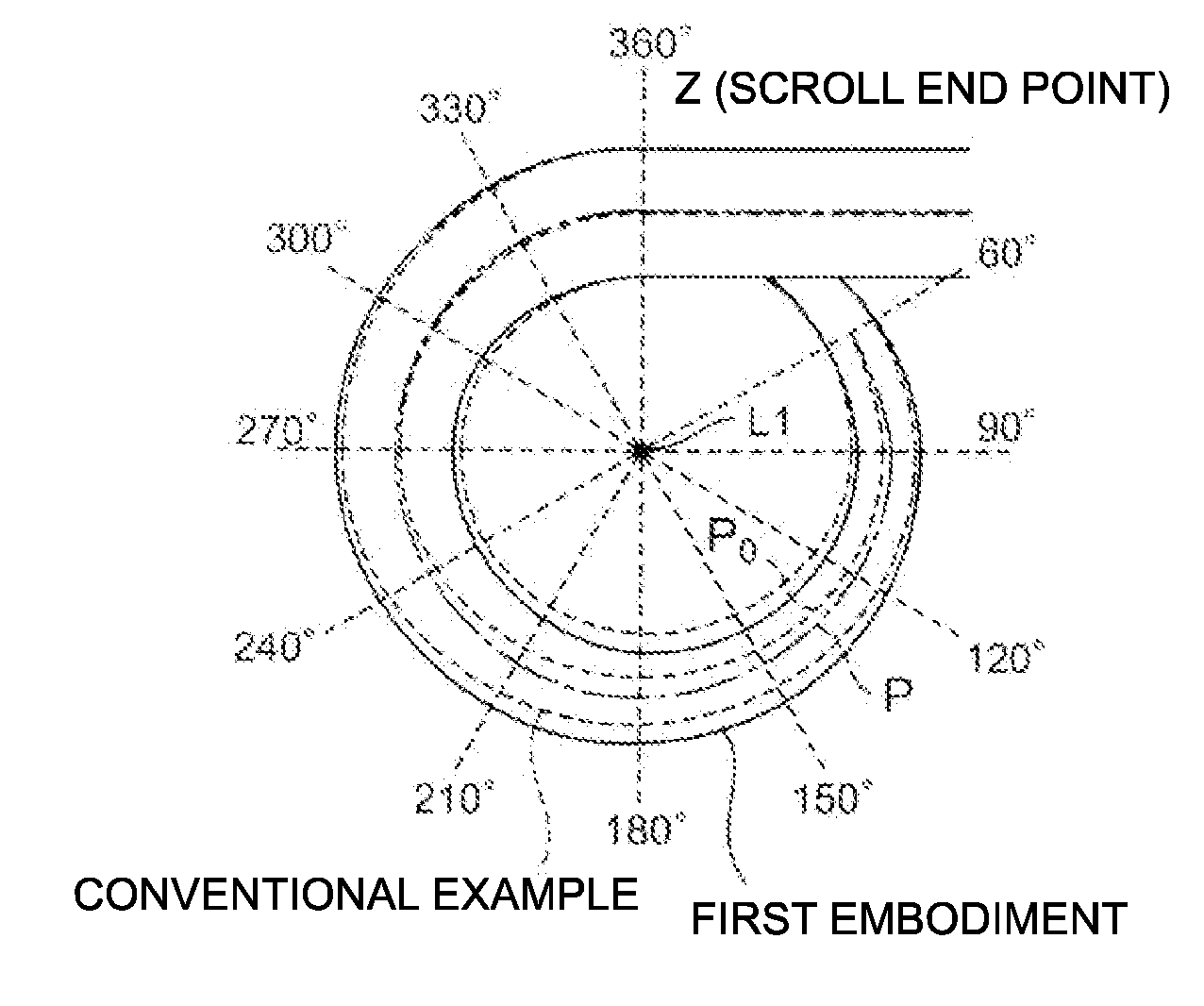

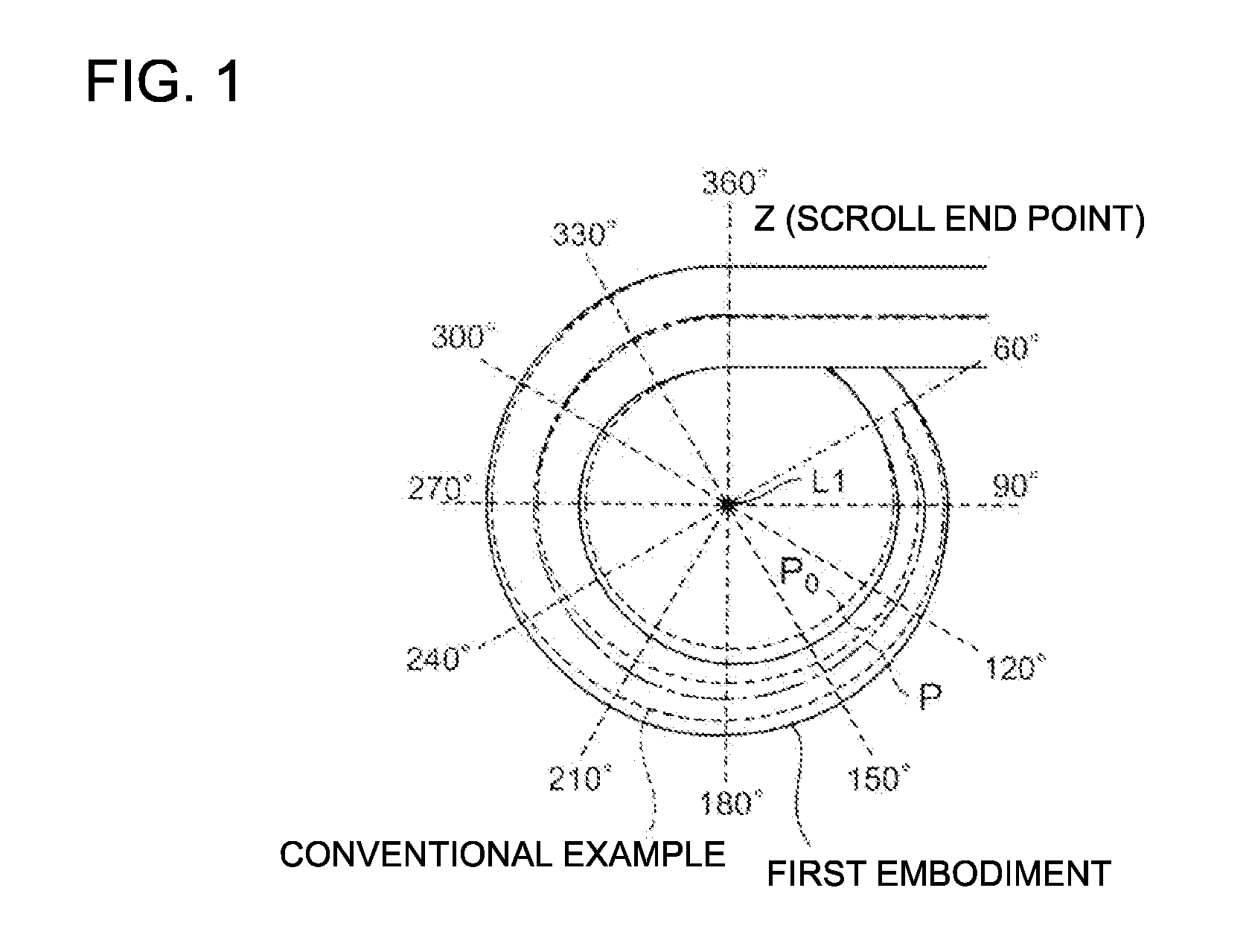

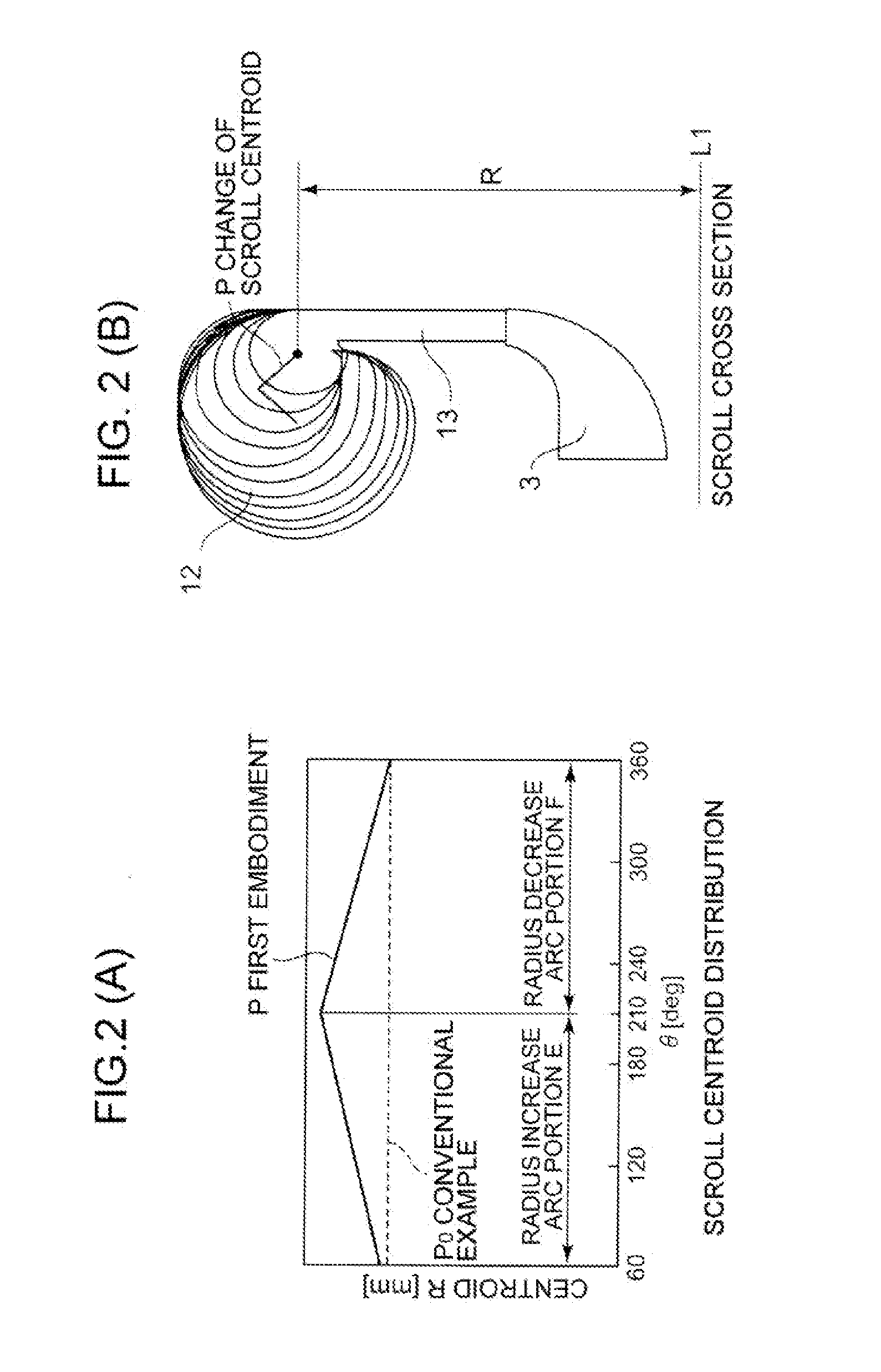

Scroll structure of centrifugal compressor

ActiveUS20130272865A1Turbulence of fluid is suppressedReduce layeringEngine manufacturePump componentsCentrifugal compressorEngineering

In a scroll structure of a centrifugal compressor, there are provided a radius increase arc portion E in which a radius from the center of a scroll 12 to a scroll centroid P of the cross section of the scroll 12 is gradually increased in any range in a circumferential direction from the start of winding of the scroll, and a radius decrease arc portion F in which the radius is gradually decreased toward a scroll end point Z.

Owner:MITSUBISHI HEAVY IND LTD

Utilization of bypass refrigerant to provide reheat and dehumidification function in refrigerant system

InactiveUS20060075767A1Improve compressor performanceReliability problemFluid circulation arrangementRefrigeration safety arrangementRefrigerantEvaporator

A refrigerant system is provided with an unloader bypass line to selectively unload the compressor and deliver refrigerant from a partially (or fully) compressed location back to a suction port of the compressor. A section of this unloader bypass line is placed in the path of air having passed over an evaporator and towards an environment to be conditioned. This section of the unloader bypass line would contain refrigerant that is at a higher temperature than the refrigerant, which had been delivered into the evaporator by the main circuit. In this manner, this bypass line section will provide the function of reheating the air above the temperature to which it had been cooled in the evaporator to achieve a desired humidity level. Thus, the reheat function is obtained without requiring a dedicated reheat loop, associated components and additional structure. Also, through the refrigerant temperature reduction, compressor reliability and performance are improved. Furthermore, the flow control device may be of an adjustable type (e.g. modulating or pulsating) to achieve variable sensible heat ratios and to cover a wide range of potential applications. Lastly, the bypass line may have extended heat transfer elements allowing heat transfer enhancement between the air and refrigerant.

Owner:CARRIER CORP

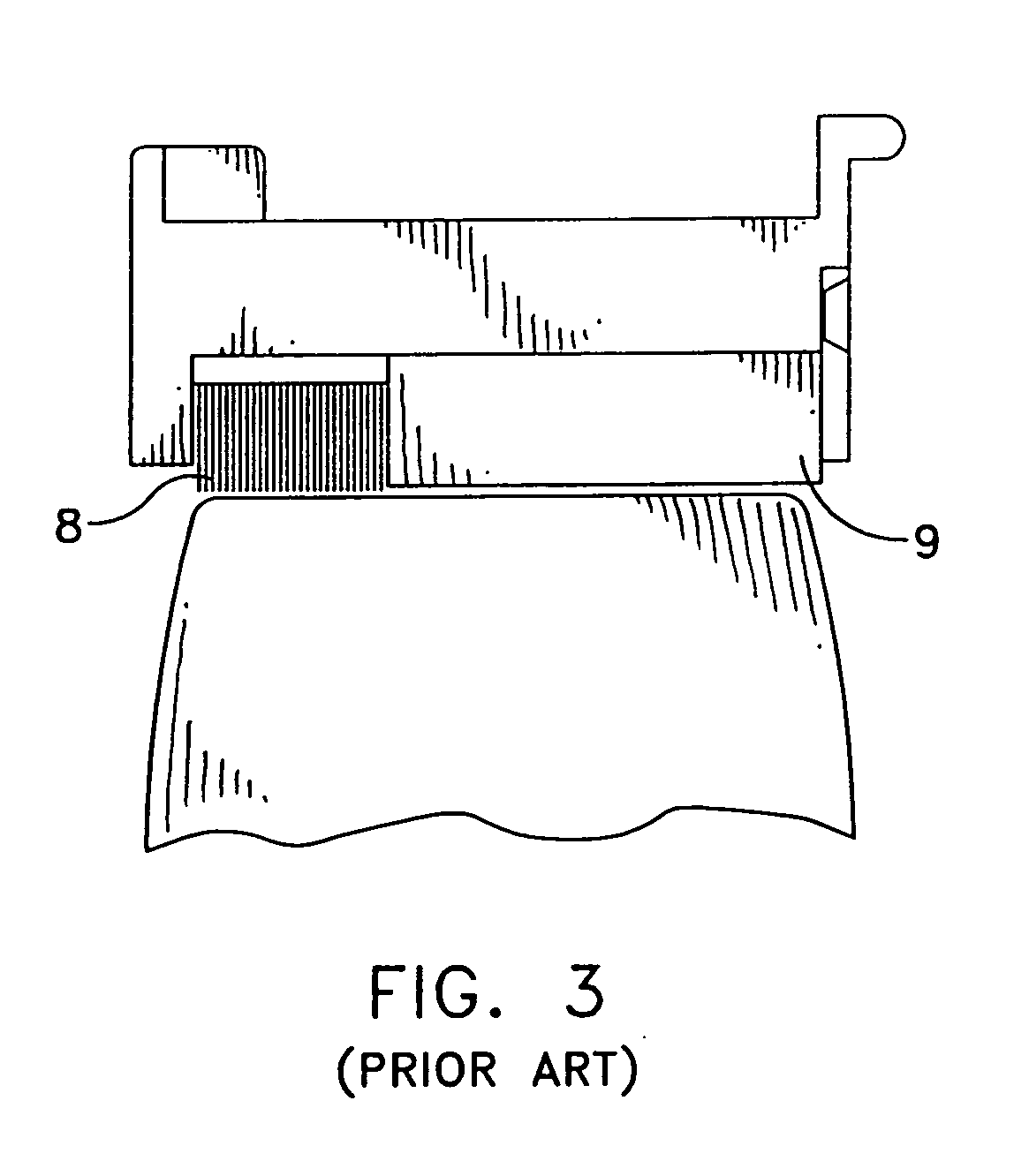

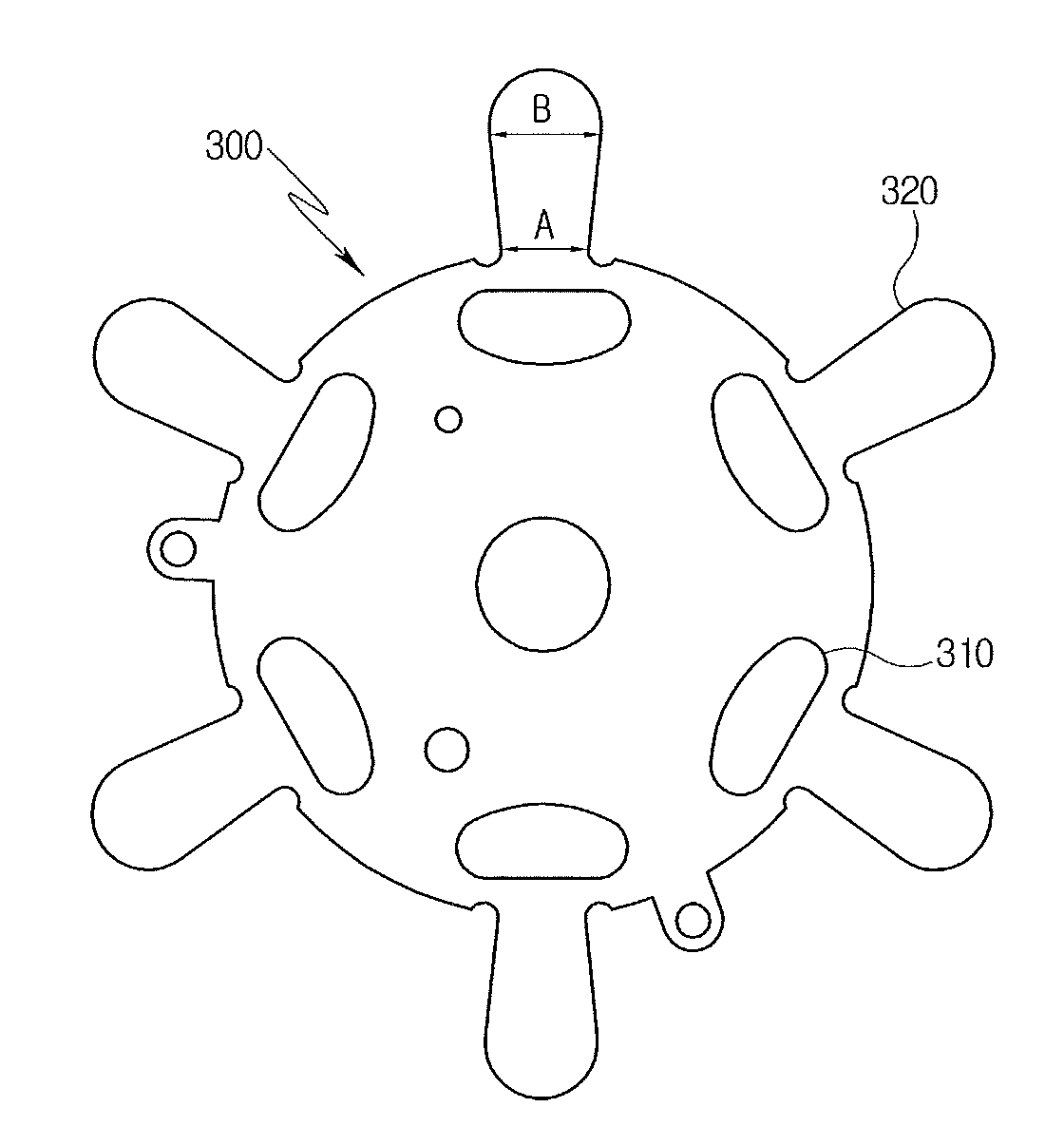

Valve assembly for variable swash plate compressor

ActiveUS20150086400A1Enhance performanceIncrease flow ratePositive displacement pump componentsMulti-stage pumpsRefrigerantEngineering

Disclosed herein is a valve assembly for a variable swash plate compressor. Since an opening hole of a suction reed is enlarged toward a suction port of a valve plate and refrigerant is also introduced into a cylinder bore through the opening hole when the suction port is opened, performance of a compressor may be enhanced by an increase in flow rate.

Owner:HANON SYST

Scroll refrigeration compressor with anti-return device

InactiveUS9017050B2Simple and cost-effective structureImprove compressor performanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeRefrigeration compressorEngineering

The scroll refrigeration compressor includes a stationary volute and a moving volute provided with spiral wraps defining variable-volume compression chambers, a separating member sealably mounted on a plate of the stationary volute so as to allow a relative movement between the separating member and the stationary volute, a delivery chamber at least partially defined by the separating member and the sealed casing. The compressor further includes a bypass passage arranged to communicate the delivery chamber with an intermediate compression chamber, and a anti-return device comprising a closing member movable between closing and opening positions for closing and opening the bypass passage, and an enclosure, positioned between the separating member and the plate of the stationary volute, including a first portion sealably mounted in a housing defined by the separating member and oriented substantially parallel to the longitudinal axis of the compressor.

Owner:DANFOSS COMML COMPRESSORS

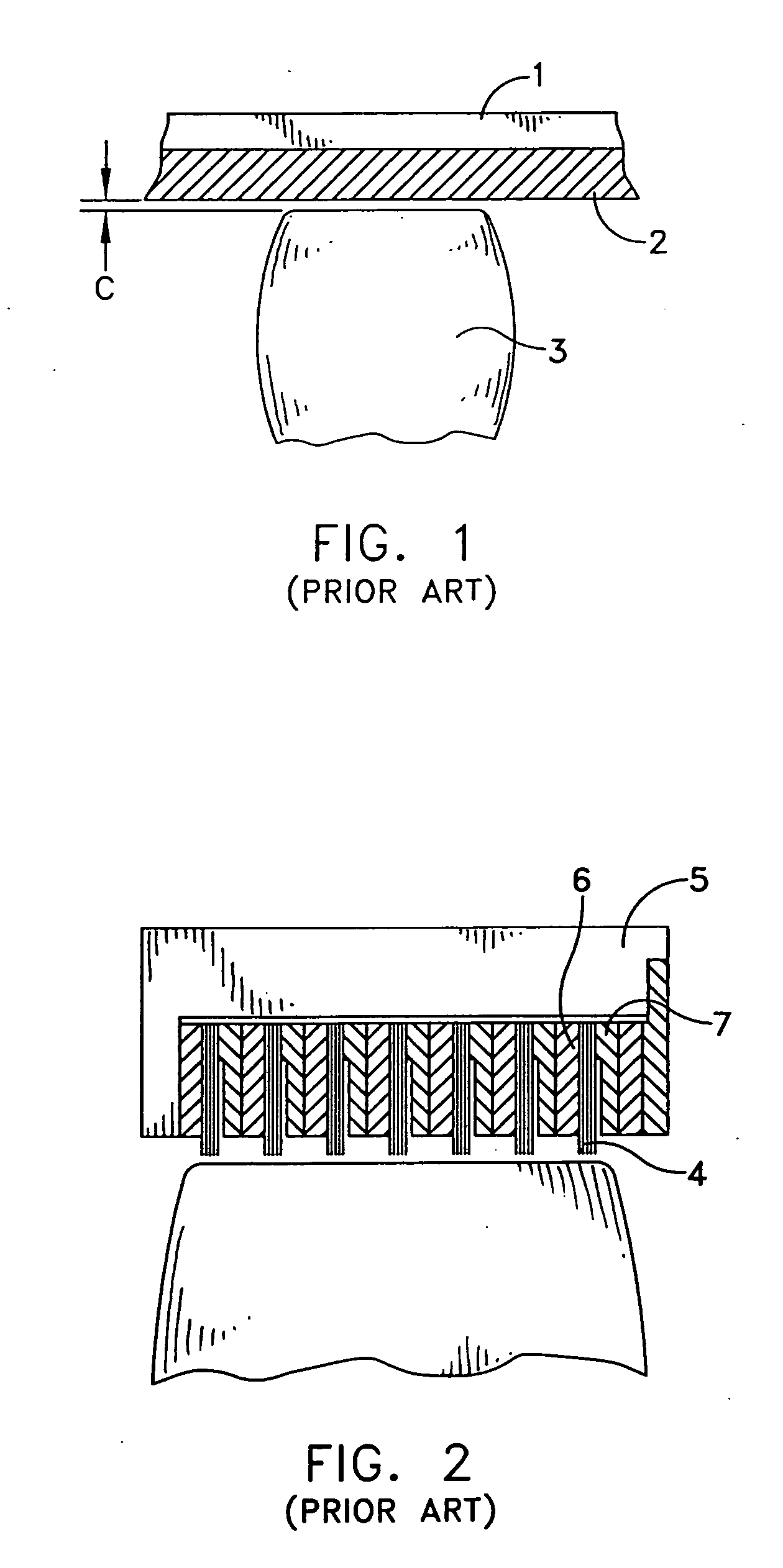

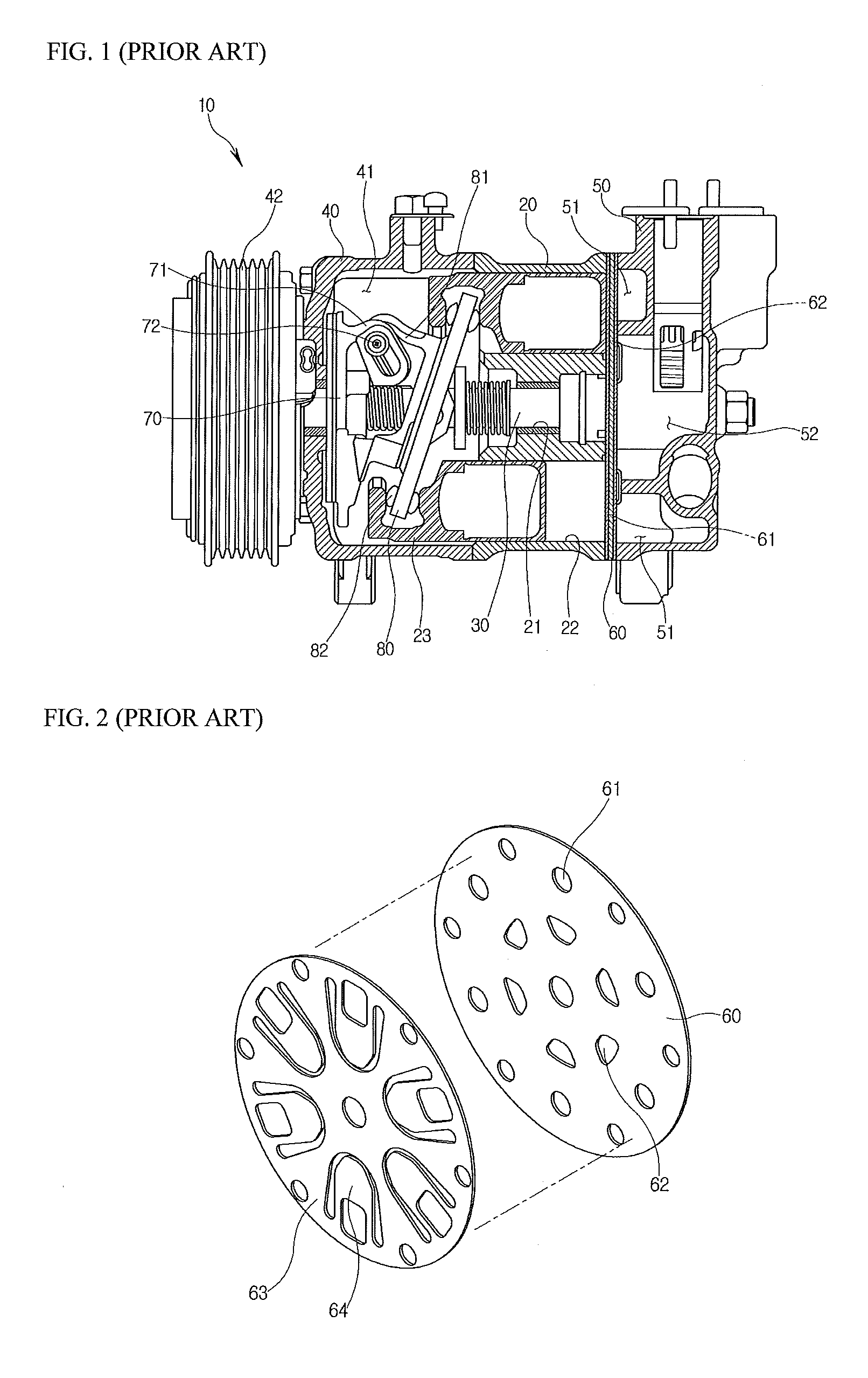

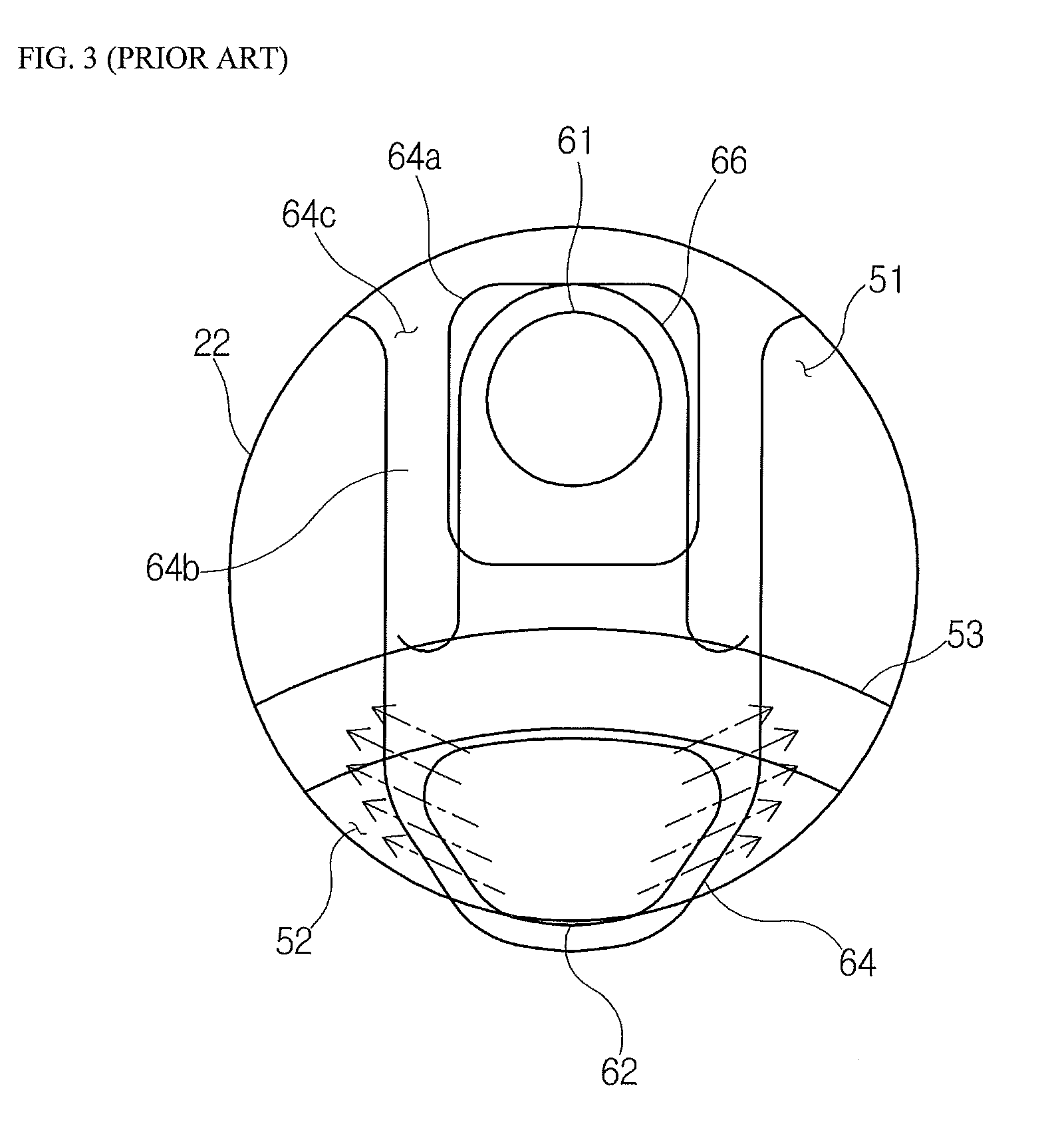

Discharge valve arrangement for a hermetic compressor

InactiveUS20110103937A1Reduce load lossSolve the lack of spaceWind motor controlPositive displacement pump componentsEngineeringRefrigeration

Discharge valve arrangement applied in a hermetic compressor used, for example, in household refrigeration systems including a valve plate closing an end of a compression cylinder and provided with suction and discharge orifices contained within the inner contour of the axial projection of the compression cylinder, said suction orifice occupying an annular sector external to the axial projection of a discharge orifice and being closed by a flexible suction vane having a bending median portion. The valve plate is provided with a plurality of discharge orifices distributed in at least one of the regions defined externally and internally to the contour of the flexible suction vane, each discharge orifice provided internally to the contour of the flexible suction vane being axially aligned with a respective through opening provided in said bending median portion.

Owner:WHIRPOOL SA +1

Air conditioner

ActiveUS20120174615A1Enhance heat exchange performanceEnhance performanceCompressorCompression machines with non-reversible cycleThermodynamic cycleRefrigerant

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com